Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Resolve skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

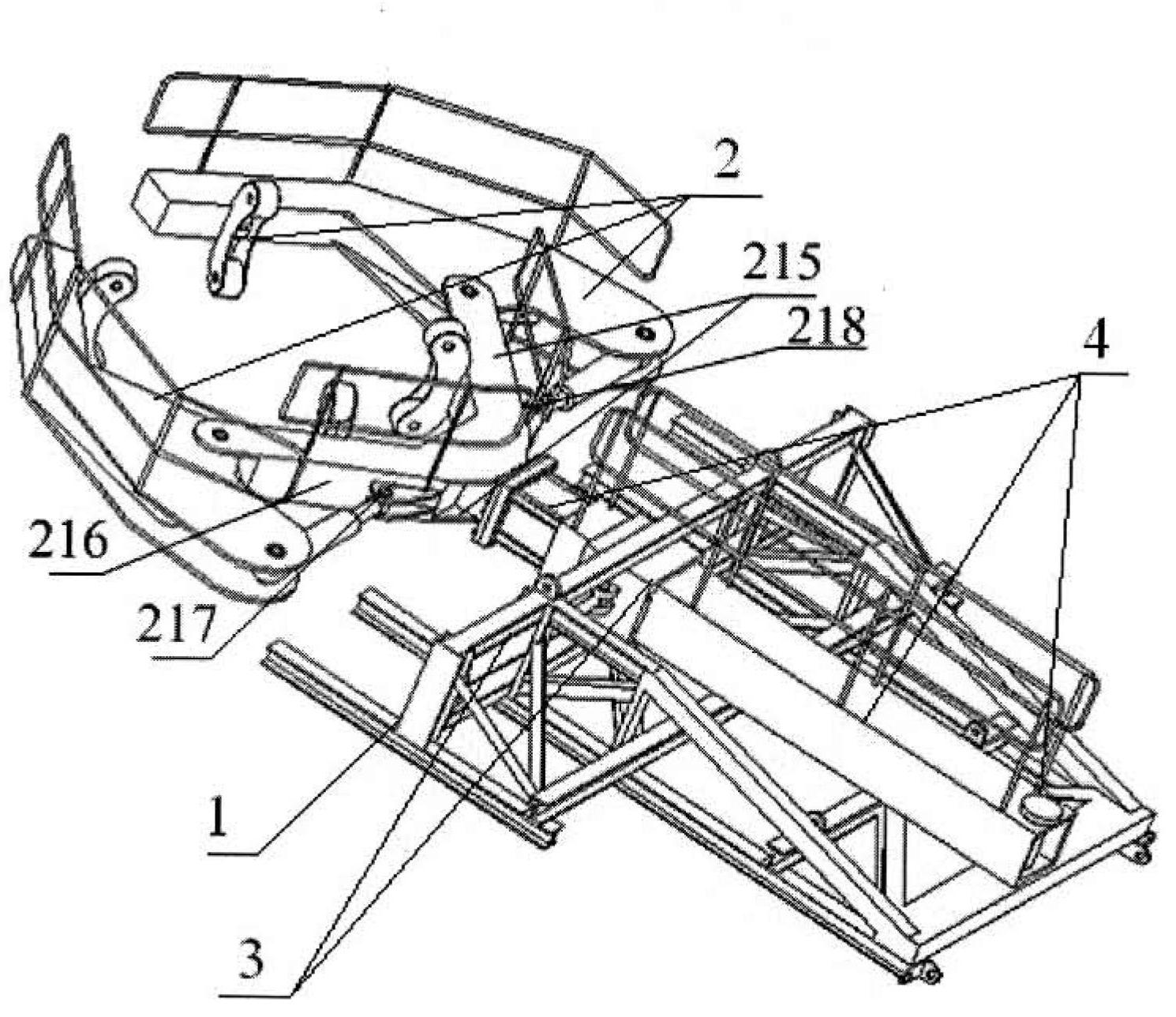

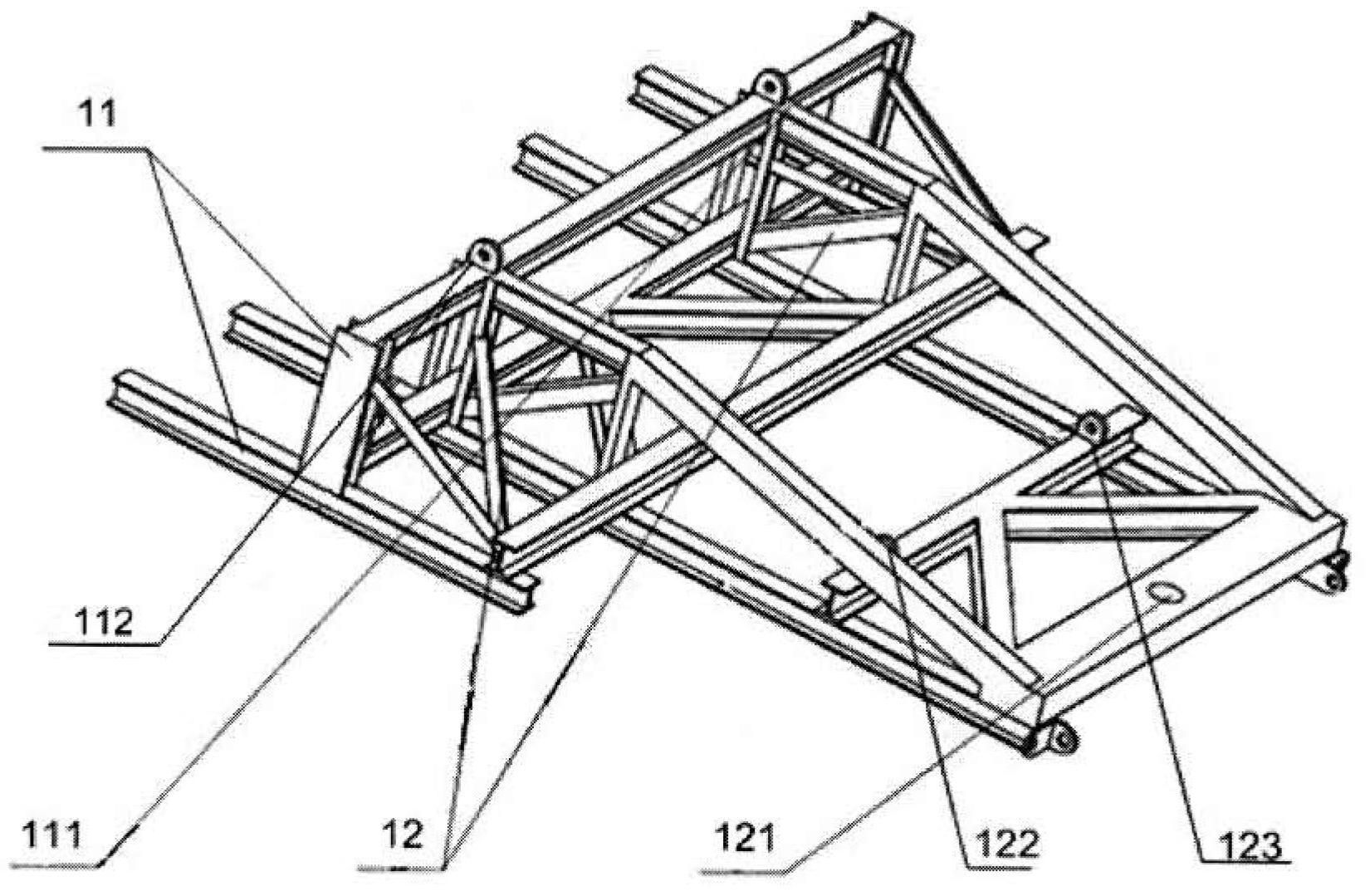

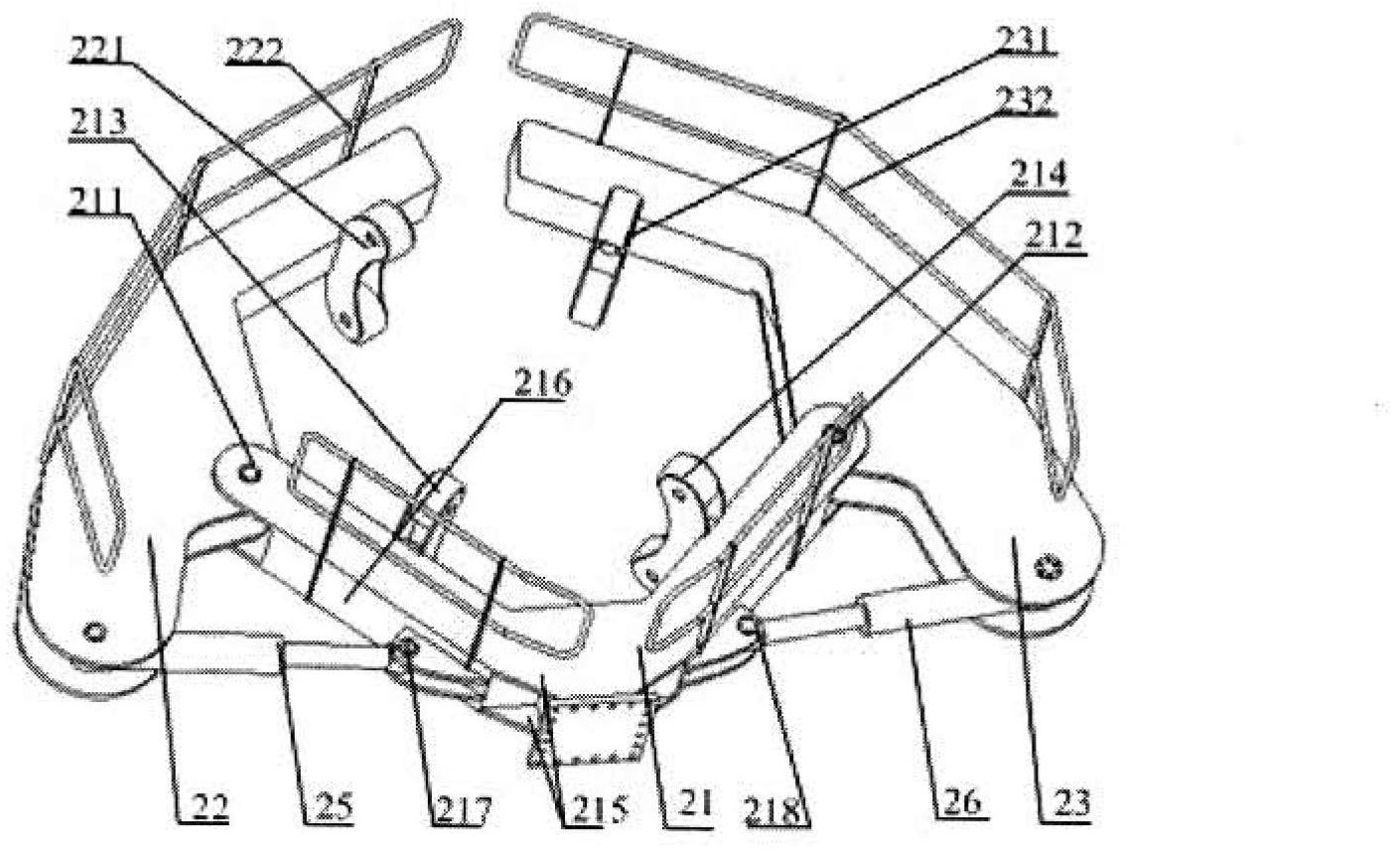

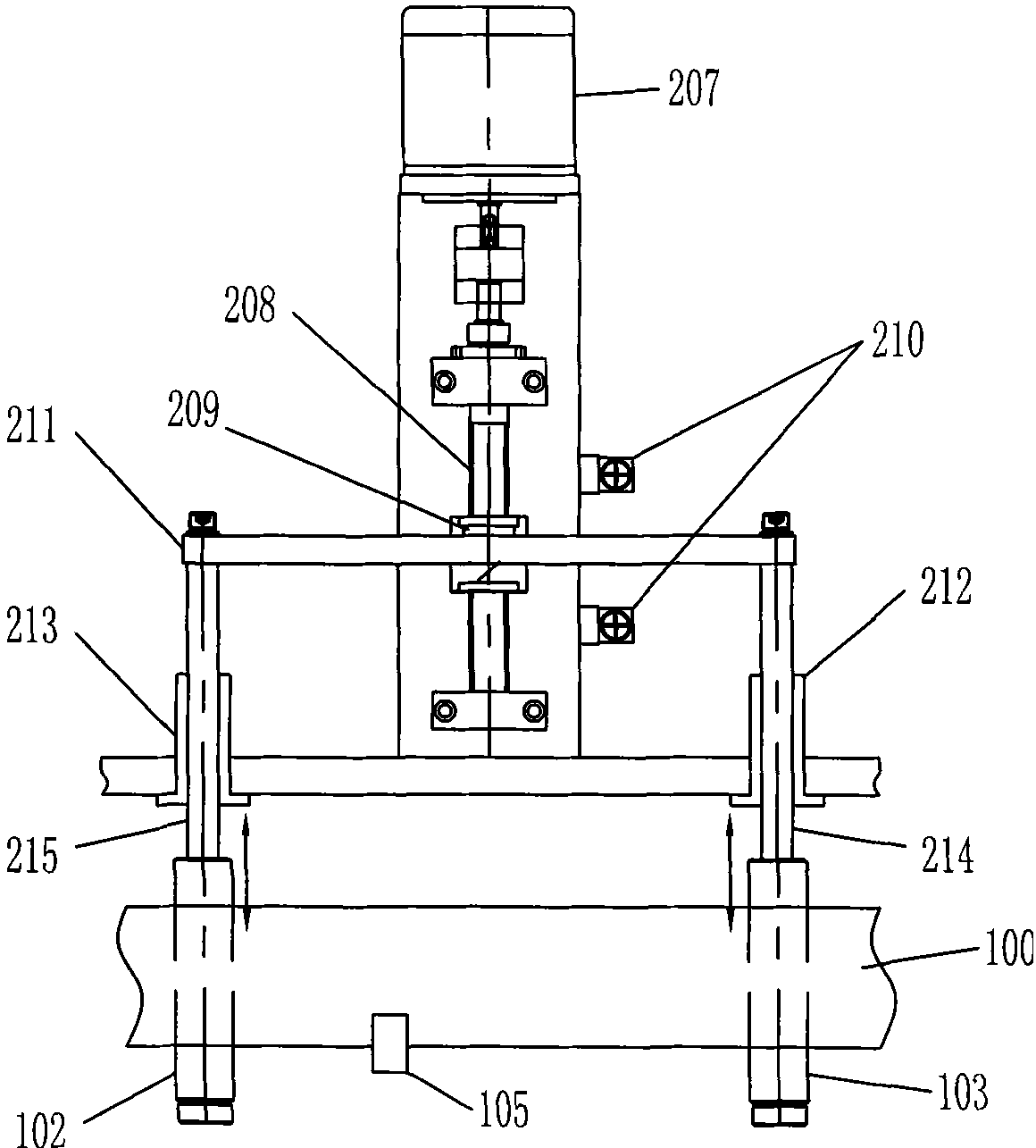

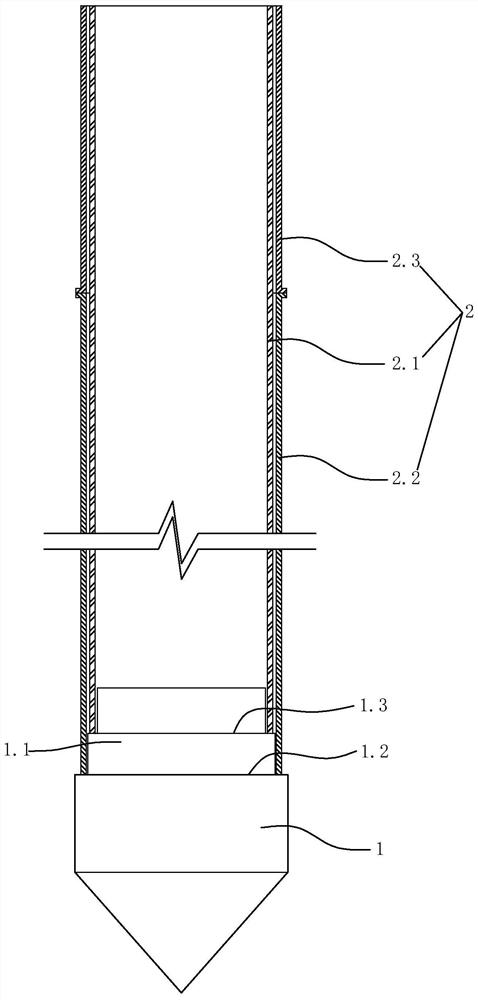

Guiding centralizer mechanism for single-pile foundation of offshore wind turbine

InactiveCN102660950AGuaranteed normal operationMeet the requirements of verticalityBulkheads/pilesHydraulic cylinderTurbine

The invention provides a guiding centralizer mechanism for a single-pile foundation of an offshore wind turbine. The guiding centralizer mechanism comprises a frame, a clamping and guiding mechanism, a horizontal adjusting mechanism and a vertical adjusting mechanism, wherein the frame is fixed onto a workboat, the horizontal adjusting mechanism and the vertical adjusting mechanism are arranged on the frame, and the clamping and guiding mechanism is connected with the vertical adjusting mechanism. The guiding centralizer mechanism is driven and controlled by a hydraulic cylinder and functions in clamping, guiding and centralizing the single-pile foundation of the offshore wind turbine, the pile foundation can be vertically piled into a seabed by a pile hammer during piling and prevented from deflecting during piling, normal running of the wind turbine is ensured, and wind generation efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Slurry wall protection construction method for bored pile

InactiveCN104120716AResolve skewSolve the problem of pile body concrete with mudBulkheads/pilesSlurry wallArchitectural engineering

The invention discloses a slurry wall protection construction method for a bored pile. The slurry wall protection construction method includes the following steps that step 1, a pile hole is positioned; step 2, a pile casing is buried; step 3, a drilling machine is in place; step 4, qualified slurry is prepared; step 5, hole forming and hole clearing are performed; step 6, a steel reinforcement cage is lifted for placing; step 7, underwater concrete is cast. According to the slurry wall protection construction method for the bored pile, operation is easy, the problems that the pile hole deviates, and pile body concrete is mixed with slurry are solved, and the construction method is suitable for slurry wall protection hole forming bored pile engineering of soft and hard soil layers high in underground water level in industrial and civil buildings.

Owner:杨哲

Ramp compensation device and method for FDM type 3D printer platform during inclination

ActiveCN107379530AResolve skewManufacturing platforms/substratesIncreasing energy efficiencyFinal heightComputer printing

The invention relates to a ramp compensation device for a FDM type 3D printer platform during inclination. The ramp compensation device comprises a horizontal supporting table, a hot bed arranged on the horizontal supporting table and a printing head located above the hot bed. A first distance measuring sensor and a second distance measuring sensor for measuring the height difference of the hot bed in a printing region are arranged on the printing head; the first distance measuring sensor and a second distance measuring sensor are arranged in central symmetry related to the printing head; and the mean value of measured values of the two distance measuring sensors is taken as the final height difference. The invention also discloses a ramp compensation method for the FDM type 3D printer platform during inclination. By performing printing compensation on corresponding height difference by analytical calculation to further establish a horizontal substrate, the problem that the quality of printout is affected as height error exists in a common 3D printer manual adjusting platform and a model deflects as the printing height is only compensated in only one direction by automatic leveling is solved.

Owner:SOUTH CHINA UNIV OF TECH

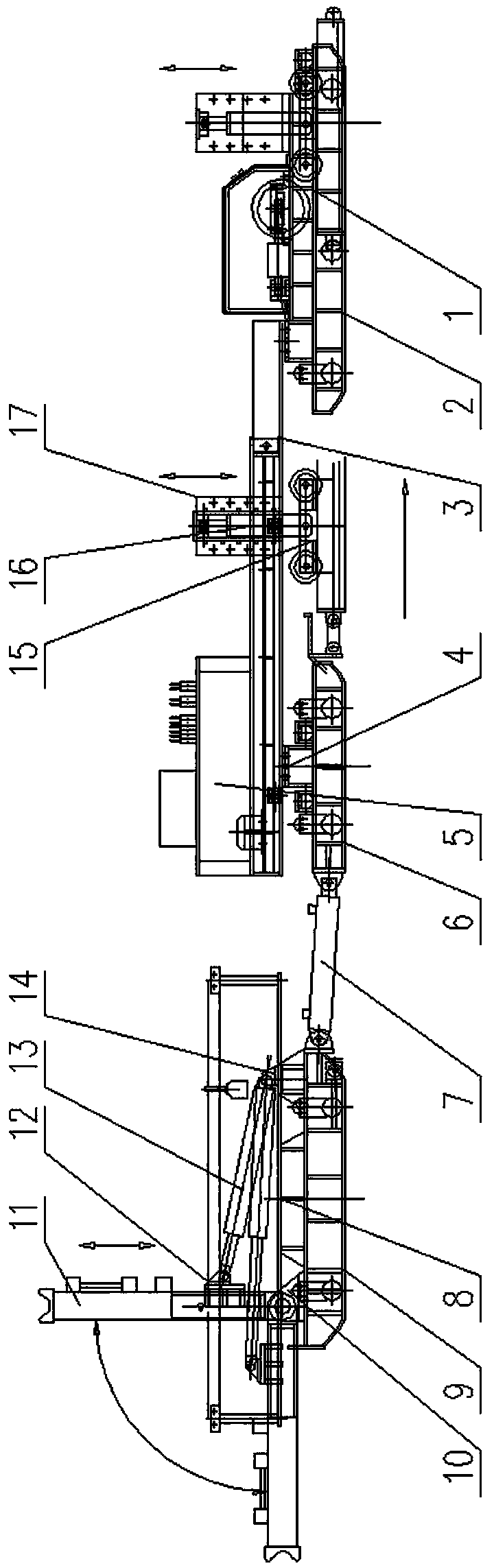

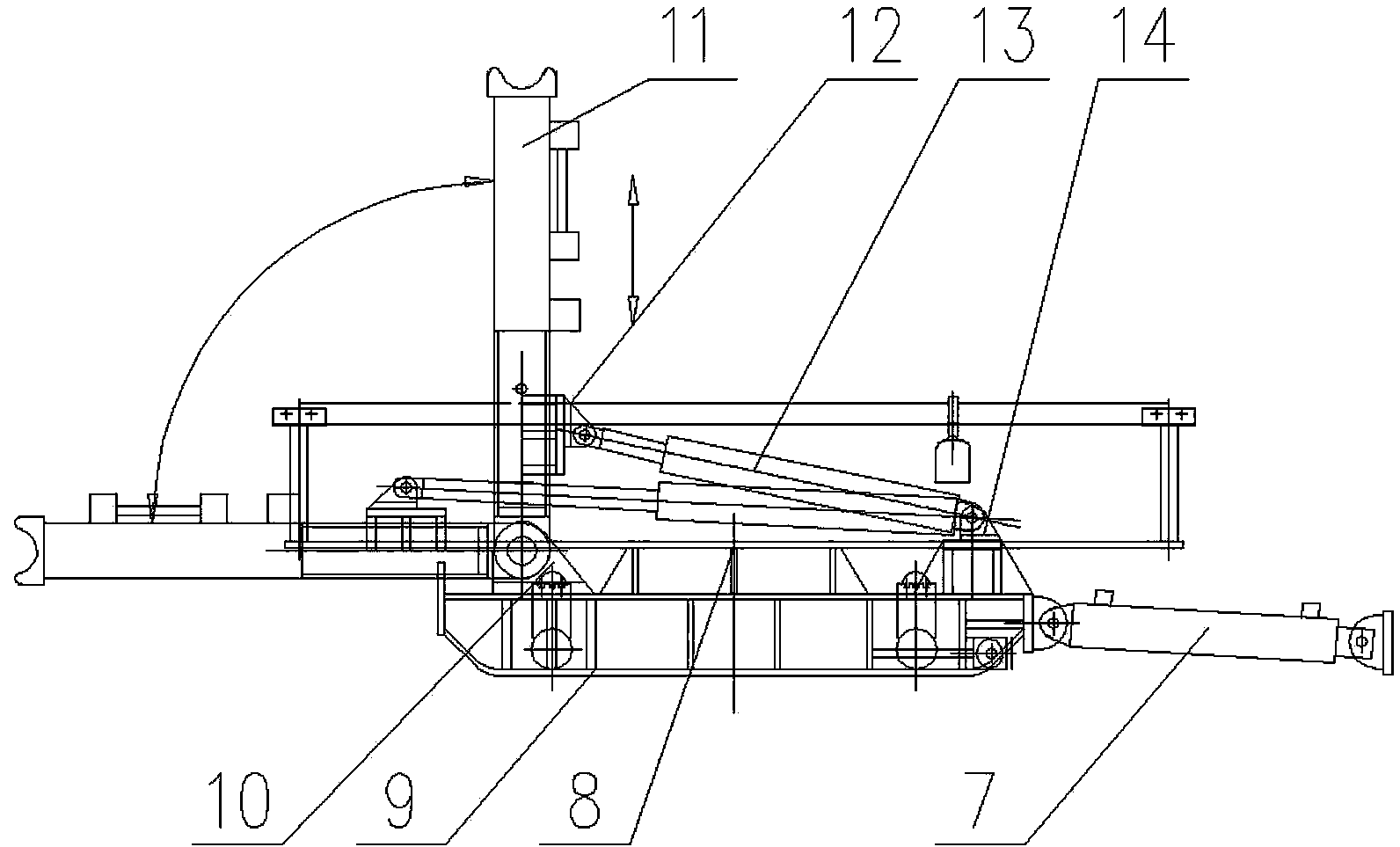

Self-moving belt conveyor tail

ActiveCN103410561AReduce the number of demolitionImprove work efficiencyEarth drilling and miningUnderground transportDislocationBelt conveyor

The invention relates to belt conveyor moving devices, particularly to a self-moving belt conveyor tail. The self-moving belt conveyor tail comprises a conveyor tail, a middle portion, a driving portion and a hydraulic system and is characterized by further comprising a moving oil cylinder, one end of the moving oil cylinder is hinged to the base of the driving portion, the other end of the moving oil cylinder is hinged to the middle portion, and a beam arranged on a middle portion base is connected with a conveyor tail base. The self-moving belt conveyor tail further comprises tracks which are arranged on two sides of the conveyor tail and the middle portion, and the rear ends of the tracks are connected with the base of the driving portion; the middle portion and the conveyor tail portion is provided with a lifting mechanism, the driving portion is provided with an anti-slipping fixing mechanism which can personally achieve fixation to prevent dislocation of the conveyor tail during transportation, the middle portion is provided with an offset regulating mechanism which can solve the off-tracking problem of belts, the conveyor tail is provided with a roller offset regulating mechanism which can solve the deviation of a conveyor tail roller. The self-moving belt conveyor tail can move by itself, each movement distance maximally reaches 1.8 meters, the lifting mechanism and the moving oil cylinder enable the conveyor tail and the middle portion to move along the tracks; and the tacks can smoothly move in two side tunneling directions of the conveyor tail portion.

