Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce the number of patterning processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

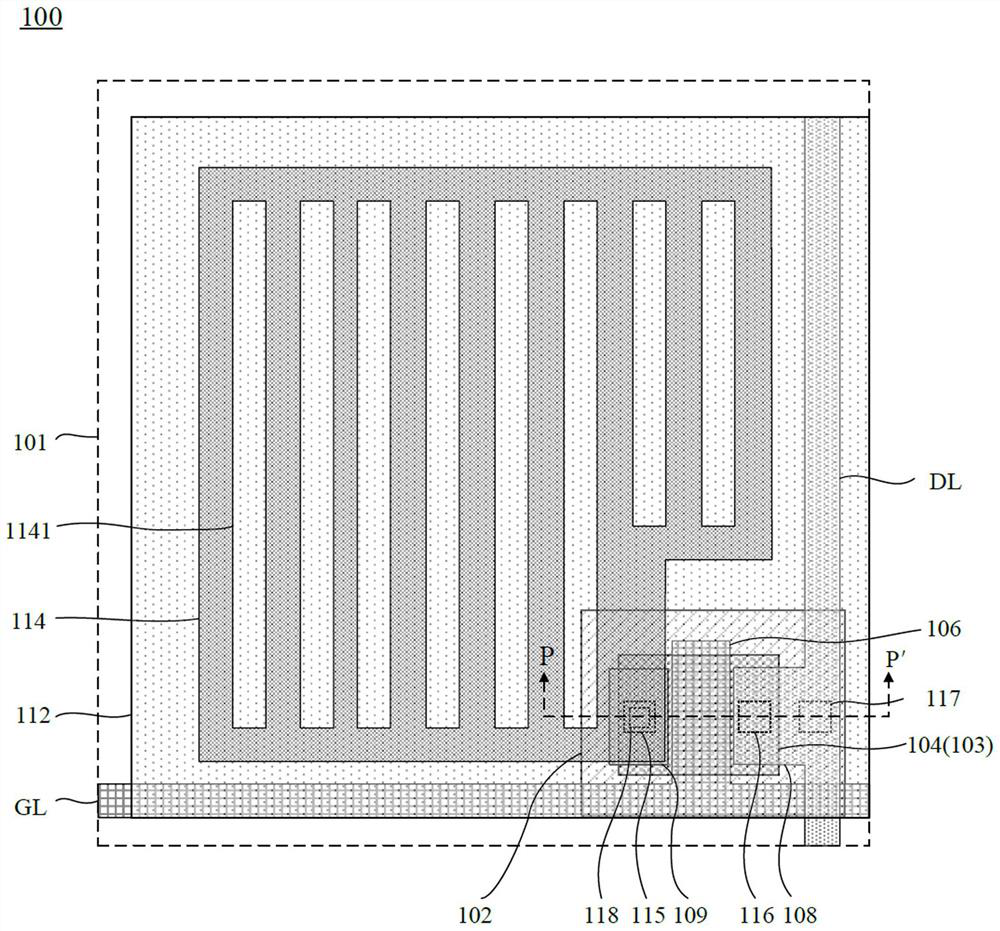

Array substrate, preparing method thereof and display device

ActiveCN104022076AImprove yieldReduce the number of patterning processesSolid-state devicesSemiconductor/solid-state device manufacturingComposition processDisplay device

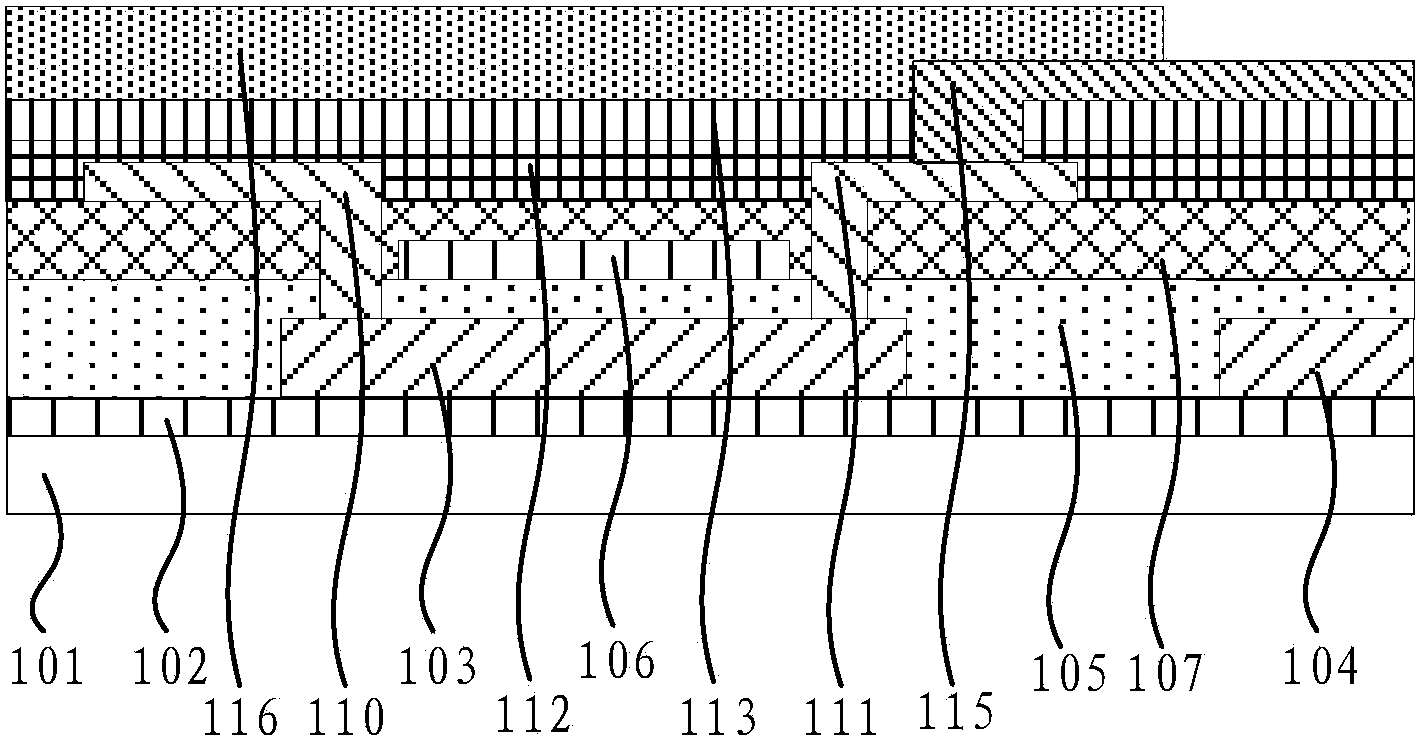

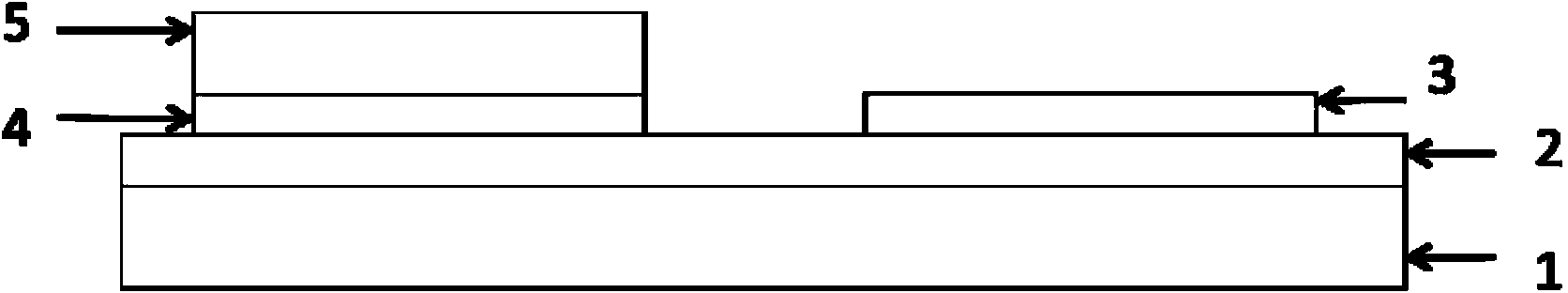

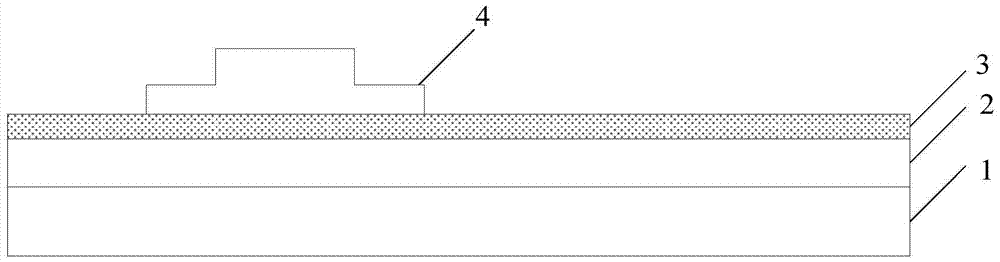

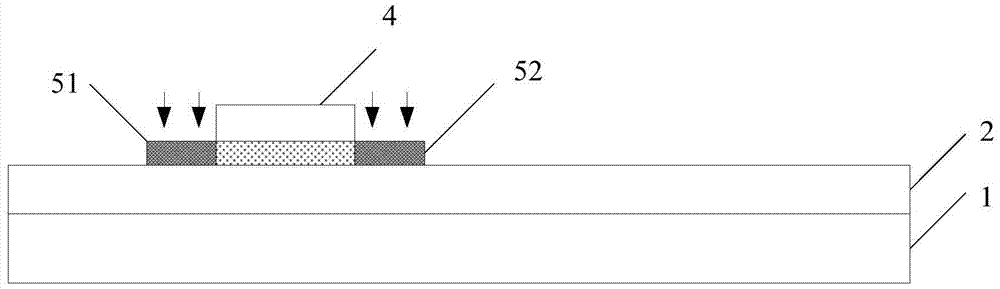

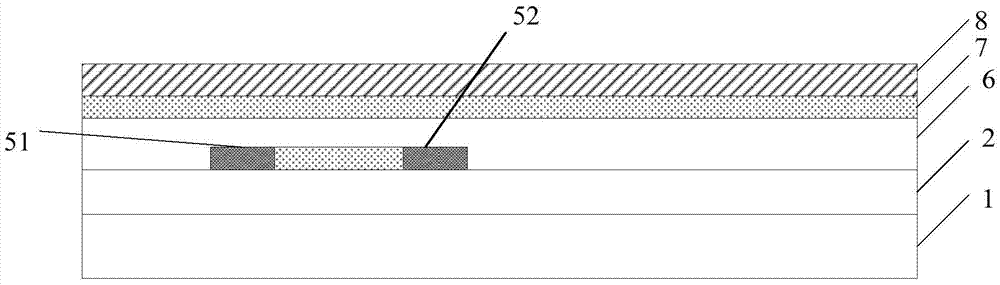

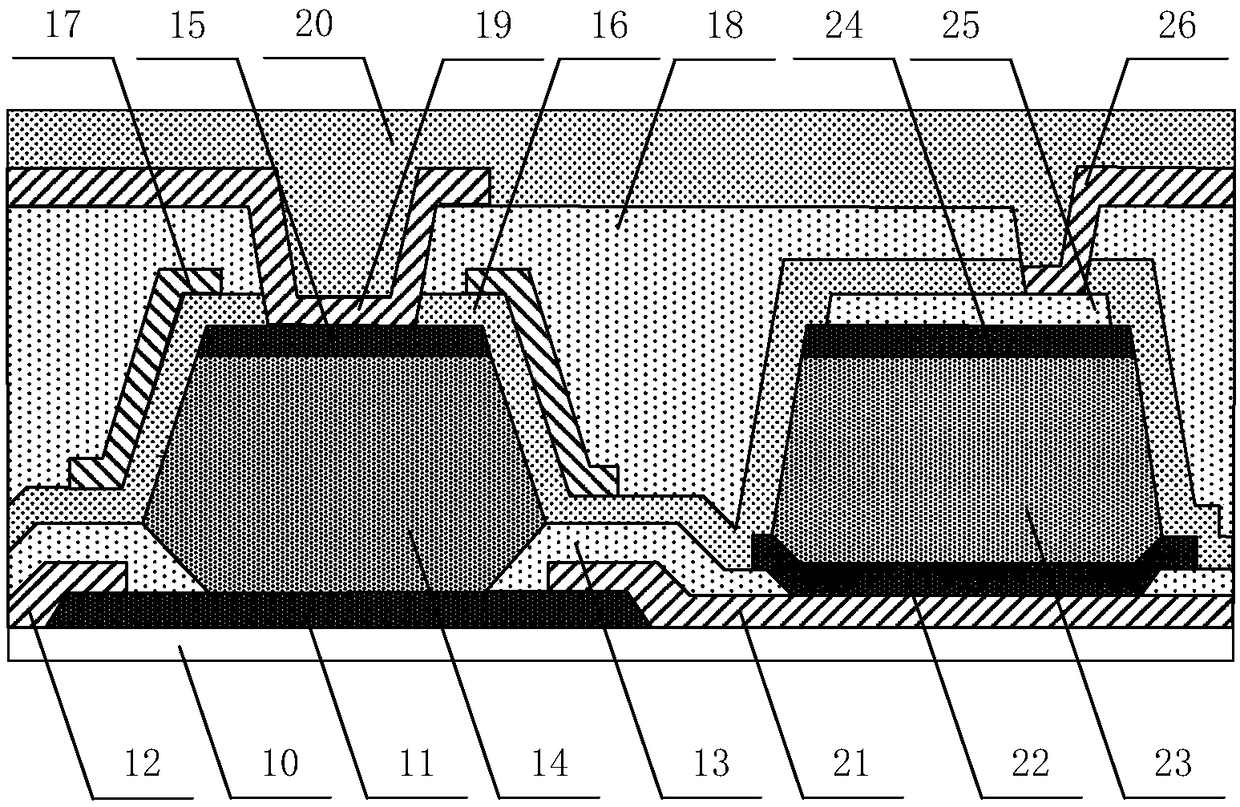

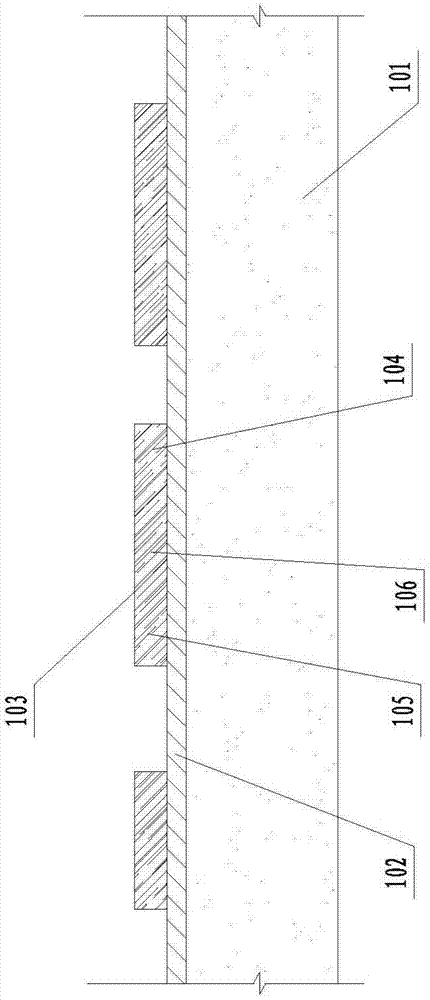

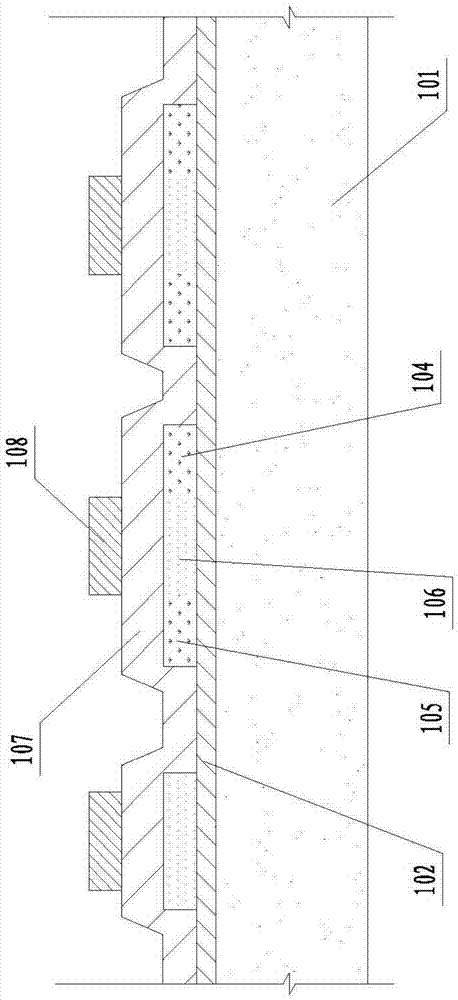

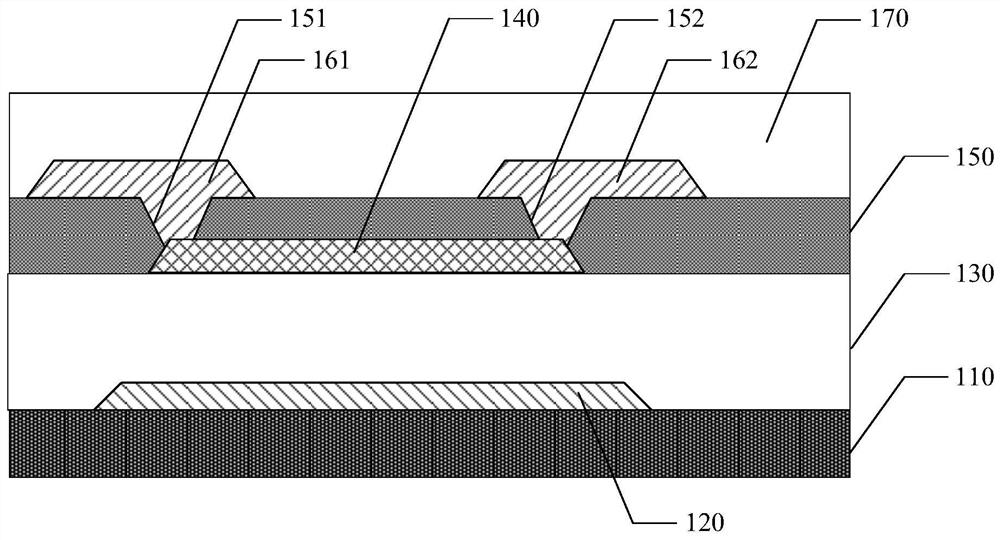

The invention provides an array substrate, a preparing method thereof and a display device, wherein the preparing method comprises the steps of: forming an active material layer, a gate electrode insulating layer and a metal film on a substrate, forming a pattern which comprises an active layer and a pattern that comprises a gate electrode, a source electrode, a drain electrode, a gate line and a data line through a primary composition process; forming a passivation layer on the substrate, forming a source electrode contact hole, a drain electrode contact hole and an over-bridge structure contact hole through a secondary composition process; and forming a transparent conductive film on the substrate, eliminating partial transparent conductive film through a film peeling process for forming a source electrode contact part, a drain electrode contact hole, a pixel electrode and an over-bridge structure. According to the preparing method, number of times in using the composition process is reduced. The array substrate has advantages of simple preparing process, high production efficiency and high yield rate.

Owner:BOE TECH GRP CO LTD

Array substrate, manufacture method of array substrate and display device

ActiveCN103123910AShorten production timeReduce the number of patterning processesTransistorSolid-state devicesDisplay deviceComposition process

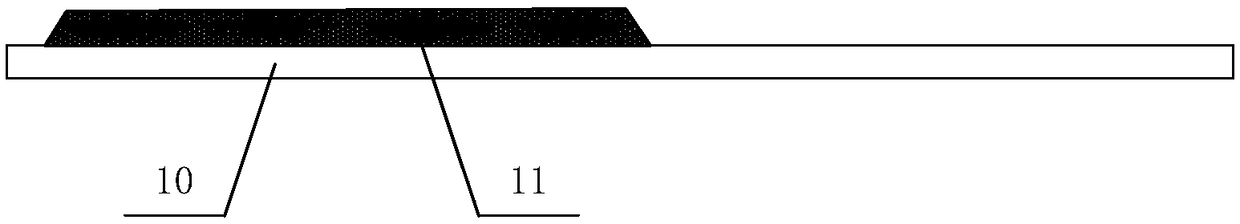

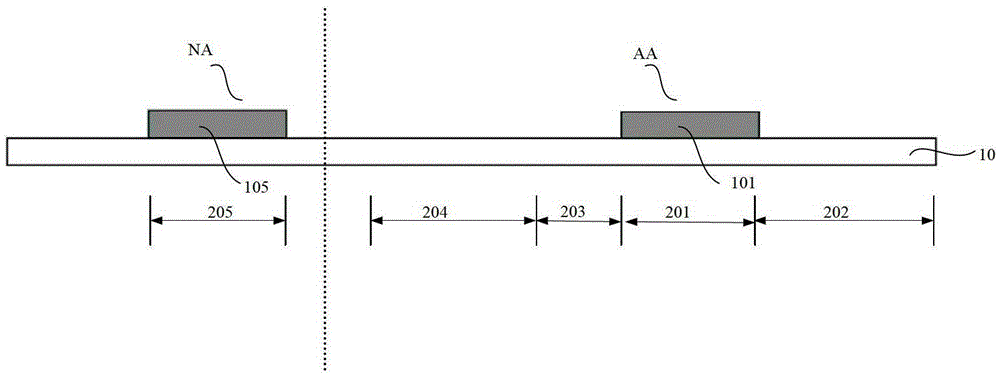

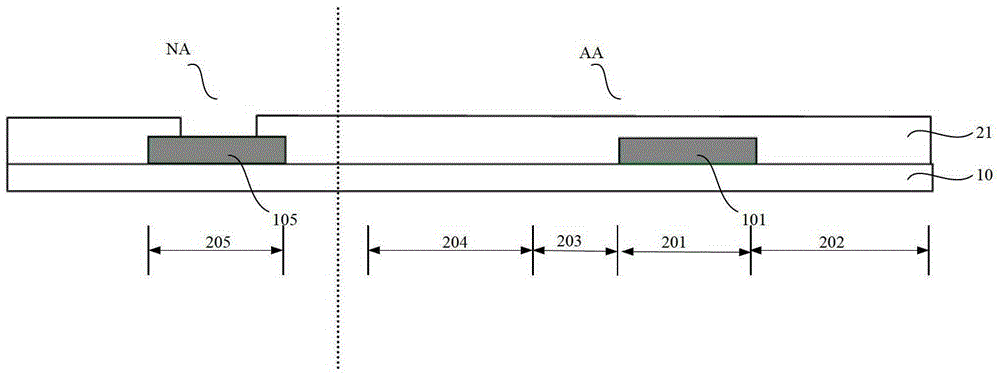

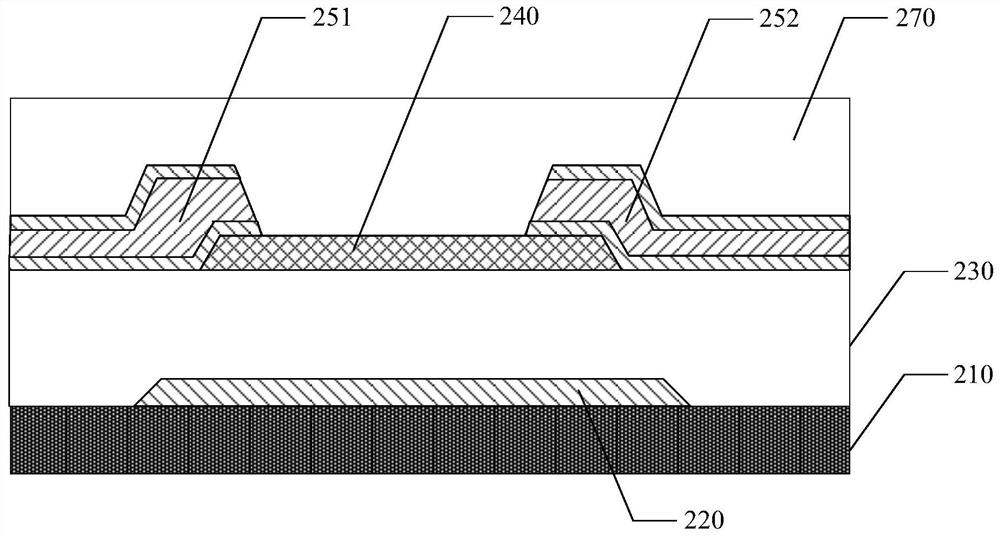

The invention belongs to the technical field of display and discloses an array substrate and a manufacture method of the array substrate. Source electrode patterns, drain electrode patterns, pixel electrode patterns and active layer patterns of the array substrate are formed through the once picture composition process. Compared with the traditional manufacture process of the array substrate, the manufacture method of the array substrate is simple in process, shortens production time, reduces product cost and improves product quality.

