Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Simple weaving process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

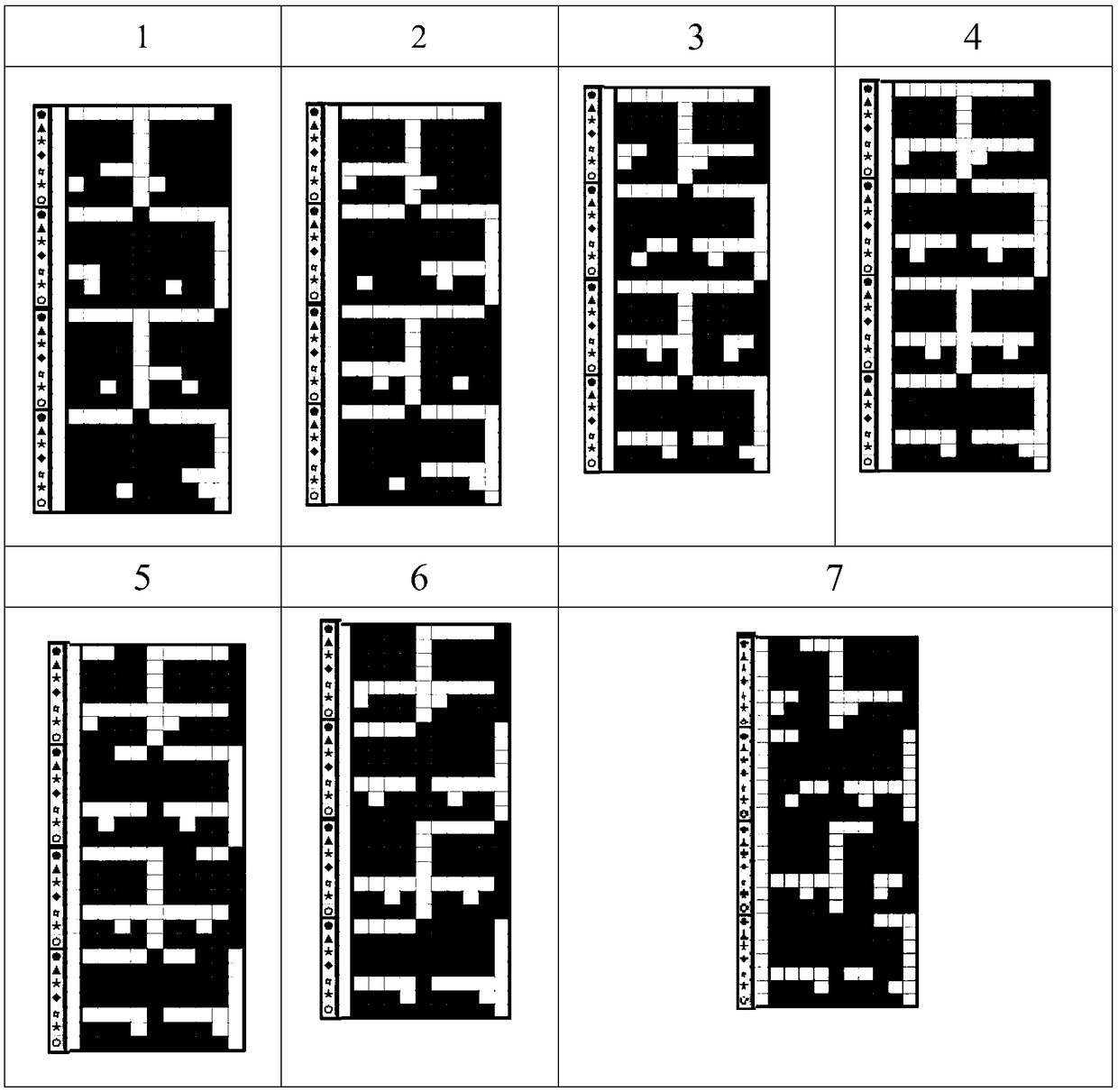

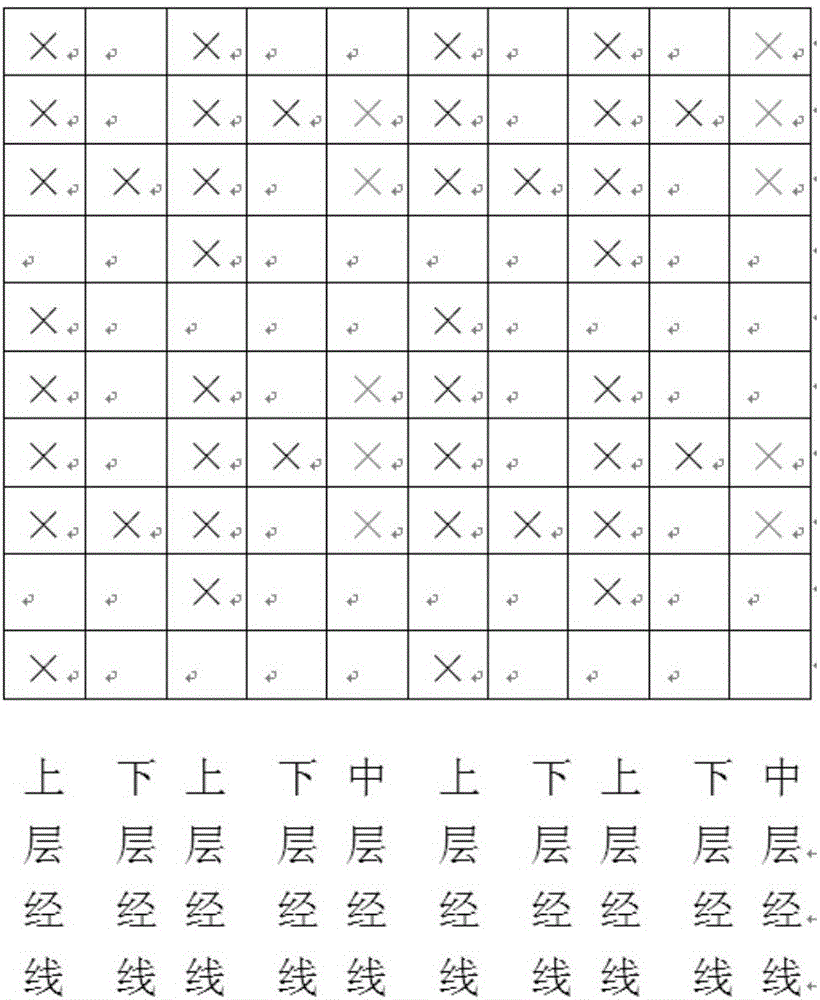

Three-layer fabric and tatting technique thereof

InactiveCN101660237ASimple weaving processEasy to produceSwivel-woven fabricsLappet-woven fabricsState of artSurface layer

The invention discloses a three-layer fabric and a tatting technique thereof. Side openings at both sides of the cloth width of the three-layer fabric are tatted into a single layer, a surface layer and a liner layer comprise foundation tissues and jacquard or pattern tissues, the foundation tissue of the surface layer is tatted by surface warp and surface weft, the jacquard or pattern tissue is tatted by liner warp and liner weft, the foundation tissue of the liner layer is tatted by the liner warp and the liner weft, the jacquard or pattern tissue is tatted by the surface warp and the surface weft, and a middle layer comprises a layer of middle weft and is clamped and fixed by a binding tissue in a complete tissue; at the junction of the foundation tissue and the jacquard or pattern tissue, surface-liner connection and liner-surface connection are carried out to form the binding tissue; the tatting technique comprises seven procedures of fabric design, warp beaming, loom tacking, tatting, desizing, softening and water washing, adopts a set of surface weft yarn system, a set of middle weft yarn system, a set of liner weft yarn system and two sets of warp yarn systems for tatting,and the tatting sequence is the surface firstly, the middle secondly and the liner thirdly or is reverse; and the invention solves the problem that the prior art is difficult to tatt a fabric which can be directly used for producing an air-conditioning bedding and has the required thickness, and has obvious use value and economic value.

Owner:孔伟文

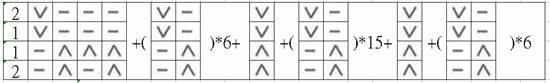

Weaving method of knotless net

Owner:孙以泽 +1

Fabric with eyed structures and weaving process thereof

InactiveCN102182003AReduce manufacturing costSimple weaving processWarp knittingLiquid/gas/vapor textile treatmentSoluble fiberIndustrial engineering