Owner:山西潞安环保能源开发股份有限公司常村煤矿

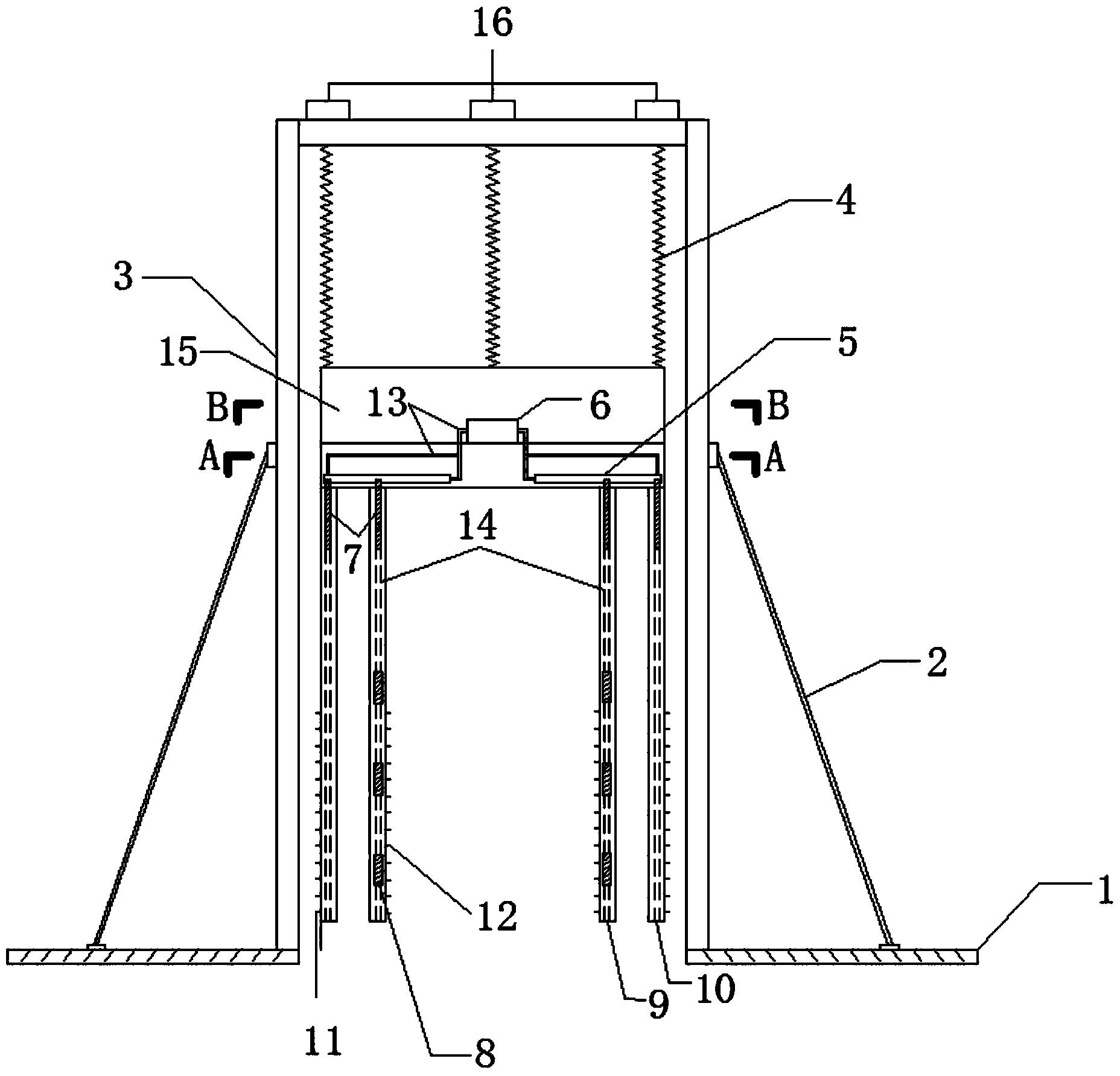

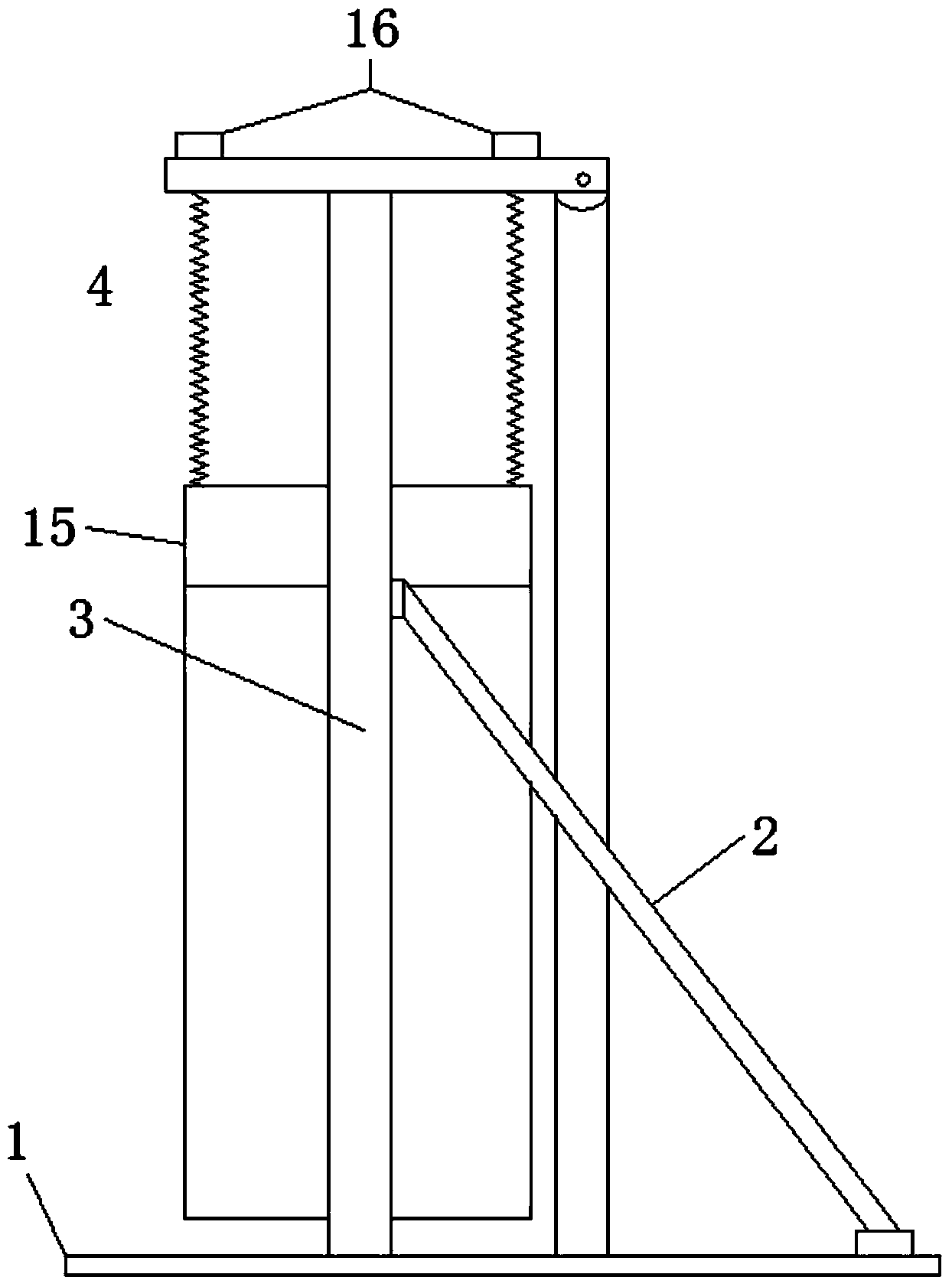

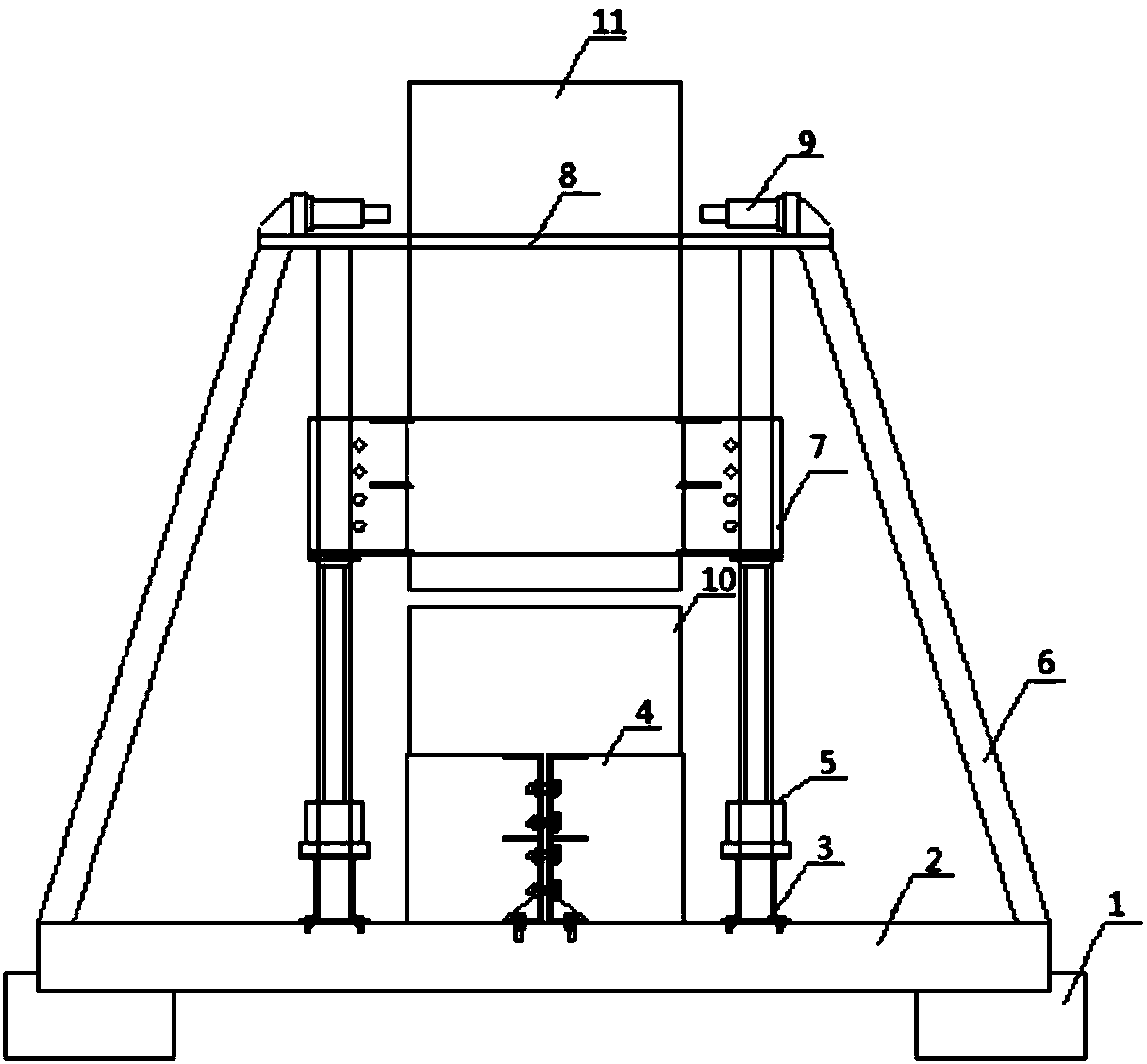

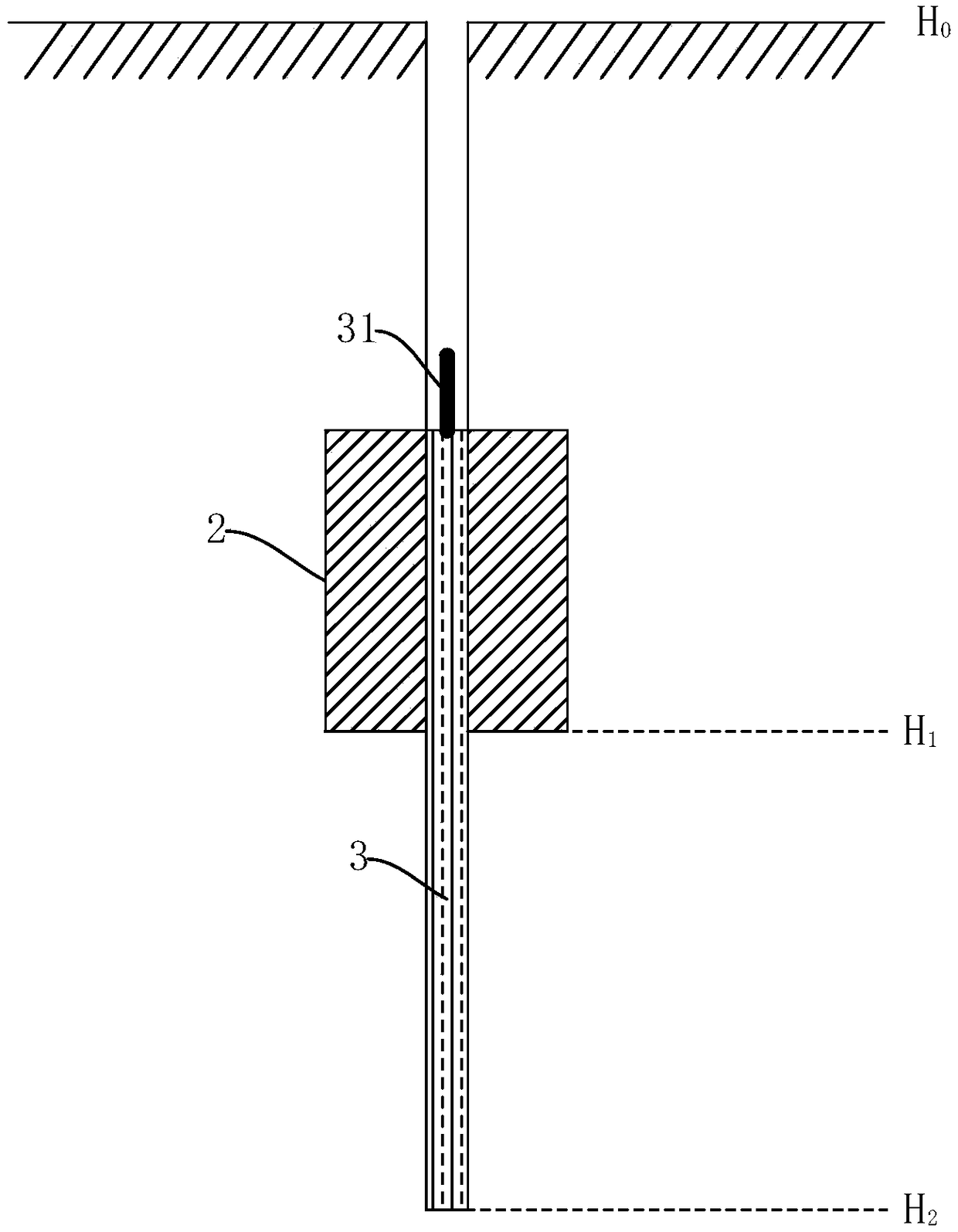

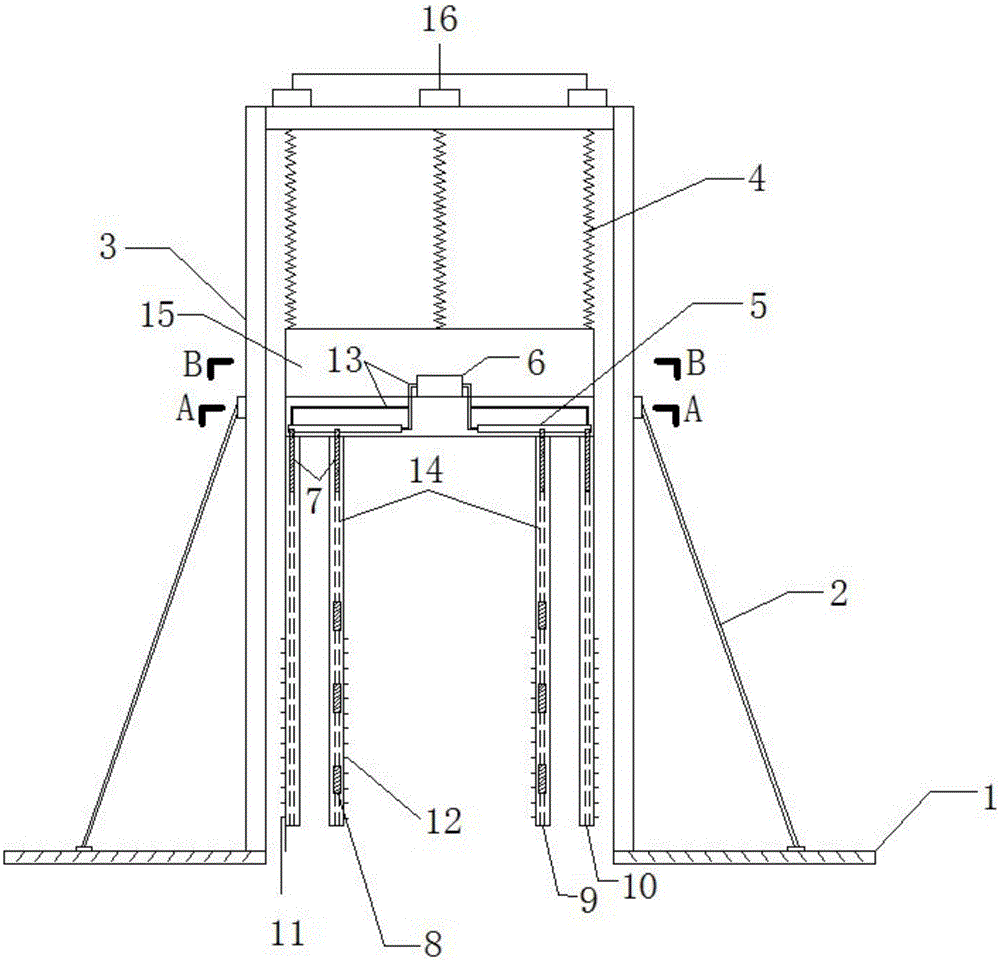

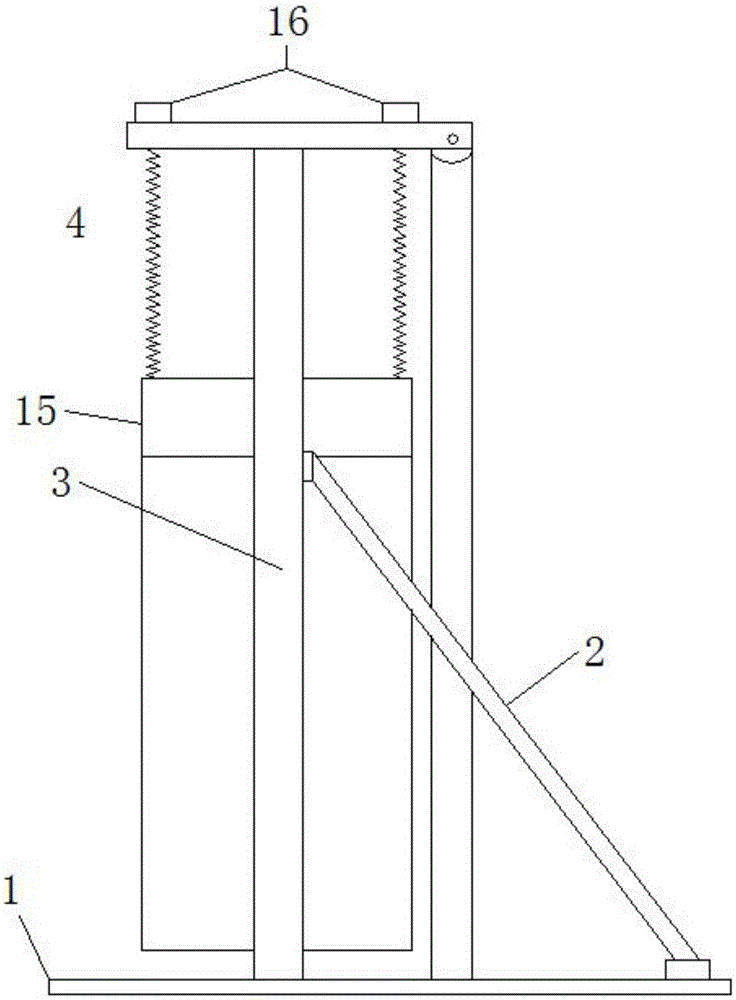

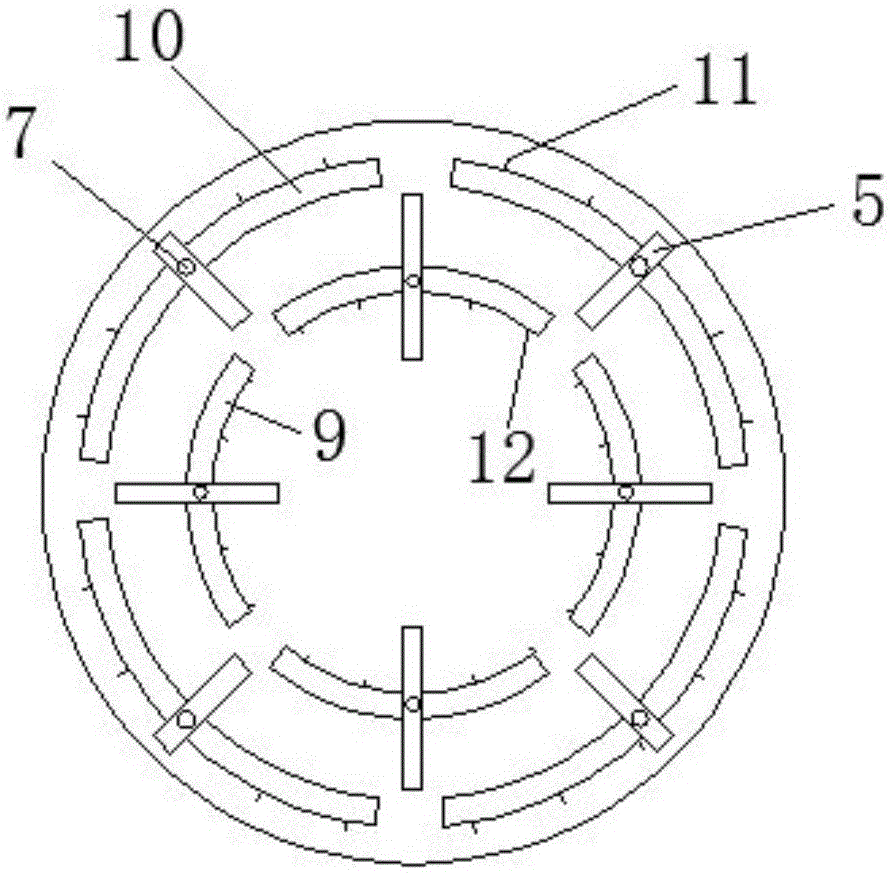

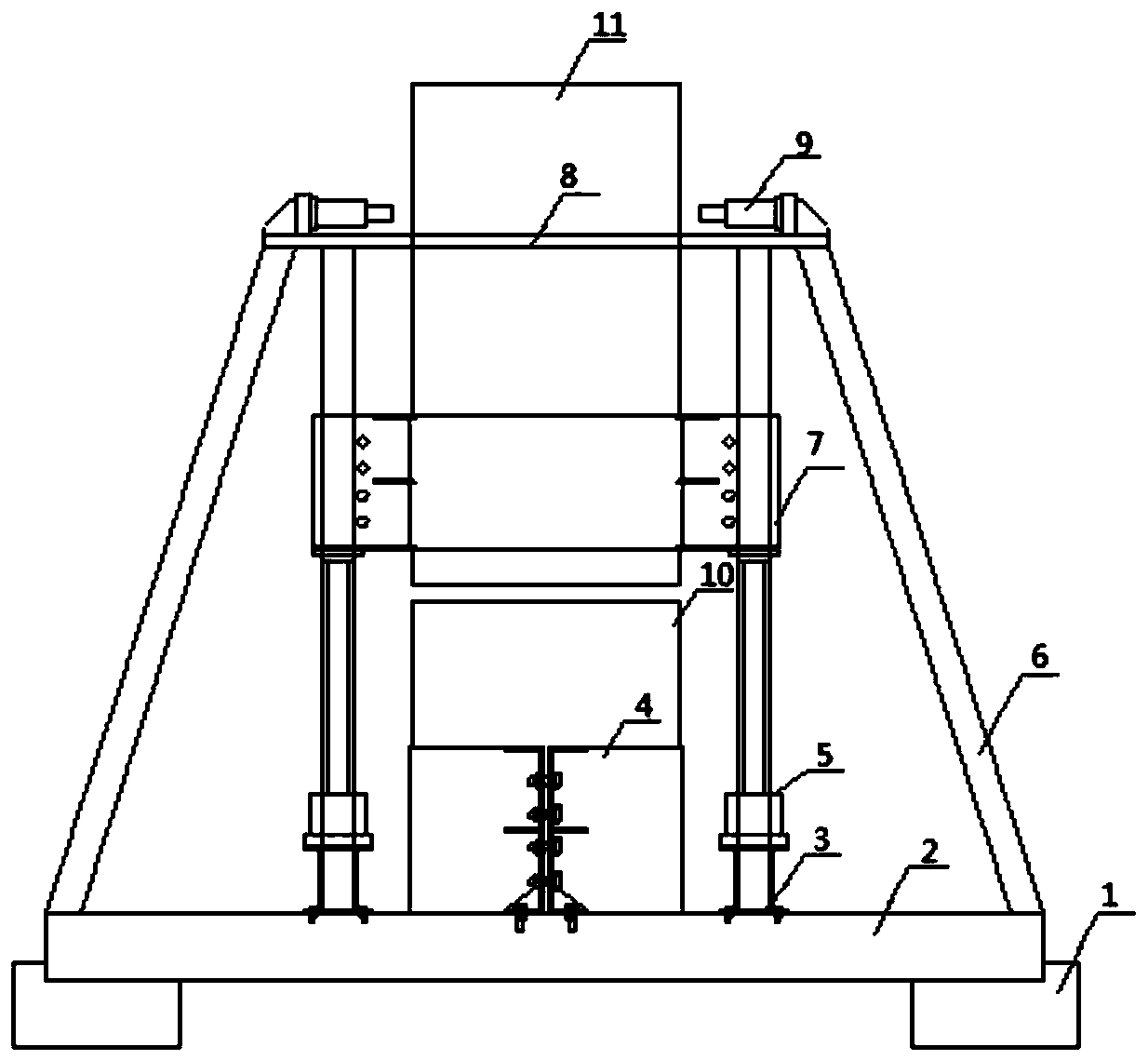

Retaining wall type open caisson sinking device and construction method thereof

The invention discloses a retaining wall type open caisson sinking device and a construction method of the retaining wall type open caisson sinking device. The retaining wall type open caisson sinking device comprises a door type support unit, a deviation rectification unit, a sinking-assisting unit and an auxiliary unit. The door type support unit is composed of a device foundation, a door-type support and side supporting frames. The deviation rectification unit comprises an inner retaining wall, an outer retaining wall and slinging chains. The sinking-assisting unit comprises a device layer, an inner air box, an outer air box and longitudinal high-pressure air conveying pipelines. The auxiliary unit is composed of a headstock gear and an electromagnet. The retaining wall type open caisson sinking device further comprises a posture monitoring unit composed of a posture sensor and a controller processor. The construction method of the retaining wall type open caisson sinking device is used for constructing an open caisson with a deep overburden foundation and with the high automation degree, enabling the posture of the open caisson to be monitored in real time and enabling deviation rectification to be conducted on the posture of the open caisson in time. According to the retaining wall type open caisson sinking device and the construction method of the retaining wall type open caisson sinking device, when the open caisson sinks due to the dead load, new measures such as sink assistance, deviation rectification, the electromagnet and the retaining walls are thoroughly combined, it is guaranteed that sinking of sections of the open caisson can be continuously, effectively and accurately conducted on the deep overburden foundation, the automation degree is high, and mutual interference between open caissons is small.

