Shallow foundation building rectification and reinforcement structure and construction method thereof

A technology for strengthening structures and shallow foundations, which is applied in the field of rectifying and strengthening structures for shallow foundation buildings, can solve problems such as reducing the work intensity of construction workers and failing to correct the deflection, and achieves the effects of reducing losses, preventing lateral movement, and improving positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

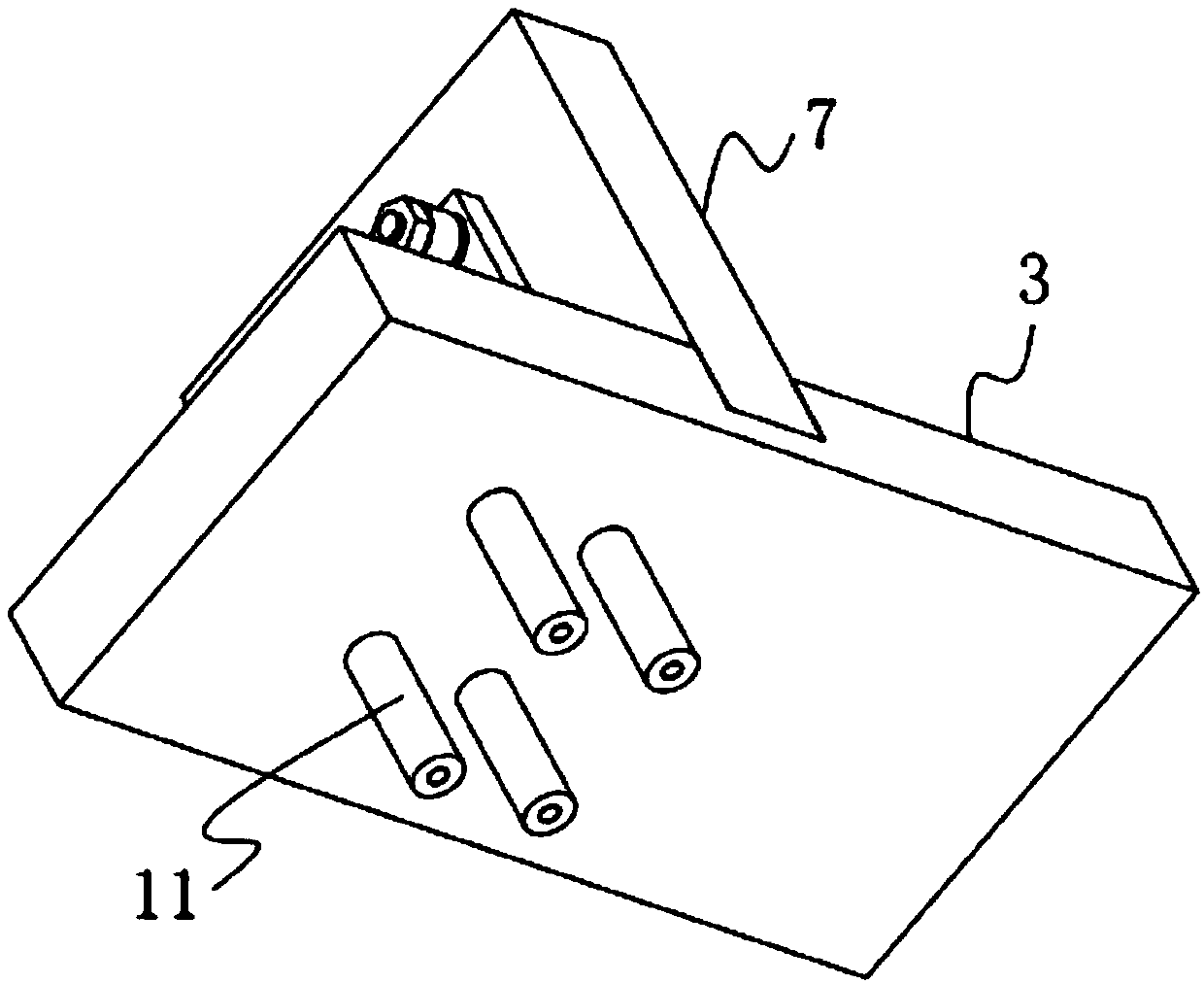

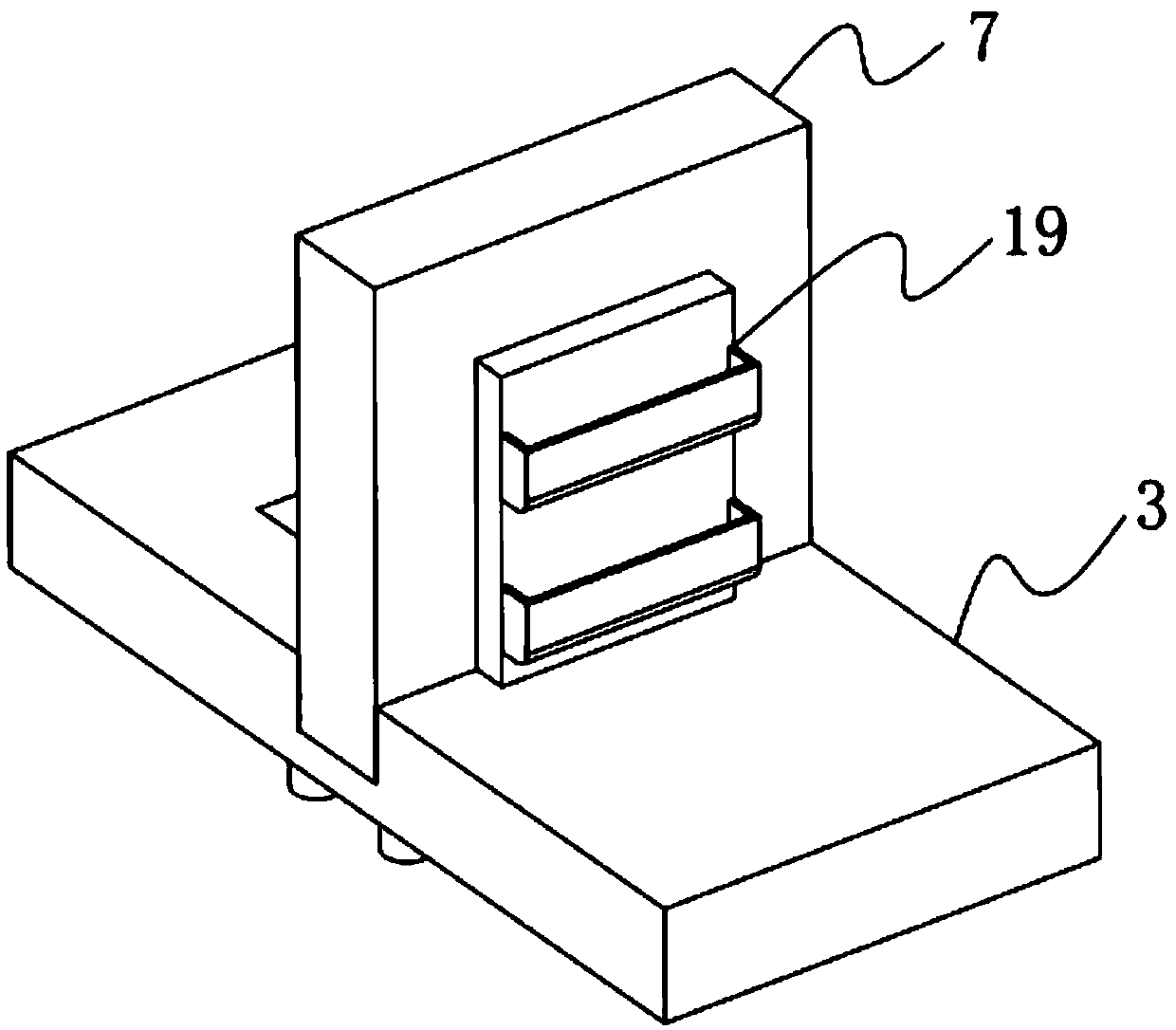

[0060] A deflection correction and reinforcement structure for shallow foundation buildings, such as Figure 1-4 As shown, it includes a shallow foundation construction part 1 and a deflection correction and reinforcement part 2, and the deflection correction and reinforcement part 2 is fixedly installed on the shallow foundation construction part 1;

[0061] Such as Figure 5-6 As shown, the shallow foundation building part 1 includes a foundation 3 and a vertical wall 7, and the upper part of the foundation 3 is provided with a first installation groove 4 and a second installation groove 5 perpendicular to each other, and the first installation groove 4 and the second installation groove The two installation grooves 5 are communicated with each other, the vertical wall 7 is fixedly installed inside the first installation groove 4, and there are four symmetrical openings on the vertical wall 7 located outside the first installation groove 4. the first through hole 8;

[006...

Embodiment 2

[0086] The difference from Example 1 is that the surfaces of the first fixing plate 9 and the second fixing plate 12 are provided with a protective layer, and the protective layer is prepared by the following method:

