Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Short construction period on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

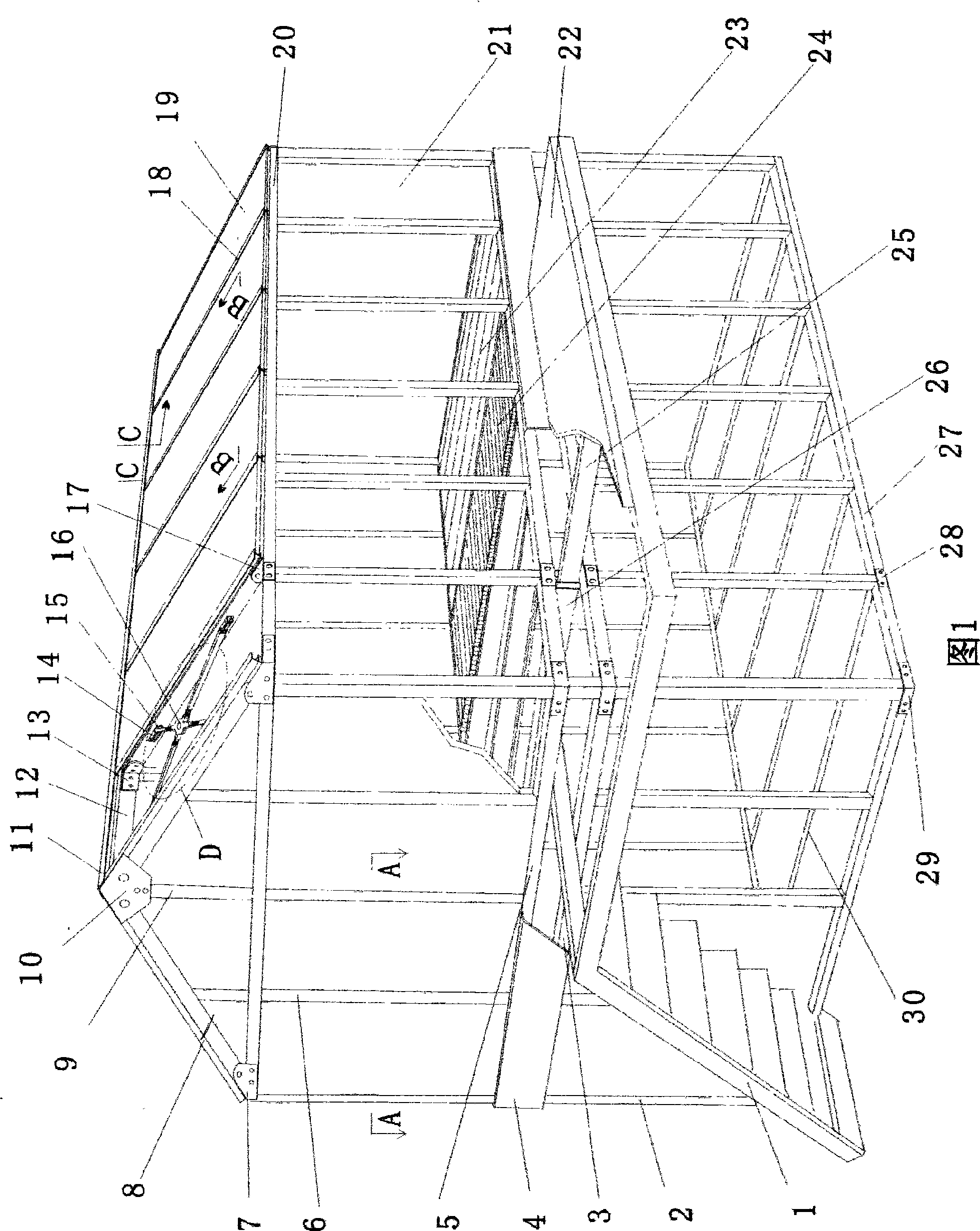

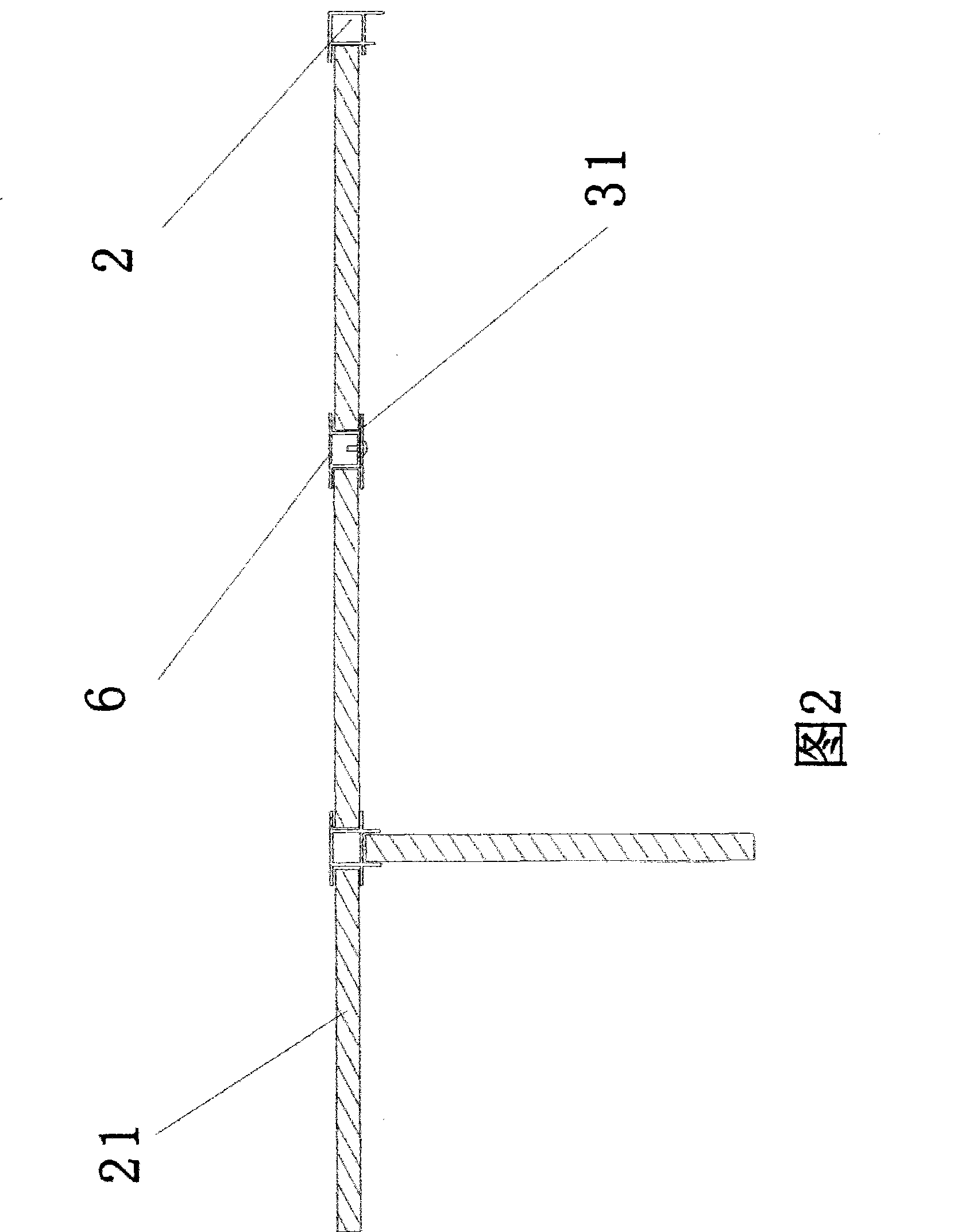

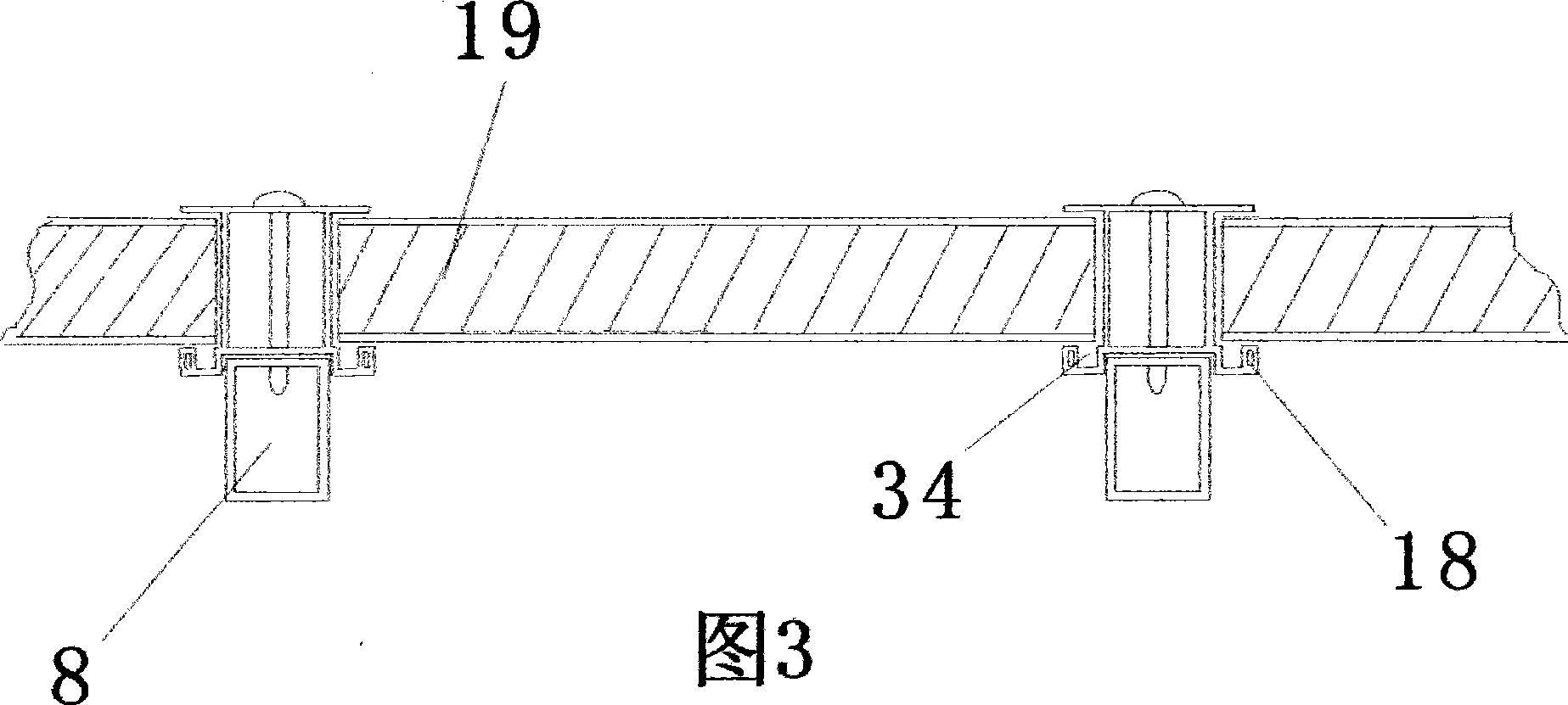

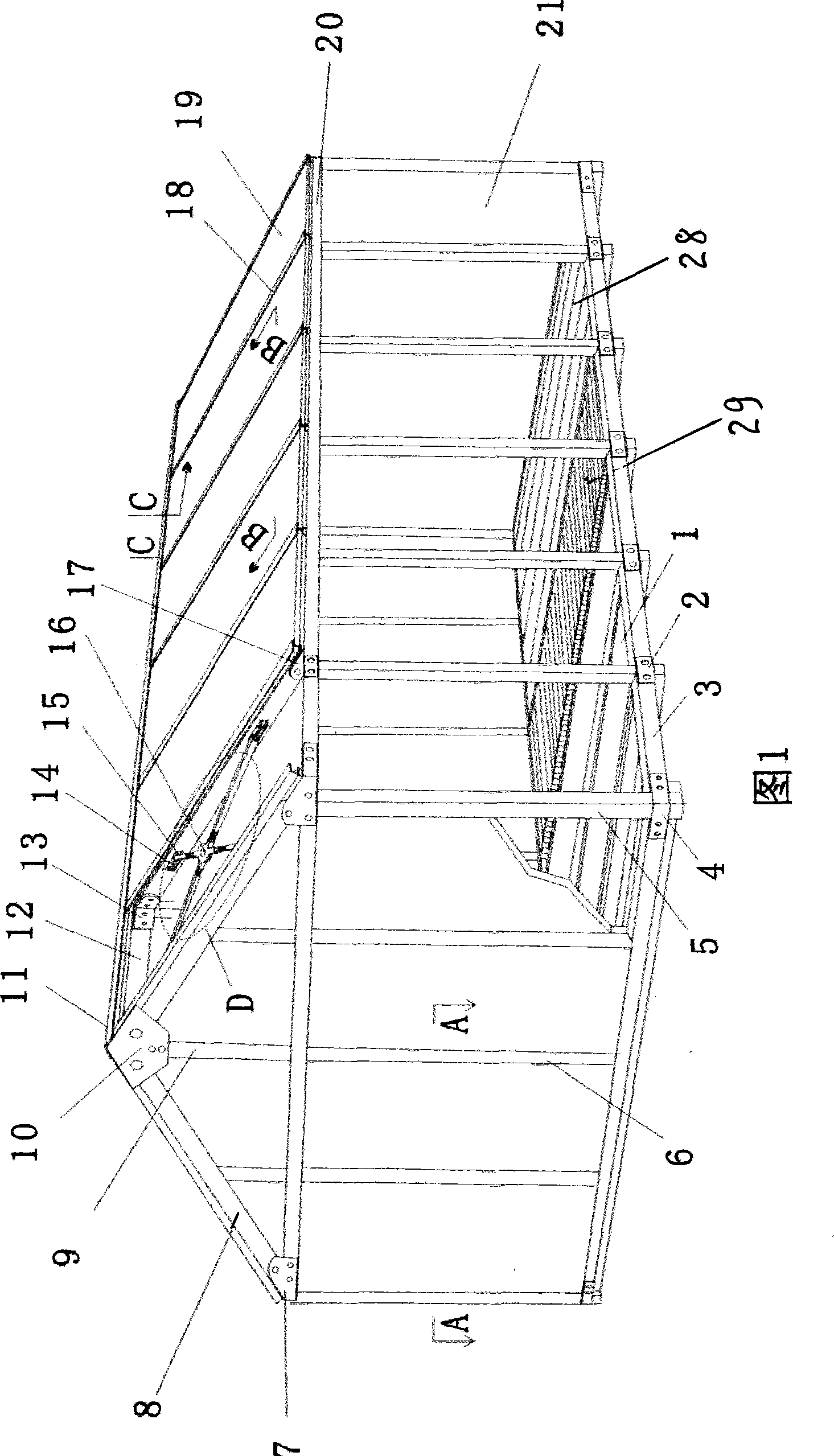

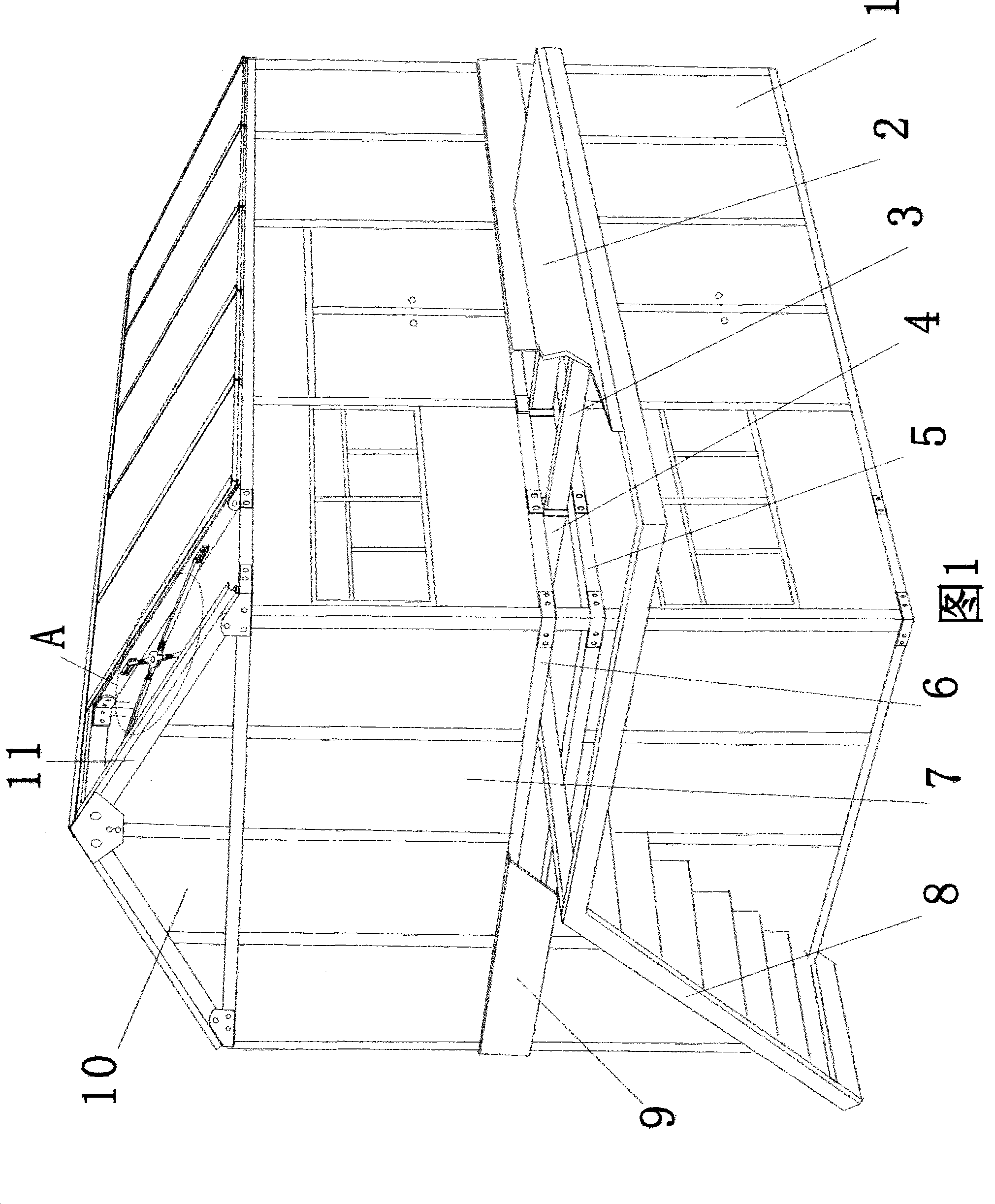

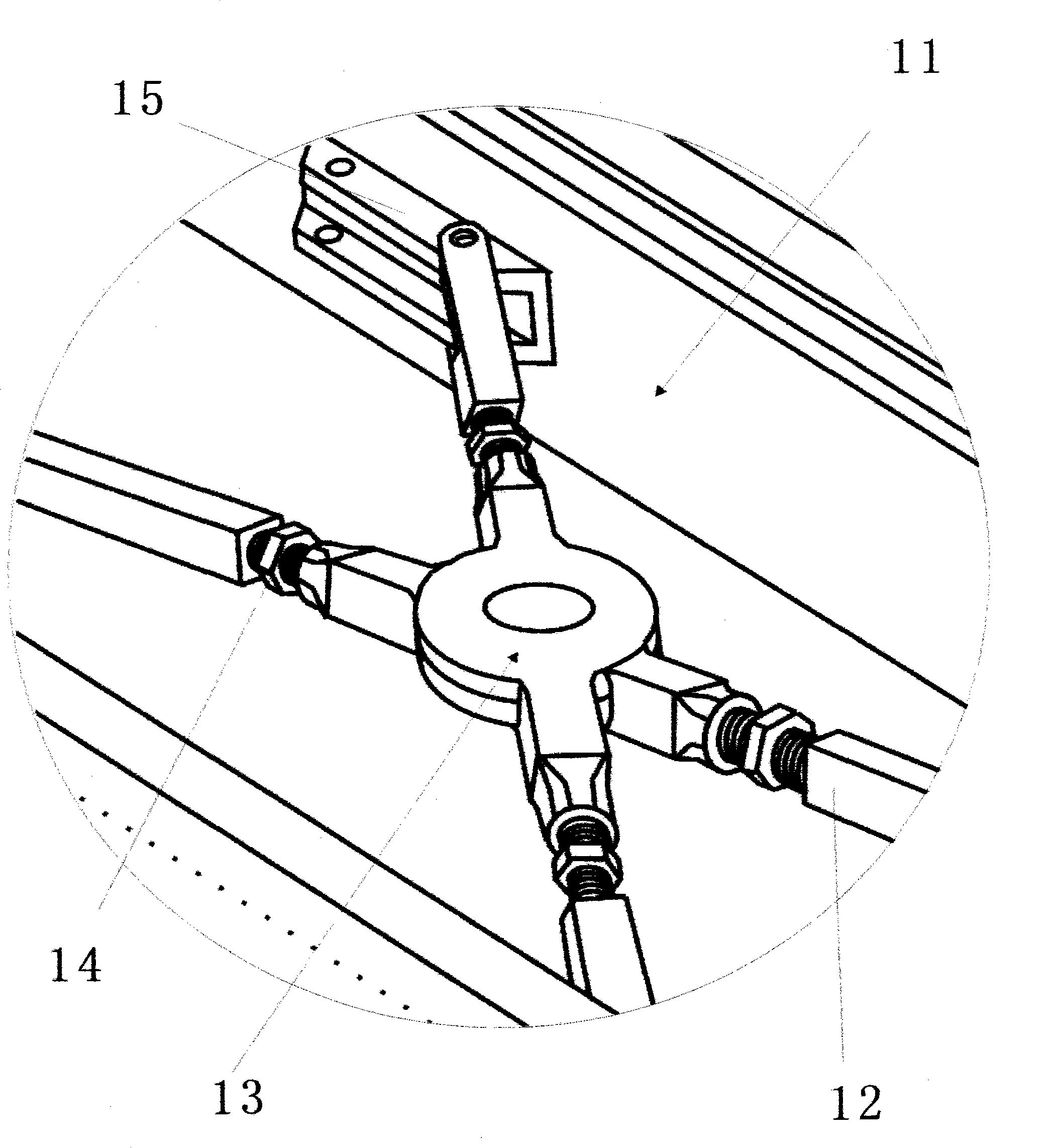

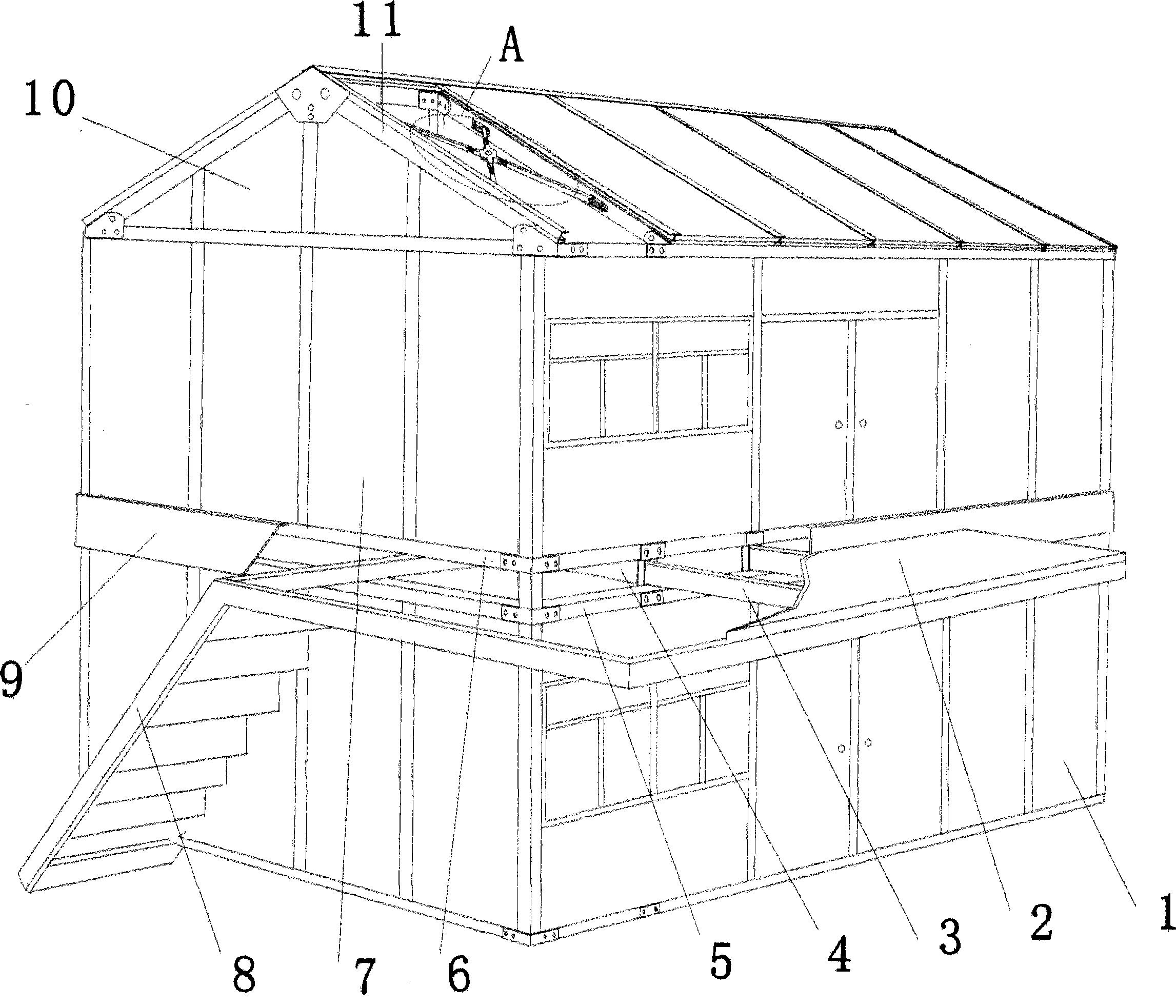

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

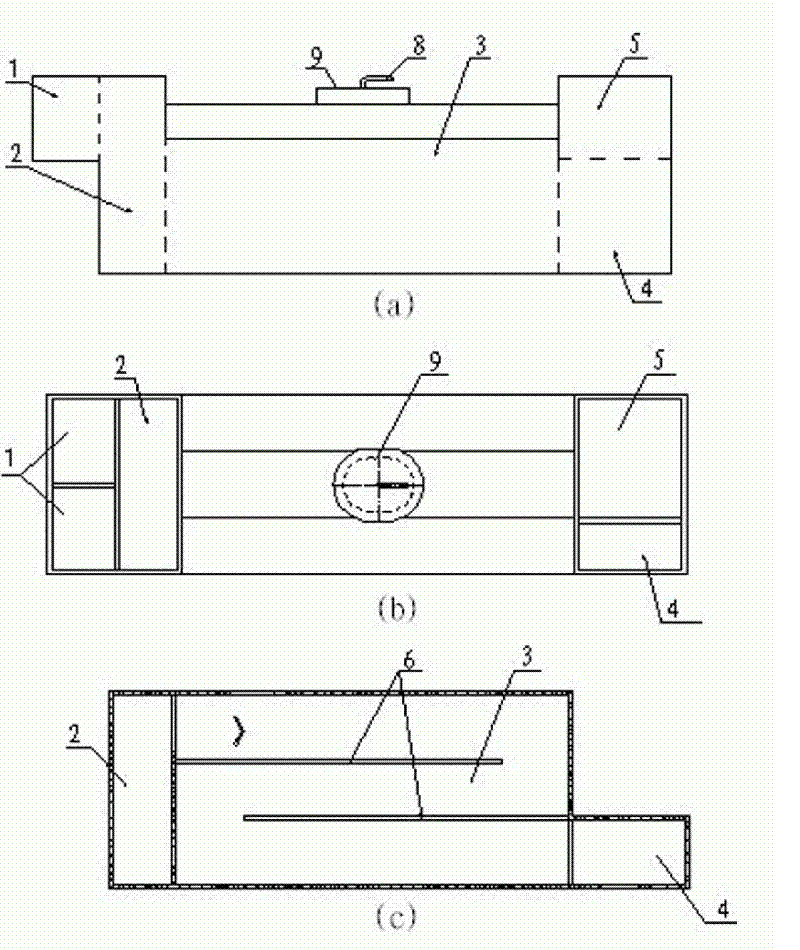

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

Method for preventing corrosion of concrete members in tidal range zone and splash zone of ocean

ActiveCN102383619AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesBuilding repairsEndcappingStructural engineering

The invention discloses a method for preventing corrosion of concrete members in a tidal range zone and a splash zone of an ocean, belonging to the field of concrete member corrosion prevention. Aiming at the protection requirement in special corrosion environment, the method comprises the following steps: coating a layer of silane impregnant on the outer surface of concrete, wherein the penetration depth is more than 1mm; after natural air drying, coating a layer of silane end sealing polyether sealant in a scraping way, wherein the thickness is 2-5mm; then wrapping a prefabricated protective cover immediately; coating a layer of sealant in the protective cover in a scraping way; sealing the upper and lower ends and the corners of the protective cover with the sealant; and coating the whole wrapping system with weatherproof finishing paint. In the method, the glass reinforced plastic protection technology is adopted and combined with the sealing protection technology of the silane end sealing polyether sealant and the silane impregnating protection technology, thus realizing the effective protection on the concrete members in the tidal range zone and the splash zone. The technical construction is simple as well as convenient and fast, and the sealant has a reliable and excellent protection effect, therefore, the method has a good market popularization prospect.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

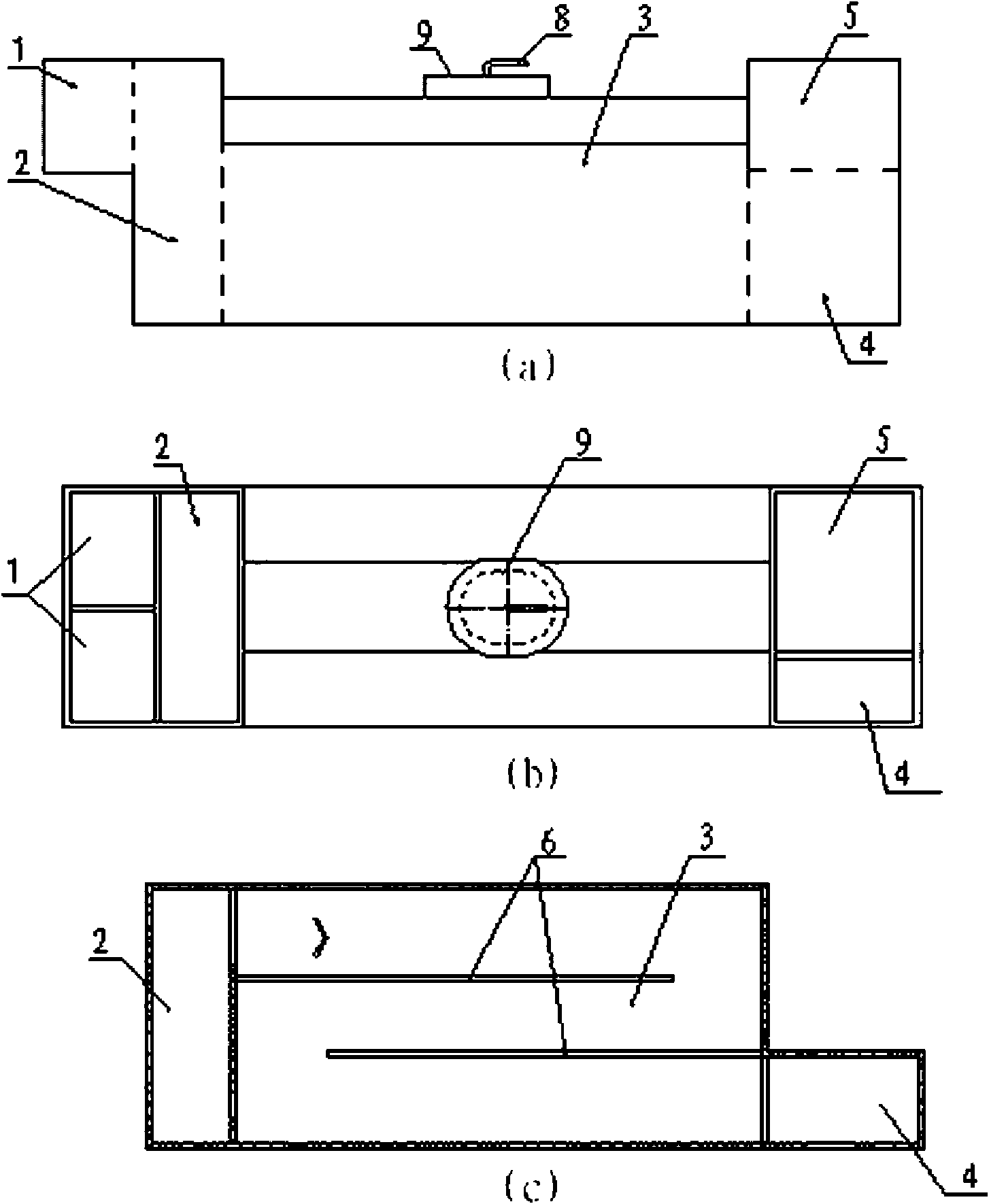

Plate type prefabricated concrete comprehensive pipe gallery

InactiveCN105672355AImprove construction efficiencyImprove build qualityArtificial islandsUnderwater structuresPrecast concreteSingle compartment

The invention relates to a plate type prefabricated concrete comprehensive pipe gallery which is applied to urban municipal engineering. The plate type prefabricated concrete comprehensive pipe gallery is formed by assembling a prefabricated concrete bottom plate, prefabricated concrete side walls and a prefabricated concrete top plate together. The prefabricated concrete side walls and the prefabricated concrete bottom plate are connected through rigid connection joints. The prefabricated concrete side walls and the prefabricated concrete top plate are connected through semi-rigid connection joints which are convenient to construct. The comprehensive pipe gallery is fastened in the longitudinal direction through bolts or stretched in the longitudinal direction through prestressed tendons, so that reliable connection is achieved. Single-compartment or multi-compartment pipe galleys meeting different requirements can be assembled through different numbers of prefabricated concrete plates of different dimensions.

Owner:上海同预建筑科技有限公司

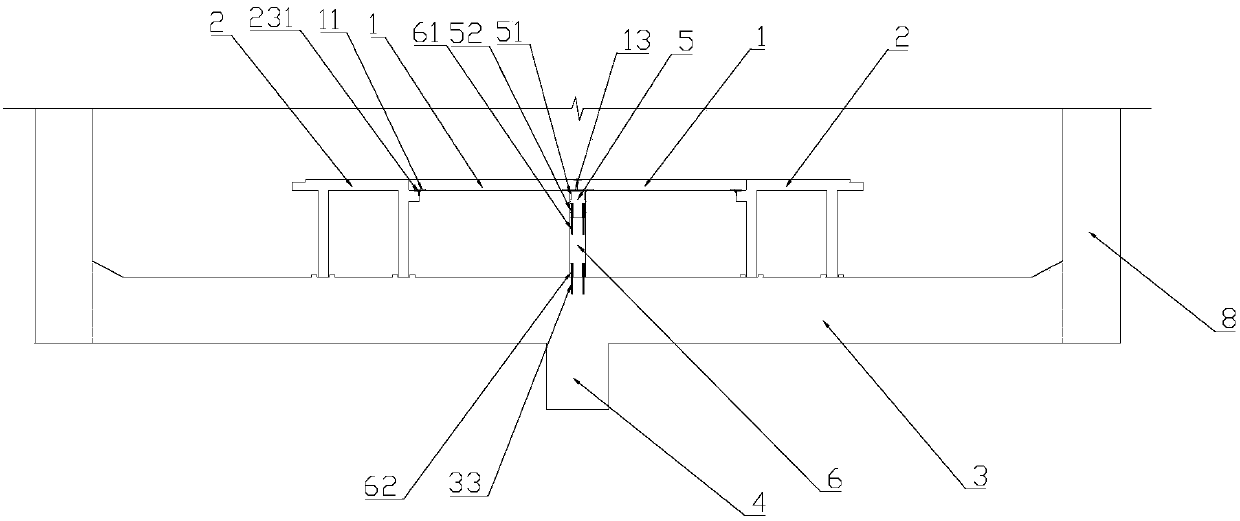

Prefabricated assembly type subway station platform and construction method thereof

PendingCN107939074AFlexible construction operationBuild fastSpecial buildingBuilding material handlingArchitectural engineeringSubway station