Owner:HOHAI UNIV +1

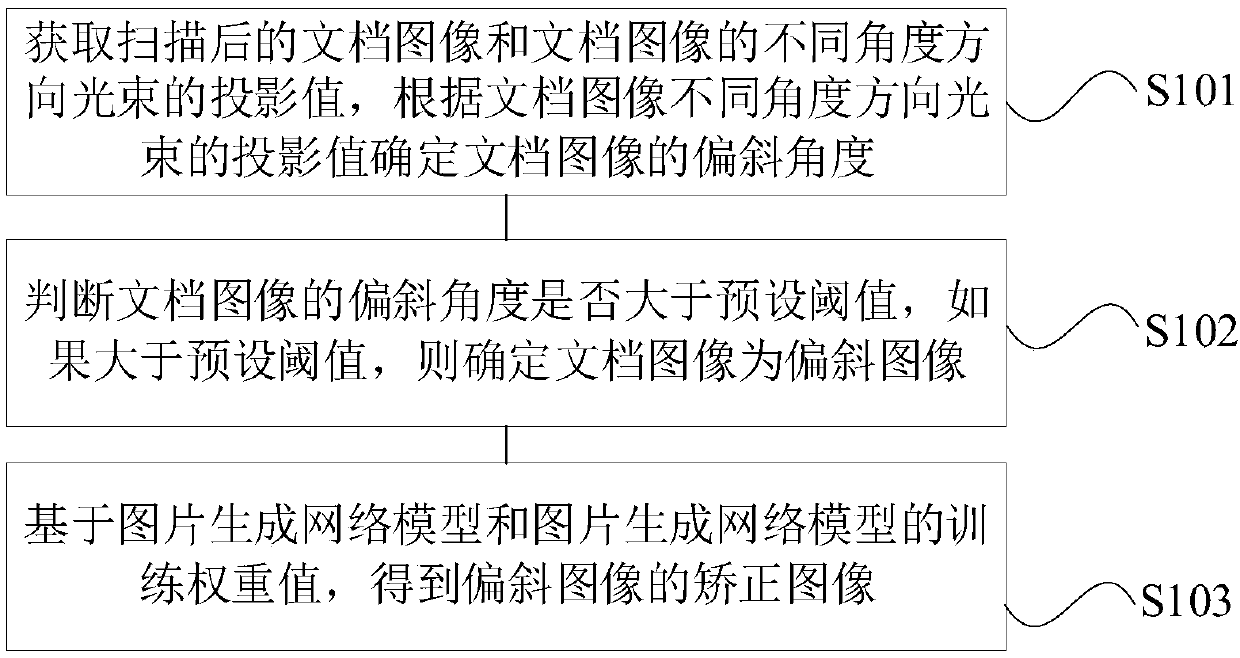

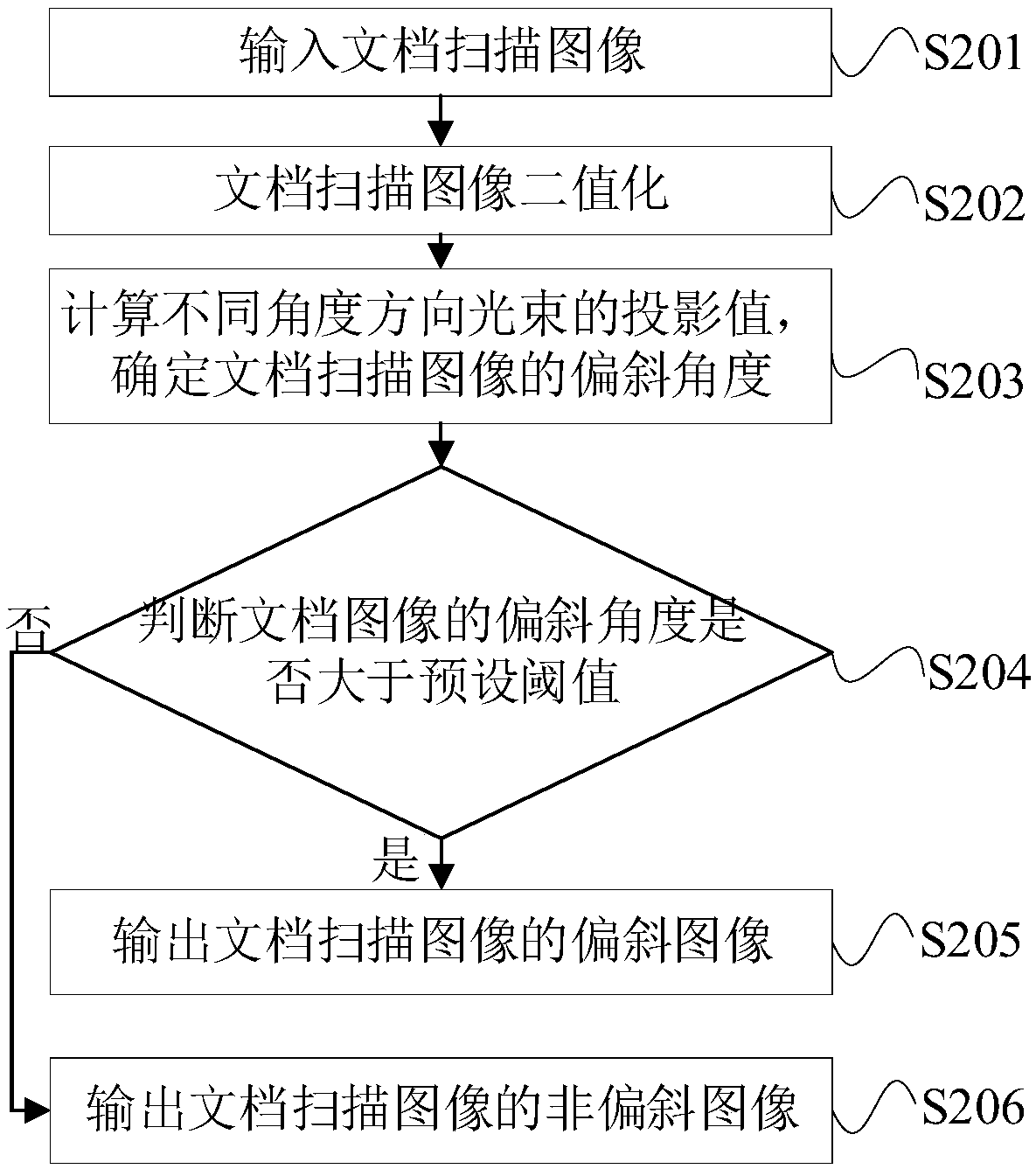

Document scanning image correction method and device

PendingCN109635714AAvoid Manual InspectionReduce labor costsCharacter and pattern recognitionNeural architecturesWeight valueNetwork model

The invention provides a document scanning image correction method and device, and relates to the technical field of archive management. The document scanning image correction method comprises the following steps: correcting a document scanning image; obtaining scanned document images and projection values of light beams of the document images in different angle directions; the deflection angle ofthe document image is determined according to the projection values of the light beams in different angle directions of the document image; judging whether the deflection angle of the document imageis greater than a preset threshold value or not, if yes, determining the document image as the deflection image, and obtaining a corrected image of the deflection image based on the picture generationnetwork model and the training weight value of the picture generation network model, so that the labor cost is reduced, and meanwhile, the document scanning efficiency is improved.

