Burnishing reamer for high precision deep-hole processing

A high-precision, reamer technology, used in reamers, metal processing equipment, manufacturing tools, etc., can solve the problems of hole processing quality that cannot meet process requirements, low precision, and short service life, to improve surface finish and ensure processing. Quality, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

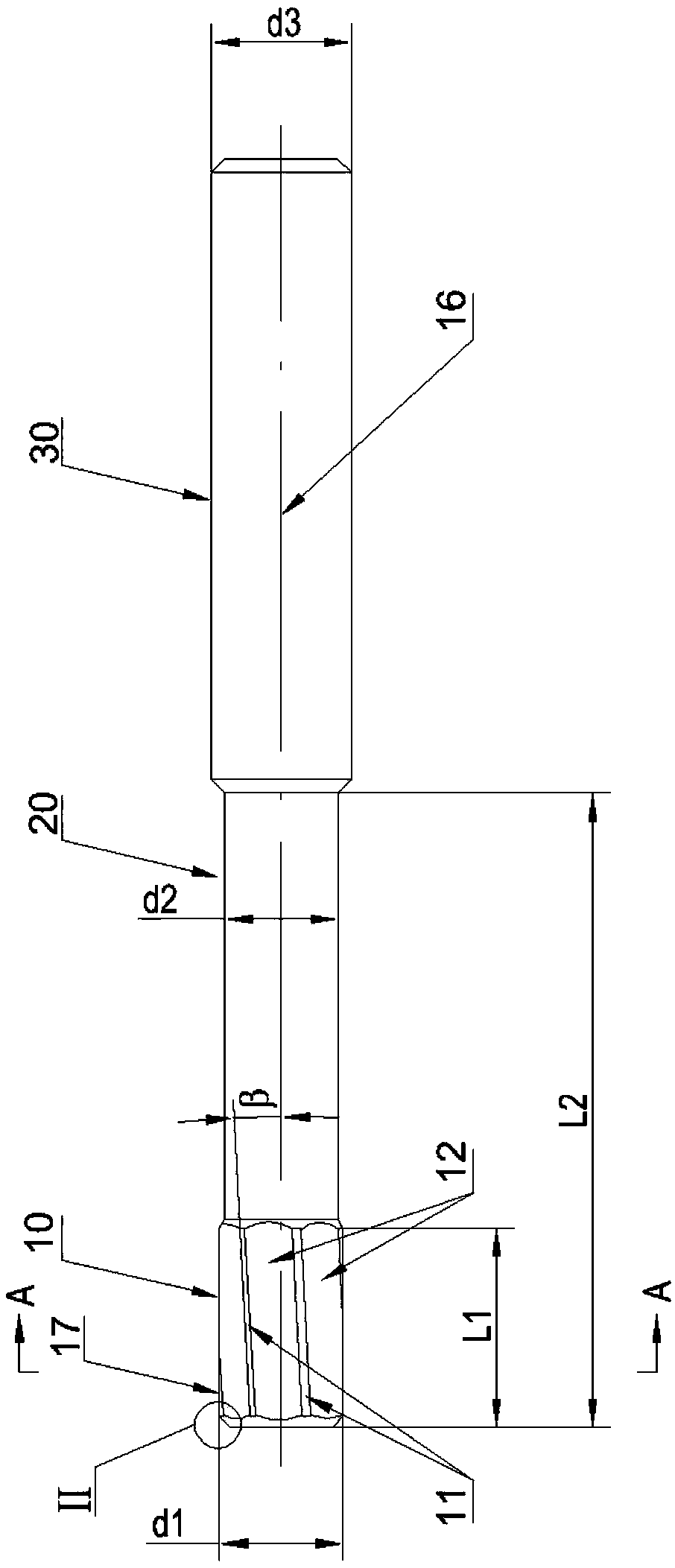

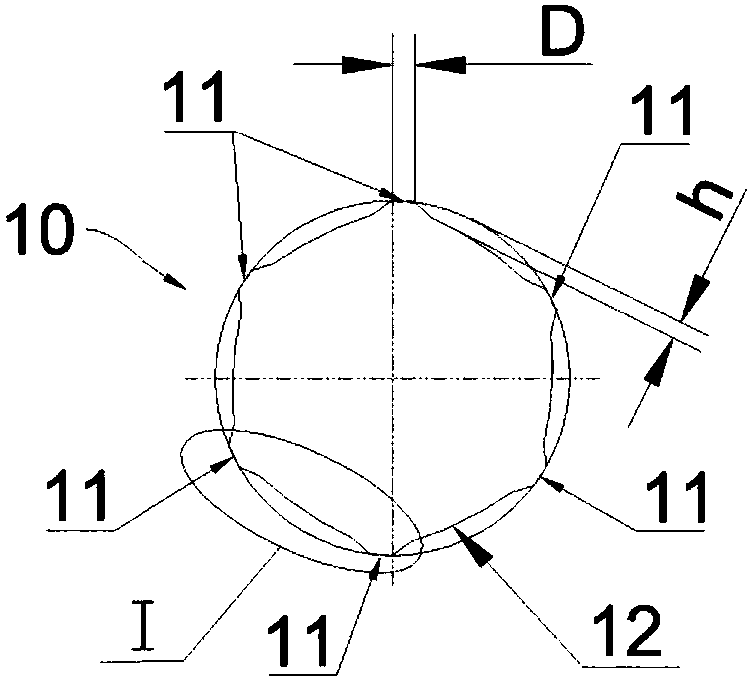

[0020] See figure 1 and figure 2 , the squeezed reamer used for high-precision deep hole processing of the present invention, which includes a first cylinder, a second cylinder and a third cylinder connected coaxially and integrally in sequence, the first cylinder is a reamer head 10 with