The invention provides a prefabricated assembly type subway station platform. The prefabricated assembly type subway station platform comprises a prefabricated platform plate and further comprises a prefabricated door type member and a bearing mechanism which are used for bearing the prefabricated platform plate, and the prefabricated door type member and the bearing mechanism are fixed to a station bottom plate. The invention further provides a construction method of the prefabricated assembly type subway station platform. The prefabricated assembly type subway station platform and the construction method have the advantages that construction operation is flexible, the construction speed is high, the site construction period is short, labor force is saved, and the labor cost is reduced are achieved; adopted prefabricated members are all produced in a prefabricating yard in a standardized mode, and materials and energy consumption can be controlled in the prefabricating yard in a centralized mode, so that the production efficiency is improved greatly, and the quality, time and material cost can be controlled simultaneously; and the construction environment is good, and site pollution and noise are low.

Owner:GUANGZHOU METRO DESIGN & RES INST

Box type water medium radiation cold roof plate and cooling and warming floor system

InactiveCN101220972APromote development and utilizationStrong comfortLighting and heating apparatusEnergy industryWater sourceArchitectural engineering

The invention relates to an HVAC technique field used for buildings, providing a product which can be manufactured in a factory and applied in construction site.

Owner:何政林

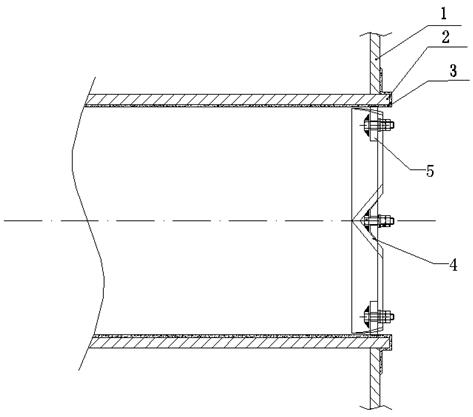

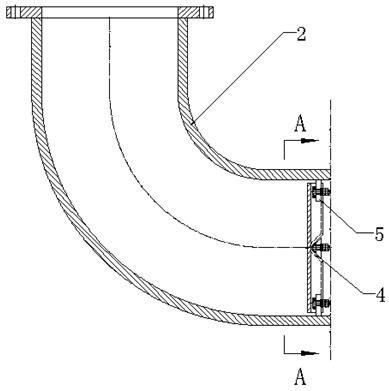

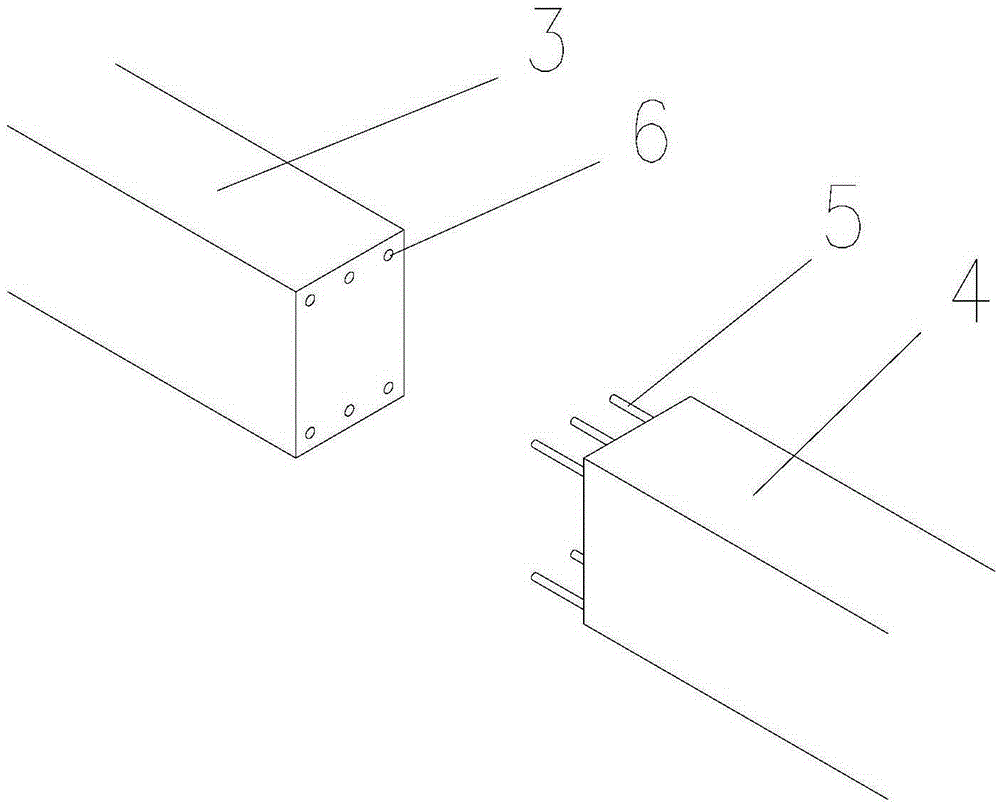

Anti-corrosion structure for chimney and construction method thereof

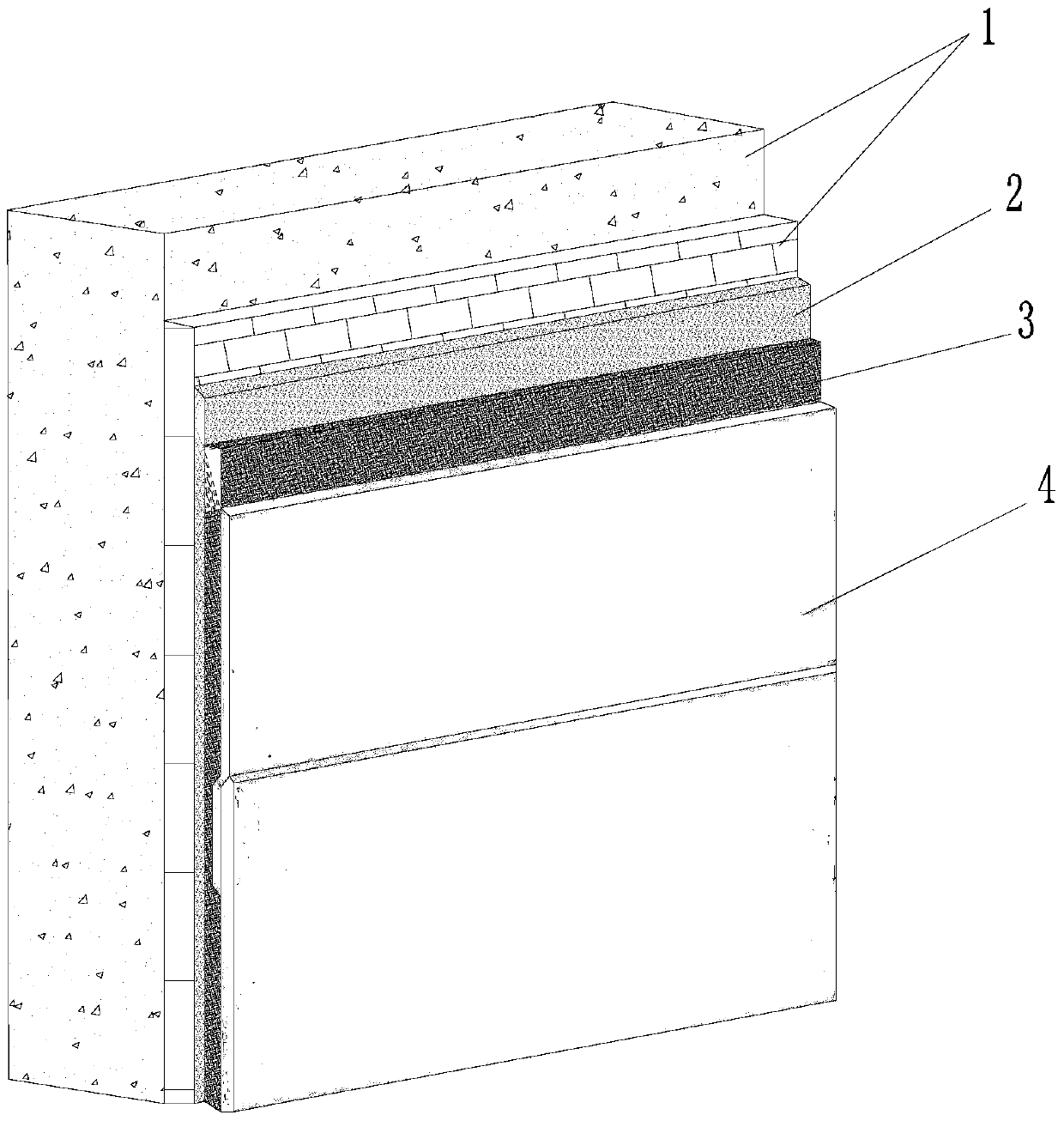

ActiveCN104989167AAvoid spot weldingAvoid Weld Quality IssuesTowersBuilding insulationsAdhesiveTitanium plate

The invention discloses an anti-corrosion structure for a chimney. The anti-corrosion structure comprises a first coat (2), an adhesive layer (3) and a titanium plate layer (4) which are arranged in sequence, wherein a chimney base (1) is coated with the first coat (2), and the titanium plate layer (4) adheres to the first coat (2) through the adhesive layer (3). The invention further discloses a construction method of the anti-corrosion structure for the chimney. The method comprises the steps of cleaning the chimney base, coating the cleaned chimney base with the first coat material, applying adhesive and sticking a titanium plate after the first coat material on the chimney base is solidified, and conducting inspection and repair. According to the method, the lapped titanium plate is directly stuck onto the structural layer of a chimney by means of the titanium plate adhesive. The method has the advantages that construction period is short, the requirement for the site construction environment is low, and the problem that titanium plate welding quality is poor due to poor construction site welding environment is solved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

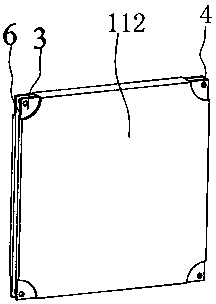

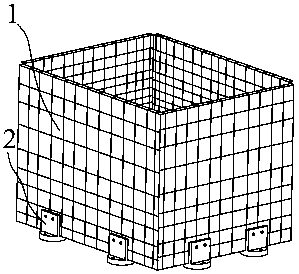

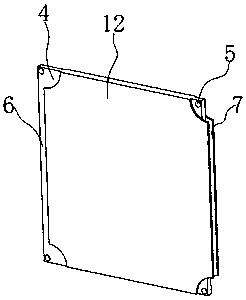

Assembly building modularized frame structure

The invention belongs to the technical field of buildings, and particularly relates to an assembly building modularized frame structure. The assembly building modularized frame structure comprises several basic panels, corner modules and base modules; the basic panels are spliced by several flat plate modules, the corner modules are located at all corners to be connected with the basic panels at different positions, and the base modules are located on the lower portions of the basic panels and used for installation and positioning of the basic panels. The base modules are installed on the ground as a fixation basis. The basic panels are spliced by the flat plate modules, the corner modules are located at all the corners to be connected with the basic panels at different positions, the basic panels are installed on the base modules, and the corner modules are connected with the adjacent basic panels to form a building basic body structure; the flat plate modules, the corner modules andthe base modules can be produced in a factory according to standards and rapidly assembled through modularization after being transported to a construction site, in the whole process, the constructionperiod is short, and multi-profession skilled personnel cooperation can be reduced during installation.