Owner:DONGGUAN TEXWINCA HLDG

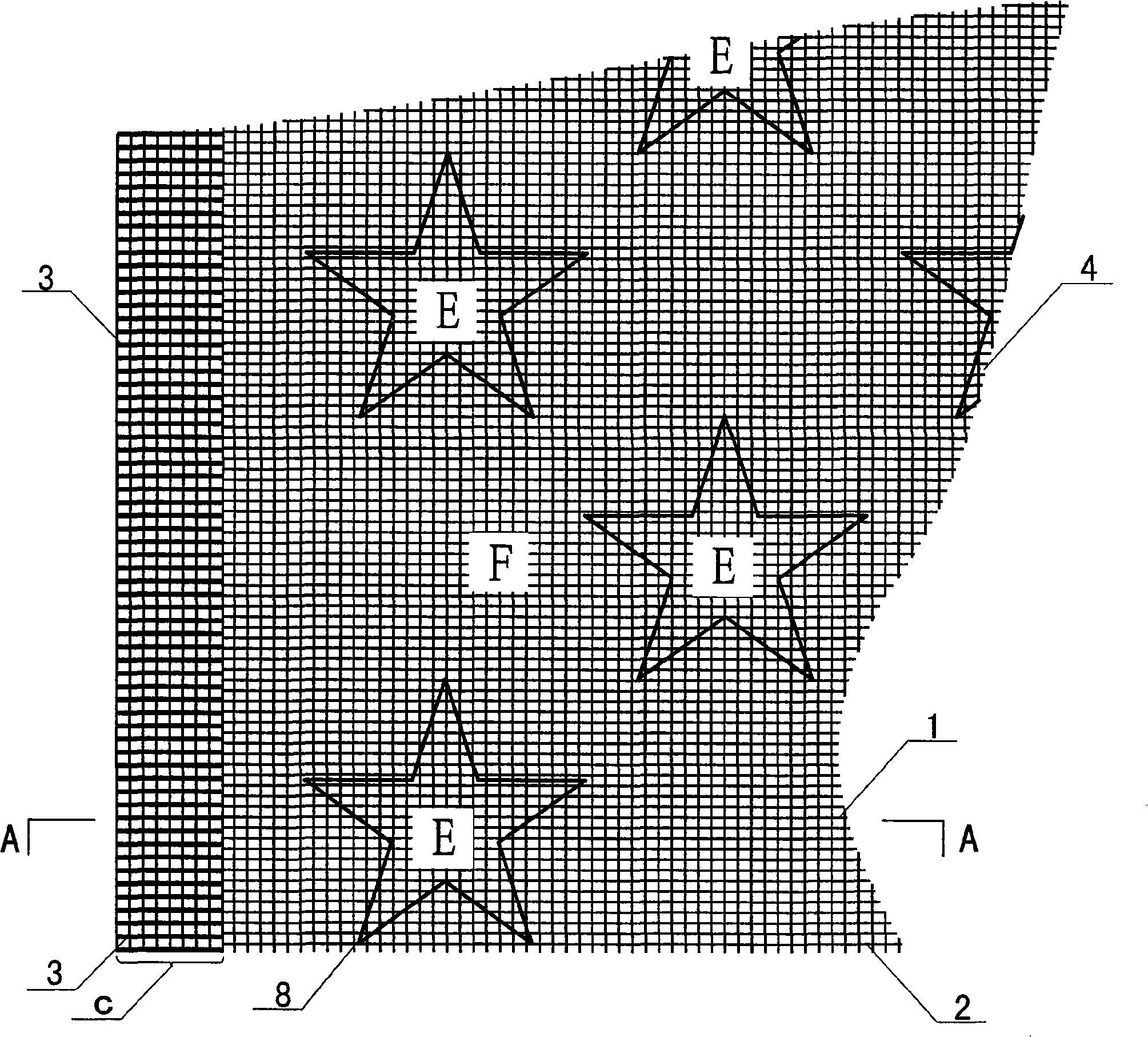

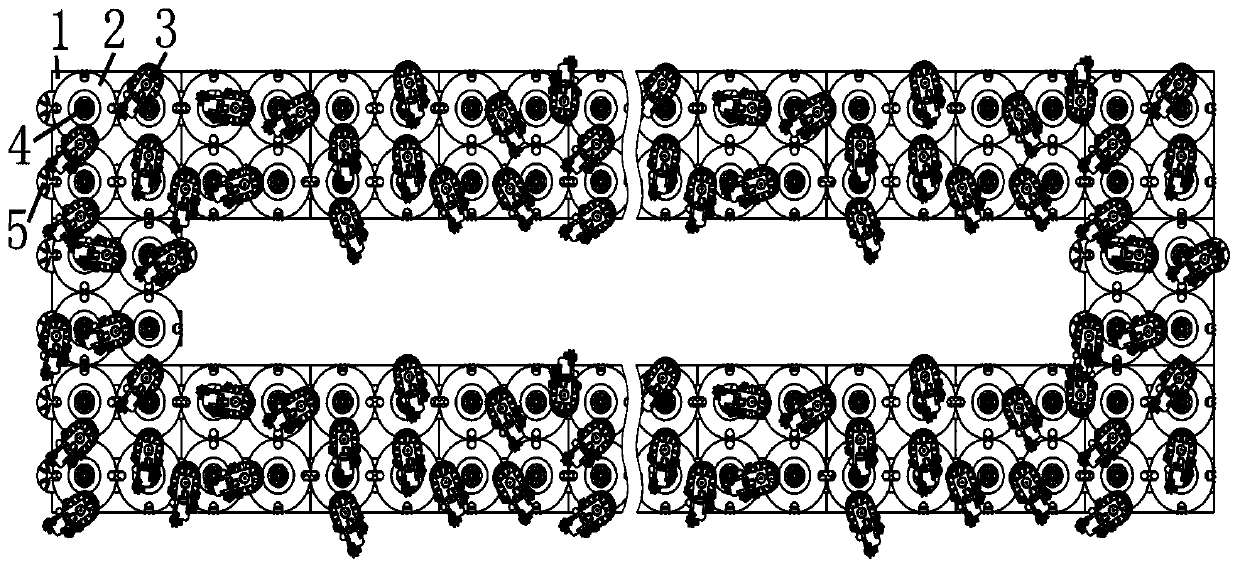

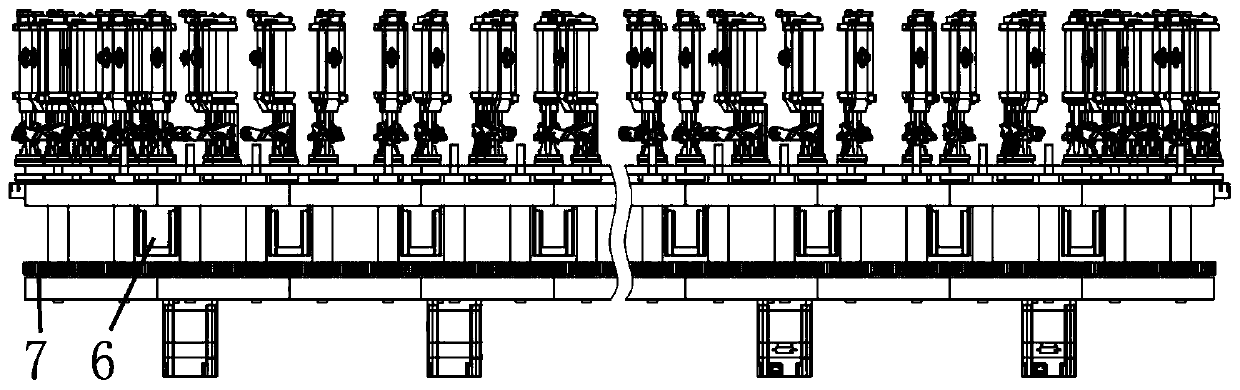

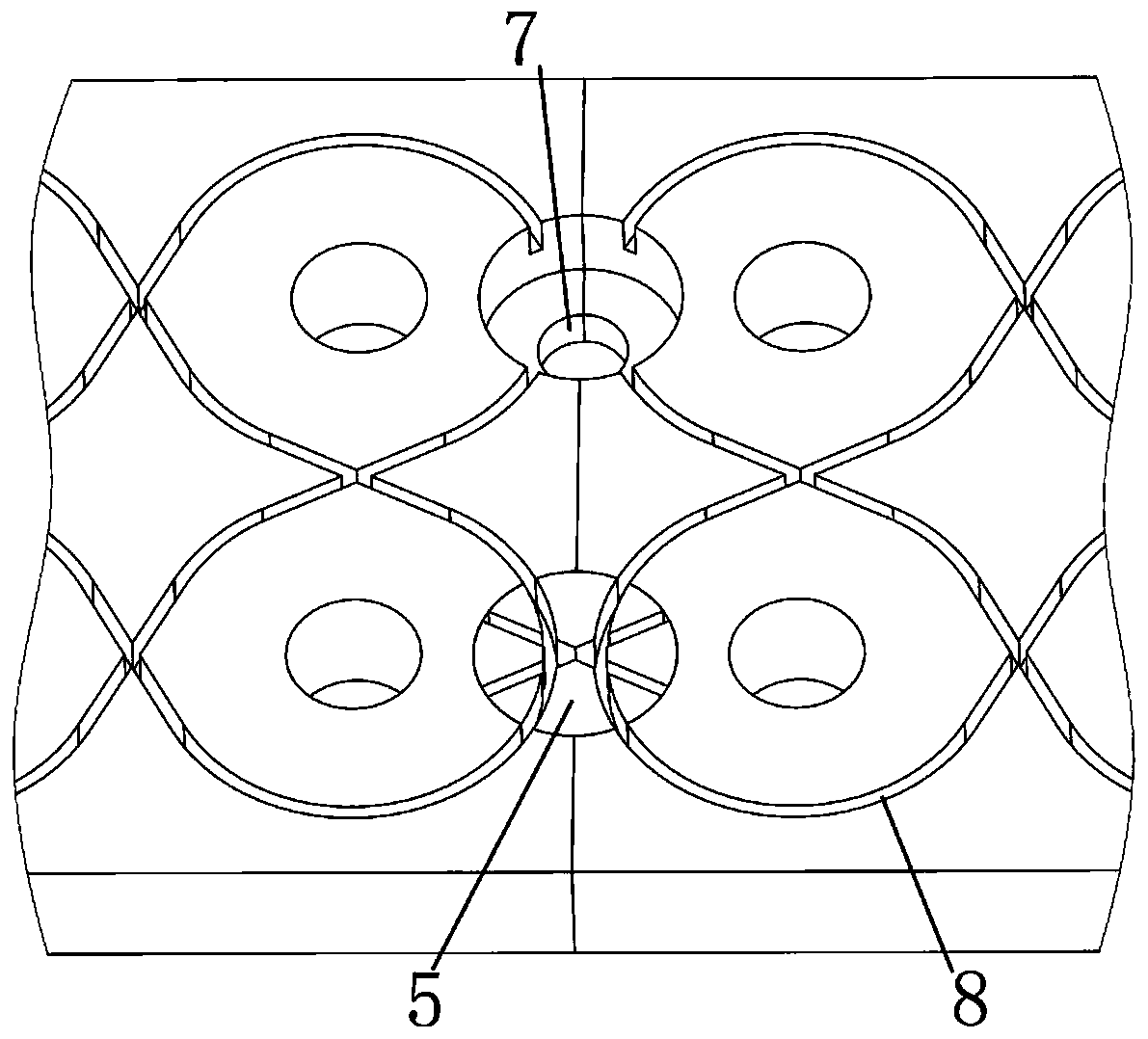

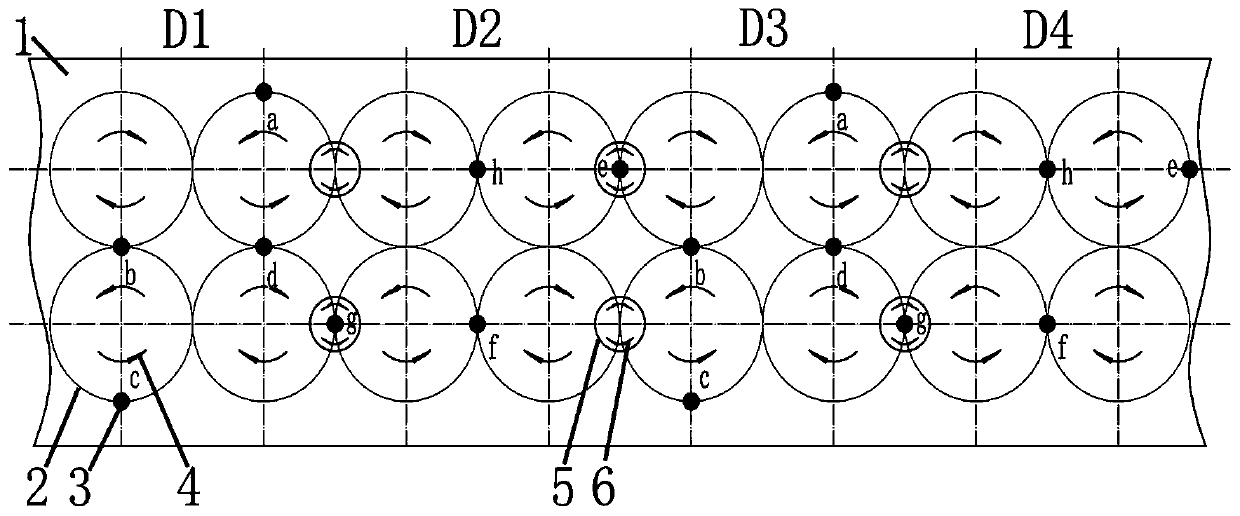

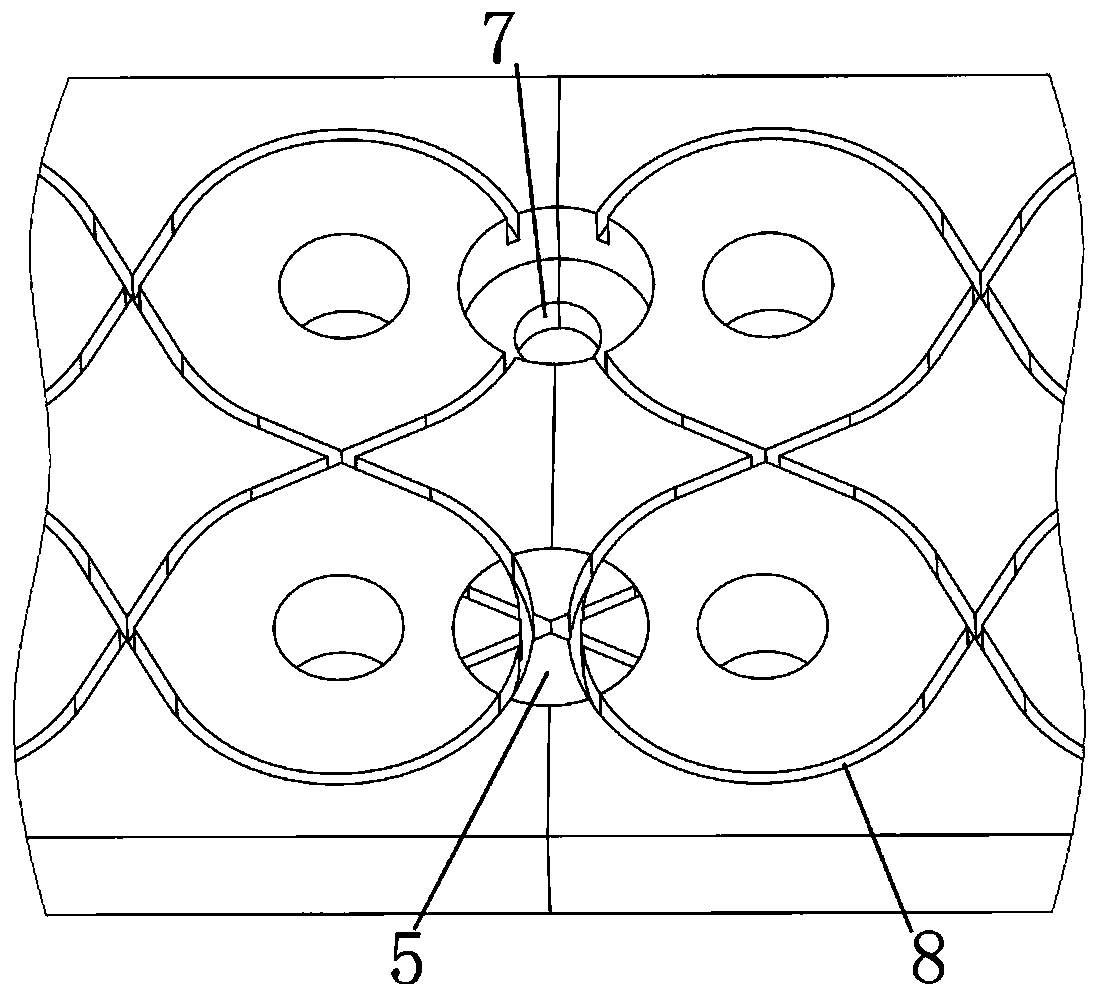

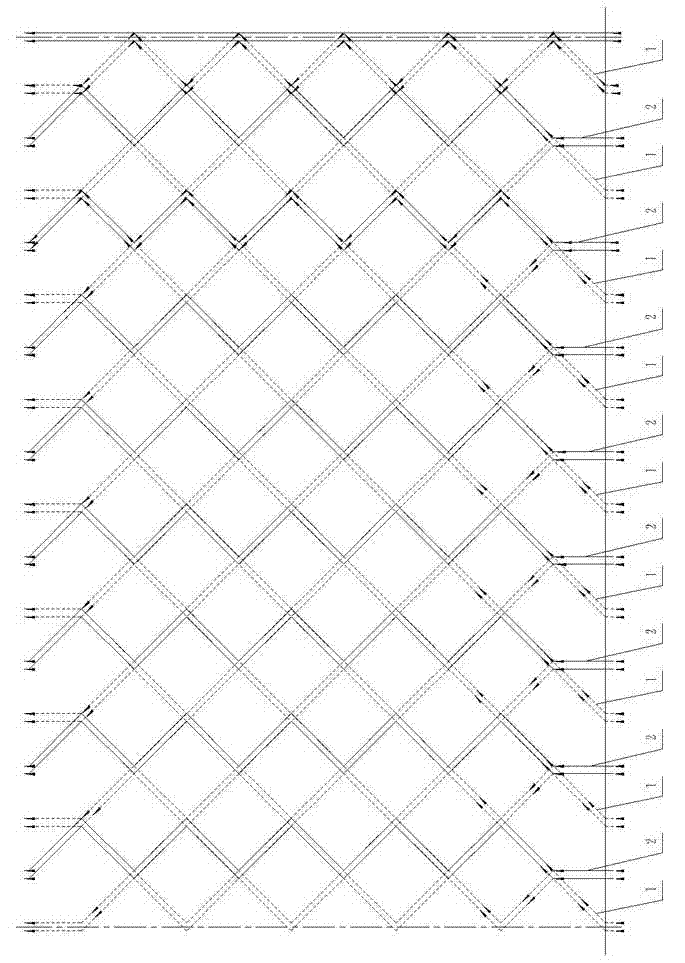

Modularized knotless net weaving equipment

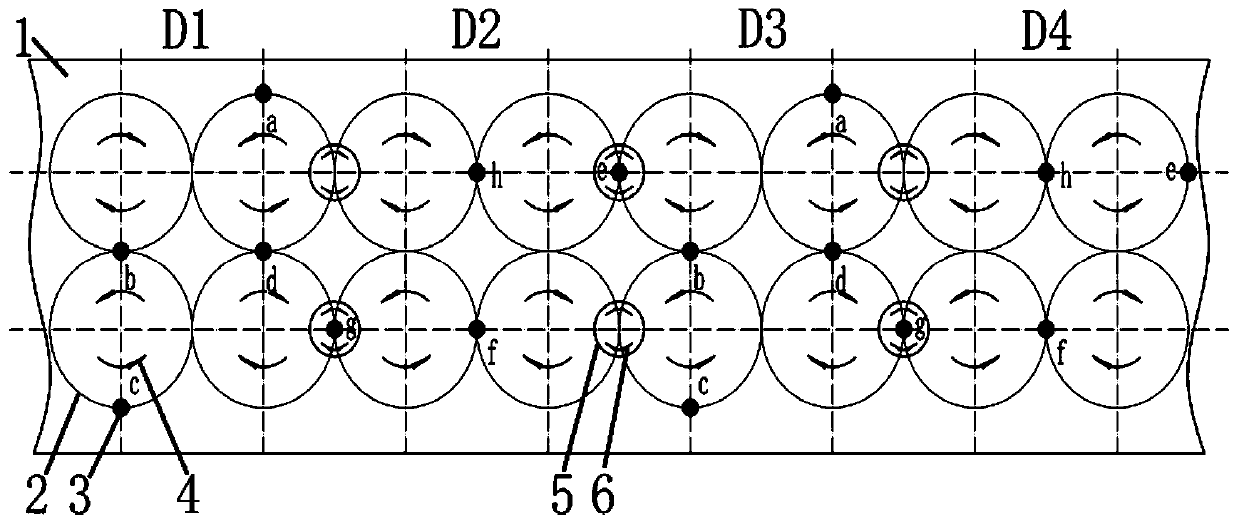

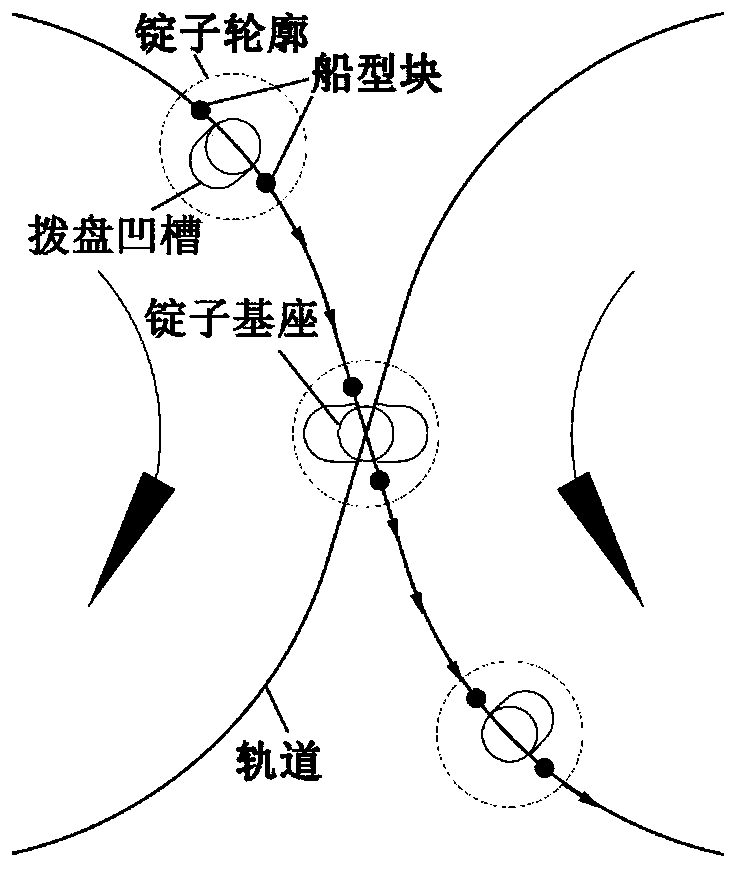

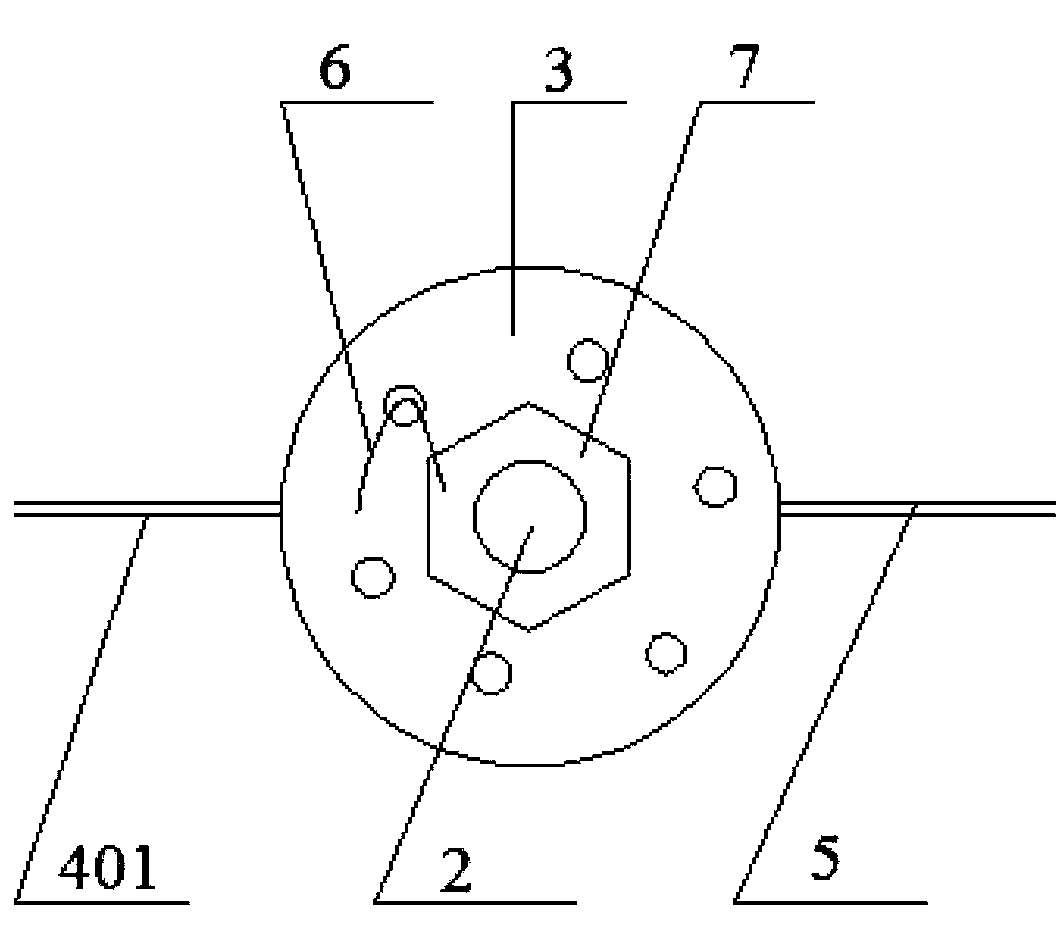

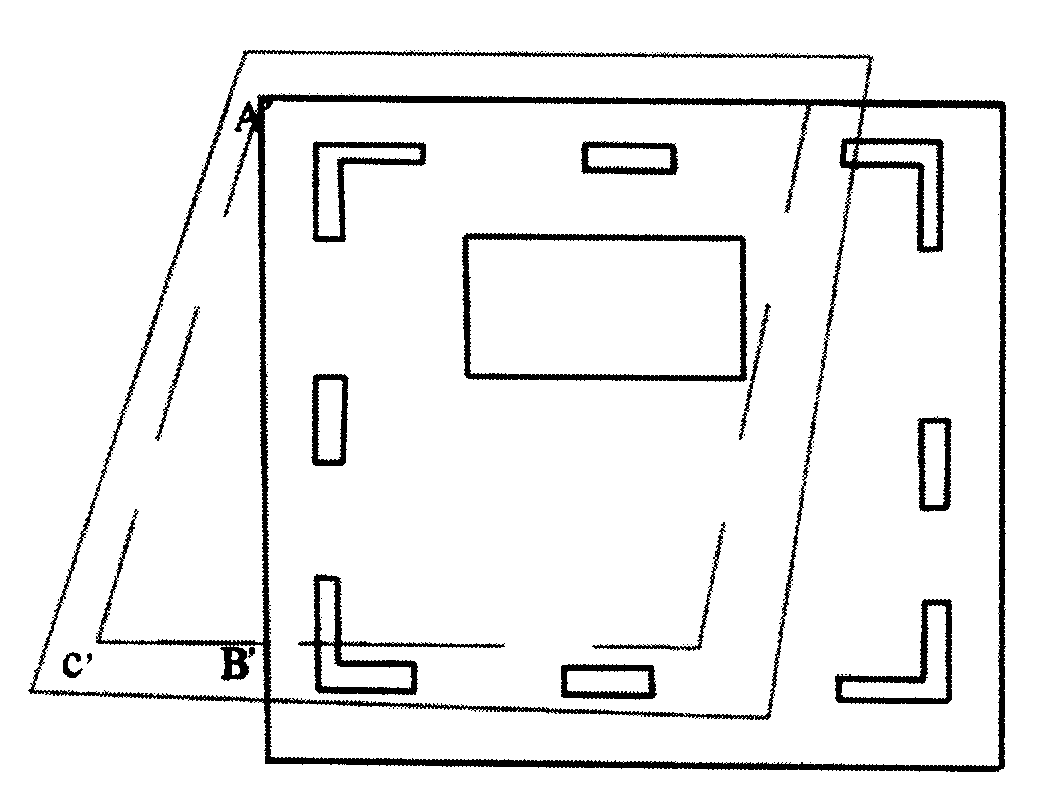

The invention relates to modularized knotless net weaving equipment. The equipment is formed by combining a plurality of modules A and a plurality of modules B. Each module A comprises a weaving chassis, a stirring disc, a spindle and a stirring disc driving part, wherein conversion block semicircular mounting holes are formed in the left and right sides of the upper surface of the weaving chassis, and a fixed spindle rail is arranged on the upper surface of the weaving chassis. Each module B comprises a conversion block and a conversion block driving part, wherein a variable spindle rail is arranged on the upper surface of the conversion block, the variable spindle rail of the conversion block comprises a set of crossed spindle rails and a set of non-crossed spindle rails, the crossed spindle rails are linear grooves with two middle points crossed with each other, the non-crossed spindle rails are composed of two opposite arcs, and the radius of the arcs is equal to that of the fixedspindle rails of the weaving chassis. The fixed spindle rails of the module A and the variable spindle rails of the module B are tangentially connected. The modularized knotless net weaving equipmentcan achieve the aim of weaving knotless nets in various types and specifications by changing the number and layout of the weaving modules.

Owner:孙以泽 +1

Process for weaving knitted lace cloth and knitted lace cloth

InactiveCN102182004AReduce manufacturing costPlay the role of lockingWarp knittingLiquid/gas/vapor textile treatmentFiberYarn

The invention relates to a process for weaving knitted lace cloth and the knitted lace cloth. The process comprises the following steps of: weaving, namely performing mixed weaving of elastic serging yarn, soluble vinylon fiber and basic raw fiber of fabric to obtain primary fabric, wherein the elastic serging yarn is woven in a horizontal row of an adjacent coil of a horizontal-row coil in which the soluble vinylon fiber is located; and 2, performing post finishing, namely soaking the primary fabric woven obtained in the step 1 in water, dissolving the soluble vinylon fiber to enable corresponding vertical rows which exist in a looping structure of the soluble vinylon fiber to lose connection, and contracting the elastic serging yarn to form a lace structure and then obtain a fabric product with the lace structure. The knitted lace cloth is provided with the lace structure which is woven by the process and arranged on the knitted lace cloth, and has the characteristics of simplicity in process, low production cost and easiness of promotion.