a diameter of d1, The second cylinder is a neck 20 with a diameter of d2, and the diameter of the neck 20 is d2=d1-0.5mm, the third cylinder is a shank 30 with a diameter of d3 for tool clamping, and the outer peripheral surface of the reamer head 10 There are six left-handed guide lands 11 arranged at intervals on the top, and the back of the engraved arc surface 12 is formed by grinding the grinding wheel between adjacent guide lands 11; the length L1 of the reamer head 10=(1~2) d1, the sum L2 of the length L1 of the reamer head 10 and the length of the neck 12 is 5 mm to 10 mm longer than the hole depth of the part to be processed; The height h is (0.01~0.03)d1.

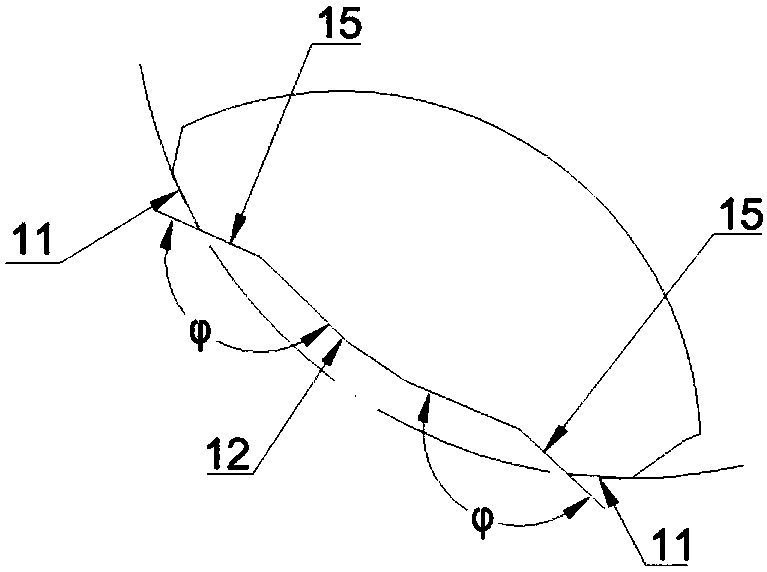

[0021] See Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com