Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Reduce stirring dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

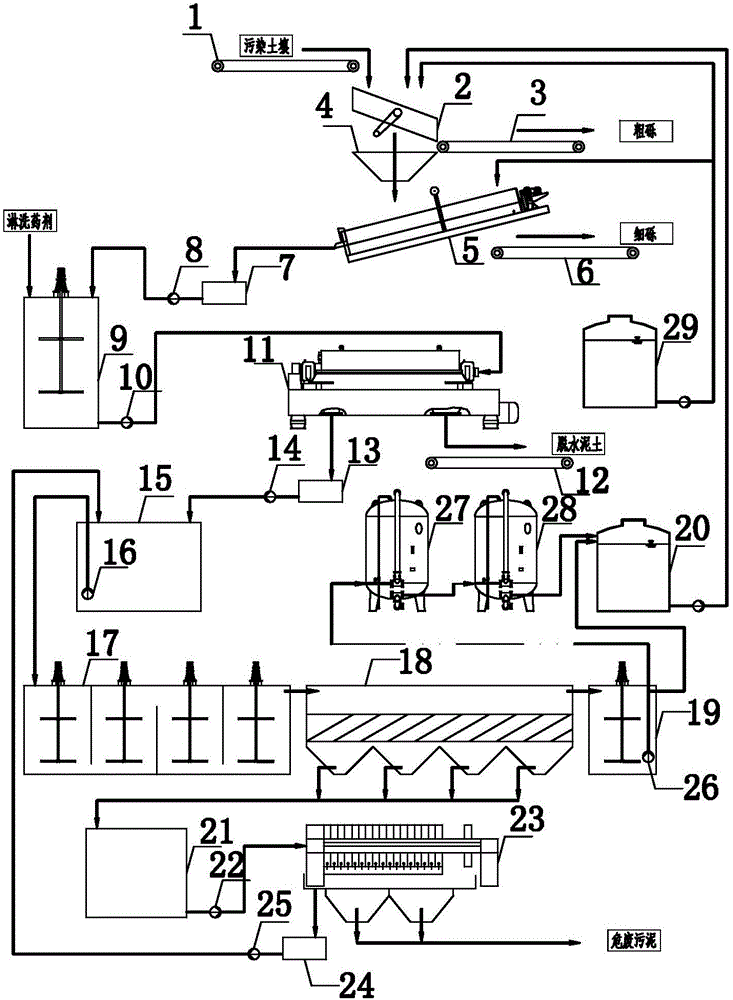

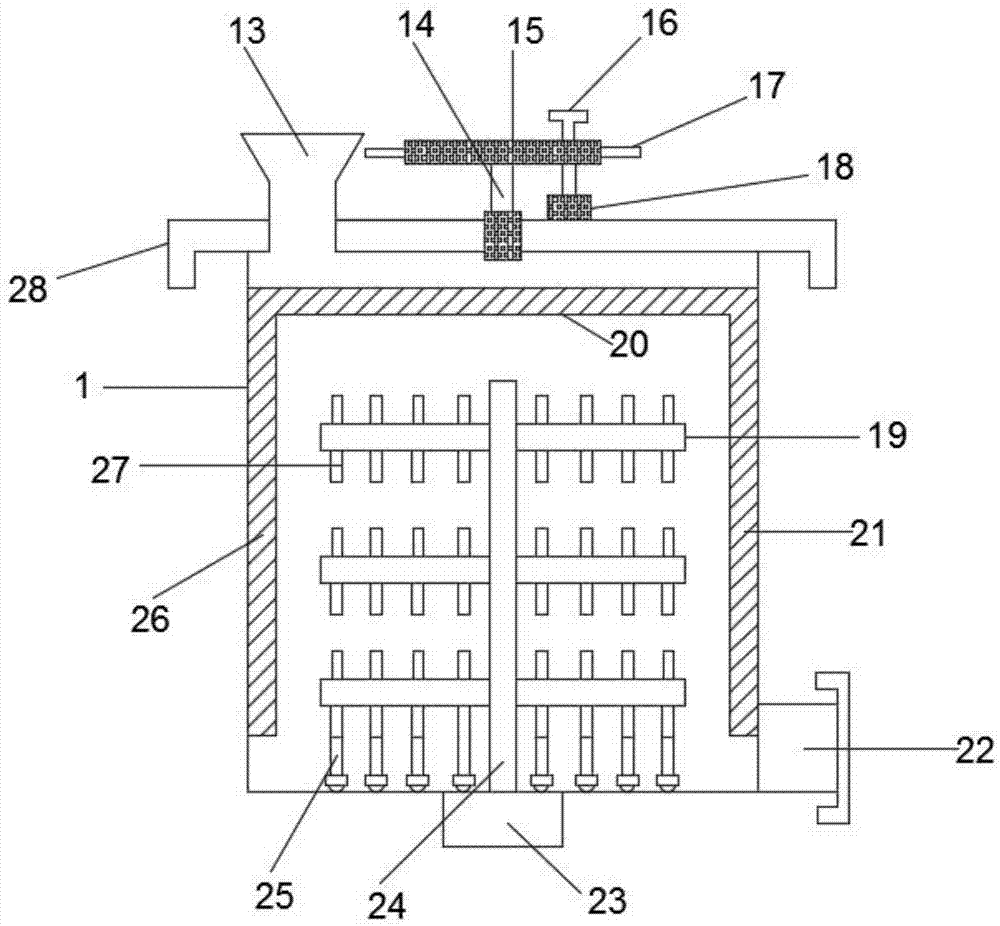

Soil ectopic leaching restoring complete equipment

ActiveCN105772497AEasy to useReduce total rinse volumeSludge treatment by de-watering/drying/thickeningWater contaminantsSoil textureUltimate tensile strength

The invention provides soil ectopic leaching restoring complete equipment, belongs to the technical field of site contamination repairing, and solves the problems that existing leaching equipment is generally poor in soil texture applicability, single in repairable pollutant, numerous and jumbled in leaching equipment system, high in operation intensity, large in water consumption and drainage quantity and the like. The equipment comprises a wet-type screening mechanism, a spiral classifying mechanism, a leaching restoring mechanism, a waste water treatment mechanism and a waste water recycling mechanism which are arranged successively, and polluted soil is separated from the spiral classifying mechanism and the leaching restoring mechanism via the wet-type screening mechanism to obtain coarse gravels, fine gravels and clean soil so as to implement a soil ectopic leaching restoring process. The soil ectopic leaching restoring complete equipment is suitable for restoring of heavy metal and / or organic polluted soil and ectopic leaching restoring of soil with different grain diameters, and has the advantages of wide application range, good decrement effect, stable repairing effect, simplicity and convenience in operation and running, small water consumption, high waste water recycling rate and the like.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