Owner:四川恒达兴铁科技有限公司

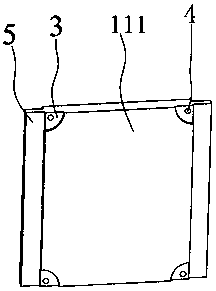

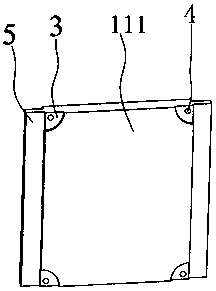

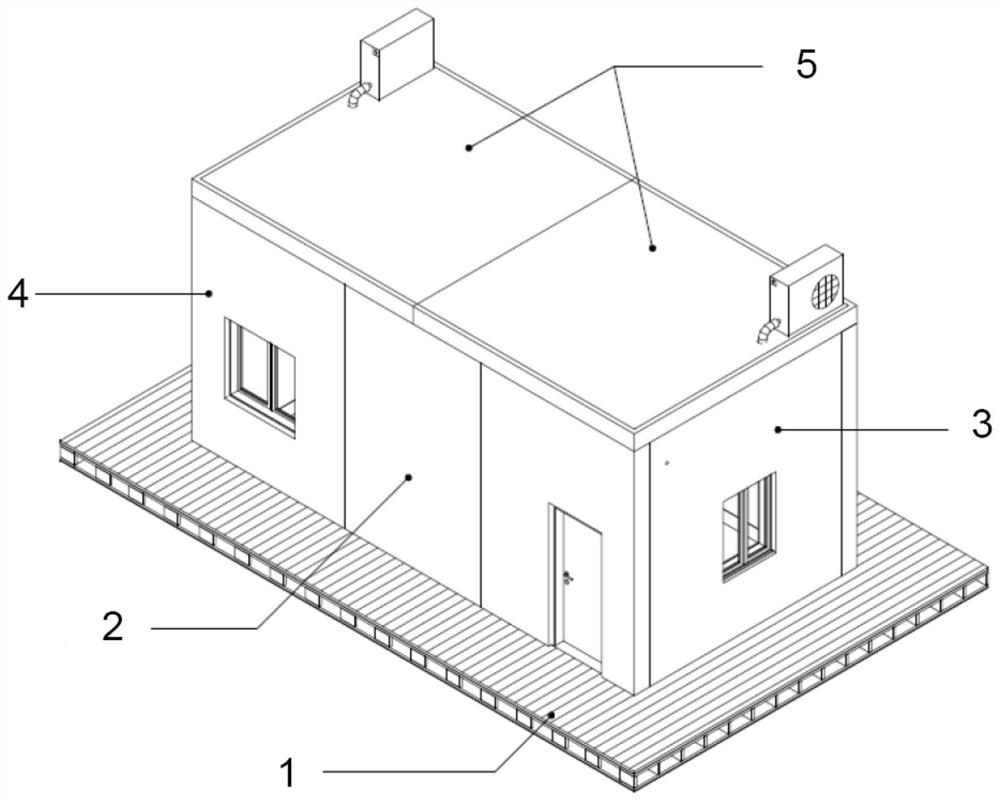

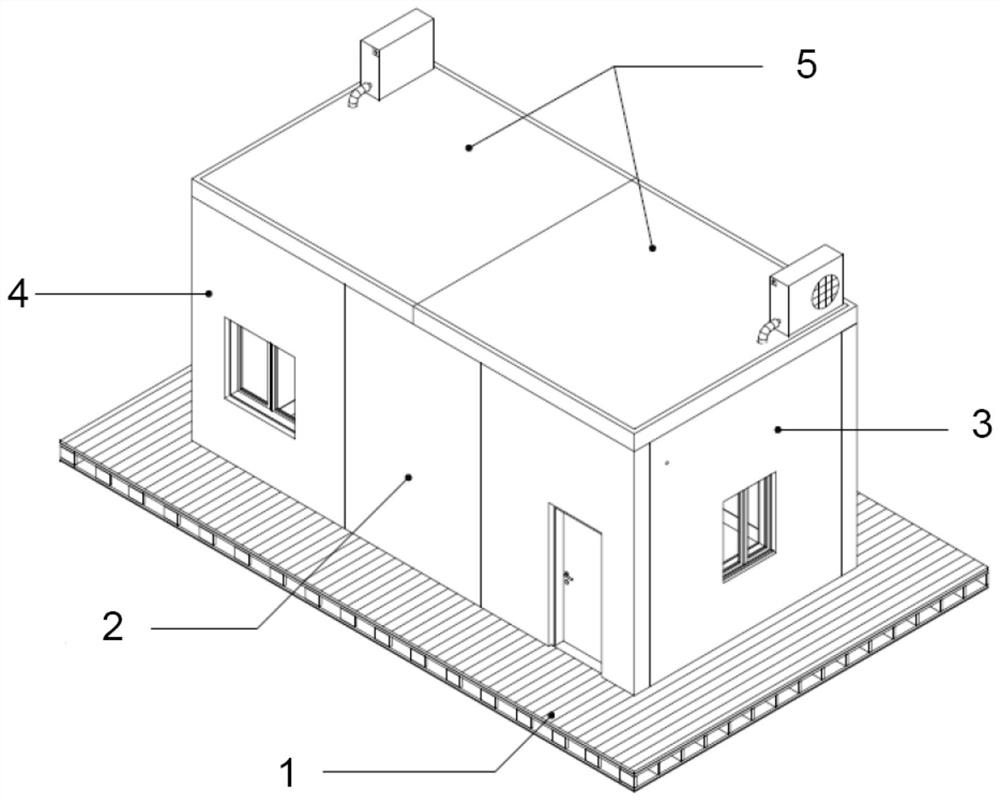

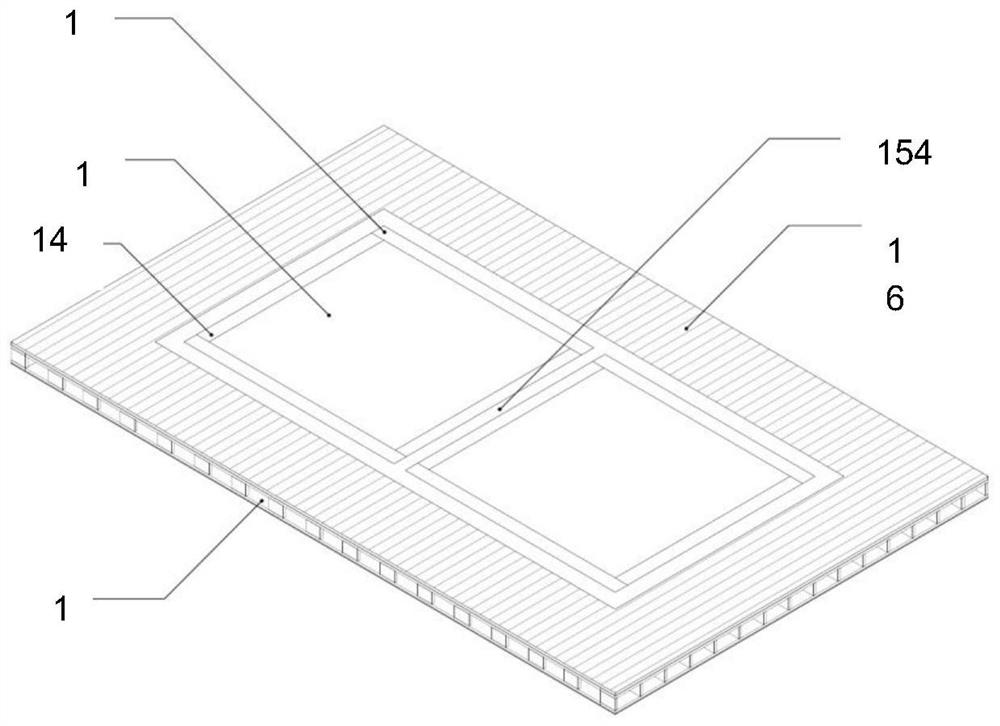

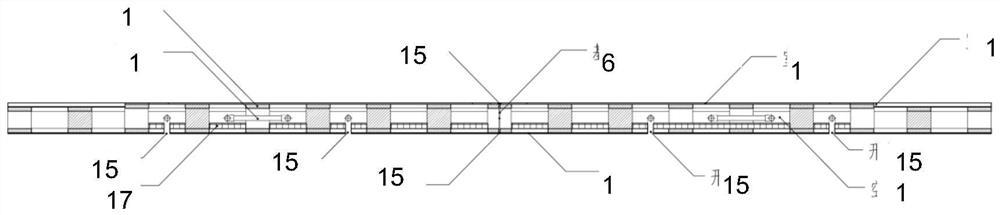

Modularized prefabricated integrated building construction system and construction method thereof

ActiveCN113090076AReduce wasteGuaranteed performanceWallsSpecial buildingArchitectural engineeringHeat conservation

The invention provides a modularized prefabricated integrated building construction system. The modularized prefabricated integrated building construction system comprises a building base part (1), side outer wall parts (3), corner outer wall parts (4), middle outer wall parts (2), inner wall parts (6) and roof parts (5), and the building base part (1), the side outer wall parts (3), the corner outer wall parts (4), the middle outer wall parts (2), the inner wall parts (6) and the roof parts (5) are combined and connected through wooden dovetail joints to form an integral house. A building structure, a heat preservation layer, a decorative surface material and an outer enclosure structure are integrated in each part, and meanwhile, electromechanical equipment and a pipeline system used by the building are integrated and preassembled. The modularized prefabricated integrated building construction system is high in integration degree and high in assembly rate, installation errors and errors are reduced, and the transportation mode is flexible; and the construction method is simple, wet operation is avoided, and the construction period is short.

Owner:北京林婉嫕空间艺术设计有限公司

Device for discharge outboard pipe and water diversion plate of ship and manufacturing process

PendingCN113184109AWill not affect the docking planImprove rigiditySelf-bailing equipments/scuppersVessel partsMarine engineeringStructural engineering

The invention relates to a device for a discharge outboard pipe and a water diversion plate of a ship and a manufacturing process, and the device mainly comprises a base, the discharge outboard pipe, the water diversion plate and an outboard plate; the base is fixed in a spot welding mode, the inner portion and the outer portion of the base are both coated with GRE, the discharge outboard pipe is made of carbon steel, the inner surface of the discharge outboard pipe is coated with GRE, the discharge outboard pipe and the outboard plate are fixed in a conventional welding mode, the outboard plate does not need to be replaced in a large area, and a hole can be formed according to a conventional discharge outboard pipe. According to the process for coating the GRE inside the discharge outboard pipe, acidic corrosion wastewater can be completely isolated from the carbon steel discharge outboard pipe, the risk of perforation of the discharge outboard pipe is reduced, the cost required by the process is also reduced, the site construction period is short, and the dock period plan of the whole ship is not influenced.

Owner:南通惠尔船舶科技有限公司

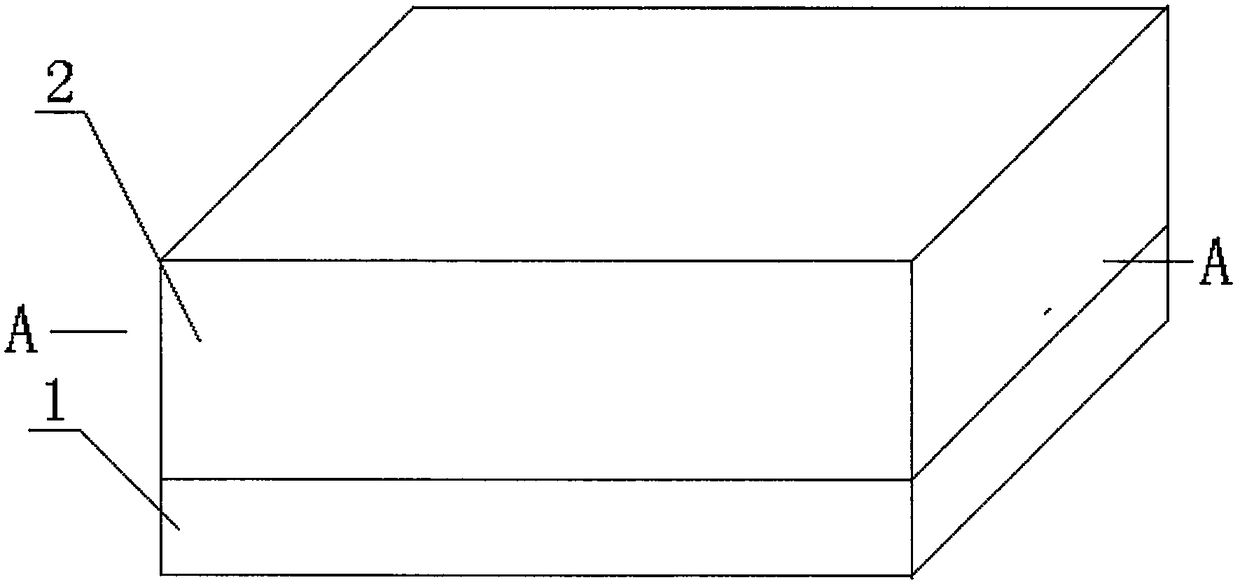

Wear-resistant corrosion-resistant grade level and preparation method thereof

ActiveCN109367168AReasonable designSimple structureSynthetic resin layered productsEpoxy resin adhesivesEpoxyFertilizer plant

The invention relates to a wear-resistant corrosion-resistant grade level and a preparation method thereof. The wear-resistant corrosion-resistant grade level fits units such as chemical plants, brewing plants and fertilizer plants. The wear-resistant corrosion-resistant grade level is formed by an epoxy resin-based composite material base layer and a mixed resin-based composite material structural layer. The structural layer is located above the base layer; a groove is formed in the upper part of the base layer, a bump is arranged on the lower part of the structural layer, the bump is correspondingly consistent to the groove in dimension, the bump is embedded into the groove, and is sealed with the groove together through an epoxy resin coating layer. The wear-resistant corrosion-resistant grade level is reasonable in design, simple in structure, convenient to produce and manufacture and low in production cost. Compared with an on-site coated corrosion-resistant layer, the wear-resistant corrosion-resistant grade level is high in strength, good in wear resistance, short in on-site construction period, long in service life and the like. Compared with on-site casting corrosion-resistant mortar, the grade level is smooth in ground and high in attractiveness, does not adsorb dust by static electricity, can avoid ground pollution, is extremely easy to clean as a result of little dust, is short on on-site construction period, can be replaced flexibly in the using process as a result of local quality problem and the like.