Owner:BOE TECH GRP CO LTD

Array substrate, preparing method thereof and display device

ActiveCN104022077AReduce parasitic capacitanceExcellent electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveData lines

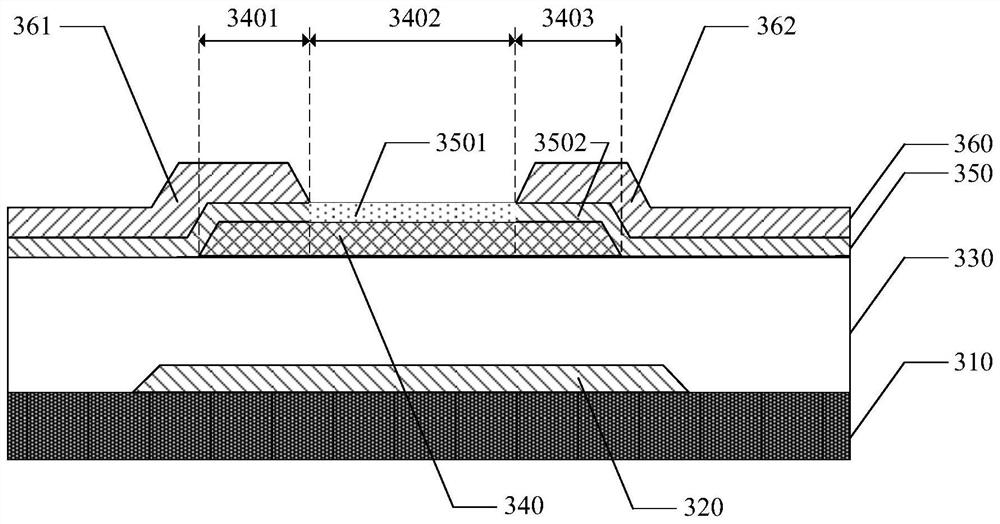

The invention provides an array substrate, a preparing method thereof and a display device, wherein the preparing method comprises the steps of: forming a pattern and a gate electrode insulating layer on a substrate, wherein the pattern comprises an active layer; forming a metal film on the gate electrode insulating layer, patterning the metal film through a primary composition process for forming the pattern which comprises a gate electrode, a source electrode, a drain electrode, a gate line and a data line; forming a passivation layer on the substrate; patterning the passivation layer through the primary composition process for forming a source electrode contact hole, a drain electrode contact hole and an over-bridge structure contact hole; and forming a transparent conductive film on the substrate, eliminating partial transparent conductive film through a film peeling process for forming a source electrode contact part, a drain electrode contact hole, a pixel electrode and an over-bridge structure. According to the preparing method, number of times in using the composition process is reduced. The array substrate has advantages of simple preparing process, high production efficiency and high yield rate.

Owner:BOE TECH GRP CO LTD

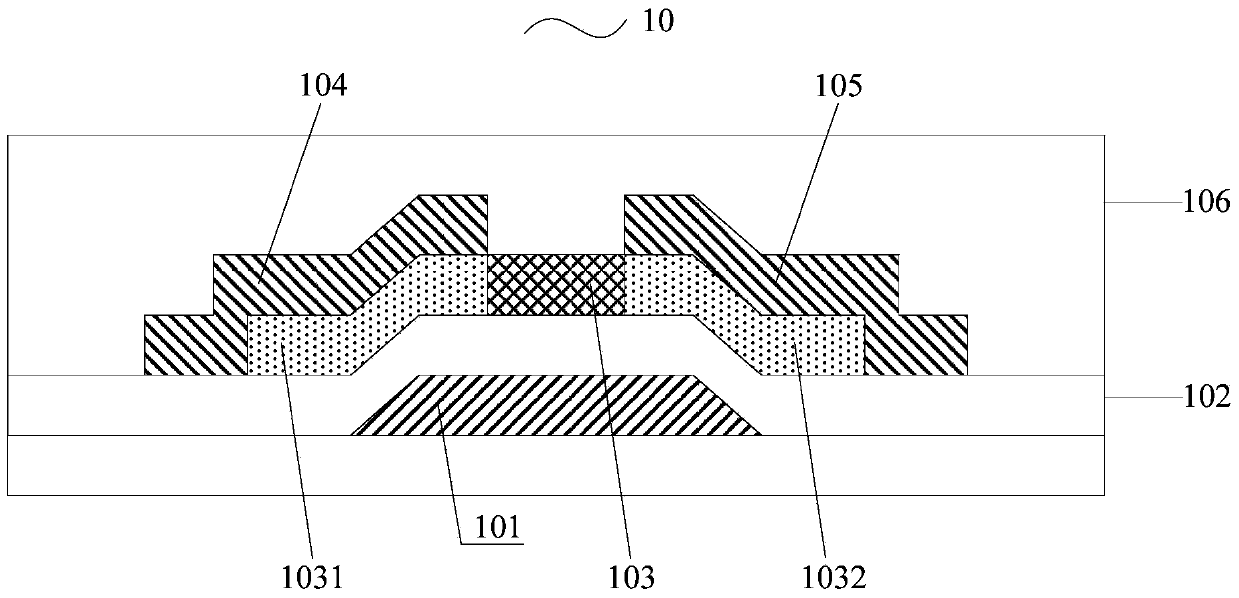

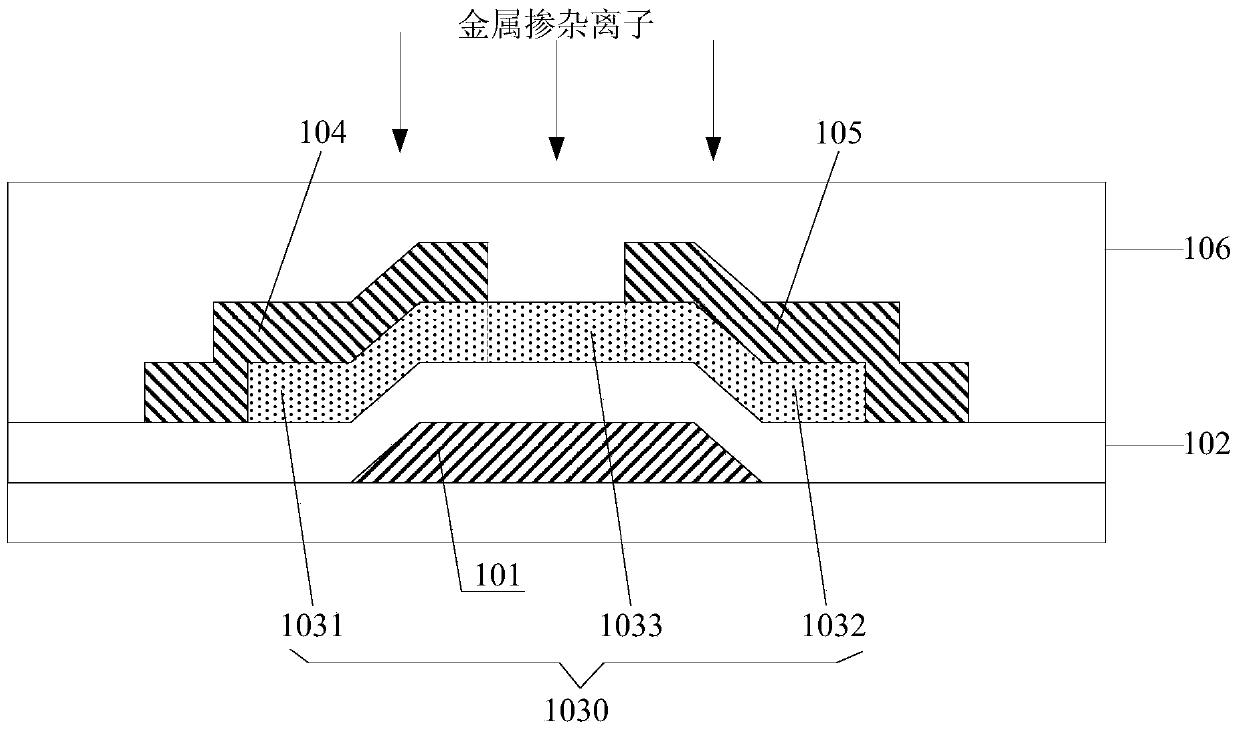

Thin film transistor and manufacturing method thereof, array substrate and display device

ActiveCN103730346ASolve the problem of contact resistanceSkip the manufacturing processTransistorSolid-state devicesIndiumDisplay device

The embodiment of the invention provides a thin film transistor and a manufacturing method of the thin film transistor, an array substrate and a display device, and relates to the technical field of display. The thin film transistor can solve the problem that the contact resistance exists between a source electrode and a semiconductor active layer and exists between a drain electrode and the semiconductor active layer, reduce the number of times of the picture composition technology and reduce the cost. The manufacturing method comprises the steps of forming a grid electrode, a grid insulating layer, the metal-oxide semiconductor active layer, the source electrode and the drain electrode on a substrate, wherein the formed metal-oxide semiconductor active layer comprises an indium-oxide series binary metal-oxide pattern layer making direct contact with the source electrode and the drain electrode, and a first pattern, a second pattern and a third pattern are included in the indium-oxide series binary metal-oxide pattern layer; using the insulating layer formed above the source electrode and the drain electrode as a barrier layer, adopting the ion implantation technology to implanting metal doping ions into the indium-oxide series binary metal-oxide pattern layer, conducting annealing treatment, converting the binary metal oxide of the third pattern into a polybasic metal-oxide semiconductor, and forming the metal-oxide semiconductor active layer. The thin film transistor is used for manufacturing the display device.