Owner:DONGGUAN TEXWINCA HLDG

Process for manufacturing antibacterial and abrasion-resistant lace from apocynum venetum fibers

ActiveCN103046218AAdd feminine styleRetain propertiesSucessive textile treatmentsBiochemical fibre treatmentChemistrySpecial design

The invention relates to a process for manufacturing antibacterial and abrasion-resistant lace from apocynum venetum fibers. The process has the advantages that after a special design for fiber preprocessing, yarn spinning, lace forming and weaving and low-temperature heating post-processing and special optimization for relevant parameters, technical difficult problems that large quantities of chemical antibacterial agents are used in the prior art, damage environments and injure users, and laces are not graceful, are hardened and stiff, and are complicated in pattern, troublesome in process, high in production cost and difficult to popularize are solved, characteristics of fabrics made from natural fibers can be kept, and excellent technical effects such as graceful style, lightness, thinness and breathability of the lace are realized.

Owner:FUJIAN CHANGLE HANGGANG TEXTILE

Low-bias-weft-skew knitted fabric

InactiveCN103572482ASimple structureReduce torqueWeft knittingHeating/cooling textile fabricsYarn tensionEngineering

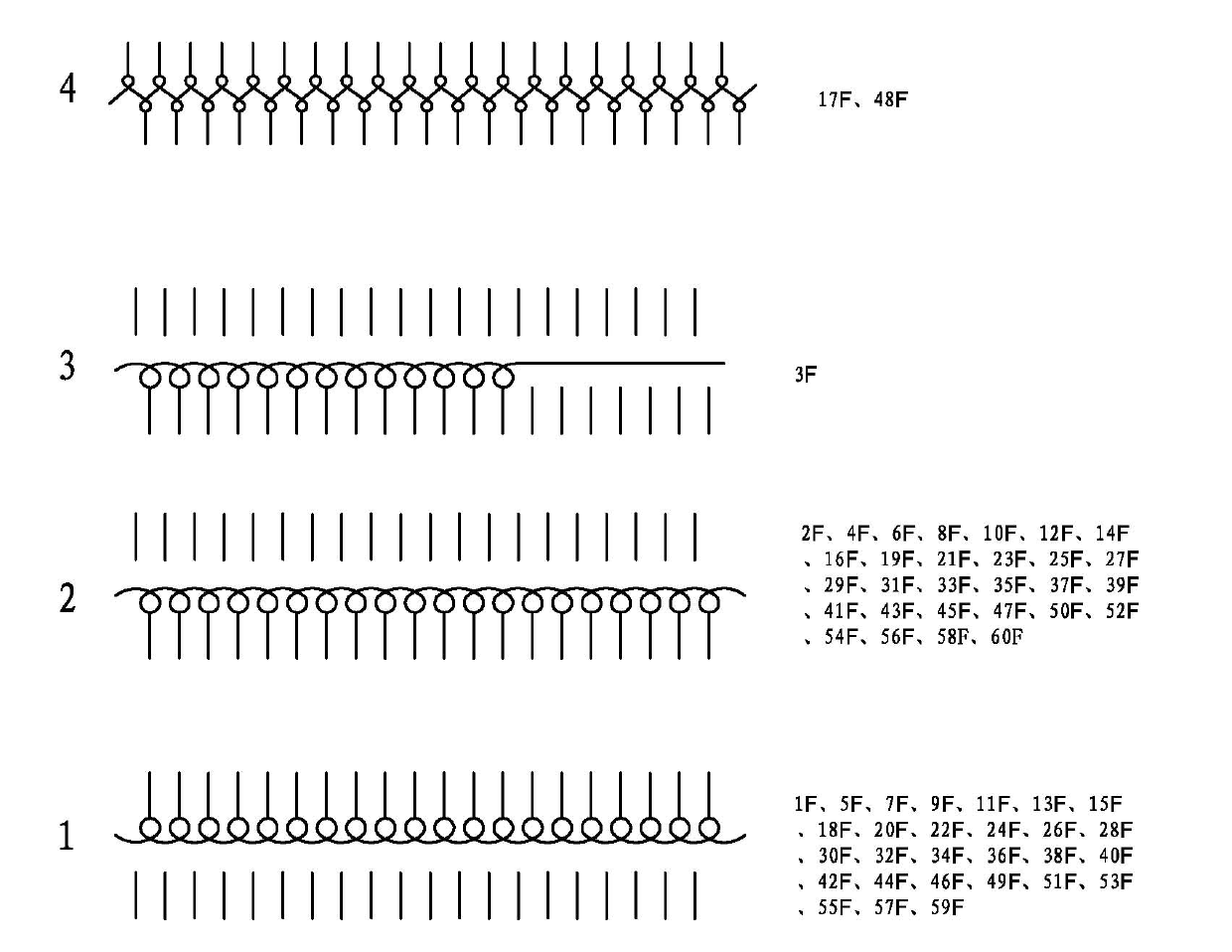

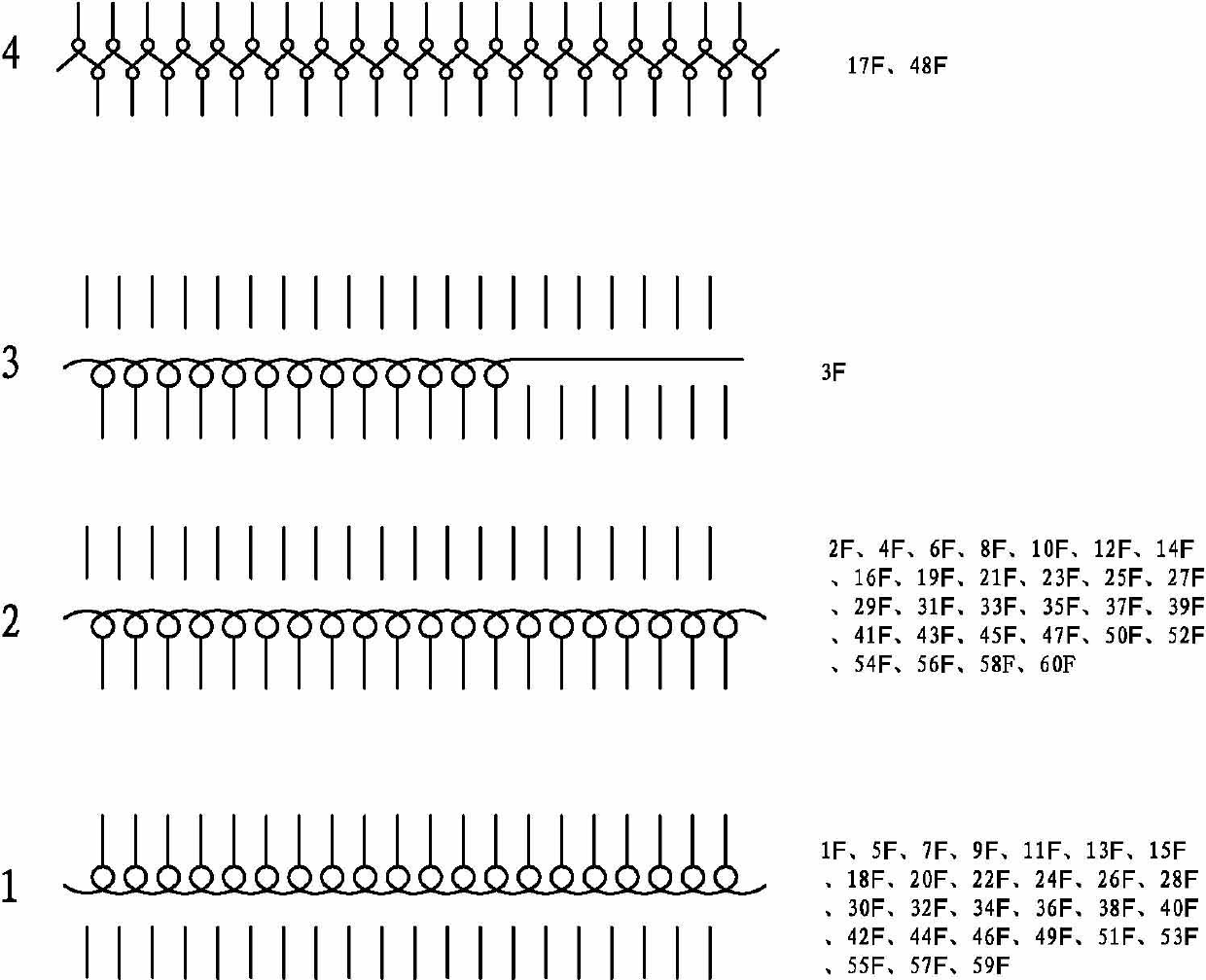

The invention discloses a low-bias-weft-skew knitted fabric which is characterized in that all-cotton false-twisting low-torque yarn with different colors is taken as a raw material and processed through the steps of spooling, yarn dyeing, drying, tightening, weaving, bleaching and dyeing, and after-finishing, so that the knitted fabric is formed; according to the weaving process, the fabric is woven on a single-sided round machine by using single-sided weft plain stitches; a threading manner is as follows: a fabric 1-32 F is threaded into all-cotton low-torque yarn in the same color, and a fabric 3-48 F is threaded into all-cotton low-torque yarn in another color; the weaving density is 300 millimeters per 100 stitches, and the yarn tension is 10-12 g; and the woven fabric is dyed, washed with water and subjected to low-temperature tenter setting treatment. According to the low-bias-weft-skew knitted fabric, the weaving process is simple, the operation is easy, and the false-twisting low-torque yarn is taken as the raw material, so that the yarn structure is improved, the torque of the yarn is greatly reduced, and loop skewing caused by the fact that the yarn is untwisted in a weaving and looping process is effectively avoided. Weaving parameters of the weaving process and the tenter setting treatment after weaving are adjusted, so that the bias weft skew of the knitted fabric is reduced further.

Owner:NANTONG TIMES CLOTHING

Weaving method for machine knitting wrinkle fabric

ActiveCN104404685AEasy to operateTo achieve the wrinkle effectOrnamental textile articlesBed linenPolymer scienceCombing

The invention relates to a weaving method for a machine knitting wrinkle fabric and is characterized in that the weaving method comprises the following steps: (1) preparing the raw material, the warp yarn adopts the high and low double beam, the high beam adopts the combing pure cotton yarn, the yarn count of which is 60 / 2, the low beam adopts the combing pure cotton yarn, the yarn count of which is 40 / 2, the weft yarn adopts the common cotton yarn, the yarn count of which is 40; (2) beaming: beaming in a batch mode; (3) slashing; (4) preparing rapier jacquard weaving: for the characteristic of the wrinkle fabric, the warp beam of the existing rapier loom is improved into the high and low double beam; preparing the flower type: small figured texture weave; (5) weaving via rapier-340 high and low double beam; (6) finishing; (7) desizing, pre-shrinking and sizing.

Owner:JIANGSU YUEDA HOME TEXTILE

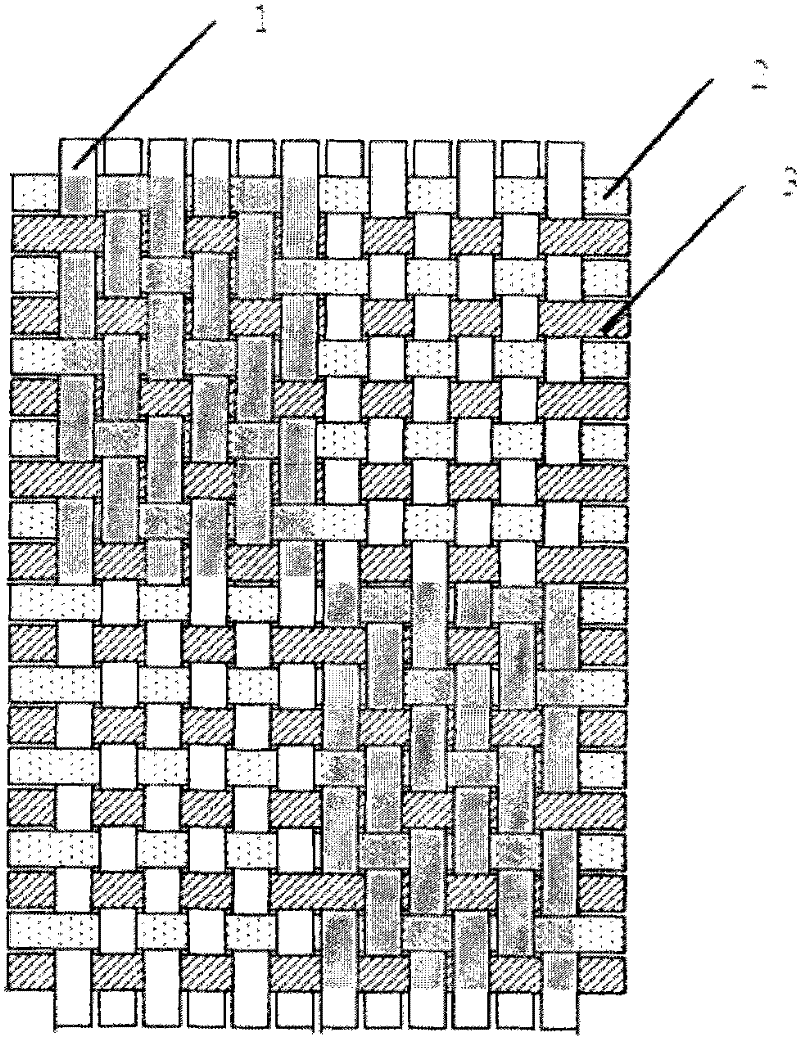

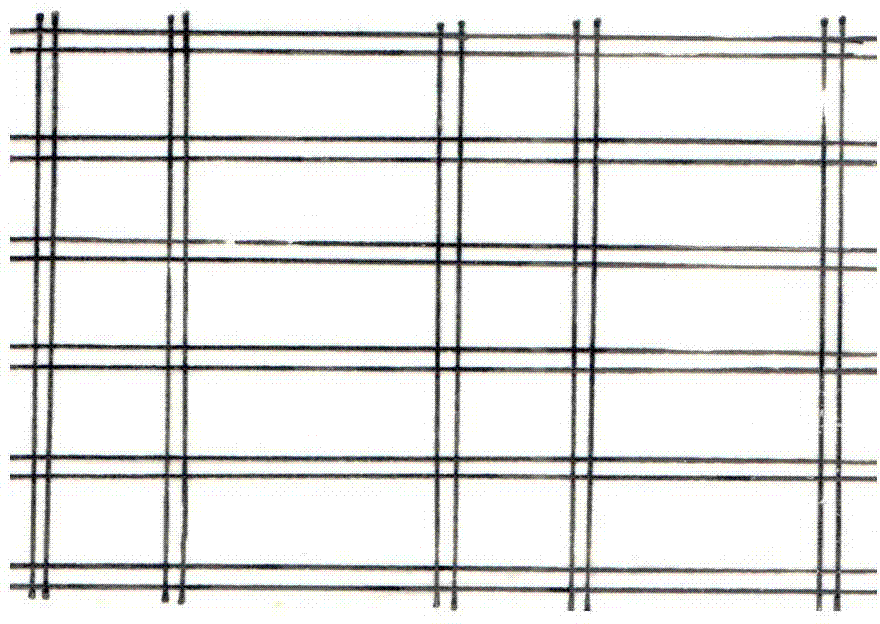

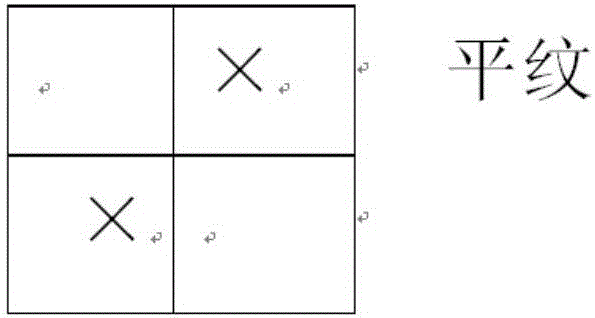

Chemical fiber/cotton blended colored woven fabric and weaving process thereof

The invention discloses a chemical fiber / cotton blended colored woven fabric which is interweaved by warps and wefts. The fabric is in 1 / 1 plain weave; the warps include four raw materials of rose 50S ecological cotton, brown 50S ecological cotton, white 50S ecological cotton and sea blue 50S ecological cotton; the wefts also include four raw materials of pink 70D / 40D brocade / spandex, green 70D / 40D brocade / spandex, white 70D / 40D brocade / spandex and dark green 70D / 40D brocade / spandex; the warp density of the fabric is 175 / ft. and the weft density of the fabric is 90 / ft. The chemical fiber / cotton blended colored woven fabric provided by the invention has the following technical effects of soft handfeeling of the fabric, clear and good-looking patterns, mild luster, bright color, simple and easy weaving process, high production efficiency and low cost.

Owner:HAIAN LIANFA ZHANGSHI YARN DYED

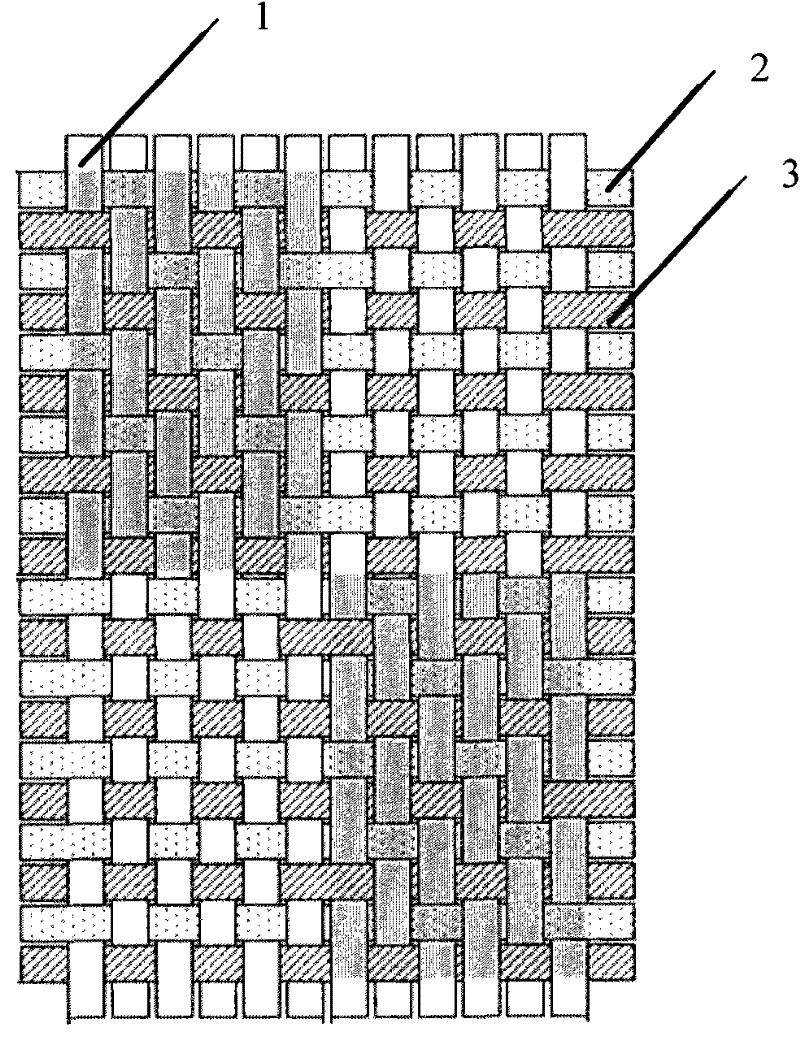

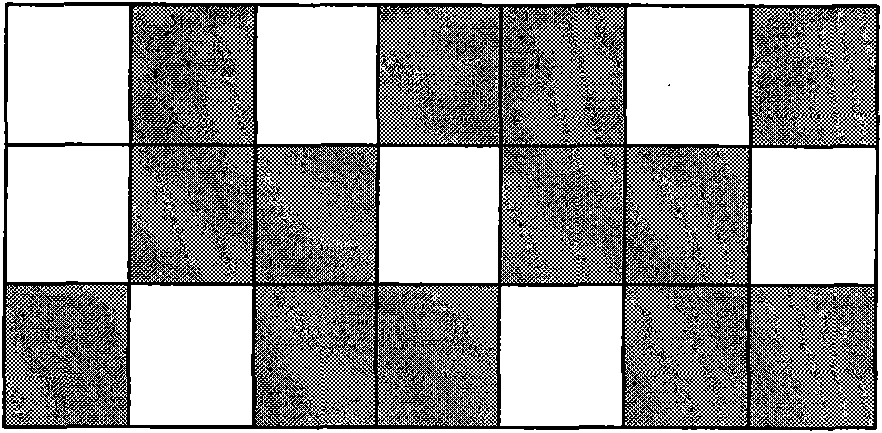

Textile fabric with jacquard effect

The invention discloses textile fabric with a lattice jacquard effect, and warps and wefts are interwoven into twill weave units and plain weave units, which are alternately arranged, wherein the warp and wefts in each twill weave unit are arranged by enabling one thread of warp to be arranged at the upper part and enabling two threads of wefts to be arranged at the lower part, and the warp and weft in each plain weave unit are arranged by enabling one thread of warp to be arranged at the upper part and enabling one thread of weft to be arranged at the lower part. 20D single-hole nylon yarns are utilized as the warps, and 32S linen yarns and 32S rayon filter yarns are utilized as the wefts. The textile fabric with the lattice jacquard effect can form the jacquard effect of enabling plain weave lattices and twill weave lattices to be scattered alternately on the whole and simultaneously achieve the visual effect enabling flash and dull gloss to be scattered alternately; and furthermore, the fabric is compact, and the weaving process steps are simple. As the linen component in the fabric is higher, produced ready-to-wear clothes can be worn next to the skin and are comfortable, environmentally-friendly and excellent in functions of absorbing moisture and removing sweat.

