Non-mechanical bubble fabric production process

A production process, non-mechanical technology, applied in the field of fabric processing, can solve the problems of complex production process, high cost, loss of foam and wrinkle effect, etc., and achieve the effect of high decomposition efficiency, good resilience and high specific activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

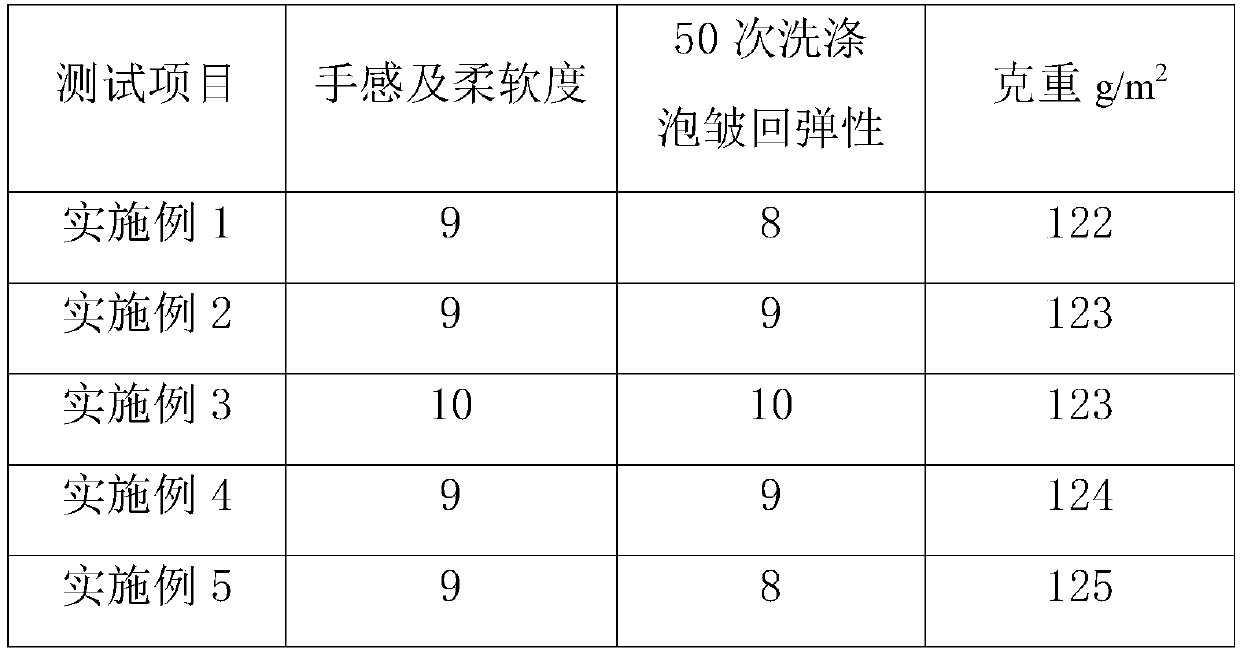

Examples

Embodiment 1

[0042] Embodiment 1: a kind of non-mechanical bubble fabric production process comprises the following steps:

[0043]S1. Yarn selection: the warp direction includes the first warp yarn and the second warp yarn, the first warp yarn is cotton yarn, and the second warp yarn is spandex; the weft yarn includes JC50S combed cotton yarn with a yarn number ratio of 10:3, and high-elastic polyester length Silk;

[0044] S2, warping: Warp the first warp yarn and the second warp yarn respectively onto different warp beams, set the tension of the first warp beam to 38N, and the warp tension of the second warp yarn to 45N;

[0045] S3, drawing in heald: the warp after warping is drawn in heald, the selvedge is 60 yarns, the reed is selected as No. 102 reed, the reed is carried out according to the method of 3 in / 2 in / 3 in, and the reed width is 175.9 cm, set the sand-wrapped weft densities 54T / 1T;

[0046] S4. Paralleling: after sizing, the first warp yarn and the second warp yarn are p...

Embodiment 2

[0054] Embodiment 2: a kind of non-mechanical bubble fabric production process, comprises the following steps:

[0055] S1. Yarn selection: the warp direction includes the first warp yarn and the second warp yarn, the first warp yarn is cotton yarn, and the second warp yarn is spandex; the weft yarn includes JC50S combed cotton yarn with a yarn number ratio of 10:4, and high-elastic polyester length Silk;

[0056] S2, warping: Warp the first warp yarn and the second warp yarn to different warp beams respectively, set the tension of the first warp beam to 40N, and the warping tension of the second warp yarn to 47N;

[0057] S3, drawing in heald: the warp after warping is drawn in heald, the selvedge is 60 yarns, the reed is selected as No. 102 reed, the reed is carried out according to the method of 3 in / 2 in / 3 in, and the reed width is 175.9 cm, set the sand-wrapped weft densities 54T / 1T;

[0058] S4. Paralleling: after sizing, the first warp yarn and the second warp yarn ar...

Embodiment 3

[0066] Embodiment 3: a kind of non-mechanical bubble fabric production process comprises the following steps:

[0067] S1. Yarn selection: the warp direction includes the first warp yarn and the second warp yarn, the first warp yarn is cotton yarn, and the second warp yarn is spandex; the weft yarn includes combed cotton yarn of JC50S with a yarn number ratio of 10:5, and high elastic polyester length Silk;

[0068] S2, warping: Warp the first warp yarn and the second warp yarn respectively onto different warp beams, set the tension of the first warp beam to 42N, and the warp tension of the second warp yarn to 49N;

[0069] S3, drawing in heald: the warp after warping is drawn in heald, the selvedge is 60 yarns, the reed is selected as No. 102 reed, the reed is carried out according to the method of 3 in / 2 in / 3 in, and the reed width is 175.9 cm, set the sand-wrapped weft densities 54T / 1T;

[0070] S4. Paralleling: after sizing, the first warp yarn and the second warp yarn a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com