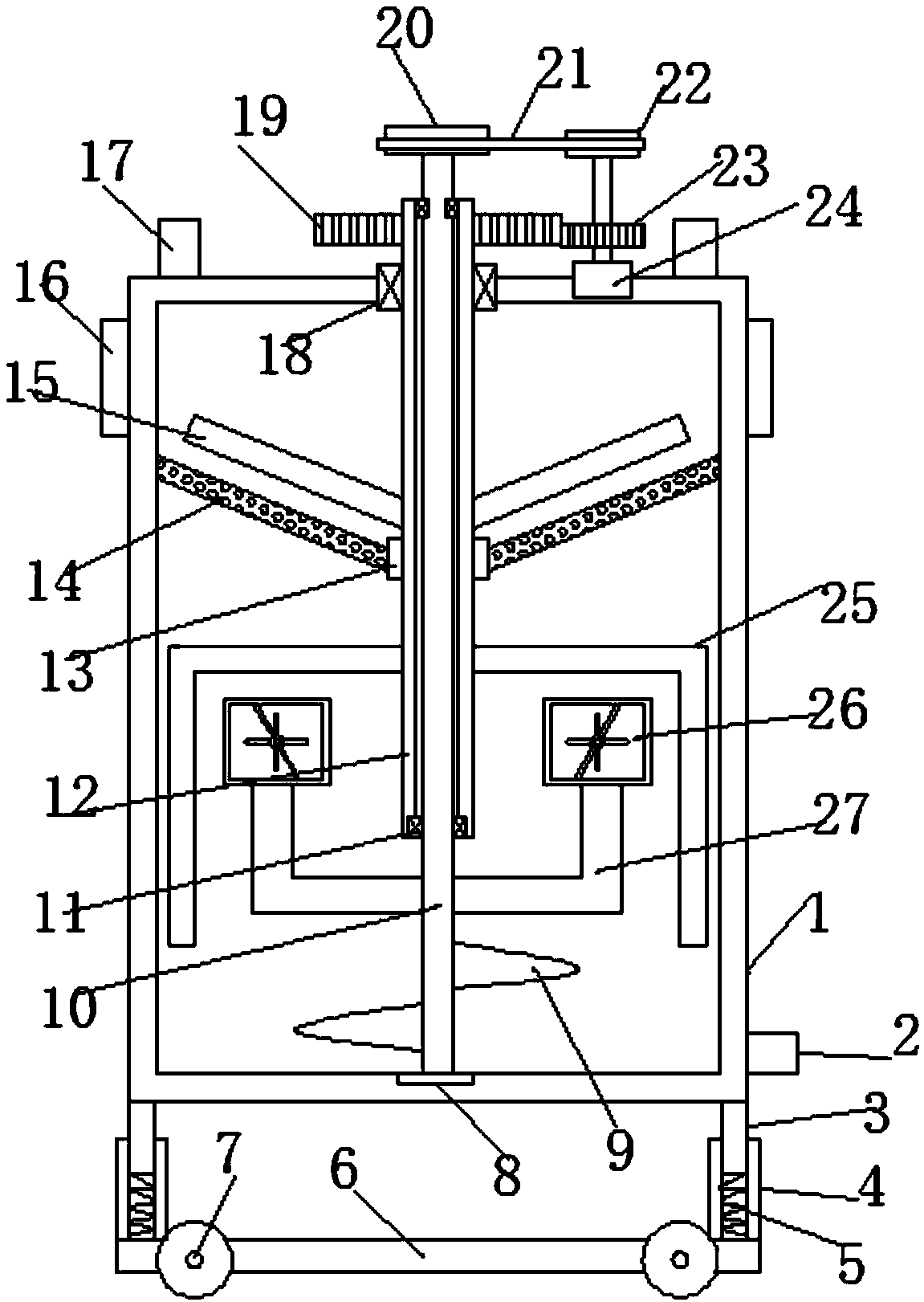

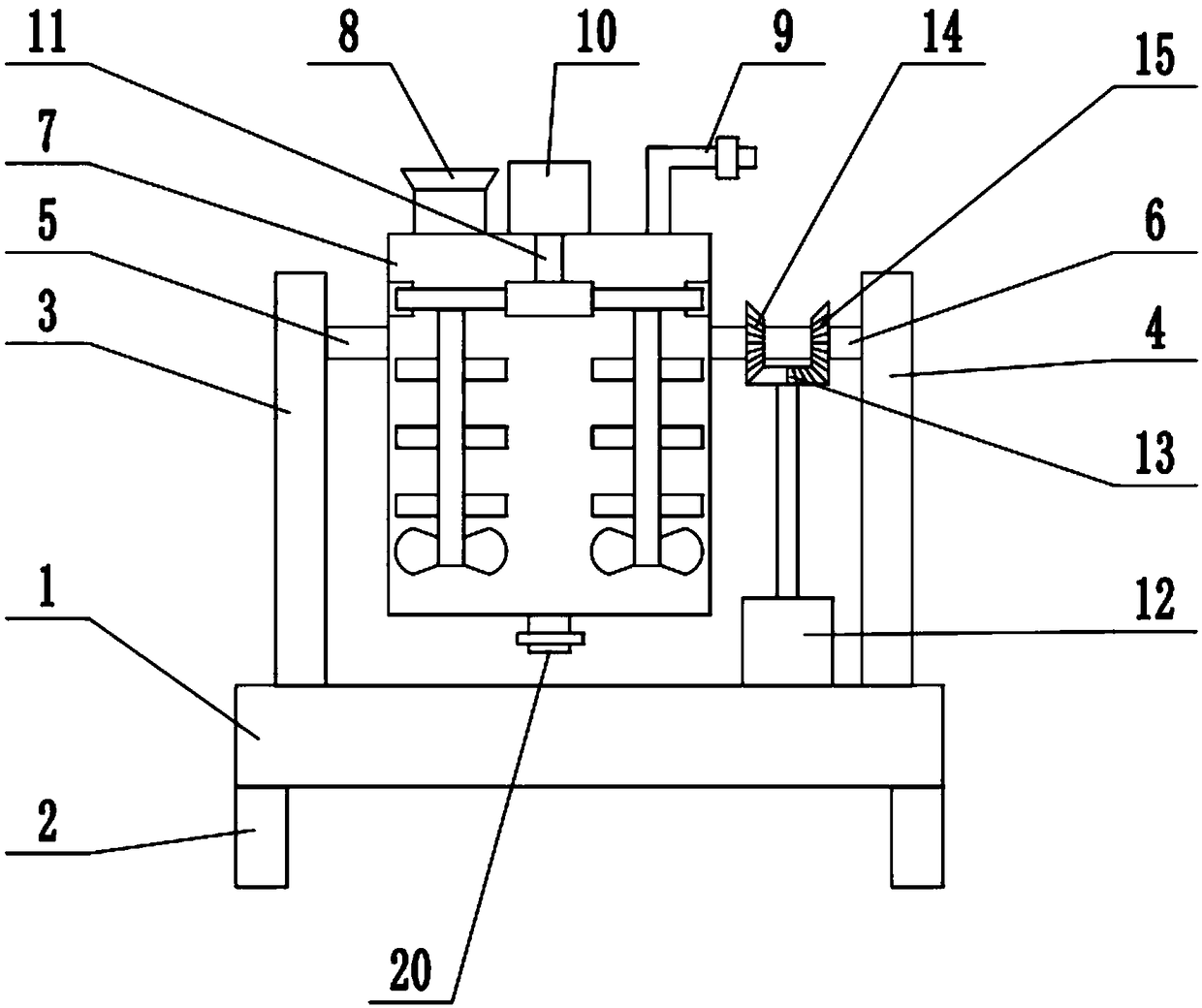

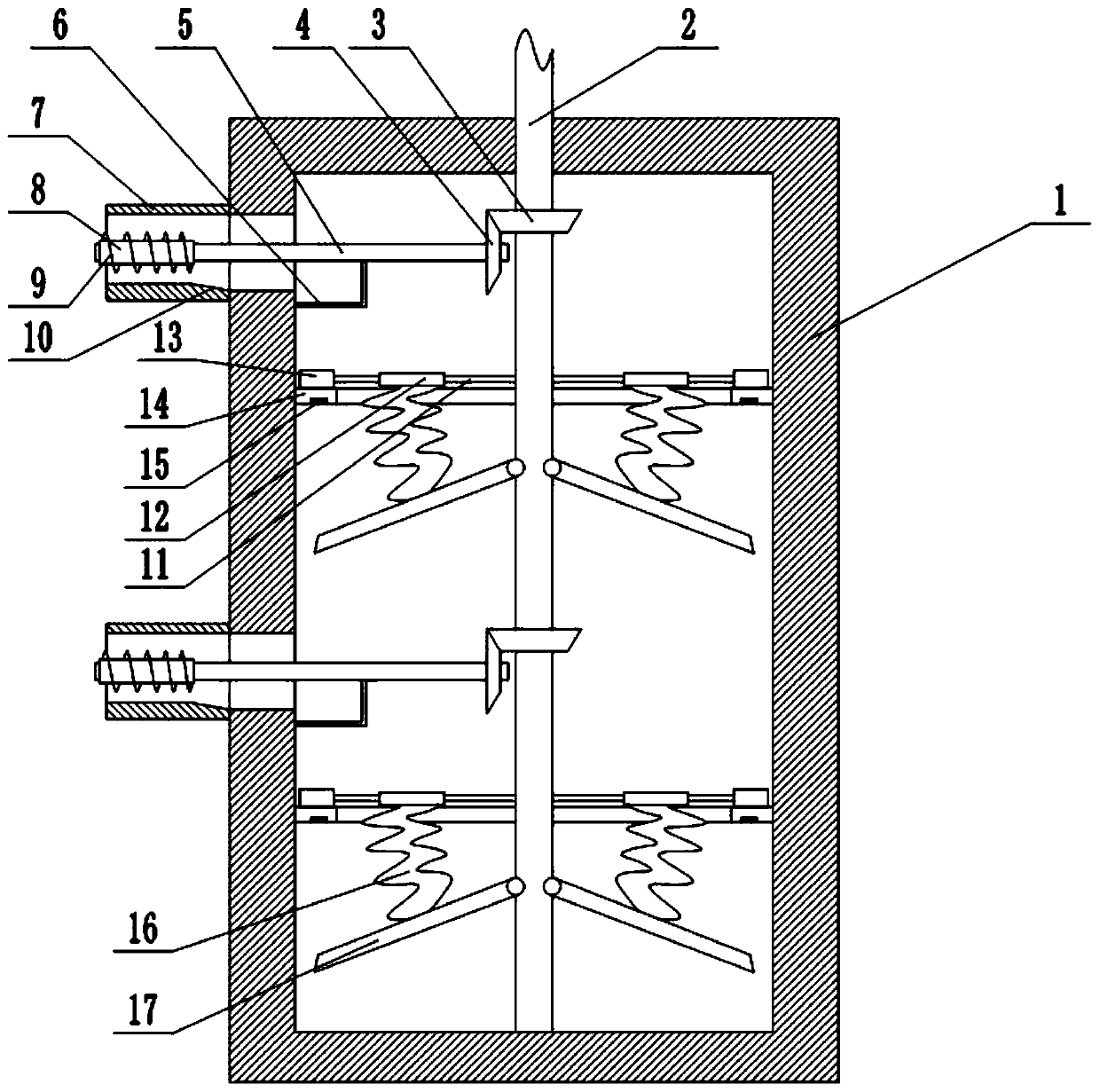

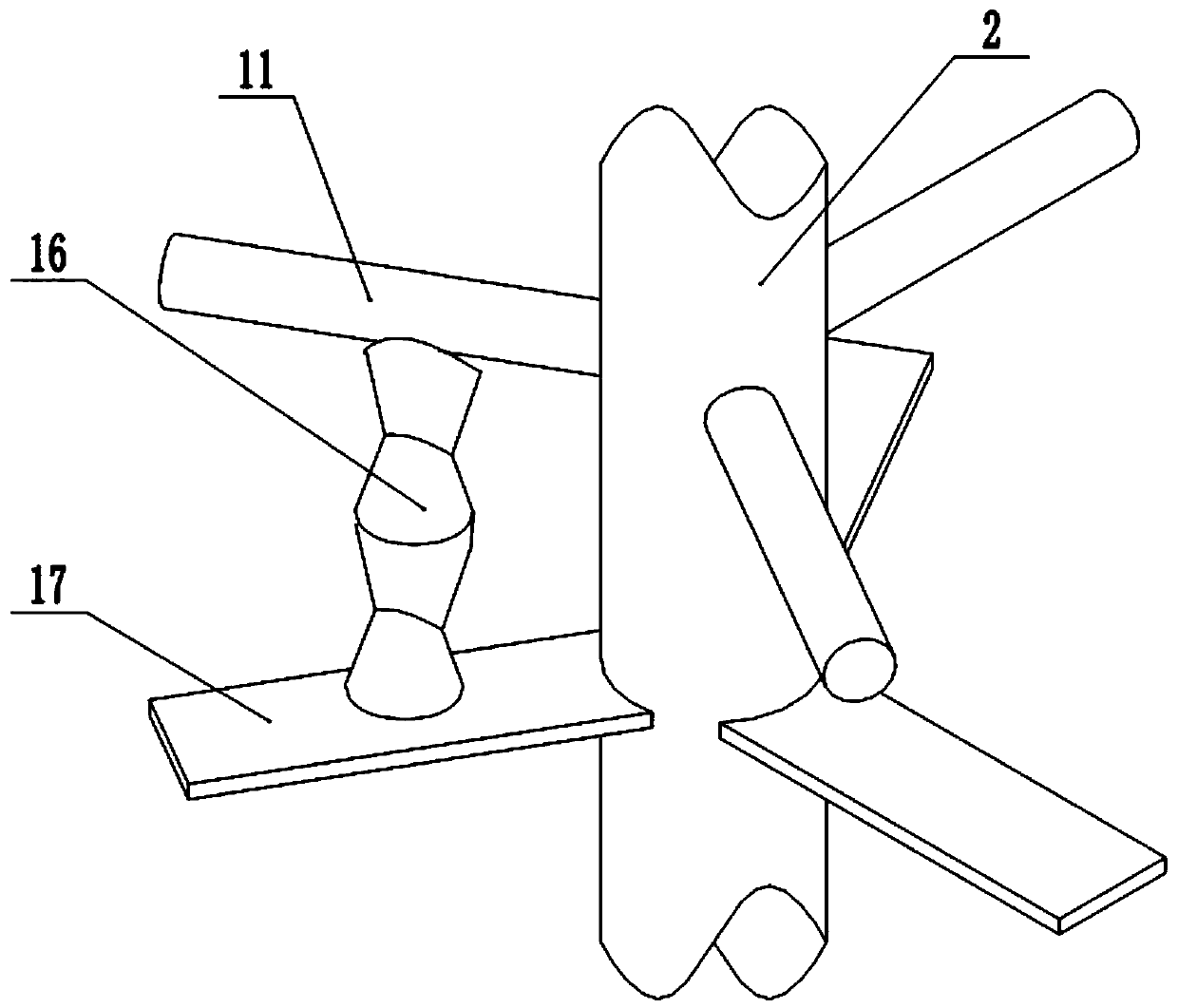

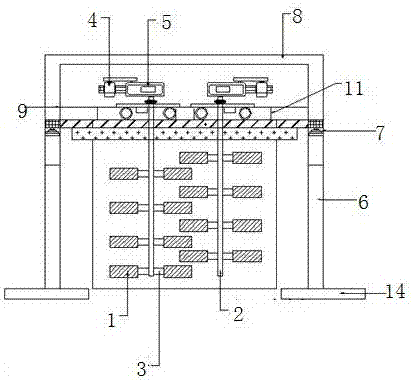

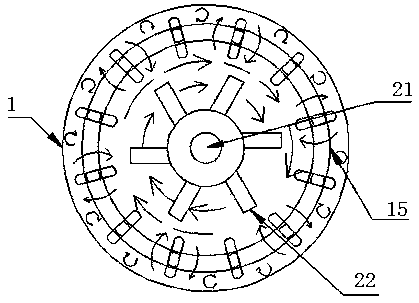

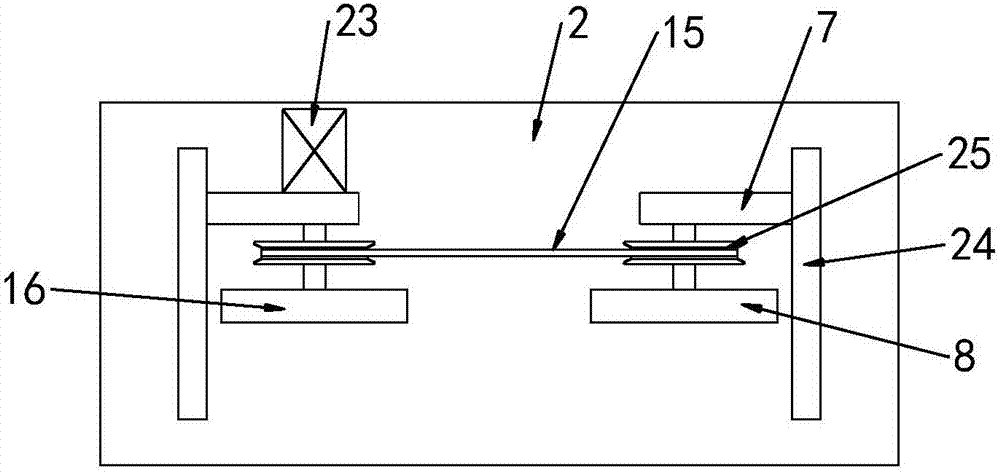

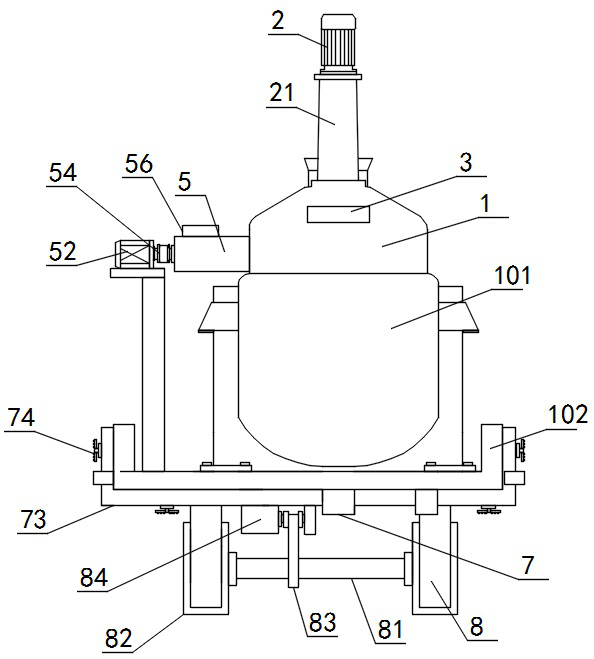

Bidirectional stirring chelating device for producing feed

InactiveCN107694450AReverse rotationImprove the mixing effectFeeding-stuffTransportation and packagingSpiral bladeHelix

The invention discloses a bidirectional stirring chelating device for producing feed. The bidirectional stirring chelating device comprises a processing box, wherein a base is arranged