Owner:WUJIANG HANTONG TEXTILE

Supporting structure of ejector anchor net

InactiveCN103850695AAccelerated corrosionImprove the protective effectAnchoring boltsGlass fiberMetallic materials

The invention discloses a supporting structure of an ejector anchor net. The supporting structure comprises an anchor net and a plurality of anchor rods fixed in the anchor net, wherein trays are sleeved on the outer ends of the anchor rods, and the trays are fixed on the anchor net; the anchor net is composed of a glass fiber reinforced plastics anchor net main body and a plurality of reinforced ribs intermittently arranged on the glass fiber reinforced plastics anchor net main body, and the anchor rods are fixed on connections between the reinforced ribs and the glass fiber reinforced plastics anchor net body, and hooks are arranged on the reinforced ribs and penetrate through the trays. The anchor net body is made from glass fiber reinforced plastics instead of a metal material, so that the condition that concrete can be cracked and fallen off due to the fact that the anchor net is corroded while meeting water can be prevented; furthermore, the reinforced ribs are arranged on the glass fiber reinforced plastics anchor net main body, so that the integral structural strength can be improved; meanwhile, the trays are secondarily fixed through the hooks, so that the connection between the trays and the anchor net can be enhanced, the loosing or failure of the trays due to outside factors such as vibration of blasting can be prevented, and the shock resistance and supporting effect of the supporting structure of the ejector anchor net can be improved; in addition, the supporting structure provided by the invention is high in strength, good in tenacity, light in weight, and good in manufacturability, and the working efficiency can be improved and the maintenance cost can be reduced.

Owner:武钢集团有限公司

Three-dimensional braiding ribbed tube process and ribbed tube

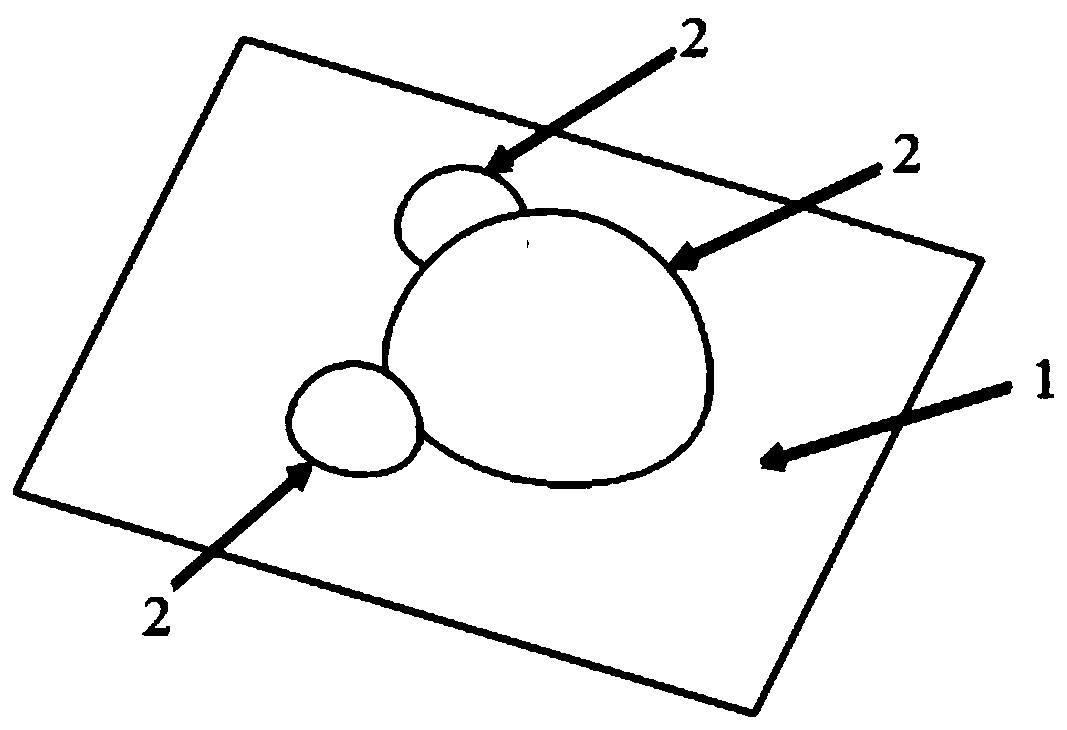

ActiveCN111926454AImprove mechanical propertiesImprove bending strengthBraidYarnStructural engineering

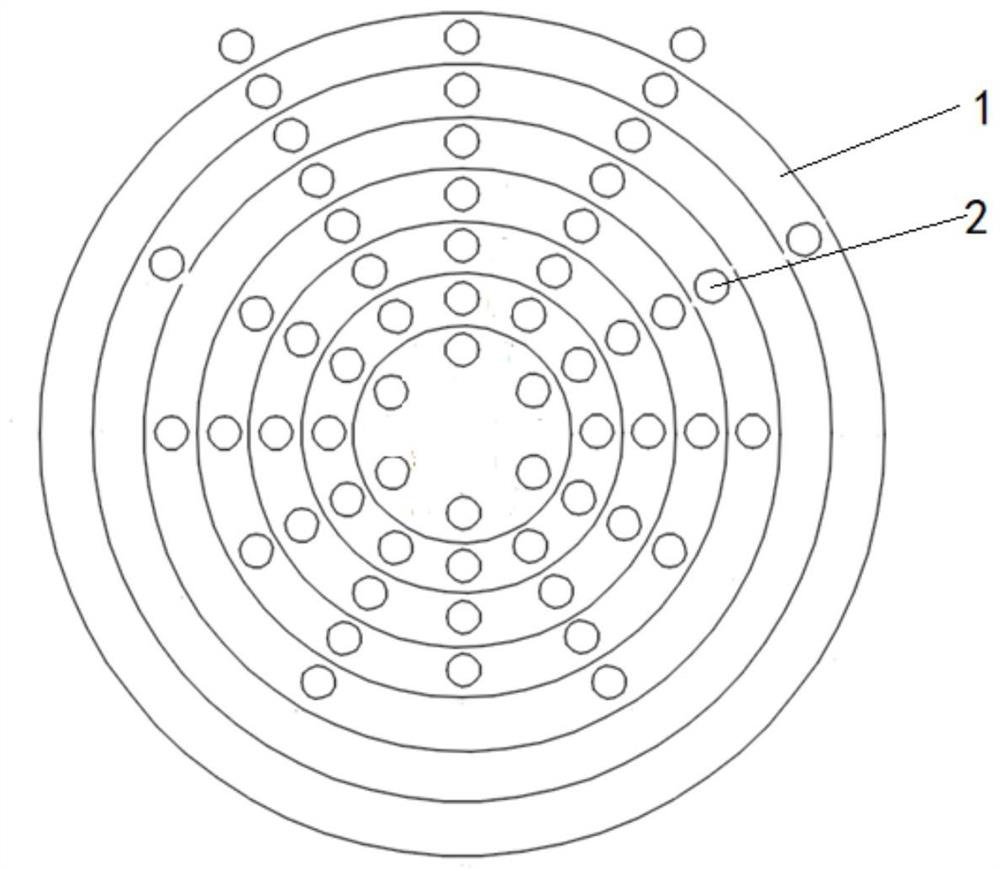

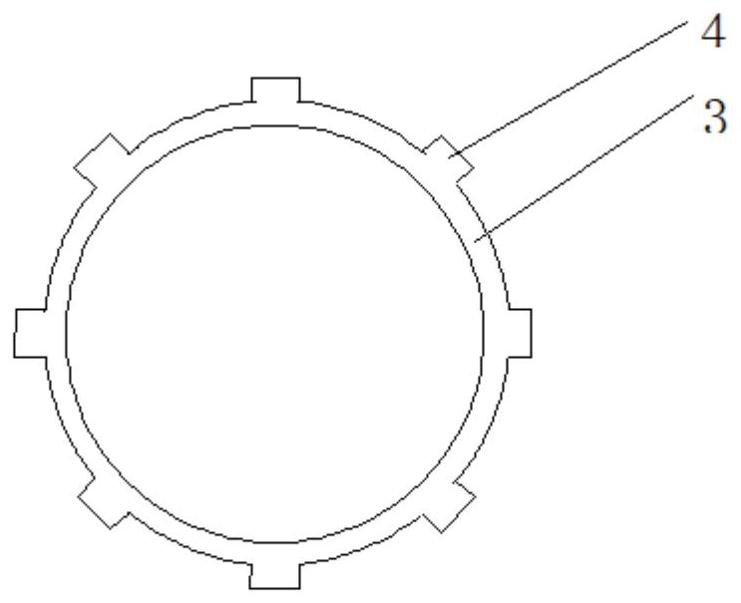

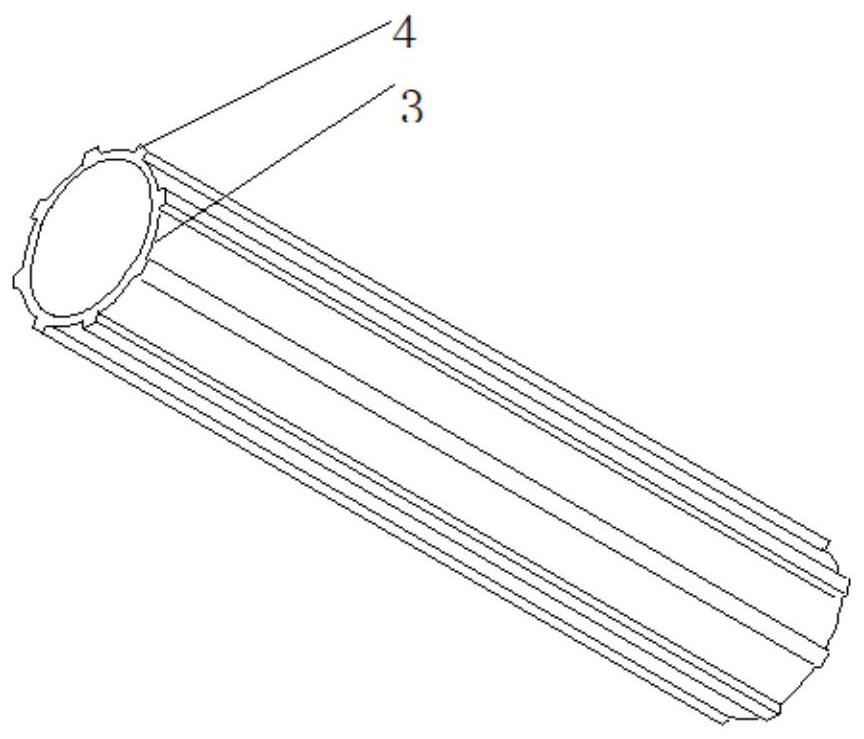

The invention discloses a three-dimensional braiding ribbed tube process and a ribbed tube. The process is completed on a three-dimensional braiding machine. The three-dimensional braiding machine comprises yarn carriers, wherein the plurality of yarn carriers corresponding to a plurality of main body braiding yarns are distributed on the circumferences of concentric circles with different diameters, and are continuously distributed on the circumferences; a part of the plurality of yarn carriers corresponding to a plurality of rib braiding yarns are distributed on the same circumferences as the main body braiding yarns, and the other part of yarn carriers are distributed in the innermost / outermost ring circumferences of the main body braiding yarns and are arranged concentrically on the circumference with the innermost / outermost ring circumferences; and the yarn carriers move radially and circumferentially to drive the main body braiding yarns and the rib braiding yarns to be knitted for forming the ribbed tube which comprises reinforcing ribs axially arranged on the outer / inner circumferential side walls. The ribbed tube which comprises reinforcing ribs axially arranged on the outer / inner circumferential side walls is formed through the radial and circumferential movement of the main body braiding yarns and the rib braiding yarns; the knitting technology is simple, and easilyrealizes the continuous production; and the obtained ribbed tube has a good mechanical property.

Owner:CHINESE TEXTILE ACAD

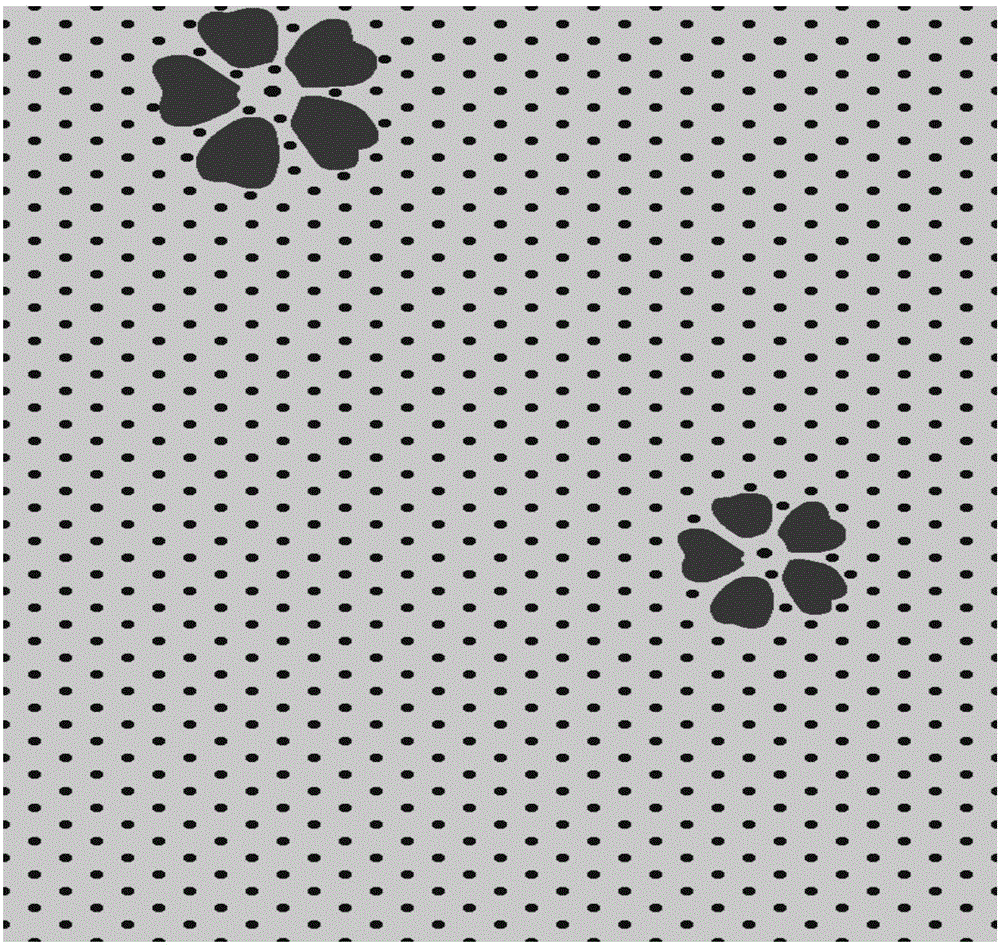

Textile fabric, and weaving process and application thereof

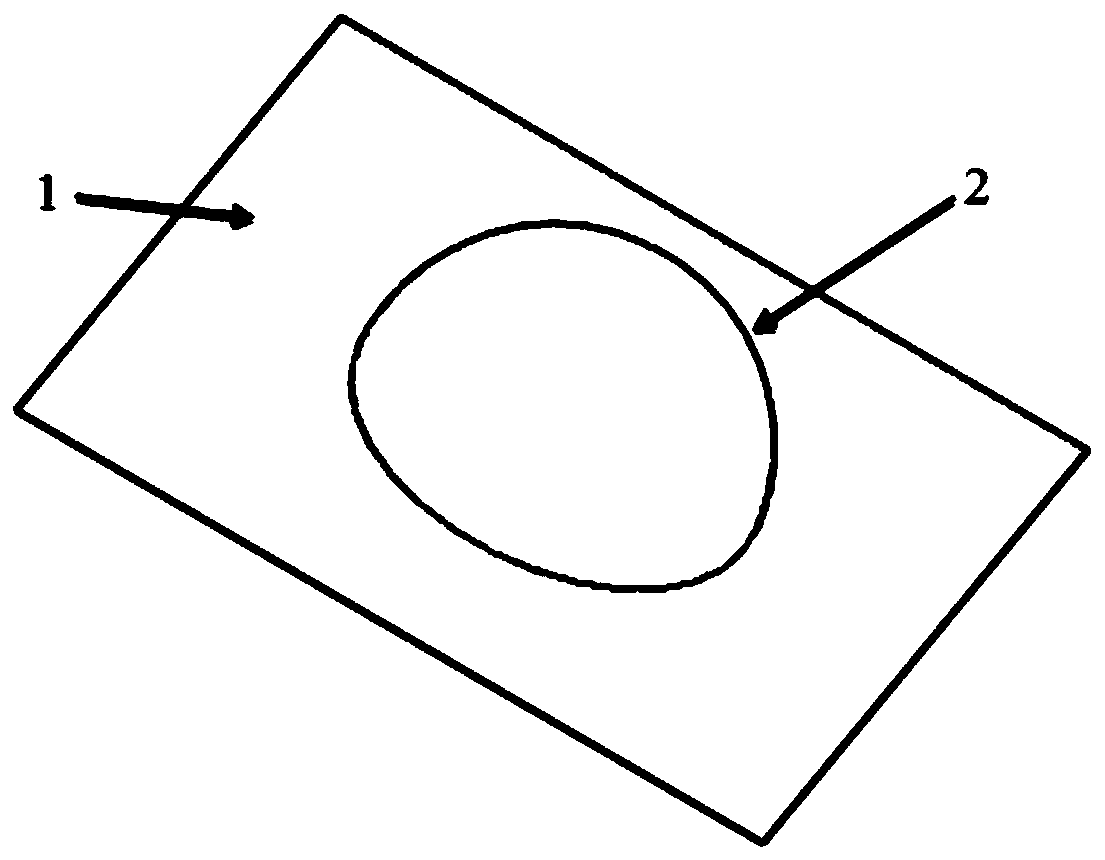

InactiveCN105922680ASimple weaving processAdd dimensionWeft knittingSynthetic resin layered productsVolumetric Mass DensityCivil engineering

The invention relates to a textile fabric. The textile fabric comprises a plurality of fabric layers, wherein the fabric layers are connected through soluble matters which are arranged on the fabric layers at equal or unequal intervals; meanwhile, the distance of the soluble matters and the density of the fabric layers are in an inverse relationship. The textile fabric provided by the invention is added with the soluble matters, and the connected fabrics can form a plurality of fabric layers, so stereoscopic sensation of the fabric is reinforced; meanwhile, compared with a single-layer fabric, the textile fabric provided by the invention is greatly increased in artistic appearance.