[0087] Take the following raw materials and weigh them by weight: 25 parts of epoxy resin, 8 parts of calcium carbonate powder, 10 parts of titanium dioxide powder, 12 parts of phenolic resin, 8 parts of porcelain powder, 11-16 parts of polyurethane, 3 parts of paraffin, alcohol ester twelve 2 parts, 2 parts of triethanolamine, 1 part of emulsified silicone oil and 30 parts of ethanol;

[0088] S1. Add the weighed paraffin, alcohol ester dodeca, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 20min at a stirring speed of 600r / min to prepare a mixed solution;

[0089] S2, adding epoxy resin, calcium carbonate powder, titanium dioxide powder, phenolic resin, porcelain powder and polyurethane into the pulverizer and pulverizing unti...

Embodiment 3

[0095] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0096] Take the following raw materials and weigh them by weight: 30 parts of epoxy resin, 11 parts of calcium carbonate powder, 13 parts of titanium dioxide powder, 14 parts of phenolic resin, 9 parts of porcelain powder, 14 parts of polyurethane, 4 parts of paraffin wax, 3 parts of alcohol ester twelve , 3 parts of triethanolamine, 2 parts of emulsified silicone oil and 40 parts of ethanol;

[0097] S1. Add the weighed paraffin, alcohol ester dodecane, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 25min at a stirring speed of 650r / min to prepare a mixed solution;

[0098] S2, adding epoxy resin, calcium carbonate powder, titanium dioxide powder, phenolic resin, porcelain powder and polyurethane into the pulverizer and pulverizing until the particle diameter of the material is not greater than 40um to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com