A kind of thin film transistor drive backplane and its manufacturing method, display panel

A technology for thin film transistors and driving backplanes, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as expensive capital, and achieve the effect of simplifying production steps, reducing the number of patterning processes, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

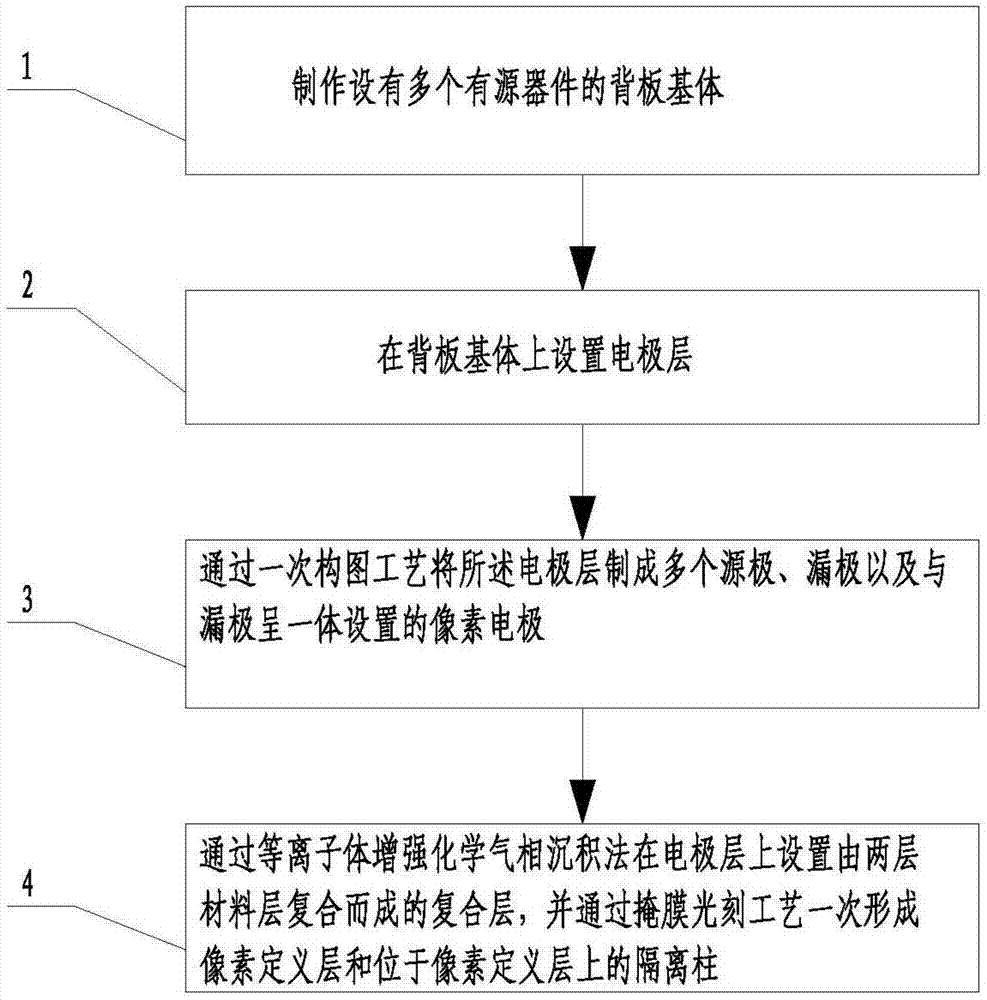

[0048] see figure 1 As shown, this embodiment provides a method for manufacturing a thin film transistor driven backplane, including the following steps:

[0049] Step 1. Fabricate a backplane matrix with multiple active device structures; wherein, the backplane matrix includes a substrate substrate, a semiconductor layer, a gate insulating layer, a gate layer, an isolation protection layer, an interlayer dielectric layer, and a contact holes; the semiconductor layer has a plurality of active channels, and the gate layer has a plurality of gates; each active channel and the gate corresponding to its position constitute the active device structure.