Owner:无锡市中舶远航环保科技有限公司

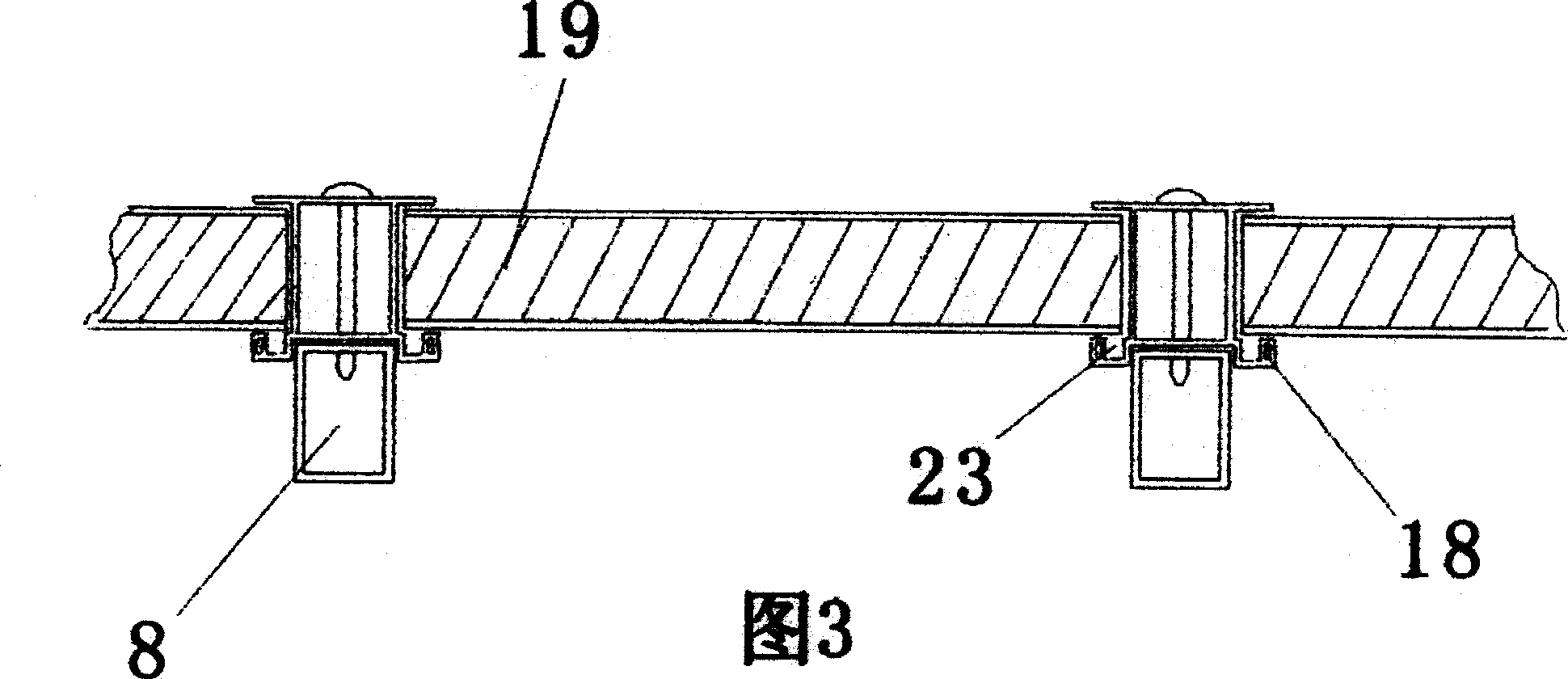

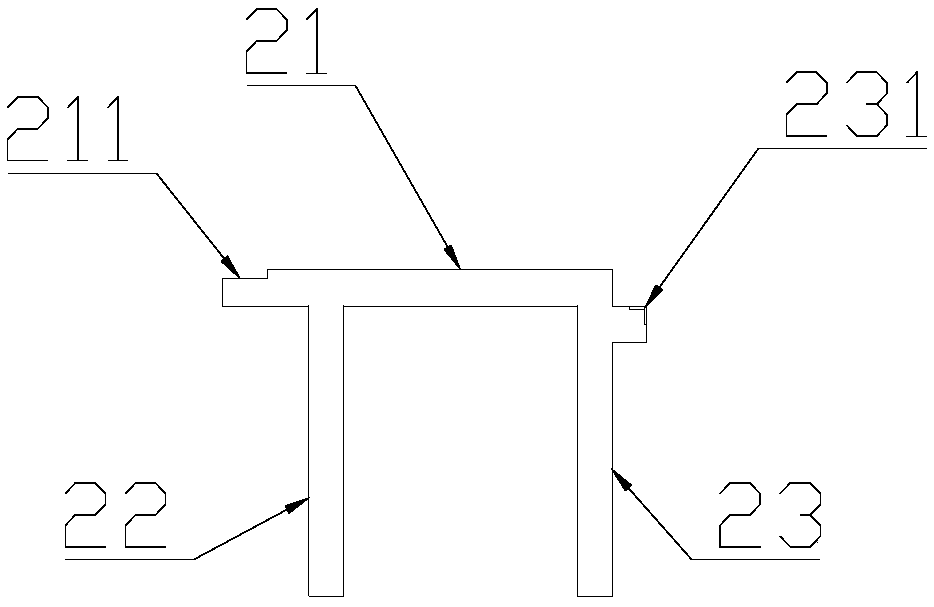

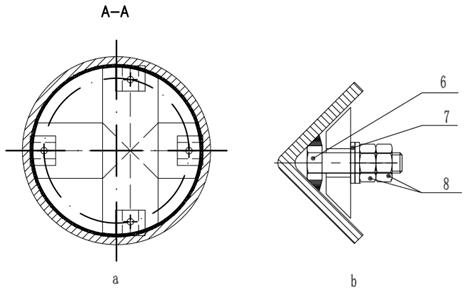

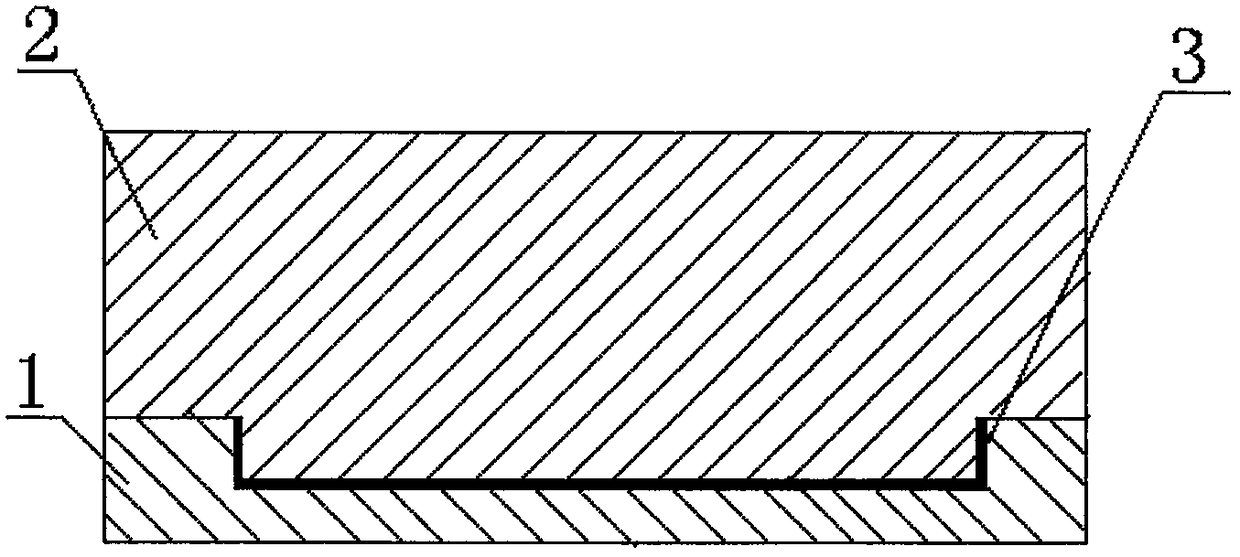

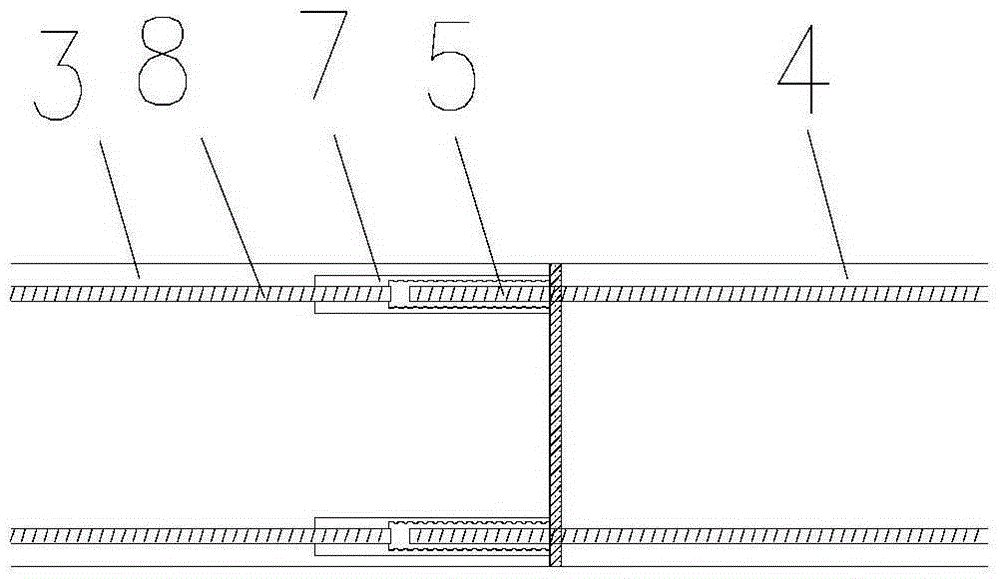

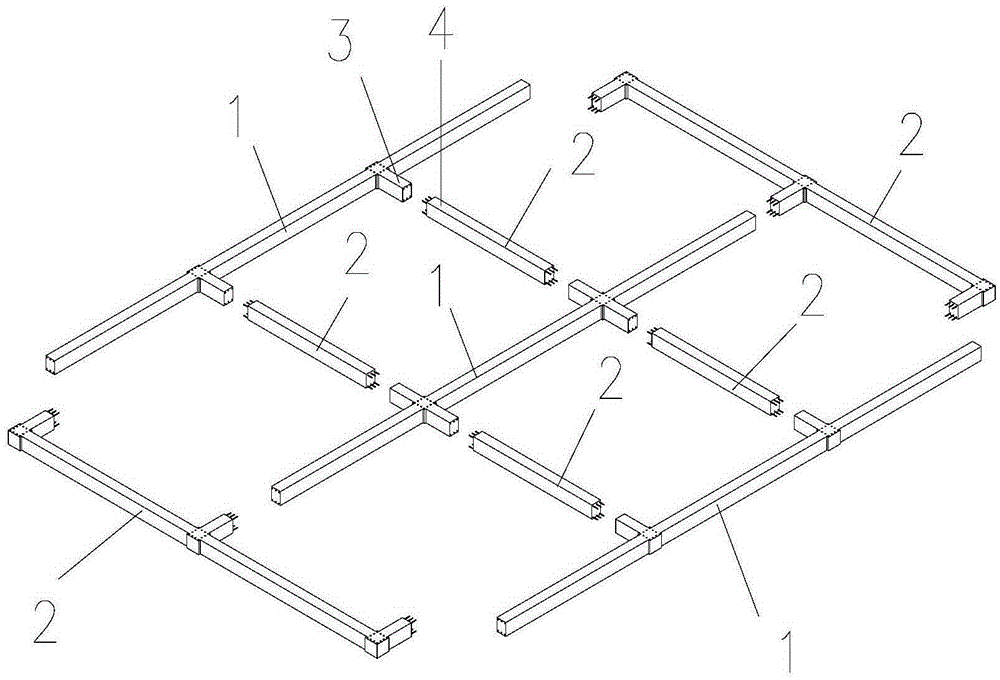

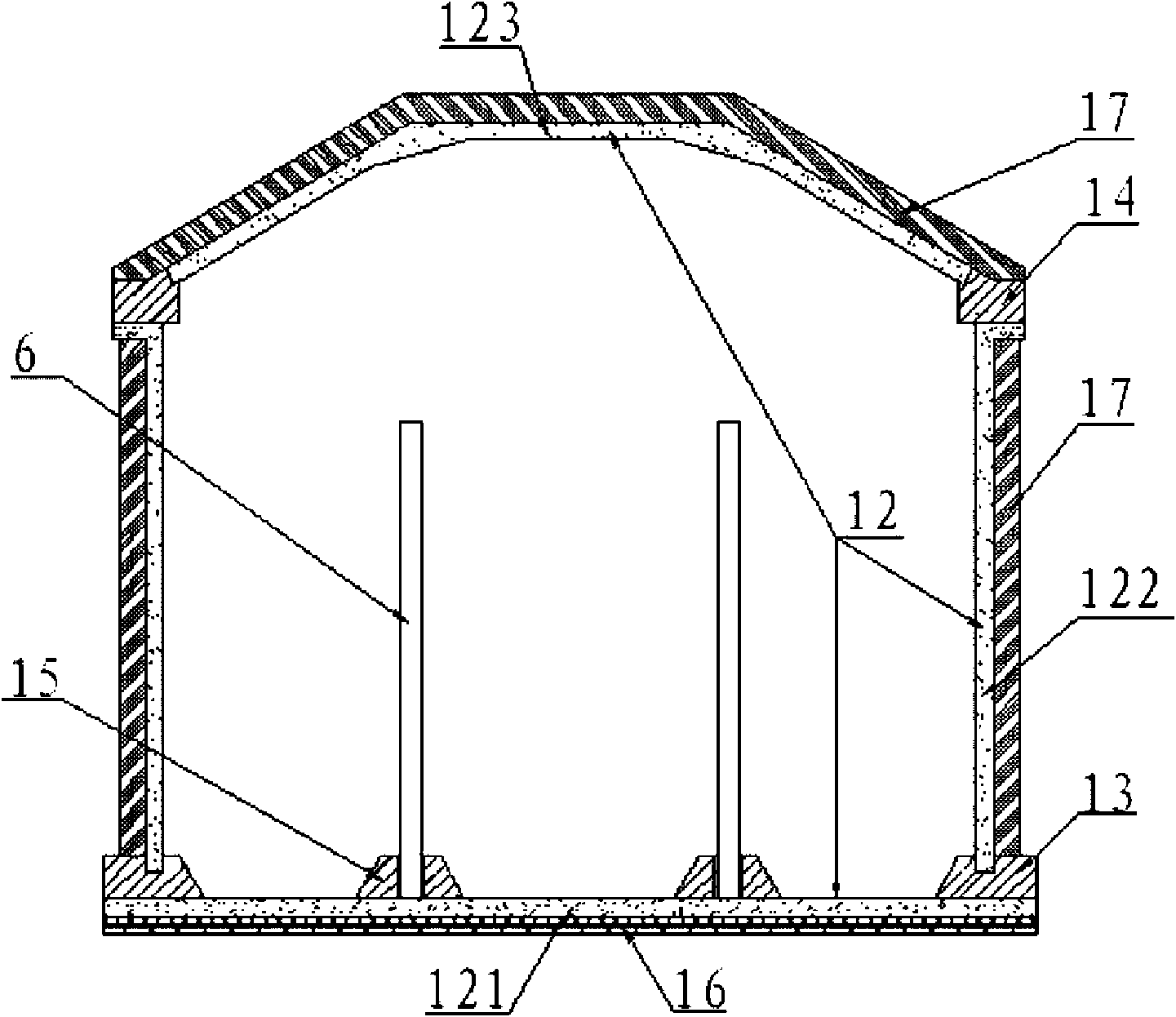

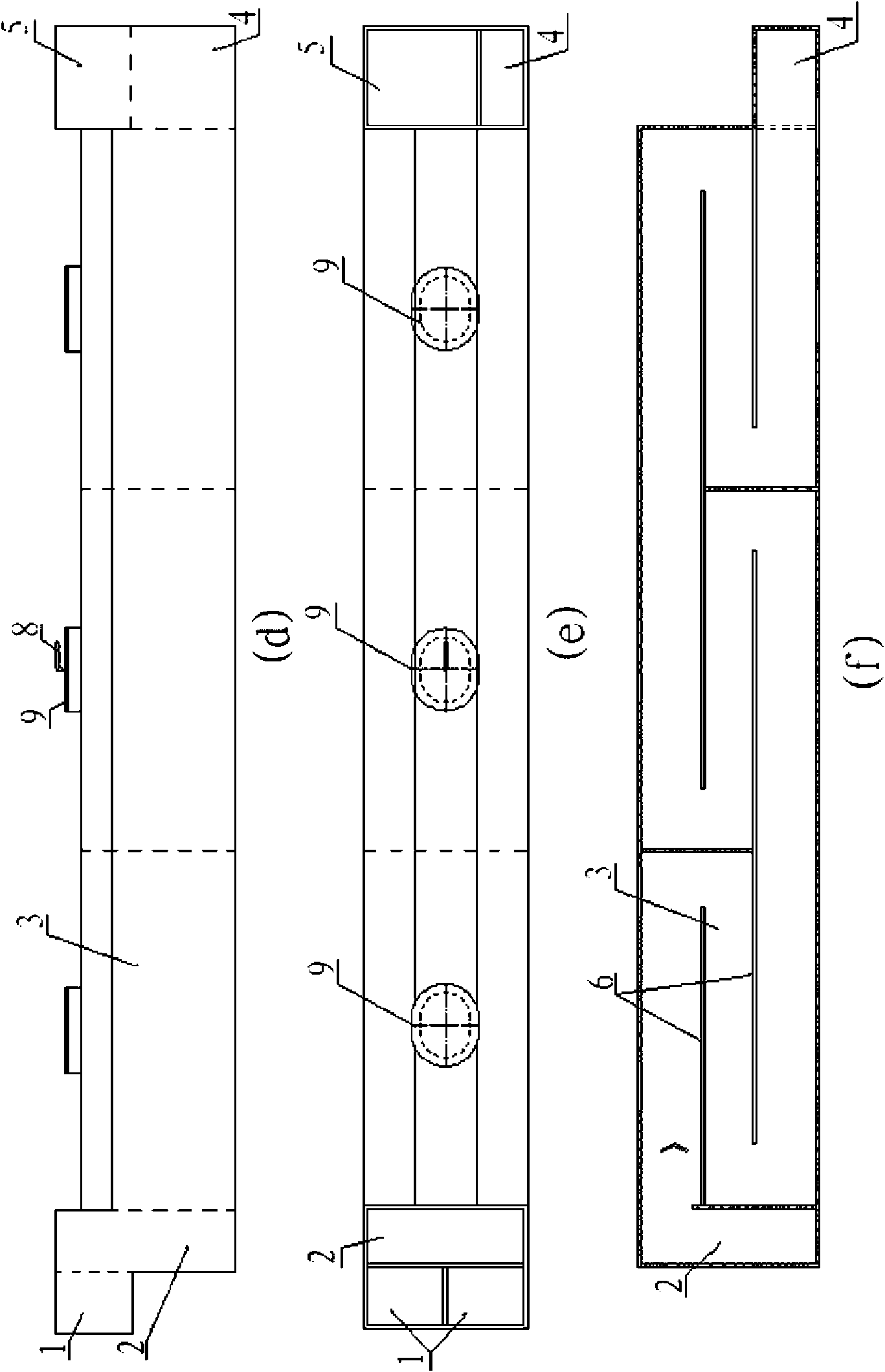

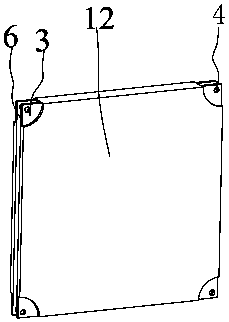

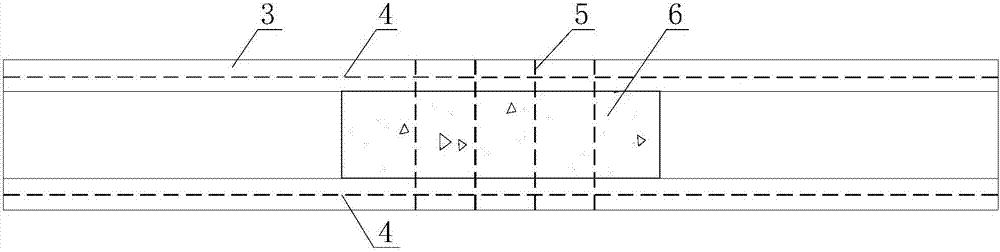

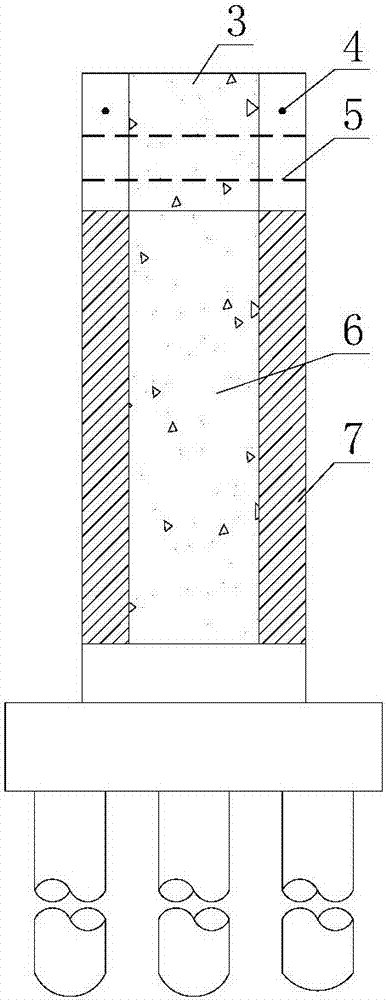

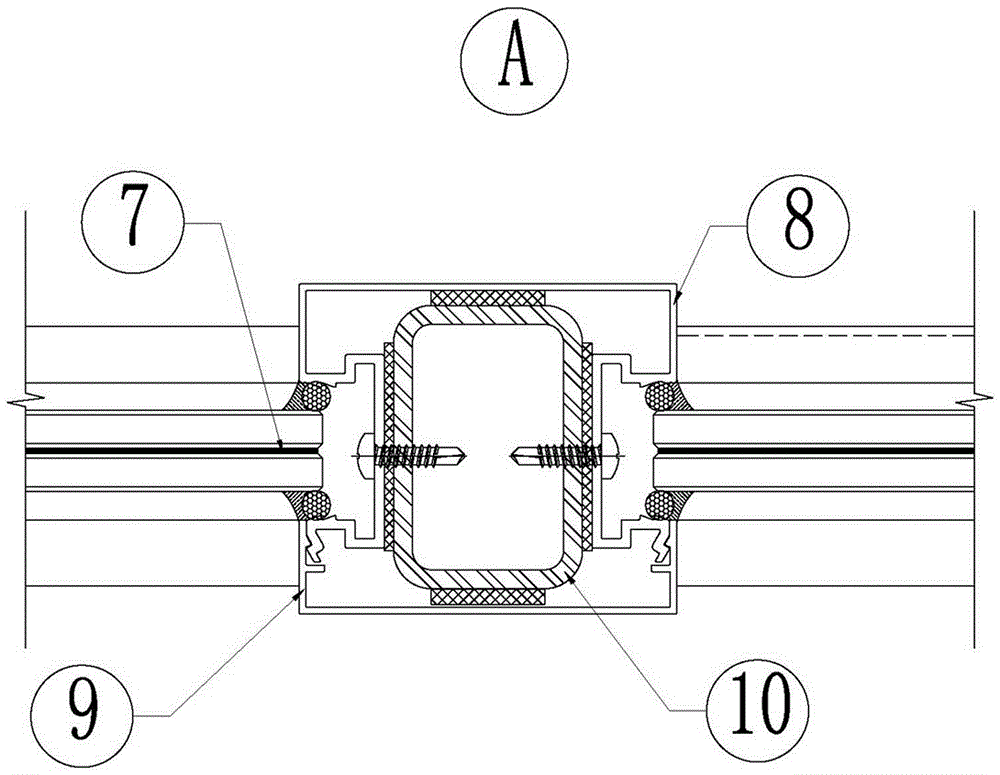

Prefabricated Reinforced Concrete Longitudinal Beam and Crossbeam Connection Structure

InactiveCN103669597BEasy constructionShort construction period on siteBuilding constructionsReinforced concreteEngineering

The invention discloses a connecting structure for a prefabricated reinforced concrete longitudinal beam and a prefabricated reinforced concrete transverse beam. The connecting structure comprises the prefabricated reinforced concrete longitudinal beam and the prefabricated reinforced concrete transverse beam. The prefabricated reinforced concrete longitudinal beam is provided with a transverse beam connecting end, the prefabricated reinforced concrete transverse beam is provided with the longitudinal beam connecting end, and the center line of the transverse beam connecting end of the prefabricated reinforced concrete longitudinal beam and the center line of the longitudinal beam connecting end of the prefabricated reinforced concrete transverse beam are coincided; the transverse beam connecting end of the prefabricated reinforced concrete longitudinal beam is connected with the longitudinal beam connecting end of the prefabricated reinforced concrete transverse beam in an inserted mode through reinforcing steel bar plugs and reinforcing steel bar insertion holes, the reinforcing steel bar insertion holes are formed by corrugated steel pipes, connecting agents are arranged between the corrugated steel pipes and the reinforcing steel bar plugs, and the joint position between the longitudinal beam connecting end of the prefabricated reinforced concrete transverse beam and the transverse beam connecting end of the prefabricated reinforced concrete longitudinal beam is provided with a joint connecting agent. According to the connecting structure, the prefabricated reinforced concrete longitudinal beam and the prefabricated reinforced concrete transverse beam can be prefabricated, splicing installation can be carried out on site, construction is conveniently achieved, and site construction pollution can be reduced.

