Bidirectional sealing butterfly valve

A two-way sealing, butterfly valve technology, applied in the direction of lift valve, valve device, engine components, etc., can solve problems such as leakage of sealing pair, and achieve the effect of saving man-hours, simple assembly process, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

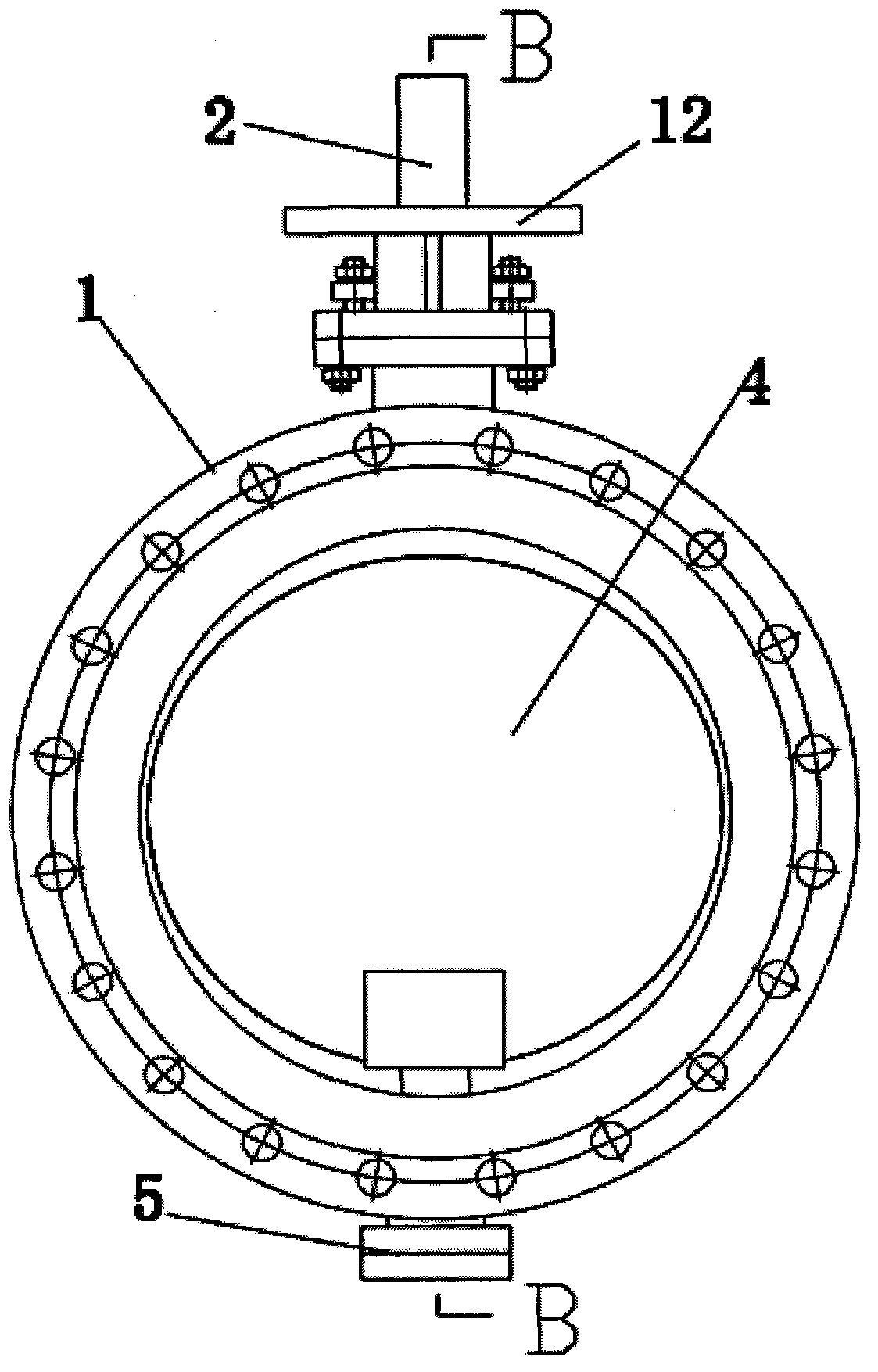

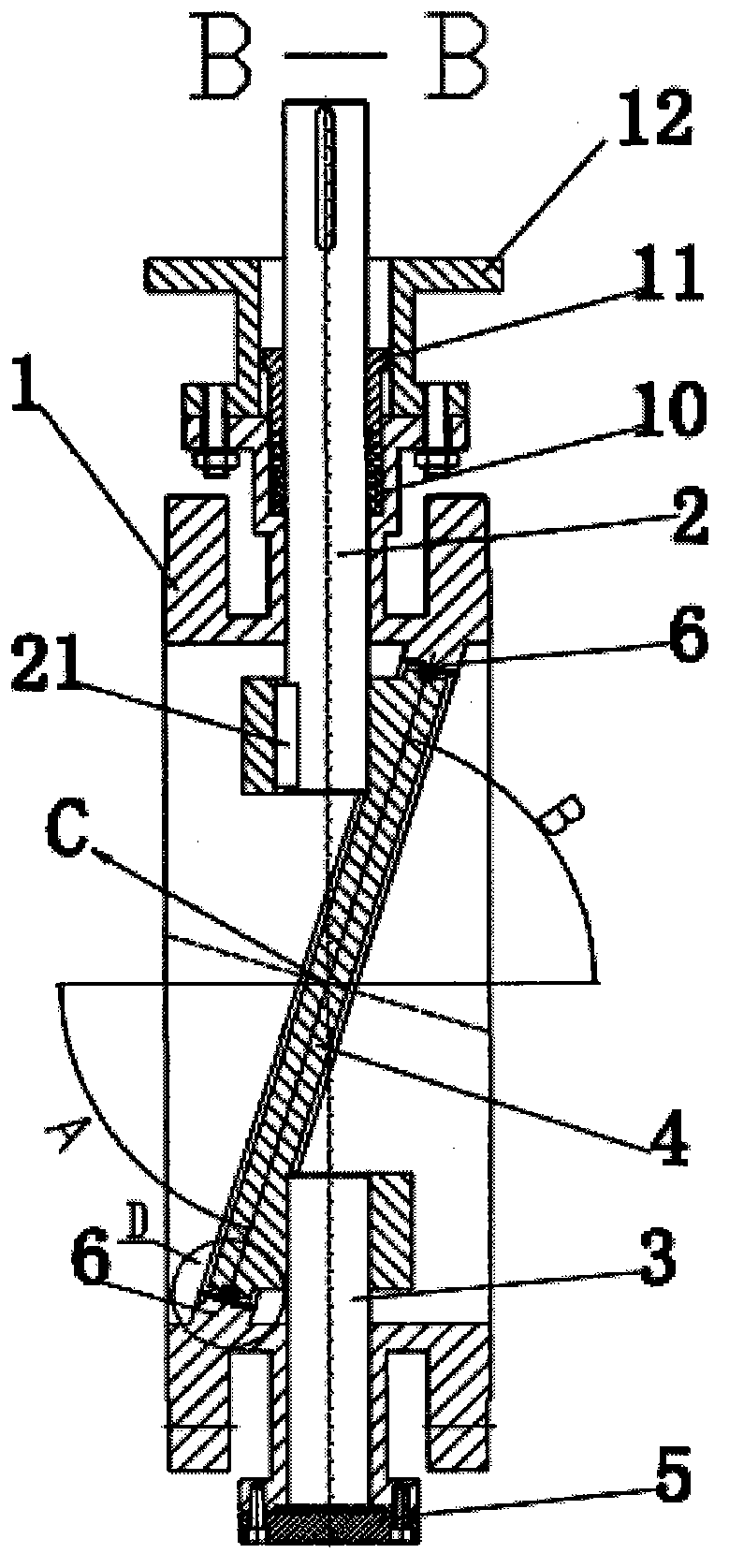

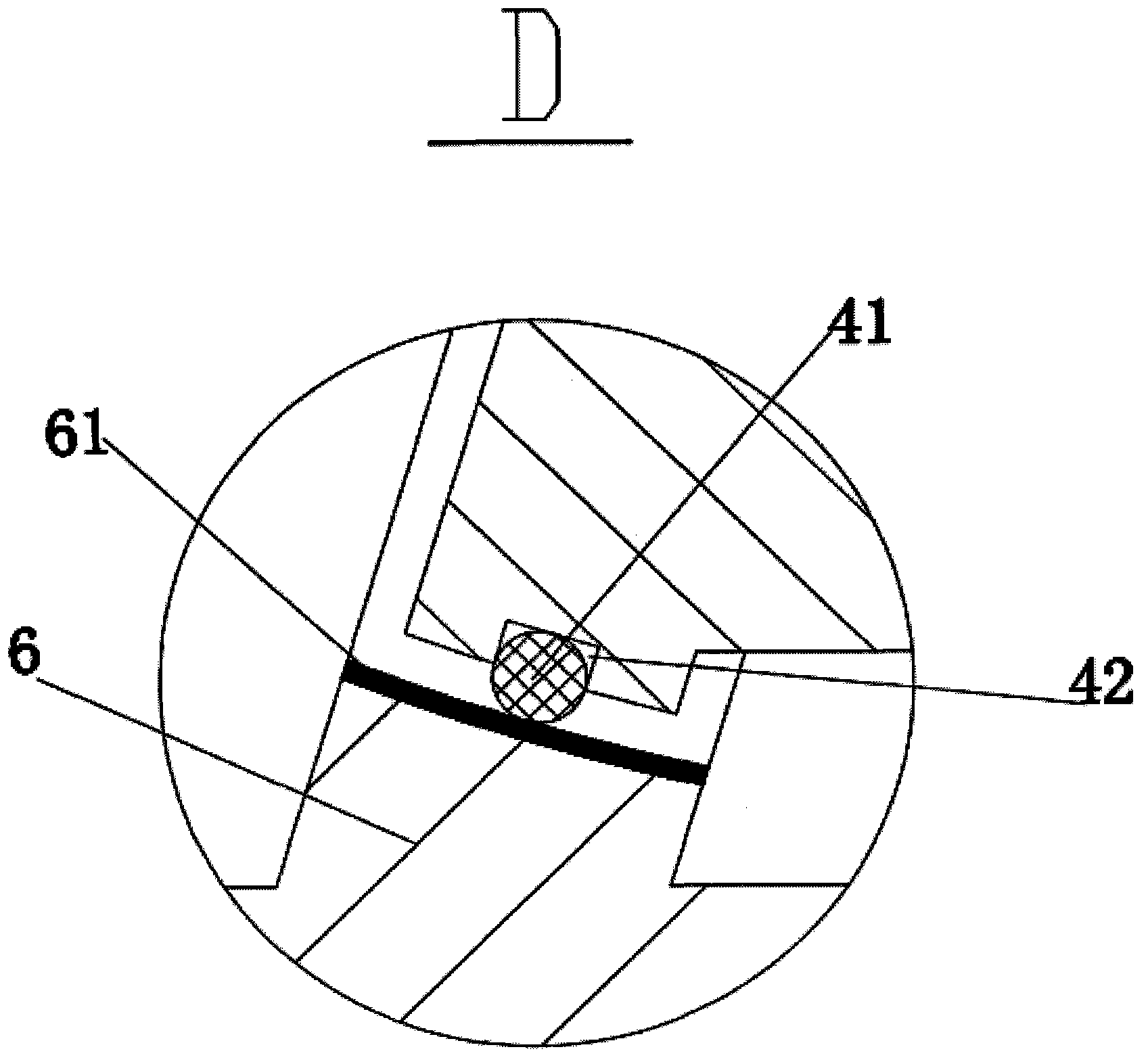

[0023] Such as figure 1 , figure 2 , image 3 As shown, the two-way sealing butterfly valve provided in this embodiment includes a valve body 1, a bracket 12 threadedly connected to the valve body 1, upper and lower valve stems 2, 3 in the valve body, a valve seat 6 in the valve body, and The butterfly plate 4 and the end cap 5 in the valve body. One end of the upper stem 2 is placed outside the valve body, and the other end is connected with the butterfly plate 4 placed in the valve body. A packing 10 is installed between the upper stem 2 and the valve body 1. The upper end is provided with a packing gland 11 to achieve a better sealing effect. One end of the lower valve stem 3 is matched and fixed with the end cover 5, and the other end of the lower valve stem is connected and fixed with the butterfly plate 4 through the key 21. The connection between the valve stem 2 and the butterfly plate 4 is a key 21 connection. The upper and lower valve stems and the butterfly plate 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com