Five-eccentric butterfly valve

An eccentric butterfly valve and eccentric distance technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of large opening and closing torque, short service life, unreliable sealing, etc., achieve fast opening and closing speed, and improve service life , Sealing and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

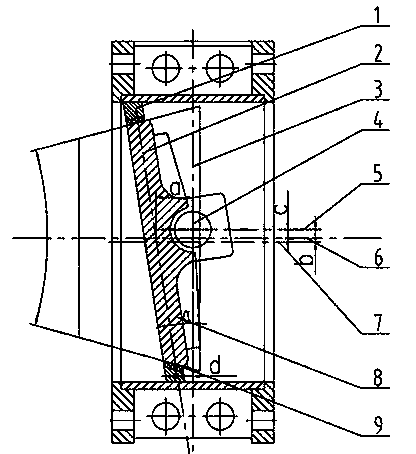

[0009] Such as figure 1 As shown, the five-eccentric butterfly valve has a rotatable shaft 4 in the longitudinal hole of the valve body 1, a transverse valve port on the valve body 1, and a valve plate 8 inside the valve port, and the valve plate 8 is installed on the shaft 4, and the valve plate 8 is an elliptical truncated cone. The conical surface of the elliptical truncated cone is used as a dynamic sealing surface and the static sealing surface matched with it on the valve body to form a sealing pair. The symmetrical central plane 2 of the sealing surface formed by it and the axial central plane of the rotating shaft There is an eccentricity a between 3, there is an eccentricity b between the center plane 7 of the flow passage and the radial center plane 5 of the rotating shaft, and the symmetrical center plane 2 of the sealing surface and the axial center plane 3 of the rotating shaft form an angular eccentricity of α There is an eccentricity c between the axis 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com