Owner:BOE TECH GRP CO LTD

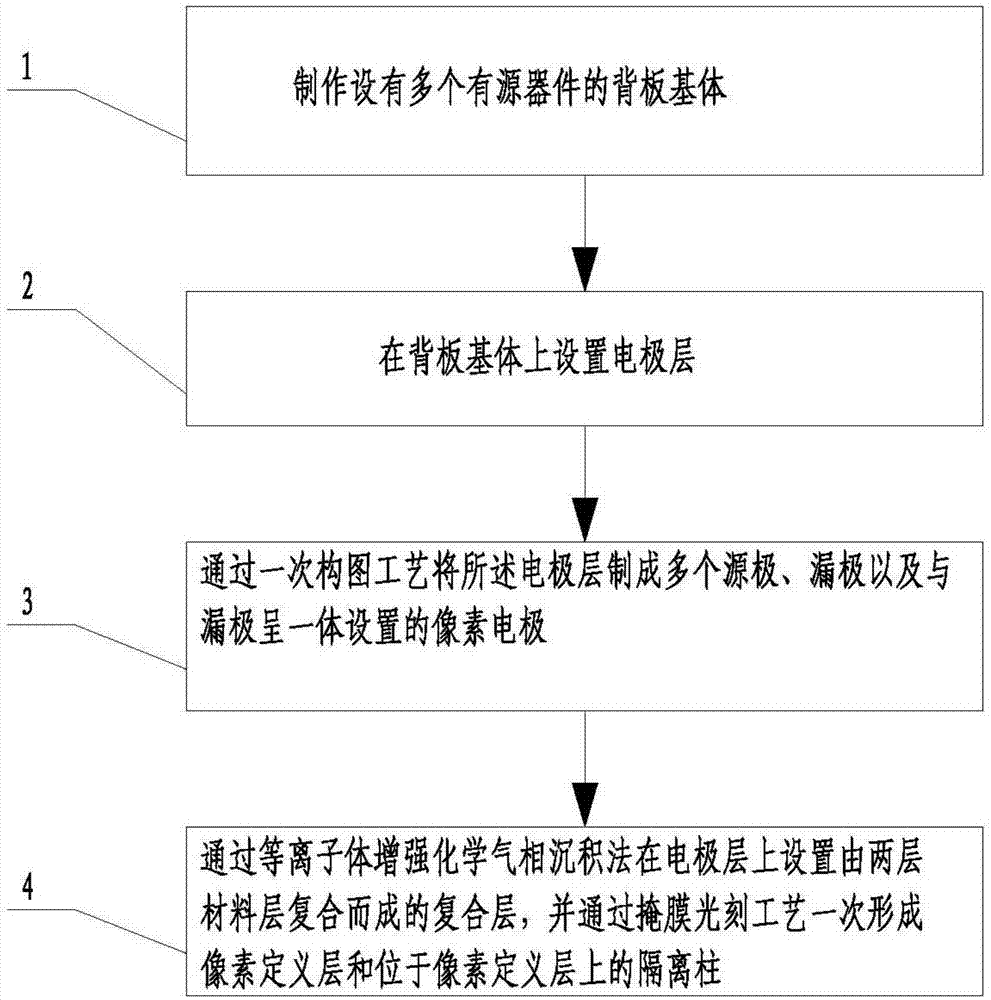

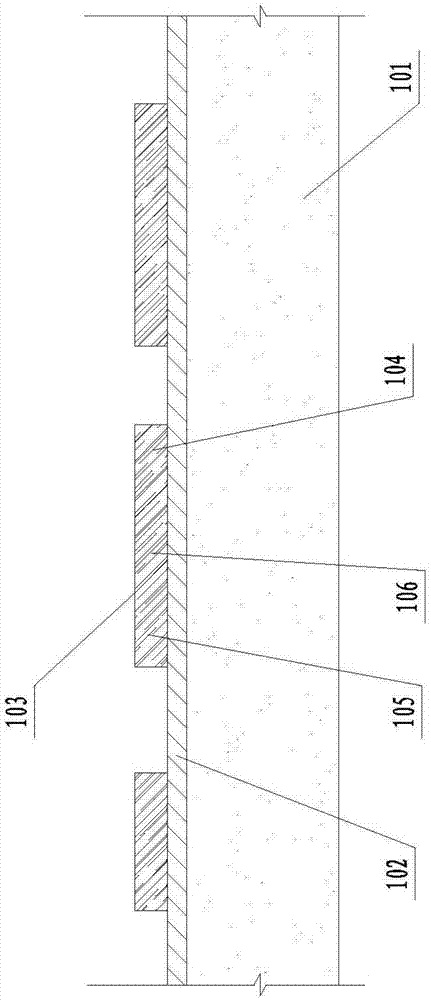

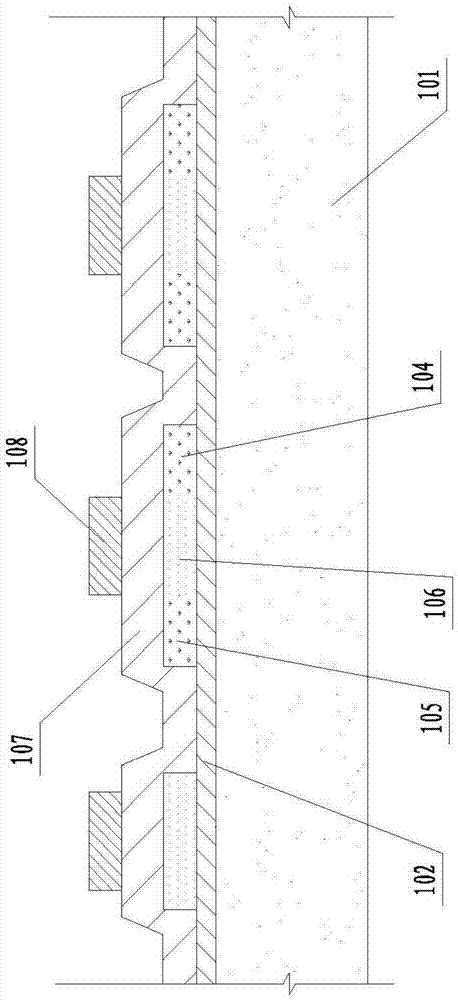

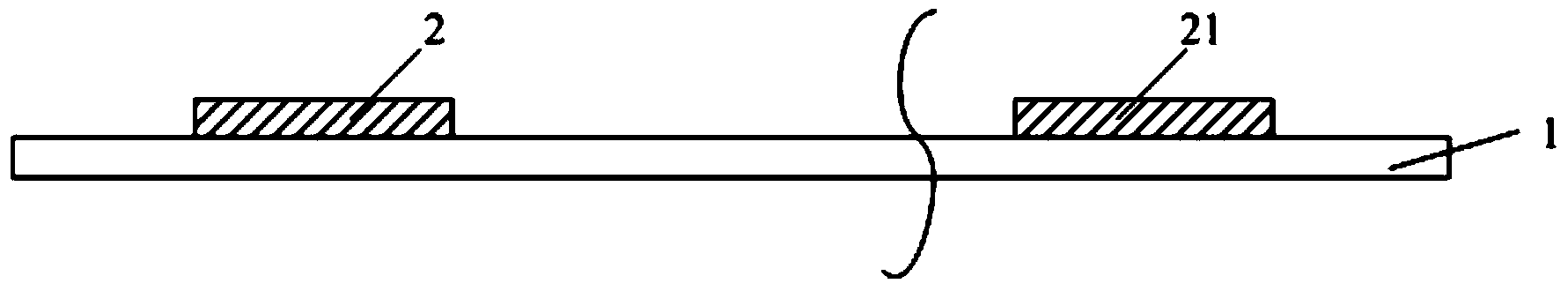

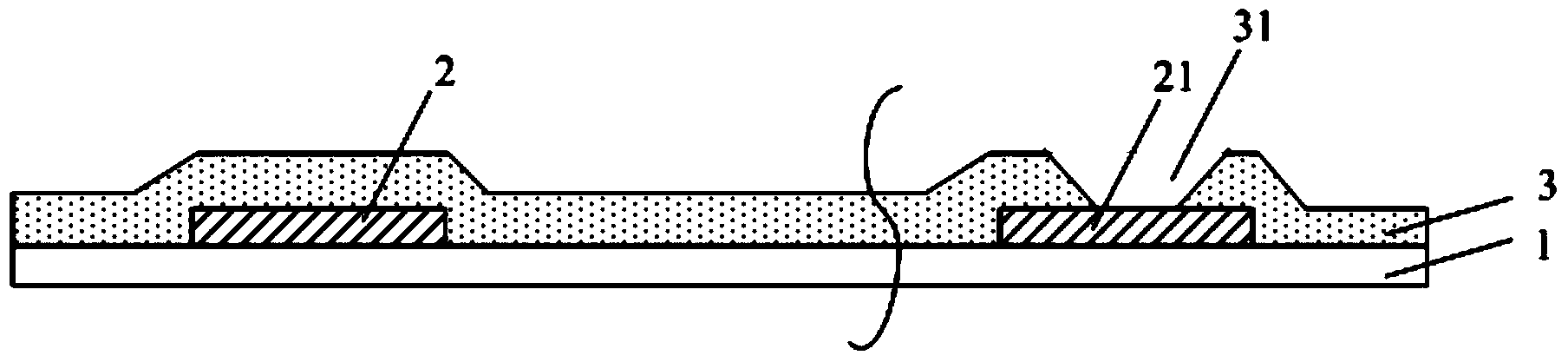

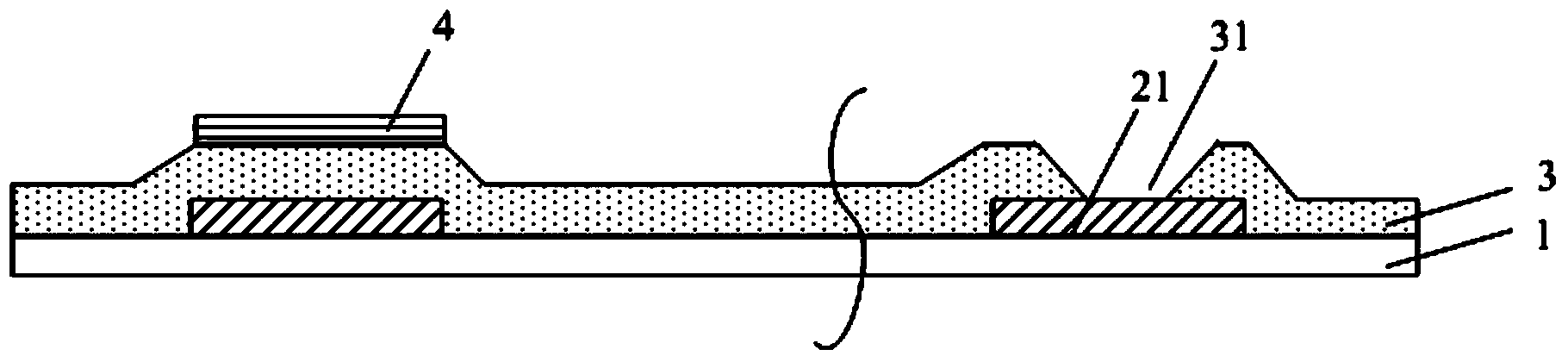

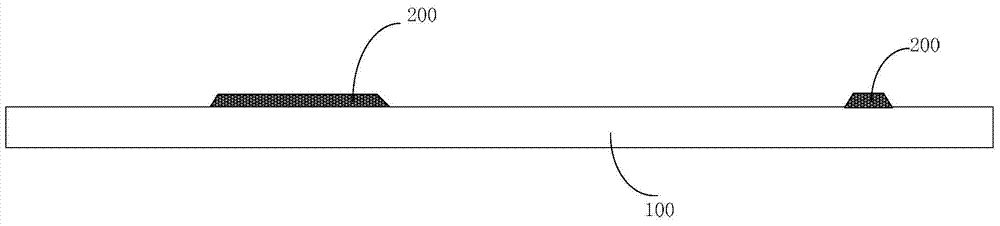

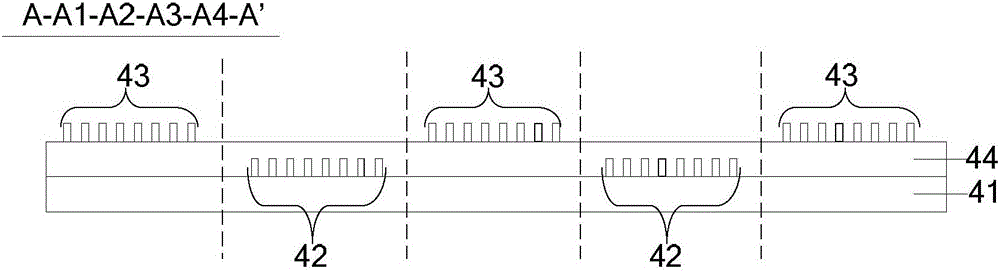

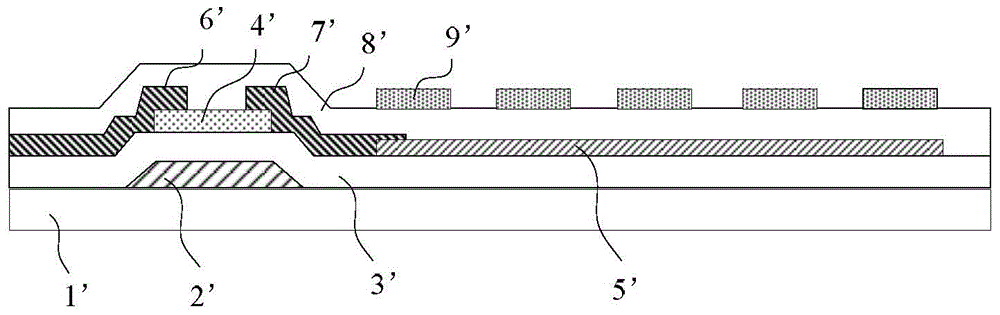

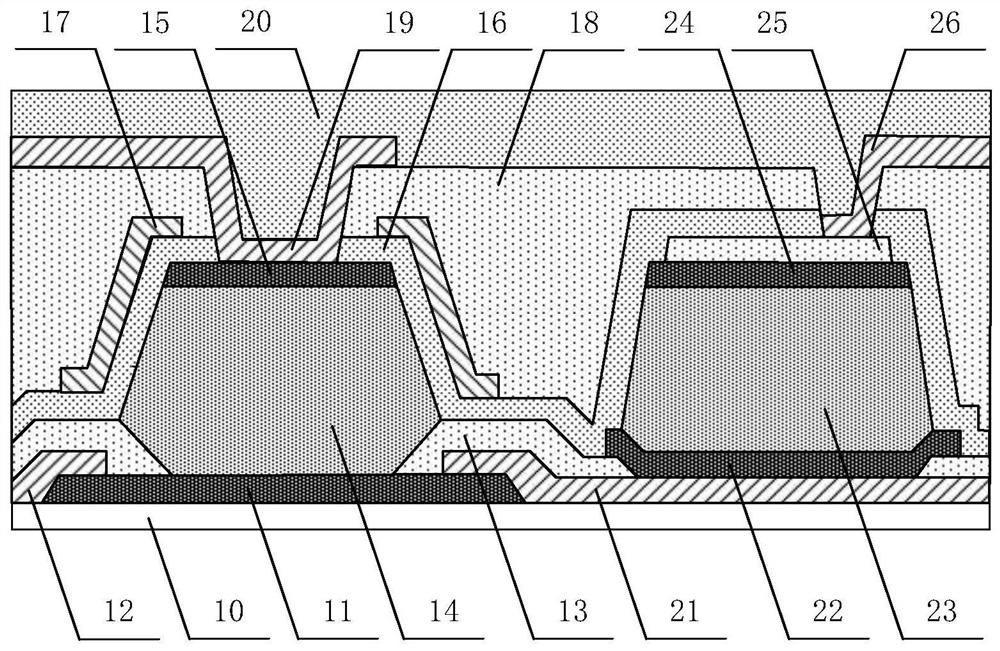

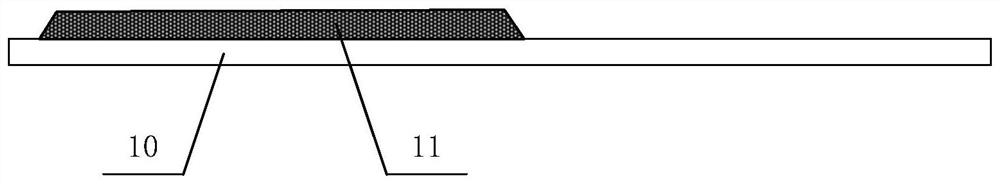

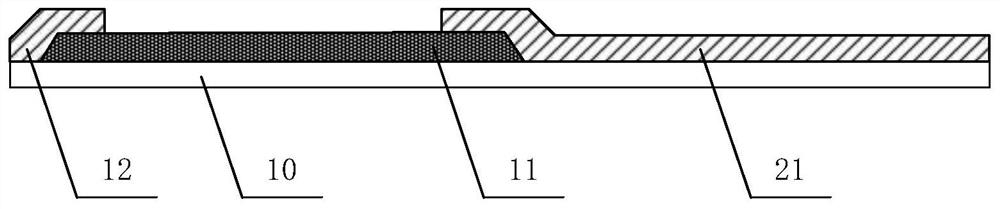

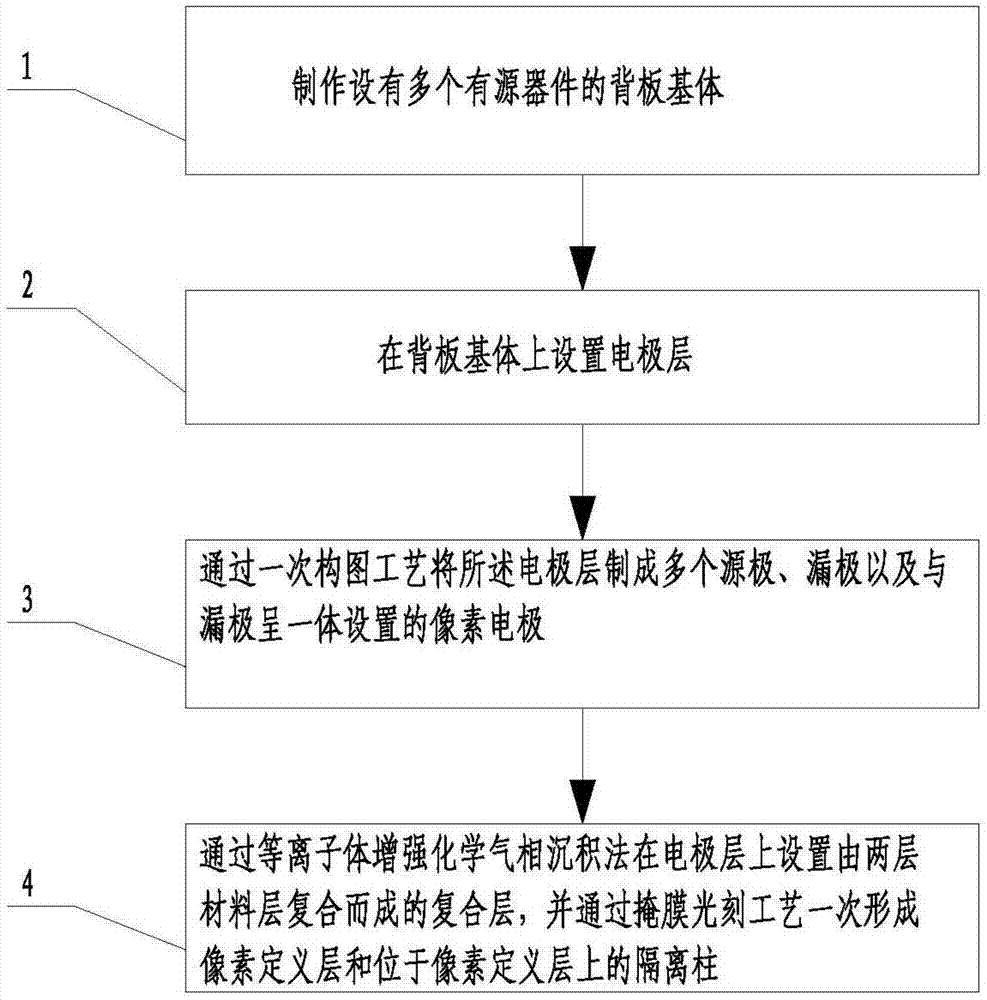

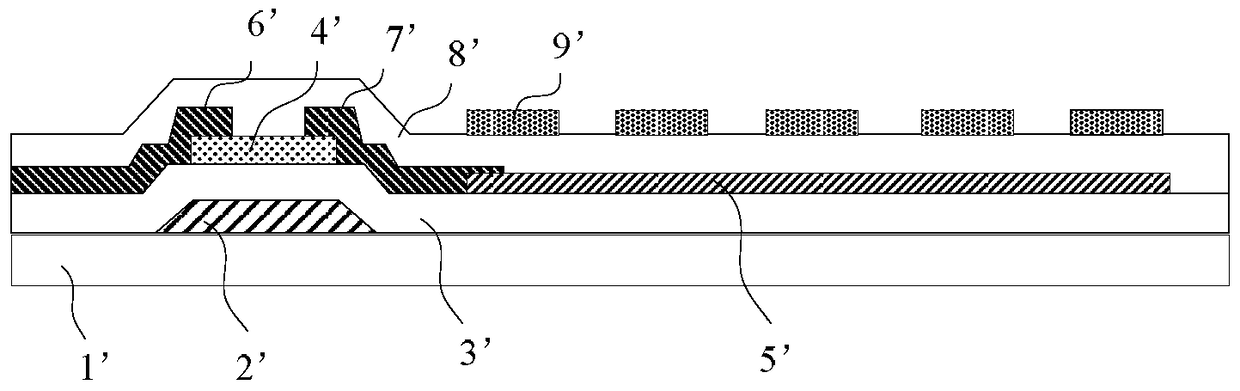

Thin film transistor driving backplane, manufacturing method thereof and display panel

ActiveCN103489827AReduce thicknessEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingBackplaneActive devices

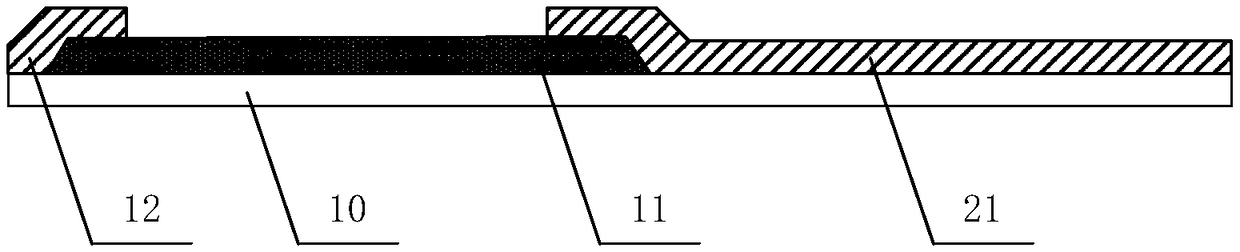

The invention relates to the technical field of display, in particular to a thin film transistor driving backplane, a manufacturing method and a display panel. The manufacturing method of the thin film transistor driving backplane comprises the following steps that a backplane substrate provided with a plurality of active device structures is manufactured; an electrode layer is arranged on the backplane substrate; the electrode layer is made into source electrodes, drain electrodes and pixel electrodes by the adoption of the one-time picture composition technology, wherein the pixel electrodes and the drain electrodes are arranged in an integrated mode. According to the manufacturing method, the electrode layer is made into the source electrodes, the drain electrodes and the pixel electrodes by the adoption of the one-time picture composition technology, wherein the pixel electrodes and the drain electrodes are arranged in the integrated mode; therefore, the source electrodes, the drain electrodes and the pixel electrodes are located on the same electrode layer; the prior art that the source electrodes, the drain electrodes and the pixel electrodes are formed through two-time picture composition technology is simplified into the manufacturing method that the source electrodes, the drain electrodes and the pixel electrodes can be formed only through the one-time picture composition technology; the thickness of the thin film transistor driving backplane is greatly reduced, the manufacturing steps are simplified, and the manufacturing cost is saved.

Owner:BOE TECH GRP CO LTD

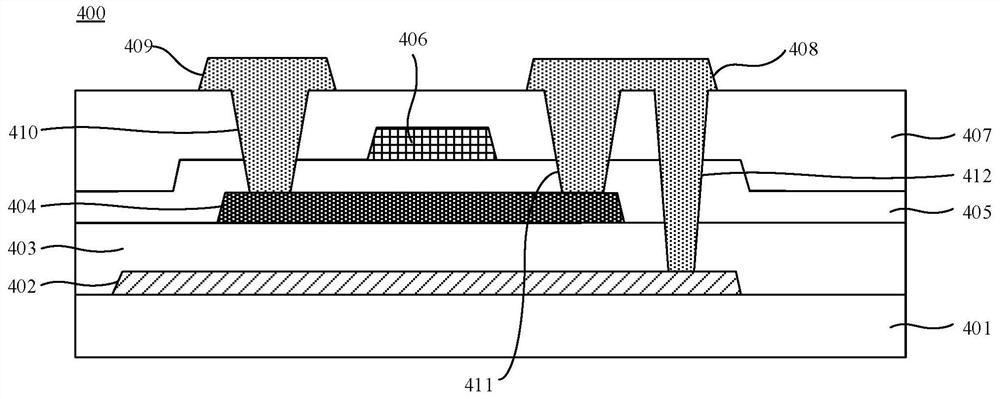

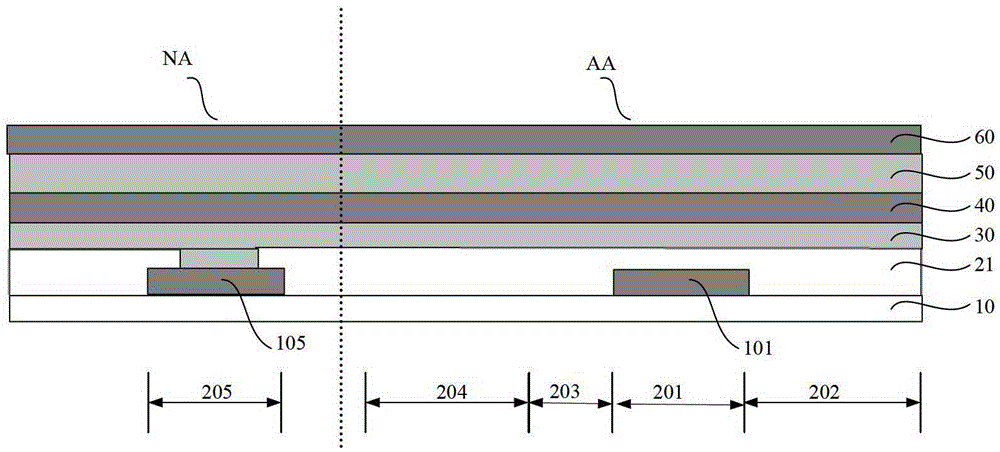

Array substrate preparation method, array substrate and display device

InactiveCN104037126AIncrease production capacityReduce composition processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor

The invention belongs to the display technical field and relates to an array substrate preparation method, an array substrate and a display device. The array substrate preparation method includes steps for forming a thin film transistor, a pixel electrode and a common electrode line. Steps for forming the thin film transistor include steps for forming patterns of a gate, a gate insulating layer, a semiconductor layer, an etching stopping layer, a source and a drain, the gate and the common electrode line being formed in the same layer. The array substrate preparation method is characterized in that: a gate insulating thin film and a semiconductor thin film are formed sequentially, and a pattern containing the semiconductor layer is formed through one-step patterning process; and an etching stopping thin film is formed, and a pattern containing the gate insulating layer and the etching stopping layer is formed through one-step patterning process. With the array substrate preparation method of the invention adopted, the number of times of patterning process can be decreased, and production process can be simplified, and the manufacturing capacity of array substrate products can be improved, and production efficiency can be improved, and production cost can be reduced.

Owner:BOE TECH GRP CO LTD +1

Thin film transistor and manufacturing method thereof as well as display device

ActiveCN104716198AEtching speed is fastSolve the problem of easy corrosionTransistorSemiconductor/solid-state device manufacturingEtchingDisplay device

Owner:BOE TECH GRP CO LTD

Array substrate, manufacturing method thereof and display device

ActiveCN103489877AAvoid badReduce the number of patterning processesSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor

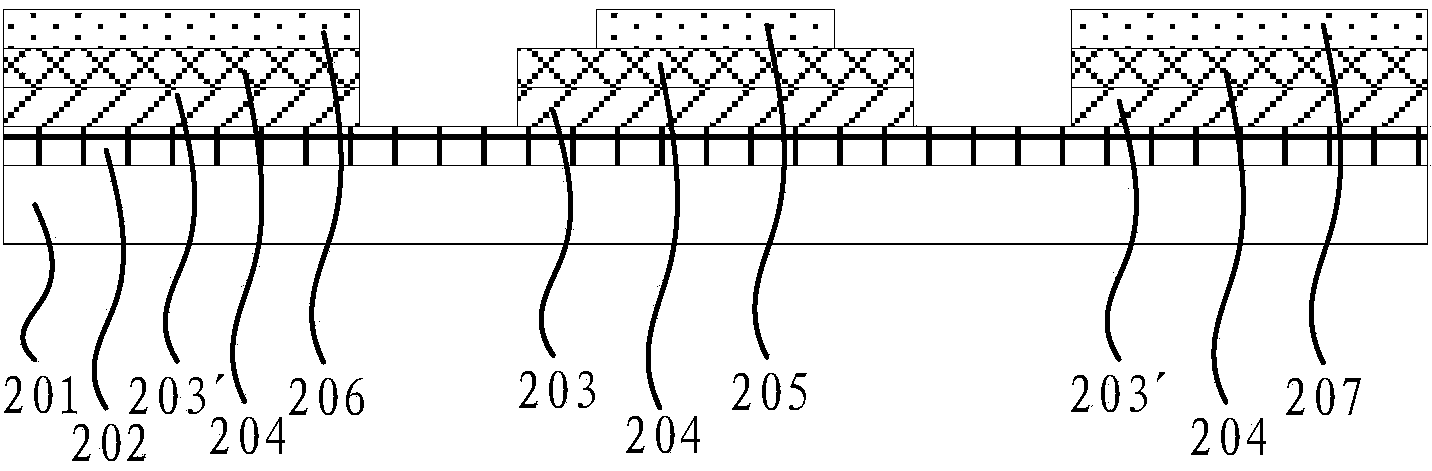

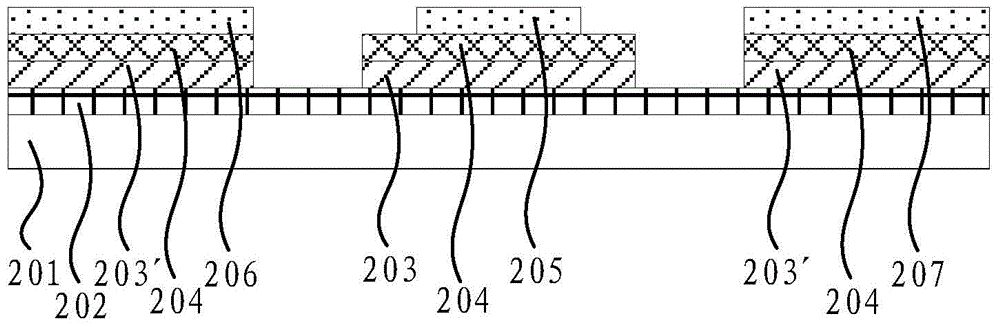

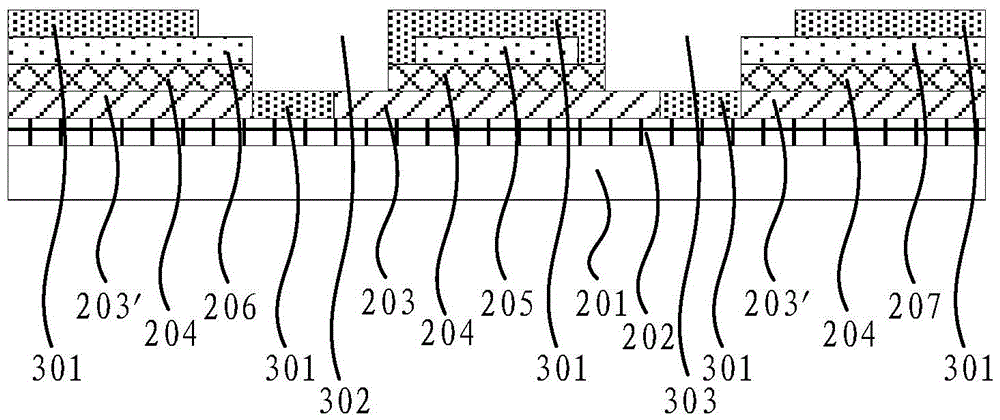

The invention provides an array substrate, a manufacturing method thereof and a display device. The manufacturing method comprises the steps that a grid metal film is deposited on a substrate body, and a first graph comprising a grid is formed through a primary composition technology; a grid insulating film, a first transparent conductive film, a source drain metal film and a doped a-si film are sequentially deposited, and a second graph comprising a pixel electrode, a source, a drain and a doped semiconductor layer is formed through a secondary composition technology; the a-si film is deposited, and a third graph comprising a TFT channel, a semiconductor layer and a grid insulating layer via hole is formed through a third composition technology; a passivation layer film is deposited and a fourth graph comprising a passivation layer via hole is formed through a fourth composition technology, wherein the passivation layer film via hole corresponds to the grid insulating layer via hole in position; a second transparent conductive layer is deposited and a fifth graph comprising an electric connecting part is formed through a fifth composition technology. By means of the manufacturing method, manufacturing processes can be reduced and the product quality can be improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

