Simple and easy preparation method of nanometer-scale PPS (Patterned Sapphire Substrate)

A nano-scale, substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of complex processing and high cost, and achieve the effects of reduced processing costs, fast etching speed, and low technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

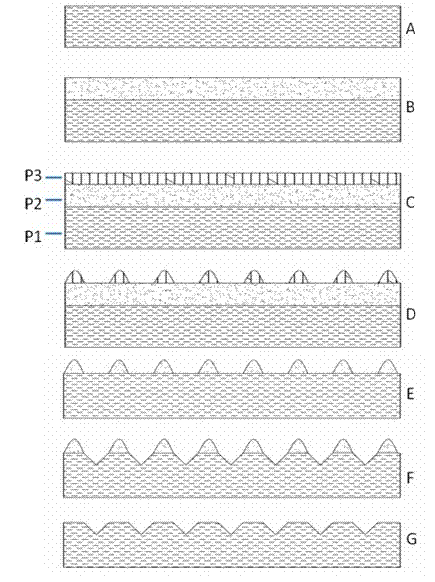

[0023] First deposit a layer of SiO2 film on the sapphire substrate with PECVD equipment, with a thickness of about 2000-5000 angstroms;

[0024] Then deposit a layer of ITO or ZnO film on the SiO2 film with a thickness of about 1000-3000 angstroms; anneal the ITO or ZnO film at a temperature of 300-600 ° C for 0.5-2 hours to form a uniform ITO or ZnO film on the surface of the SiO SiO2 film. ZnO grains (80-300 angstroms); then use RIE equipment (parameters: CF4: 30-60sccm; reaction pressure: 20-100mTorr; power: 300-500W, etching time: 10-30 minutes), then use sulfuric acid and Phosphoric acid mixing volume ratio: 3:1; etch in the mixed solution at temperature (230-350°C) for 10-30 minutes; finally use HF acid to etch the SiO2 mask for 10-30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com