Owner:SHAOXING WUCHENG KNITTING

Weaving method of variable-mesh knotless net

Owner:孙以泽 +1

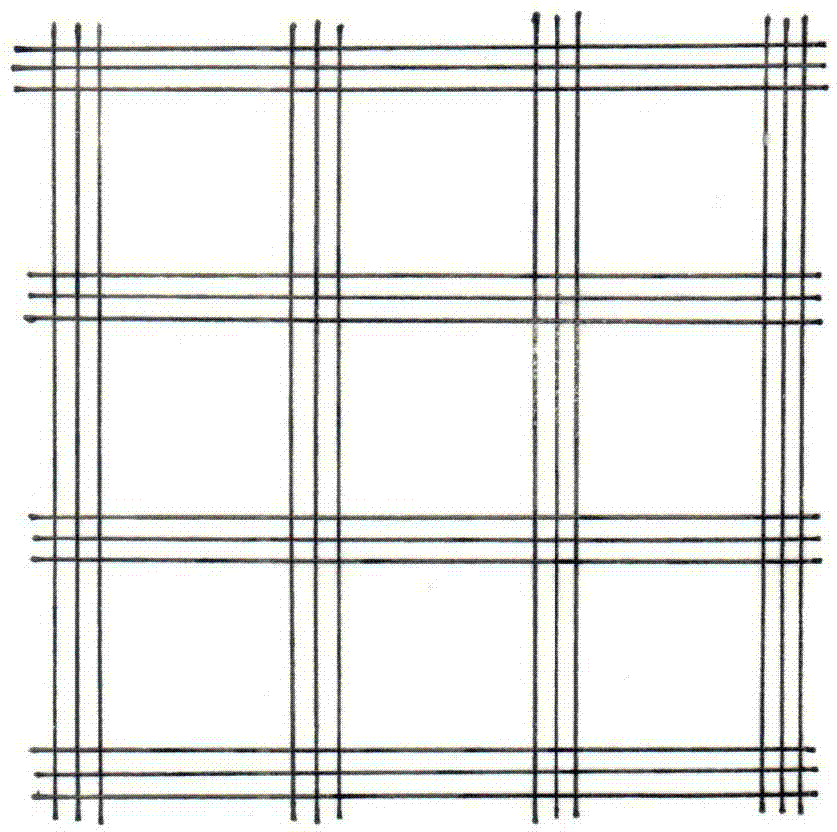

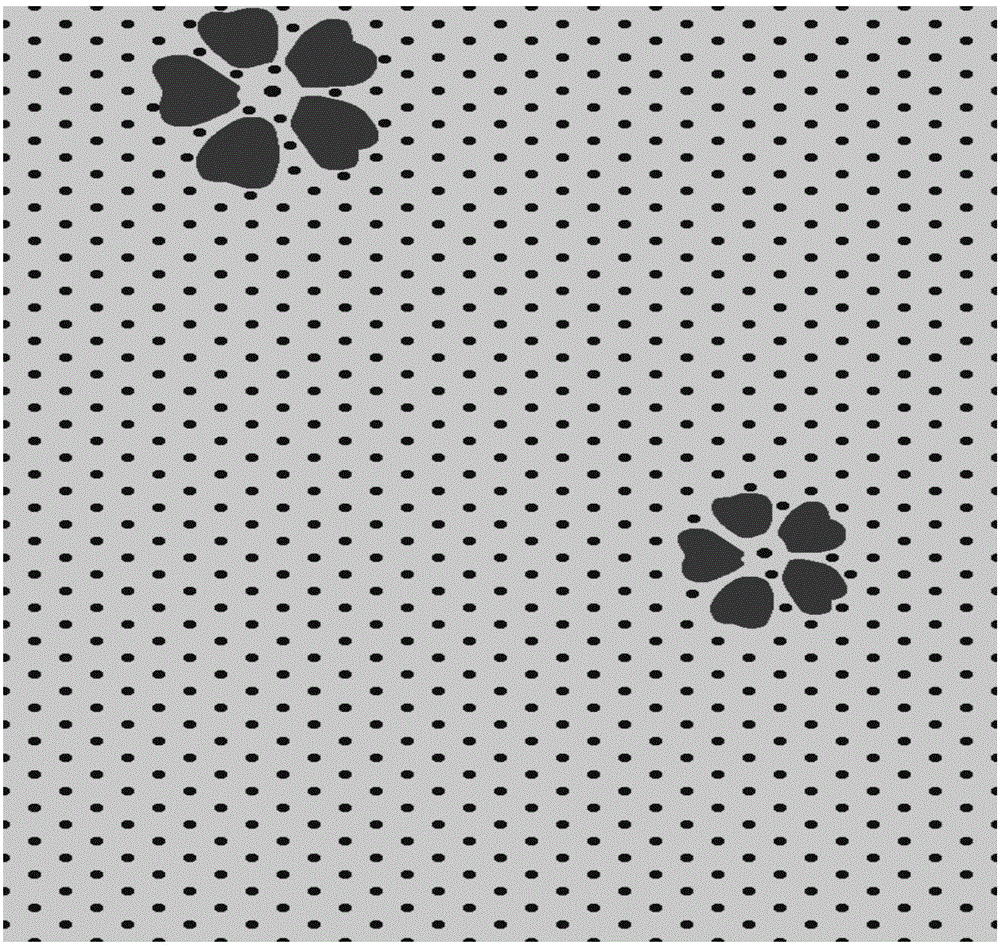

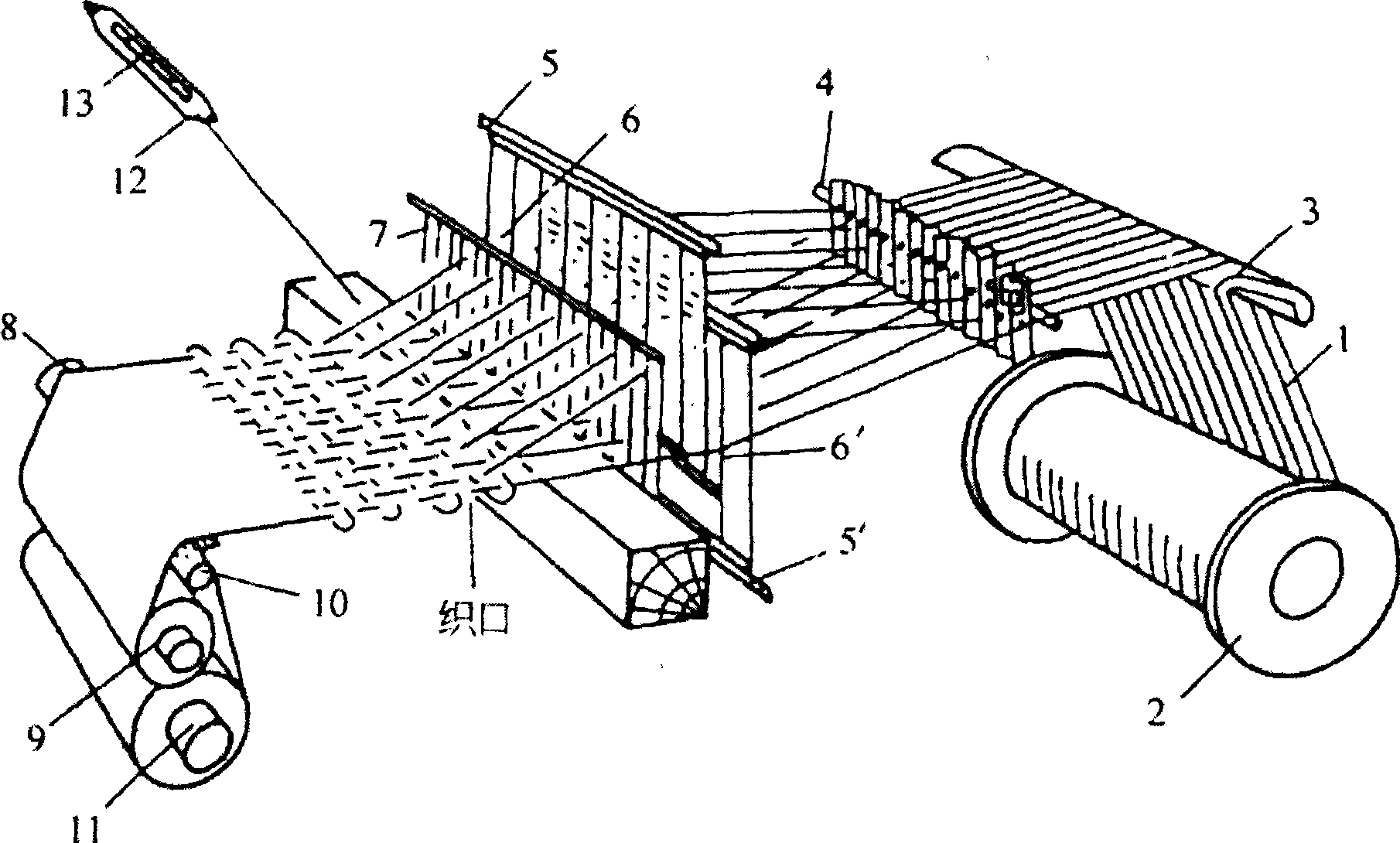

Real silk fabric with square meshes and production method thereof

ActiveCN103696090ASoft touchSimple weaving processHeating/cooling textile fabricsOpen work fabricsPolymer sciencePolymer chemistry

The invention discloses a real silk fabric with square meshes and a production method of the real silk fabric with square meshes. The real silk fabric with square meshes is woven by a normal weaving loom, degummed real silk yarns are adopted as main material of warp and weft, and a piece of low-temperature thermal bonding silk is embedded in a cabling manner, multiple pieces of water soluble silk are embedded in both warp and weft directions at intervals in a parallel arrangement manner, the fabric is designed with plain weave with simple weaving technology, two different yarns are interwoven in both warp and weft directions, performing open width washing to the fabric produced by the method at the water temperature of 50 DEG C, the fabric is hot pressed after being dried, the hot pressing is performed at the temperature of 85 DEG C, at last the finished product is the real silk fabric with square meshes with stable warp and weft structure.

Owner:SUZHOU VOCATIONAL UNIV

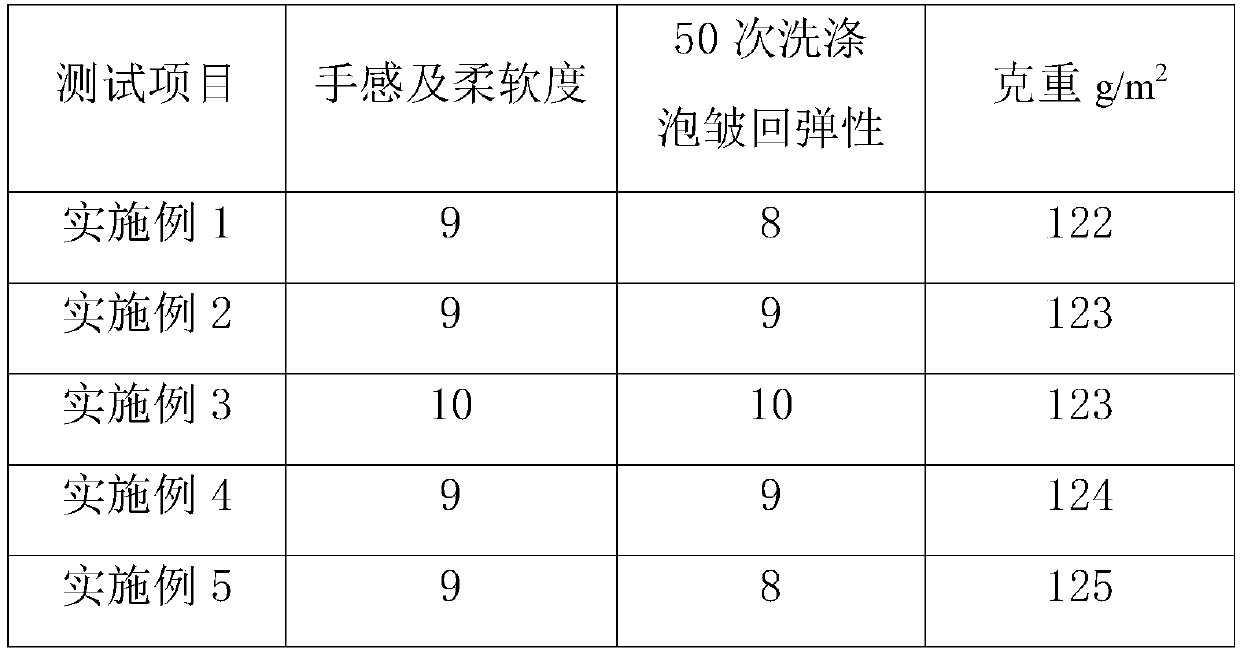

Non-mechanical bubble fabric production process

InactiveCN110129953ASimple weaving processImprove efficiency and stabilitySucessive textile treatmentsSingeingPolyesterSizing

The invention discloses a non-mechanical bubble fabric production process. The process comprises warping, sizing, weaving, desizing, scouring and bleaching and dyeing and finishing. The specific production process comprises the following steps: S1, yarn selection: first warp and second warp are included in the warp direction, the first warp is cotton yarn, and the second warp is one of spandex andPTT; weft comprises cotton yarn and polyester filament in the yarn number ratio being 10:(3-7); S2, warping; S3, drafting; S4, warp rebeaming: the first warp and the second warp after desizing are rebeamed by a warp rebeaming machine to single warp beam, and weaving is performed by the single warp beam; S5, weaving; S6, singeing; S7, pretreatment by an overflow machine; S8, presetting; S9, whitening by the overflow machine; S10, setting and rolling. The production process is efficient and stable, the produced bubble fabric is comfortable, soft and lasting in bubble crease, and the bubble crease has the advantage of high resilience effect.

Owner:江苏锐晟纺织科技有限公司

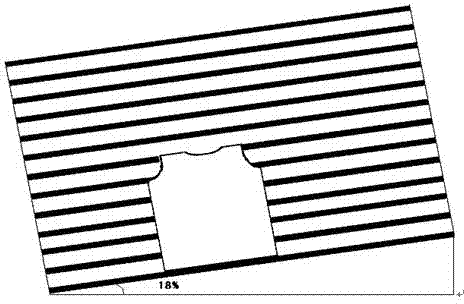

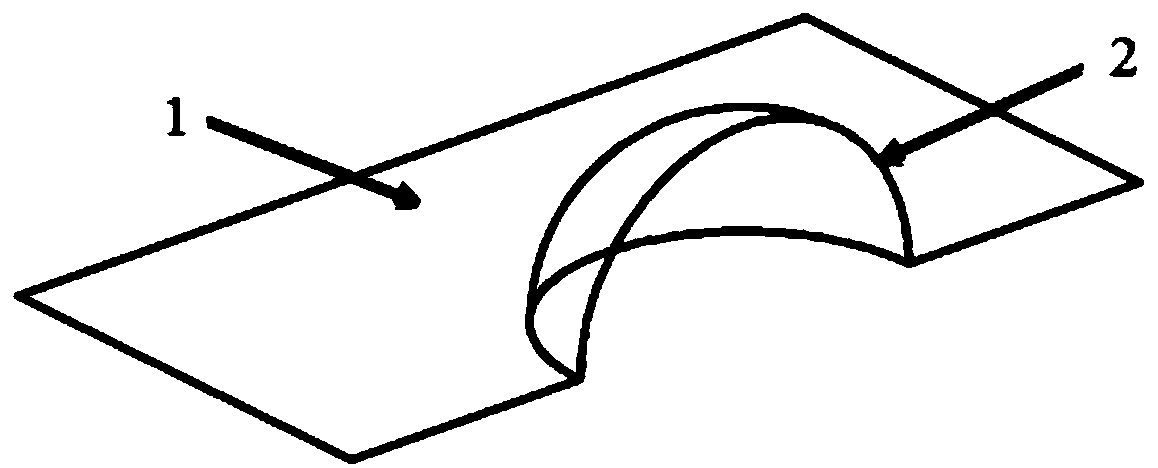

Elastic and wrinkled multi-layer fabric and weaving method thereof

InactiveCN106192130AImprove breathabilityGood flexibilityMulti-ply fabricsSwivel-woven fabricsYarnSurface layer

The invention provides elastic and wrinkled multi-layer fabric. The fabric comprises an upper surface layer, a middle layer and a lower surface layer, all of which are connected in order. The middle layer is woven by elastic yarns. The elastic and wrinkled multi-layer fabric has following beneficial effects: the middle layer is woven by elastic yarns and subjected to water processing, tentering, shaping and drying operation after weaving such that the middle layer can contract and be wrinkled; the fabric has elasticity in all direction so that application and decoration performance of the fabric are improved greatly; in addition, shrinkage rate of the elastic yarns is great; lower density is used so that the fabric is more breathable.