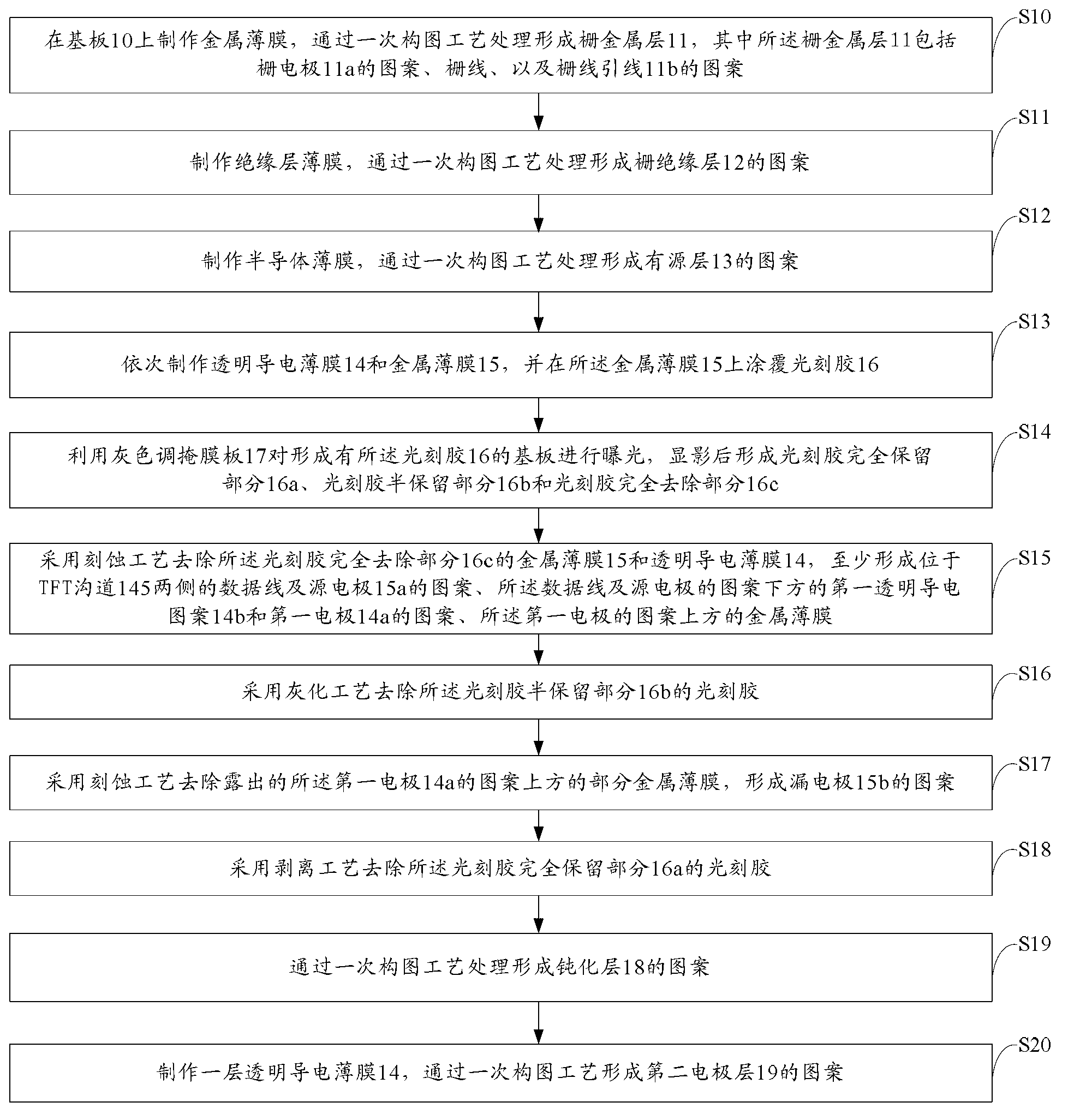

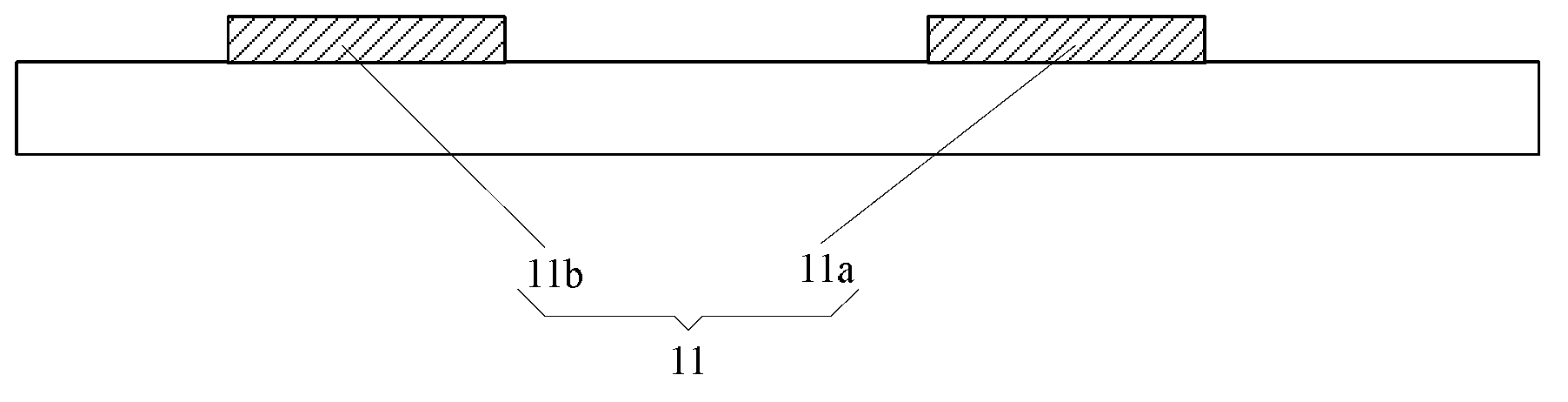

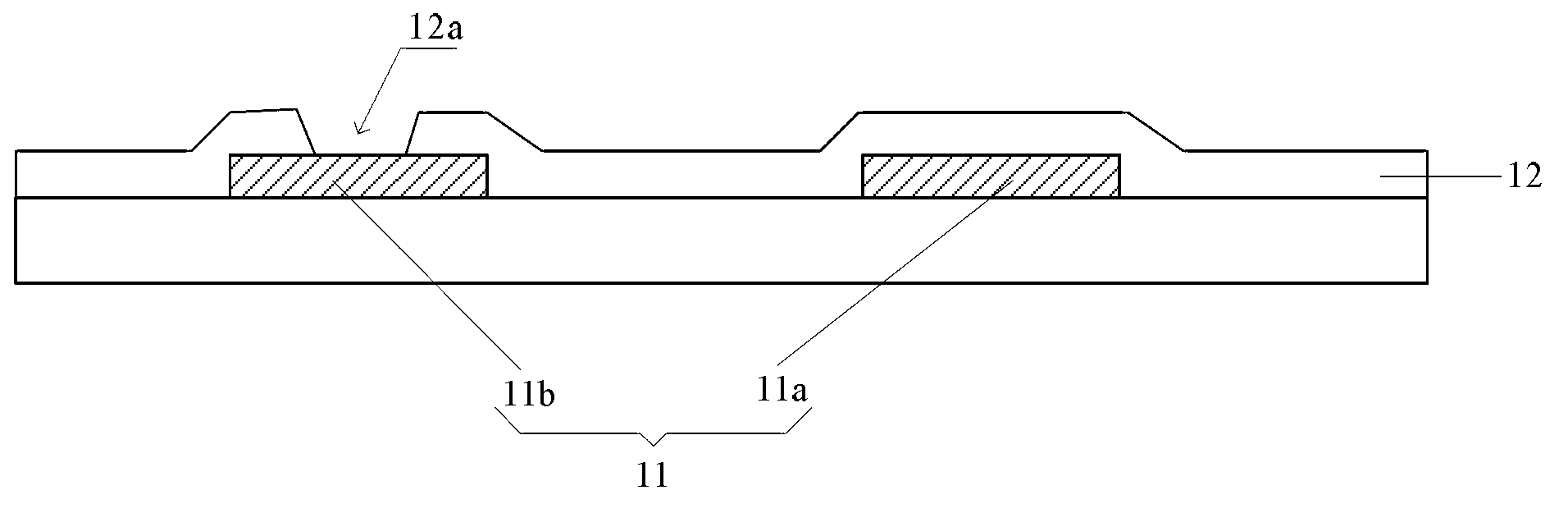

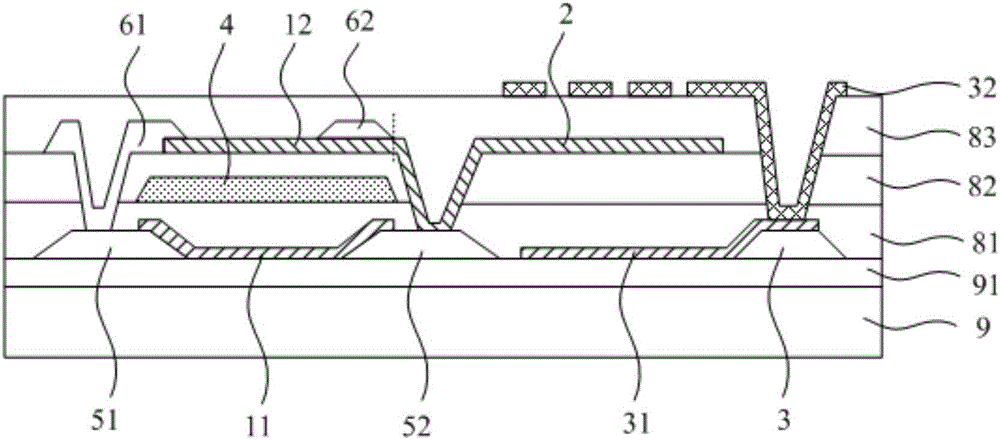

Array substrate, manufacturing method of array substrate, and display device

InactiveCN103022055AIncrease production capacityReduce the number of patterning processesSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

An embodiment of the invention provides an array substrate, a manufacturing method of the array substrate, and a display device, and relates to the technical field of display. The manufacturing method includes steps of 1, forming a pattern layer with a grid electrode on a substrate; 2, forming a pattern layer with a grid insulation layer on the substrate subjected to the last step; 3, forming a pattern layer with an active layer on the substrate subjected to the second step; 4, sequentially forming a transparent conductive thin film and a metal thin film on the substrate subjected to the third step, and forming a pattern layer with a first electrode, a data line, a source electrode, a drain electrode and a thin film transistor (TFT) channel through pattern composition process; 5, forming a pattern layer with a passivated layer on the substrate subjected to the fourth step; and 6, forming a pattern layer with a second electrode on the substrate subjected to the fifth step. The manufacturing method is used for manufacturing the array substrate and the display device and the like. The array substrate, the manufacturing method of the array substrate and the display device have the advantages that pattern composition process times can be decreased, and accordingly, productivity of mass production products is improved, and cost is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Array substrate and preparation method thereof

ActiveCN105097829AImprove transmission performanceReduce the number of patterning processesTransistorSolid-state devicesIon implantationSemiconductor

The invention provides an array substrate and a preparation method thereof, belongs to the technical field of array substrates, and aims at solving the problem of complicated preparation technology of the existing array substrate employing a double-channel thin-film transistor. The array substrate provided by the invention comprises a plurality of thin-film transistors, a first electrode and a second electrode, wherein each thin-film transistor comprises a grid, a first active region and a second active region; each first active region and each second active region are respectively located below and above each grid and are composed of metal-oxide semiconductors; the first electrode and the first active regions are located on the same layer; the second electrode and the second active regions are located on the same layer; and the first electrode and the second electrode are composed of ion-implanted metal-oxide semiconductors.

Owner:BOE TECH GRP CO LTD

Array substrate manufacturing method, array substrate and display device

InactiveCN104078423AReduce the number of patterning processesReduce process complexitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyInsulation layer

The invention provides an array substrate manufacturing method, an array substrate and a display device. The array substrate manufacturing method includes the steps of forming patterns of an active layer, a grid insulation layer, a grid and a grid line with the once layout technology; forming a passivation layer on a substrate where the active layer, the grid insulation layer, the grid and the grid line are formed, and forming a via hole in the passivation layer with the once layout technology; forming patterns of a data line, a source, a drain and a pixel electrode on the substrate where the passivation layer is formed with the once layout technology, wherein the drain makes contact with the active layer through the via hole. By means of the array substrate manufacturing method, the array substrate and the display device, the number of times of the layout technology adopted in the low temperature polycrystalline silicon array substrate manufacturing technology process is decreased, the technology complexity is accordingly lowered, and the technology cost is reduced while the manufacturing technology time is shortened.

Owner:BOE TECH GRP CO LTD

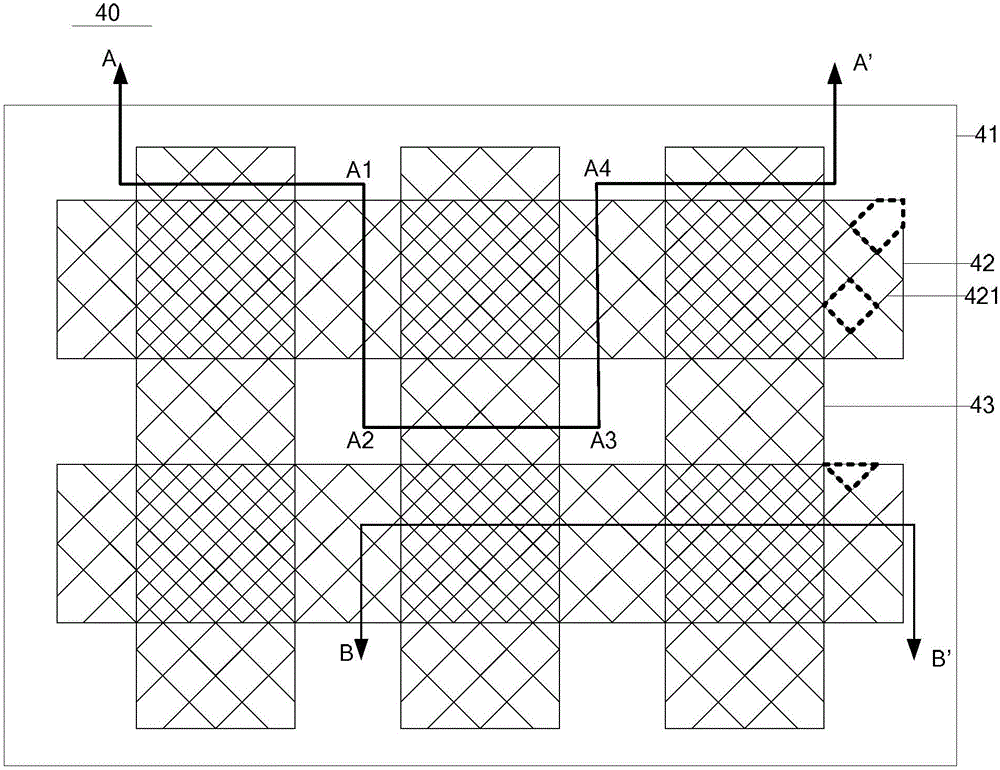

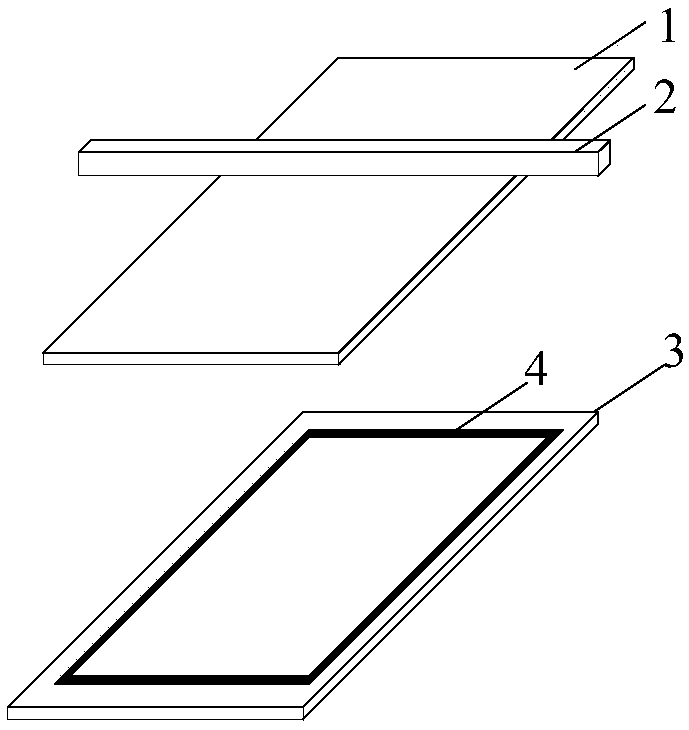

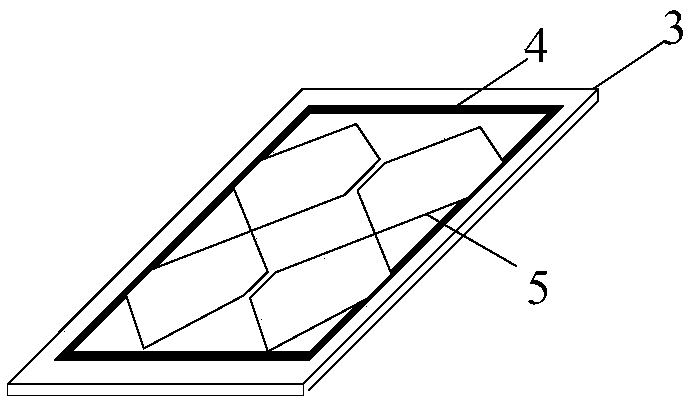

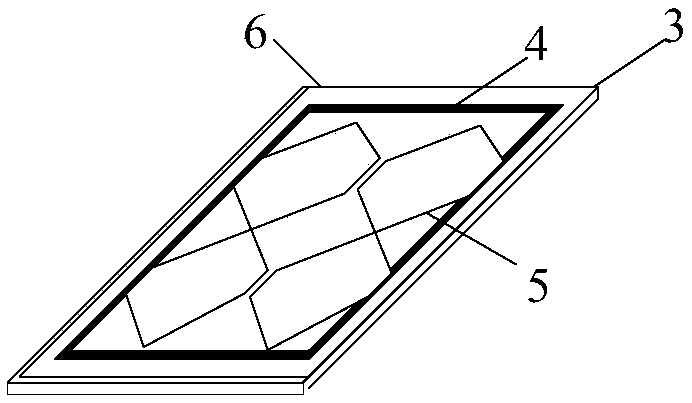

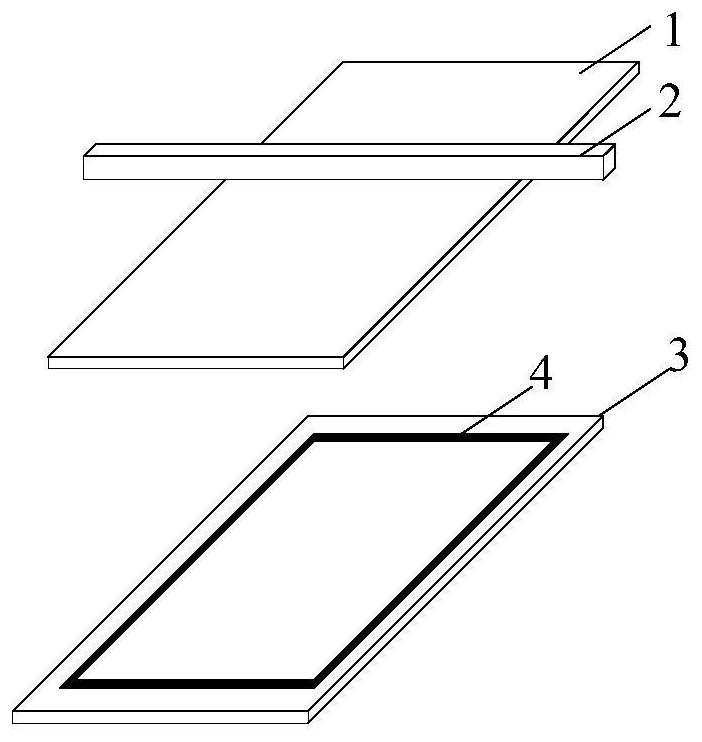

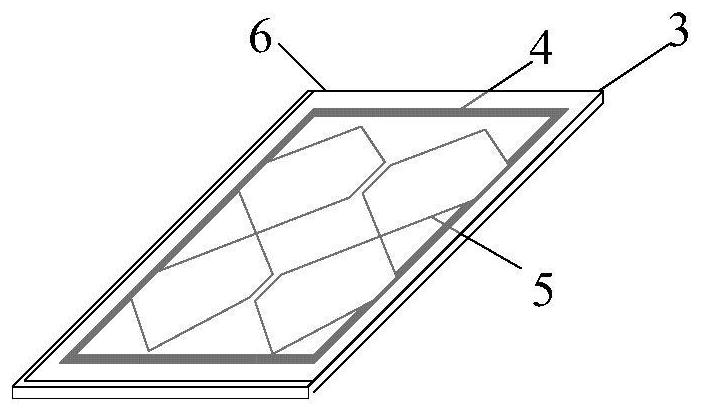

Upper substrate and preparation method thereof, touch display panel and preparation method thereof