Owner:CHINA JINGYE ENG TECH CO LTD +1

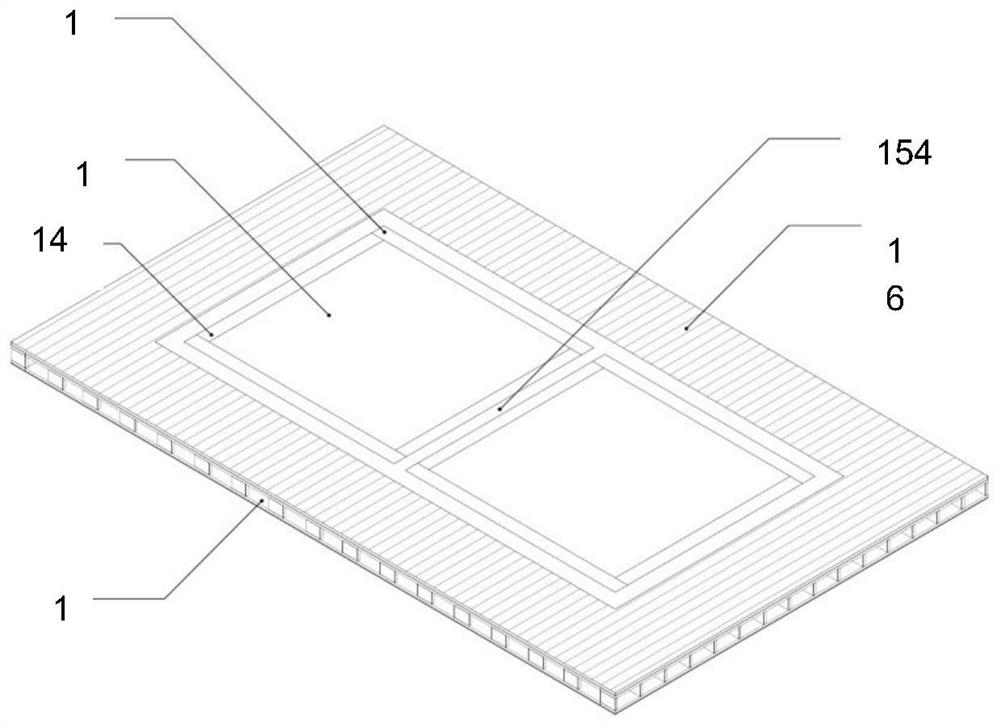

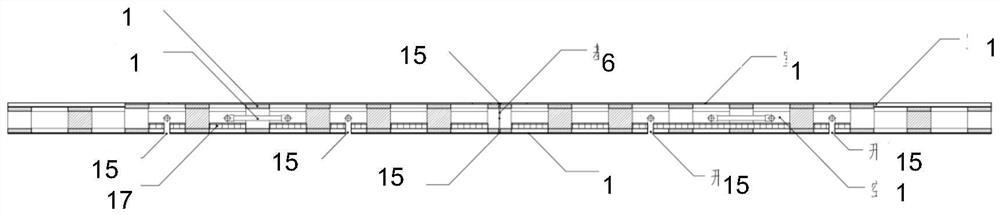

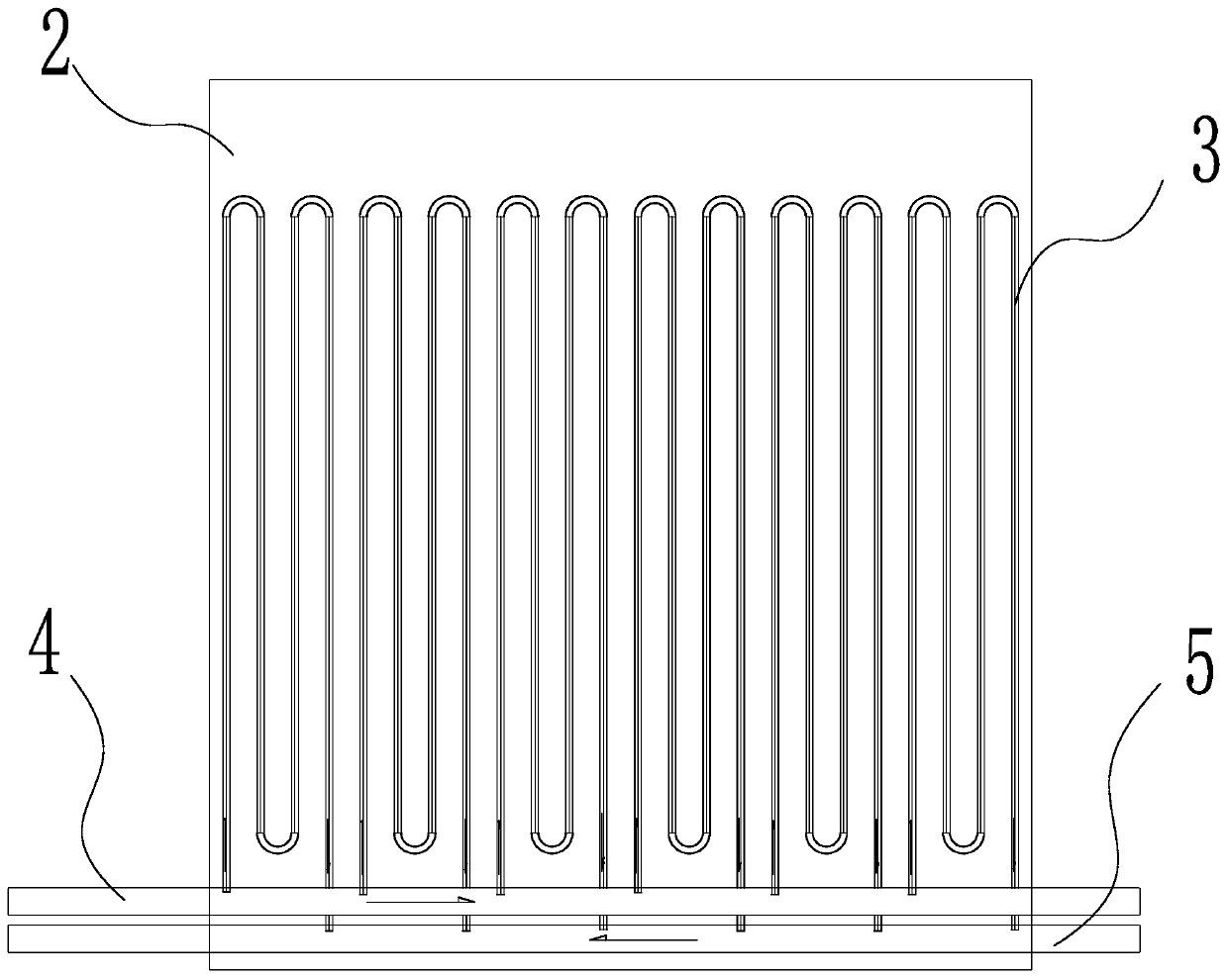

Composite board with capillary tubes and forming method of composite board

InactiveCN111576730AEasy to install and fixImprove thermal efficiencyLighting and heating apparatusBuilding componentsCapillary TubingComposite plate

The invention relates to the field of buildings, and provides a composite board with capillary tubes and a forming method of the composite board. The composite board is simple in structure, high in heat efficiency, energy-saving and environment-friendly, and solves the technical problem that a heating system is complex in structure, non-uniform in heating space temperature, low in heat efficiency,high in energy and the like in the prior art. The composite board comprises an insulation board flatly laid and fixed on a ceiling, wherein a honeycomb metal board is flatly laid and fixed outside the insulation board, the plurality of capillary tubes are clamped between the honeycomb metal board and the insulation board, and the two ends of each capillary tube are connected to a temperature-regulating water supply source through a water supply pipe and a water return pipe.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

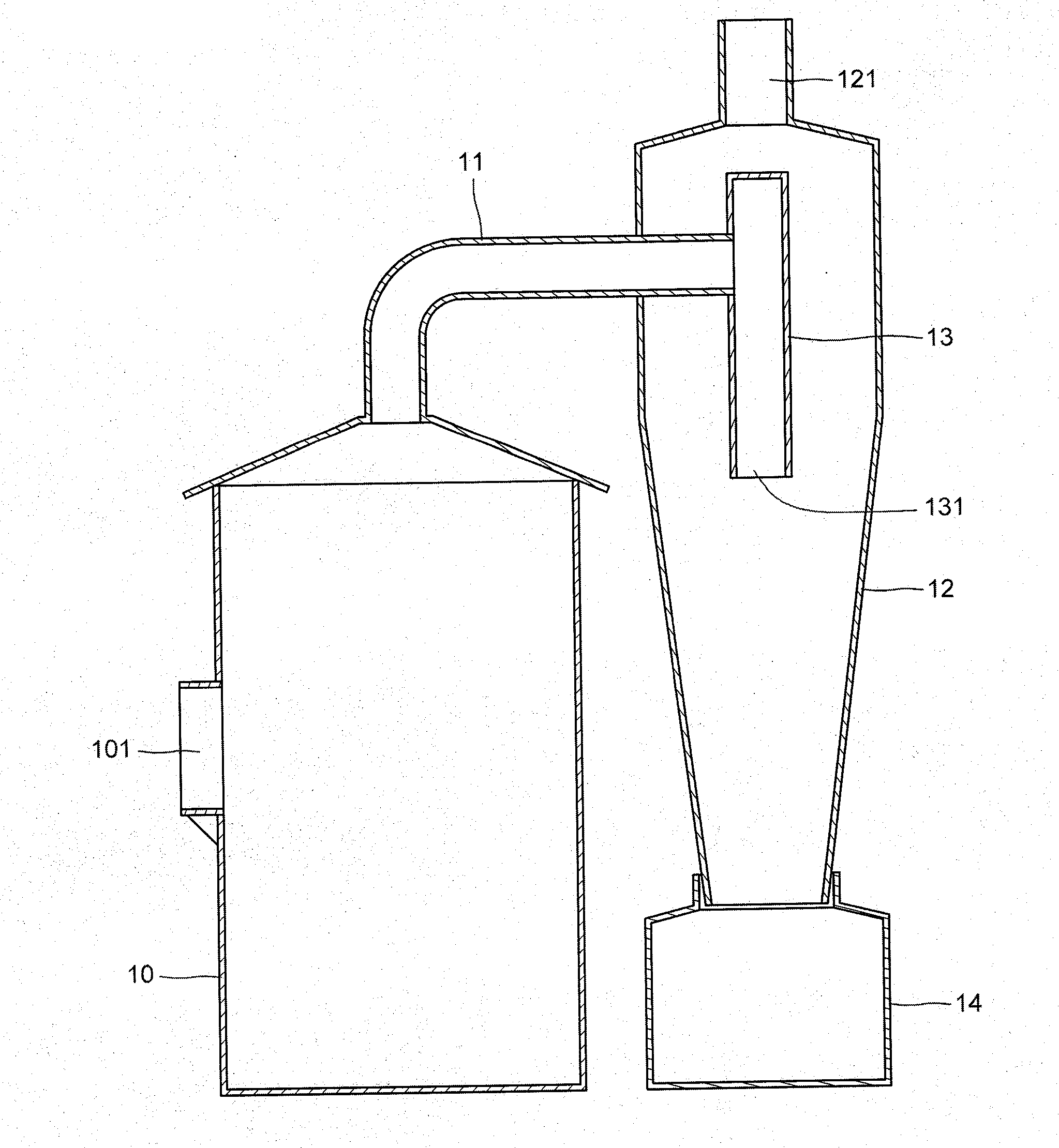

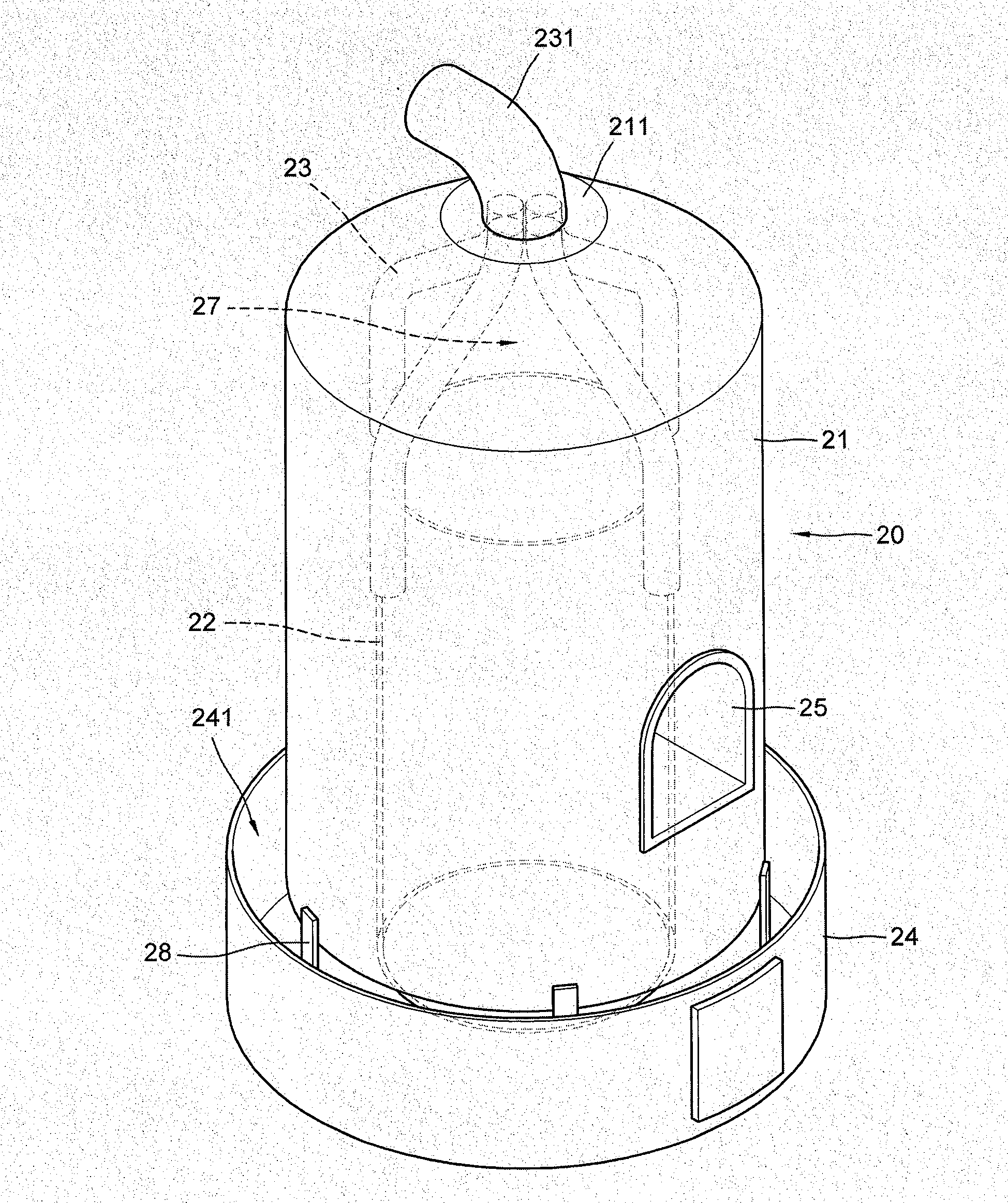

Golden paper stove

InactiveCN101869423AReduce volumeDoes not take up spaceReligious equipmentCombustion chamberHeat current

The invention provides a golden paper stove, which is a stove body comprising an outer cylinder, an inner cylinder, a plurality of exhaust pipes and a collecting cylinder, wherein the bottom of the outer cylinder is provided with an intake port and the top of the outer cylinder is provided with a closed plate, an intake space is formed between the inner cylinder and the outer cylinder, a secondary combustion chamber is arranged between the top of the inner cylinder and the closed plate, the exhaust pipes are arranged above the exhaust space and pass through the closed plate, the collecting cylinder is provided with an external communication space, golden paper is subject to primary combustion within the inner cylinder, heat current rises to the secondary combustion chamber, oxygen is supplied to the inner cylinder through the external communication space and to the secondary combustion chamber through the intake port and the intake space, rising floating micro particles are subject to combustion in the secondary combustion chamber, gases generated by complete high-temperature combustion are exhausted by pressurization, thus the purpose of complete primary and secondary combustion is achieved and exhaust of the floating micro particles is avoided.

Owner:耀坤兴业有限公司

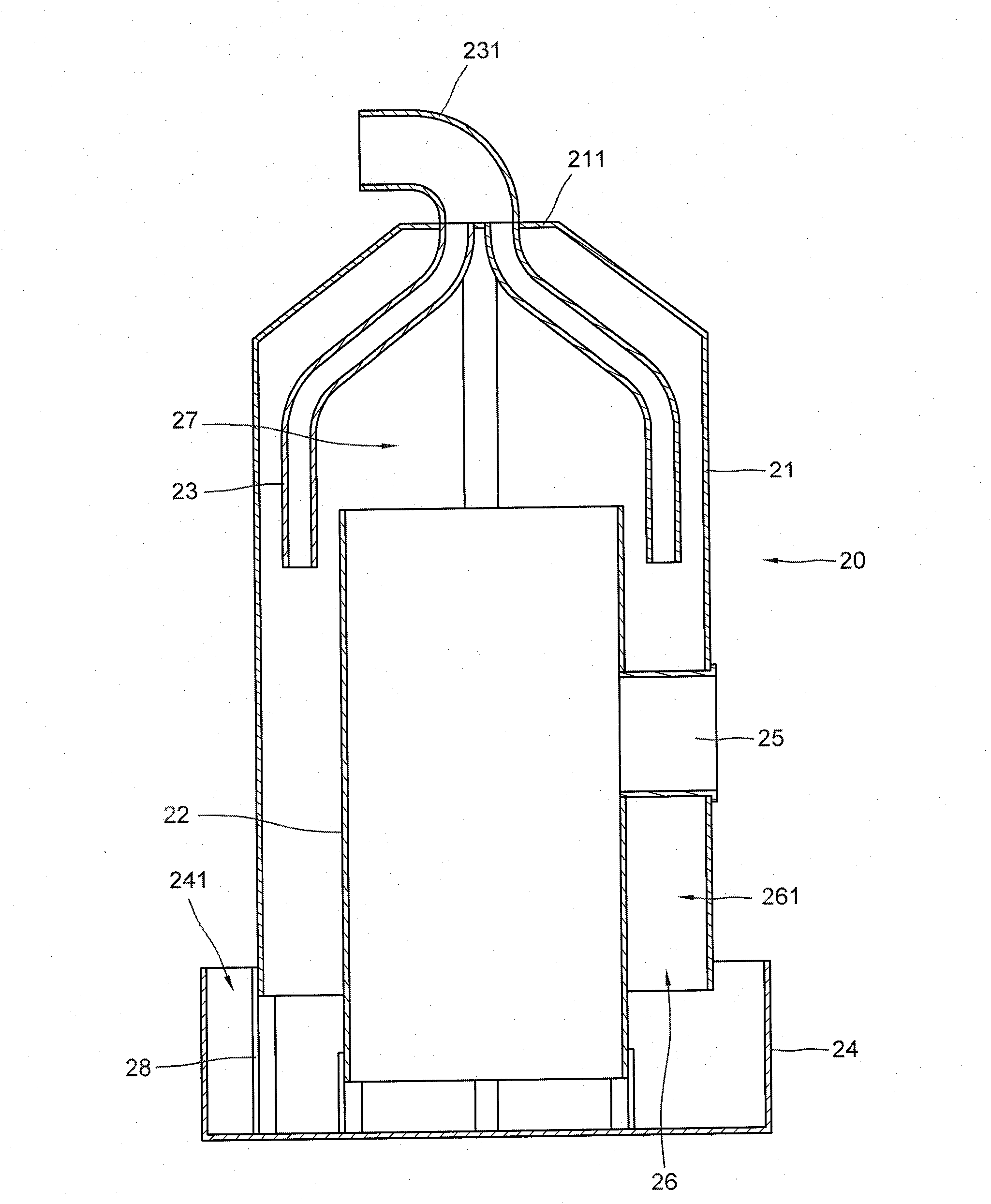

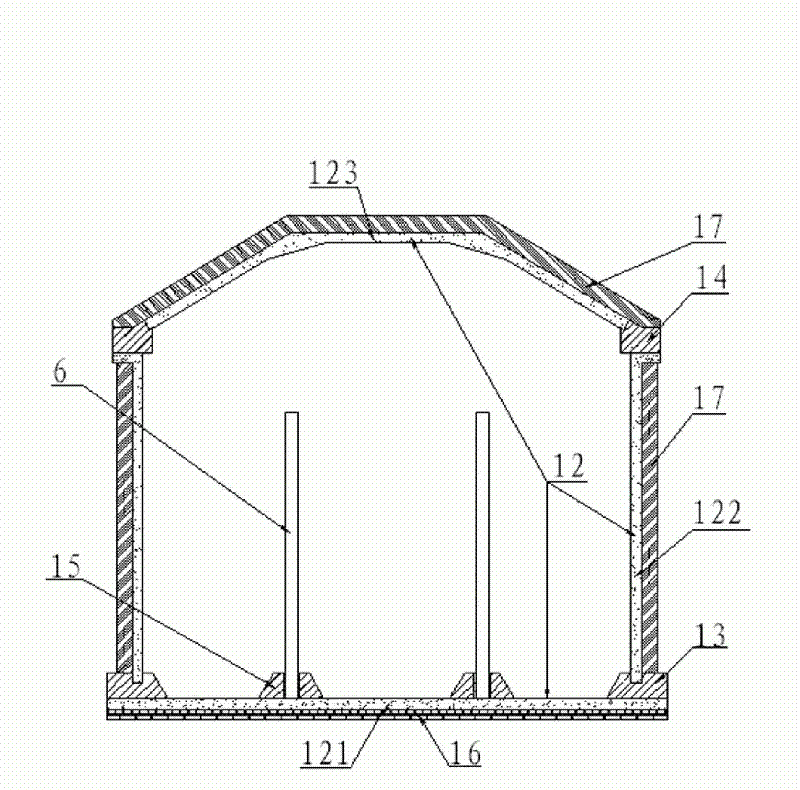

Ferrocement biogas digester

InactiveCN101555451AIncreased durabilityImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsUltimate tensile strengthFermentation

The invention relates to a ferrocement biogas digester which is a box-shaped structure body formed by the splicing of a plurality of ferrocement panels; the biogas digester comprises an acidification feeding pool, a feeding room, a fermentation pool, a discharging pool and a water pressure room, which are connected and communicated in sequence; and the upper surface of the fermentation pool is provided with a manhole cover which is provided with an air outlet pipe. The invention has the advantages of good integrity, high local strength, strong compactness and impermeability, high safety and reliability, and effectively enhances the durability of the main structure in a corrosive medium; simultaneously, the invention also has short on-site construction period and less processes with high technical requirements, can be effectively controlled in the construction scope, and avoids the defects of easy omission when in large-scale construction.

Owner:朱元康 +4

Ferrocement biogas digester

InactiveCN101555451BIncreased durabilityImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsUltimate tensile strengthFermentation

The invention relates to a ferrocement biogas digester which is a box-shaped structure body formed by the splicing of a plurality of ferrocement panels; the biogas digester comprises an acidification feeding pool, a feeding room, a fermentation pool, a discharging pool and a water pressure room, which are connected and communicated in sequence; and the upper surface of the fermentation pool is provided with a manhole cover which is provided with an air outlet pipe. The invention has the advantages of good integrity, high local strength, strong compactness and impermeability, high safety and reliability, and effectively enhances the durability of the main structure in a corrosive medium; simultaneously, the invention also has short on-site construction period and less processes with high technical requirements, can be effectively controlled in the construction scope, and avoids the defects of easy omission when in large-scale construction.

Owner:朱元康 +4

Easily disassembled building frame structure

The invention belongs to the technical field of buildings, and particularly relates to an easily disassembled building frame structure which comprises a plurality of basic surface plates and a plurality of base modules. A plurality of flat plate modules are spliced to form the basic surface plates, the base modules are positioned on the lower portions of the basic surface plates and used for mounting and positioning the basic surface plates, the base modules serve as fixing foundations and are mounted on the ground, the flat plate modules are spliced to form the basic surface plates, the basicsurface plates are mounted on the base modules to form a building basic body structure, the flat plate modules and the base modules can be produced in a factory in a standardized manner and transported to a construction site and then can be rapidly and modularly assembled, a whole site construction period is shortened, multi-type skilled personnel matching can be decreased in the assembly process, so that whole construction safety and site management difficulties are reduced, site construction site environmental pollution can be reduced, and used material stacking site area is decreased and the like.