Owner:河北瑞春纺织有限公司

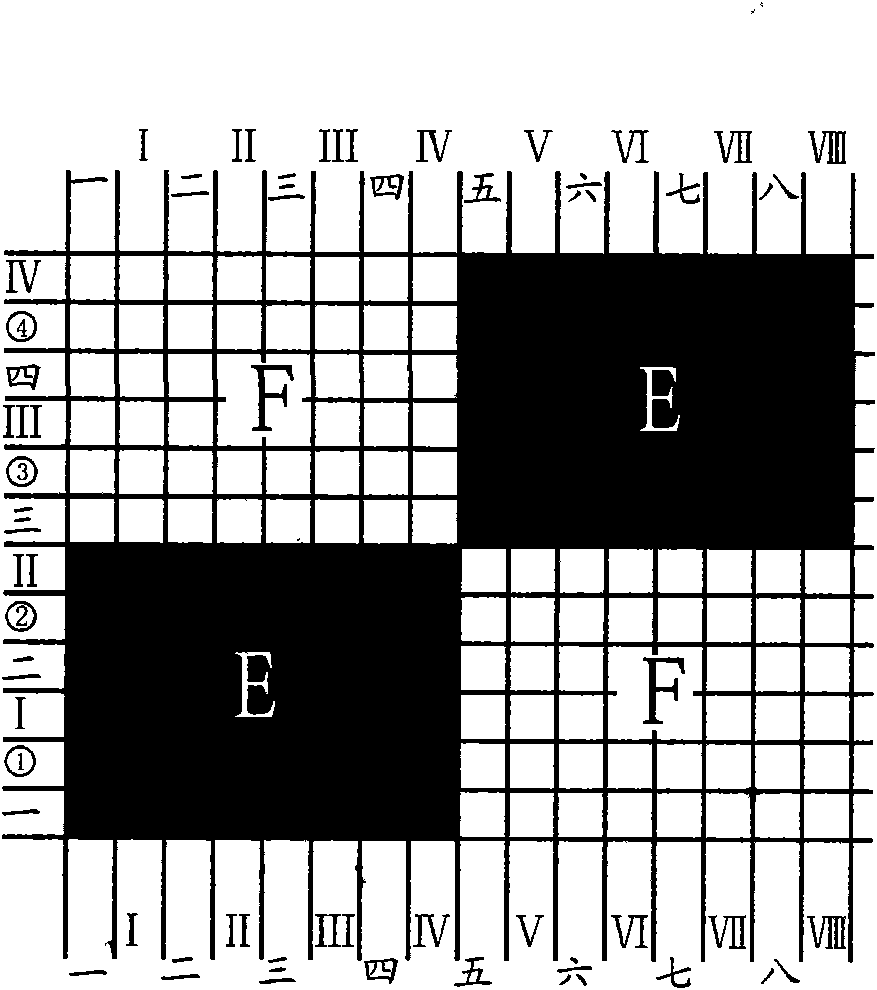

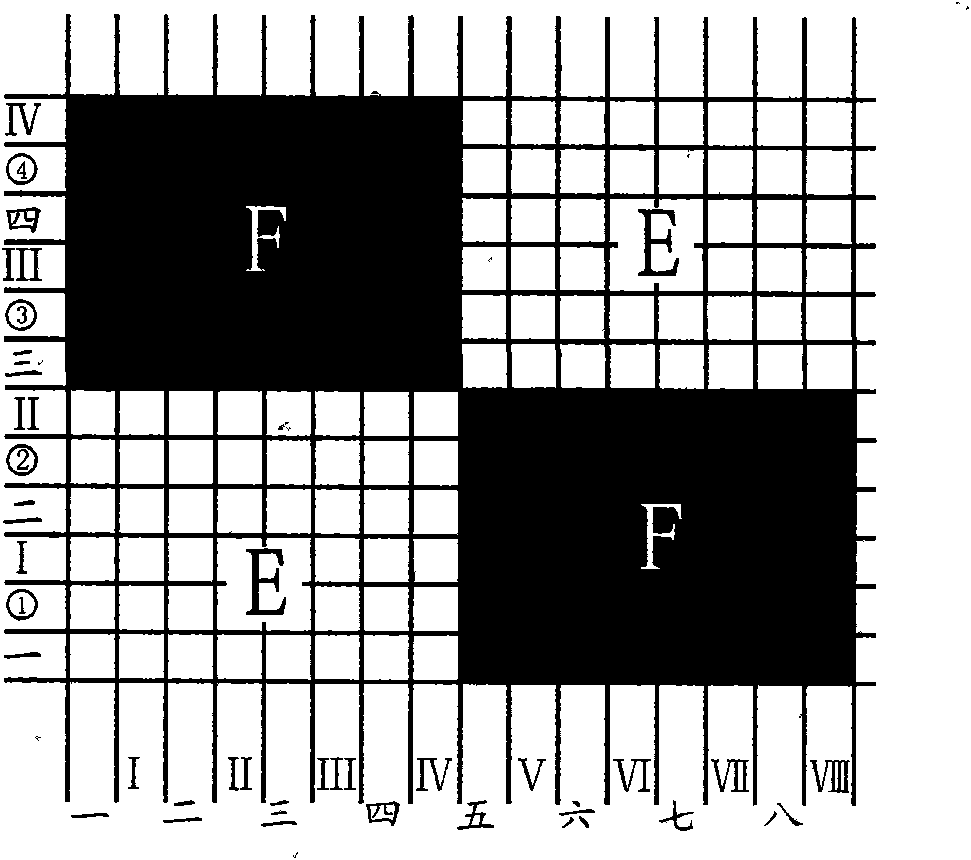

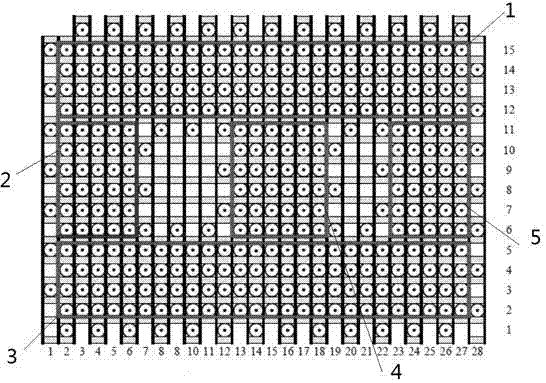

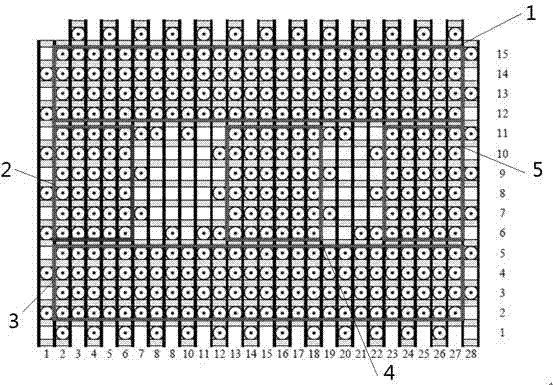

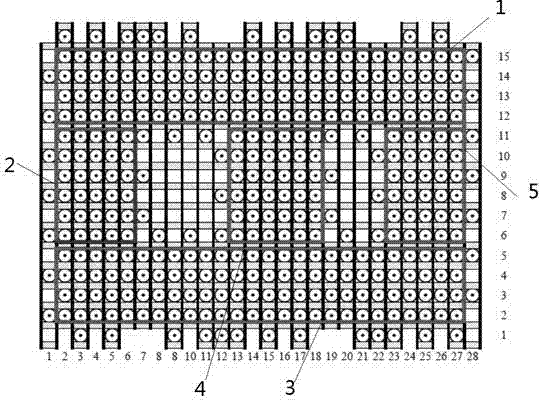

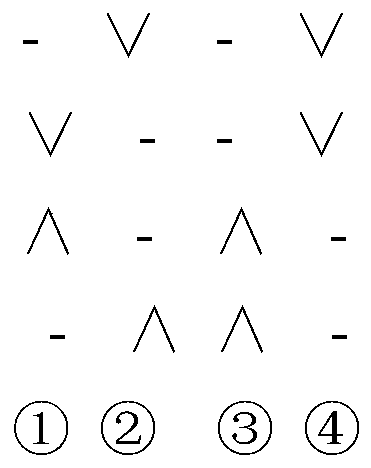

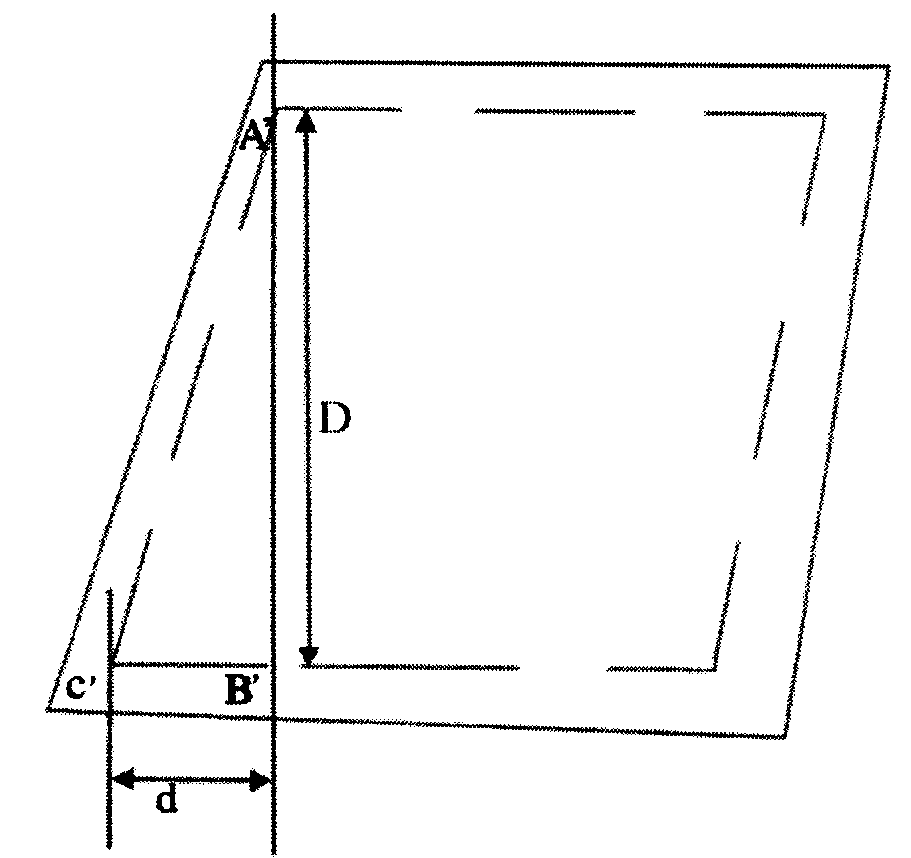

A 3D weaving method about special-shaped section

The invention discloses a 3D (Three-dimensional) knitting method for a special-shaped section. A whole knitting region is divided into a plurality of rectangular knitting regions which are connected with one another and have the same size; each rectangular knitting region is divided into 5 knitting working regions; the 3D knitting method adopts a four-step-process 1*1 knitting method and a knitting cycle is finished through 7 process steps; the 3D knitting method for the special-shaped section is finished through a plurality of knitting cycles. According to the knitting method disclosed by the invention, yarn carriers are separated into a plurality of rectangular knitting regions, which are independently connected with one another, on a common rectangular knitting machine according to a section structure of a prefabricated part, and then the 7 knitting steps are carried out so that the yarn carriers in the plurality of knitting regions finish one time of four-step-process knitting in the seven-step knitting cycle; the knitting regions are completely connected together so that 3D knitting of the prefabricated part with the complicated section is realized; the knitting process is simple and the knitting efficiency is high.

Owner:IANGSU COLLEGE OF ENG & TECH

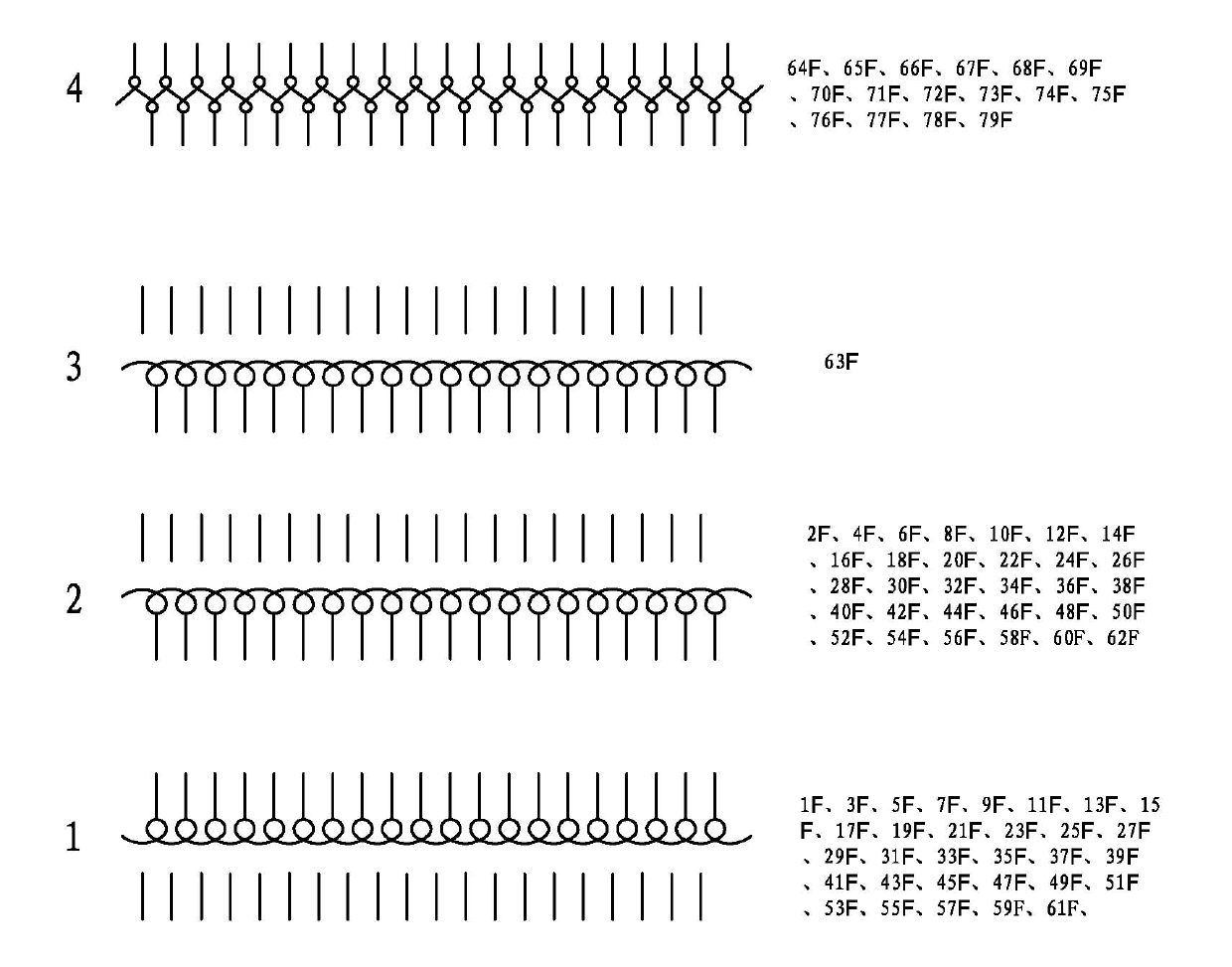

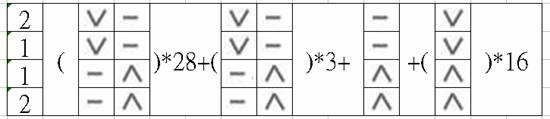

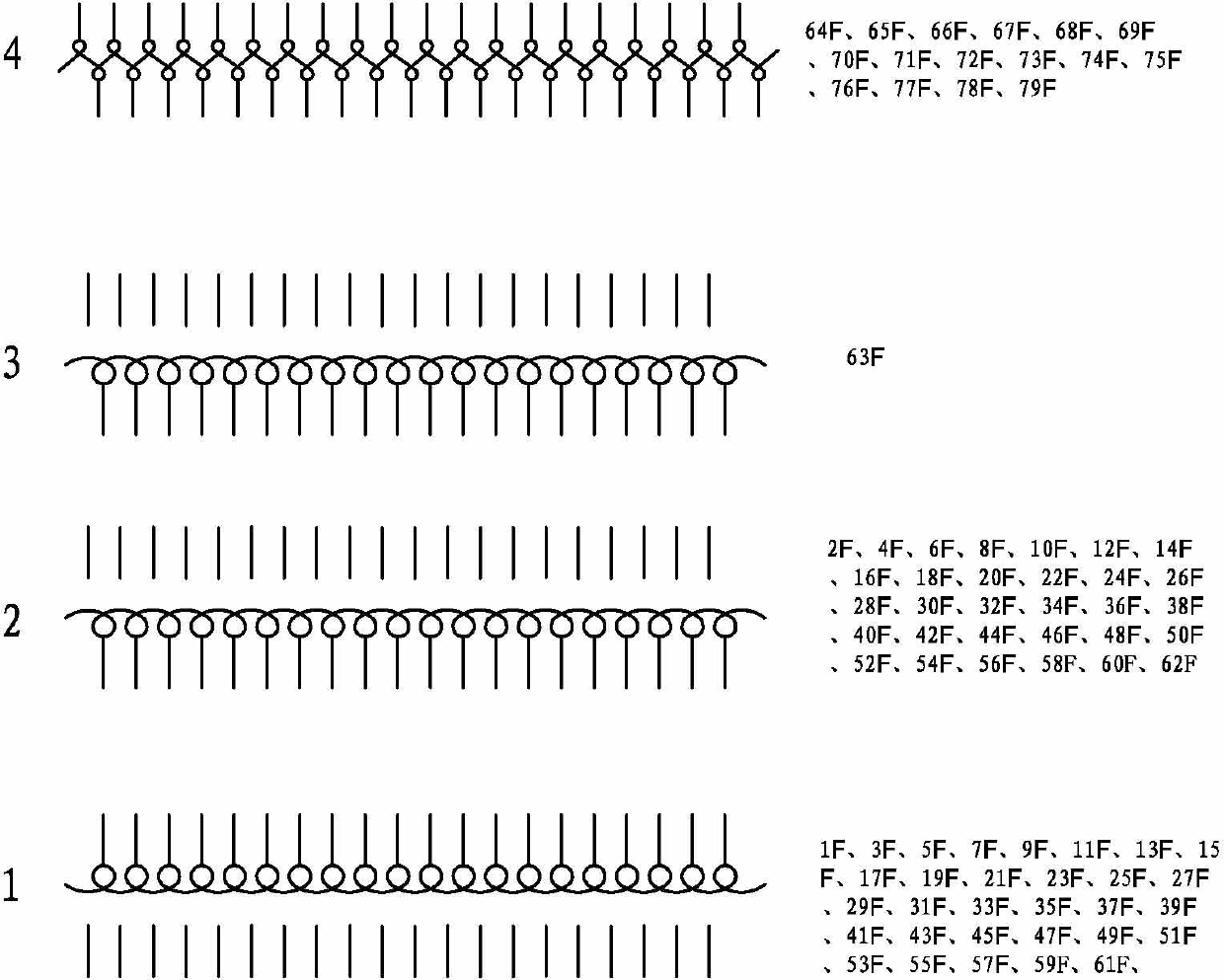

Tatting-imitation knitted Roman cloth fabric and preparing method thereof

InactiveCN109825938ALow elongationSmall shrinkageWeft knittingHeating/cooling textile fabricsYarnEngineering