Owner:光典信息发展有限公司

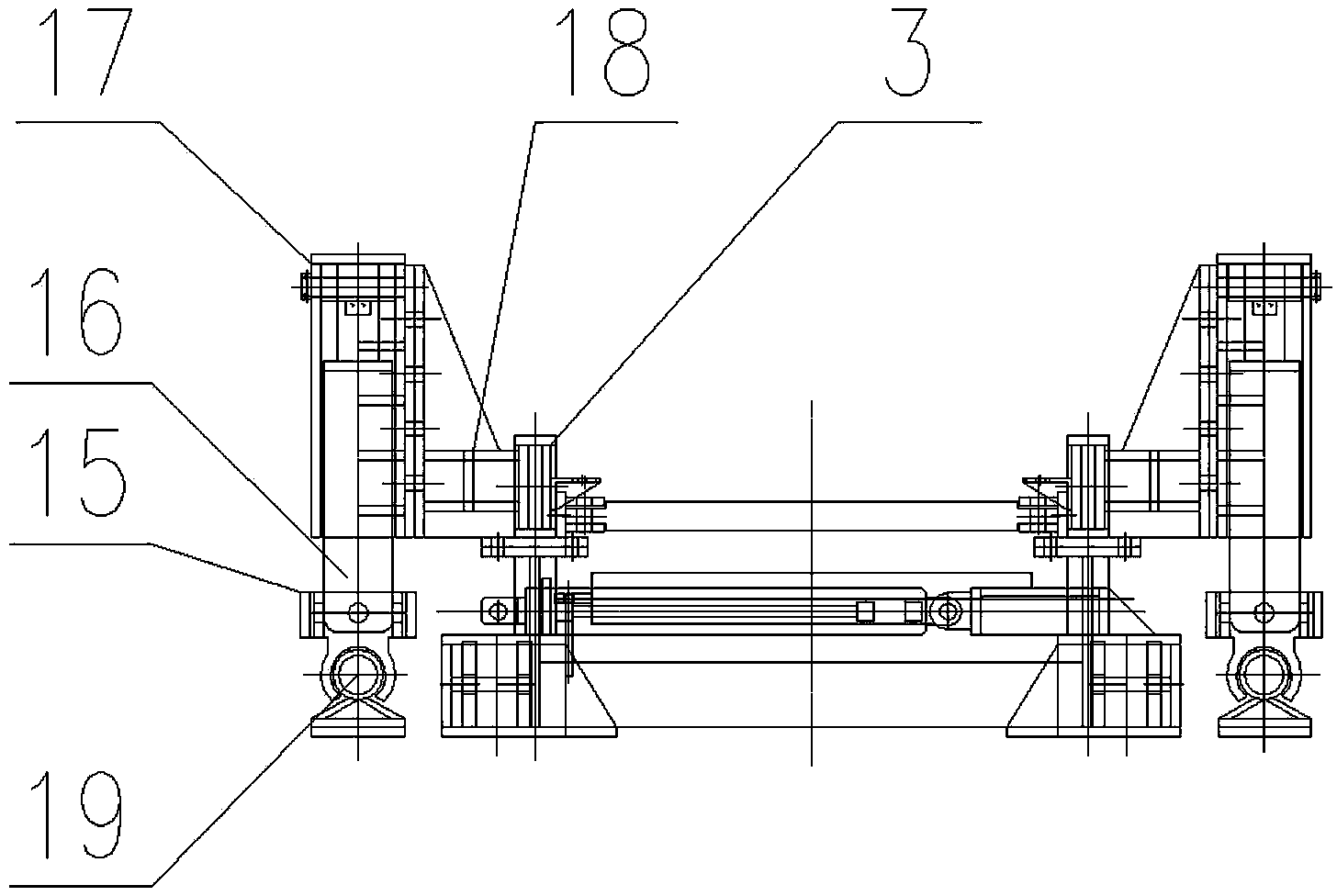

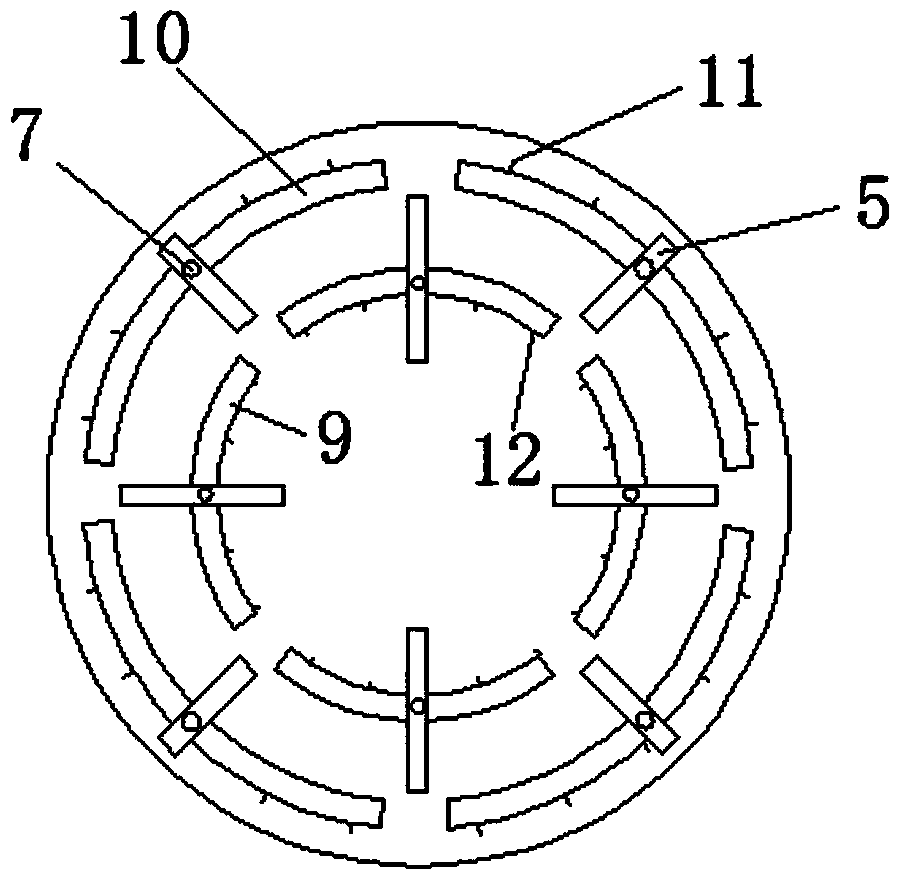

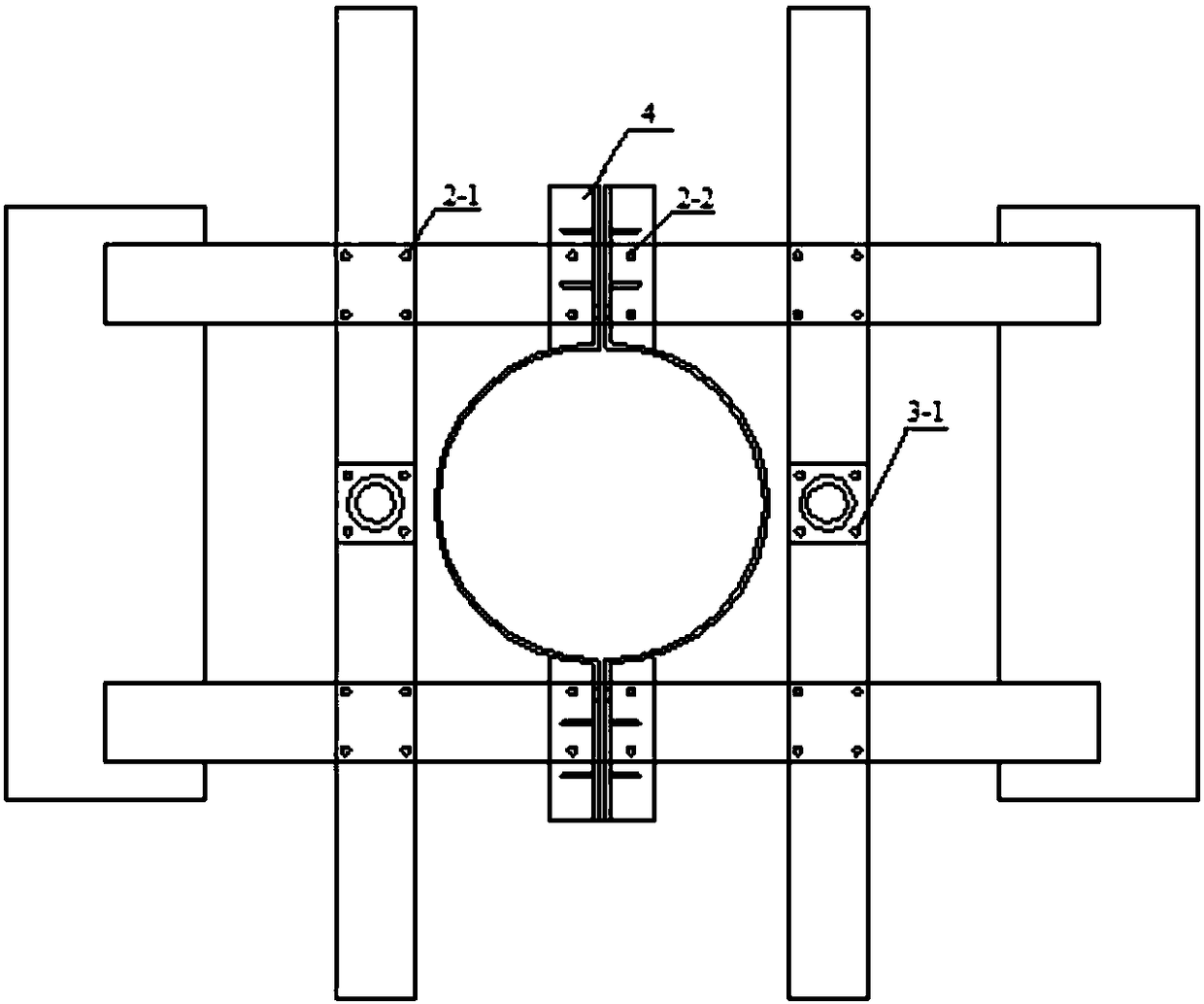

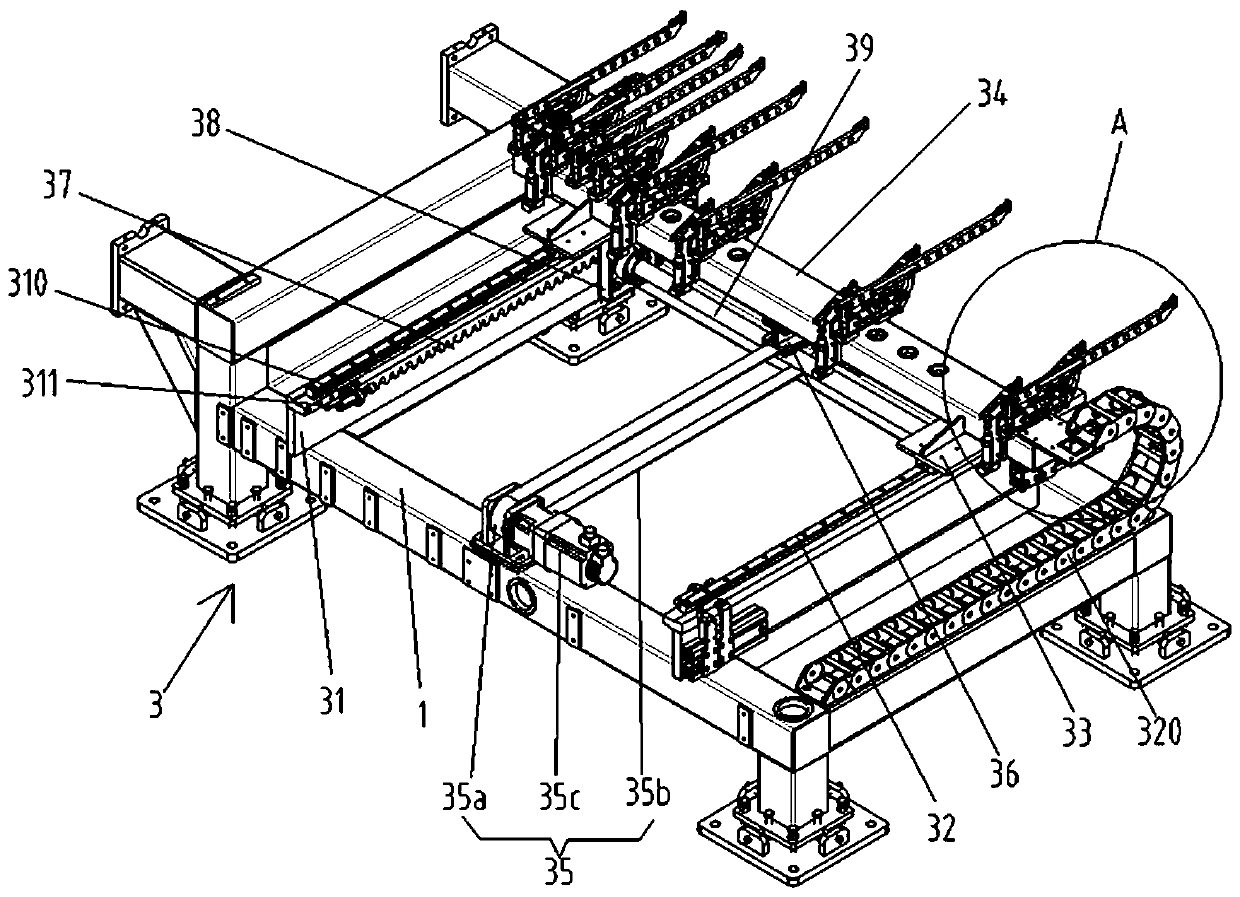

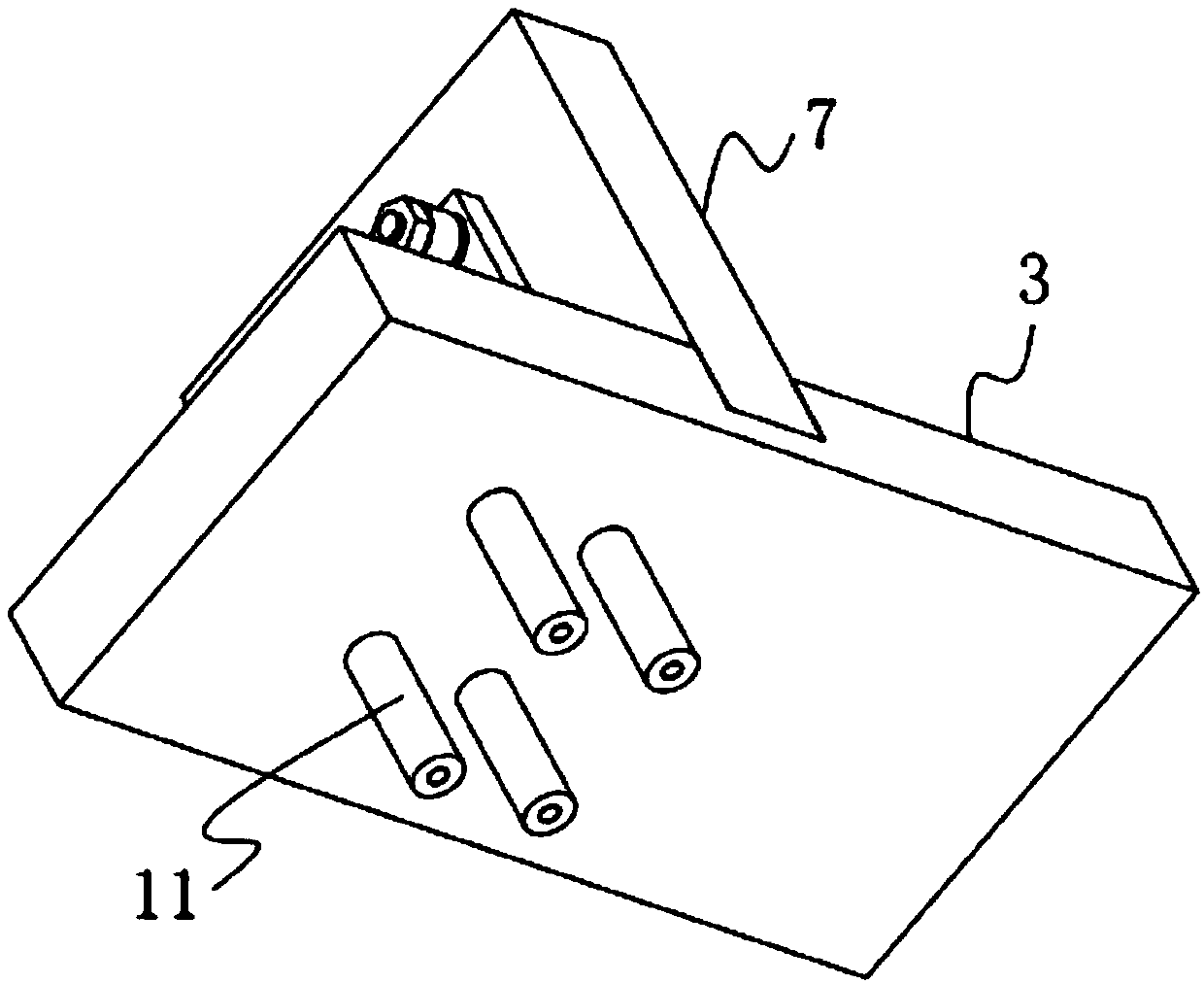

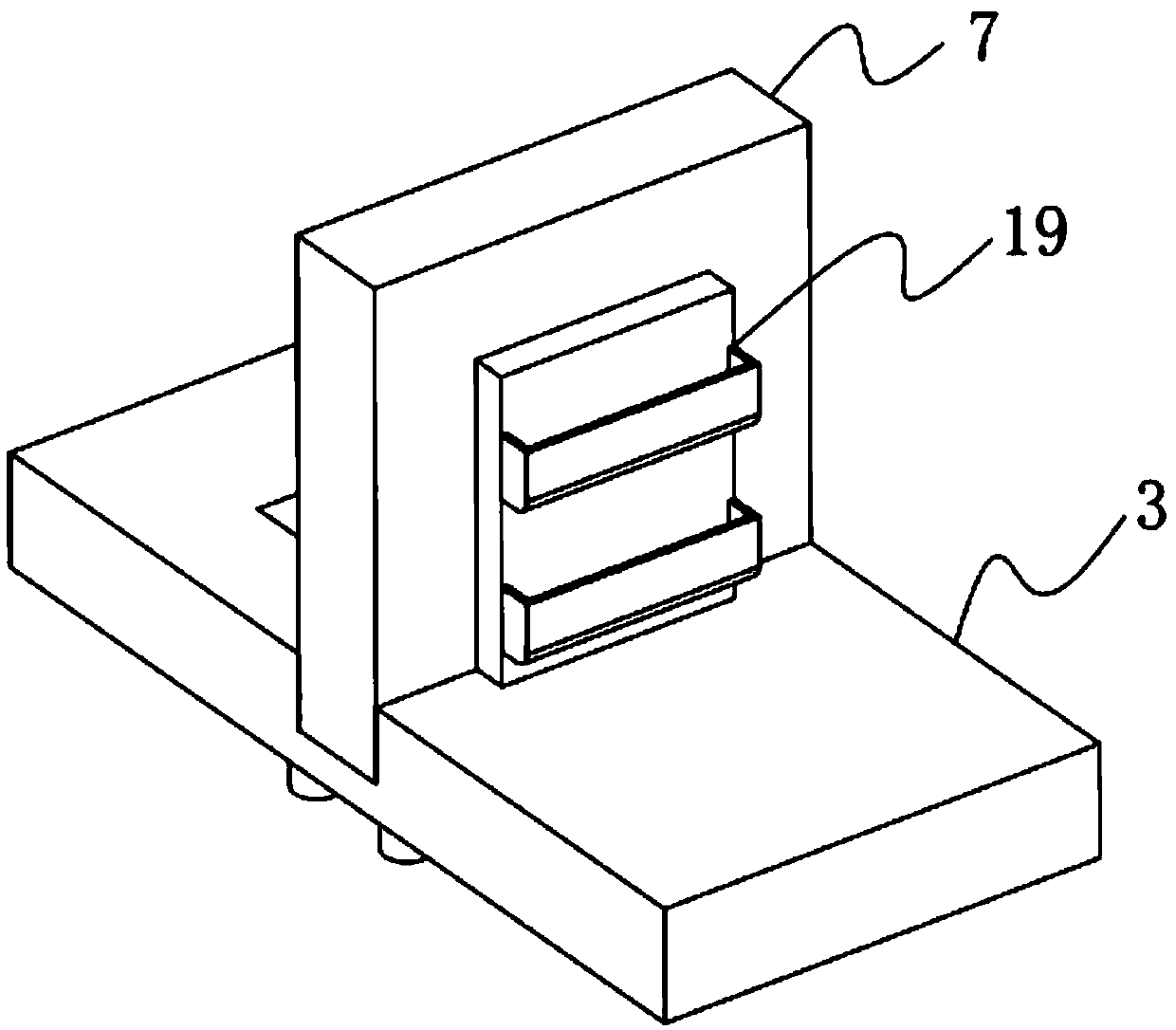

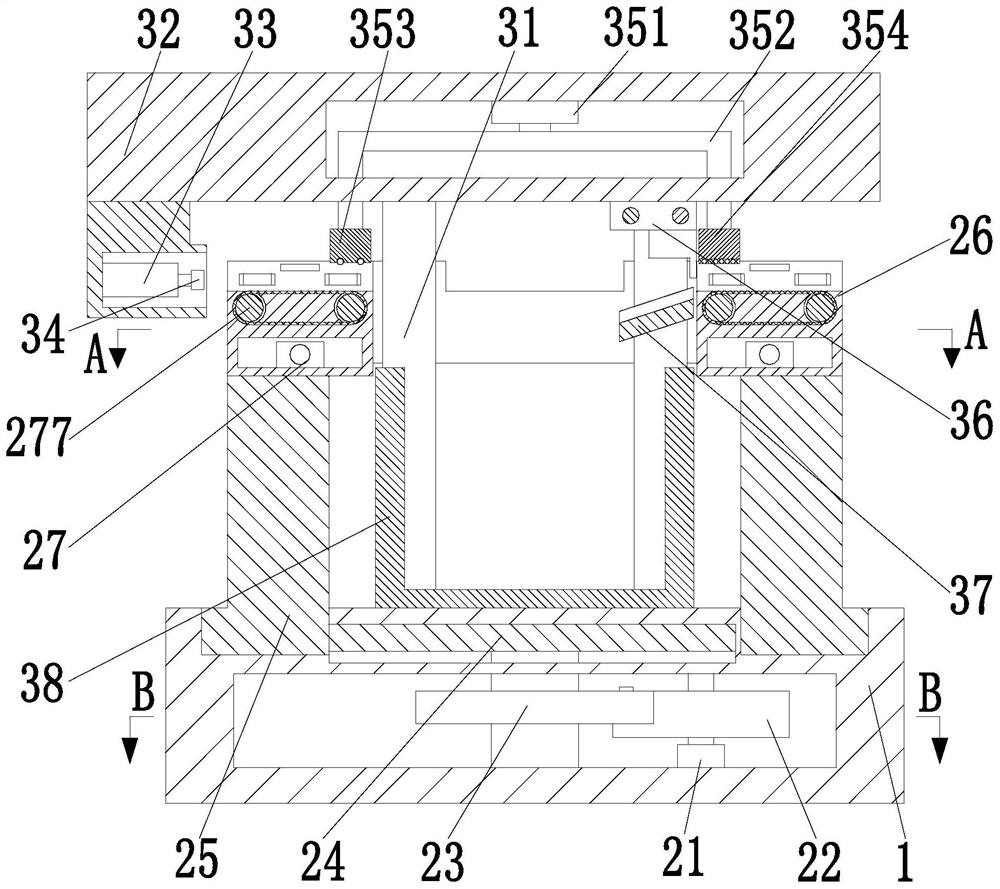

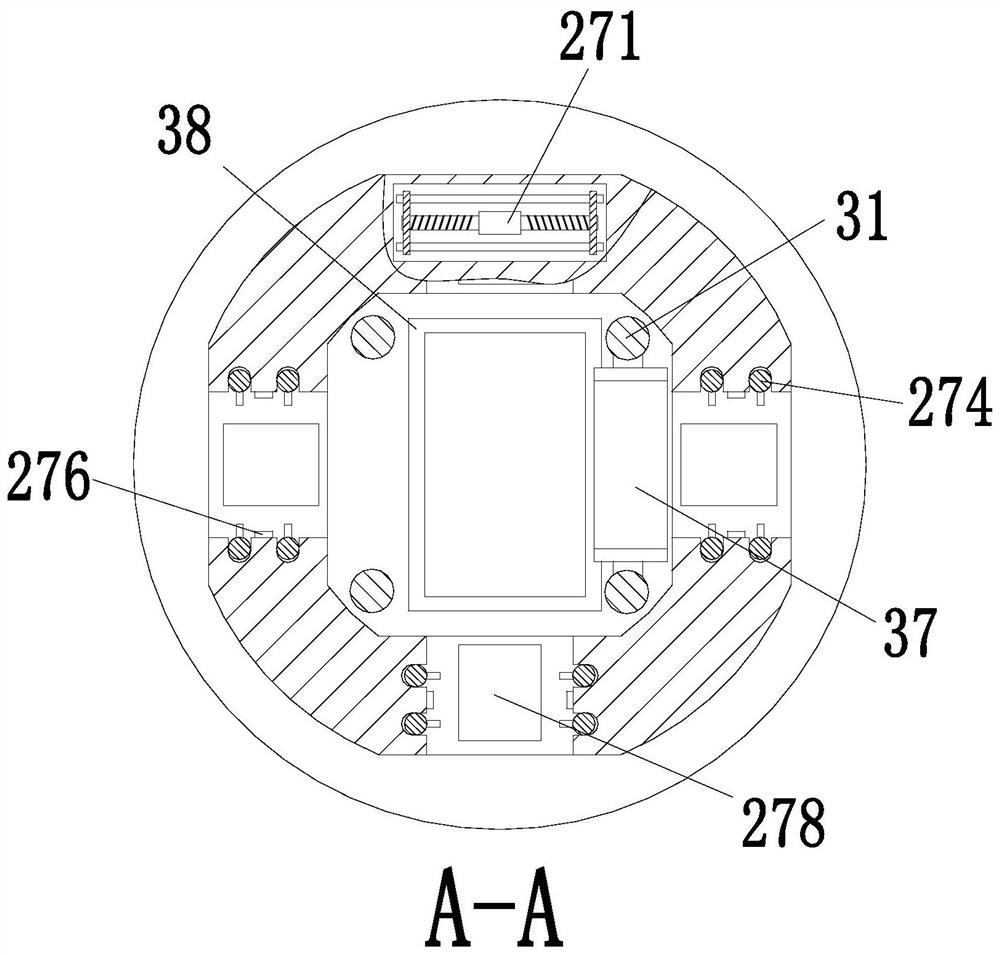

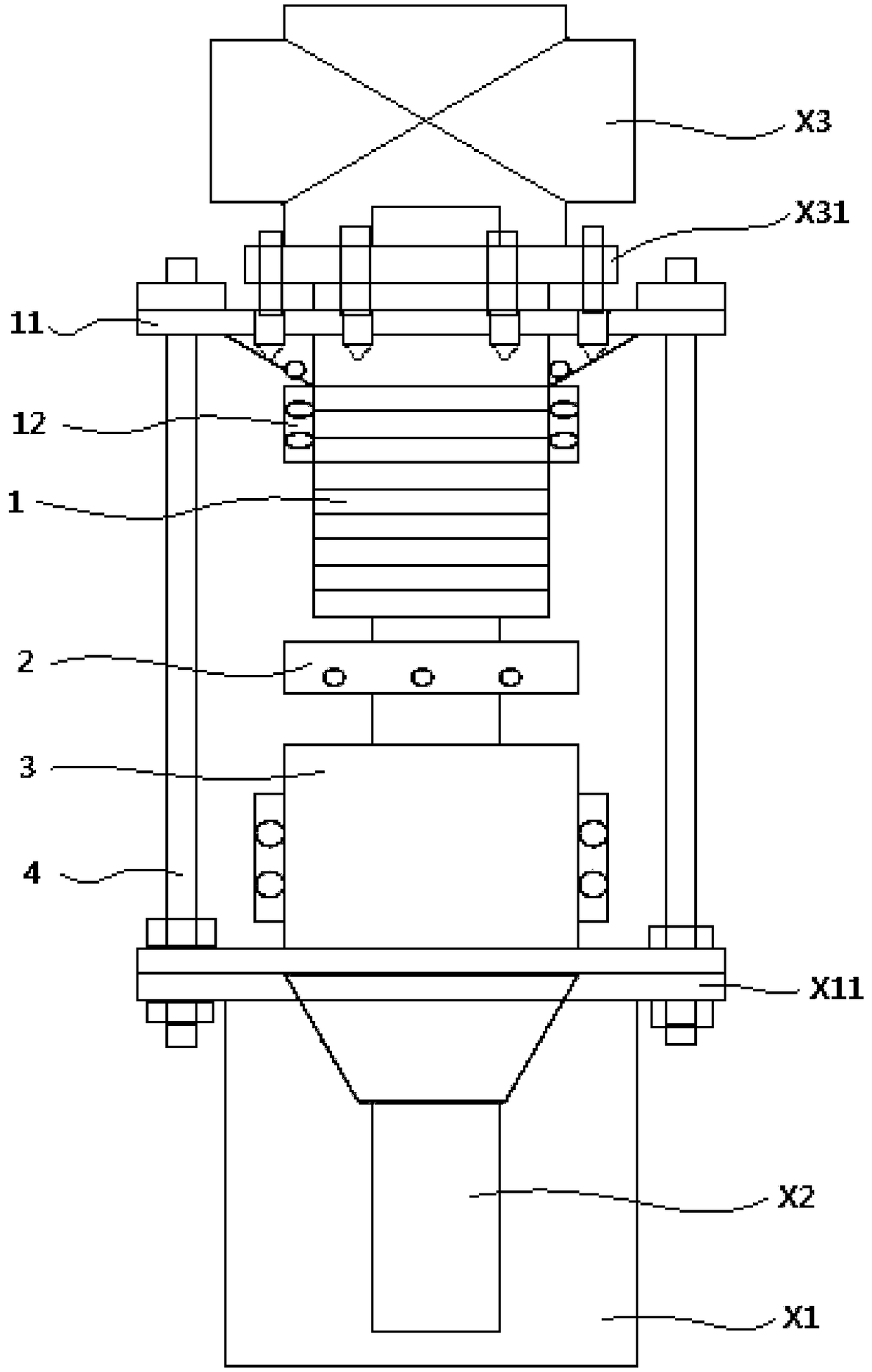

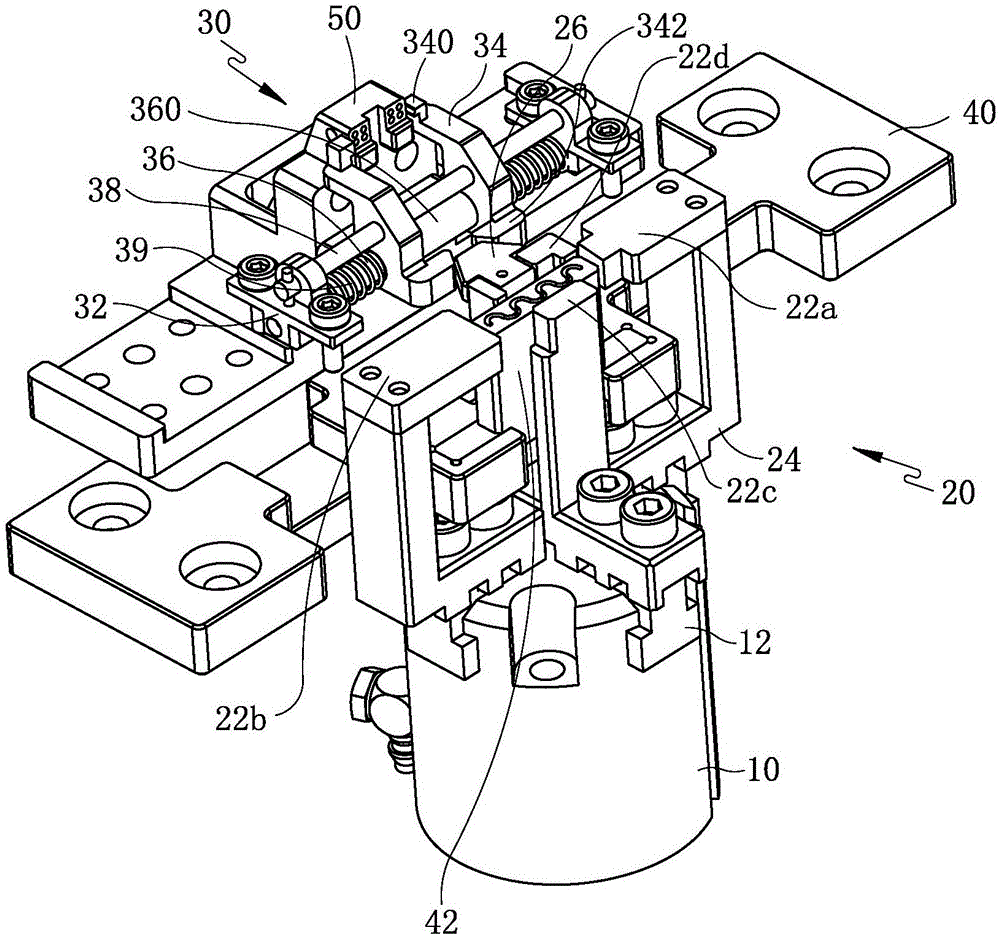

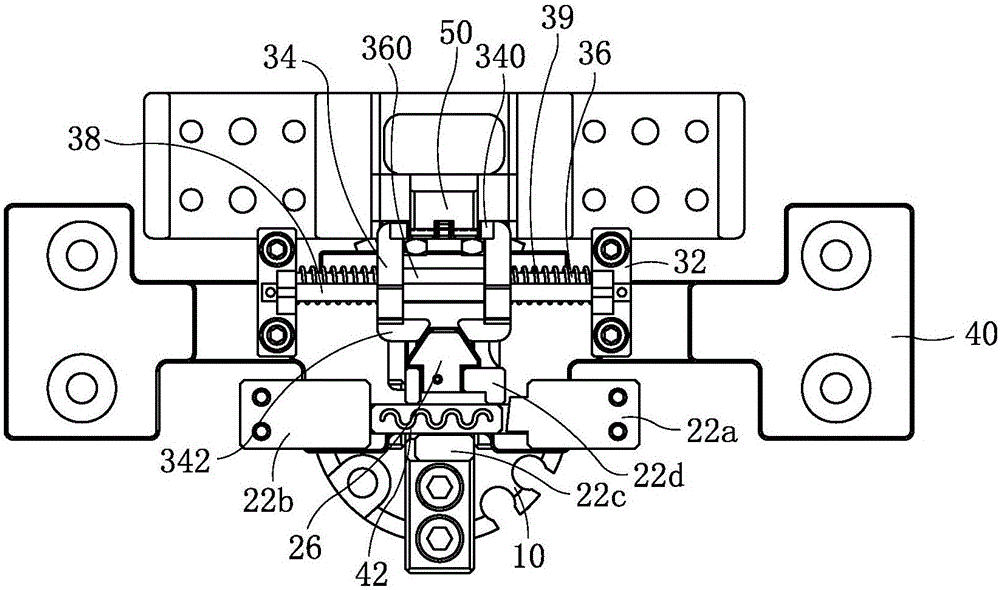

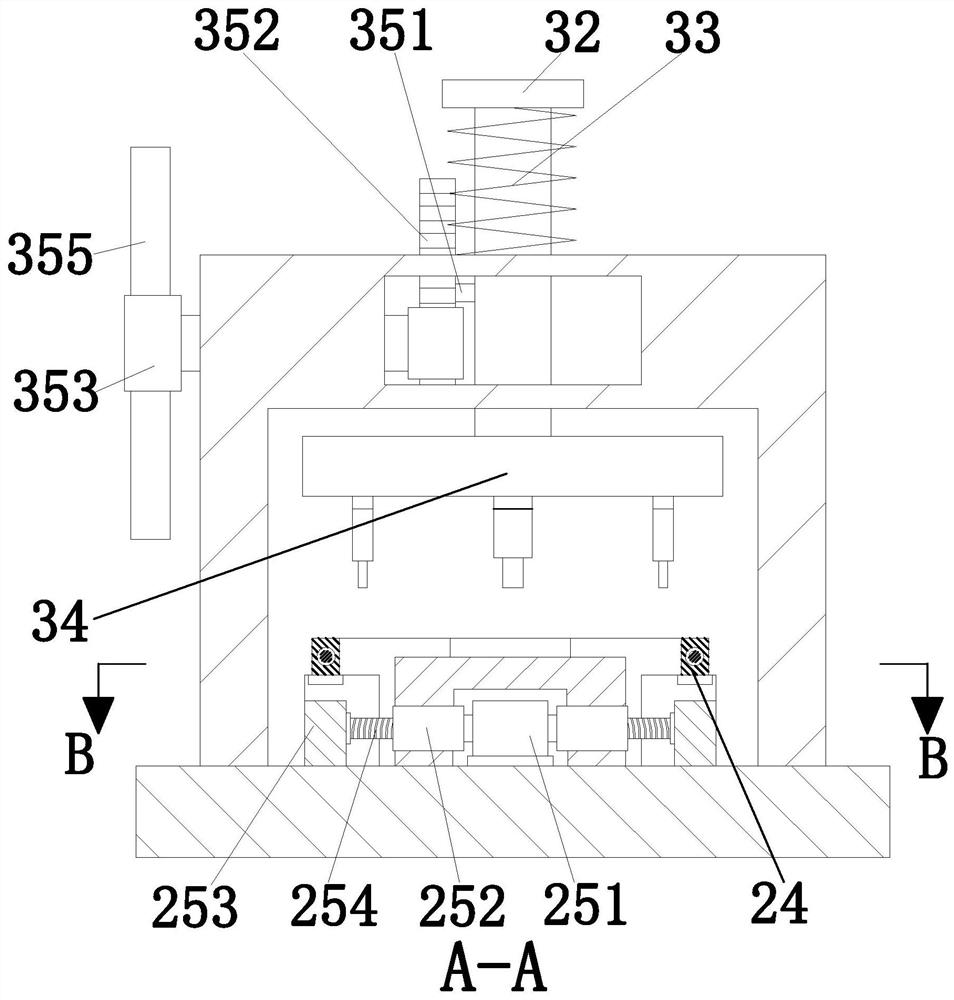

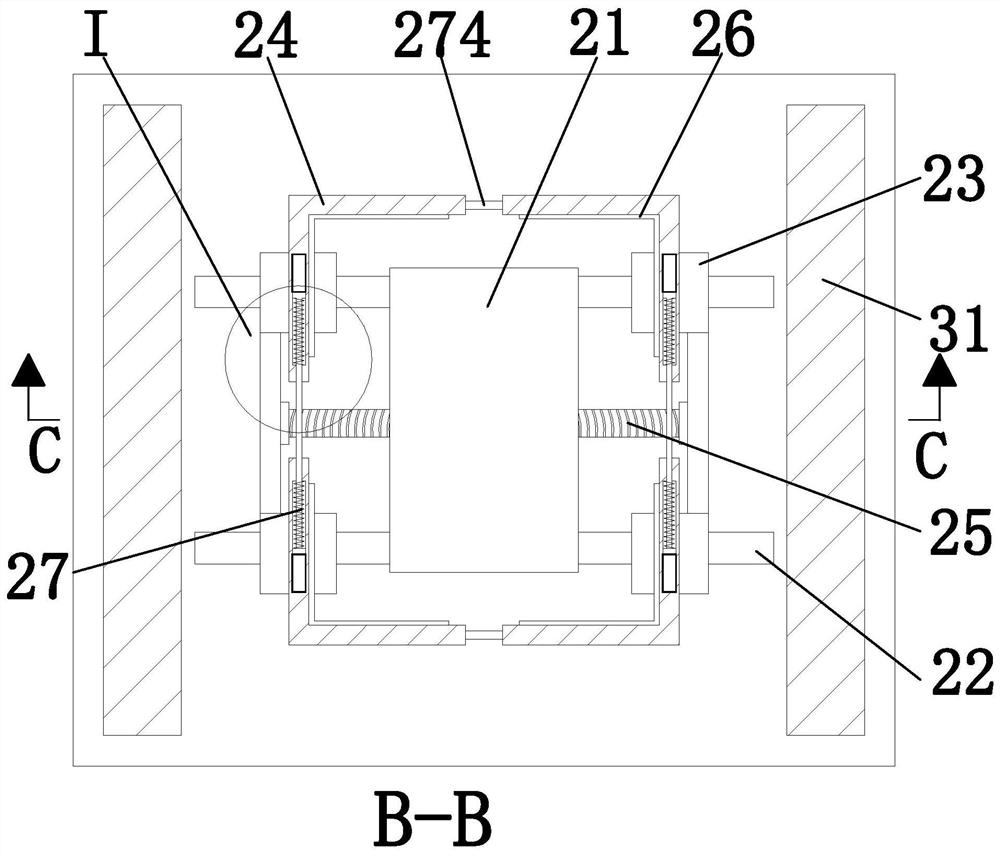

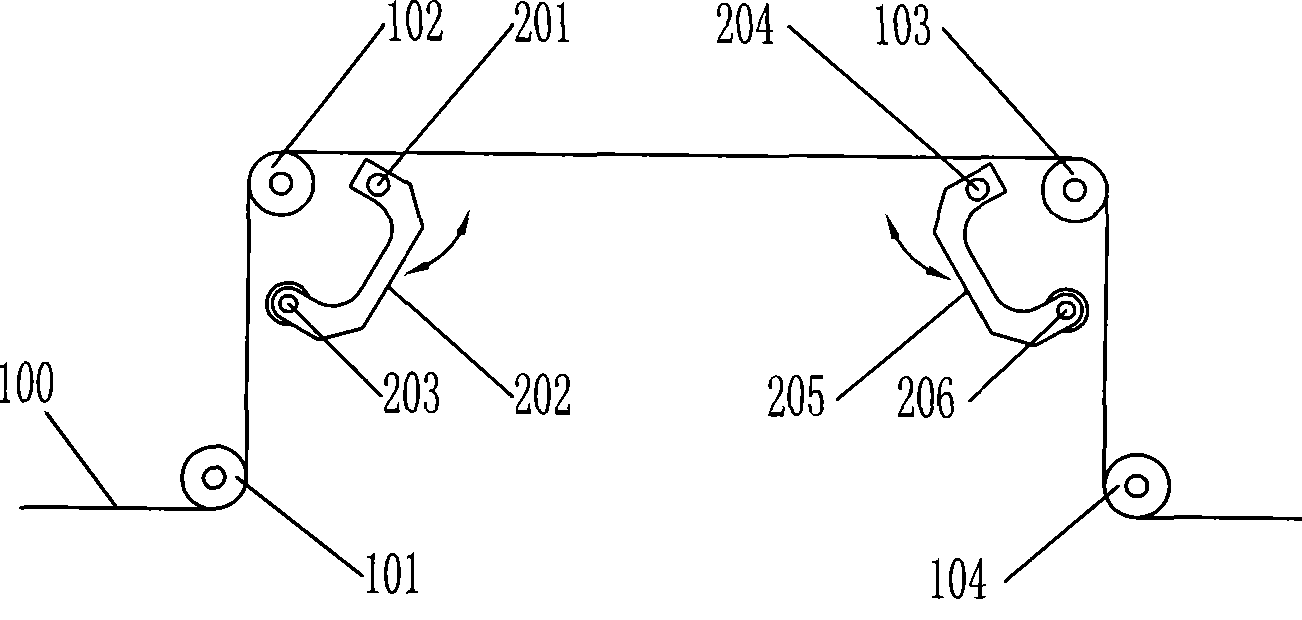

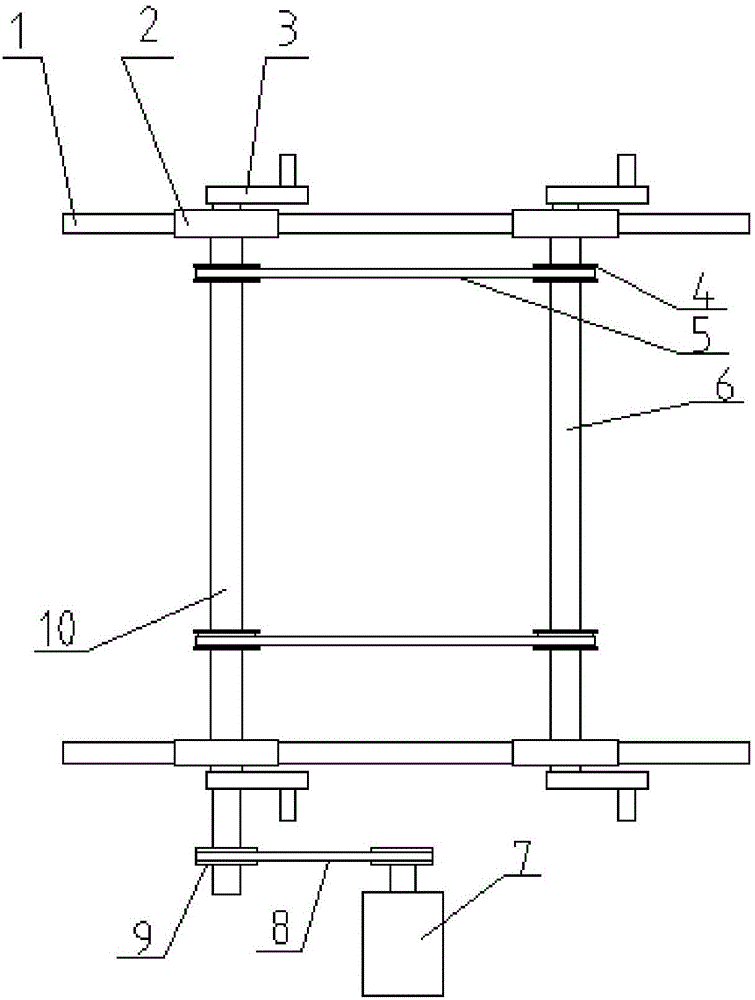

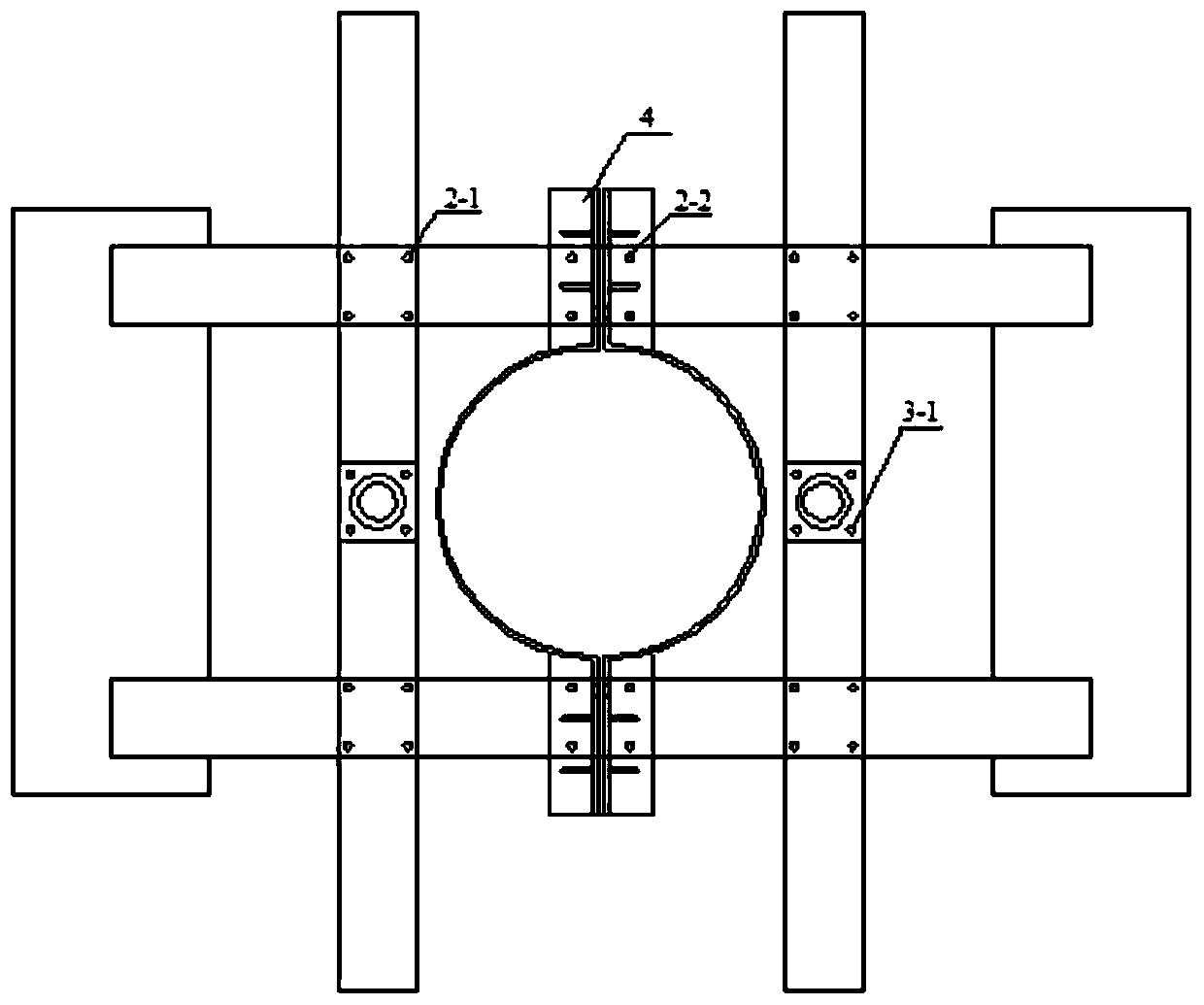

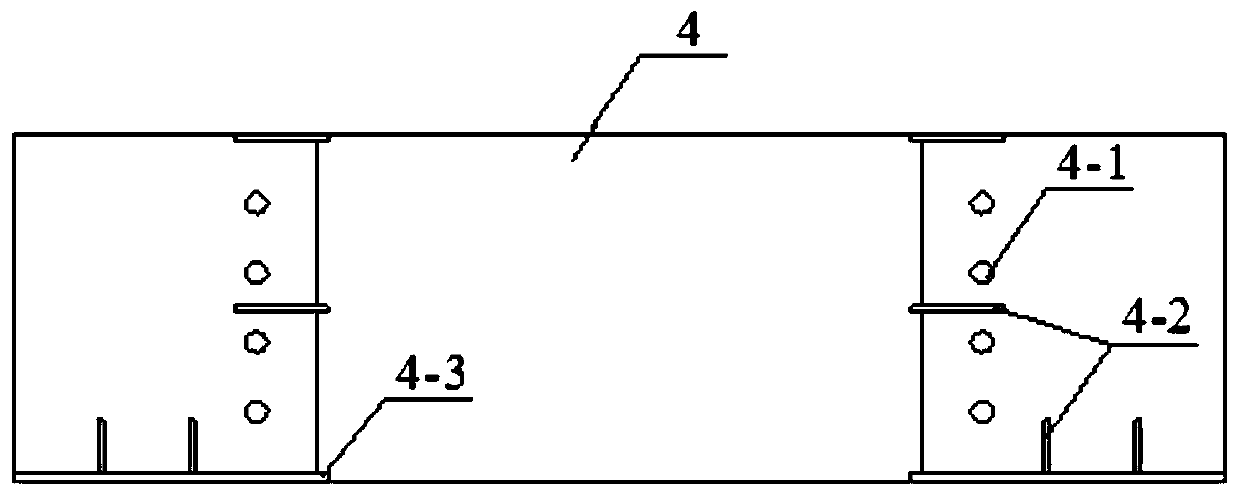

Centering positioning device for pile splicing

ActiveCN108330974AGuaranteed alignmentFlexible adjustment of embedding depthBulkheads/pilesData platformStructural engineering

The invention provides a centering positioning device for pile splicing, applies to prestressed concrete pipe piles and aims at solving pile splicing problems of the prestressed concrete pipe piles inactual use. Datum platforms are arranged firstly and adjusted by instruments such as a leveling rod and the like, and levelness of the datum platforms is guaranteed; then a lower pipe pile is fixed by a fixator I and fixed at positioning screw holes of the corresponding datum platform, screw lifters are mounted, levelness of an upper pipe pile is adjusted by combination of lifting platforms and fixators II connected with the upper pipe pile, the datum platforms are then connected with a centering positioner through inclined struts, finally, position of the upper pipe pile is adjusted precisely through the centering positioner, complete centering connection of the upper pipe pile and the lower pipe pile is realized, vertical perpendicularity is calibrated, and the problems that upper and lower pipe piles in splicing of prefabricated pipe piles are not aligned easily and whole pile body deflects after pile sinking are solved effectively.