Owner:四川恒达兴铁科技有限公司

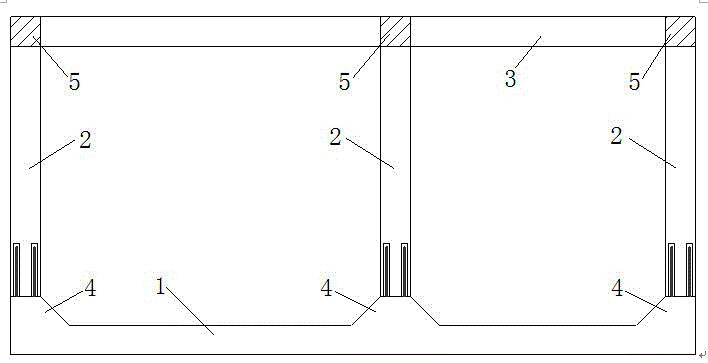

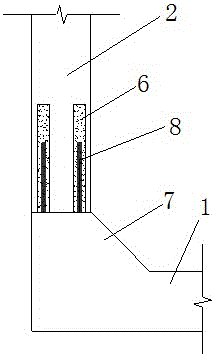

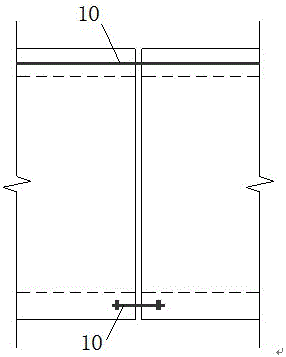

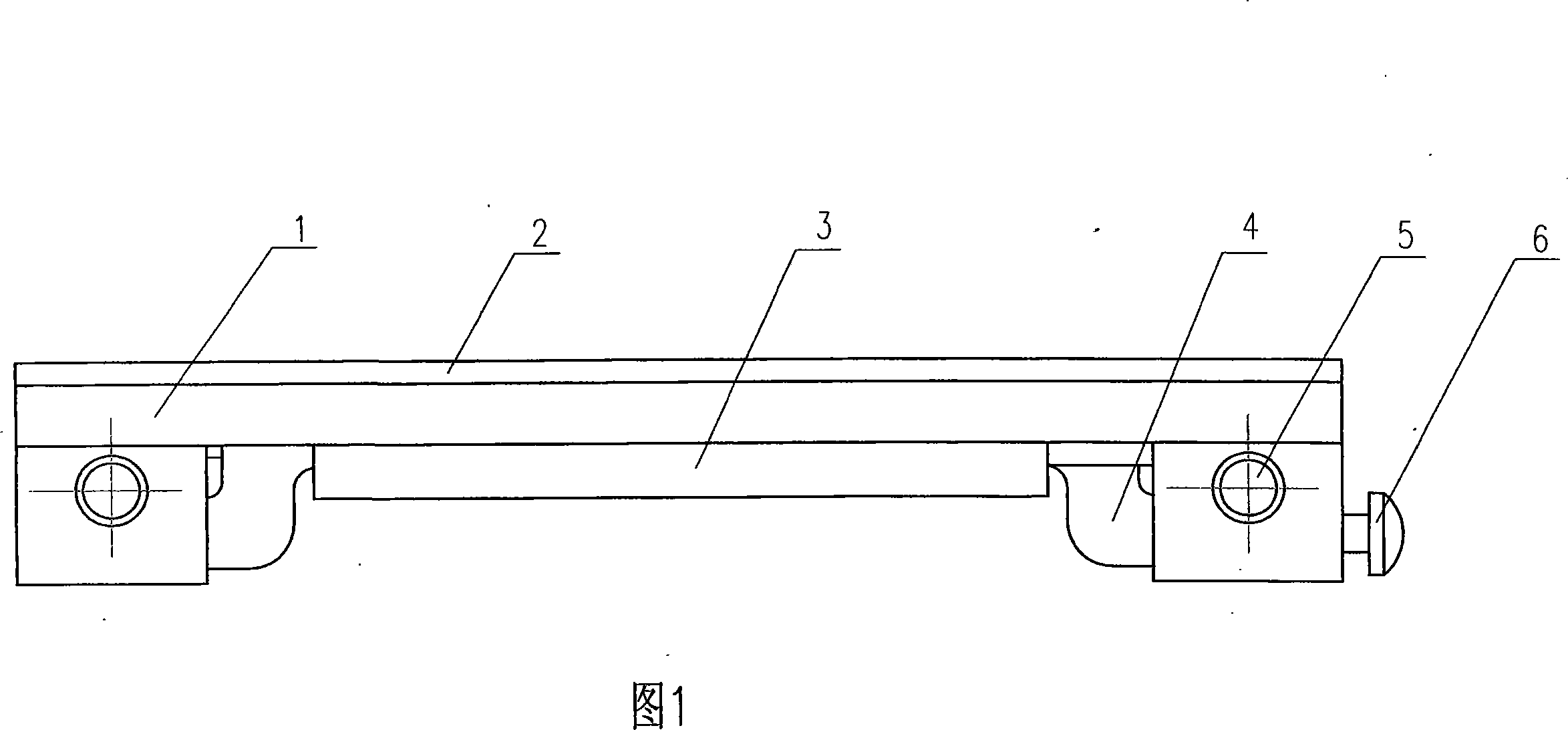

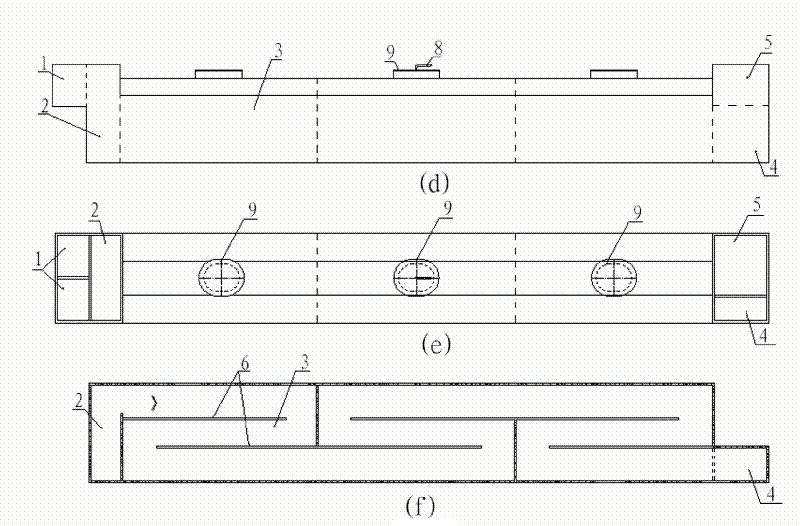

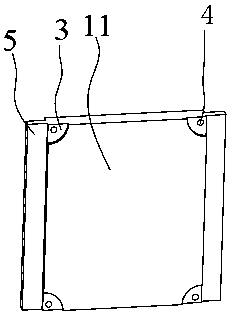

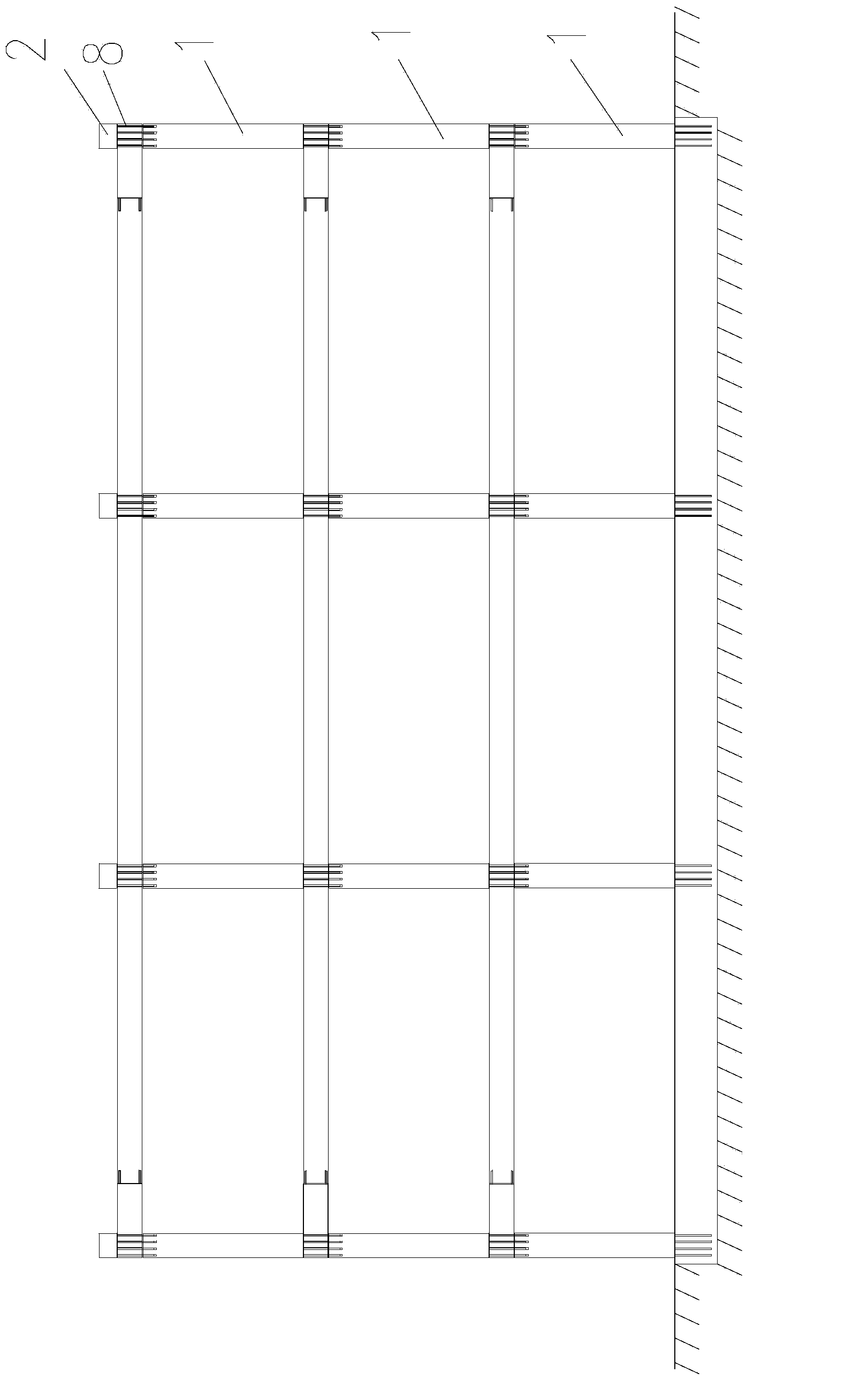

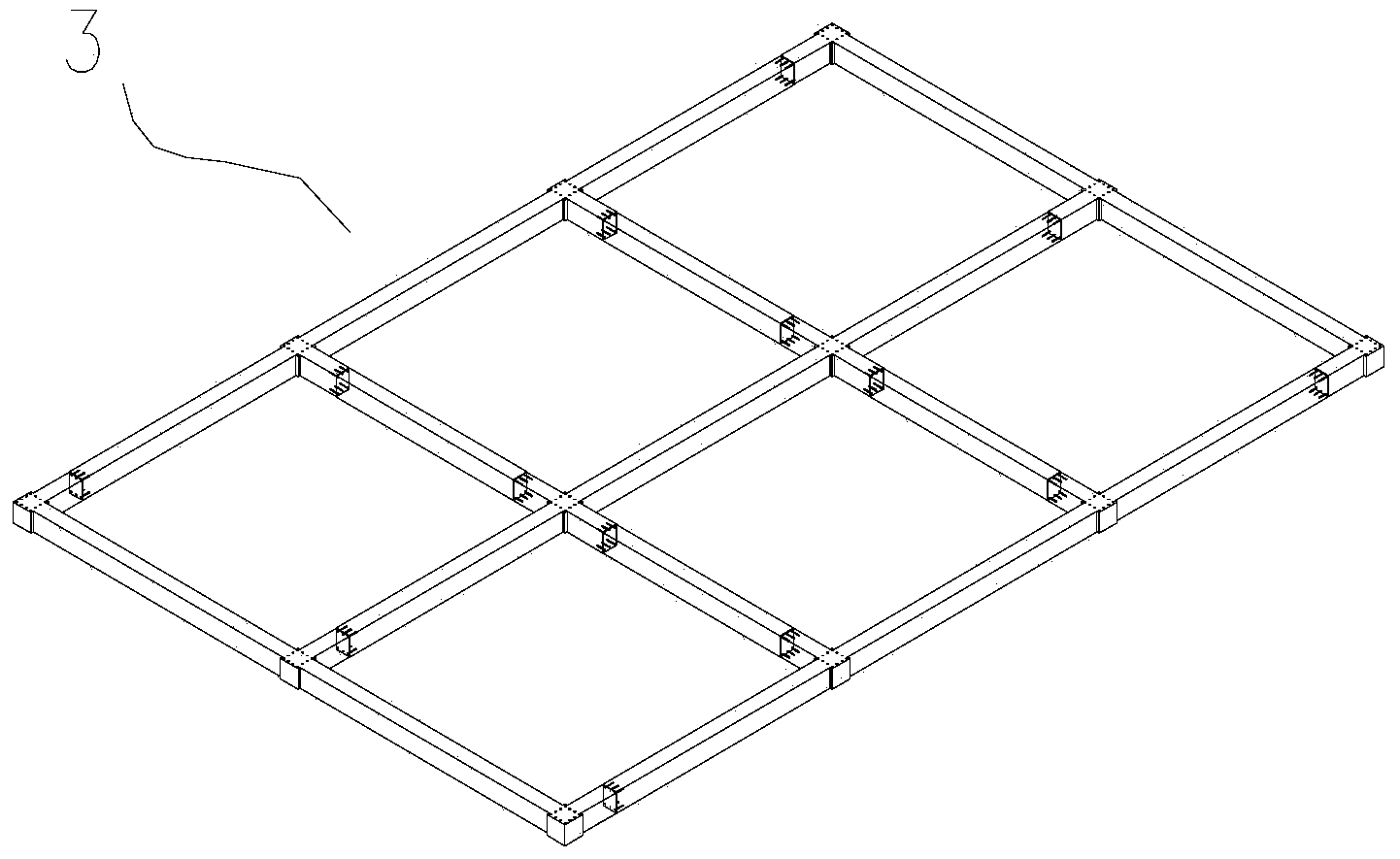

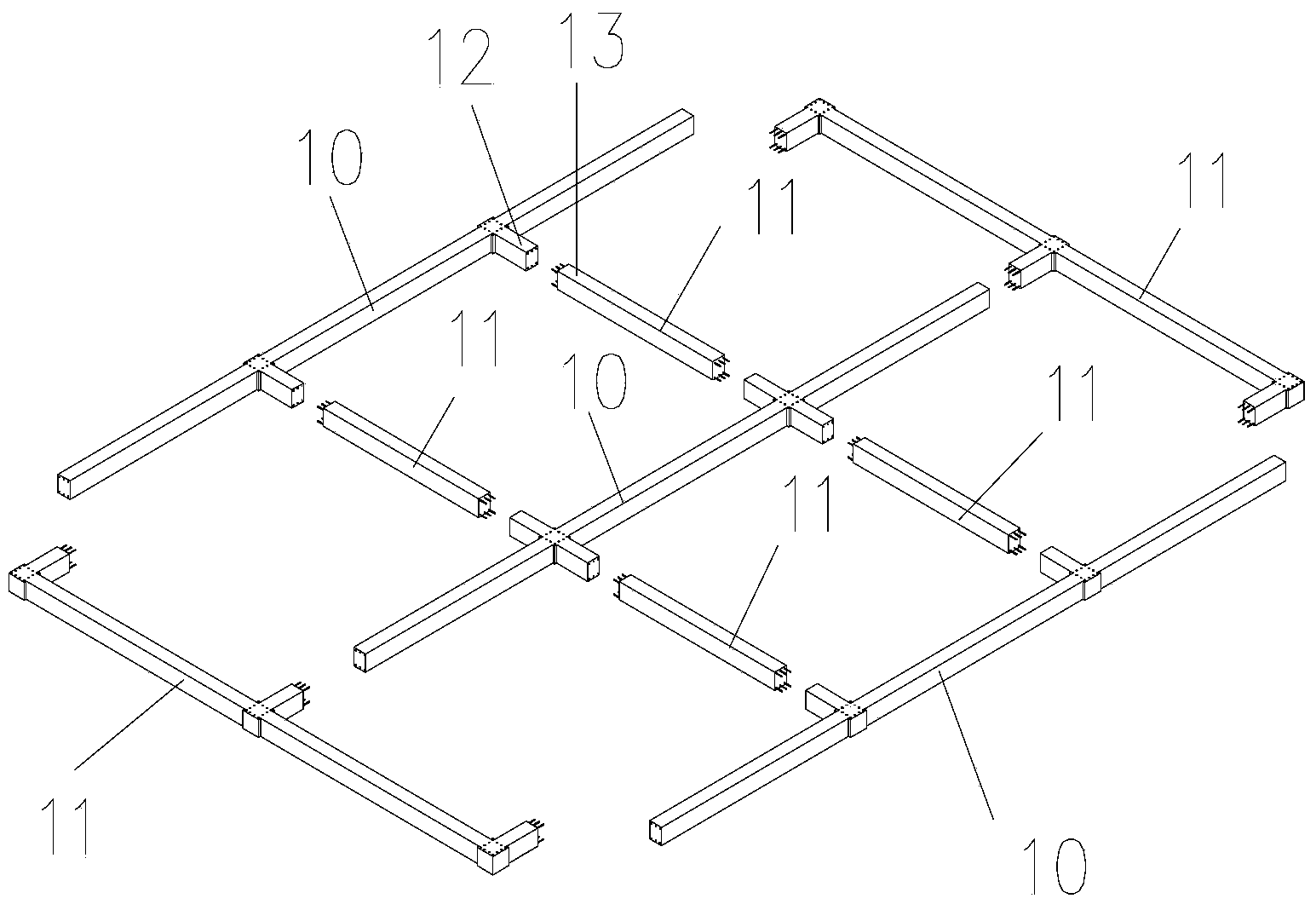

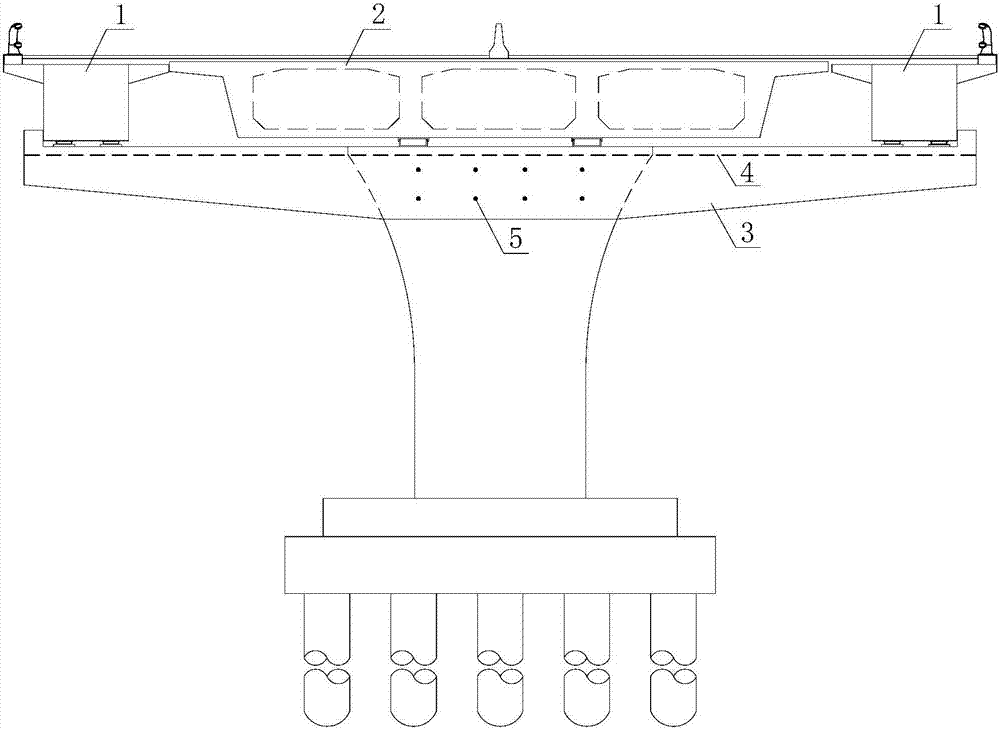

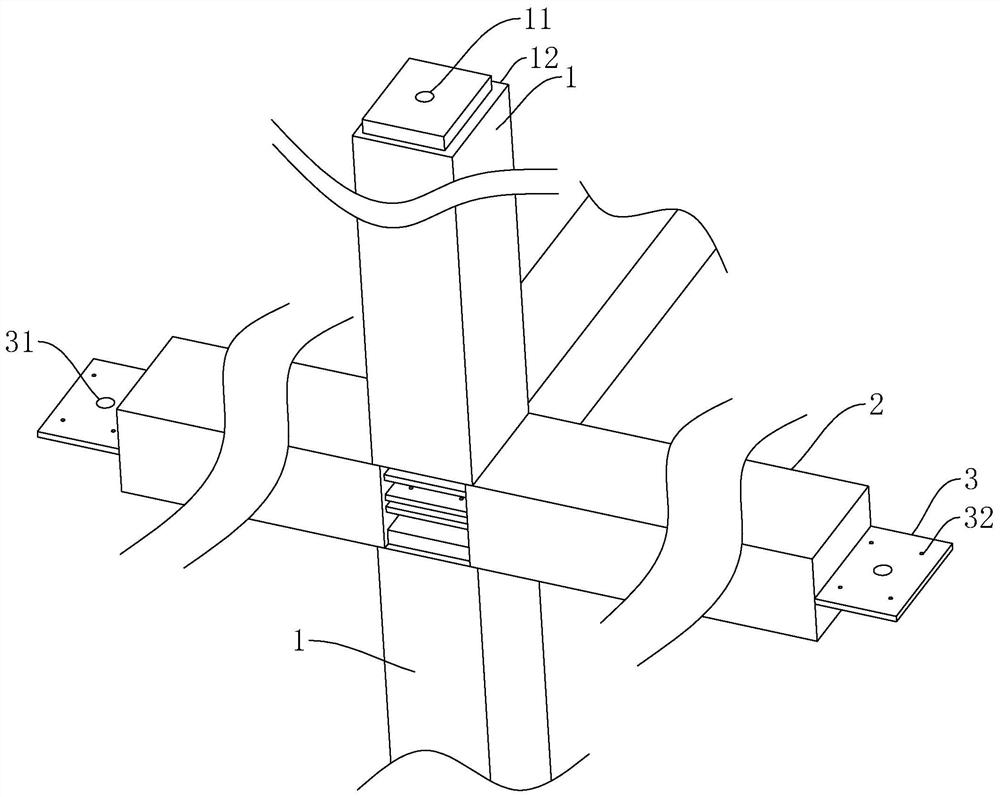

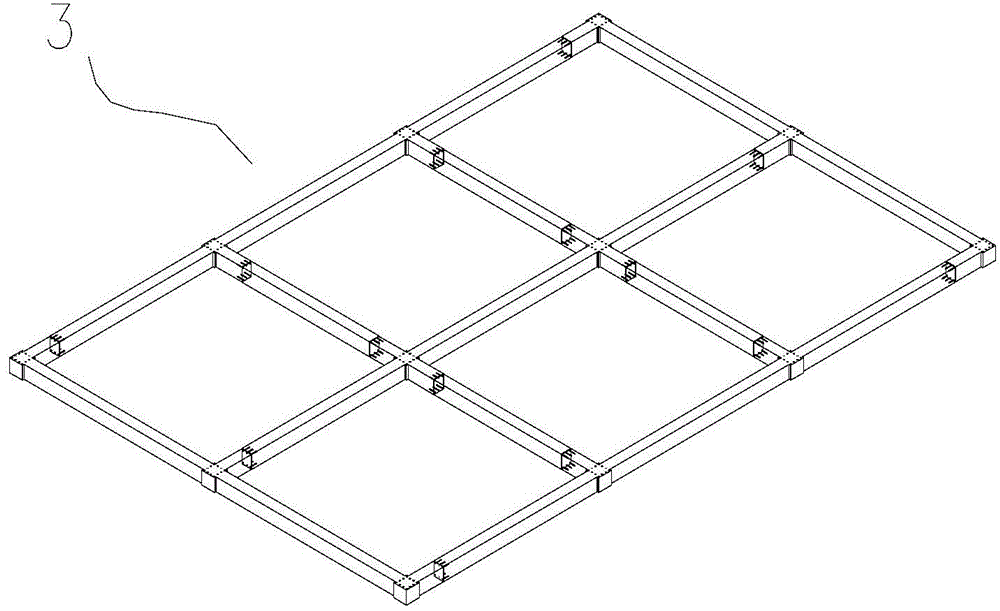

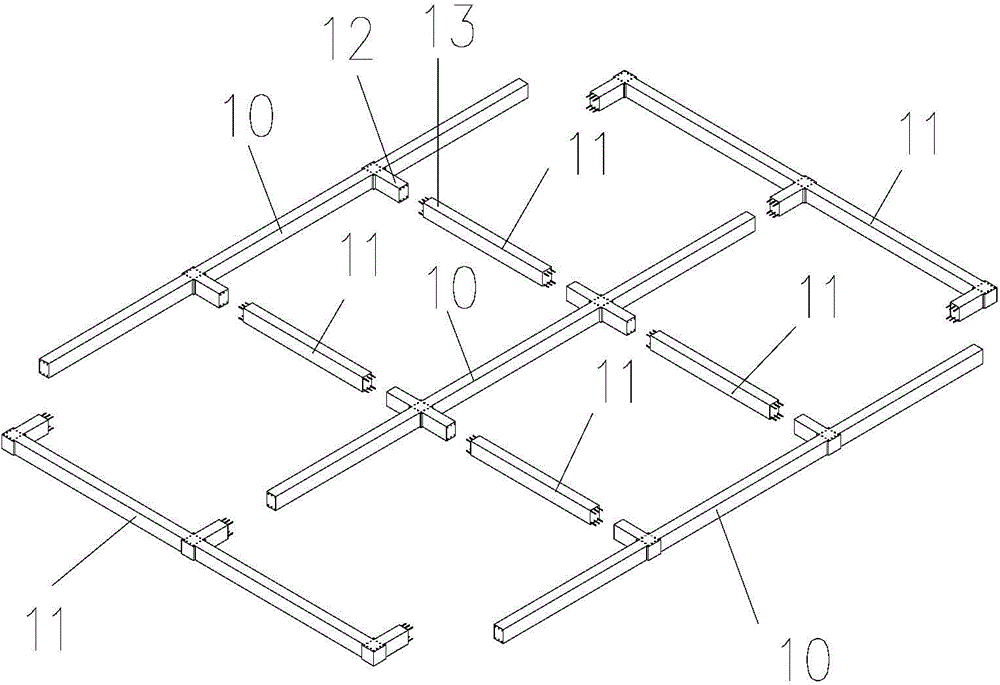

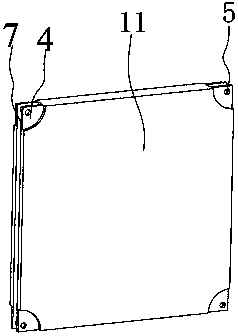

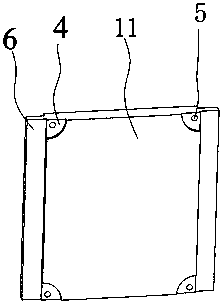

Multilayer stereotactic frame assembled by prefabricated reinforced concrete members

InactiveCN103643737AEasy constructionShort construction periodBuilding constructionsRebarEngineering

The invention discloses a multilayer stereotactic frame assembled by prefabricated reinforced concrete members. The multilayer stereotactic frame comprises prefabricated reinforced concrete vertical columns, prefabricated reinforced concrete column heads and a plugging type prefabricated reinforced concrete beam frame, wherein a plurality of vertical-column steel bar insertion heads are reserved in the lower ends of the prefabricated reinforced concrete vertical columns, and a plurality of vertical-column steel bar insertion holes matched with the vertical-column steel bar insertion heads are reserved in the upper ends of the prefabricated reinforced concrete vertical columns; a plurality of column-head steel bar insertion heads matched with the vertical-column steel bar insertion holes of the prefabricated reinforced concrete vertical columns are reserved in the lower ends of the prefabricated reinforced concrete column heads; a plurality of through holes corresponding to the vertical-column steel bar insertion holes of the prefabricated reinforced concrete vertical columns are formed in nodes of beam columns of the plugging type prefabricated reinforced concrete beam frame; the prefabricated reinforced concrete vertical columns and the plugging type prefabricated reinforced concrete beam frame are arranged in a multilayered manner. The multilayer stereotactic frame disclosed by the invention has the advantages that the construction is convenient and the pollution in site construction can be reduced.

Owner:SHENZHEN YJY BUILDING TECH +2

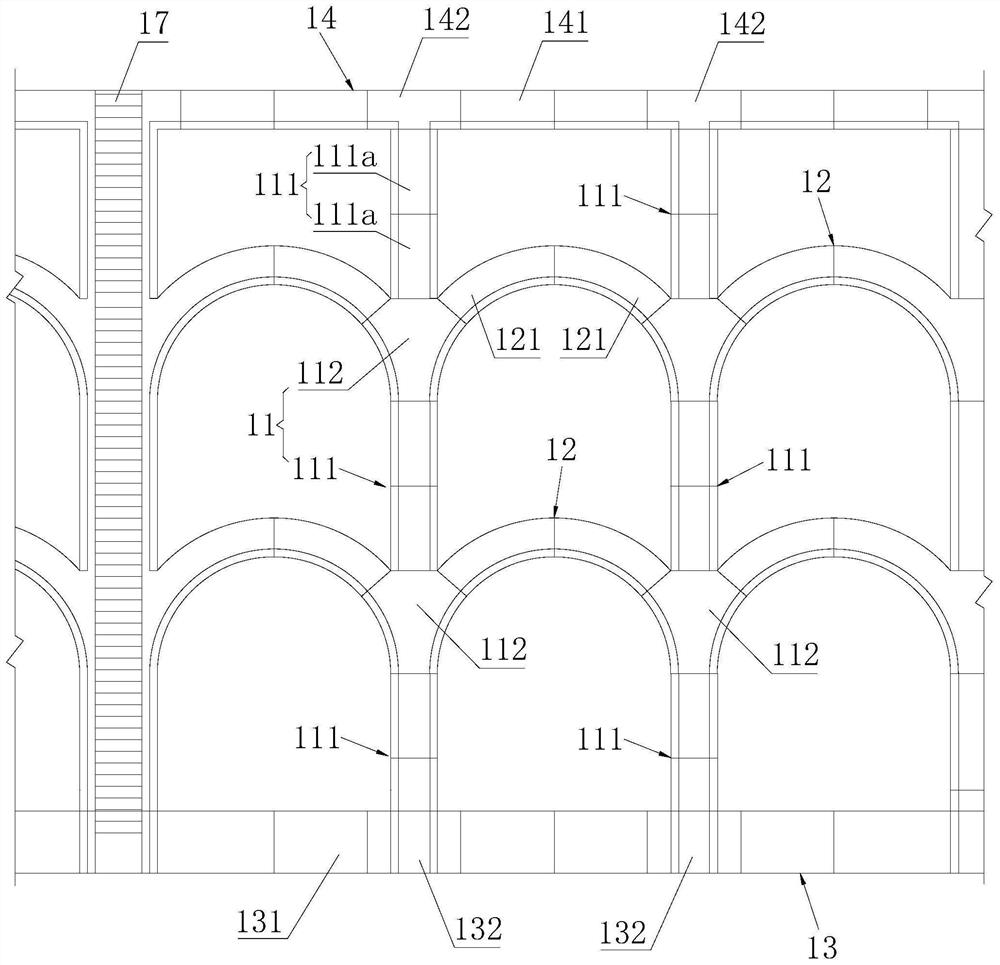

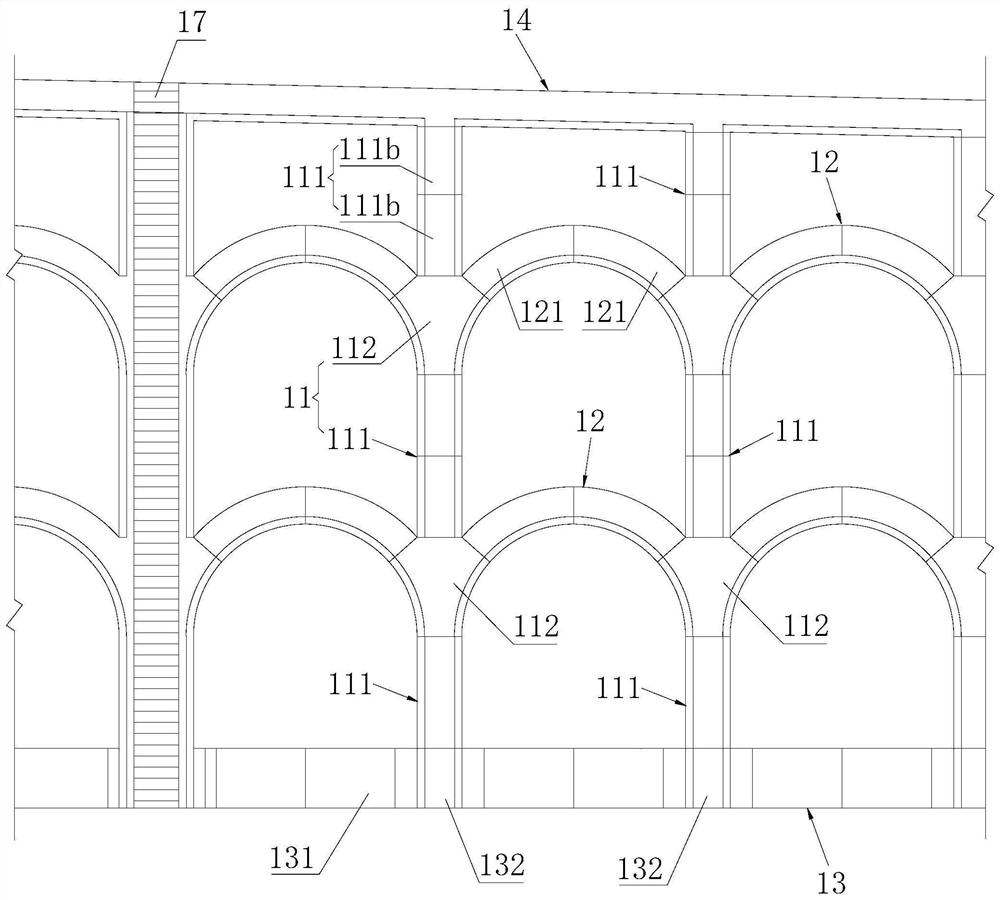

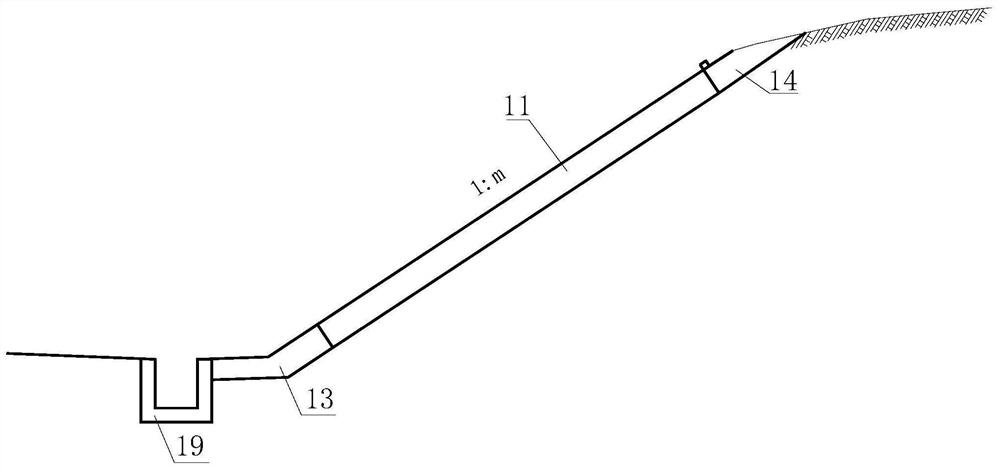

Fabricated roadbed slope protection structure and construction method

PendingCN112177018AQuality is easy to controlReduce dosageExcavationsSewer pipelinesArchitectural engineeringStructural engineering

The invention is suitable for the field of slope protection engineering, and provides a fabricated roadbed slope protection structure and construction method. The fabricated roadbed slope protection structure comprises a plurality of main frameworks, arch frameworks, a top edge and a bottom edge. The main frameworks are arranged on a roadbed slope at intervals. The arch frameworks are connected between every two adjacent main frameworks, and a plurality of arch frameworks are arranged between every two adjacent main frameworks at intervals. The top edge is arranged at the upper part of the roadbed slope, and the upper end of each main framework is connected with the top edge. The bottom edge is arranged at the bottom of the roadbed slope, and the lower end of each main framework is connected with the top edge. At least the main frameworks, the arch frameworks and the bottom edge are respectively formed by splicing a plurality of corresponding splicing blocks. According to the fabricated roadbed slope protection structure and construction method, the roadbed slope protection structure is formed by splicing prefabricated splicing blocks, the quality is controllable, and the number ofwet working faces is small. And pollution of solid garbage, dust, sewage, noise and the like can be reduced, and the influence on the construction site environment is small. Meanwhile, construction is not easily affected by weather, and the construction efficiency is high.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A bridge widening structure with a steel cap beam added to the top of the pier

InactiveCN105672145BUnlimited design loadGuaranteed economyBridge erection/assemblyBridge strengtheningBridge engineeringPre stress

