Shuttle looms-like knitting needle fabric and production method thereof

A technology for knitted fabric and manufacturing method, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of difficult setting of knitted fabrics, poor dimensional stability, low production efficiency, etc., and achieves low development cost, high production efficiency, Low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

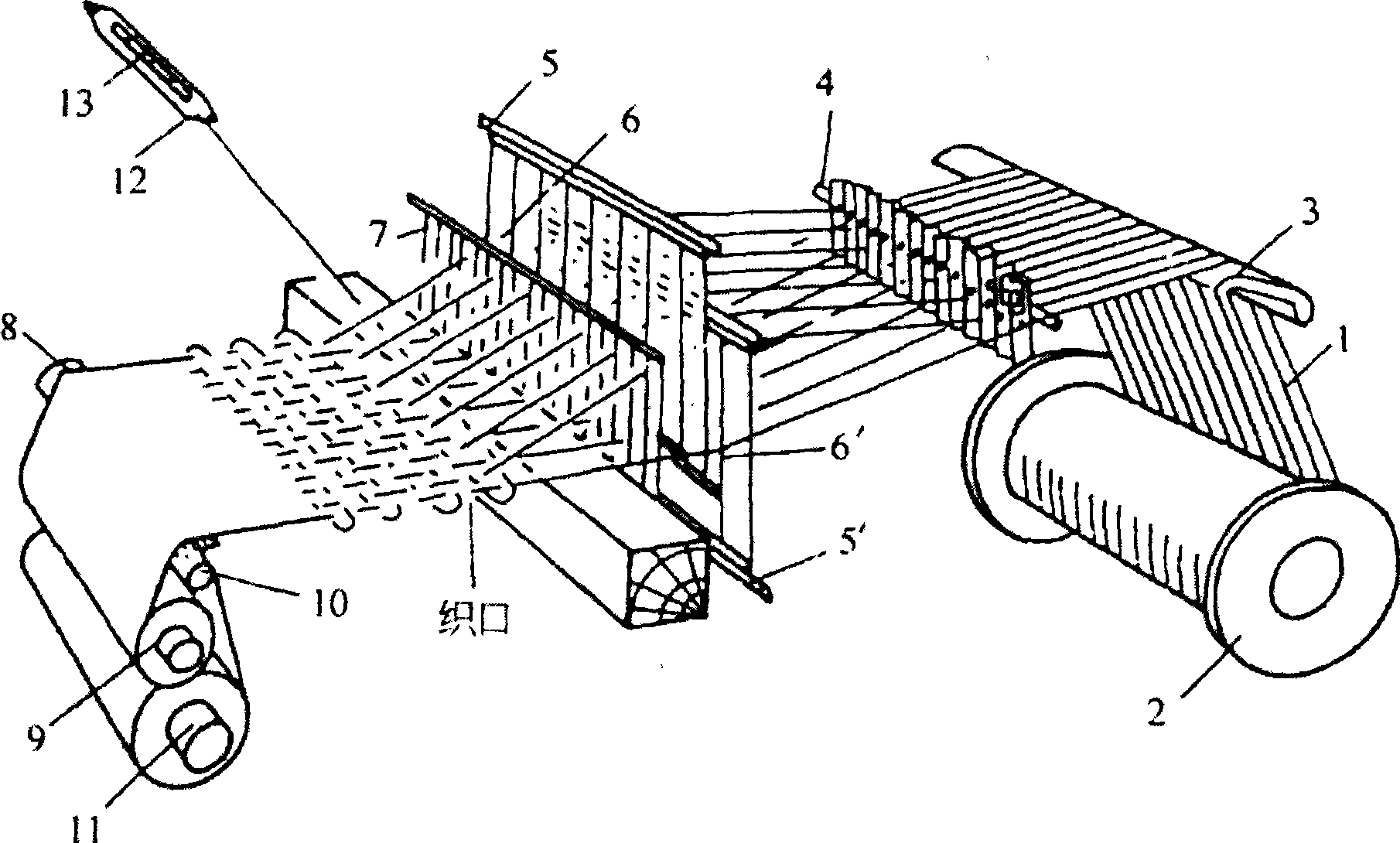

[0052] [Example 1]: a kind of manufacture method of imitation weaving knitted fabric, comprises knitting and weaving and dyeing and finishing two technological process steps, wherein: 1. each technical equipment and technical parameter of knitting and weaving technological process are:

[0053] 1. Yarn raw material: T100D / 96F DTY (39%)×T75D / 72F FDY (61%), that is, polyester stretched yarn with a denier number of 100 and a fiber count of 96 accounts for 39%, and a denier number of 75 , the number of fibers is 72 polyester raw silk accounts for 61%;

[0054] 2. Main parameters of knitting equipment: Model - Taiwan Hechun Xingye Co., Ltd. factory, model KH-D double-sided circular knitting machine, machine size - 28 needles / 25.4mm, barrel diameter - 34 inches, number of channels - 72F, total Number of needles - 3000N;

[0055] 3. Arrangement of knitting needles: the dial needles are arranged according to AB, and the cylinder needles are arranged according to CDEF;

[0056] 4. Tr...

Embodiment 2

[0135][Example 2]: Another manufacturing method of imitation woven knitted fabrics, including two process steps of knitting weaving and dyeing and finishing, wherein: only the technical equipment and technical parameters of the knitting and weaving process flow are the same as those in Example 1 different, as follows:

[0136] 1. Yarn raw material: T100D / 96F DTY (46%)×T75D / 72F DTY (54%), that is, polyester stretched yarn with a denier number of 100 and a fiber count of 96 accounts for 46%, and a denier number of 75 , polyester textured yarn with 72 fiber strands accounts for 54%;

[0137] 2. Main parameters of knitting equipment: Model - Taiwan Hechun Industrial Co., Ltd. factory, model KH-D double-sided circular knitting machine, machine size - 26 needles / 25.4mm, cylinder diameter - 34 inches, number of channels - 72F, total Number of pins - 2784N;

[0138] 3. Arrangement of knitting needles: the dial needles are arranged according to AB, and the cylinder needles are arrang...

Embodiment 3

[0162] [Example 3]: Another manufacturing method of imitation woven knitted fabric, including two process steps of knitting weaving and dyeing and finishing, wherein: only the technical equipment and technical parameters of the knitting and weaving process flow are the same as those in Example 1 or 2 differently, as follows:

[0163] 1. Yarn raw material: T100D / 96F DTY (45%)×T75D / 72F DTY (55%), that is, polyester stretched yarn with a denier number of 100 and a fiber count of 96 accounts for 45%, and a denier number of 75 , the number of fibers is 72 polyester textured yarns accounted for 55%;

[0164] 2. Main parameters of knitting equipment: Model - Taiwan Hechun Industrial Co., Ltd. factory, model KH-D double-sided circular knitting machine, machine size - 26 needles / 25.4mm, cylinder diameter - 34 inches, number of channels - 72F, total Number of pins - 2784N;

[0165] 3. Arrangement of knitting needles: the dial needles are arranged according to AB, and the cylinder need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com