Owner:WUHAN UNIV +2

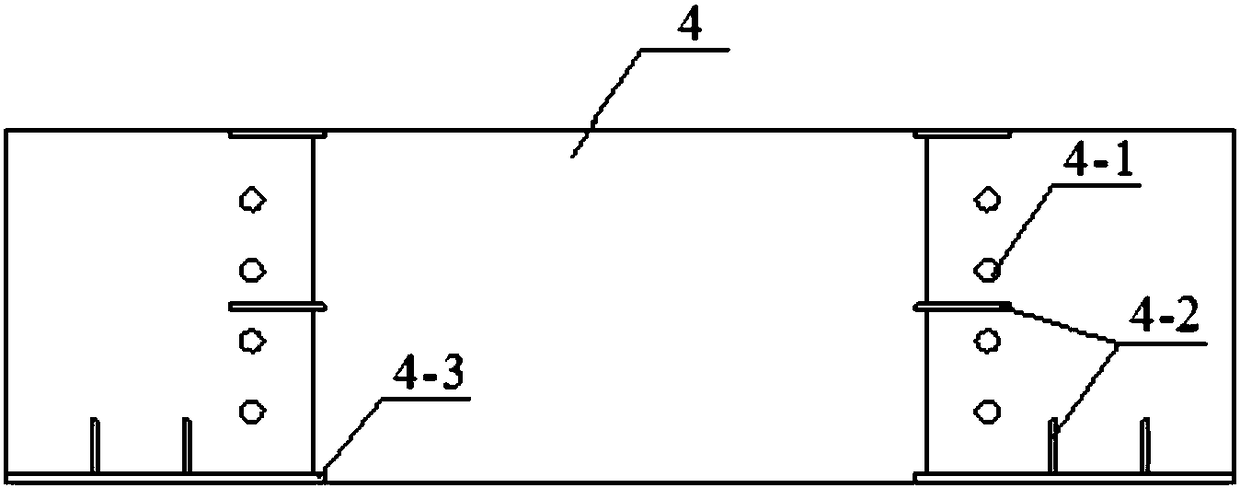

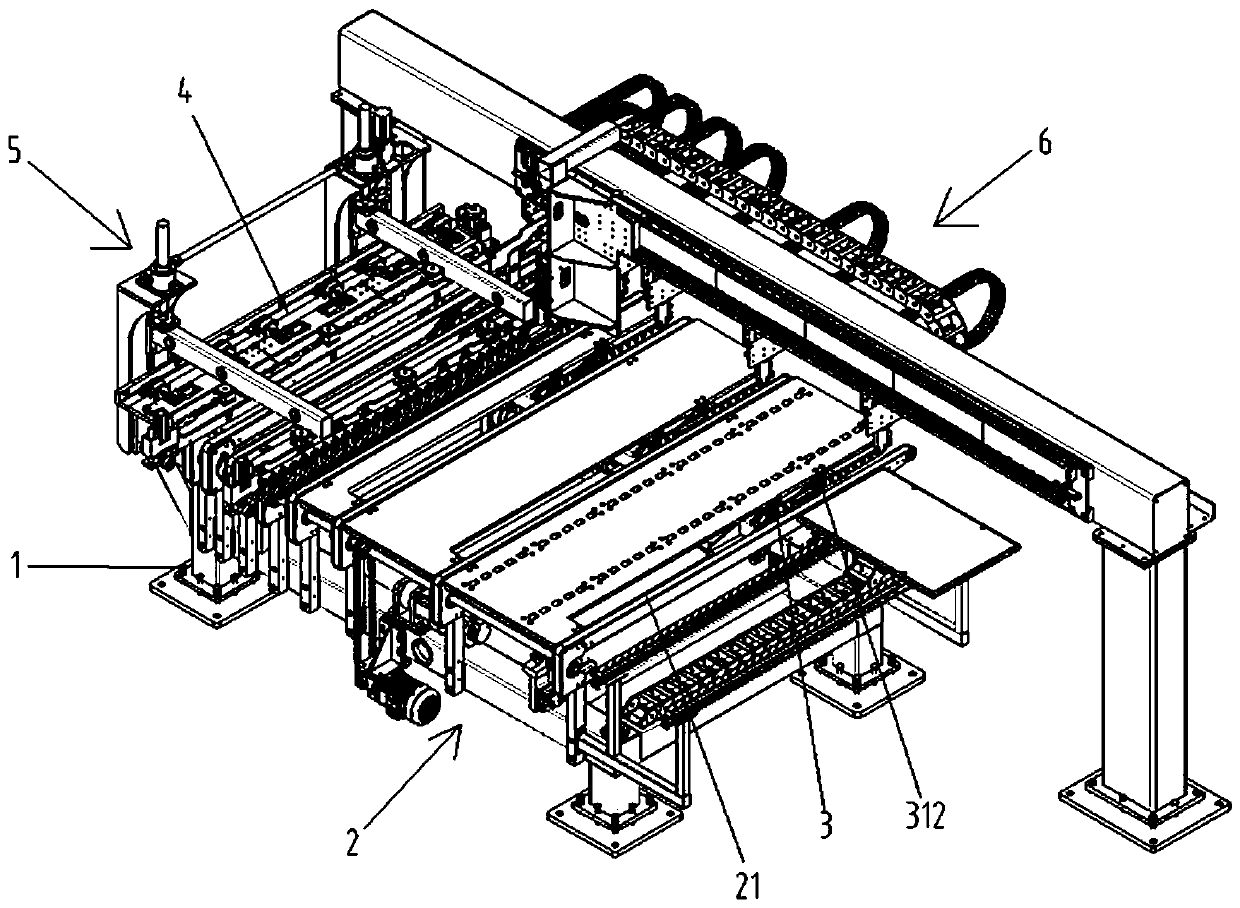

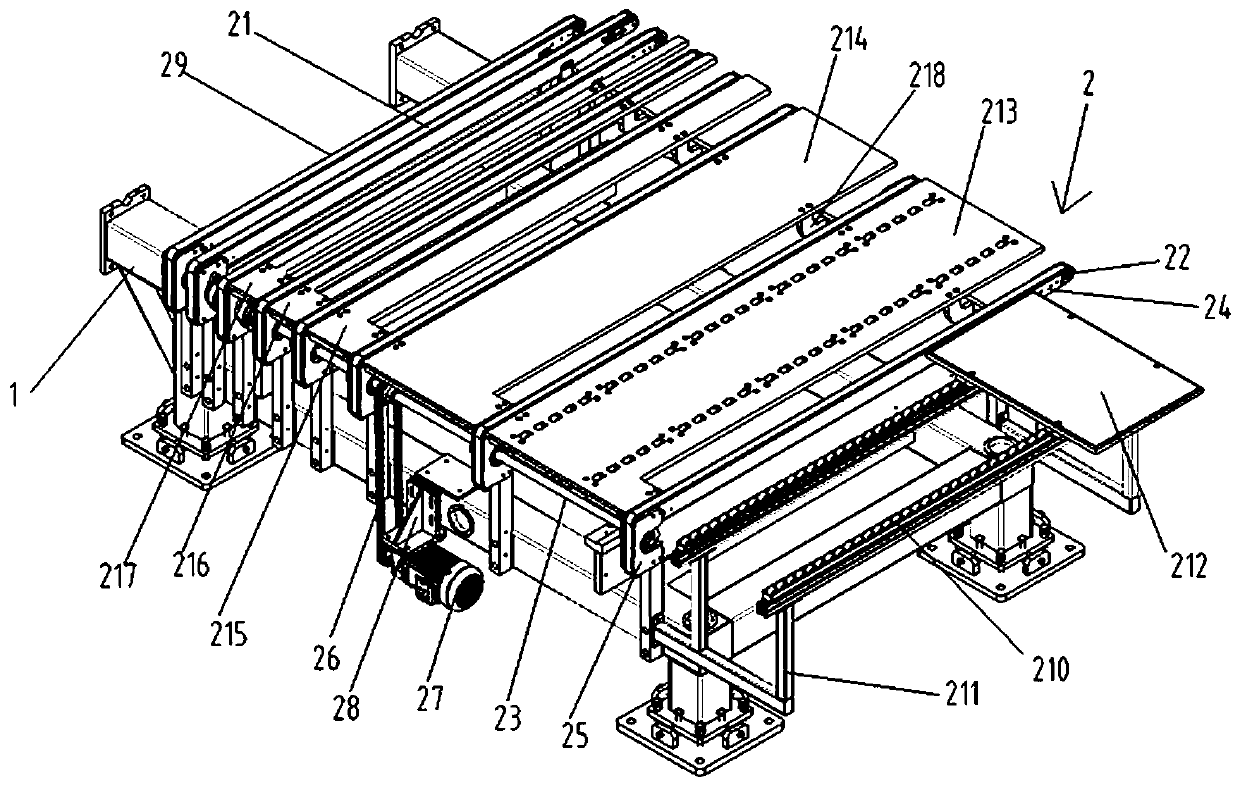

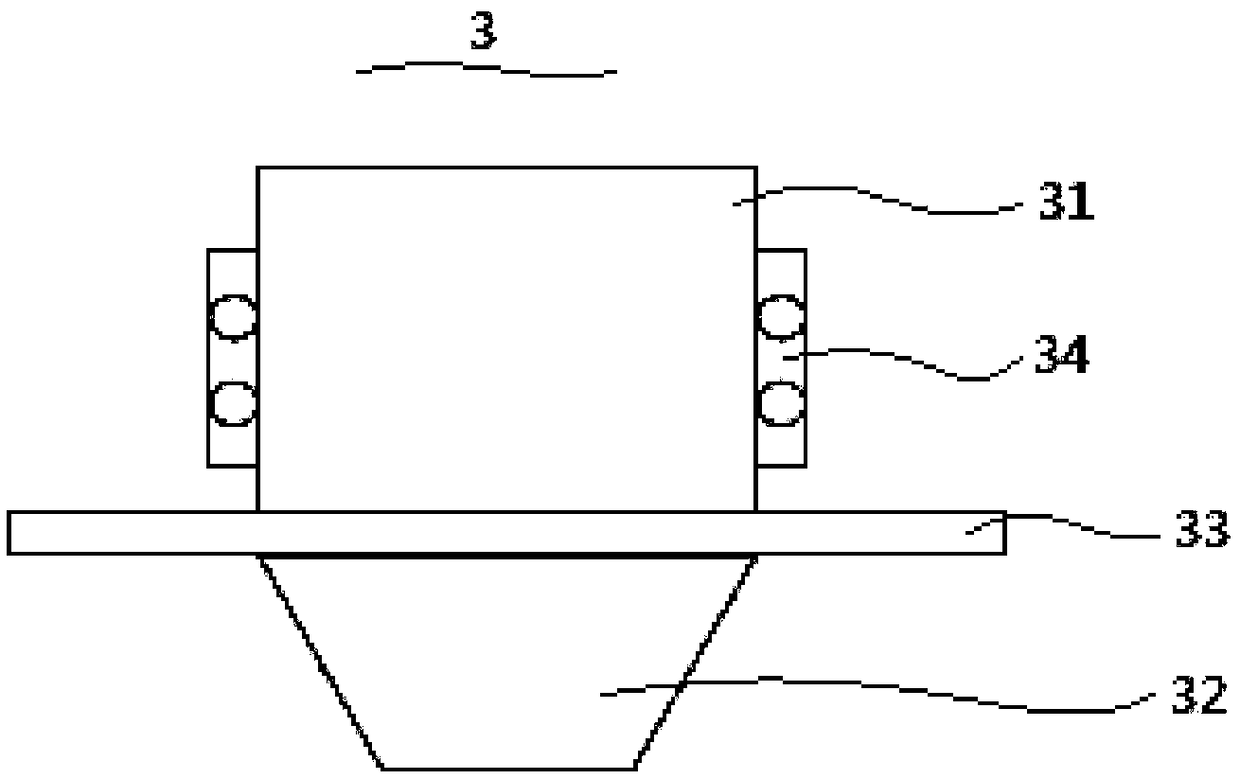

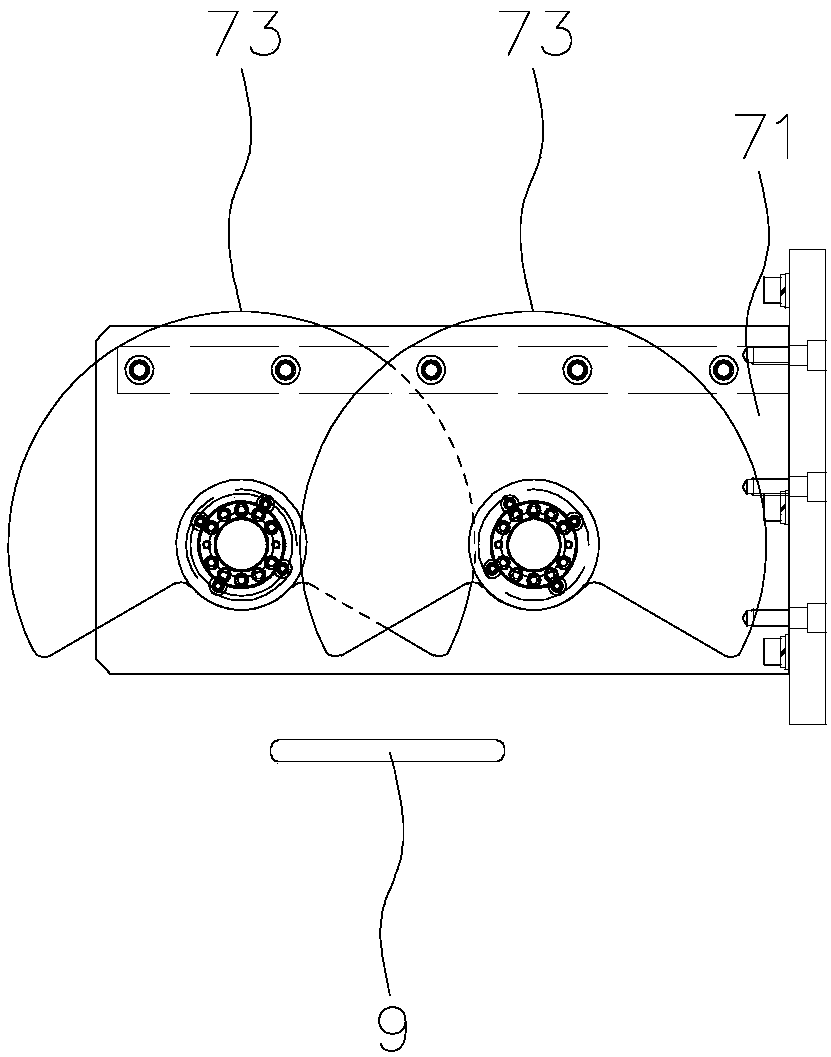

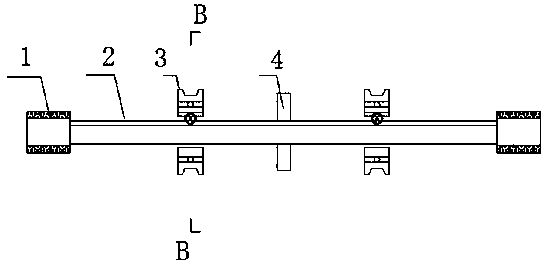

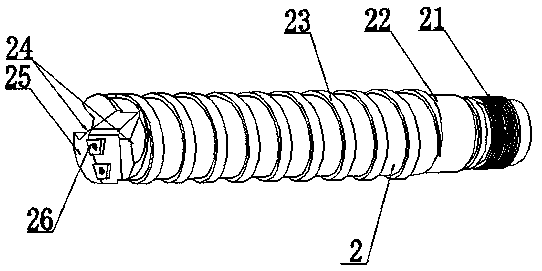

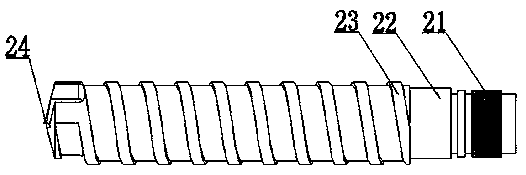

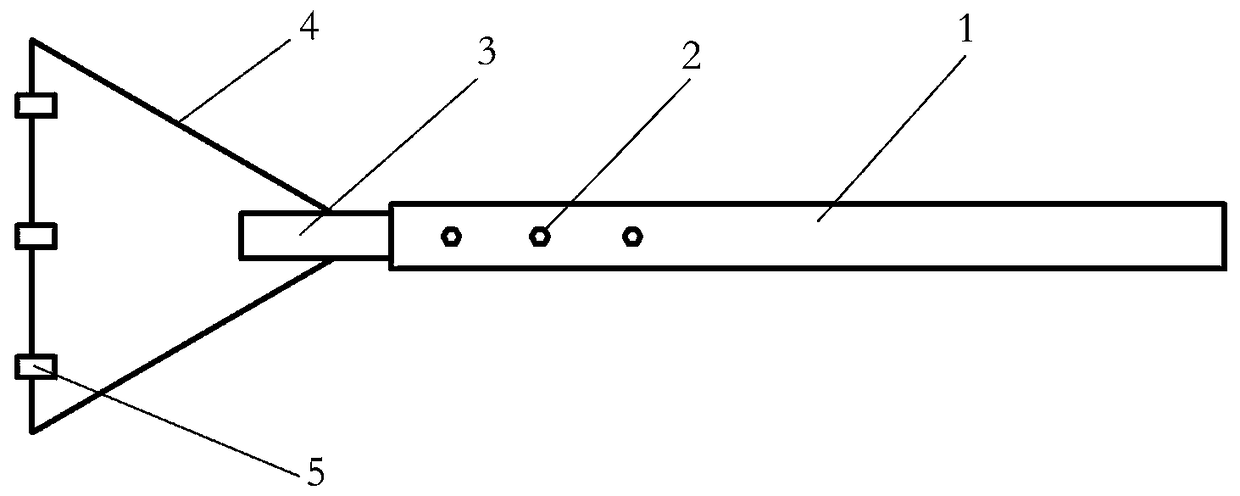

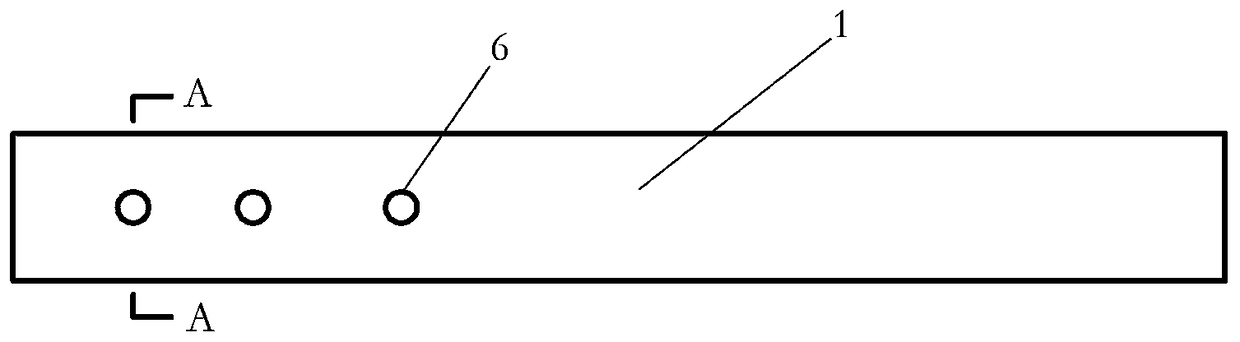

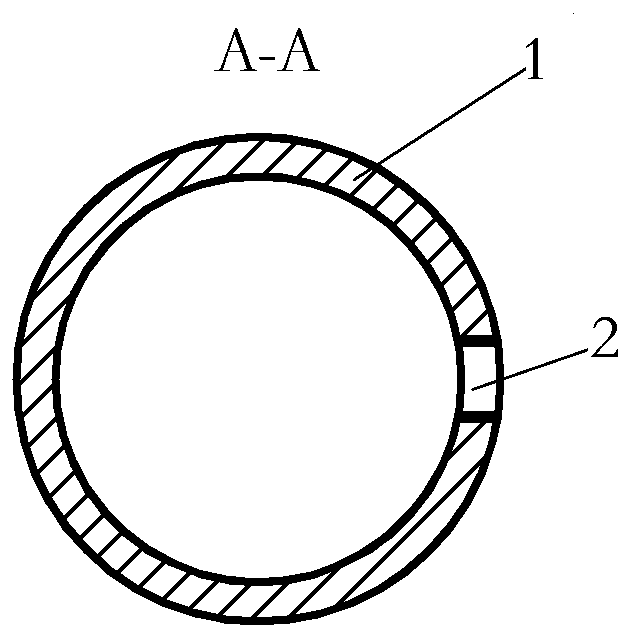

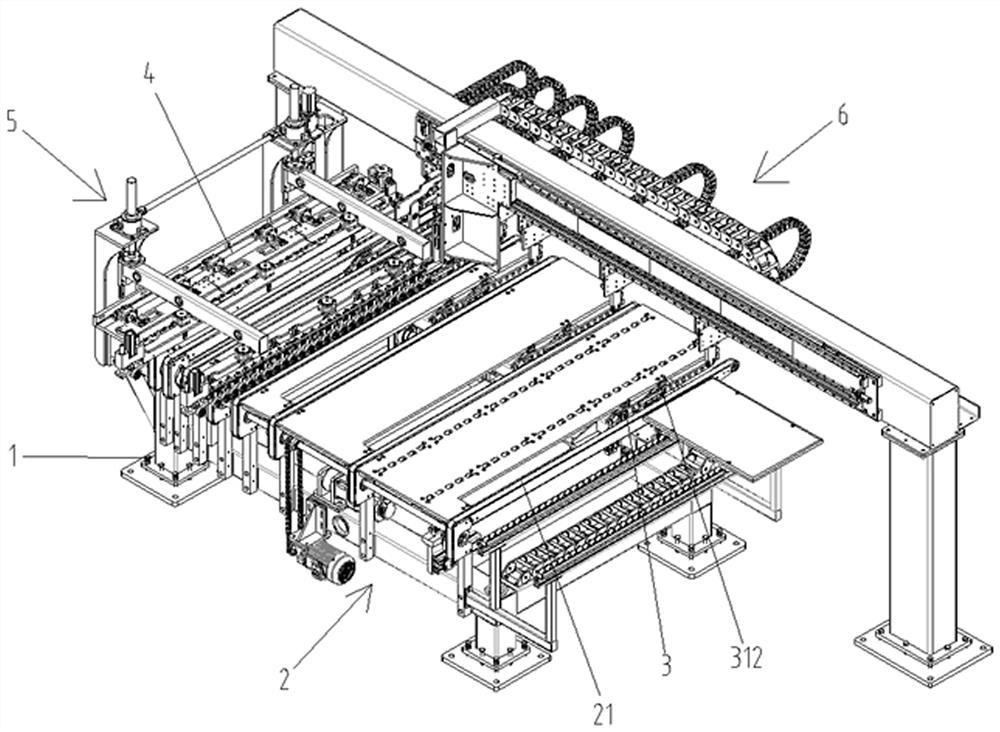

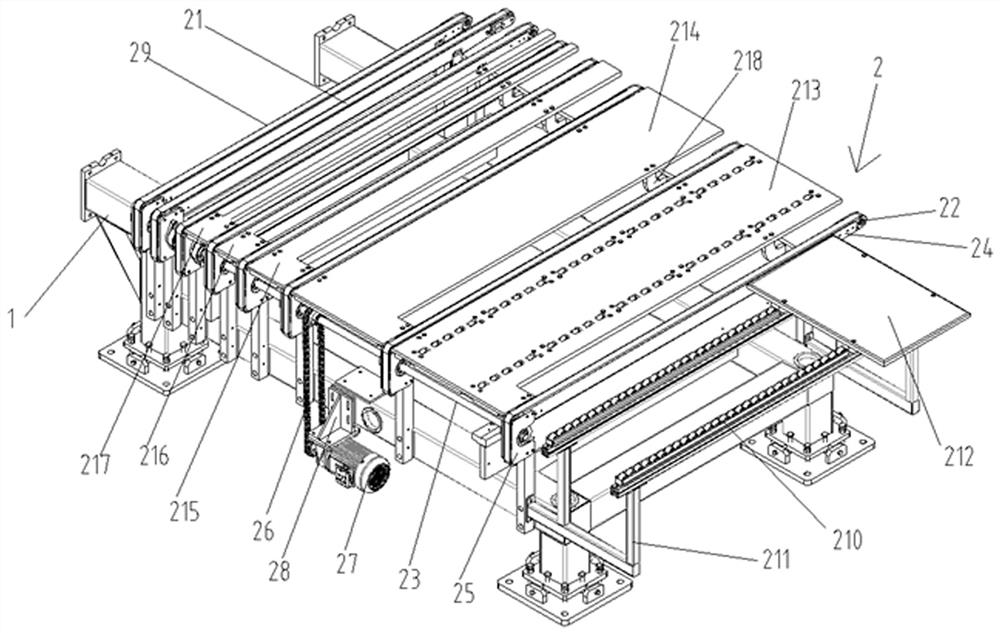

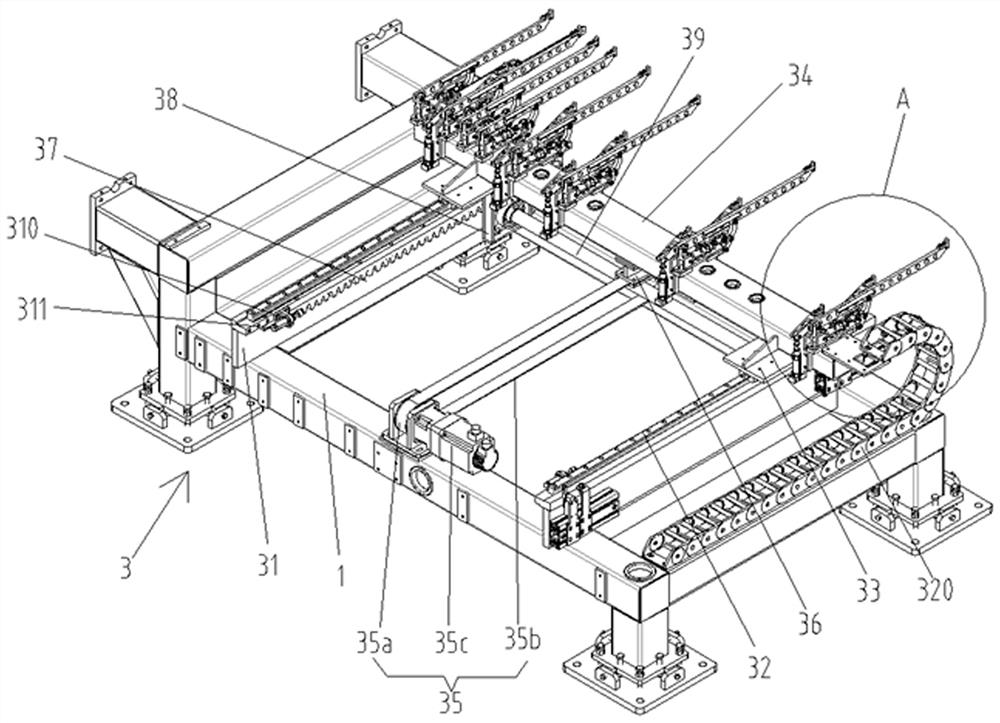

Efficient flexible plate inlet machine used for positioning, tracking and correcting of plates

ActiveCN110936463AResolve skewAutomatic connection is efficientWood working apparatusDomestic articlesClassical mechanicsMachine

The invention discloses an efficient flexible plate inlet machine used for positioning, tracking and correcting of plates. The efficient flexible plate inlet machine comprises a rack (1). A conveyingdevice (2) is arranged on the rack (1). The conveying device (2) comprises long synchronous belts (21), and a push claw device (3) is arranged at the position, between the long synchronous belt (21),on the rack. A flexible abutting and blocking device (4) and a flexible pressing wheel device (5) are arranged on one side of the rack (1), and a flexible correction device (6) is arranged on the rearside of the rack (1). The flexible correction device (6) comprises a portal frame (61), a set of blocking claw devices (62) arranged on the portal frame (61) and a squaring device (63). The efficientflexible plate inlet machine has the beneficial effects that the problem of plate deflection is avoided, pretreatment can also be conducted on parallelogram-similar plates, the automation degree andthe plate inlet efficiency are improved, and the plate quality is improved.

Owner:杨万国

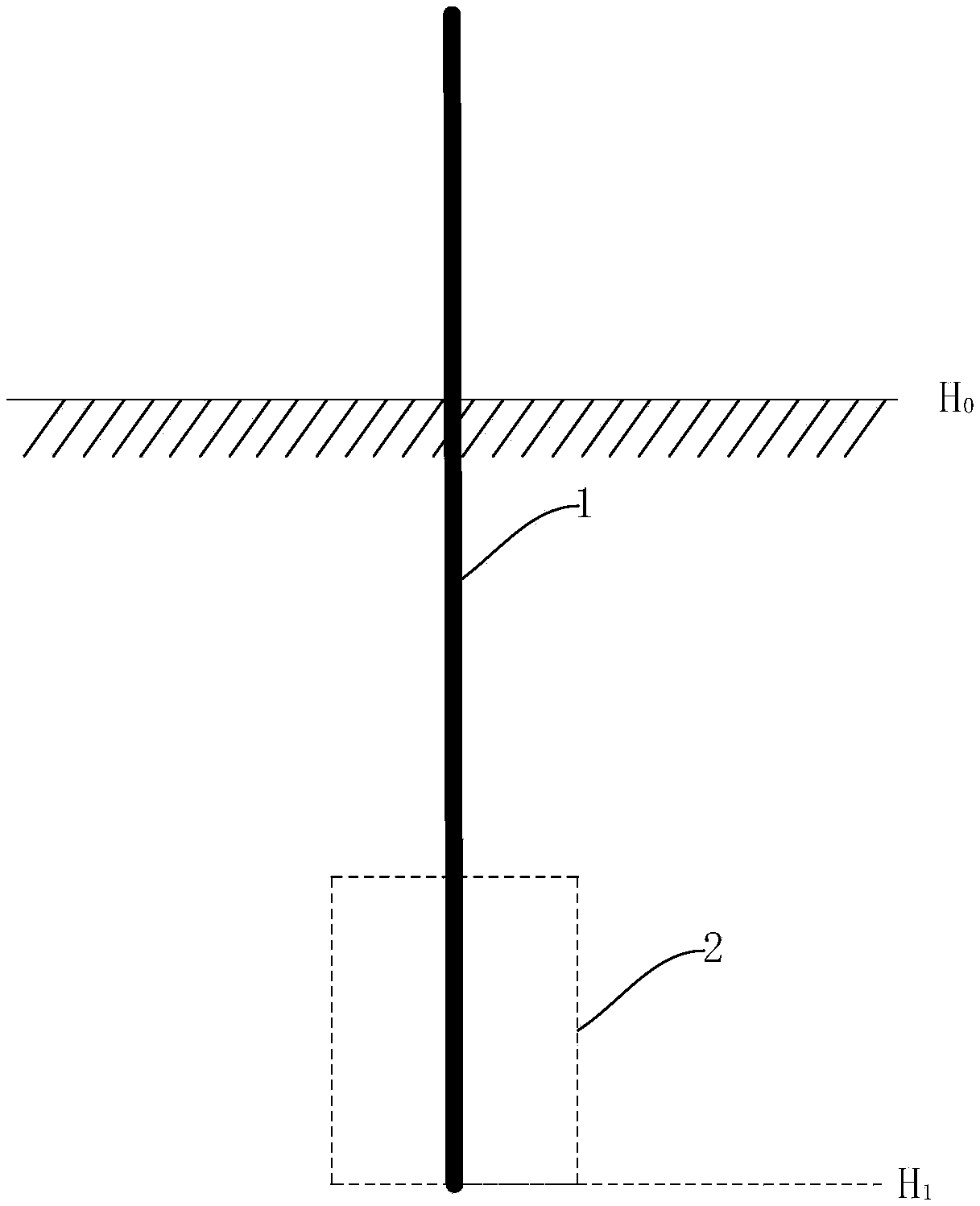

Anti-floating anchor rod construction method

ActiveCN109183857ASynchronous maintenanceSpeed up the scheduleProtective foundationEngineeringHigh pressure

The invention discloses an anti-floating anchor rod construction method. According to the anti-floating anchor rod construction method, an anchor rod is constructed before a foundation pit is excavated, a reinforcing part is formed in the soil body surrounding the upper part of the anchor rod through high-pressure rotary spraying, and it is guaranteed that the anchor rod does not deflect when thefoundation pit is excavated. In addition, beforehand construction of the anti-floating anchor rod can be synchronized with the construction of a pile foundation and the maintenance, no extra construction period is occupied, and thus the construction period progress can be accelerated; the anti-floating anchor rod can be constructed before the foundation pit is excavated, so that the problem that the working plane after excavation is not beneficial to mechanical construction due to the fact that the soil at the bottom of the foundation pit is poor is solved; and the high-pressure rotary spraying method is adopted by the construction method, partial cement soil below the designed excavation bottom plane is reinforced, so that the stability of the anchor rod itself and the stability of the whole foundation pit, especially the soft soil foundation pit, are enhanced.

Owner:浙江坤德创新岩土工程有限公司

Shallow foundation building rectification and reinforcement structure and construction method thereof

ActiveCN109537653AReduce lossesSave spaceProtective foundationPolyurea/polyurethane coatingsEngineeringStructural engineering

The invention discloses a shallow foundation building rectification and reinforcement structure. The structure comprises a shallow foundation building part and a rectification and reinforcement part,and the rectification and reinforcement part is fixedly installed on the shallow foundation building part. Accordingly, the stability is good, the reinforcement effect is good, the structure is suitable for rectifying deflection occurring after construction of a shallow foundation building is completed, the problem that in the prior art, deflection occurring after construction of the shallow foundation building is completed is effectively solved, the phenomenon that deflection occurs again on a vertical wall in the later period can be prevented, in the installation process, the structure is moistly installed on the outer side of the vertical wall, and the loss brought by conducting rectification on the shallow foundation building can be effectively lowered. According to the construction method, the rectification and reinforcement part can be prefabricated and formed, the construction speed can be greatly increased, and meanwhile the construction difficulty can be lowered, the construction steps are simple, the construction process is safe, not only can the personal safety of constructors be guaranteed, but also the working intensity of the constructors can be lowered.

Owner:NANTONG SIJIAN CONSTR GRP

Laser cutting equipment capable of realizing multi-station circulating operation

ActiveCN111906457AResolve skewArrangement is simple and convenientLaser beam welding apparatusLaser cuttingMechanical engineering

The invention relates to laser cutting equipment capable of realizing multi-station circulating operation. The equipment comprises a base, a fixing and position changing unit and a feeding and cuttingunit; the fixing and position changing unit is arranged on the inner wall of the lower end of the base; and the feeding and cutting unit is arranged at the upper end of the base. According to the equipment, by means of the design concept of multi-station reciprocating cutting of axial feeding, the problem that during multi-station plate cutting, the larger the number of stations is, the larger the equipment is is solved, the size of the equipment installation space is reduced while the cost of a factory is saved, and therefore arrangement of stations of the factory is simpler and more convenient; according to the equipment, the fixed ends of the feeding position and the cutting position are inconsistent through separation of feeding and cutting, so that a plate is fed in the mode of feeding during fixing in a subdivision mode, the plate is completely fixed during cutting, and the problem that the plate can deflect due to the fact that the plate is not limited when the fixed length isfed is solved.

Owner:武汉御拓激光设备有限公司

Material strip deflection correction control device and method

InactiveCN102180374AResolve skewGuaranteed transmission qualityWebs handlingControl systemClassical mechanics

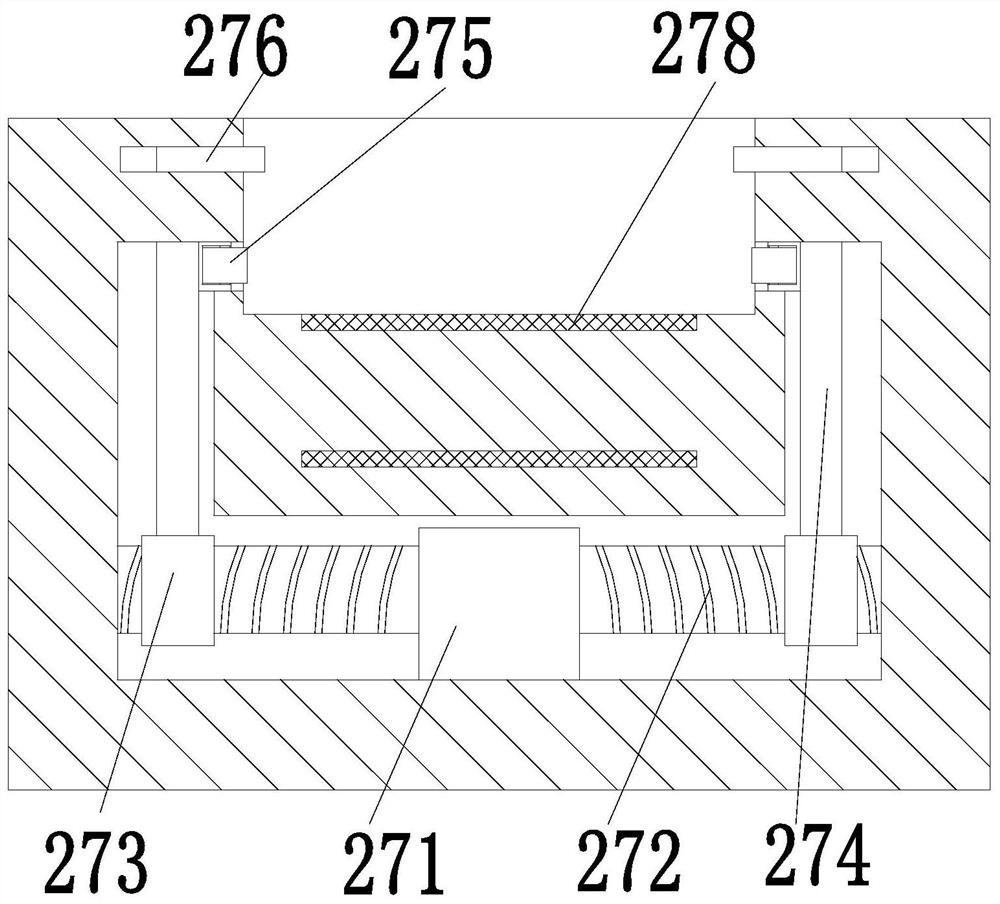

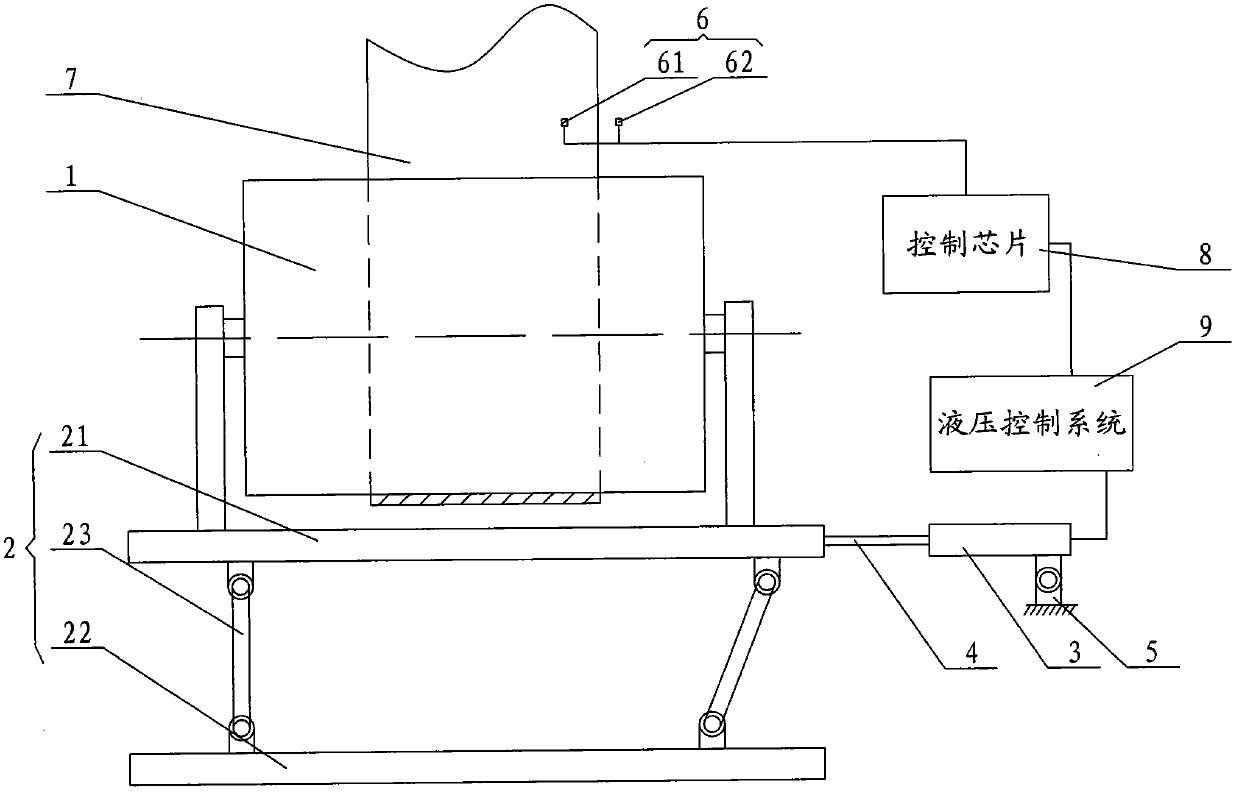

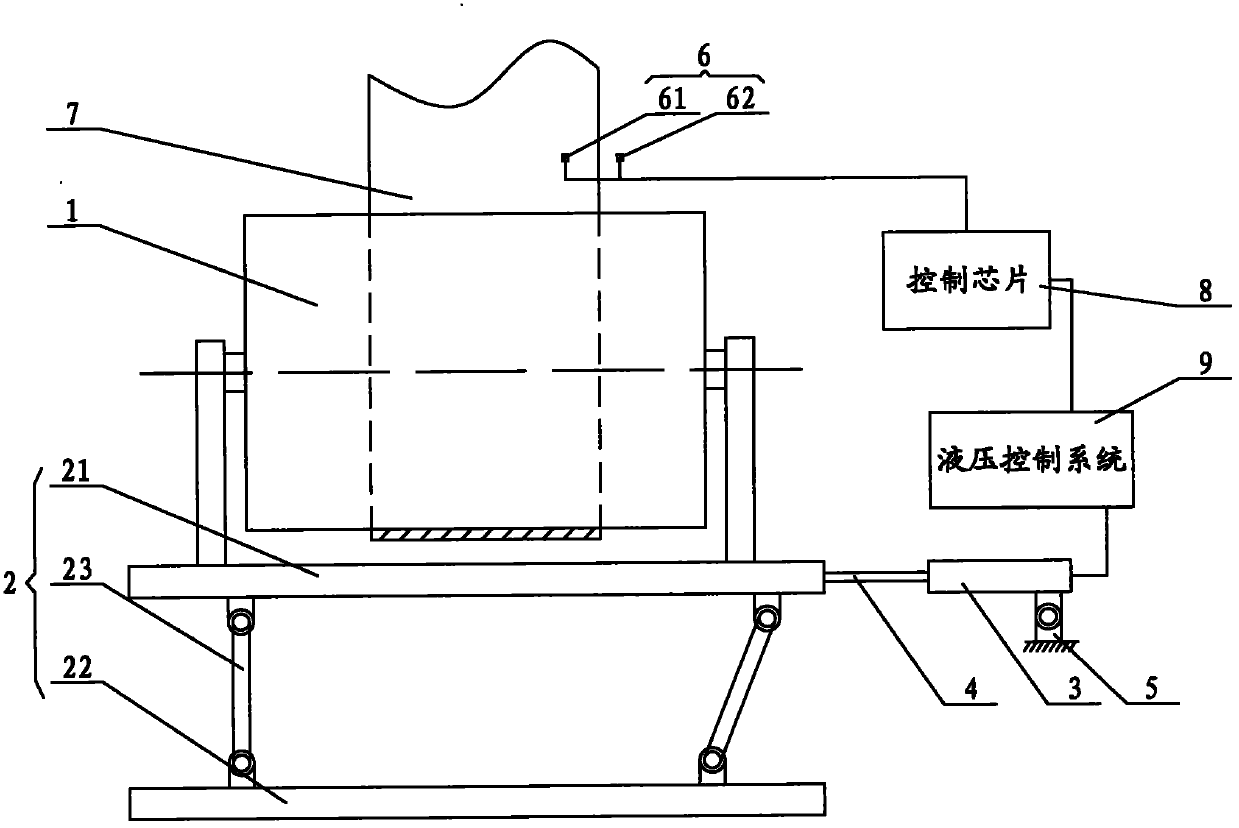

The invention provides a material strip deflection correction control device which mainly comprises a roller, a roller slope control mechanism, a driving cylinder and two photosensors mounted on one side edge of a material strip. The material strip deflection correction control device is characterized in that the roller is mounted on the roller slope control mechanism; one end of the roller slope control mechanism is connected with the piston rod of the driving cylinder; the two photosensors are respectively located on the outer side and inner side of one side edge of the material strip, and are electrically connected to a control chip; the driving cylinder is connected with a hydraulic control system; and the hydraulic control system is electrically connected with the control chip. Through the roller slope control device, an upper panel can be driven by the piston rod of the driving cylinder to move left and right, and the upper panel can be driven by two hinged support plates to generate deflection in the horizontal direction during the movement of the upper panel so as to control the force of the material strip on the roller and finally adjust the position of the material strip on the roller. The invention also discloses a material strip deflection correction control method.

