Mesh correcting tool

A technology of tooling and mesh, which is applied in the field of synchronous correction tooling of front mesh and side mesh for injection molding, can solve problems such as deflection of injection molding mesh, and achieve the effect of solving deflection and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0020] The orientations involved in this manual are all based on the orientation of the mesh calibration tool of the present invention when it is in normal operation, and do not limit its orientation during storage and transportation. It only represents a relative positional relationship, not an absolute positional relationship.

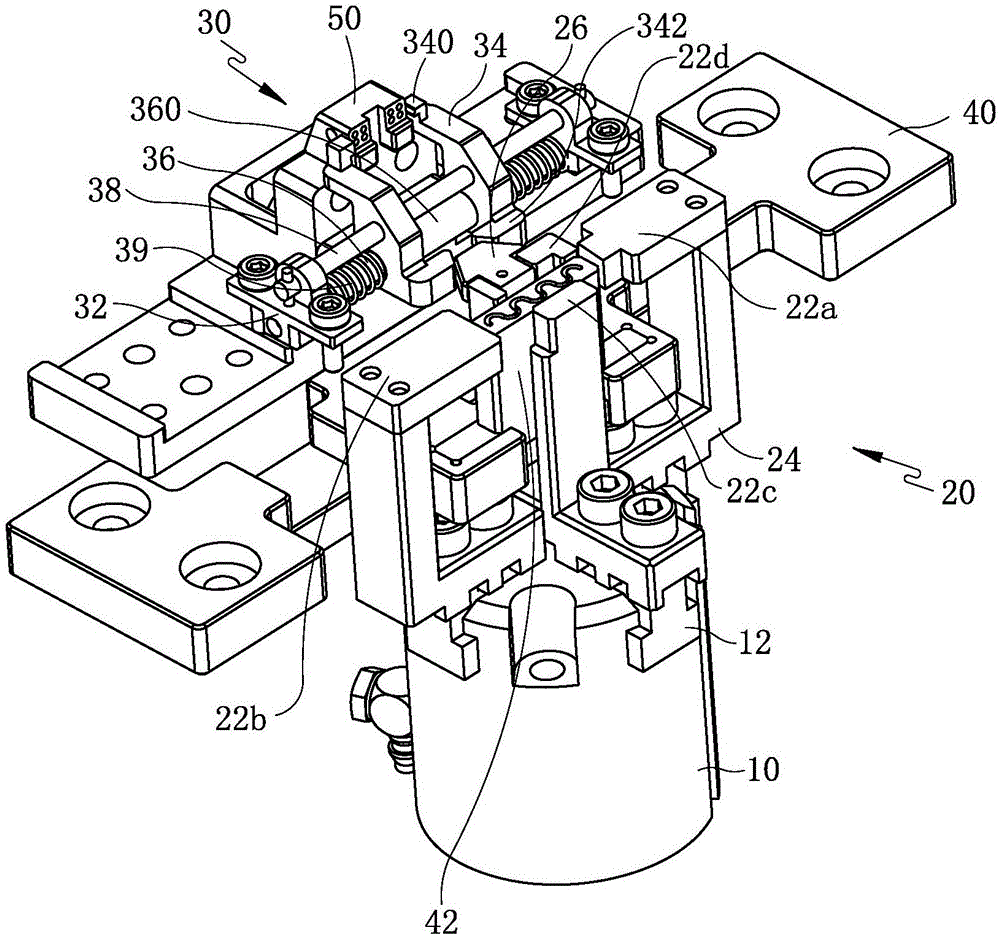

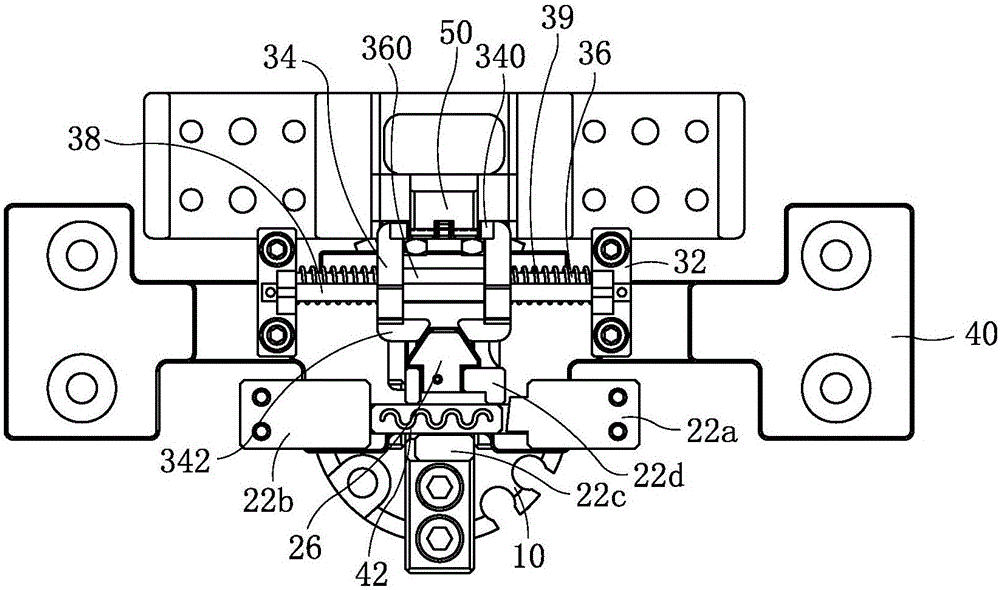

[0021] Such as figure 1 As shown, a mesh correction tool includes a front mesh correction mechanism 20 and a side mesh correction mechanism 30 linked with the front mesh correction mechanism 20 .

[0022] Such as figure 1 and figure 2 Commonly shown, the front mesh correction mechanism 20 includes a four-claw cylinder 10, and each of the four cylinder claws 12 of the four-claw cylinder 10 is equipped with a front mesh correction claw 22a, 22b, 22c and 22d, and the four front mesh The correction claws 22 a , 22 b , 22 c and 22 d are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com