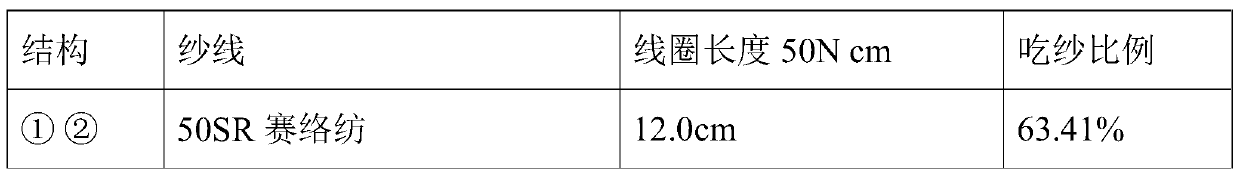

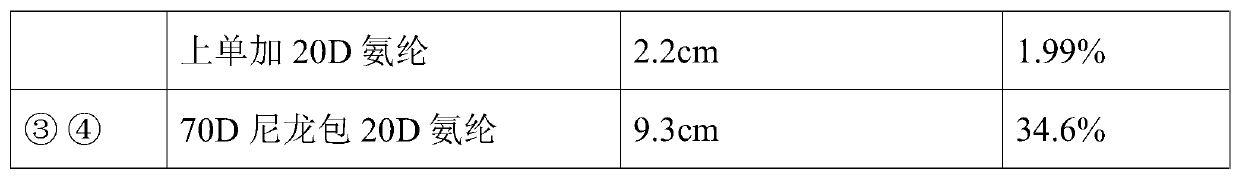

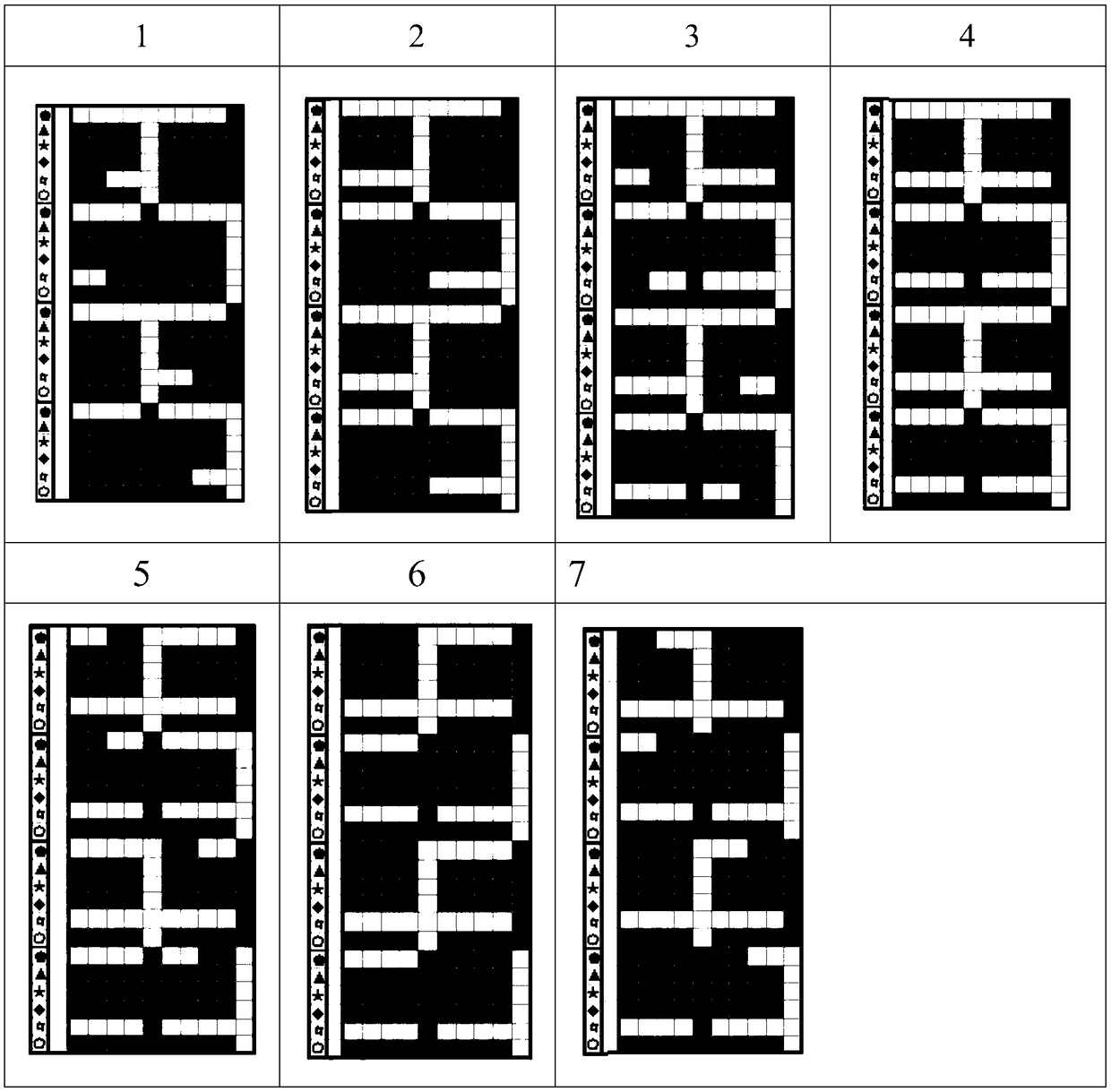

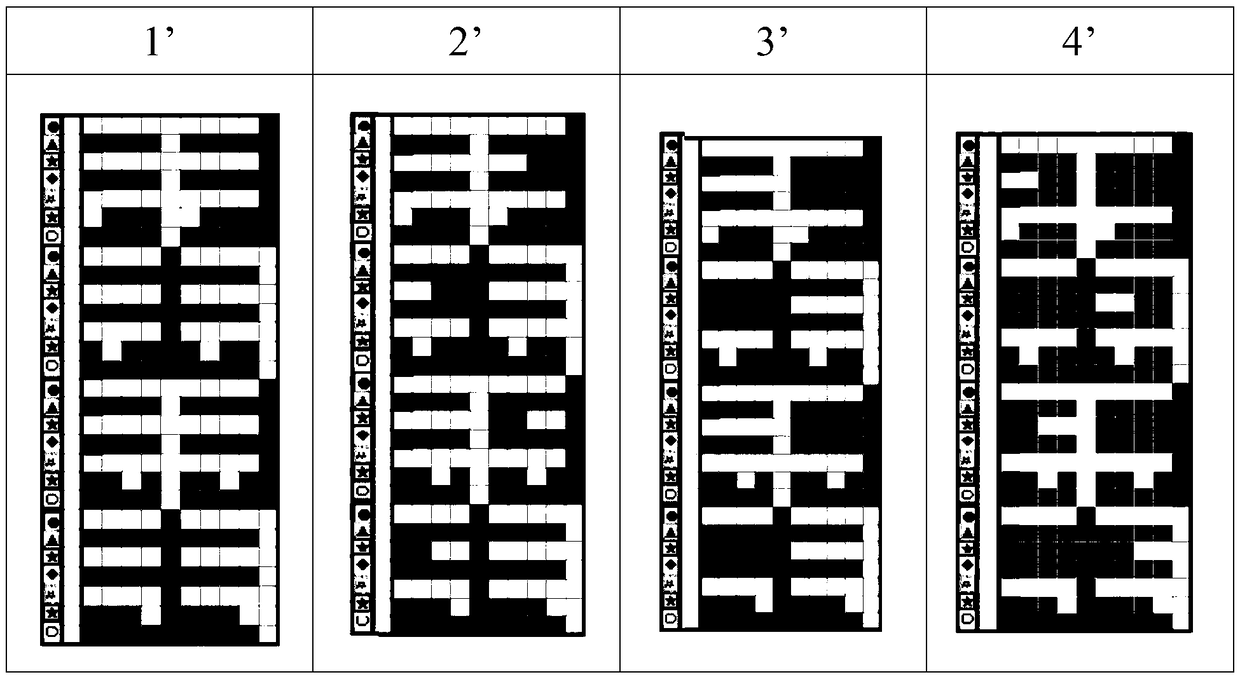

The invention relates to the technical field of spinning, in particular to a tatting-imitation knitted Roman cloth fabric and a preparing method thereof. The fabric is prepared from, by weight, 63.41%of 50SR siro spinning yarn, 1.99% of 20D spandex and 34.6% of 70D nylon covered 20D spandex. The fabric has the advantages that the prepared fabric has the tatting fabric characteristics of small ductility, low shrinkage rate and the like, is good in sizing performance and can be used as a fashion fabric, and meanwhile the knitted fabric is low in development cost, simple in weaving process and high in unit occupied area production efficiency.

Owner:SHANGHAI JIALE

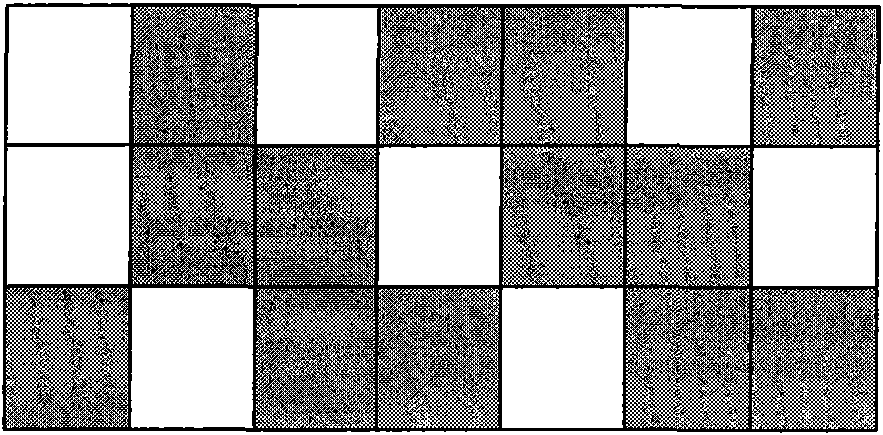

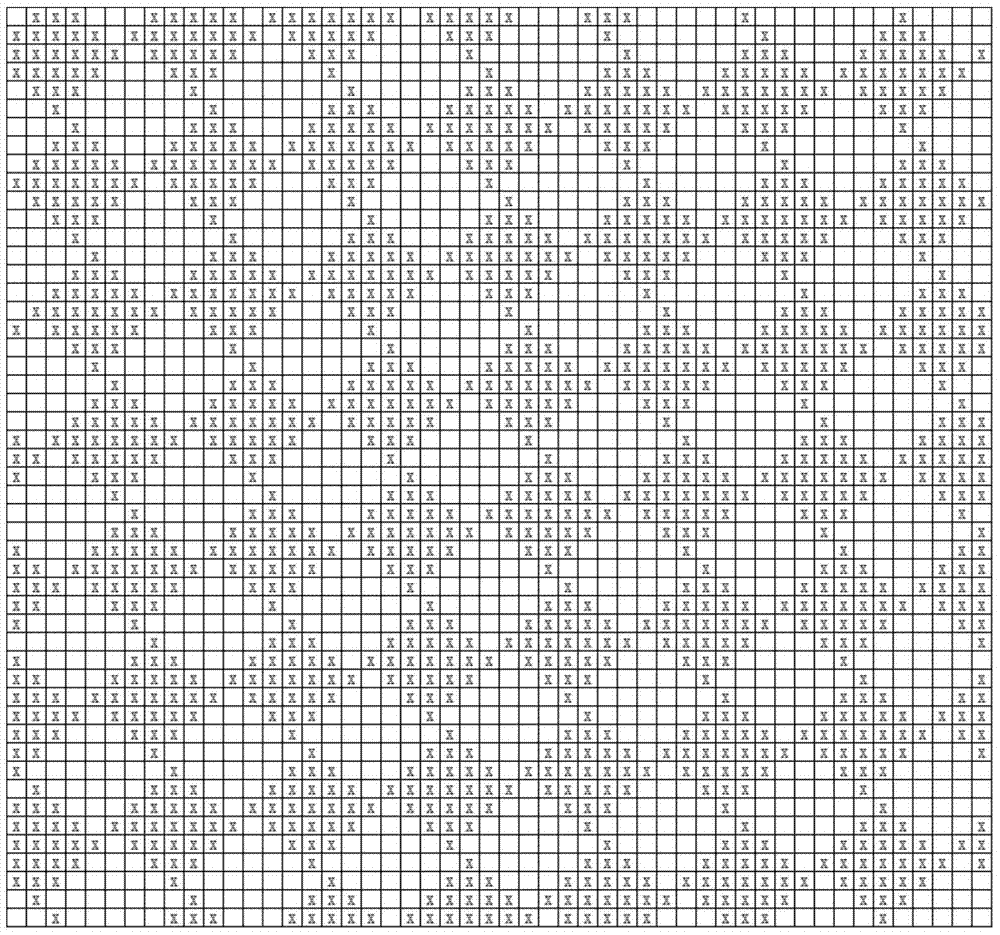

Surface color development and weaving method of single-color warp and multicolor weft woven fabric

The invention provides a surface color development and weaving method of a single-color warp and multicolor weft woven fabric. Exposure of warp yarns on the surface of the fabric can be decreased, thecolor purity and the saturability of the fabric are improved, and design and weaving efficiency is improved. The surface color development and weaving method includes the steps: 1) selecting the number of mixed color development weft yarns corresponding to design colors, determining the color development proportion of the weft yarns in various colors in unit cycle, placing the mixed color development weft yarns on a surface weave by taking a weft-backed or weft-triple fabric weave as a support, placing color retardation weft yarns on a bottom weave and drawing a fabric weave diagram; 2) weaving the fabric on a loom according to the drawn fabric weave diagram. By a weft-triple weave structure form, different colors are effectively represented, exposure of the warp yarns on the surface of the fabric is decreased, the influence of the warp yarns and bottom weft yarns on the surface brightness and the colors of the fabric is greatly reduced, and the high-quality colored fabric can be woven.

Owner:THE HONG KONG POLYTECHNIC UNIV

Elastic wrinkling multi-layer fabric and weaving method thereof

The invention provides an elastic wrinkling multi-layer fabric and a weaving method thereof. The elastic wrinkling multi-layer fabric comprises an upper surface layer, a middle layer and a lower surface layer which are connected in sequence, wherein the middle layer is woven by using elastic yarns. Due to the fact that the middle layer of the woven elastic wrinkling multi-layer fabric provided by the invention is woven by using the elastic yarns, the fabric is treated after water processing and tentering shaping drying after the weaving is completed, and the middle layer can be shrunk and concentrated to wrinkle; meanwhile, the fabric has elasticity in multiple directions, so that the applicability and decoration of the fabric are greatly improved; moreover, the shrinking percentage of the elastic yarns is relatively large, and relatively small density can be used during weaving, so that the breathability of the fabric is relatively good.

Owner:河北瑞春纺织有限公司

Warp-knitted fabric of three-dimensional spatial structure and knitting method of warp-knitted fabric

ActiveCN109881352ASimple weaving processVariety of flower patternsFlat warp knitting machinesEngineeringWarp knitting

The invention discloses a warp-knitted fabric of a three-dimensional spatial structure and a knitting method of the warp-knitted fabric. When the spatial structure is knitted, part of knitting needlesconduct knitting on some transverse rows to form coil rows more than non-knitted coil rows on other knitting needles, after the operation is completed on a warp-knitting machine, excessive coils formprotrusions on the surface of the fabric due to the fact that other coil yarns are in a tensioning state, and the spatial structure is formed. According to the warp-knitted fabric of the three-dimensional spatial structure and the knitting method of the warp-knitted fabric, knitting can be conducted on the warp-knitting machine with a single needle bed, the knitting technology is simple and easyin operation, the pattern changes are rich and diversified, and the product application field is wide.

Owner:TIANJIN POLYTECHNIC UNIV

Process for manufacturing antibacterial and abrasion-resistant lace from apocynum venetum fibers

ActiveCN103046218BAdd feminine styleRetain propertiesSucessive textile treatmentsBiochemical fibre treatmentYarnSpinning

The invention relates to a process for manufacturing antibacterial and abrasion-resistant lace from apocynum venetum fibers. The process has the advantages that after a special design for fiber preprocessing, yarn spinning, lace forming and weaving and low-temperature heating post-processing and special optimization for relevant parameters, technical difficult problems that large quantities of chemical antibacterial agents are used in the prior art, damage environments and injure users, and laces are not graceful, are hardened and stiff, and are complicated in pattern, troublesome in process, high in production cost and difficult to popularize are solved, characteristics of fabrics made from natural fibers can be kept, and excellent technical effects such as graceful style, lightness, thinness and breathability of the lace are realized.

Owner:FUJIAN CHANGLE HANGGANG TEXTILE

Shuttle looms-like knitting needle fabric and production method thereof

The invention discloses tatting-simulated knitting fabrics with the performance of tatting fabrics, and a production method thereof, belonging to the field of knitting fabric production. The production method of the tatting-simulated knitting fabric includes two steps of technological processes, namely, the knitting step and the dyeing and finishing step and is realized mainly by adjusting the yarn material and the kitting equipment of the fabric manufacturing technology, forming the comparison of the number of cycles between knitting needles of a needle cylinder and knitting needles of a needle dial of a loom and adjusting the dyeing and finishing technological process. The tatting-simulated fabrics produced according to the method is characterized by small elongation percentage and low shrinkage and the like, and can be used as the fabric for fashionable dress; and simultaneously, the fabric has low development cost, simple knitting technology, high production efficiency for unit occupied area and good production and generalization potential.

Owner:福清洪良染织科技有限公司

Trousers material with memory function

InactiveCN102154760AWith memory functionGood hygroscopicityWoven fabricsYarnPolytrimethylene terephthalate

The invention relates to a trousers material with a memory function, which is formed by wraps and wefts that are interwoven, wherein the wraps adopt PTT (Polytrimethylene Terephthalate) textured yarns, the wefts adopt siro-spun nubby yarns, and the wraps and the wefts adopt A two-upper and two-lower left twill-weave. The trousers material with the memory function, disclosed by the invention, has the memory function, simultaneously, has reminiscent texture and better moisture absorption, is comfort to wear, is an ideal trousers fabric, and has simple textile process and low cost.

Owner:WUJIANG FEIXIANG WARP KNITTING TEXTILE

Fine spinning flax mat

The invention discloses a spinning flax pad which is formed by the following steps: first folding and enveloping the flax thread, then coloring, drying, bobbin-winding, beaming and weaving it, then singeing, washing softening and pre-recessing it, and then tailoring, knitting, ironing it, at last packaging it and warehouse-in. in the said process, first inputting the designed pattern into computer, then using digital jacquard machine to weave it.

Owner:烟台众联实业有限责任公司

A terry toweling fabric with a stick stitch style

Owner:SUNVIM GROUP

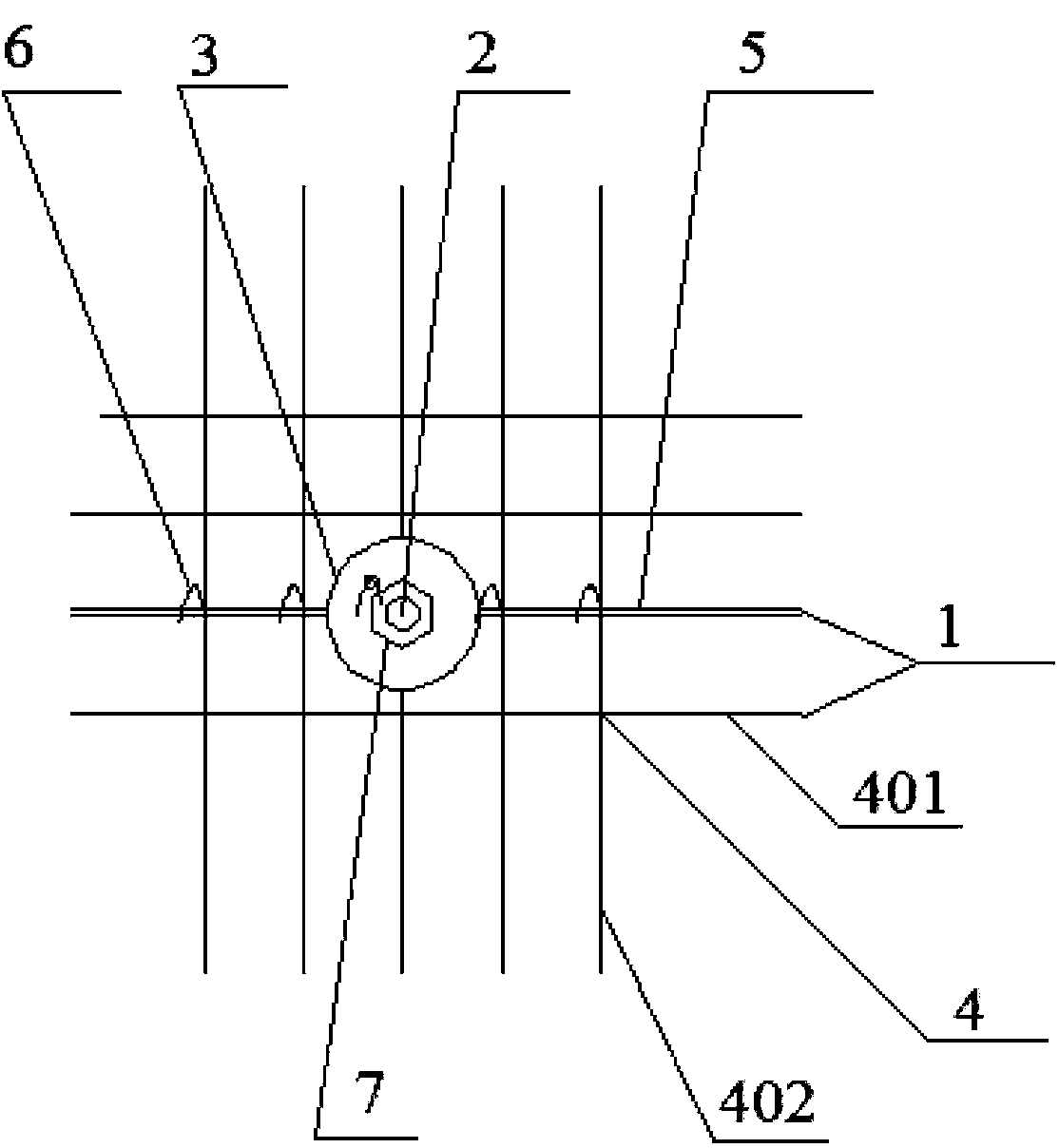

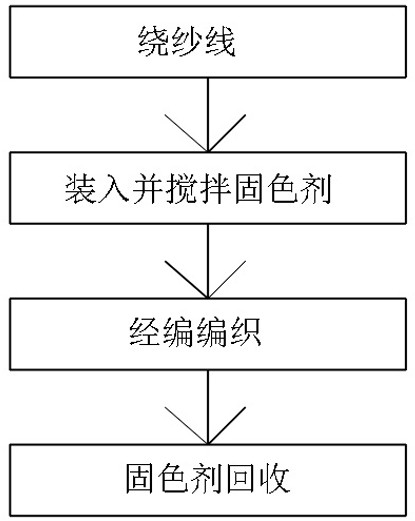

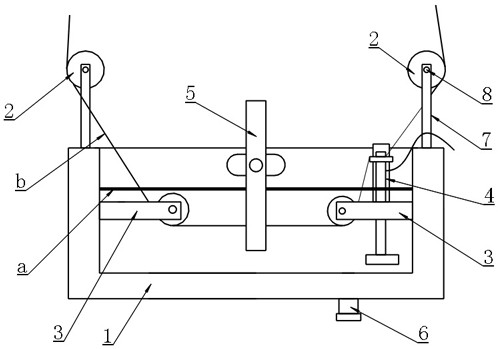

Novel weaving process for printing and dyeing cloth

ActiveCN112746383ASimple weaving processNot easy to fall offWarp knittingProcess engineeringChemistry