Owner:唐虎

Device and method for governing oil-water-well oil-string-casing channeling

The invention discloses a device and method for governing oil-water-well oil-string-casing channeling, and belongs to the technical field of oil extraction equipment. The device comprises a jacking cylinder, a jacking nut, a base cylinder and tension pieces; the jacking cylinder sleeves an oil-string casing, a first flange extending outwards is arranged at the upper end of the jacking cylinder, and an external thread is formed in the outer wall of the jacking cylinder; the jacking nut sleeves the jacking cylinder, and an internal thread matched with the external thread in the outer wall of thejacking cylinder is formed in the inner wall of the jacking nut; the base cylinder comprises a supporting section and a packing section which are sequentially connected from top to bottom; the packing section is located in annular space between a surface casing and the oil-string casing, clamping teeth capable of being clenched with the outer wall of the oil-string casing are arranged on the inner wall of the packing section, and the jacking cylinder can enter the supporting section; a second flange extending downwards is arranged at the connecting portion of the supporting section and the packing section; the first flange, the second flange and a surface casing head flange are fixed through the tension pieces; the first flange is also fixed to a large four-way lower flange.

Owner:PETROCHINA CO LTD

Double-way stacking machine

The invention relates to the field of disposable sanitary product equipment, in particular to a double-way stacking machine. The double-way stacking machine comprises a machine frame, an input mechanism, a first conveying mechanism, a first stacking apparatus, a second conveying mechanism and a second stacking apparatus, and the input mechanism, the first conveying mechanism, the first stacking apparatus, the second conveying mechanism and the second stacking apparatus are arranged on the machine frame according to the production line; a flow-distribution shifting piece mechanism is disposed on the machine frame and comprises a support disposed on the machine frame, a servo motor disposed on the support and two impellers which are rotationally disposed on the support; the two impellers arein transmission connection with the servo motor; when the impellers swing, the advancing path of product inputting of the input mechanism can be blocked or non-blocked. When the path is non-blocked,the input mechanism communicates with the first conveying mechanism so as to convey products; and when the path is blocked, the products of the input mechanism move downwards to enter the second conveying mechanism. The technical problems that in existing stacking procedures, the products are input only in one way, and the working efficiency is low are solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

Mesh correcting tool

The invention discloses a mesh correcting tool and relates to the technical field of injection molding tools. The mesh correcting tool comprises a front-side mesh correcting mechanism and a lateral-side mesh correcting mechanism. The front-side mesh correcting mechanism comprises four front-side mesh correcting jaws respectively located on the periphery of a front-side mesh sucker, the four front-side mesh correcting jaws open and close by the aid of power provided by a four-jaw air cylinder, and a linkage block is connected to one of the four front-side mesh correcting jaws. The lateral-side mesh correcting mechanism comprises lateral-side mesh correcting jaws arranged on two sides of a lateral-side mesh sucker, a linkage part matched with the linkage block is arranged at the end of each of the two lateral-side mesh correcting jaws, the linkage parts and the linkage block are coordinated to allow the two lateral-side mesh correcting jaws to open and close, a limit rod transversely penetrates the two lateral-side mesh correcting jaws, and a return spring is arranged on the limit rod. The mesh correcting tool has the advantages that front-side mesh and lateral-side mesh can be corrected at the same time, injection molding product yield is increased greatly, a large amount of manpower and material resources are saved, and enterprise production cost is lowered.

Owner:GOERTEK INC

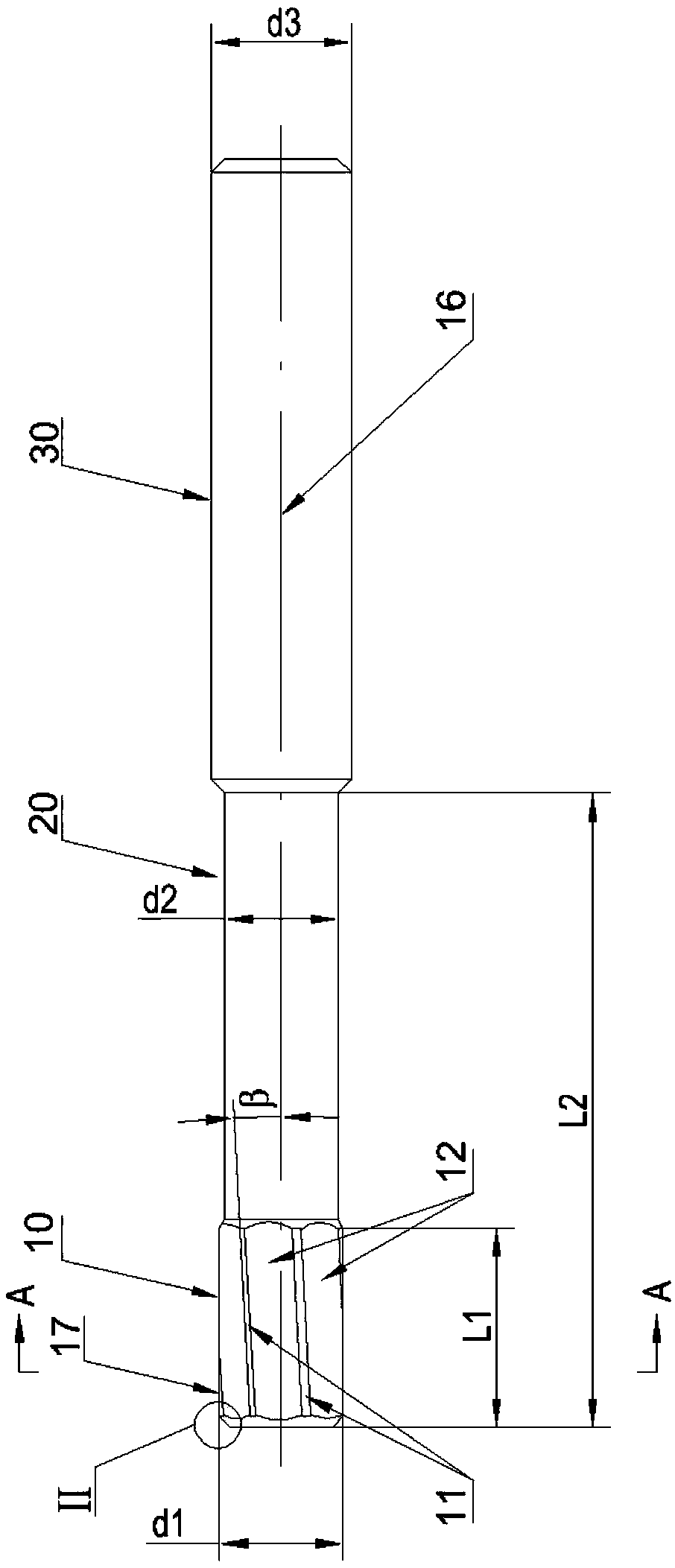

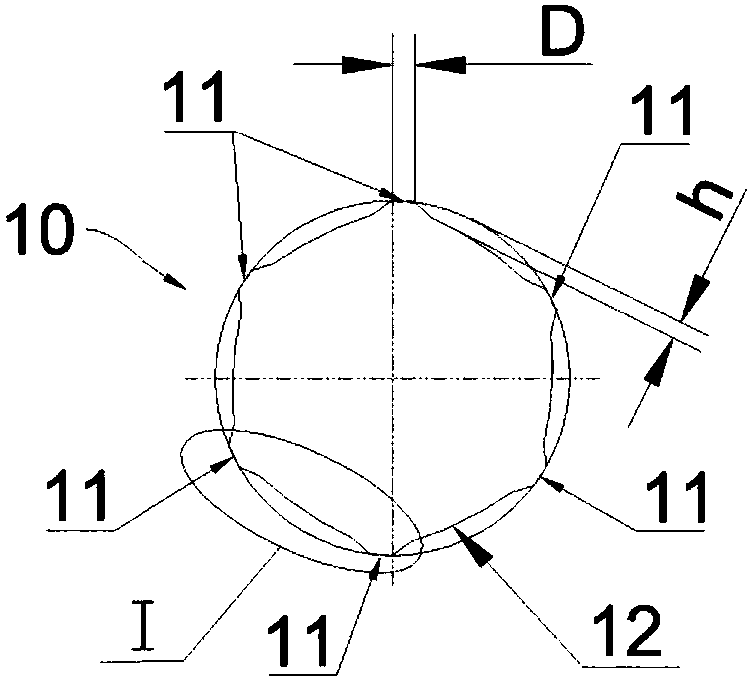

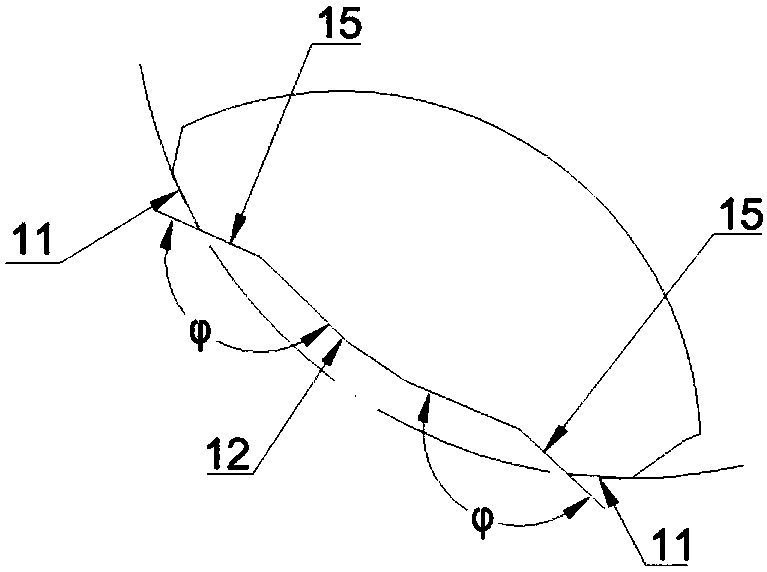

Burnishing reamer for high precision deep-hole processing

PendingCN108176896AReduce processing difficultyMachining Difficulty GuaranteedReaming toolsReamerComputer science

The invention provides a burnishing reamer for high precision deep-hole processing. According to the burnishing reamer for the high precision deep-hole processing, the problems that the precision is low, the service life is short, the quality of hole processing cannot meet technical requirements in a traditional deep-hole processing tool are solved. The burnishing reamer for the high precision deep-hole processing comprises a first cylinder, a second cylinder and a third cylinder, wherein the first cylinder, the second cylinder and the third cylinder are coaxial and are connected with each other in sequence and in order. The first cylinder is a head of the reamer with a diameter of d1. The second cylinder is a neck with a diameter of d2, and the diameter of the neck is d2=d1-0.5mm. The third cylinder is a handle with a diameter of d3. Six levorotatory guiding lands distribute on the outer circumference of the reamer head at intervals. A carved camber surface can be formed by the carving on the back portions of the adjacent guiding lands.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

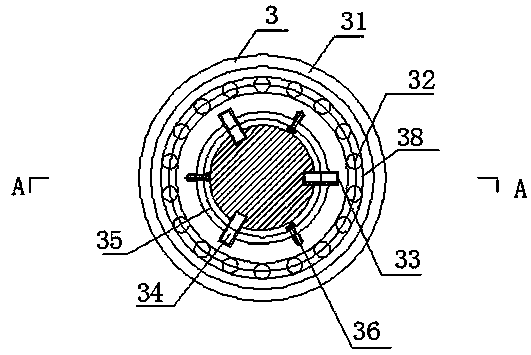

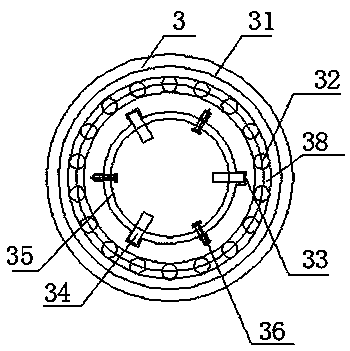

Occlusion pile flat cage hoisting-placing deviation-rectifying device

ActiveCN109368495AHighly consistentGuaranteed thicknessClimate change adaptationLoad-engaging elementsReinforced concreteEngineering

The invention discloses an occlusion pile flat cage hoisting-placing deviation-rectifying device. The occlusion pile flat cage hoisting-placing deviation-rectifying device comprises a rod body and a sliding device, wherein the rod body is a cylindrical rod, and the section of the rod body is provided with three sets of sliding grooves in the axial direction, the two ends of the rod body are provided with skid resistant layers correspondingly, the middle of the rod body is fixedly connected with a blocking block in a sleeved manner, the sliding device is composed of an axial sliding bearing setand a radial rotating bearing, the axial sliding bearing set comprises an annular connection shaft and auxiliary bearings, the auxiliary bearings are arranged three sets, and the auxiliary bearings are evenly distributed on the section of the annular connection shaft, the section of the radial rotating bearing is provided with a closed groove in the circumferential direction, and the middle of the radial rotating bearing is provided with sliding steel ball bodies, and the inner wall of the radial rotating bearing is provided with three sets of grooves. By means of the occlusion pile flat cagehoisting-placing deviation-rectifying device, guarantee of the protective layer thickness of a reinforced concrete structure is facilitated, on the other hand, relative to manual deviation-rectifying, labor can be saved, and the labor intensity is lowered.

Owner:CHINA RAILWAY TUNNEL GRP ROAD & BRIDGE ENG CO LTD

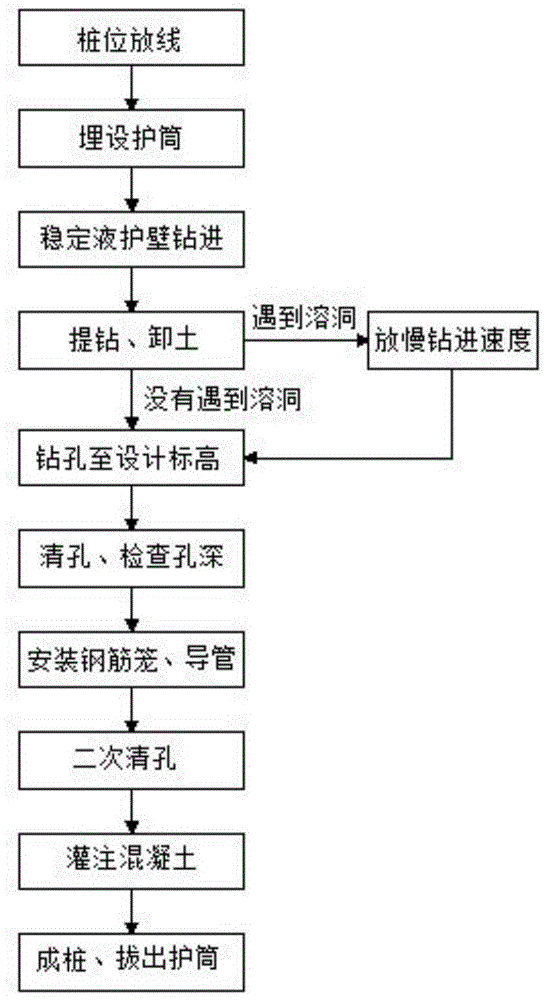

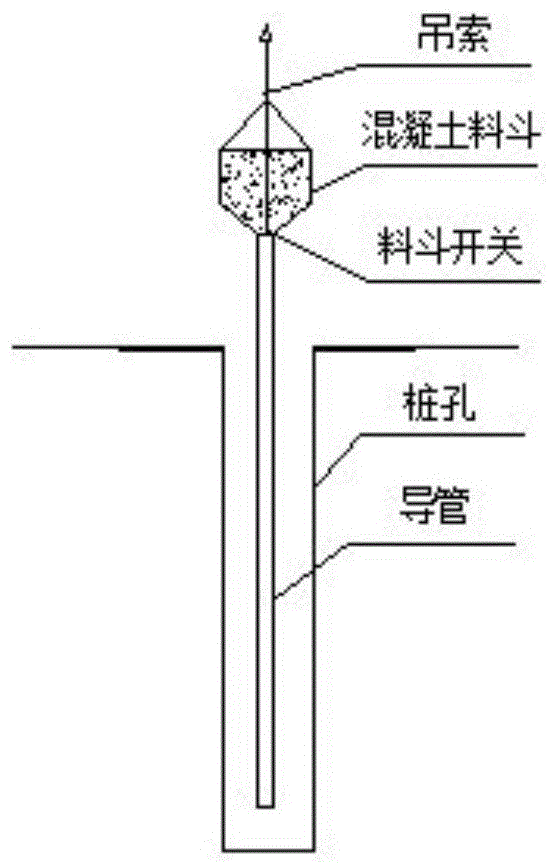

A karst geology rotary-dig cast-in-place pile hole-forming technology

The invention discloses a karst geology rotary-dug cast-in-place pile hole-forming process, which comprises the following steps: (1) leveling the site; (2) laying out the pile foundation; (3) putting a rotary drilling rig in place; (4) laying a casing; (5) Preparation of mud stabilization fluid and replenishment of mud stabilization fluid in the casing; (6) Rotary drilling into holes (slow down the drilling speed when encountering karst caves or half rocks, and drill to the bottom when not encountering karst caves or half rocks design elevation); (7) primary hole cleaning and hole depth inspection; (8) installation of reinforcement cages and conduits; (9) gas lift reverse circulation secondary hole cleaning; (10) pouring underwater concrete (considering the existence of karst caves, Prepare 30 to 40 cubic meters of concrete more to prevent the cave from breaking down, and the concrete will drop sharply to cause waste piles); (11) Form piles and pull out the casing.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Triple phase cutting hole machining tool and machining process for copper cooling wall

PendingCN110539018AReduce vibrationGood orientationTransportation and packagingBoring/drilling machinesCopperMachining process

The invention discloses a triple phase cutting hole machining tool and a triple phase cutting hole machining process for a copper cooling wall. According to the machining tool and the machining process, a drill bit body is provided with a guide groove; the drill bit body can realize direction guidance in a deep hole machining process by virtue of the guide groove; meanwhile, when the machining tool is used for machining a region of which the hole position is relatively deep, the drill bit body is additionally provided with a drill bit extension bar; the outer wall of the drill bit extension rod is provided with a plurality of guide bumps; by the structure setting, the drill bit body adopts a shape design that a spiral guide groove is provided, the guidance effect of the spiral guide groovecan reduce the vibration, at the inlet, of the drill bit body, can improve the guidance capability of the drill bit body, and can reduce hole deflection; and when the machining tool is used for machining a relatively deep hole, a plurality of guide bumps on the outer wall of the drill bit extension bar can effectively realize extension guidance so as to further guarantee the stability in machining of a center hole.

Owner:DEZHOU SANJIA MACHINE MFG

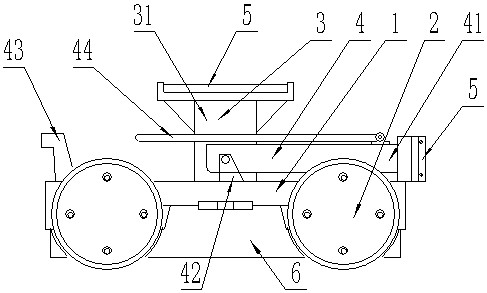

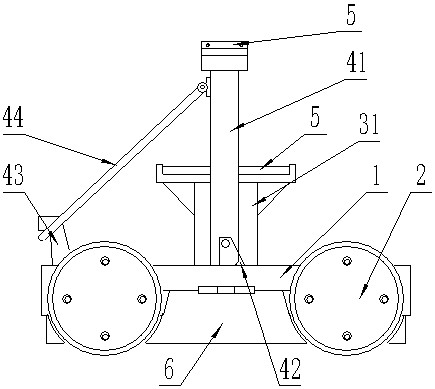

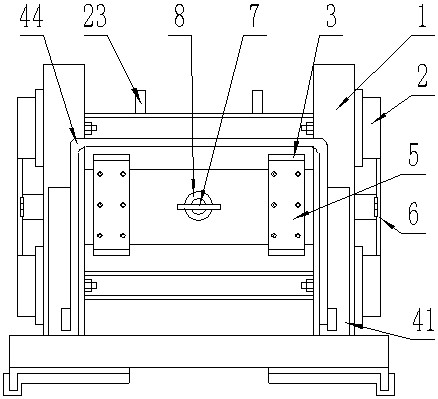

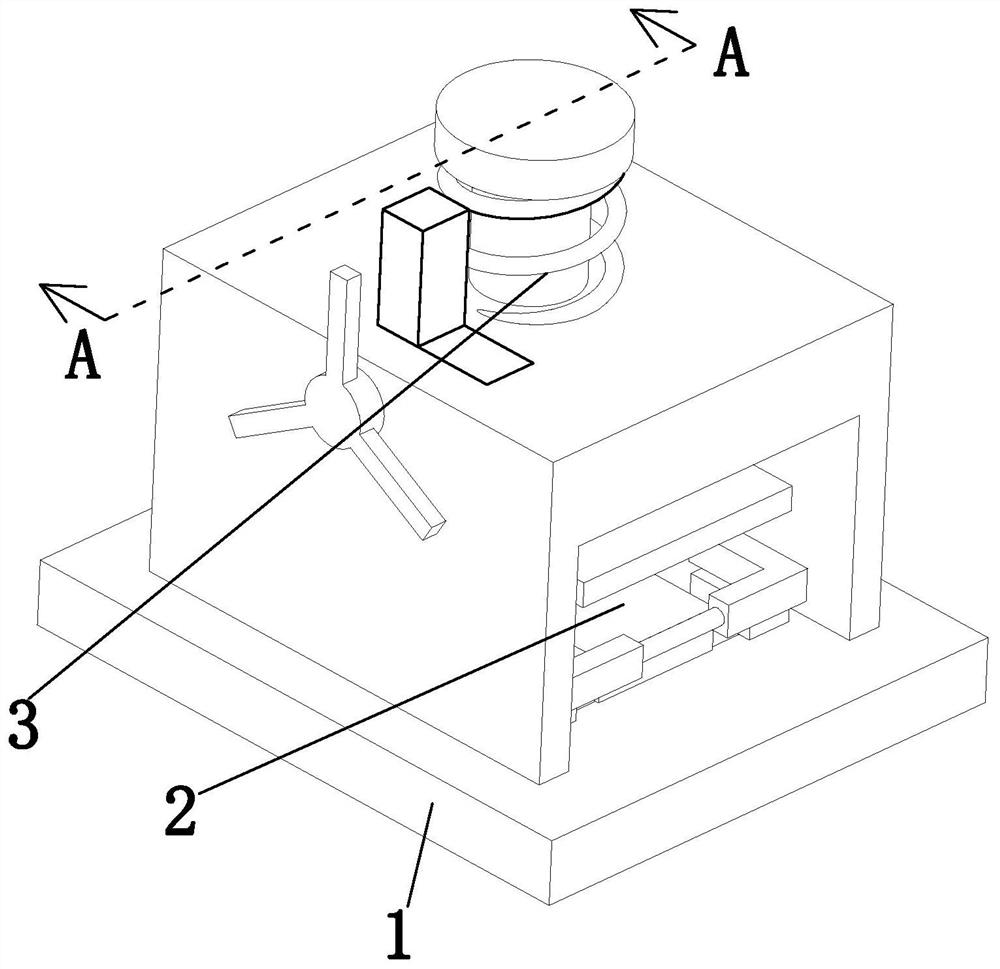

Bearing trolley, assembling and conveying equipment, underground mine car assembly line and operation method of underground mine car assembly line

PendingCN114770064AAvoid falling overImprove assembly efficiencyAssembly machinesVehicle componentsSuspension (vehicle)Vehicle frame

The invention relates to the field of standard assembly of underground mine cars, in particular to a bearing trolley, assembly conveying equipment, an underground mine car assembly line and an operation method of the underground mine car assembly line. The first station, the second station, the third station, the fourth station, the fifth station, the sixth station, the seventh station, the eighth station and the ninth station are sequentially distributed in the length direction of the cover plate. The bearing frame is arranged above the ground drag chain, and the bearing frame covers the third station, the fourth station, the fifth station, the sixth station and the seventh station; and suspension rail cranes are detachably connected to the positions, located above the fourth station, the fifth station, the sixth station and the seventh station, of the bearing frame correspondingly. Due to the fact that the ground drag chain is matched with the trolley to serve as a device for conveying the vehicle frame, the vehicle frame is conveyed at a constant speed or a variable speed, the vehicle frame passes through the first station, the second station, the third station, the fourth station, the fifth station, the sixth station, the seventh station, the eighth station and the ninth station, the vehicle frame is sequentially assembled and offline, and therefore standardized production is completed.

