Warp-knitted fabric of three-dimensional spatial structure and knitting method of warp-knitted fabric

A three-dimensional, warp-knitting technology, applied in the field of warp-knitted fabrics, can solve problems such as complex weaving process and limitations in fabric application fields, and achieve the effects of simple weaving process, rich and varied patterns, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

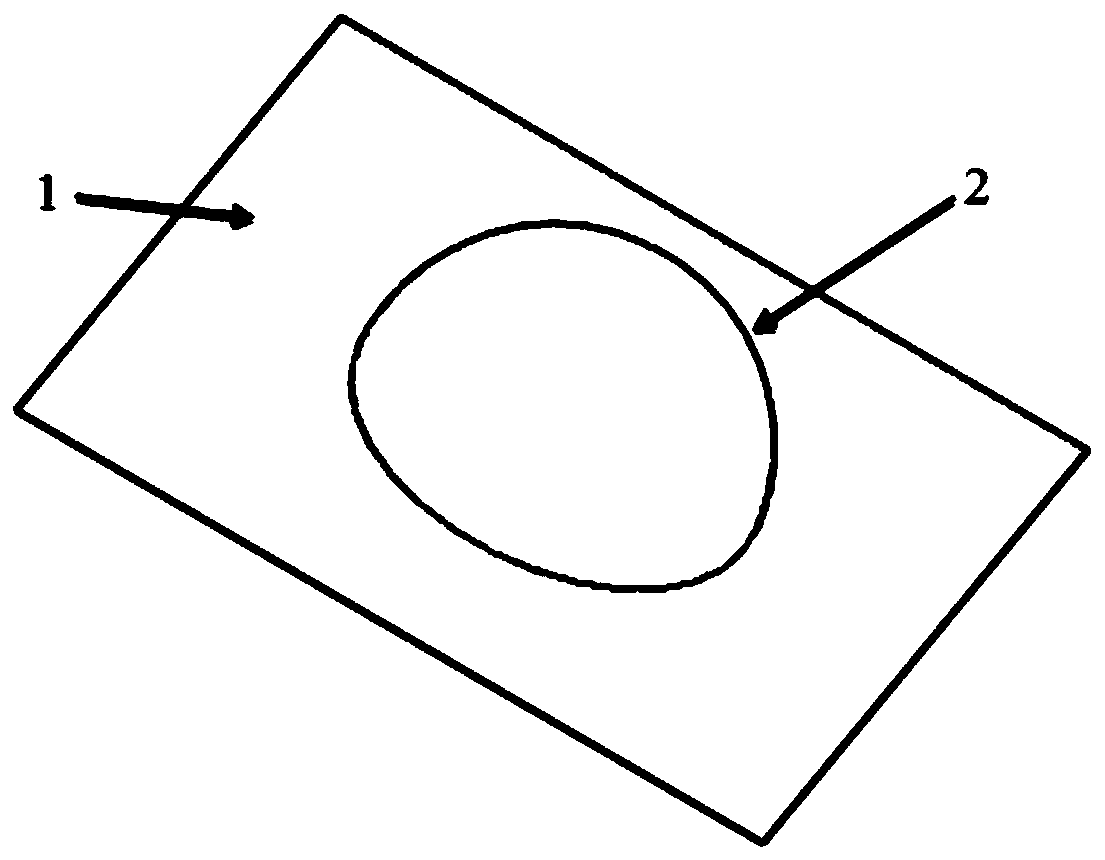

[0019] Three-dimensional structured warp-knitted fabric.

[0020] The fabric is woven by a single-needle bed warp knitting machine with a needle selection device to form a common fabric base 1, and a plurality of three-dimensional protrusions 2 are formed by weaving in its thickness direction. The cross-sectional area of the three-dimensional protrusions 2 is based on the The number of knitting needles is adjusted, and its height is adjusted according to the number of courses involved in knitting.

