Real silk fabric with square meshes and production method thereof

A technology of fabrics and meshes, which is applied in the direction of open-hole fabrics, fabrics, textiles and papermaking, etc. It can solve the problems of inability to weave mesh fabrics, the size of holes in real silk through-holes and fake yarns, etc., and achieve soft hand feeling and excellent weaving technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Raw materials: warp direction: nail warp: 40 / 44D*3 mulberry silk + 20D nylon hot-melt yarn (hot-melt temperature: 85°C)

[0014] Bjing: 150D water-soluble silk (water-soluble temperature: 50°C)

[0015] Weft direction: A weft: 40 / 44D*4 mulberry silk + 20D nylon hot-melt yarn (hot-melt temperature: 85°C)

[0016] Yiwei: 150D water-soluble silk (water-soluble temperature: 50°C)

[0017] Density: Longitudinal: 30 pieces / cm

[0018] Weft direction: 22 threads / cm

[0019] Arrangement: Meridian direction: A 1 root - B 1 root - A 1 root - B 1 root - A 1 root - B 15 roots - A 1 root - B 1 root - A 1 root - B 1 - A 1 - B 15......

[0020] Latitude: Same as above

[0021] Post-processing: Water-soluble treatment is carried out at 50°C in open width, then washed with clean water, dried in an oven, and then hot-pressed with cylinder pressure rollers at a temperature of 85°C to obtain real silk Finished square hole.

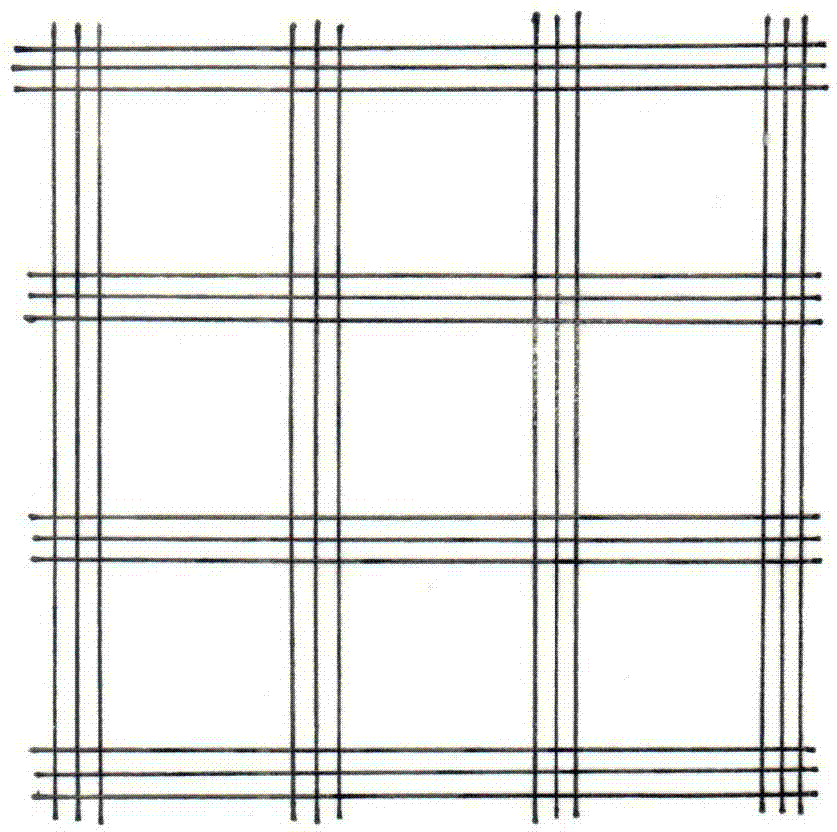

[0022] See the attached diagram for the org...

Embodiment 2

[0024] Raw materials: warp direction: nail warp: 40 / 44D*3 mulberry silk + 20D nylon hot-melt yarn (hot-melt temperature: 85°C)

[0025] Bjing: 150D water-soluble silk (water-soluble temperature: 50°C)

[0026] Weft direction: A weft: 40 / 44D*4 mulberry silk + 20D nylon hot-melt yarn (hot-melt temperature: 85°C)

[0027] Yiwei: 150D water-soluble silk (water-soluble temperature: 50°C)

[0028] Density: Longitudinal: 28 pieces / cm

[0029] Weft direction: 20 threads / cm

[0030] Arrangement: Meridian direction: A 2——B 6——A 2——B 16——A 2——B 6——A 2——B 16……

[0031] Weft: A 2 - B 6 - A 2 - B 6......

[0032] Post-processing: Water-soluble treatment is carried out at 50°C in open width, then washed with clean water, dried in an oven, and then hot-pressed with cylinder pressure rollers at a temperature of 85°C to obtain real silk Finished square hole mesh fabric.

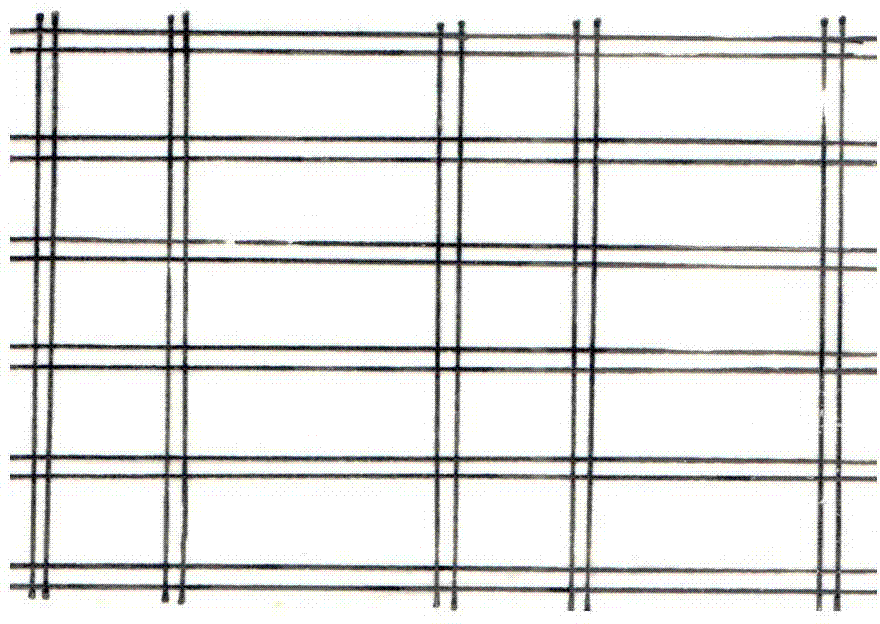

[0033] See the attached diagram for the organization diagram figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com