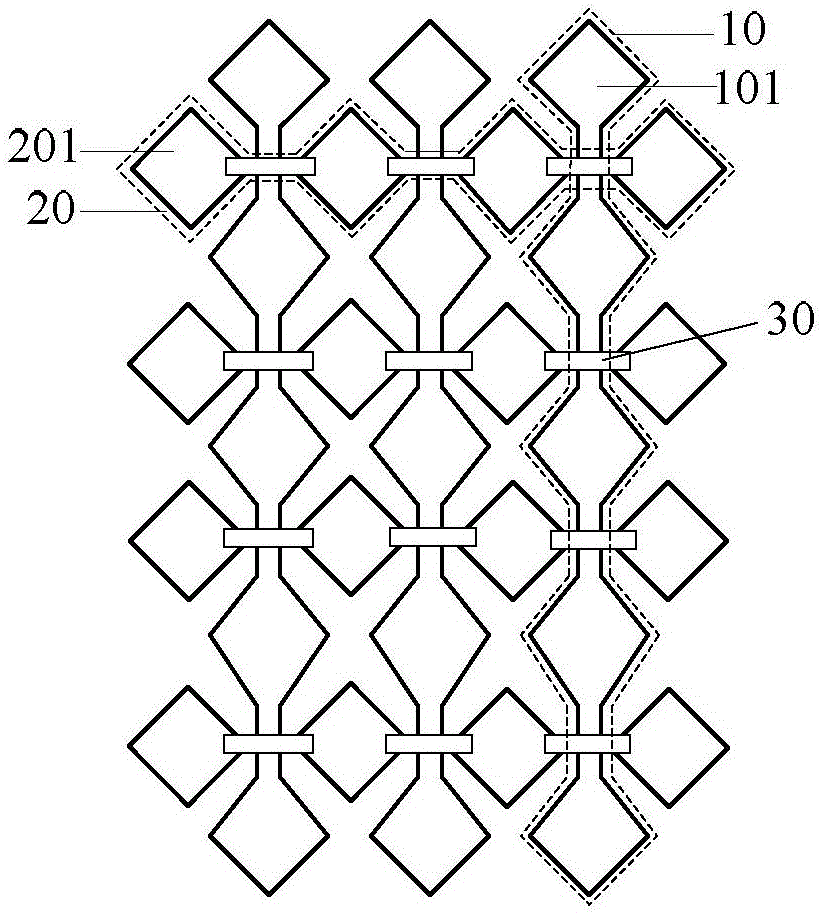

ActiveCN104571716AReduce the number of patterning processesReduce manufacturing costInput/output processes for data processingElectrically conductiveEngineering

The embodiment of the invention provides an upper substrate for the touch display panel, and a preparation method thereof, a touch display panel and a preparation method thereof, relating to the technical field of display and aiming at preventing the increase of picture composition times, and lowering the production cost. The preparation method of the upper substrate comprises the following steps: forming a black matrix through one-time composition technology, wherein the black matrix in the display area corresponds to a gap between the two adjacent touch electrodes; forming a negative photosensitive type organic resin thin film on the substrate of the black matrix, exposing and developing by taking the black matrix as a mask, removing the organic resin thin film corresponding to the black matrix so as to form an organic resin layer; forming a transparent conductive thin film above the organic resin layer, wherein the transparent conductive thin films respectively positioned above the organic resin layer and the black matrix are separated, the touch electrode is formed on the transparent conductive thin film above the organic resin layer, and a retention pattern is formed on the transparent conductive thin film above the black matrix. The preparation methods are used for manufacturing the upper substrate for the touch display panel, and the touch display panel.

Owner:BOE TECH GRP CO LTD

Array substrate and manufacturing method thereof as well as display device

ActiveCN105448824AReduce the number of patterning processesIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

The present invention provides an array substrate and a manufacturing method thereof as well as a display device, and belongs to the technical field of display. The manufacturing method of the array substrate comprises the following steps: forming a gate electrode, a gate line, a data line, a source electrode and a drain electrode on an insulation layer through a one-step patterning process; and installing the gate electrode, the gate line, the data line, the source electrode and the drain electrode in the same layer by using the same material. The technical solution of the present invention can reduce the number of times of patterning process when the array substrate is prepared, increase the production efficiency, reduce the manufacturing cost, and can also reduce a coupling capacitance among the source electrode, the drain electrode and the grate electrode of the array substrate, thereby reducing the power consumption of the array substrate.

Owner:BOE TECH GRP CO LTD

Cover plate, preparation method of cover plate and display device

InactiveCN106293200AImprove transmittanceAvoid breakdown phenomenonOpticsInput/output processes for data processingComposition processDisplay device

Owner:BOE TECH GRP CO LTD +1

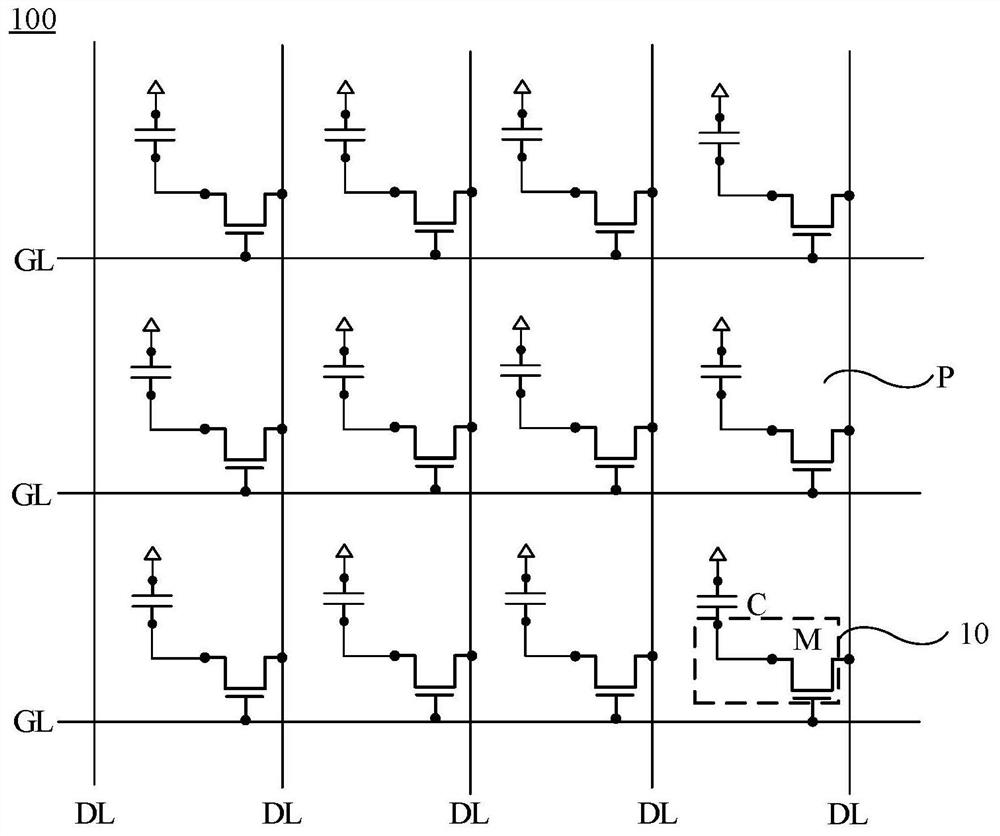

Array substrate and preparation method thereof and display device

PendingCN111897168AImprove the active layer over-etching problemReduce the number of patterning processesSolid-state devicesNon-linear opticsEngineeringDisplay device

The embodiment of the invention discloses an array substrate and a preparation method thereof, and a display device, relates to the technical field of display, and aims to prevent an active layer frombeing over-etched and reduce the process frequency and the manufacturing cost. The array substrate comprises an underlayer substrate, a light shading pattern, a buffer pattern, an active layer, a gate insulating layer, a first passivation layer and source and drain electrodes, wherein the orthographic projection of the buffer pattern on the underlayer substrate covers the orthographic projectionof the active layer on the underlayer substrate, the orthographic projection of the buffer pattern on the underlayer substrate is within the orthographic projection range of the light shading patternon the underlayer substrate, the area of the orthographic projection of the buffer pattern on the underlayer substrate is smaller than that of the orthographic projection of the light shading patternon the underlayer substrate, a first via hole, a second via hole and a third via hole are formed in the gate insulating layer and the first passivation layer, one of the source electrode and the drainelectrode is coupled with the active layer through the first via hole, and the other one is coupled with the active layer through the second via hole and is coupled with the light shading pattern through the third via hole. The array substrate is applied to the display device, so that the display device displays a picture.

Owner:BOE TECH GRP CO LTD +1

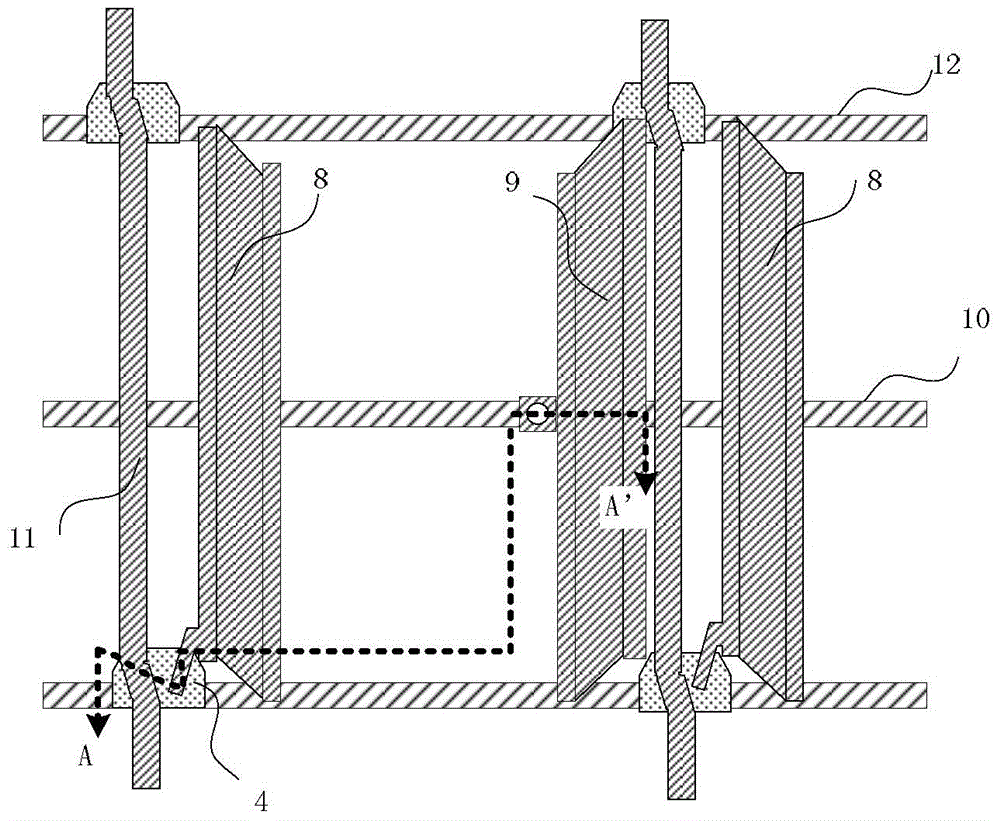

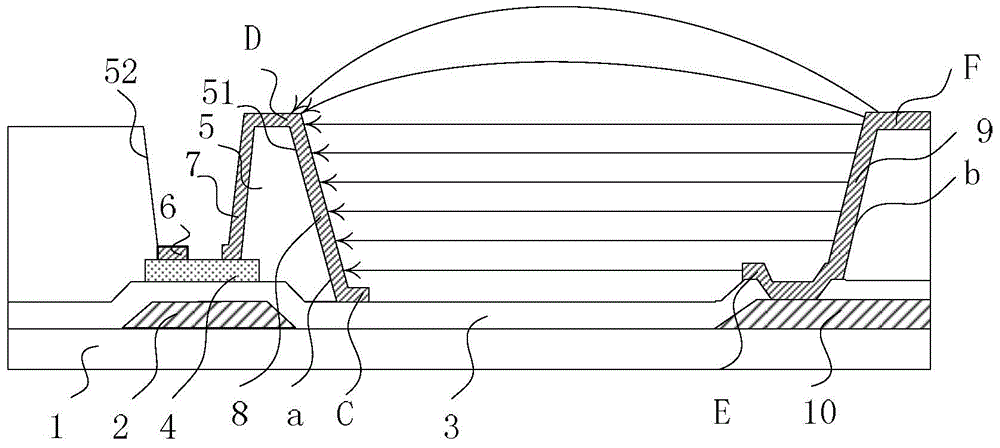

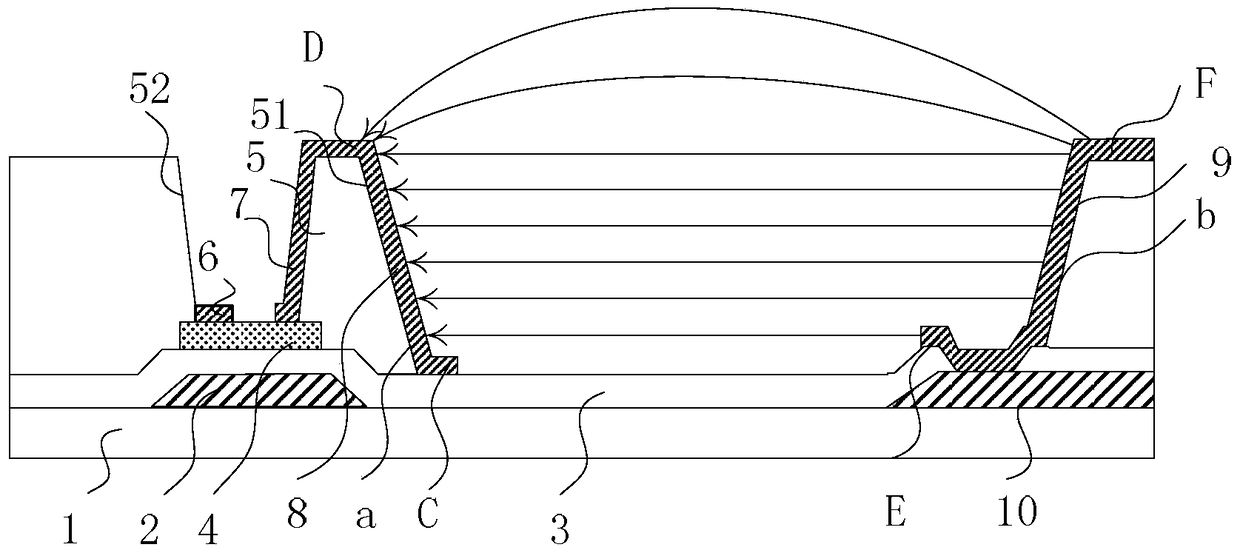

Array substrate and manufacture method thereof and display device

ActiveCN104932127AImprove yield rateReduce one composition processSolid-state devicesNon-linear opticsDisplay deviceOptoelectronics

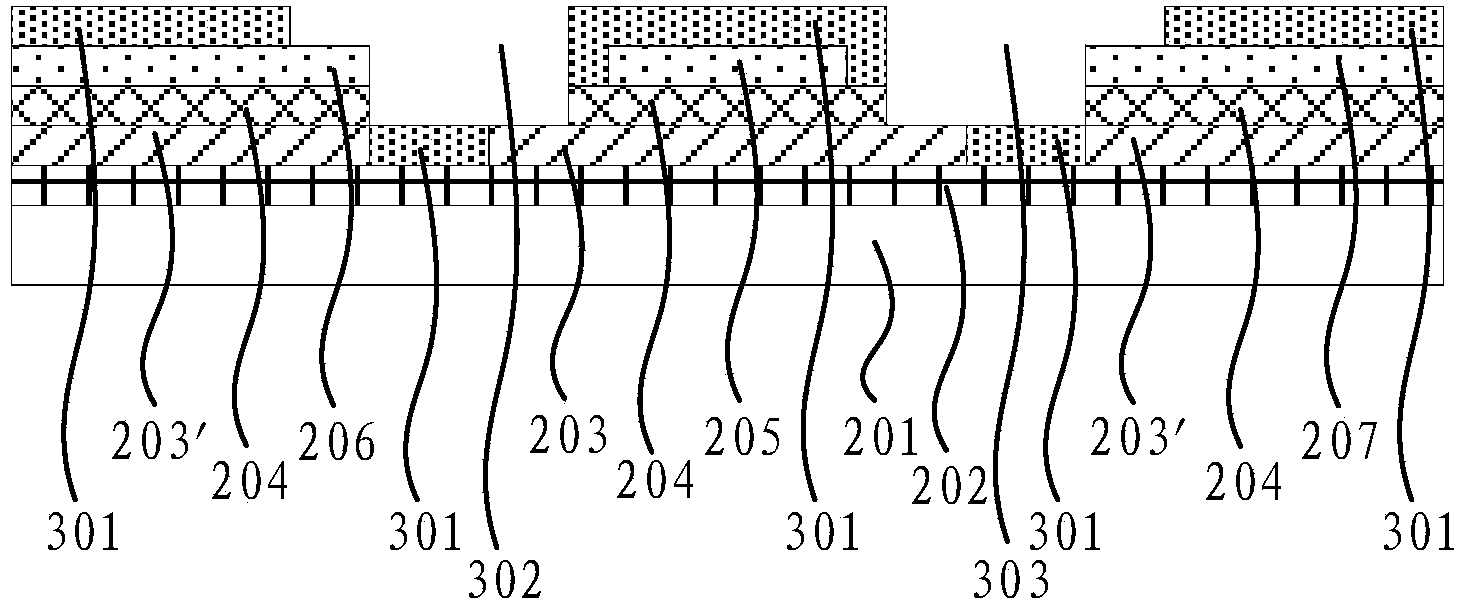

The invention discloses an array substrate and a manufacture method thereof and a display device, and relates to the technical field of display. The times of a picturing technology adopted in the manufacture process of the array substrate can be decreased. The array substrate comprises an underlayment substrate and a gate, a gate insulation layer and an active layer, and further comprises a passivation layer arranged on the active layer and a source electrode, a drain electrode, a first electrode and a second electrode which are arranged on the passivation layer in a same-layer mode; the passivation layer is provided with a first via hole which comprises two oppositely arranged inclined side surfaces; the first electrode at least partially covers one side surface of the first via hole, the second electrode at least partially covers the other side surface of the first via hole, and the second electrode is in electronic connection with a lead of a common electrode; the passivation layer is further provided with a second via hole, the source electrode and the drain electrode are connected with the active layer through the second via hole, and the first electrode is in electronic connection with the source electrode or the drain electrode. The array substrate can be applied to the display device.

Owner:BOE TECH GRP CO LTD +1

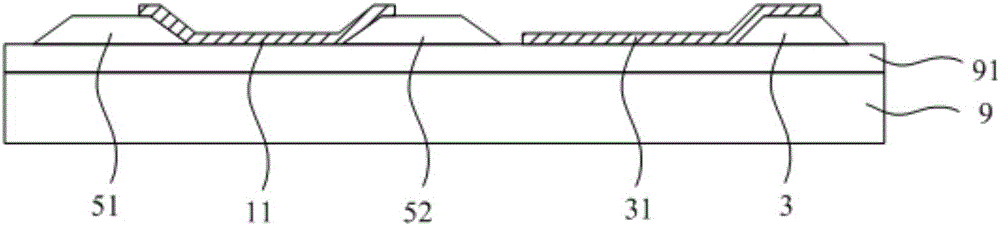

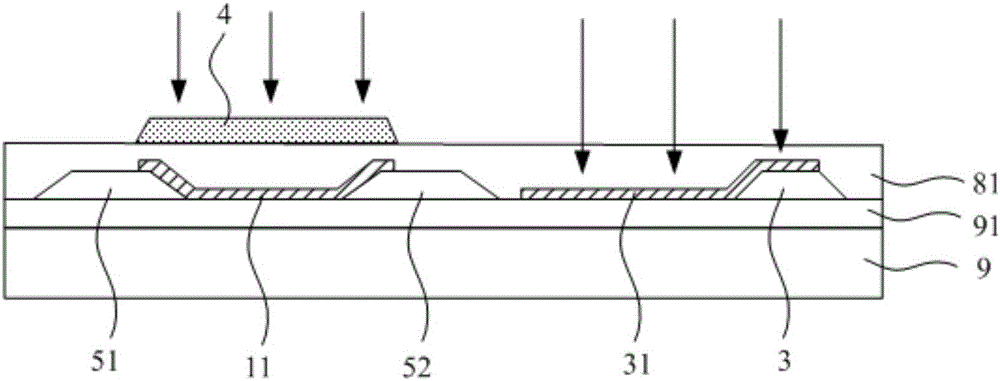

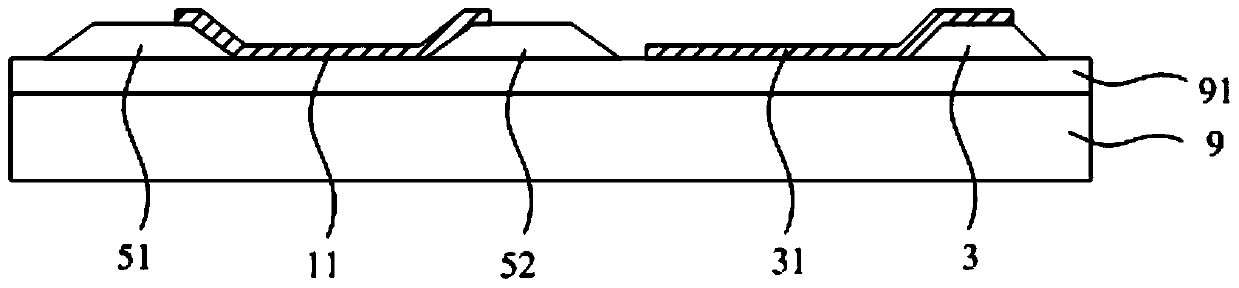

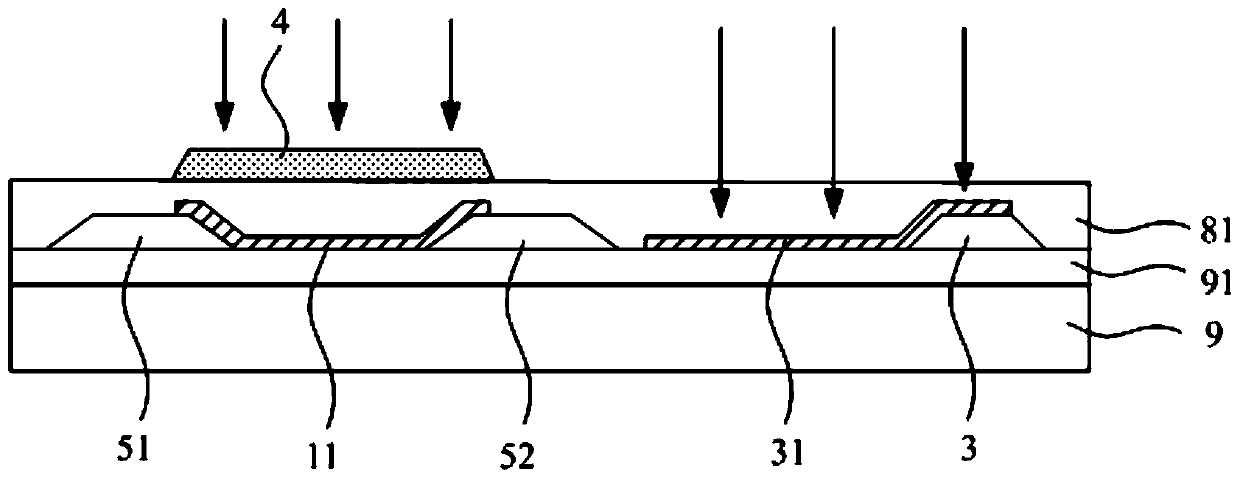

Photoelectric detection substrate, preparation method thereof, and photoelectric detection device