Owner:陕西安程合创设备有限公司

High-precision attaching system for mobile phone screen tempered film

InactiveCN112793146AResolve skewSolve the problem of not being able to adapt to the work of the street filmEngineeringMechanical engineering

The invention relates to a high-precision attaching system for a mobile phone screen tempered film. The system comprises a base, a clamping mechanism and a film attaching mechanism, the clamping mechanism is arranged in the middle of the upper end of the base, and the film attaching mechanism is arranged at the upper end of the base. According to the system, a tempered film and a mobile phone are attached in a flush mode through a machine, bubbles generated in the film attaching process are removed through a manual assistance method, and therefore the problem that the tempered film and the mobile phone deflect to a certain degree in the manual film attaching process is solved; and according to the system, various mobile phones of different specifications and matched tempered films are clamped in an adjustable mode, so that the problem that the clamping function of a single specification cannot adapt to the work of film attaching on the street due to the fact that the mobile phones have many styles in the film attaching on the street is solved.

Owner:张伟南

A kind of anti-floating anchor construction method

ActiveCN109183857BSynchronous maintenanceSpeed up the scheduleProtective foundationArchitectural engineeringSoil cement

Owner:浙江坤德创新岩土工程有限公司

Retaining wall type caisson sinking device and its construction method

The invention discloses a retaining wall type open caisson sinking device and a construction method of the retaining wall type open caisson sinking device. The retaining wall type open caisson sinking device comprises a door type support unit, a deviation rectification unit, a sinking-assisting unit and an auxiliary unit. The door type support unit is composed of a device foundation, a door-type support and side supporting frames. The deviation rectification unit comprises an inner retaining wall, an outer retaining wall and slinging chains. The sinking-assisting unit comprises a device layer, an inner air box, an outer air box and longitudinal high-pressure air conveying pipelines. The auxiliary unit is composed of a headstock gear and an electromagnet. The retaining wall type open caisson sinking device further comprises a posture monitoring unit composed of a posture sensor and a controller processor. The construction method of the retaining wall type open caisson sinking device is used for constructing an open caisson with a deep overburden foundation and with the high automation degree, enabling the posture of the open caisson to be monitored in real time and enabling deviation rectification to be conducted on the posture of the open caisson in time. According to the retaining wall type open caisson sinking device and the construction method of the retaining wall type open caisson sinking device, when the open caisson sinks due to the dead load, new measures such as sink assistance, deviation rectification, the electromagnet and the retaining walls are thoroughly combined, it is guaranteed that sinking of sections of the open caisson can be continuously, effectively and accurately conducted on the deep overburden foundation, the automation degree is high, and mutual interference between open caissons is small.

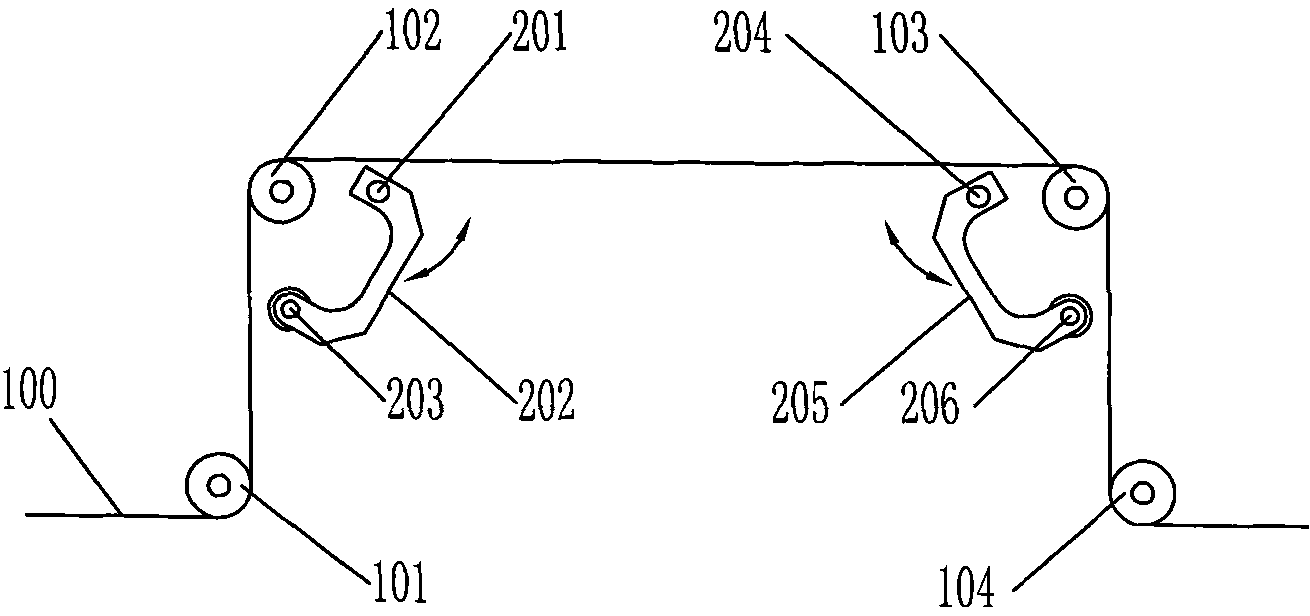

Owner:HOHAI UNIV +1

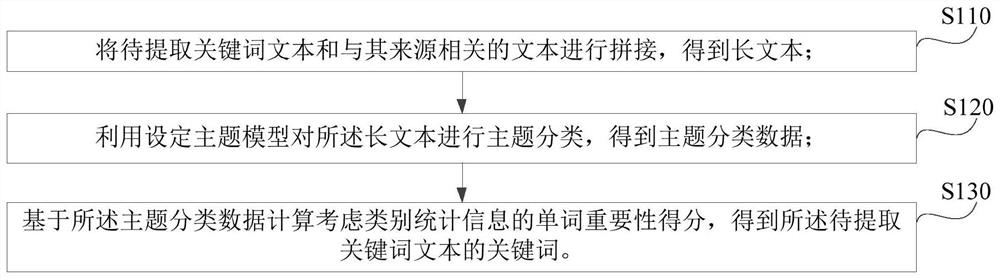

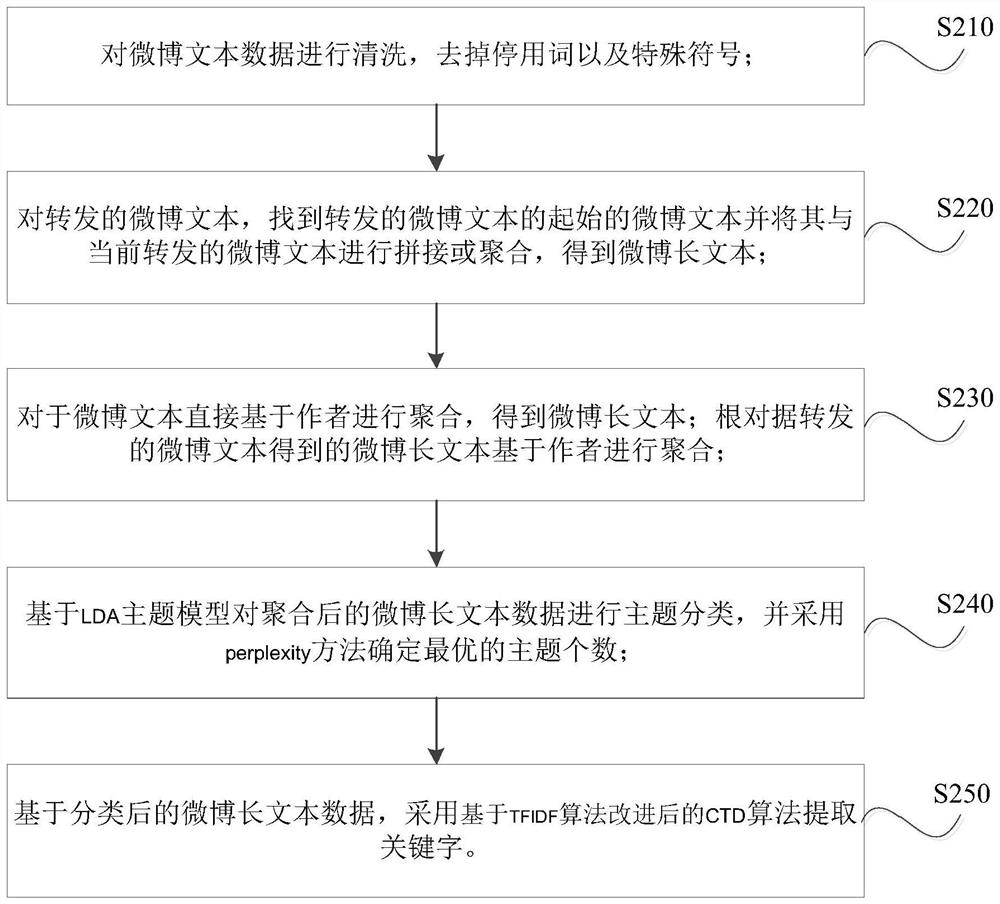

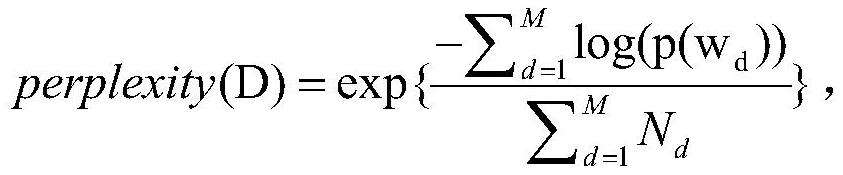

Short text keyword extraction method and device

PendingCN114386393ASolve short problemsImprove accuracyNatural language data processingText database queryingData setData mining

The invention provides a short text keyword extraction method and device.The method comprises the steps that a to-be-extracted keyword text and a text related to the source of the to-be-extracted keyword text are spliced, and a long text is obtained; performing theme classification on the long text by utilizing a set theme model to obtain theme classification data; and calculating a word importance score considering category statistical information based on the subject classification data to obtain keywords of the text to be subjected to keyword extraction. By means of the scheme, the problems that the short text is short and the data set deflects due to the fact that text differences in all fields are large can be solved, and therefore the accuracy of keyword extraction on the short text can be improved.

Owner:电科云(北京)科技有限公司

A furnace temperature uniformity test tool and test bracket

ActiveCN105466230BImprove work efficiencyEasy to useThermometer detailsFurnace componentsFurnace temperatureEngineering

The invention relates to a furnace temperature uniformity test tool and a test bracket. The furnace temperature uniformity test tool includes a test rod extending into the furnace along the axial direction of the furnace and a thermocouple fixed and installed at the front end of the test rod. The temperature measuring fixed body is provided with at least two thermocouples at intervals along the radial direction of the furnace and located on the same plane in the radial direction of the furnace, and the temperature measuring fixed body is also provided with corresponding thermoelectric Thermocouple fixing structure for couple installation. At this time, the mesh belt of the mesh belt furnace does not need to open the driving device, and the test rod is manually inserted into different positions of the furnace, which not only solves the vibration of the mesh belt caused by the movement of the temperature measuring frame with the mesh belt in the prior art The temperature measurement frame is skewed. In the prior art, due to the skew of the temperature measurement frame, the thermocouples that were originally in the same plane are no longer located in the same plane, resulting in detection failure. Moreover, this test tool improves work efficiency and is easy to use. .

Owner:河南航天精工制造有限公司

Battery pole shoe rectification mechanism

ActiveCN101447565BResolve skewQuality improvementElectrode manufacturing processesFinal product manufactureEngineeringPosition sensor

The invention provides a battery pole shoe rectification mechanism which comprises a power plant and a rectifying transition wheel that can reciprocate along a self-axial direction under the driving of the power plant. A position sensor, a spacing sensor and a transition device can also be arranged in the battery pole shoe rectification mechanism. Even the battery pole shoe stops running, the battery pole shoe rectification mechanism can also rectify the position of the pole shoe directly and process the pole shoe at a rectified part, without considering the problems that whether the pole shoe is in a running state and rectification lag, etc. The battery pole shoe rectification mechanism can effectively solve the deflexion problem of the battery pole shoe, ensure the normal proceeding of subsequent procedures and improve the battery quality. The mechanism has the advantages of simple structure, convenient operation and easy implementation.

Owner:SHENZHEN YINGHE TECH

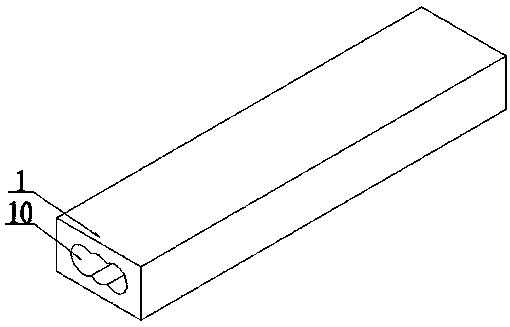

A high-efficiency flexible board feeding machine for board positioning tracking calibration

ActiveCN110936463BResolve skewAutomatic connection is efficientWood working apparatusDomestic articlesControl engineeringMachine

The invention discloses a high-efficiency flexible plate feeding machine for plate positioning, tracking and calibration, comprising a frame (1), a conveying device (2) is arranged on the frame (1), and the conveying device (2) comprises a long synchronous belt (21), the frame (1) between the long synchronous belts (21) is provided with a push claw device (3), and one side of the frame (1) is provided with a flexible stop device (4) and a flexible pressure roller device (5), a flexible calibration device (6) is provided on the rear side of the frame (1), and the flexible calibration device (6) includes a gantry frame (61) and a set of follower claw devices arranged on the gantry frame (61). (62) and a square device (63). The advantages of the invention are that the problem of plate deflection is avoided, the parallelogram-like plate can be pretreated, the automation degree and plate feeding efficiency are improved, and the quality of the plate is improved.

Owner:杨万国

Lifting mechanism for glass conveying roller way

InactiveCN106516747AImprove synchronicitySimple structureCharge manipulationConveyor partsDrive shaftSprocket

The invention discloses a lifting mechanism for a glass conveying roller way. The lifting mechanism comprises a lifting mechanism base framework and a motor, wherein the lifting mechanism base framework comprises a front lifting mechanism base and a rear lifting mechanism base; a left transmission shaft and a right transmissions haft are mounted between the front lifting mechanism base and the rear lifting mechanism base through a bearing base; the two ends of the right transmission shaft are separately equipped with cranks; the outer end of the left transmission shaft is connected with the motor through a drive chain wheel and a drive chain; and the left transmission shaft is connected with the right transmission shaft through a transmission chain wheel and a transmission chain. The lifting mechanism disclosed by the invention is simple in structure, and is convenient to manufacture, mount and debug, and solves the declining problem, in a lifting process, of glass plates.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

A centering positioning device for connecting piles

ActiveCN108330974BGuaranteed alignmentFlexible adjustment of embedding depthBulkheads/pilesData platformStructural engineering

Owner:WUHAN UNIV +2

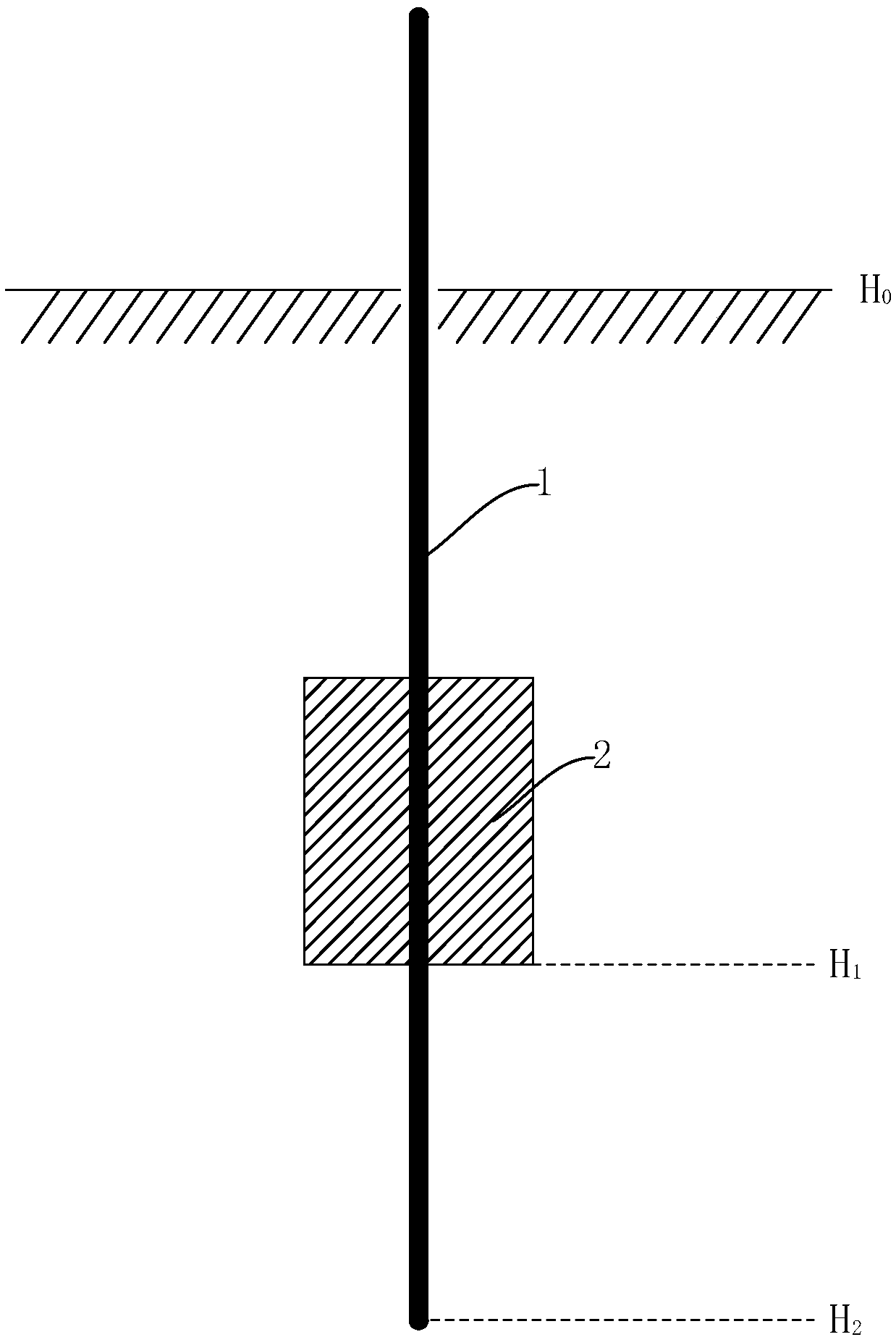

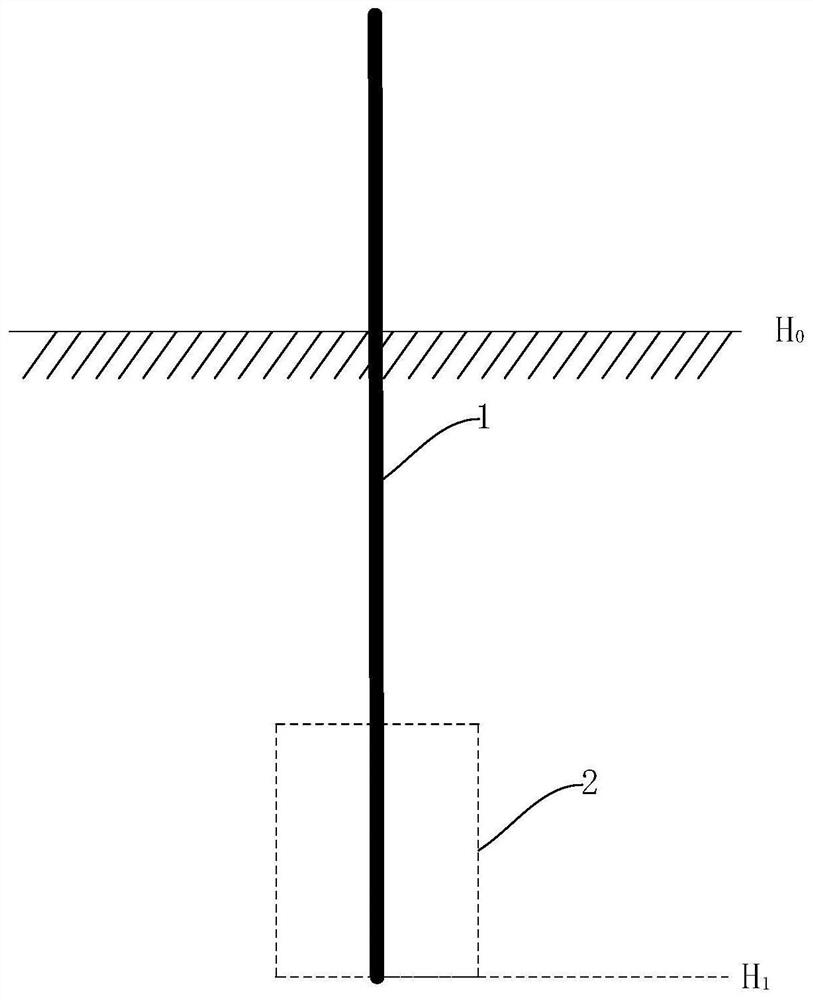

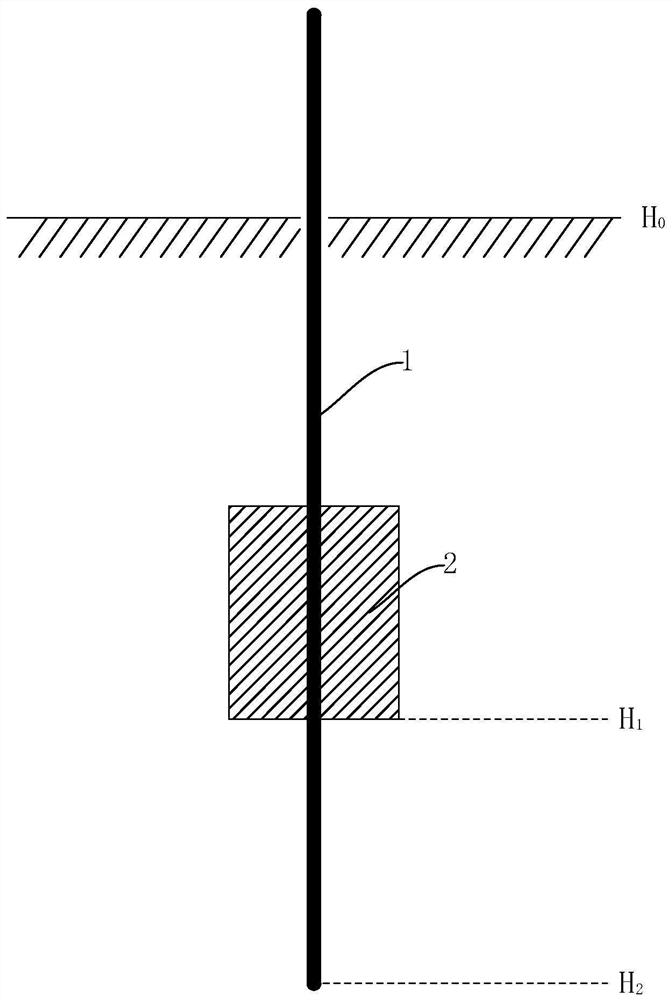

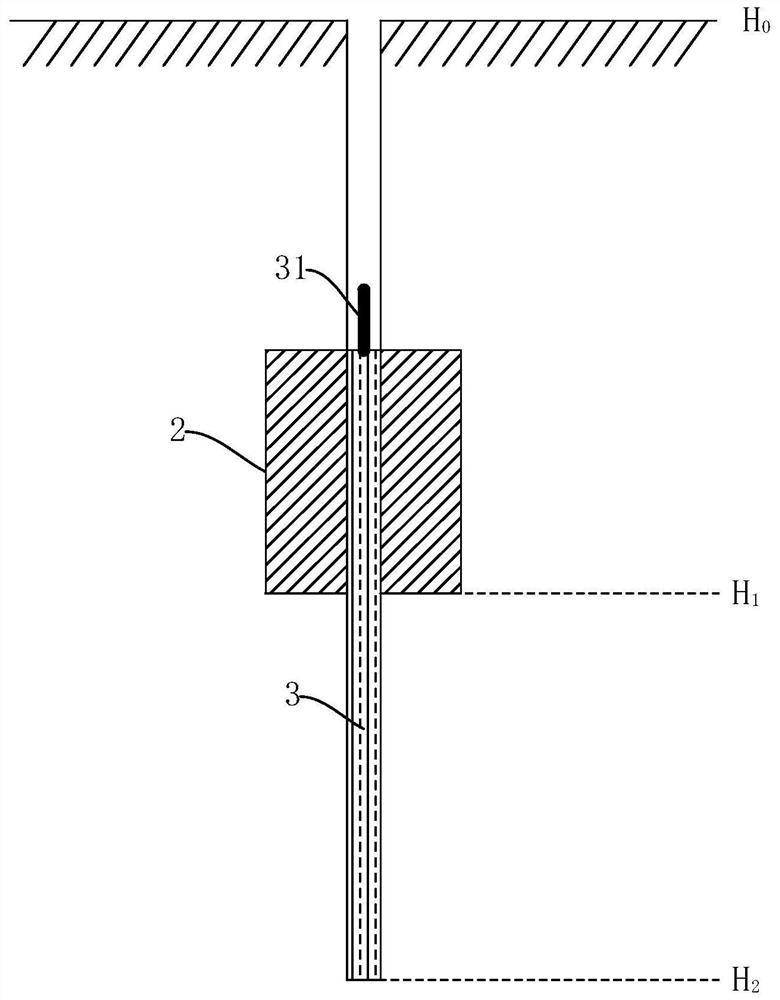

A kind of construction method of immersed pipe grouting pile

The invention discloses a construction method of a sinking tube grouting pile, and aims to provide a construction method of a sinking tube grouting pile which can effectively solve the problem of deflection due to the interference of stones during the pile tube sinking process. It includes the following steps: first, the pile point and the pile pipe are in place, and the pile pipe includes the inner pile pipe, the outer pile pipe sleeved outside the inner pile pipe and the outer lamination pile sleeved outside the inner pile pipe. pipe; second, the pipe sinking process, the pipe sinking process includes the following steps in turn, 1), using the pile sinking equipment to press the pile pipe and the pile point into the soil together until the pile point is pressed into the soil layer with a set depth of H1 meters ; 2), remove the outer laminating tube; 3), use the pile sinking equipment to press down the inner pile tube and the pile tip together; 4), put the outer laminating tube on the inner pile tube, and then, Use pile sinking equipment to press down the outer pressure tube and the outer pile tube together; 5) Return to step 2) and repeat like this until the pile tube and the pile tip are pressed into the soil to a set depth.

Owner:浙江中正岩土技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com