Device and method for governing oil-water-well oil-string-casing channeling

A technology for oil-water wells and surface casings, which is used in earth-moving drilling, wellbore/well components, sealing/packaging, etc. The effect of firmness, elimination of safety hazards and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

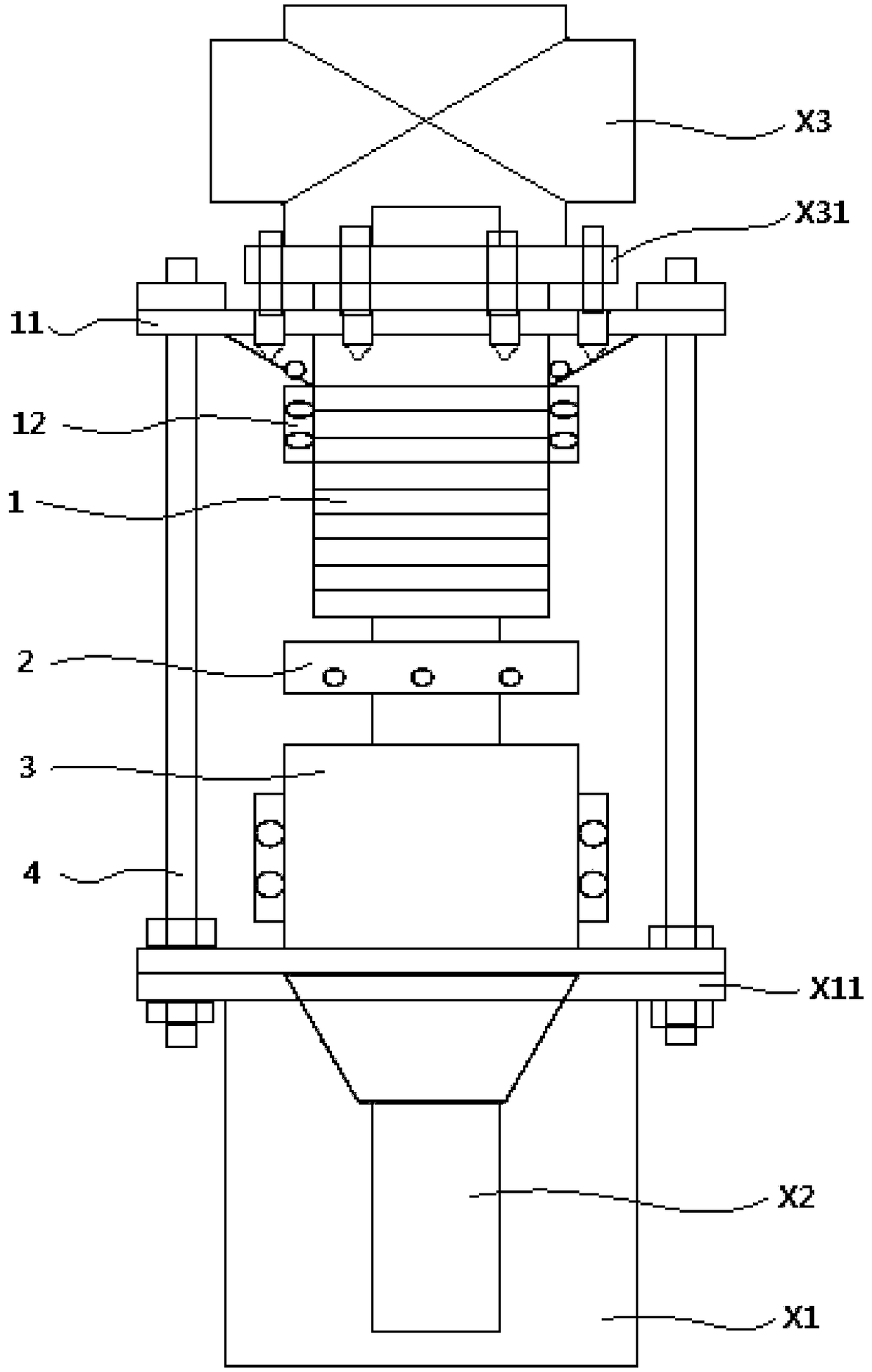

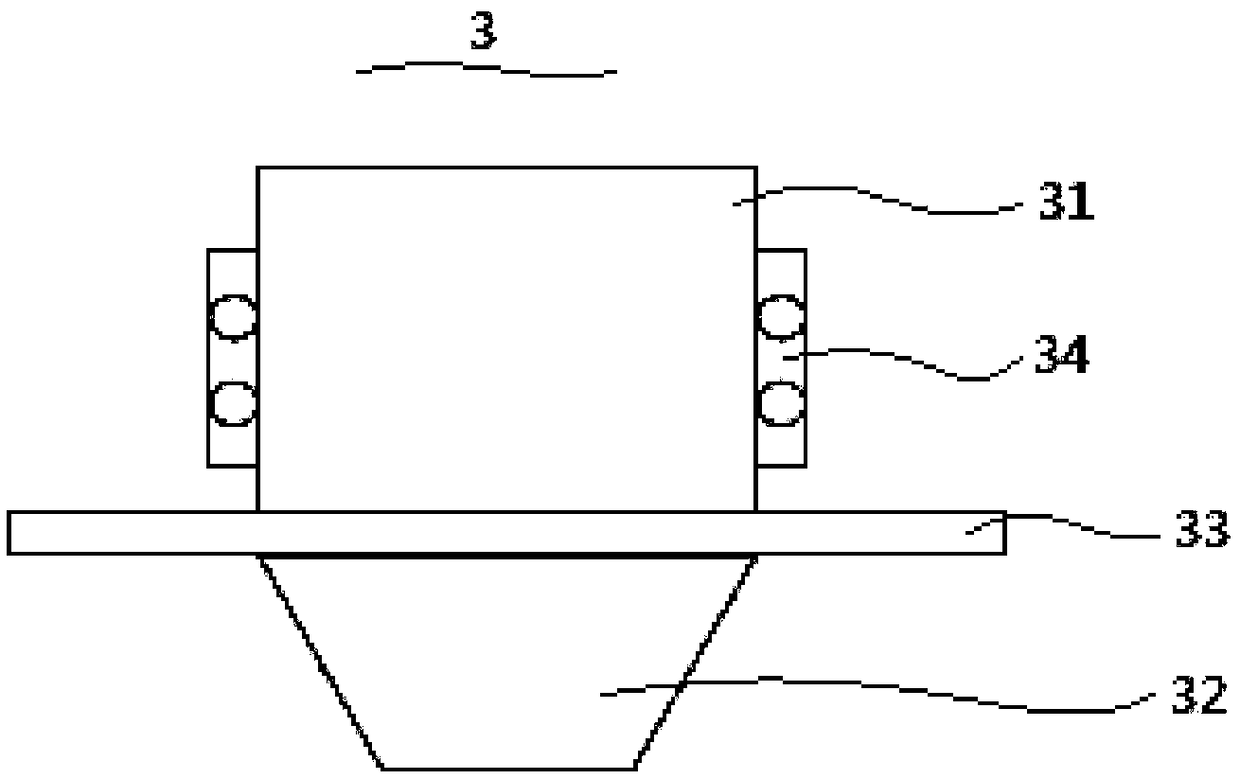

[0061] In the first aspect, the embodiment of the present invention provides a device for controlling the channeling of oil layer casing in oil and water wells, see figure 1 and figure 2 , the device includes: a jacking cylinder 1 , a jacking nut 2 , a base cylinder 3 and a tension member 4 .

[0062] Wherein, the jacking cylinder 1 is sheathed on the oil layer casing X2, the upper end of the jacking cylinder 1 is provided with a first flange 11 extending outward, and the outer wall of the jacking cylinder 1 is provided with external threads.

[0063] The jacking nut 2 is sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com