The invention provides a structure for broadening a bridge by additionally arranging a steel cap beam on the top of a pier, belonging to the technical field of bridge engineering. According to the structure for broadening the bridge by additionally arranging the steel cap beam on the top of the pier, post-pouring concrete is poured at the two sides of the original concrete pier, and the specific concrete width of the post-pouring concrete is determined according to the stress of the upper part of the bridge; the steel cap beam is additionally arranged on the top of the pier poured with the post-pouring concrete; the steel cap beam has a box cross section and is formed by steel plates in a welding way; according to the stress of the upper part of the bridge, prestressed steel beams and prestressed anchor bars are arranged in the steel cap beam; the prestressed steel beams are vertical to the prestressed anchor bars in the steel cap beam; steel box beams are additionally arranged at the two sides of an original concrete box beam; the steel box beams are positioned on the steel cap beam. The structure for broadening the bridge by additionally arranging the steel cap beam on the top of the pier has the effects and advantages that the structure of the original bridge main body is not torn down, so that the economy of widening reformation is guaranteed; the design load of the structure of the newly added steel box beams is not limited, so that the operation reliability of the broadened bridge is high; in the construction process, the traffic on the bridge is not needed to be interrupted; furthermore, the structure for broadening the bridge by additionally arranging the steel cap beam on the top of the pier is short in site construction period and has little influence on ground transportation.

Owner:DALIAN UNIV OF TECH

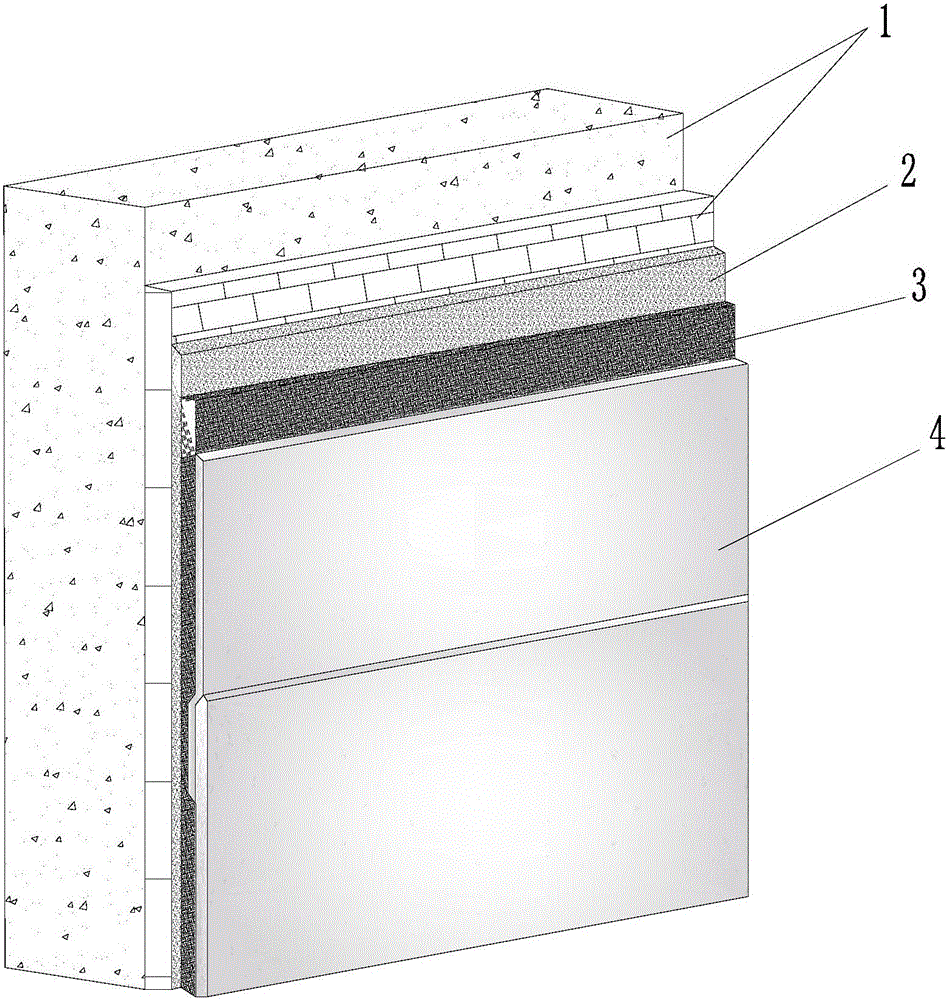

A chimney anti-corrosion structure and its construction method

ActiveCN104989167BAvoid spot weldingAvoid Weld Quality IssuesTowersBuilding insulationsStructure of the EarthTitanium

The invention discloses a chimney anticorrosion structure. The anticorrosion structure comprises a primer layer (2), an adhesive layer (3) and a titanium plate layer (4) arranged in sequence, and the primer layer (2) is coated on the chimney base On (1), the titanium plate layer (4) is adhered to the primer layer (2) through the adhesive layer (3). The invention also discloses a construction method for an anti-corrosion structure of a chimney, which comprises the following steps: cleaning the chimney base; brushing primer material on the cleaned chimney base; Glue, and paste the titanium plate; check and repair. The invention uses the titanium plate adhesive to directly stick the lapped titanium plate on the structural layer of the chimney, which has the advantages of short construction period and low requirements on the construction environment on site, and also solves the problems caused by poor welding environment on the construction site. Titanium plate welding quality problems.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

A modular prefabricated integrated building construction system and its construction method

ActiveCN113090076BReduce wasteGuaranteed performanceWallsSpecial buildingArchitectural engineeringExternal cladding

A modular prefabricated integrated building construction system, including building base components (1), side exterior wall components (3), corner exterior wall components (4), central exterior wall components (2), interior wall components (6) and a roof Component (5), the above components are combined and connected by wooden dovetails to form a whole house; each component integrates the building structure, thermal insulation, decorative surface materials and outer enclosure structure, and at the same time integrates the mechanical and electrical components used in the building. The equipment and pipeline system are integrated and pre-installed. The modular prefabricated integrated building construction system has high integration and high assembly rate, reduces installation errors and mistakes, and has flexible transportation methods; its construction method is simple, there is no wet operation, and the construction period is short.

Owner:北京林婉嫕空间艺术设计有限公司

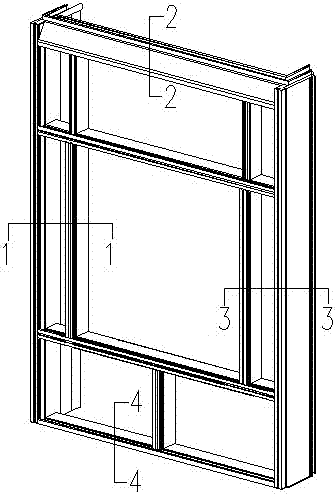

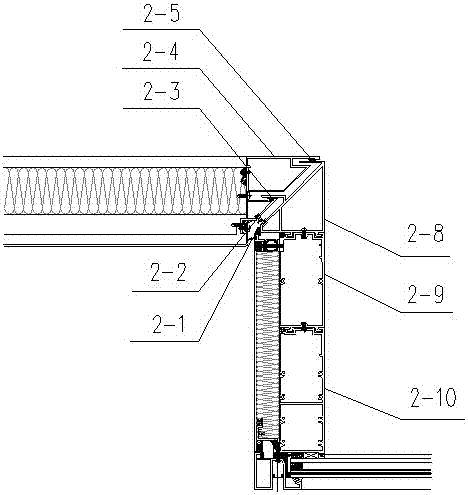

Floating window type curtain wall unit

PendingCN107503453AImprove rainwater seepage performanceImprove performance qualityWallsWater tightnessUnit type

The invention discloses a floating window type curtain wall unit. Flanges are arranged on left and right vertical sticks. A continuous sealing rod is embedded in the side face of the end and embedded into a groove in the left vertical stick, and the sealing rod is in tight fit with the side wall of the groove to form a water stopping sealing strip; the water stopping sealing strip, the left vertical stick and the right vertical stick form a longitudinal water guiding cavity rear cavity, and the side frame of a curtain wall panel, the flanges and the water stopping sealing strip form a longitudinal water guiding cavity front cavity; a flange is arranged on an upper beam, a continuous sealing rod is embedded in the side face of the end and is in tight fit with the side wall on a lower transverse beam, and the sealing rod and a water stopping decorative cover form a transverse drainage cavity. In this way, the appearance effect is the floating window three-dimensional effect, the water tightness of the unit type curtain wall structure can be improved, and by improving the structural fit between the left and right vertical sticks of two unit type curtain wall plates and the structural fit between the upper and lower transverse beams, the rain leakage prevention performance of the unit type curtain wall is improved.