[0050] Concretely making the backplane matrix specifically includes the following steps:

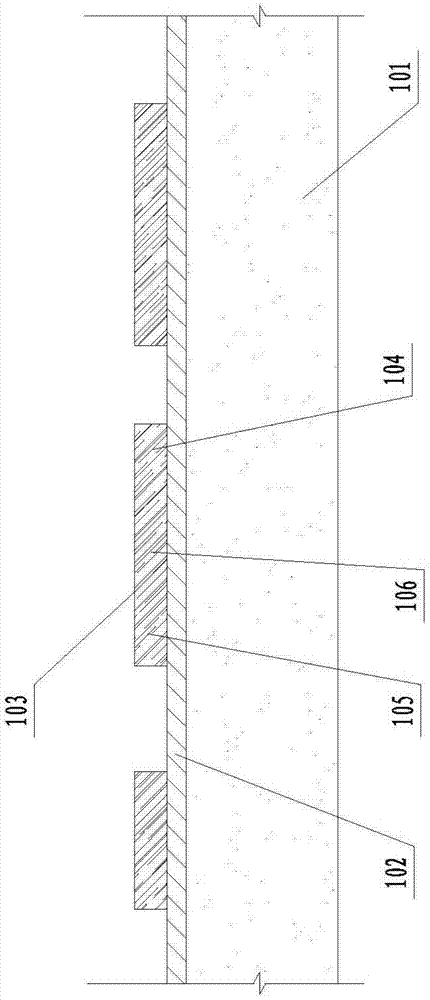

[0051] see figure 2 As shown, the base substrate 101 is cleaned, and a buffer layer 102 is provided on the base substrate by plasma-enhanced chemical vapor deposition; wherein, the base substrate is made of glass, transparent plastic, etc....

Embodiment 2

[0073] The TFT driving backplane in this embodiment is made by the manufacturing method described in Embodiment 1. Therefore, the technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to this embodiment. public content.

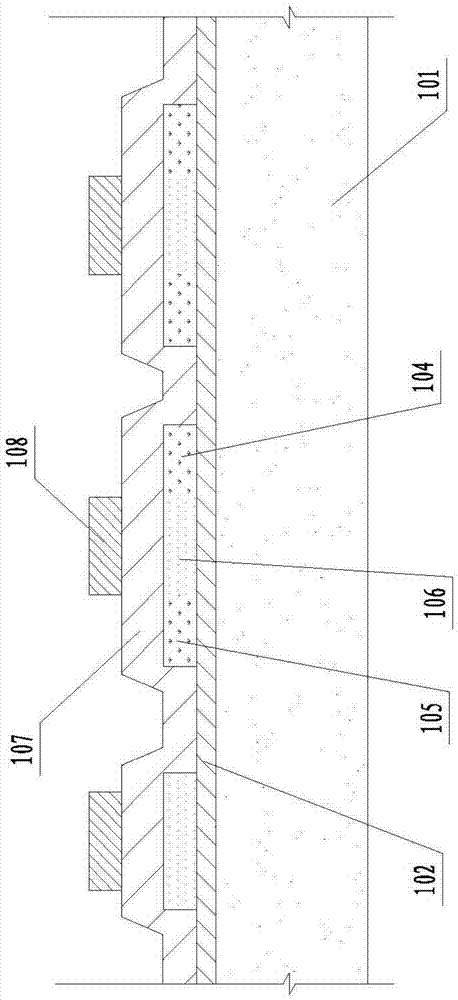

[0074] see Figure 7 As shown, this embodiment provides a thin film transistor driven backplane, which is made by the manufacturing method of the thin film transistor driven backplane as described above; the thin film transistor driven backplane includes a backplane with a plurality of active device structures A base body and an electrode layer arranged on the back plate base body; a plurality of source electrodes, drain electrodes and pixel electrodes integrally arranged with the drain electrodes are formed on the electrode layer.

[0075] The backplane base in this embodiment includes a base substrate, on which a semiconductor layer with multiple active channels, a gate insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com