Seal valve with no-wear helical surface

A helical, wear-free technology, applied in valve details, valve device, valve housing structure, etc., can solve the problems of difficult manufacturing process, increase in the number of parts, increase manufacturing cost, etc., and achieve no friction torque and small opening and closing torque. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

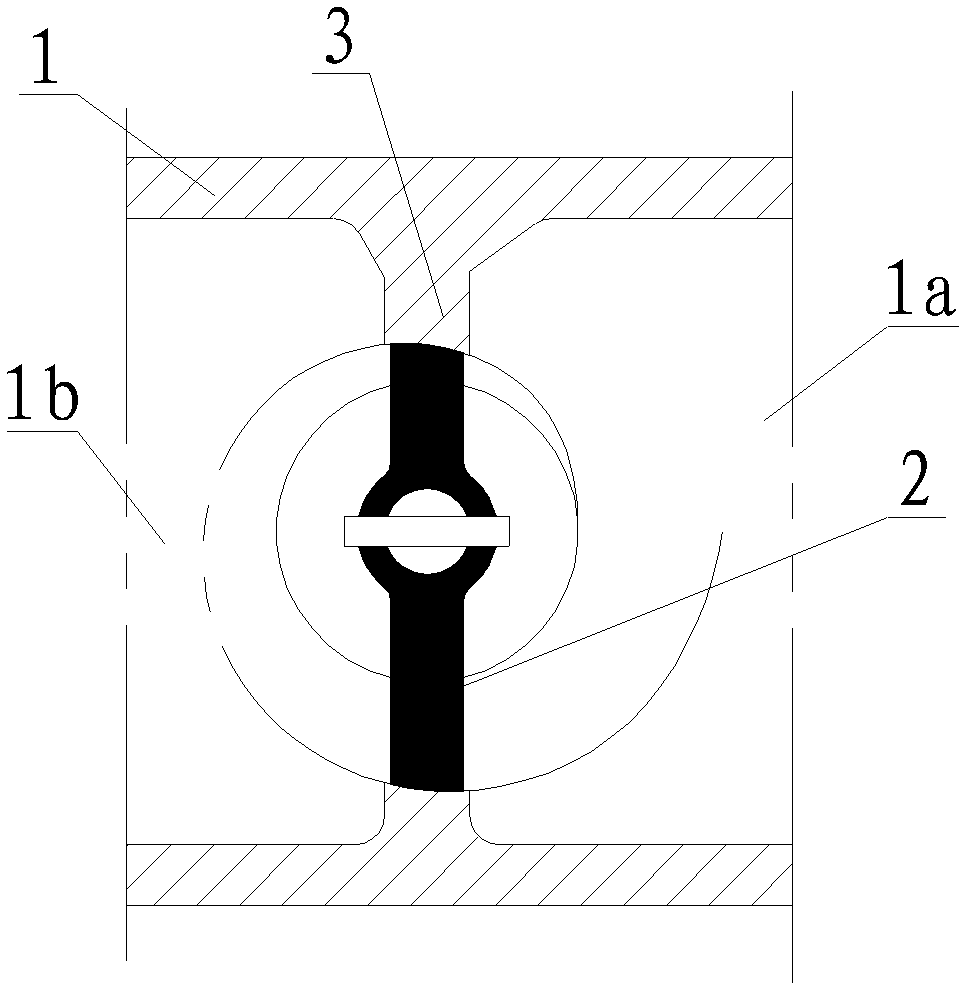

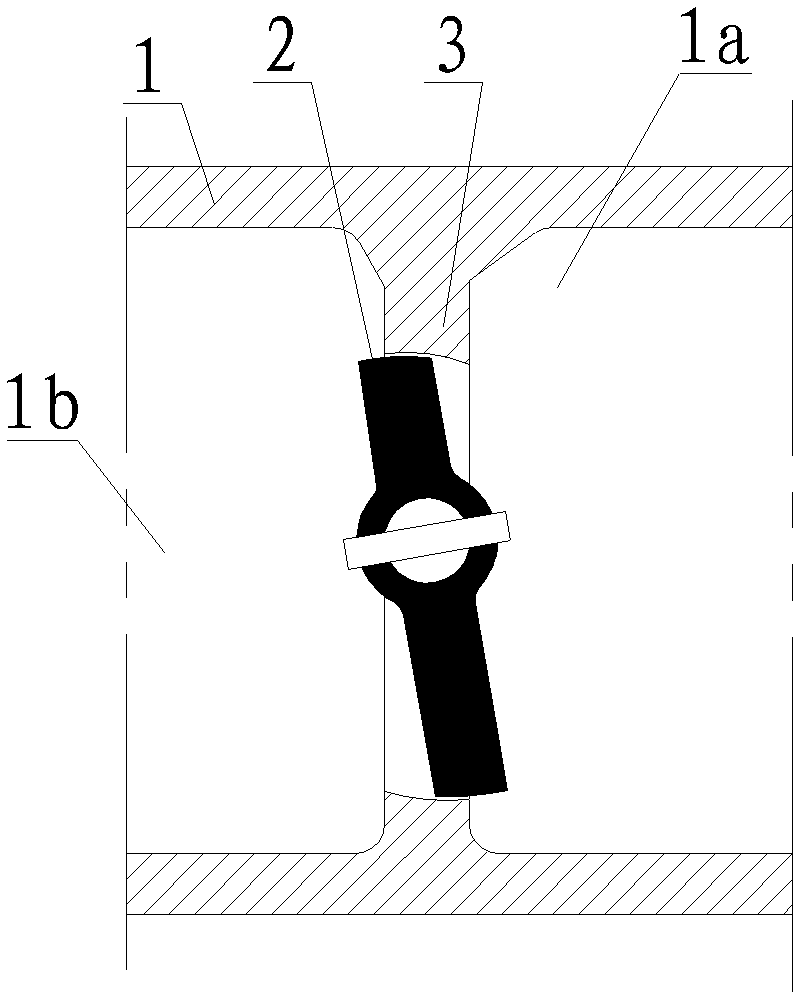

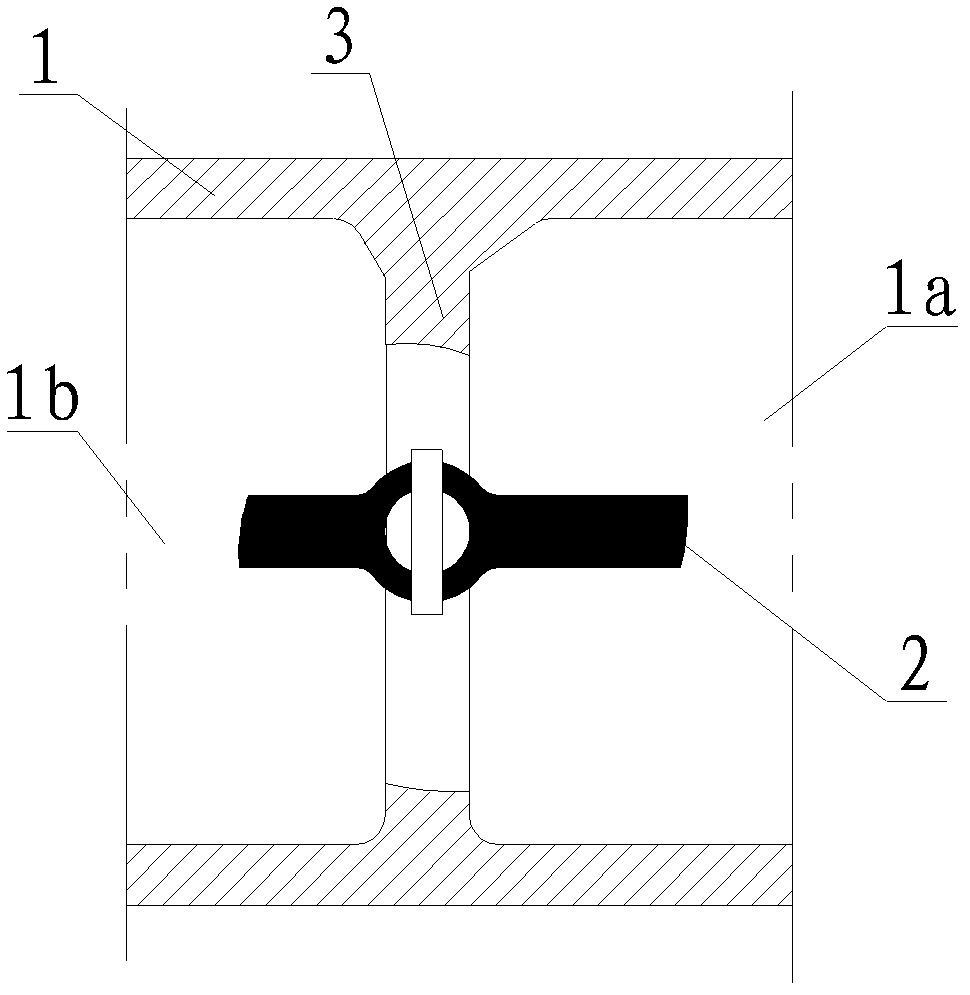

[0021] refer to Figure 1 to Figure 3 As shown, a wear-free helicoid sealing valve of the present invention includes a valve body 1, on which a medium inlet 1a and a medium outlet 1b are provided, and a valve core 2 and a valve seat 3 are arranged in the valve body 1, The contour line of the cross-section of the contact part when the valve core 2 and the valve seat 3 are closed is part of the same constant velocity spiral, that is, the contour line of the cross-section of the valve core 2 and the corresponding cross-section of the valve body 1 The contact parts of the inner contour line are located on the same constant velocity spiral; when the valve core 2 and the valve seat 3 are closed, the valve core 2 rotates outward along the constant velocity spiral, the valve core 2 is separated from the valve seat 3, and the valve opens; When the valve core 2 is separated from the valve seat 3, the valve core 2 rotates along the constant speed spiral, the valve core 2 and the valve se...

Embodiment 2

[0023] refer to Figure 4 to Figure 6 As shown, a wear-free helicoid sealing valve of the present invention includes a valve body 1, on which a medium inlet 1a and a medium outlet 1b are provided, and a valve core 2 and a valve seat 3 are arranged in the valve body 1, A cavity 4 is provided in the valve body 1, and the cavity 4 is respectively connected to the medium inlet 1a and the medium outlet 1b. The valve core 2 is set in the cavity 4, and the valve seat 3 is set in the medium inlet 1a. Or on the valve body 1 on the periphery of the medium outlet 1b; the valve core 2 cooperates with the valve seat 3 to form a sealing surface. Specifically, the valve core 2 in this embodiment is composed of a support 2a and a seal 2b arranged on the support 2a, the seal 2b cooperates with the medium outlet 1b to form a sealing surface; the outer surface of the seal 2b is As a spherical surface, the outer contour of the cross-section of the seal 2b is located on a constant velocity spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com