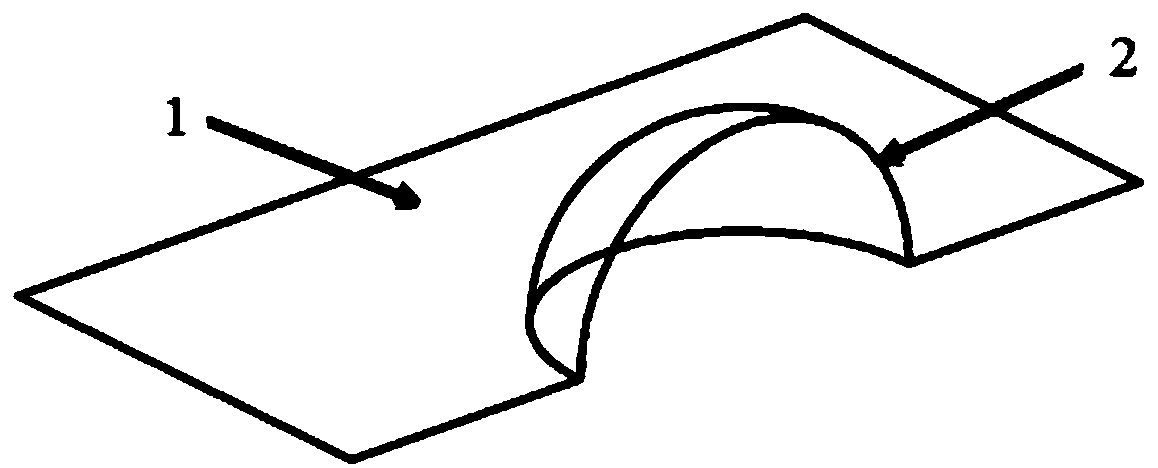

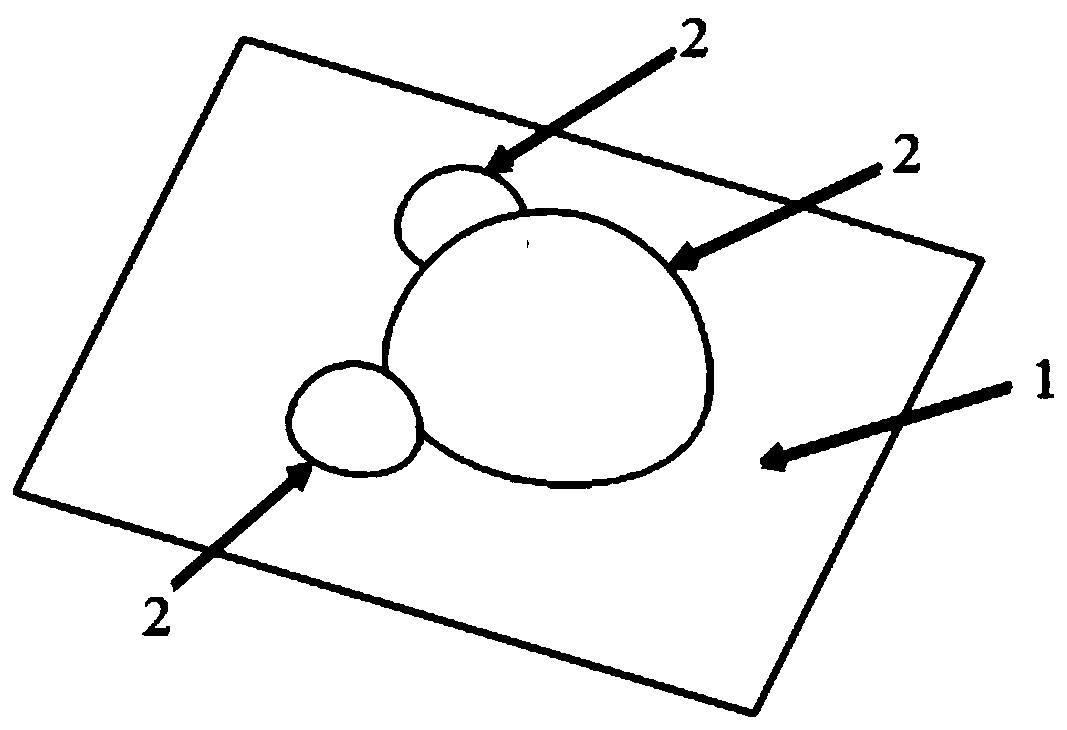

[0021] refer to Figure 1~4 , the three-dimensional protrusions 2 are locally distributed on the surface of the fabric.

[0022] refer to Figure 3-4 , a plurality of three-dimensional protrusions 2 are mutually independent in terms of cross-sectional area and height during weaving.

Embodiment 2

[0024] A weaving method for warp knitted fabrics with a three-dimensional structure.

[0025] This method is used for weaving the warp knitted fabric with three-dimensional structure in Example 1.

[0026] Wherein, the ordinary fabric base 1 is woven by a single-needle bed warp knitting machine with a needle selection device. When knitting the three-dimensional protrusions 2, some knitting needles knit in some courses to form more loops than other unknitted knitting needles. Course, after the machine is off, the excess coil courses form protrusions on the surface of the fabric due to the tension of the rest of the coil yarns, forming a three-dimensional structure.

[0027] The cross-sectional area of the three-dimensional protrusion 2 is adjusted according to the number of knitting needles involved in weaving, and its height is adjusted according to the number of courses involved in weaving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com