ActiveCN109087928AReduce thicknessReduce deformationTransistorSolid-state devicesImage resolutionEngineering

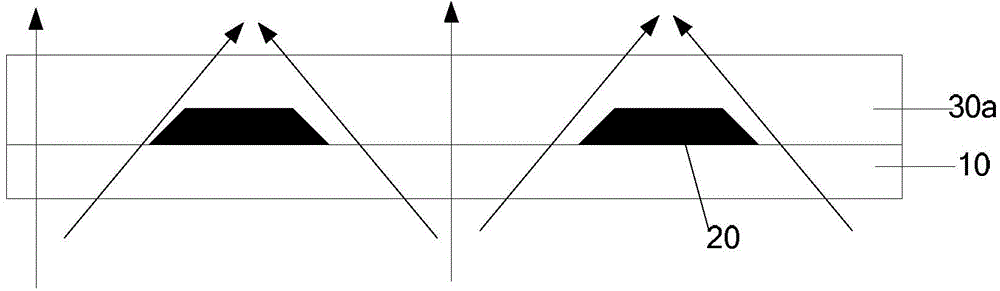

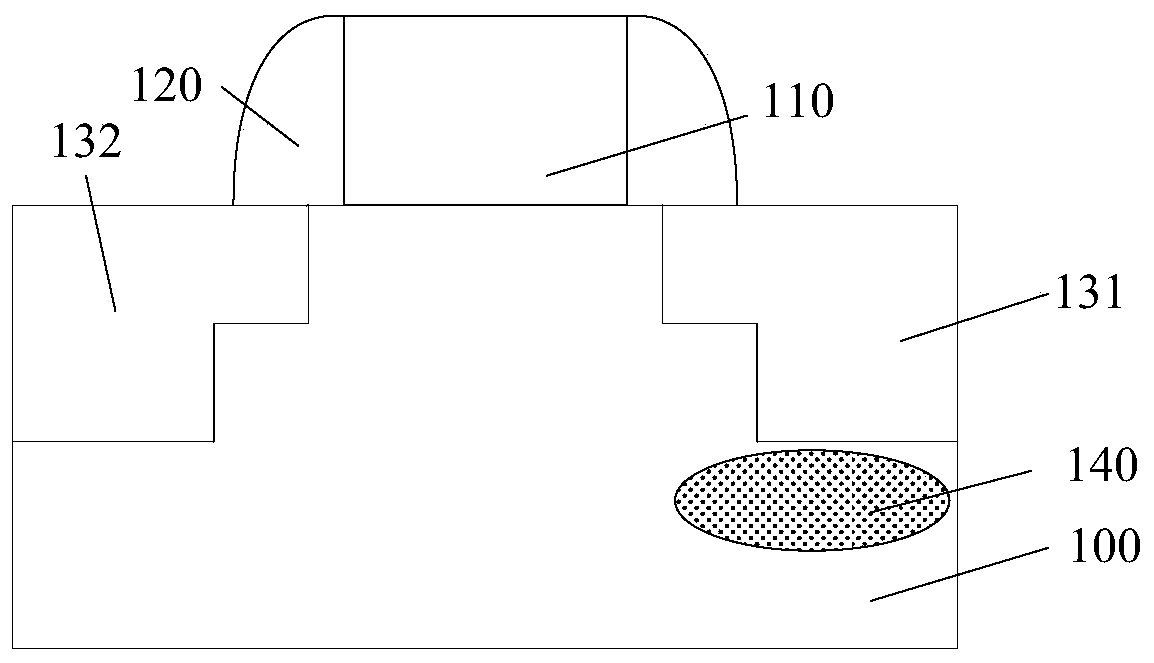

The invention provides a photoelectric detection substrate, a preparation method thereof, and a photoelectric detection device. The photoelectric detection substrate comprises a thin film transistor and a photodiode having coplanar structure, and the thin film transistor is a vertical channel structure. By forming a coplanar structure of the thin film transistor with a vertical channel structure and the photodiode, the invention effectively reduces the overall thickness of the photoelectric detection substrate, reduces the deformation of the substrate caused by stress, avoids damage caused bythe deformation of the substrate, and improves the yield of the product. At the same time, because of the coplanar structure, the thin film transistor and the photodiode can be fabricated simultaneously, the number of times of the patterning process are reduced, the preparation process is simplified, and the production cost is reduced. As the occupied area of the vertical channel structure thin film transistor is small, the photodiode photosensitive area can be increased, so that the detection efficiency can be improve and the resolution of the product can be improved.

Owner:BOE TECH GRP CO LTD

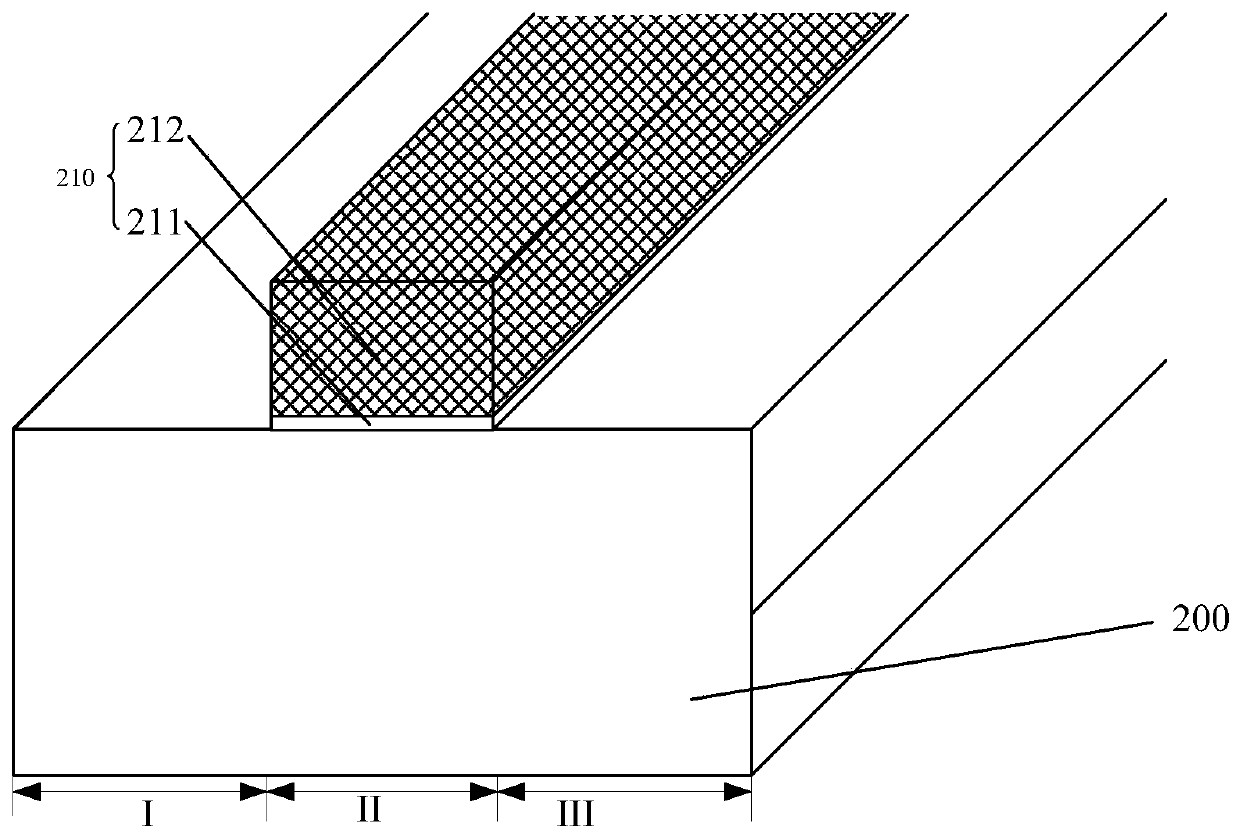

Electrostatic discharge protection structure and forming method and working method thereof

InactiveCN109994467AImprove performanceReduce the number of timesTransistorSolid-state devicesElectrostatic discharge protectionIon

The invention relates to an electrostatic discharge protection structure and a forming method and a working method thereof. The forming method comprises steps that a substrate is provided, and the substrate includes a first region, a second region and a third region; a first well region is formed in the substrate, and the first well region has first ions with the first concentration; a first gatestructure is formed on a surface of the second region; a first doping region is formed in the first region, and the first doping region has second ions having a conductivity type opposite to the firstions; a second doping region is formed in the third region, the second doping region has second ions with the second concentration, and the second concentration is greater than the first concentration; a third doping region is formed in the third region, the second doping region and the third doping region are arranged parallel to the first direction, the second doping region is adjacent to the third doping region, the three doping region has third ions with the third concentration, a conductivity type of the third ions is opposite to the second ions, and the third concentration is greater than the first concentration. The method is advantaged in that performance of the electrostatic discharge protection structure is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

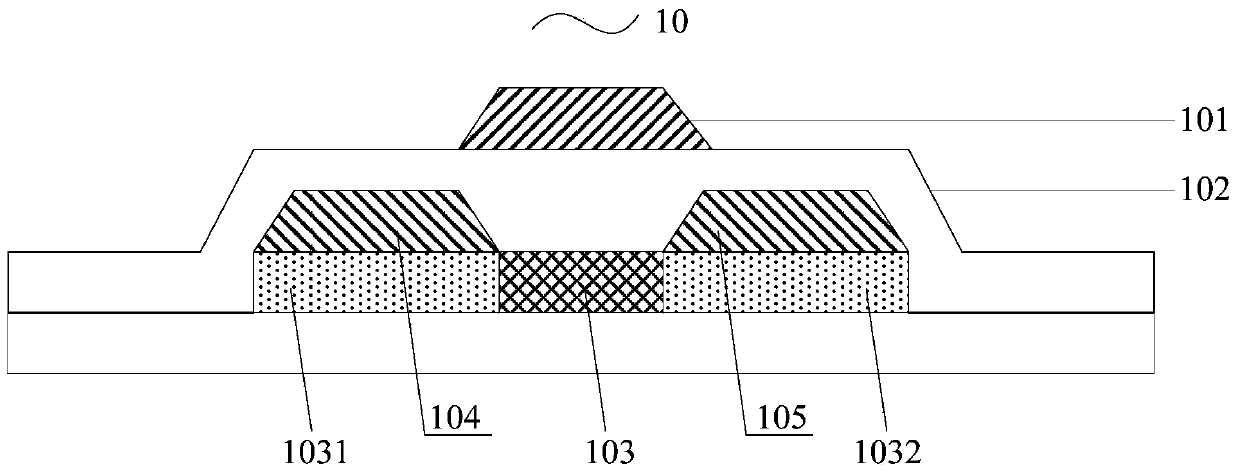

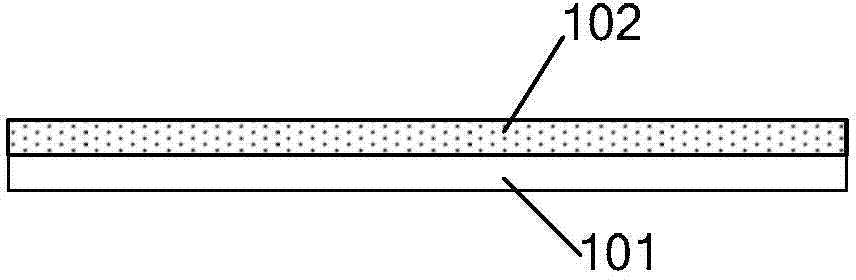

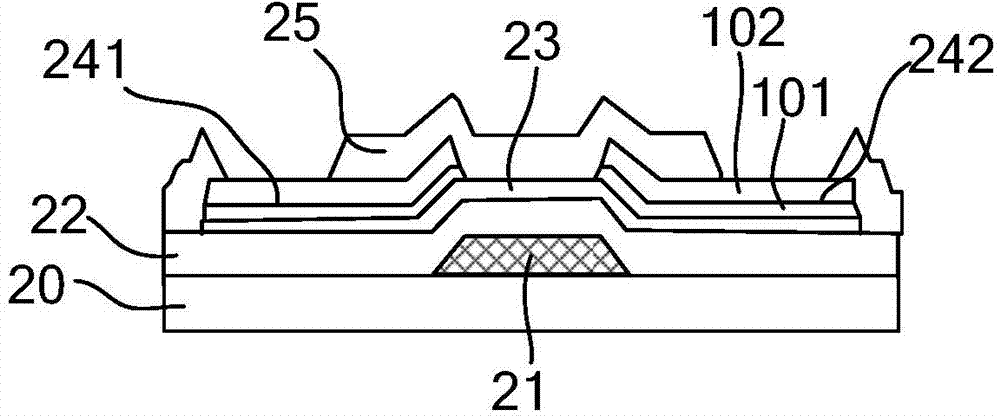

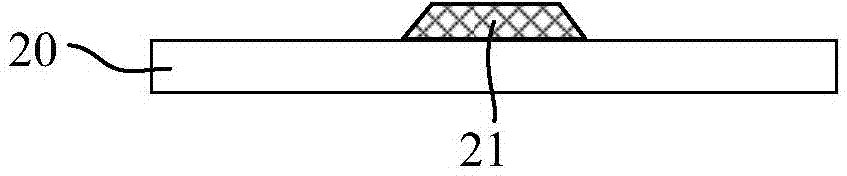

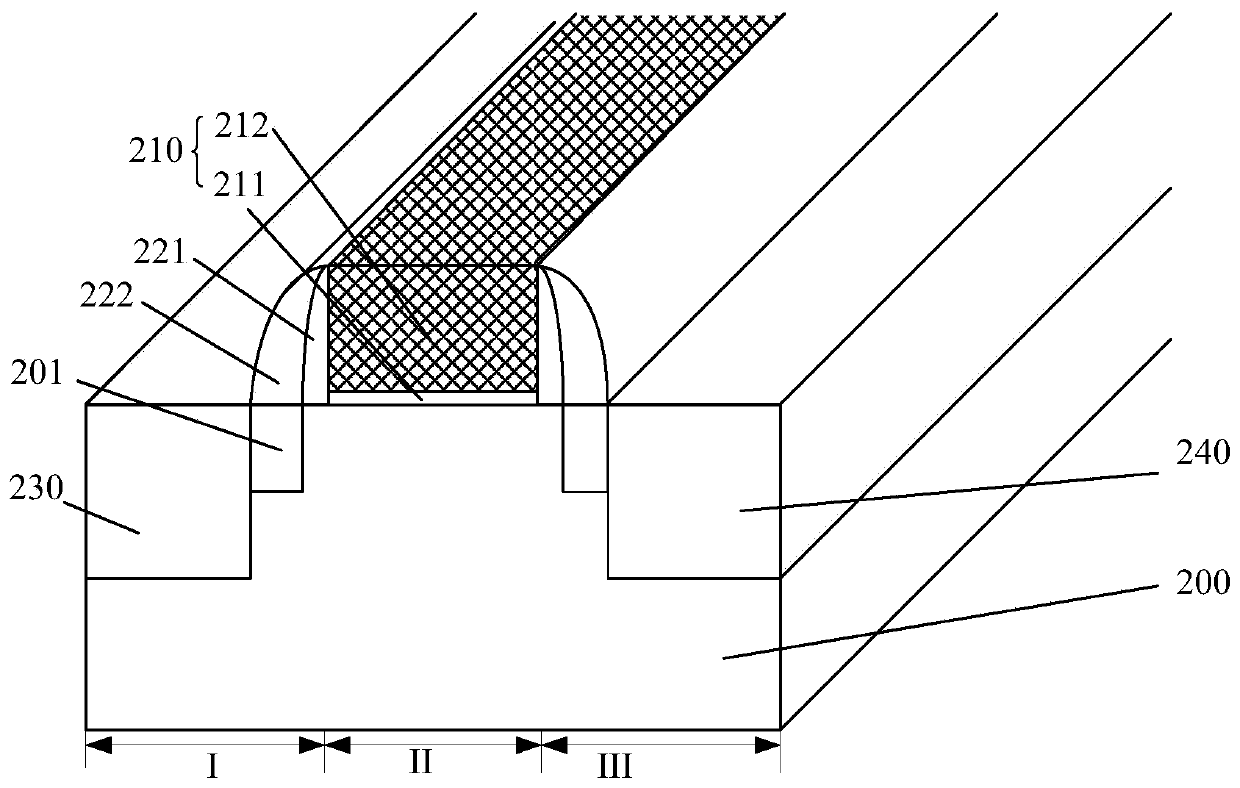

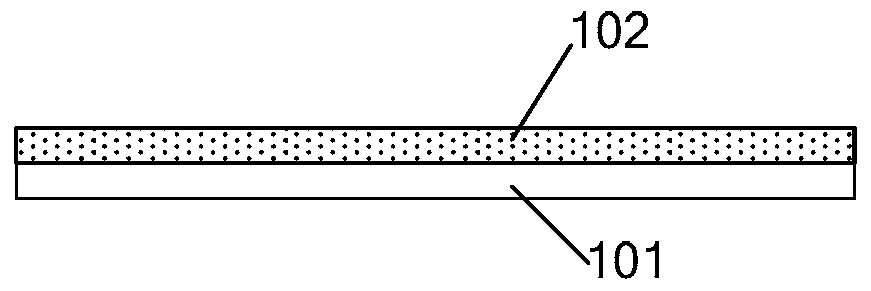

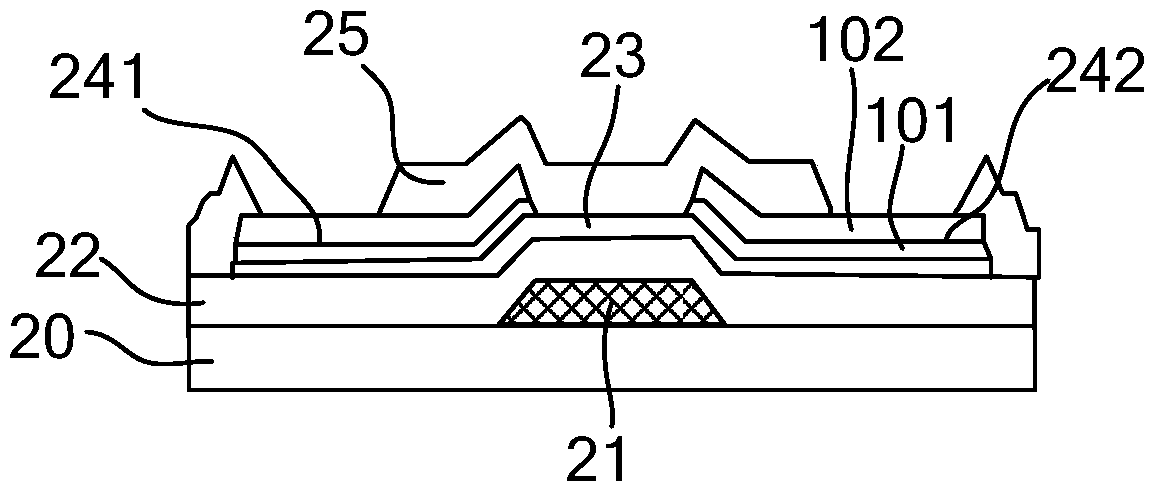

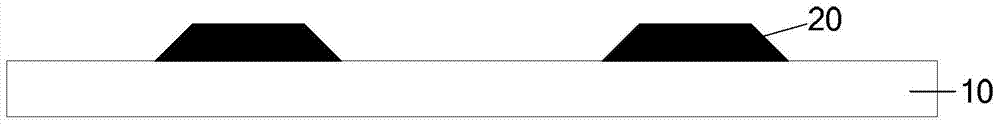

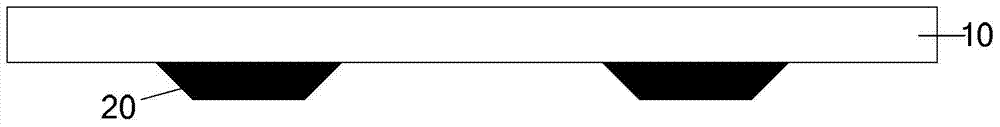

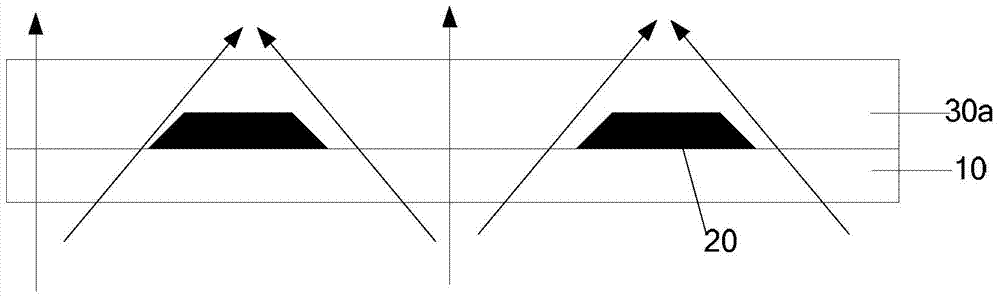

Thin film transistor, method for manufacturing the same, and display device

ActiveCN104716198BEtching speed is fastSolve the problem of easy corrosionTransistorSemiconductor/solid-state device manufacturingDisplay deviceEngineering

