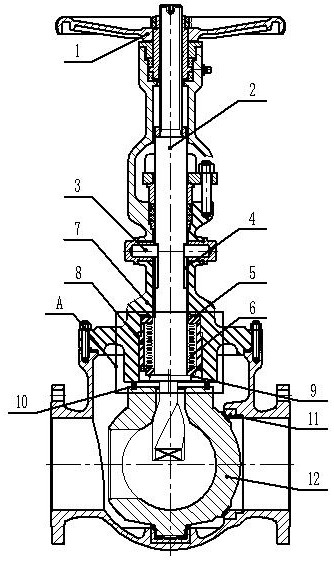

Corrugated pipe track ball valve

A bellows and rail technology, applied in valve details, valve devices, shaft seals, etc., can solve the problems such as the sealing surface of the ball and the valve seat is not tightly closed, the medium leaks, and the extrusion deformation, so as to achieve reliable sealing and extended use. Longevity, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

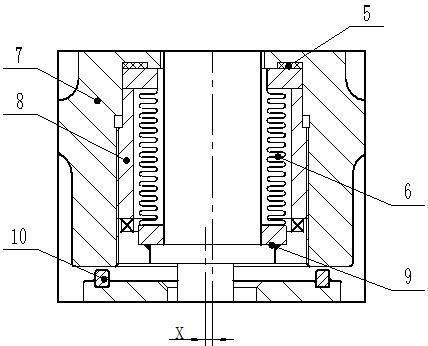

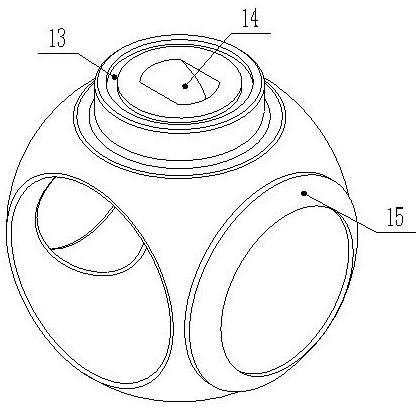

[0016] As shown in the figure, a bellows track ball valve includes a valve stem 2, a valve cover 7, a valve seat 11, and a ball 12. A bellows 6 is provided between the valve stem 2 and the valve cover 7, and a valve is provided on the outside of the bellows 6. The cover nut 8, the bonnet nut 8 and the bonnet 7 are matched by a thread pair, the design of the bonnet nut 8 ensures the detachability of the bellows 6, and facilitates the replacement of the wearing part gasket. The lower part of the valve stem 2 is provided with a positioning shoulder 9 welded with the bellows 6, and there is one more bellows seal, which can effectively prevent the medium from leaking from the valve stem.

[0017] The valve cover 7 is provided with a guide pin 3, and the valve stem 2 is provided with a guide rail groove 4 that cooperates with the guide pin 3. The guide rail groove 4 is linear, so that the valve stem 2 only moves up and down along the guide rail groove, not in the guide rail groove 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com