Supporting structure of ejector anchor net

A technology of support structure and sprayed anchor net, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problem of widely used sprayed anchor net support, cannot effectively guarantee the support effect, and the safety of mines or tunnels Hidden dangers and other problems, to improve corrosion resistance and protection performance, improve support effect, prevent loosening or damage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

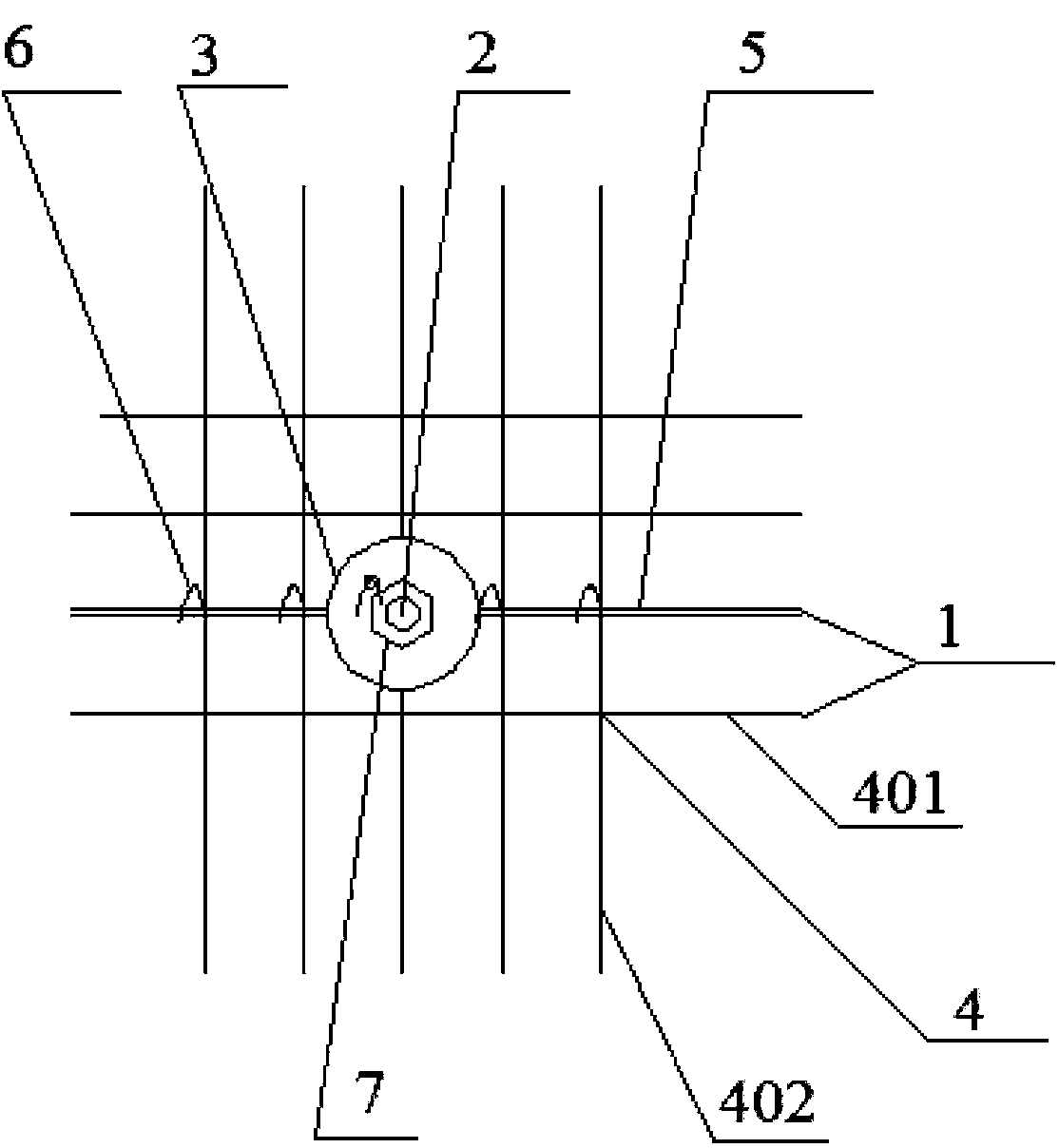

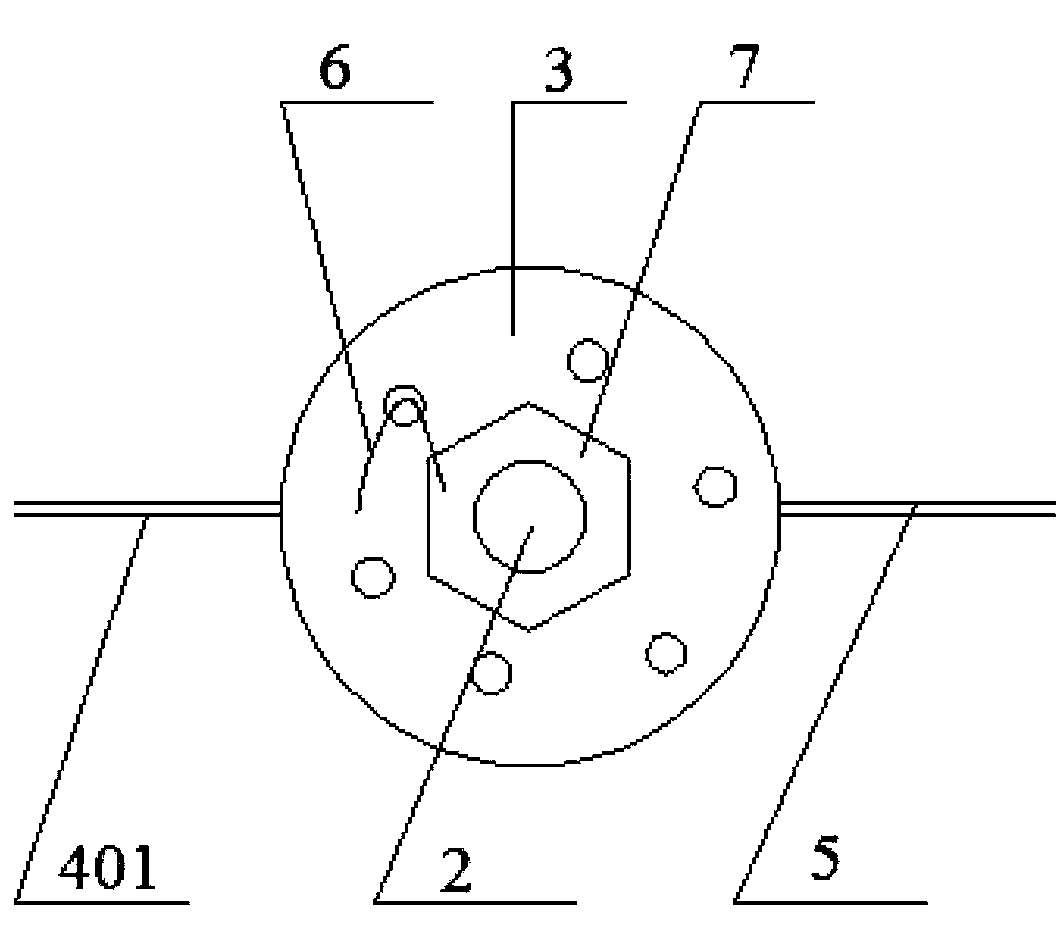

[0017] like figure 1 , figure 2 As shown, the spray anchor mesh support structure includes an anchor mesh 1 and an anchor rod 2, the anchor mesh 1 is composed of a glass fiber reinforced plastic anchor mesh main body 4 and a reinforcing rib 5, and the FRP anchor mesh main body 4 The glass steel wire 402 is interwoven and connected point by point. The interwoven grid is square, and the grid size is preferably 150mm~200mm. In order to ensure the strength of the glass fiber reinforced plastic anchor mesh main body 4, the glass fiber reinforced plastic anchor mesh main body 4 is arranged at intervals of 1.1m A horizontal reinforcing rib 5, each horizontal reinforcing rib 5 is parallel to each other, and a hook 6 extending o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com