Thin film transistor, method for manufacturing the same, and display device

一种薄膜晶体管、制造方法的技术,应用在晶体管、半导体/固态器件制造、半导体器件等方向,能够解决成本提高、掩膜版数目增多、工艺复杂等问题,达到节省刻蚀时间、减少构图工艺次数、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

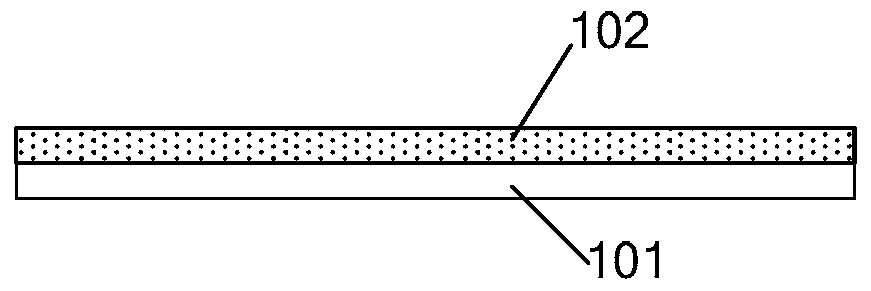

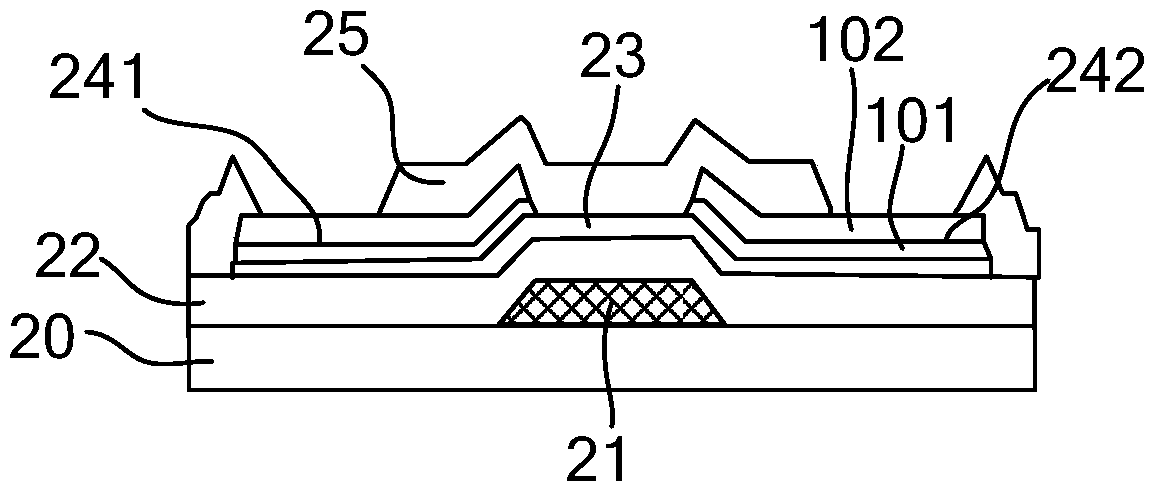

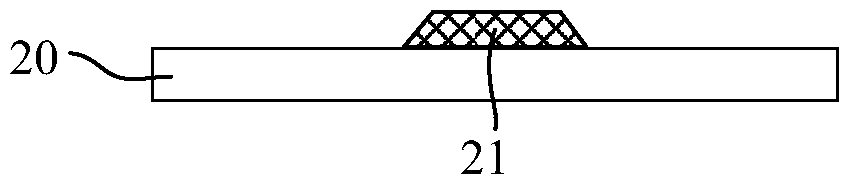

[0040] An embodiment of the present invention provides a thin film transistor, the thin film transistor includes: a gate electrode, an active layer, a source electrode and a drain electrode, the source electrode and the drain electrode are formed of at least two materials, and the source electrode and the drain electrode are formed of at least two materials. The forming material can undergo a battery reaction in the corresponding etching solution to be etched, and the etching solution does not corrode the active layer.

[0041] In view of the problem that the active layer of the existing TFT is easily corroded by the etching solution used in the source and drain formation processes, this embodiment adopts a new solution: the source and drain materials of the thin film transistor are selected to be suitable for A material that has a battery reaction in a certain electrolyte, and at the same time, the electrolyte corresponding to the battery reaction is used as an etching solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com