The invention belongs to the technical field of woven cloth, and particularly relates to a novel weaving process for printing and dyeing cloth. According to the method, the basically effective warp knitting effect of the printed and dyed cloth is guaranteed through the four steps of yarn winding, loading and stirring of a color fixing agent, warp knitting and recovery of the color fixing agent in sequence, wherein used color fixing pretreatment equipment structurally comprises a box body for color fixation, a thread body limiting ring, an immersion type thread body ring unit, a thread body clamping plate unit, a rotary stirring plate unit and a lower discharging pipe, and is used for performing color fixation pretreatment operation on yarn before warp knitting. The weaving process for printing and dyeing the cloth has the advantages that the weaving process for printing and dyeing the cloth is simple and effective, a dyeing agent is not easy to fall off after the yarn and the cloth subjected to color fixing pretreatment are printed and dyed, a color fixing agent is good in use effect and not easy to waste, the yarn immersion type color fixing pretreatment mode is flexible and efficient, the color fixing agent on the yarn is uniformly distributed, the adhesion amount of the color fixing agent is flexible and controllable, the color fixing agent is adhered while being heated, and a sufficient color fixing effect can be ensured by using a small amount of color fixing agent.

Owner:福建省新宏港纺织科技有限公司

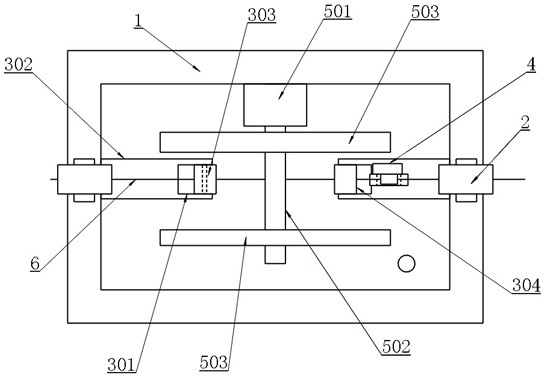

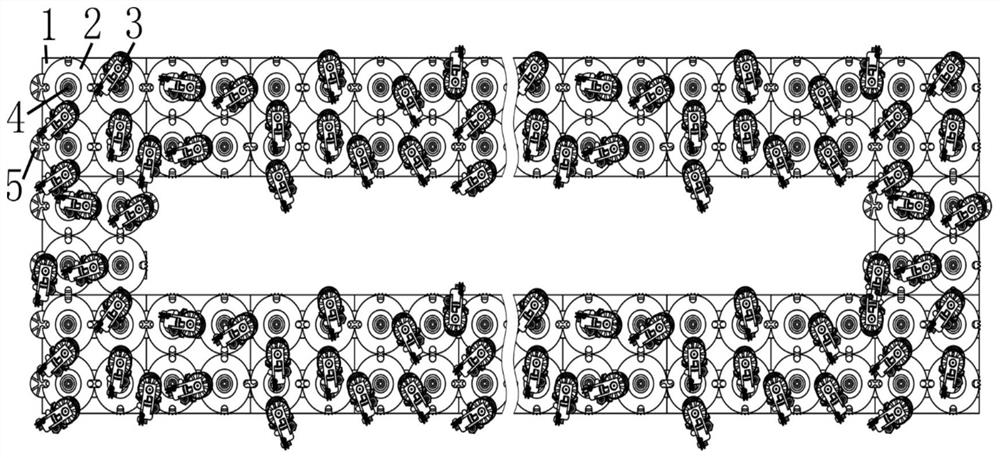

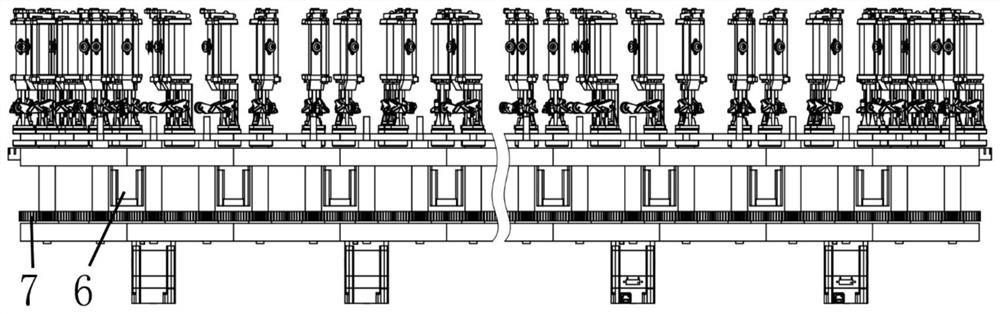

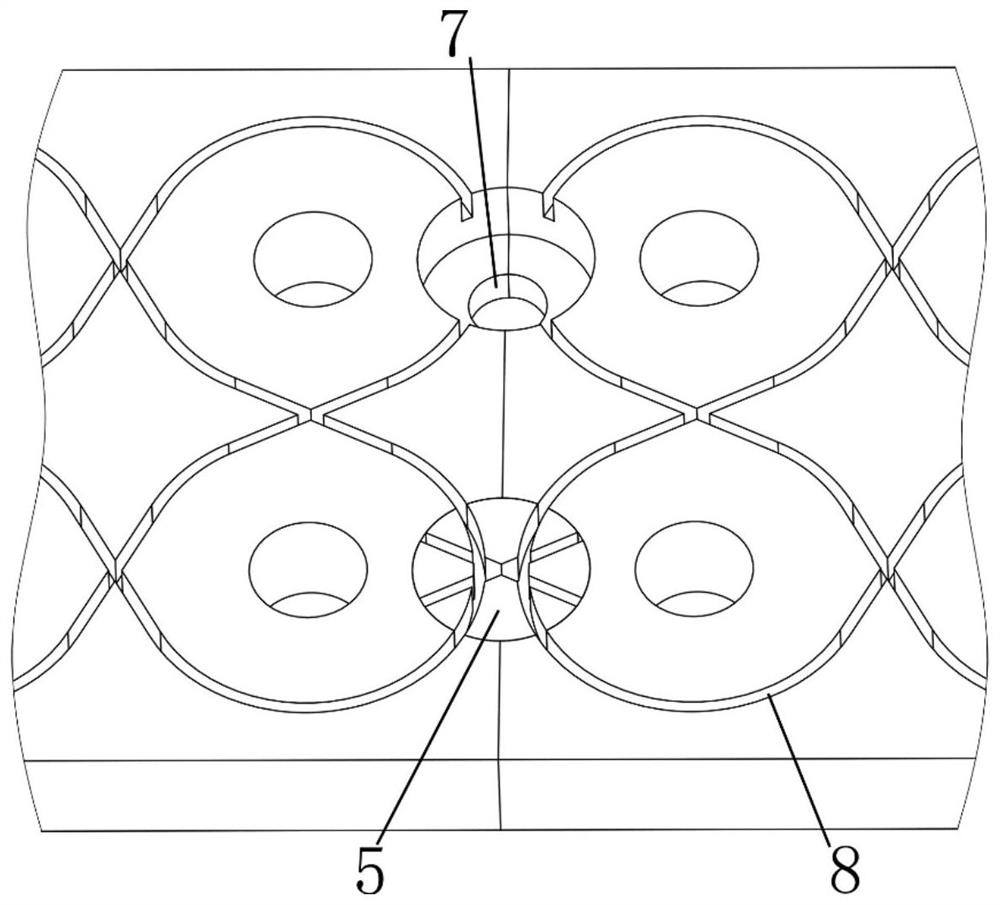

Modular Knotless Net Weaving Equipment

The invention relates to modularized knotless net weaving equipment. The equipment is formed by combining a plurality of modules A and a plurality of modules B. Each module A comprises a weaving chassis, a stirring disc, a spindle and a stirring disc driving part, wherein conversion block semicircular mounting holes are formed in the left and right sides of the upper surface of the weaving chassis, and a fixed spindle rail is arranged on the upper surface of the weaving chassis. Each module B comprises a conversion block and a conversion block driving part, wherein a variable spindle rail is arranged on the upper surface of the conversion block, the variable spindle rail of the conversion block comprises a set of crossed spindle rails and a set of non-crossed spindle rails, the crossed spindle rails are linear grooves with two middle points crossed with each other, the non-crossed spindle rails are composed of two opposite arcs, and the radius of the arcs is equal to that of the fixedspindle rails of the weaving chassis. The fixed spindle rails of the module A and the variable spindle rails of the module B are tangentially connected. The modularized knotless net weaving equipmentcan achieve the aim of weaving knotless nets in various types and specifications by changing the number and layout of the weaving modules.

Owner:孙以泽 +1

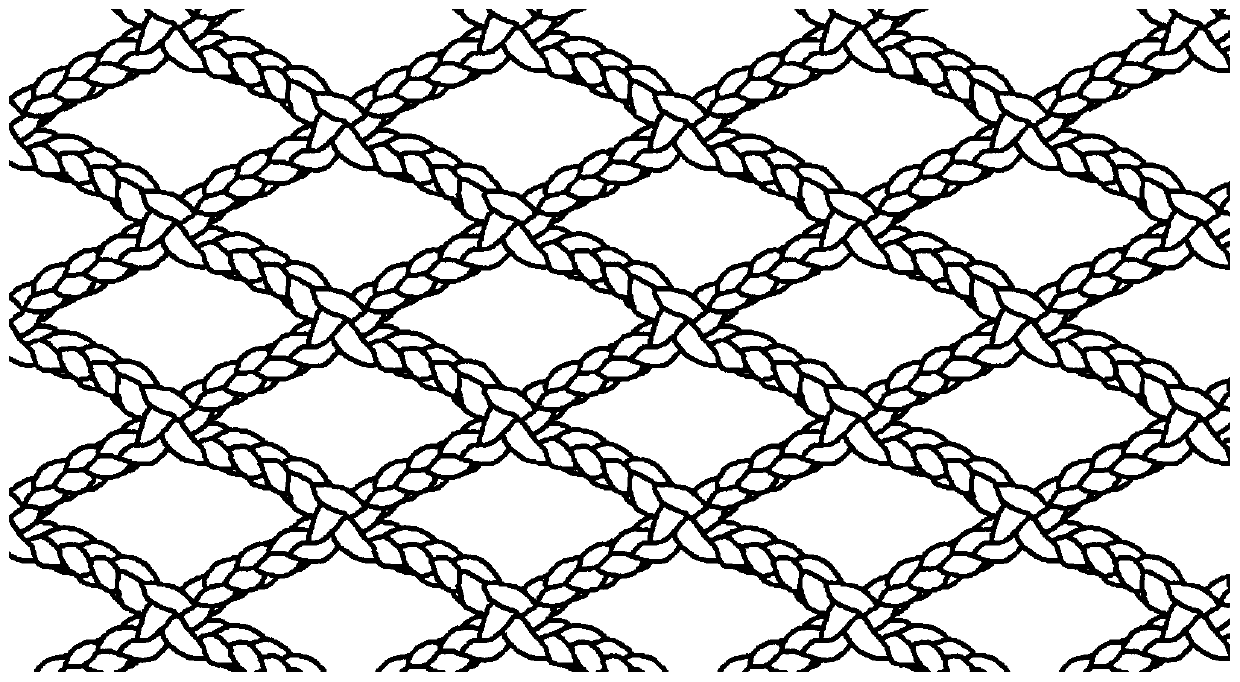

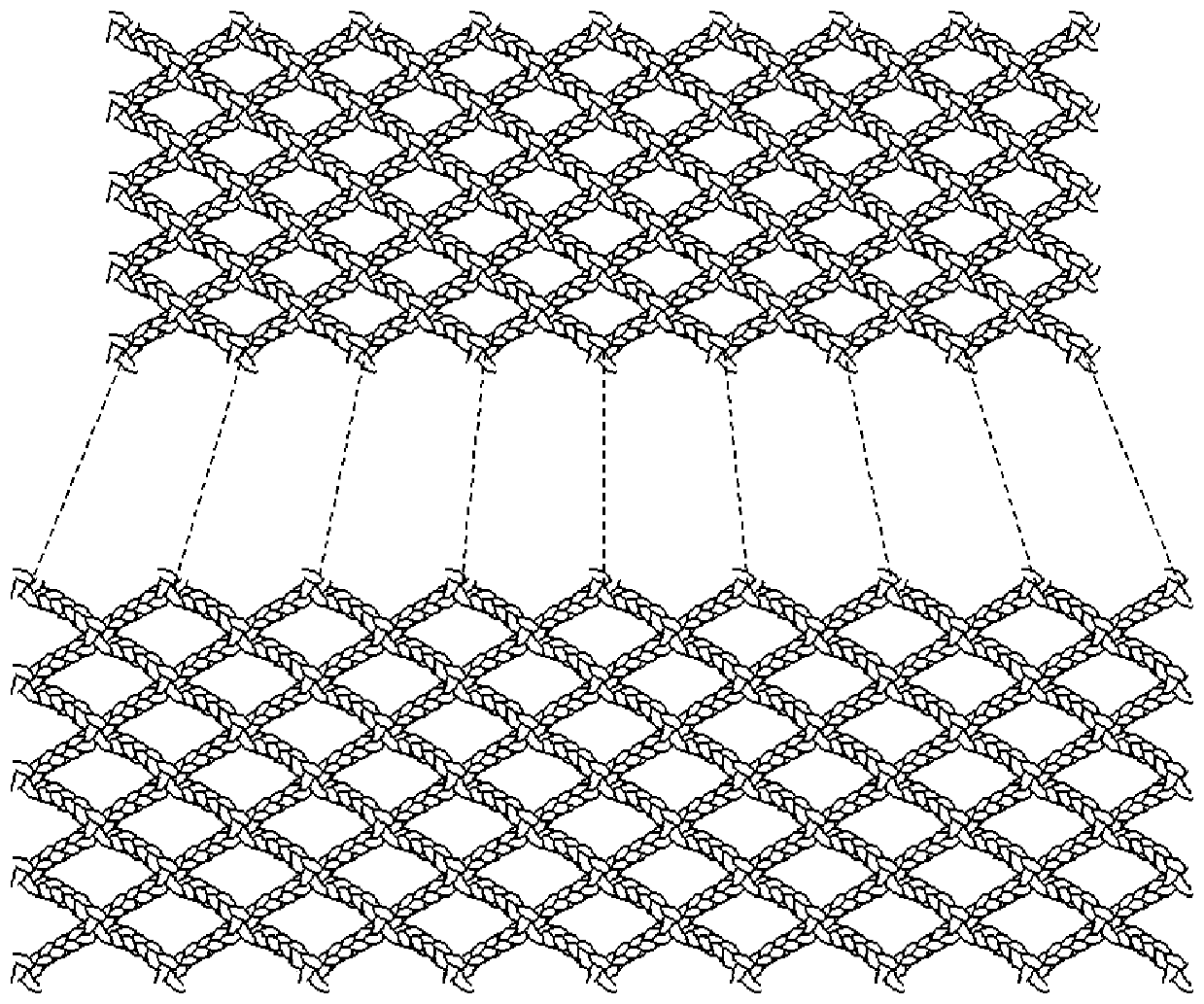

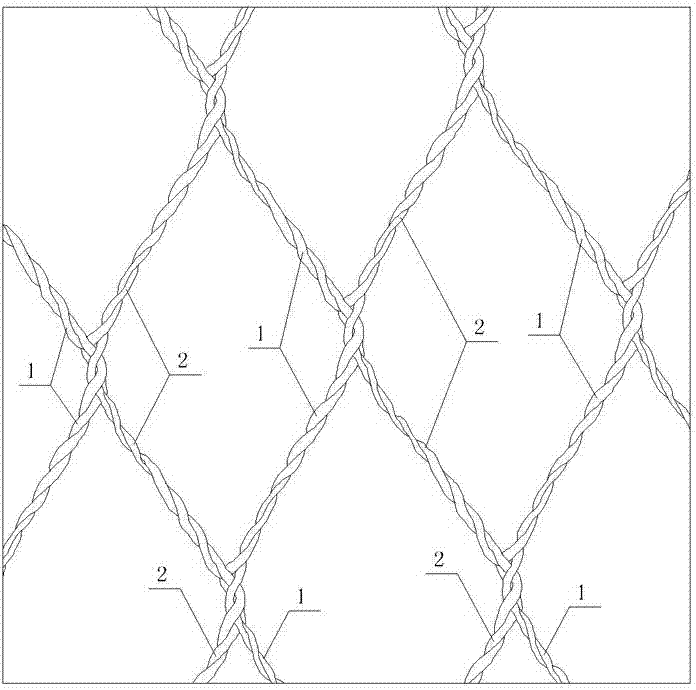

Knotless net and weaving method thereof

ActiveCN102787443BExtended service lifeSimple weaving processBraidEngineeringUltimate tensile strength

The invention discloses a knotless net and a weaving method thereof, and belongs to the technical field of fishing nets. The knotless net comprises numerous pieces of nettles I and nettles II ranged at intervals, wherein the nettles I and the nettles II are of two-strand woven type structures, each nettle II correspondingly penetrates between two strands of the nettle I placed before the nettle II, and two strands of each nettle II are separated and rewound from the two sides of the nettle I to form a woven point. The knotless net provided by the invention can be woven to an arbitrary width, the width can be woven to 10 meters while a width can only be woven to 1 meter in the prior art, and meanwhile, the strength of each woven point is increased by 50% compared with the existing structure, the service life of the woven point is long, and the woven point can be completely damaged after 3 strands of nettles are broken and the meshes are enlarged. The knotless net and the weaving method thereof simplify the weaving technology and have high production efficiency.

Owner:陈定富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com