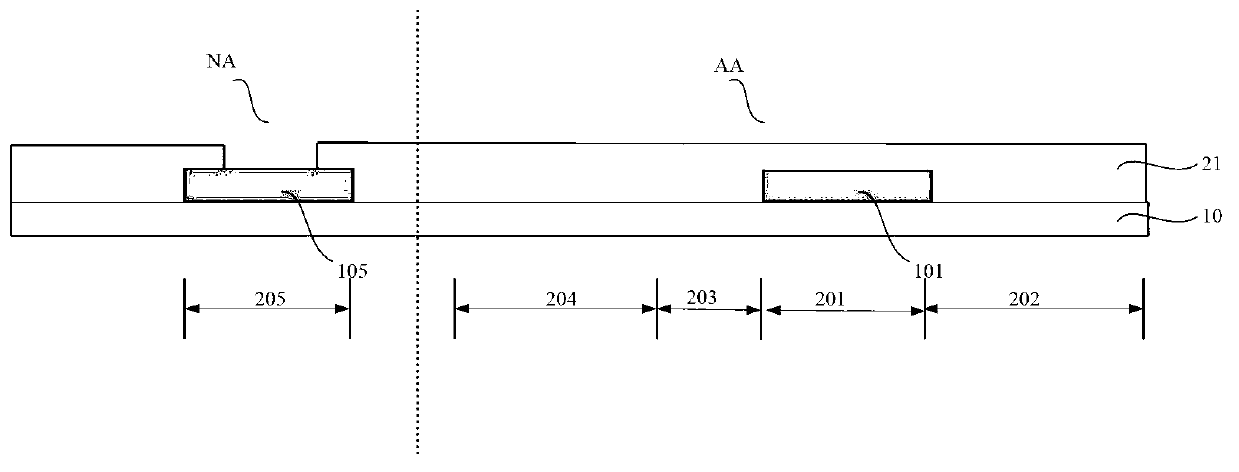

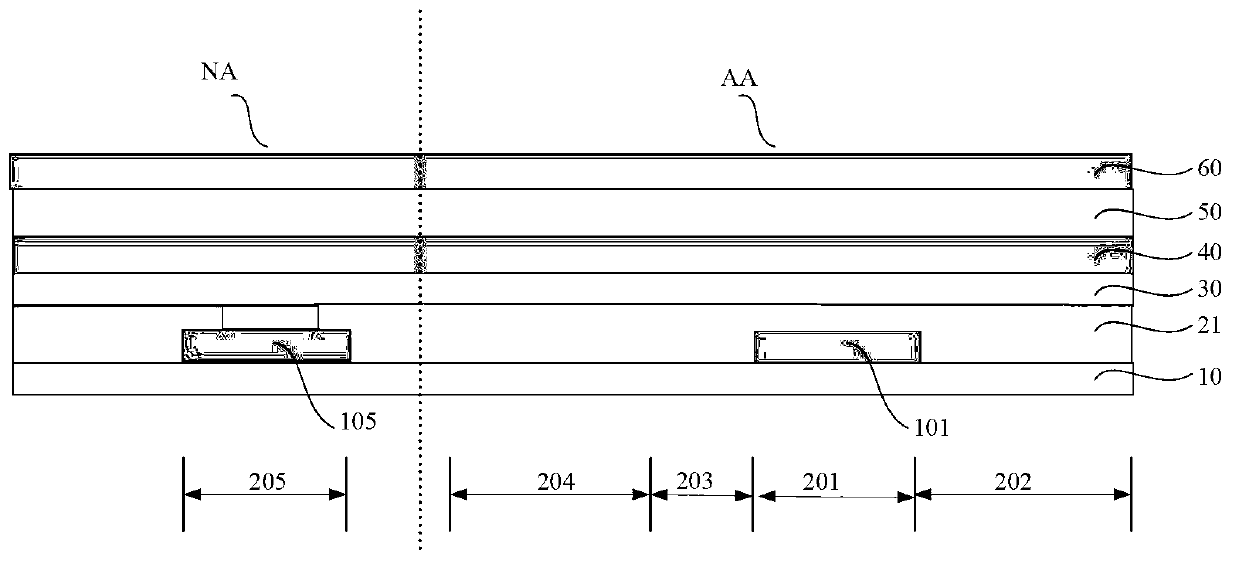

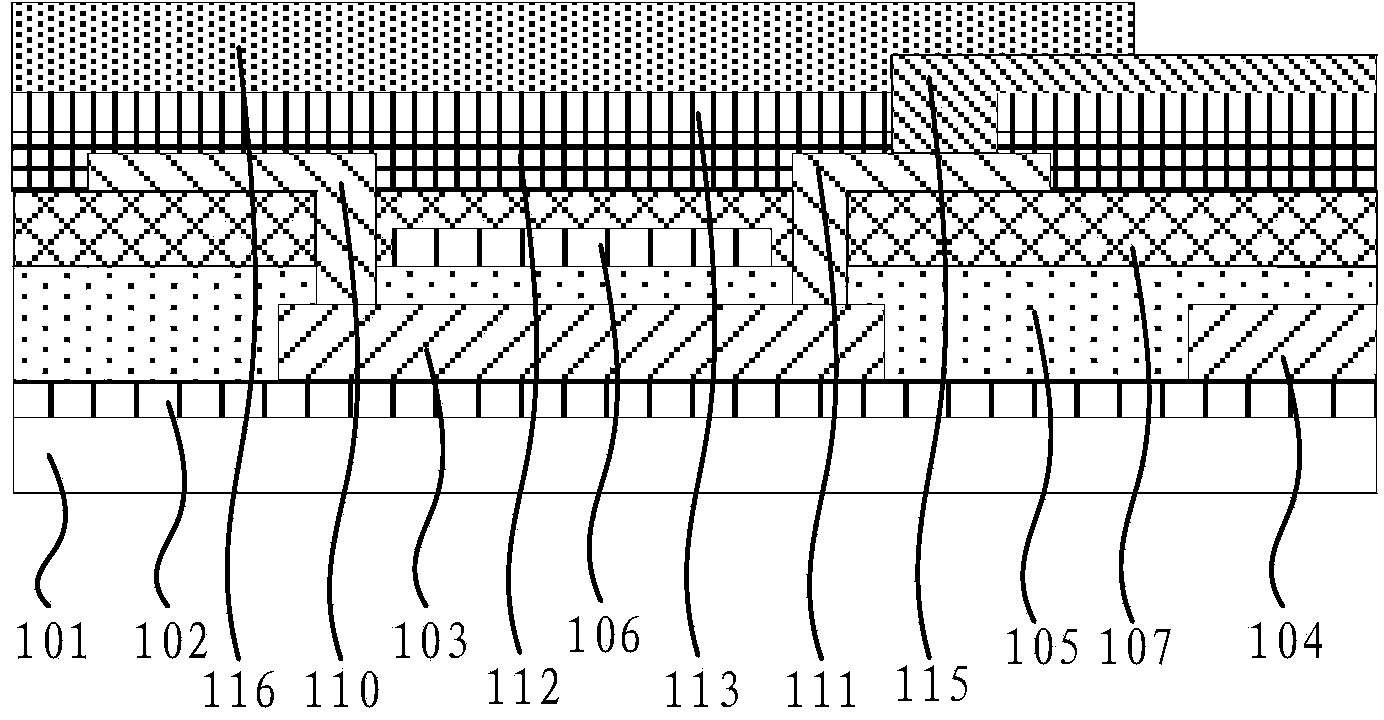

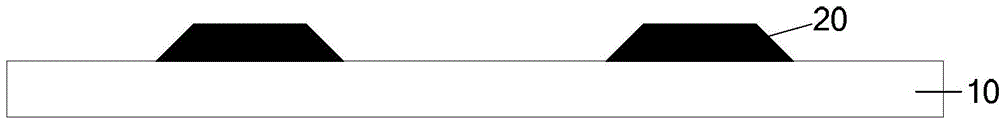

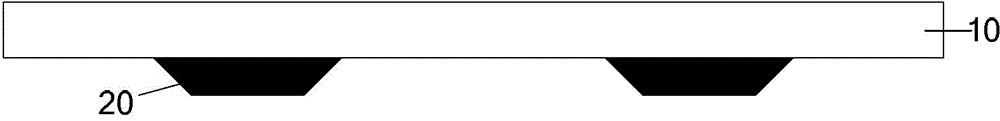

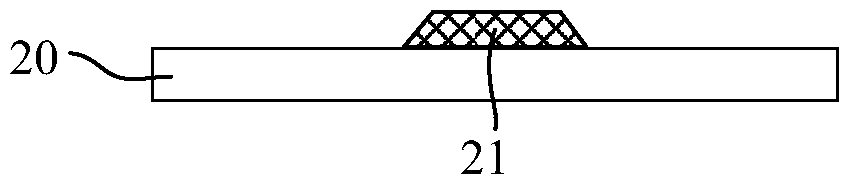

A thin film transistor, a manufacturing method thereof, and a display device are provided. The thin film transistor includes a gate electrode (21), an active layer (23), a source electrode (241) and a drain electrode (242). The source electrode (241) and the drain electrode (242) are formed of at least two materials, the forming materials of the source electrode (241) and the drain electrode (242) can create a cell reaction in a corresponding etching solution so as to be etched, and material of the active layer (23) is not corroded by the etching solution. With the thin film transistor and manufacturing method thereof according to embodiments of the invention, a problem that an active layer is liable to be corroded in an etching procedure of a source electrode and a drain electrode can be solved, and thus the thin film transistor device can be manufactured by using a back channel etch process. Consequently, the process number for manufacture of the thin film transistor is decreased, and the manufacturing cost is saved.

Owner:BOE TECH GRP CO LTD

Contact-control substrate, manufacture method thereof, and display device

ActiveCN109471559AReduce in quantityReduce the number of patterning processesInput/output processes for data processingDisplay deviceComputer science

The invention provides a touch control substrate and a manufacturing method thereof, and a display device, belonging to the technical field of display. The touch substrate comprises a first touch electrode, a first insulating layer, a second touch electrode and a second insulating layer arranged sequentially on a substrate, and the manufacturing method of the touch substrate comprises the steps offorming a pattern of the second touch electrode and the second insulating layer by a primary patterning process. The technical proposal of the invention can reduce the number of mask plates requiredfor manufacturing the touch substrate, reduce the number of patterning processes for manufacturing the touch substrate, shorten the production time of the touch substrate, and reduce the production cost of the touch substrate.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Photoelectric detection substrate and its preparation method, photoelectric detection device

ActiveCN109087928BReduce thicknessReduce deformationTransistorSolid-state devicesImage resolutionThin membrane

The invention provides a photoelectric detection substrate, a manufacturing method thereof, and a photoelectric detection device. The photodetection substrate includes coplanar thin film transistors and photodiodes, and the thin film transistors are vertical channel structures. The invention effectively reduces the overall thickness of the photodetection substrate, reduces the deformation of the substrate caused by stress, avoids the damage caused by the deformation of the substrate, and improves Product yield. At the same time, due to the coplanar structure, the thin film transistor and the photodiode can be manufactured simultaneously, which reduces the number of patterning processes, simplifies the preparation process, and reduces the production cost. In addition, since the occupied area of the thin film transistor with the vertical channel structure is small, the light-sensing area of the photodiode can be increased, thereby improving the detection efficiency and product resolution.

Owner:BOE TECH GRP CO LTD

A kind of thin film transistor drive backplane and its manufacturing method, display panel

ActiveCN103489827BReduce thicknessEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

The invention relates to the field of display technology, in particular to a thin film transistor driving backplane, a manufacturing method thereof, and a display panel. The manufacturing method includes manufacturing a backplane substrate provided with multiple active device structures; setting an electrode layer on the backplane substrate; making the electrode layer into a source electrode, a drain electrode, and a drain electrode through a patterning process. An integrated pixel electrode. The manufacturing method of the present invention adopts a design in which the electrode layer is made into multiple source electrodes, drain electrodes, and pixel electrodes integrally arranged with the drain electrodes through a patterning process; the source electrodes, the drain electrodes, and the pixel electrodes are all in the same electrode layer; The source, drain and pixel electrodes that need to be formed by two patterning processes in the existing method are simplified to only one patterning process; the thickness of the thin film transistor driving backplane is greatly reduced, the manufacturing steps are simplified, and the savings production cost.

Owner:BOE TECH GRP CO LTD

Array substrate, manufacturing method thereof, and display device

ActiveCN103123910BShorten production timeReduce the number of patterning processesTransistorSolid-state devicesDisplay deviceActive layer

The invention belongs to the field of display technology, and discloses an array substrate and a manufacturing method thereof. The source pattern, drain pattern, pixel electrode pattern and active layer pattern of the array substrate are formed by a single patterning process. Compared with the traditional array substrate manufacturing process, the process is simple, the production time is shortened, and the product cost is reduced. , Improved product quality.

Owner:BOE TECH GRP CO LTD

Array substrate, manufacturing method thereof, and display device

ActiveCN104932127BReduce the number of patterning processesSolid-state devicesNon-linear opticsDisplay deviceComposition process

The invention discloses an array substrate, a manufacturing method thereof, and a display device, which relate to the field of display technology and can reduce the number of patterning processes used in the preparation process of the array substrate. Wherein, the array substrate includes a base substrate and a gate stacked on the base substrate, a gate insulating layer and an active layer, and also includes a passivation layer disposed on the active layer and a passivation layer disposed on the passivation layer. The source electrode, the drain electrode, the first electrode and the second electrode are arranged in the same layer; the passivation layer is provided with a first via hole, and the first via hole includes two opposite inclined sides; the first electrode at least partially covers the second electrode One side of a via hole, the second electrode at least partially covers the other side of the first via hole, the second electrode is electrically connected to the common electrode lead; a second via hole is also provided on the passivation layer, and the source and drain pass through The second via hole is connected to the active layer, and the first electrode is electrically connected to the source or the drain. The array substrate provided by the present invention can be applied to display devices.

Owner:BOE TECH GRP CO LTD +1

Oxide thin film transistor and its preparation method, array substrate and display device

ActiveCN107658345BImprove electrical performanceImprove protectionTransistorSolid-state devicesOxide thin-film transistorDisplay device

The invention provides an oxide thin film transistor, a preparation method thereof, an array substrate and a display device. In the preparation method of the oxide thin film transistor provided by the present invention, the channel protection layer is formed by oxidizing the first metal layer between the source and drain during the patterning process for forming the source and drain. Therefore, under the premise that the number of patterning processes is small, a channel protective layer that effectively protects the channel can be formed, and the electrical performance of the oxide thin film transistor is effectively improved.

Owner:BOE TECH GRP CO LTD +1

Array substrate, manufacturing method thereof, and display device

ActiveCN104022076BSimple processIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceActive layer

The present invention provides an array substrate, a manufacturing method thereof, and a display device, wherein the manufacturing method includes: forming an active material layer, a gate insulating layer, and a metal thin film on the base substrate, and forming an array substrate through a first patterning process, including The pattern of the source layer and the pattern including the gate, source, drain, gate line and data line; form a passivation layer on the substrate, and form source contact holes and drain contact holes through the second patterning process and a bridge structure contact hole; a transparent conductive film is formed on the base substrate, and part of the transparent conductive film is removed by a film stripping process to form a source contact part, a drain contact part, a pixel electrode and a bridge structure. The above-mentioned manufacturing method reduces the number of use of the patterning process, and has the advantages of simple manufacturing method, high production efficiency, and high product yield.

Owner:BOE TECH GRP CO LTD

Touch substrate, manufacturing method thereof, and display device

ActiveCN109471559BReduce in quantityReduce the number of patterning processesInput/output processes for data processingGraphicsDisplay device

The invention provides a touch substrate, a manufacturing method thereof, and a display device, which belong to the field of display technology. Wherein, the touch substrate includes a first touch electrode, a first insulating layer, a second touch electrode and a second insulating layer arranged in sequence on the base substrate, and the manufacturing method of the touch substrate includes: A patterning process forms the patterns of the second touch electrodes and the second insulating layer. The technical solution of the present invention can reduce the number of masks required for manufacturing the touch substrate, reduce the number of patterning processes for manufacturing the touch substrate, shorten the production time of the touch substrate, and reduce the manufacturing cost of the touch substrate.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Upper substrate and its preparation method, touch display panel and its preparation method

ActiveCN104571716BReduce the number of patterning processesReduce manufacturing costInput/output processes for data processingEngineeringBlack matrix

The embodiment of the invention provides an upper substrate for the touch display panel, and a preparation method thereof, a touch display panel and a preparation method thereof, relating to the technical field of display and aiming at preventing the increase of picture composition times, and lowering the production cost. The preparation method of the upper substrate comprises the following steps: forming a black matrix through one-time composition technology, wherein the black matrix in the display area corresponds to a gap between the two adjacent touch electrodes; forming a negative photosensitive type organic resin thin film on the substrate of the black matrix, exposing and developing by taking the black matrix as a mask, removing the organic resin thin film corresponding to the black matrix so as to form an organic resin layer; forming a transparent conductive thin film above the organic resin layer, wherein the transparent conductive thin films respectively positioned above the organic resin layer and the black matrix are separated, the touch electrode is formed on the transparent conductive thin film above the organic resin layer, and a retention pattern is formed on the transparent conductive thin film above the black matrix. The preparation methods are used for manufacturing the upper substrate for the touch display panel, and the touch display panel.

