Zero-friction hard seal butterfly valve

A hard seal, zero-friction technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of incomplete realization of zero friction, inflexible butterfly plate movement, small translational distance, etc., to achieve diverse driving methods and structural Effect of compactness and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but it does not limit the claim of the present application.

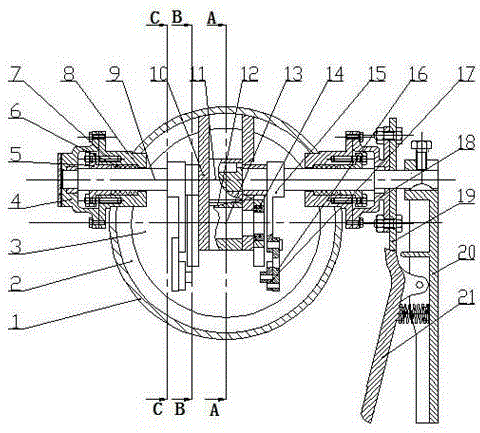

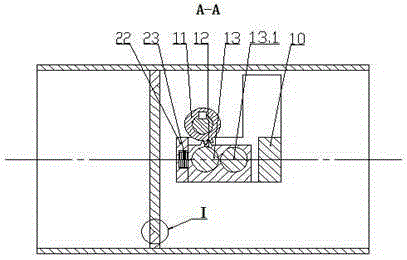

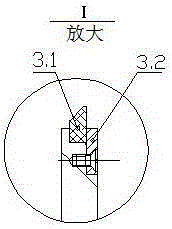

[0016] A zero-friction hard-sealed butterfly valve designed by the present invention (hereinafter referred to as butterfly valve, see Figure 1-5 ), the main structure includes valve body 1, valve seat 2, butterfly plate 3, valve shaft 9, guide groove 10' (groove body 10, end cover 22), incomplete gear 11, rack 12, No. 1 guide shaft 13, No. 2 guide shaft 13.1, self-lubricating shaft sleeve 14, linkage rod 15', intermittent mechanism 17 and its driving handle and sealing device, the valve body 1 has a through hole, and a valve neck 8 is welded at the through hole, and at the same time The inner peripheral surface of the valve body 1 is welded with a valve seat 2, and the outer surface of the valve seat 2 is a conical surface; the butterfly plate 3 is a ring-shaped structure, and a hard sealing ring 3.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com