Owner:WUXI HENGSHANG DECORATION ENG CO LTD

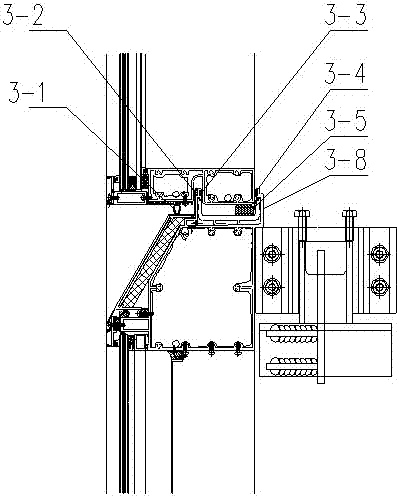

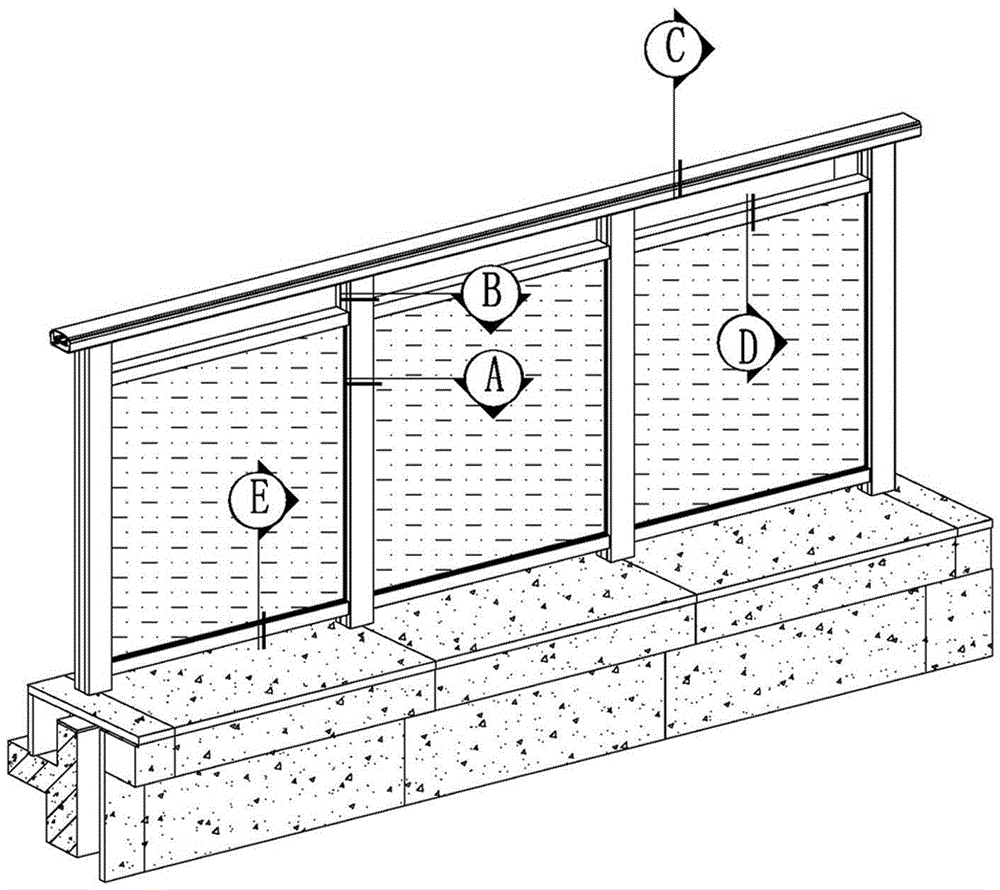

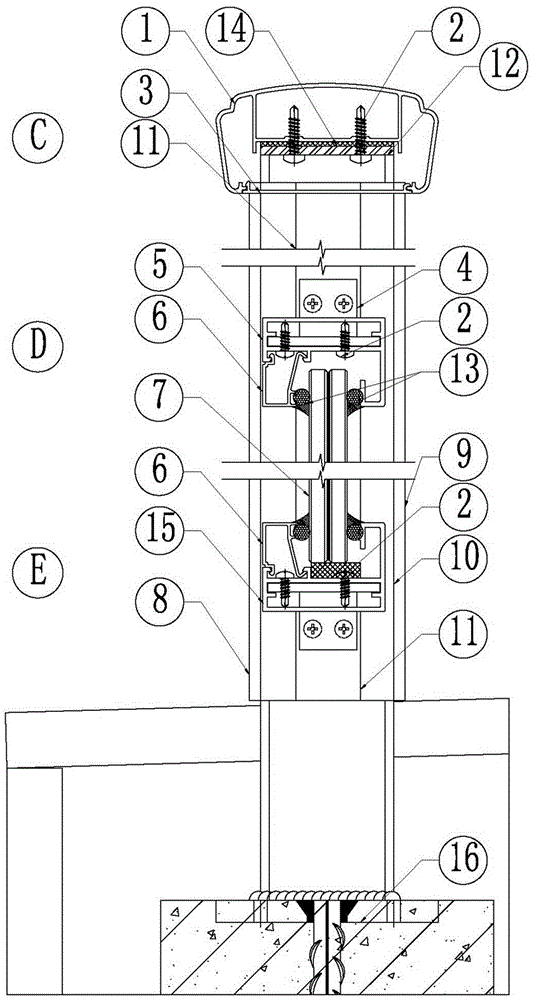

Construction method of high-rise building glass guardrail

The invention discloses a glass guardrail system for high-rise buildings and a construction method. Square steel stand columns welded to a plurality of embedded structural parts distributed evenly and connected into a line in a building structure and a handrail steel plate welded to the top ends of the square steel stand columns form a steel frame which can meet the requirement for structural safety of the area with large wind pressure. The steel frame is flexible in dimension design, so that structural safety is ensured and construction cost is reduced. Aluminum alloy main members arranged on the outer side of the steel frame and vertical column buckle plates are of split locked lid combination structures, and aluminum alloy guardrail handrails and handrail buckle plates are of split locked lid combination structures, so that assembly and disassembly are facilitated. An upper cross beam, a lower cross beam and the aluminum alloy main members are connected through aluminum alloy connectors, so that field installation is convenient, and connection quality is ensured. Tampered and laminated glass is arranged on the upper cross beam and the lower cross beam through cross beam buckle strips, so that broken glass can be replaced easily. The glass guardrail system is used for high-rise steps or the peripheries of observation decks of the high-rise buildings. The glass guardrail system is reasonable in design, simple in installation, high in precision and quality, and short in construction period, the members are produced in a standard mode according to a drawing, and later-period maintenance and member replacement are easy.

Owner:BEIJING HONG KONG YUAN CONSTR DECORATION ENG

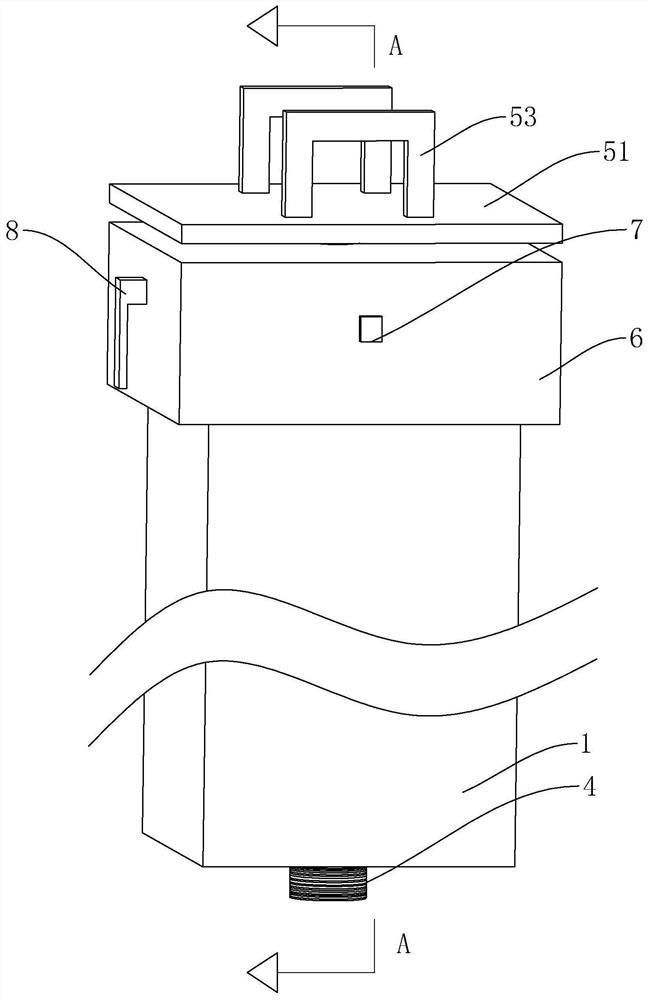

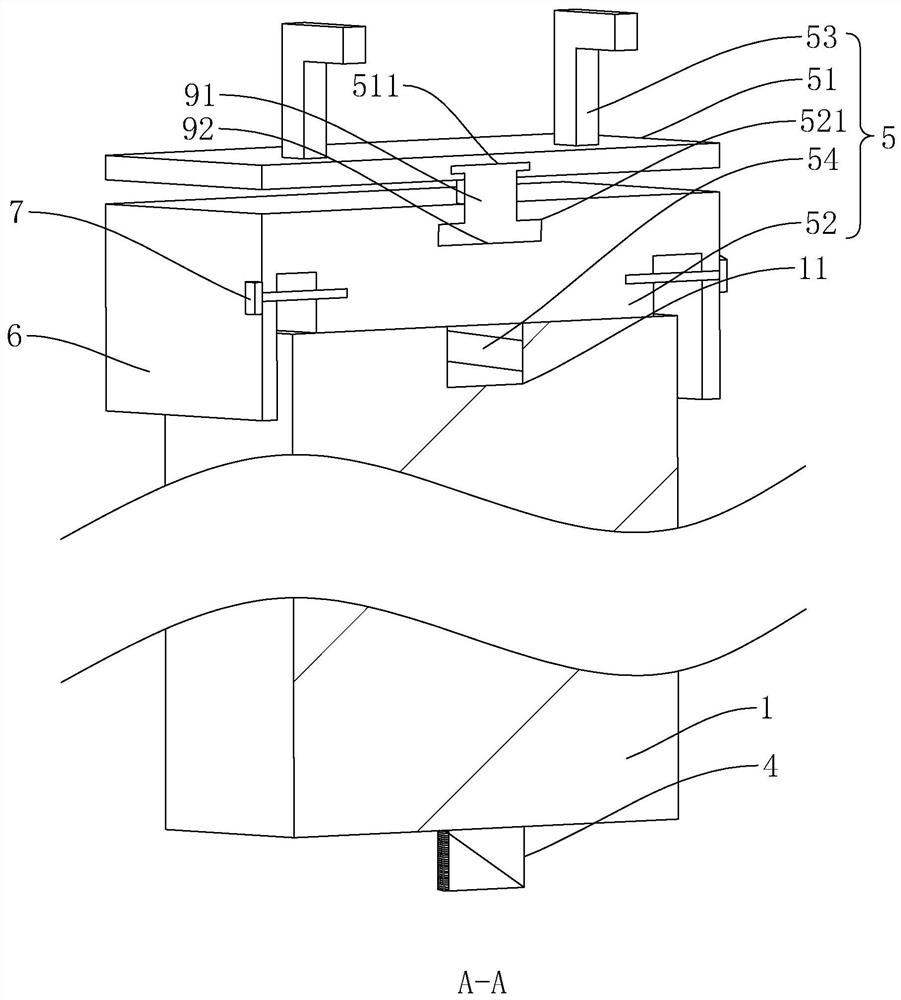

Beam-column joint connection structure and hoisting technology of prefabricated concrete building

ActiveCN113502915BImprove connection strengthShort construction period on siteBuilding material handlingScrew threadJoint (building)

Owner:中机工程有限公司

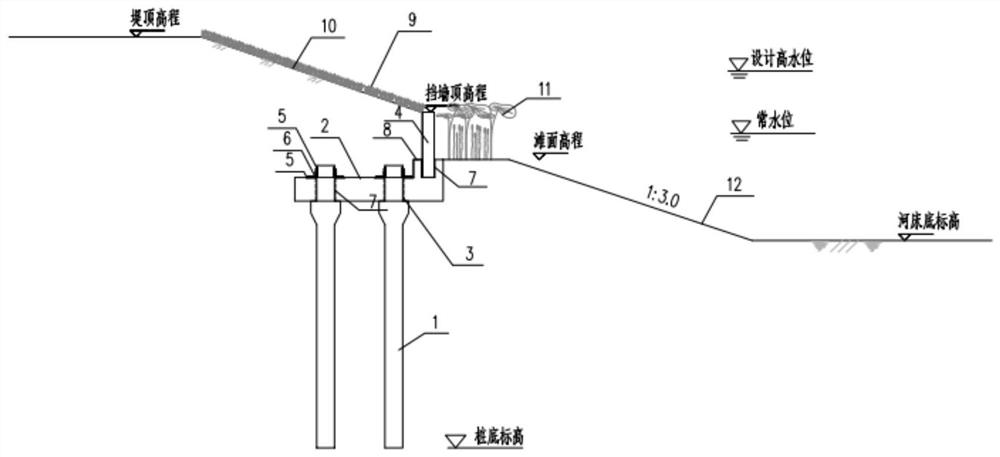

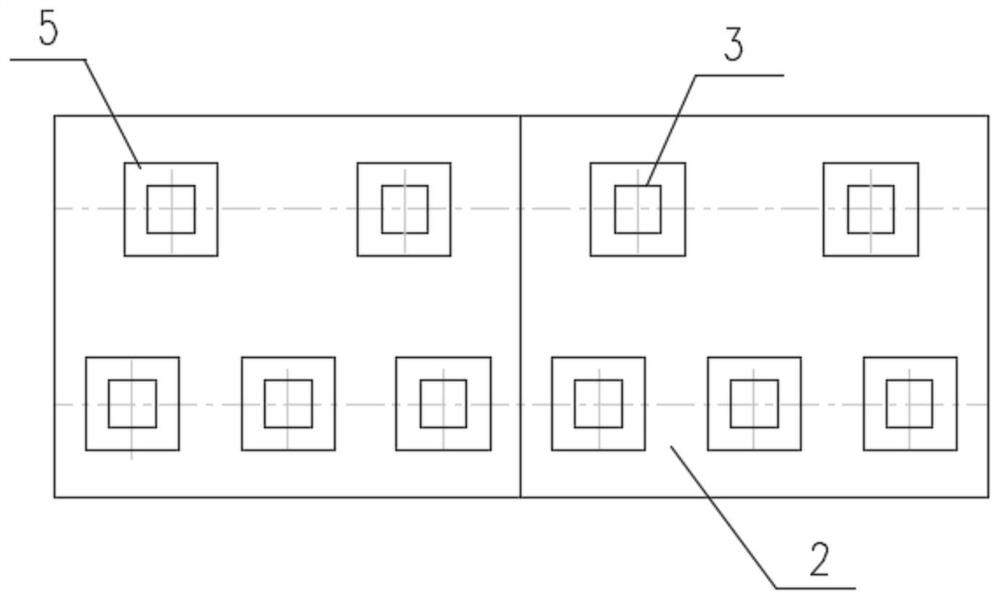

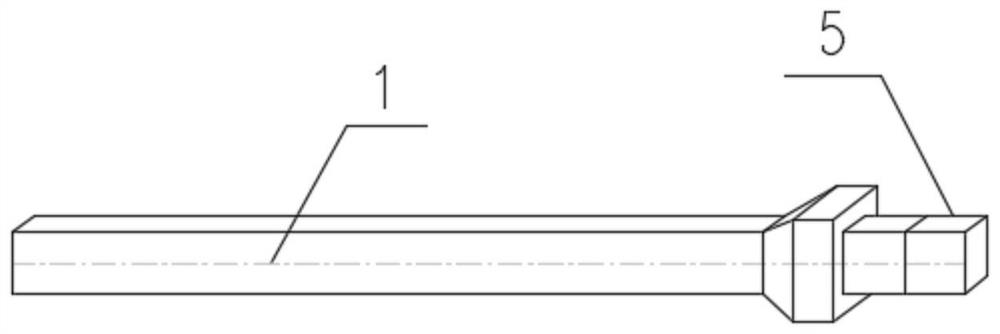

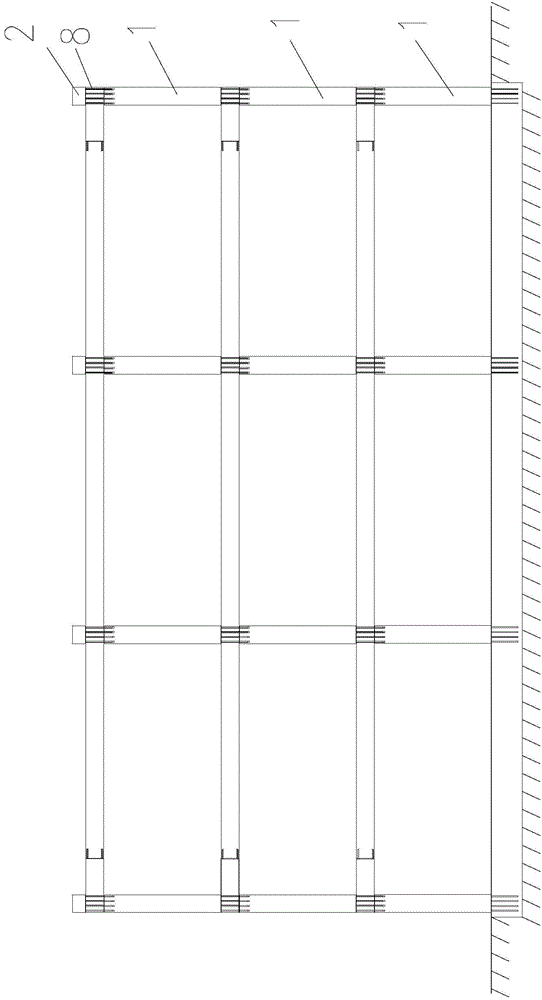

Assembly type revetment component and assembly type revetment construction method

InactiveCN112627107ARandom combinationAvoid construction stepsBreakwatersQuaysRetaining wallStructural safety

The invention discloses an assembly type revetment component and a construction method. The assembly type revetment component comprises a prefabricated square pile, a prefabricated bottom plate and prefabricated wood-like piles, wherein the lower portion of the prefabricated square pile is used for being inserted into soil, a preformed hole is formed in the prefabricated bottom plate, the prefabricated bottom plate is arranged at the top of the prefabricated square pile in a sleeving mode through the preformed hole, the multiple prefabricated wood-like piles are arranged side by side, the bottoms of the prefabricated wood-like piles are connected to the top face of the prefabricated bottom plate, and the tops of the prefabricated wood-like piles extend upwards to form a retaining wall. Effective connection is adopted for the assembly type revetment component, the requirements for soil blocking and bearing capacity can be met, and the structure is safe and reliable; and the cost is low, the universality is good, on-site cast-in-place concrete construction steps are completely avoided, the on-site construction period is shortened, the construction quality is good, and the environmental influence is small.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Method for preventing corrosion of concrete members in tidal range zone and splash zone of ocean

ActiveCN102383619BGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesBuilding repairsEndcappingStructural engineering

The invention discloses a method for preventing corrosion of concrete members in a tidal range zone and a splash zone of an ocean, belonging to the field of concrete member corrosion prevention. Aiming at the protection requirement in special corrosion environment, the method comprises the following steps: coating a layer of silane impregnant on the outer surface of concrete, wherein the penetration depth is more than 1mm; after natural air drying, coating a layer of silane end sealing polyether sealant in a scraping way, wherein the thickness is 2-5mm; then wrapping a prefabricated protective cover immediately; coating a layer of sealant in the protective cover in a scraping way; sealing the upper and lower ends and the corners of the protective cover with the sealant; and coating the whole wrapping system with weatherproof finishing paint. In the method, the glass reinforced plastic protection technology is adopted and combined with the sealing protection technology of the silane end sealing polyether sealant and the silane impregnating protection technology, thus realizing the effective protection on the concrete members in the tidal range zone and the splash zone. The technical construction is simple as well as convenient and fast, and the sealant has a reliable and excellent protection effect, therefore, the method has a good market popularization prospect.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Multi-layer three-dimensional frame assembled from prefabricated reinforced concrete members

InactiveCN103643737BEasy constructionShort construction period on siteBuilding constructionsReinforced concrete columnSteel bar

Owner:SHENZHEN YJY BUILDING TECH +2

Assembly building fame

The invention belongs to the technical field of buildings, and particularly relates to an assembly building frame. The assembly building frame comprises several basic panels, corner modules and base modules; the basic panels are spliced by several flat plate modules, the corner modules are located at all corners to be connected with the basic panels at different positions, and the base modules arelocated on the lower portions of the basic panels and used for installation of the basic panels. The base modules are installed on the ground as a fixation basis. The basic panels are spliced by theflat plate modules, the corner modules are located at all the corners to be connected with the basic panels at different positions, the basic panels are installed on the base modules, and the corner modules are connected with the adjacent basic panels to form a building basic body structure; the flat plate modules, the corner modules and the base modules can be produced in a factory according to standards and rapidly assembled through modularization after being transported to a construction site, in the whole process, the construction period is short, and multi-profession skilled personnel cooperation can be reduced during installation.

Owner:四川恒达兴铁科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com