Owner:BOE TECH GRP CO LTD

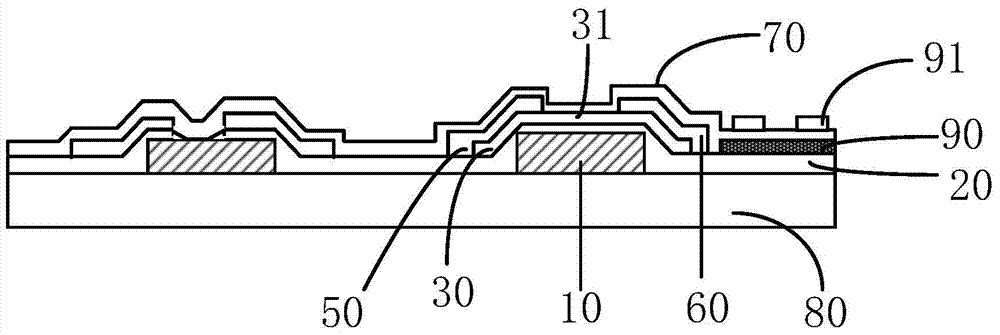

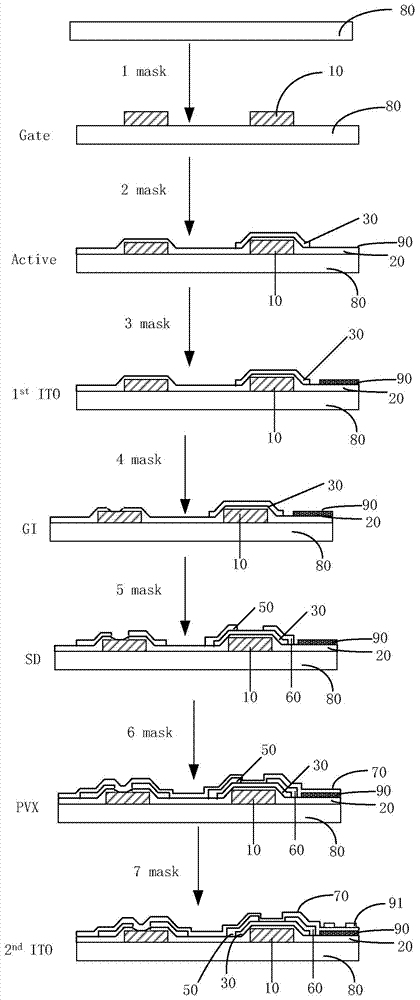

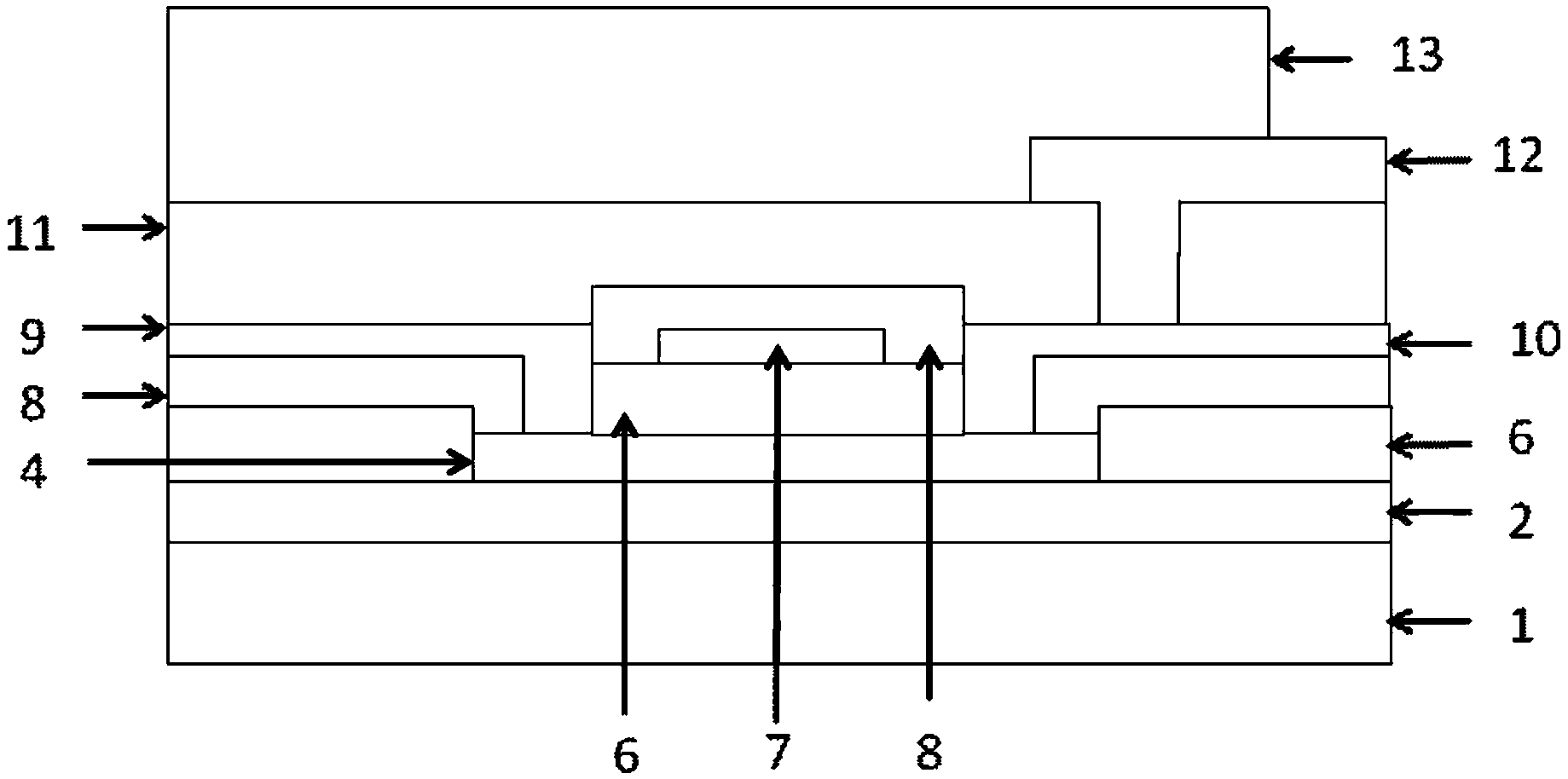

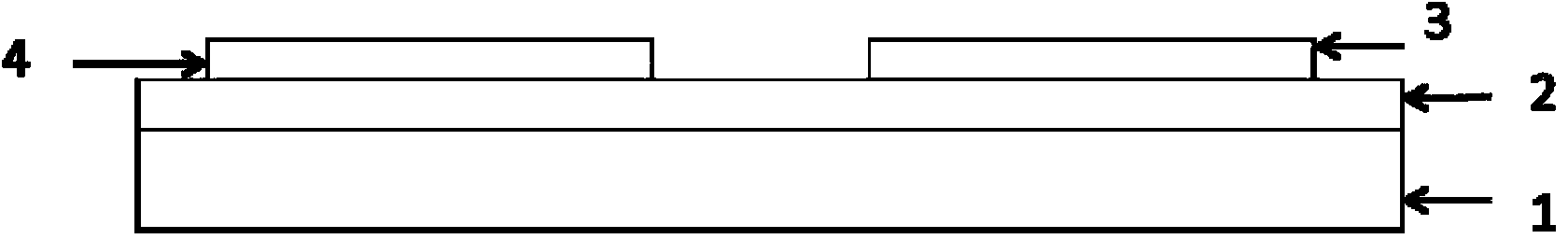

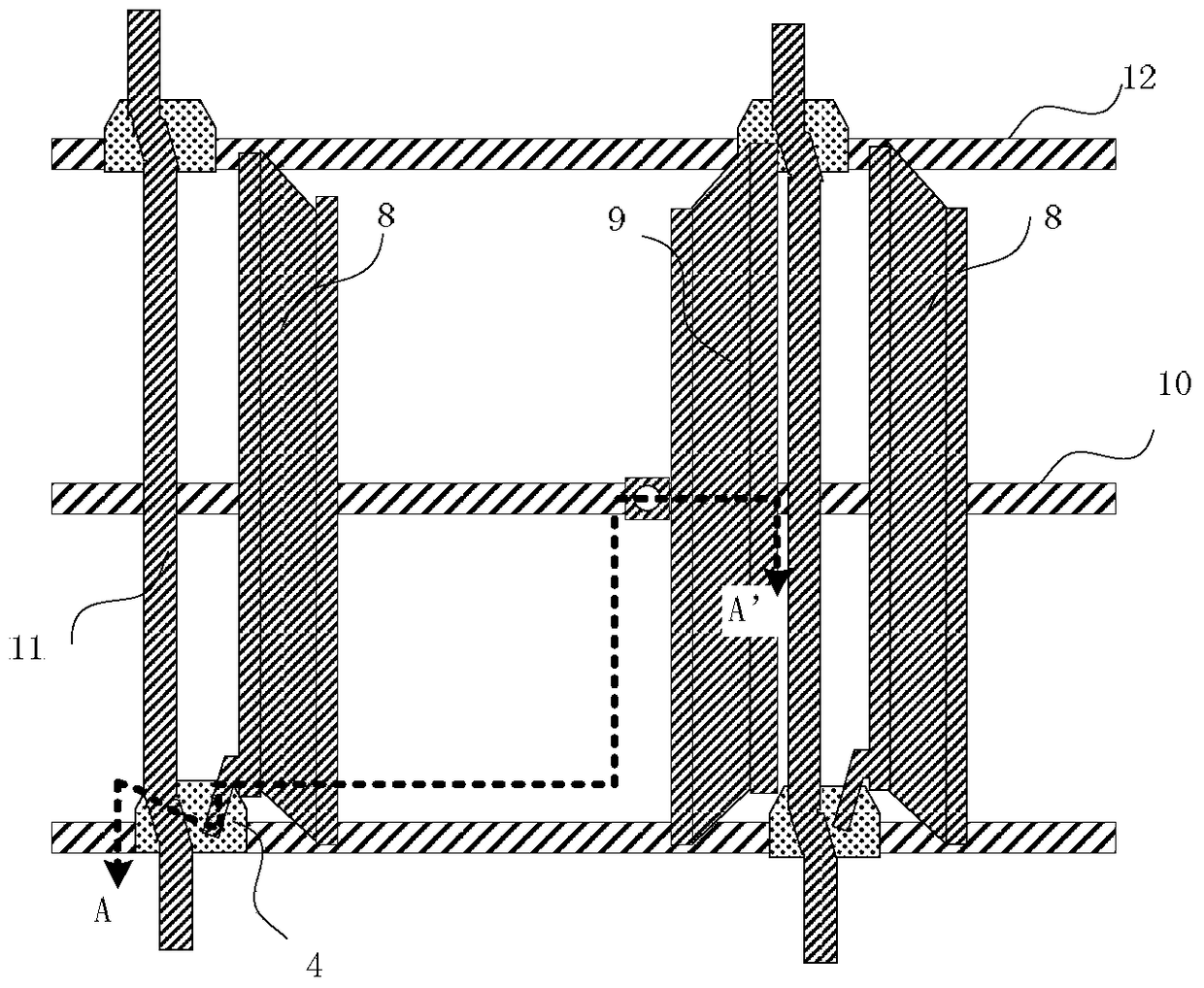

Thin-film transistor array substrate and manufacturing method and electronic devices thereof

ActiveCN102709237BSimple manufacturing processImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingTransistor arrayField effect

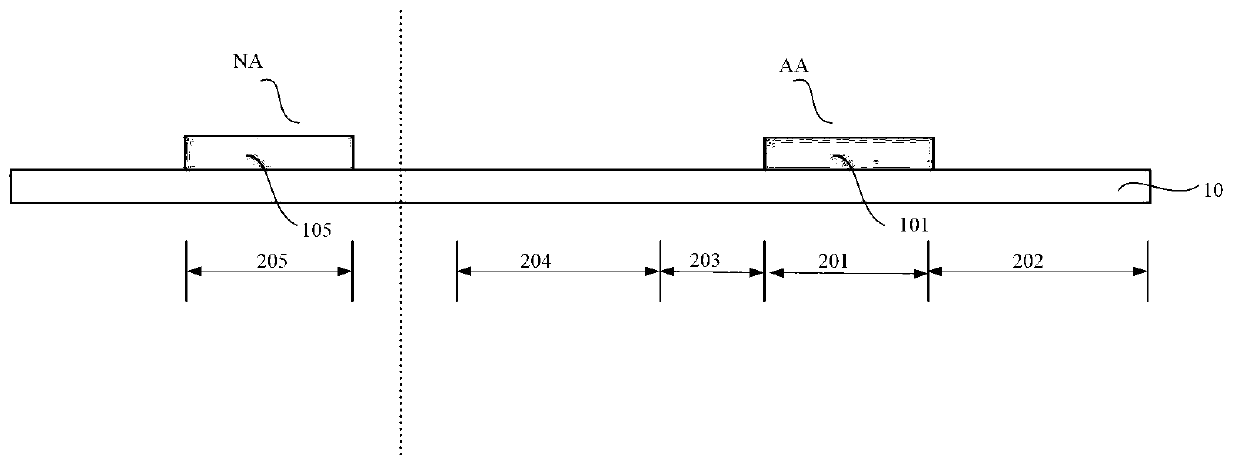

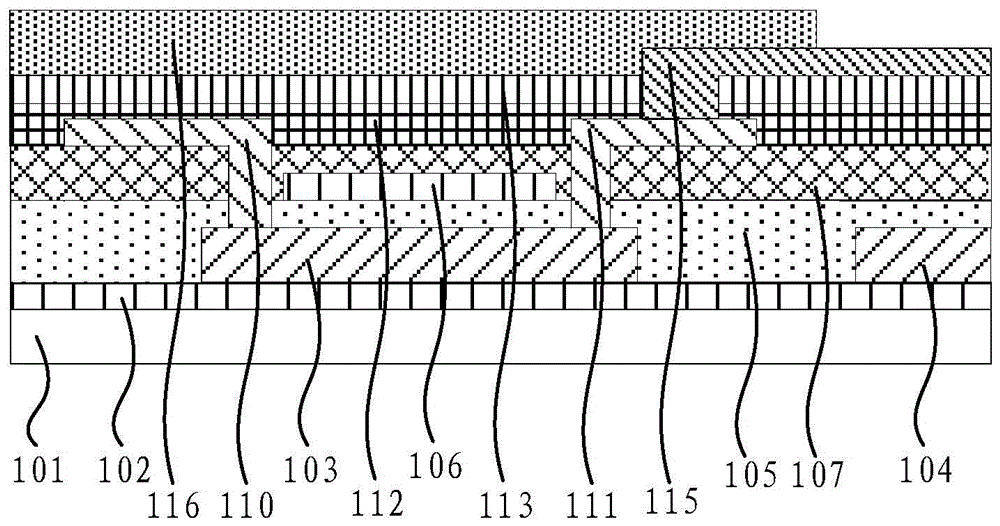

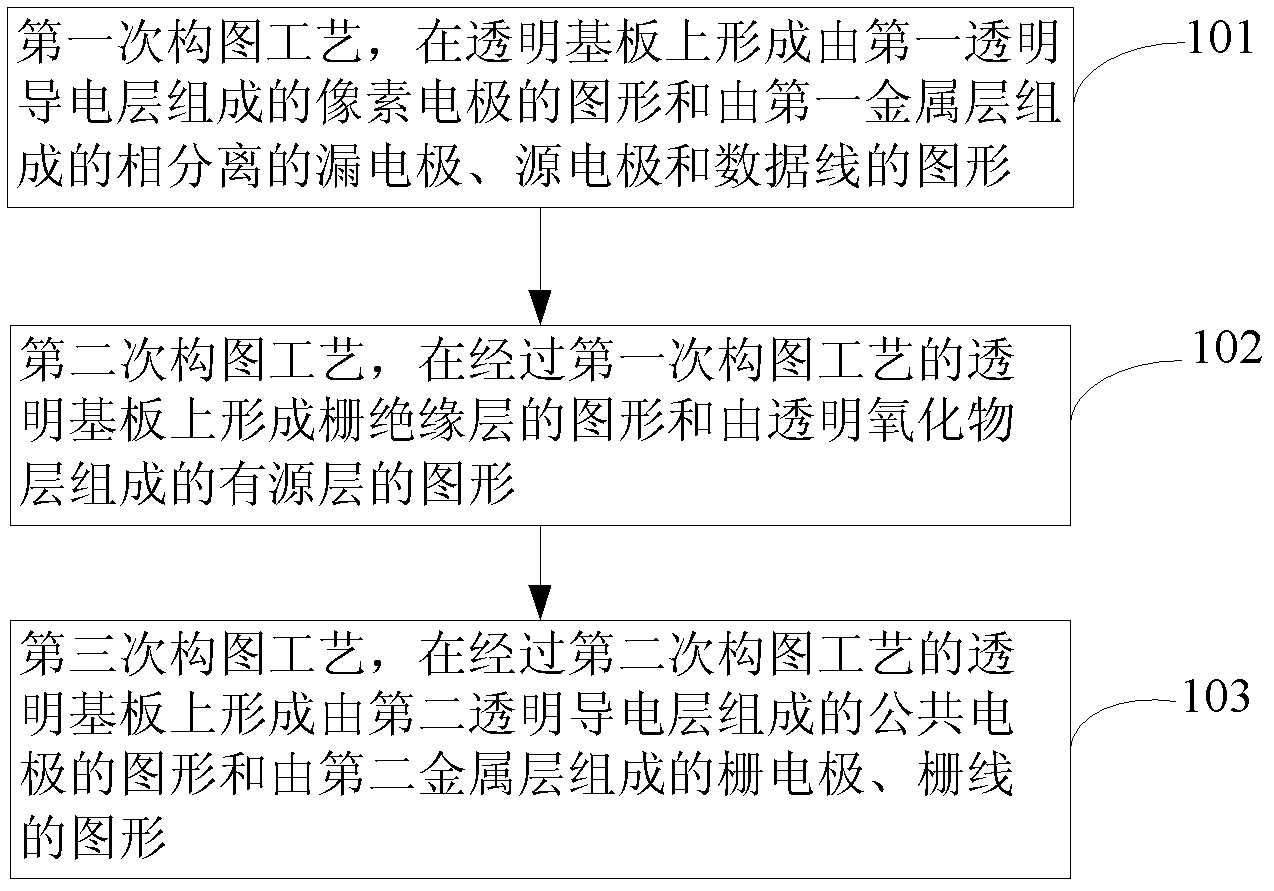

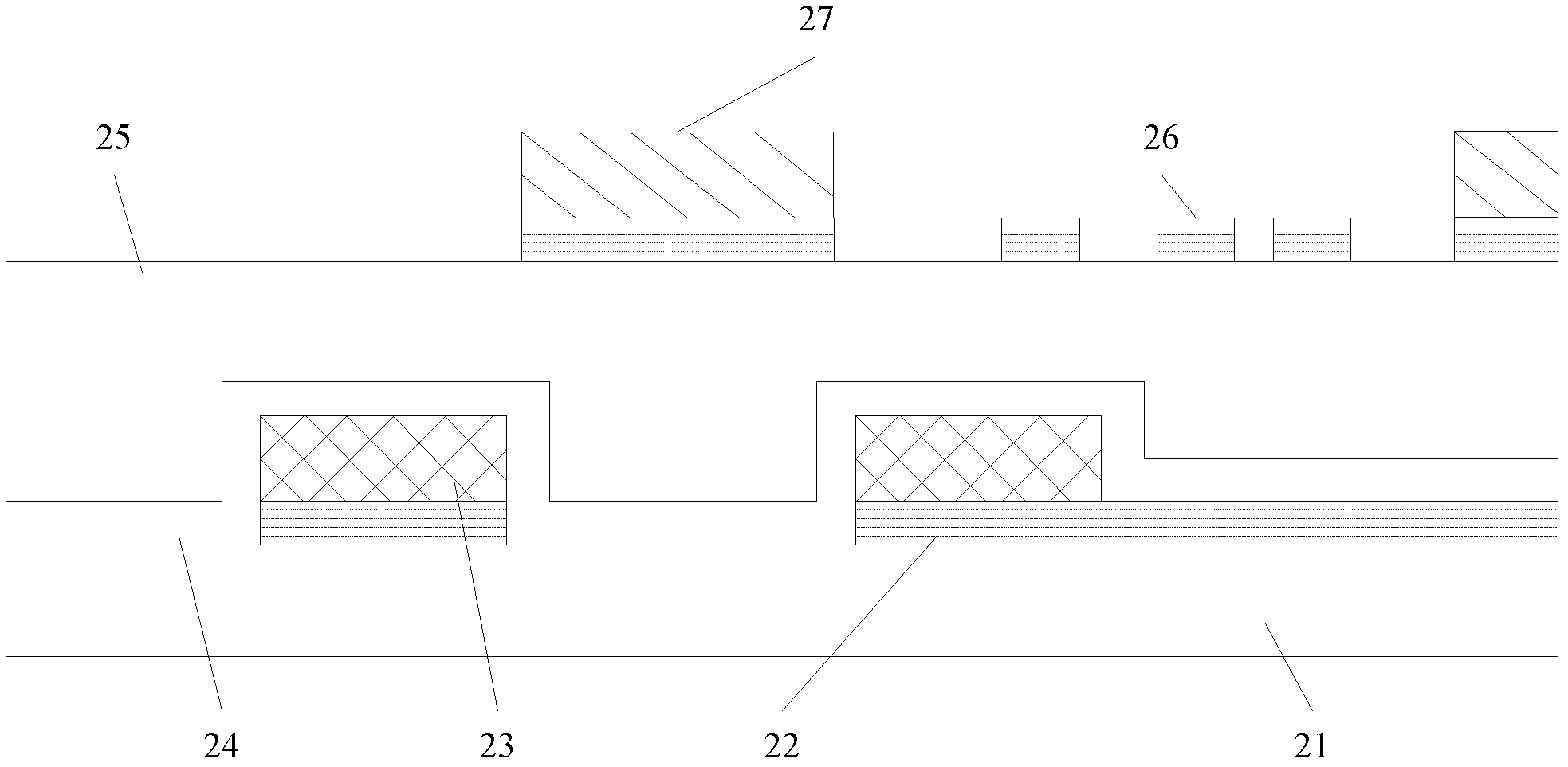

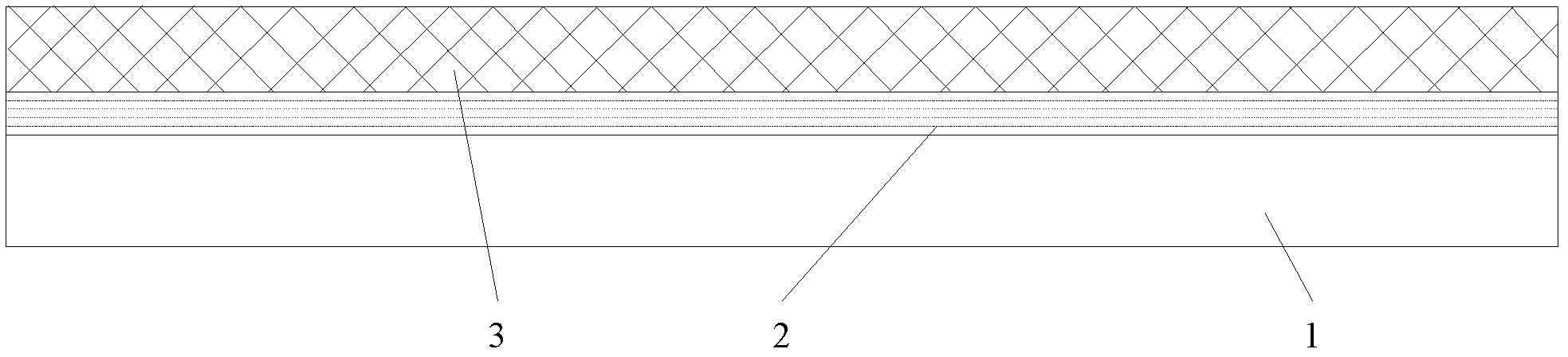

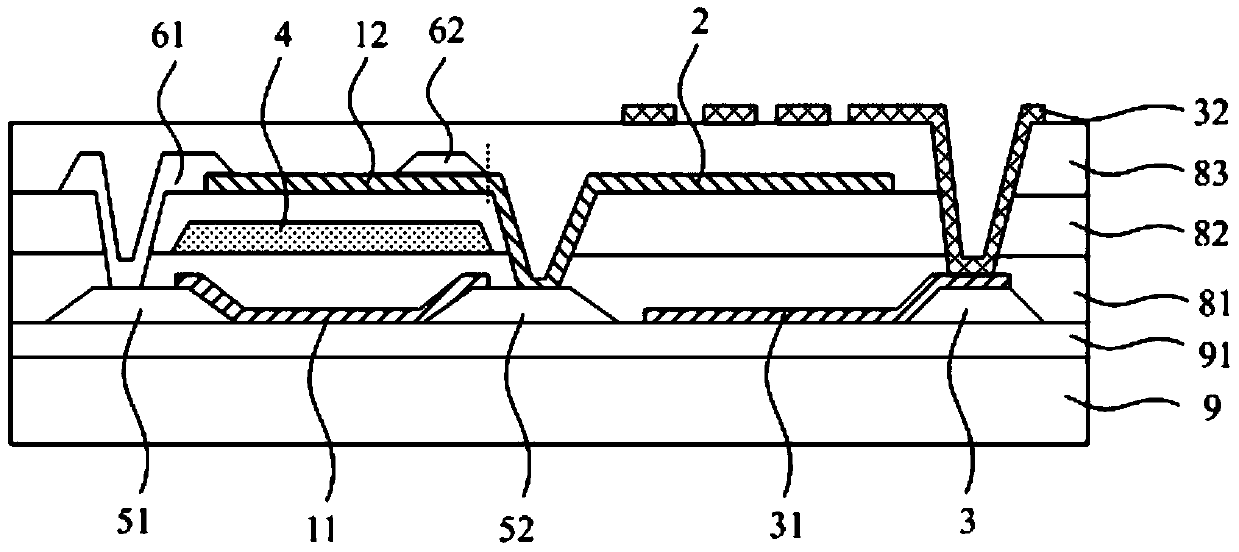

According to embodiments of the present invention, there are provided a TFT array substrate, a method for manufacturing the TFT array substrate and an electronic device. The method for manufacturing the TFT array substrate comprises: a first patterning process, in which a pattern of a pixel electrode formed by a first transparent conductive layer and patterns of a drain electrode and a source electrode that are separated from each other and a data line, which are formed by a first metal layer, are formed on a transparent substrate; a second patterning process, in which a pattern of a gate insulating layer and a pattern of an active layer formed by a transparent oxide layer are formed on the transparent substrate subjected to the first patterning process; and a third patterning process, in which a pattern of a common electrode formed by a second transparent conductive layer and patterns of a gate electrode and a gate line which are formed by a second metal layer are formed on the transparent substrate subjected to the second patterning process.

Owner:BOE TECH GRP CO LTD

Array substrate and its preparation method

ActiveCN105097829BImprove transmission performanceReduce the number of patterning processesTransistorSolid-state devicesIon implantationSemiconductor

The invention provides an array substrate and a preparation method thereof, belongs to the technical field of array substrates, and aims at solving the problem of complicated preparation technology of the existing array substrate employing a double-channel thin-film transistor. The array substrate provided by the invention comprises a plurality of thin-film transistors, a first electrode and a second electrode, wherein each thin-film transistor comprises a grid, a first active region and a second active region; each first active region and each second active region are respectively located below and above each grid and are composed of metal-oxide semiconductors; the first electrode and the first active regions are located on the same layer; the second electrode and the second active regions are located on the same layer; and the first electrode and the second electrode are composed of ion-implanted metal-oxide semiconductors.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com