below the processing box; rolling wheels for conveniently transporting the device are arranged at left and right sides of the base; supporting sleeves are symmetrically arranged at two sides of the upper end of thebase; supporting rods are matched with upper end openings of the supporting sleeves in a sliding manner; the upper ends of the supporting rods are connected and fixed with the bottom of the processingbox. The bidirectional stirring chelating device for producing the feed, disclosed by the invention, is simple and reasonable in structure and convenient to transport and has good seismic performance; reversing rotation of a first stirring shaft and a second stirring shaft is realized, so that reversing stirring of a first stirring rod and a second stirring rod is realized, a stirring dead angleis reduced and the stirring effect on materials is extremely improved; a spiral blade is arranged at the lower end of the first stirring shaft and a pushing force on materials in a vertical directioncan be generated when the spiral blade rotates, and a material internal flow is easy to form, so that the stirring dead angle is further reduced and the stirring effect on the materials is further improved; the bidirectional stirring chelating device has strong practicability.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Decorative coating stirring device

ActiveCN108187525AUp and down velocity increasesStir wellFlow mixersTransportation and packagingEngineeringPiston rod

The invention belongs to the field of decoration engineering and particularly discloses a decorative coating stirring device. The decorative coating stirring device comprises a rack and a rotating shaft, wherein a stirring tank is arranged on the rack; the rotating shaft comprises a spline section, a thread section and stirring section, a splined sleeve is connected outside the spline section, anda nut is connected outside the thread section; a hollow cavity is formed in the stirring section, a piston is glidingly connected in the hollow cavity, a piston rod is fixed on the lower side of thepiston, first feed holes are formed in the upper part of the side wall of the stirring section in the circumferential direction, first discharge holes are formed between the adjacent first feed holes,and first stirring blades which are inclined downwards are connected to the first feed holes; second feed holes and second discharge holes are formed in the lower part of the side wall of the stirring section, second stirring blades which are inclined upwards are connected to the second feed holes, and hollow grooves are formed in centers of the first stirring blades and the second stirring blades respectively. With the adoption of the scheme, the stirring is more uniform and faster.

Owner:枣庄市鹏展木制品有限公司

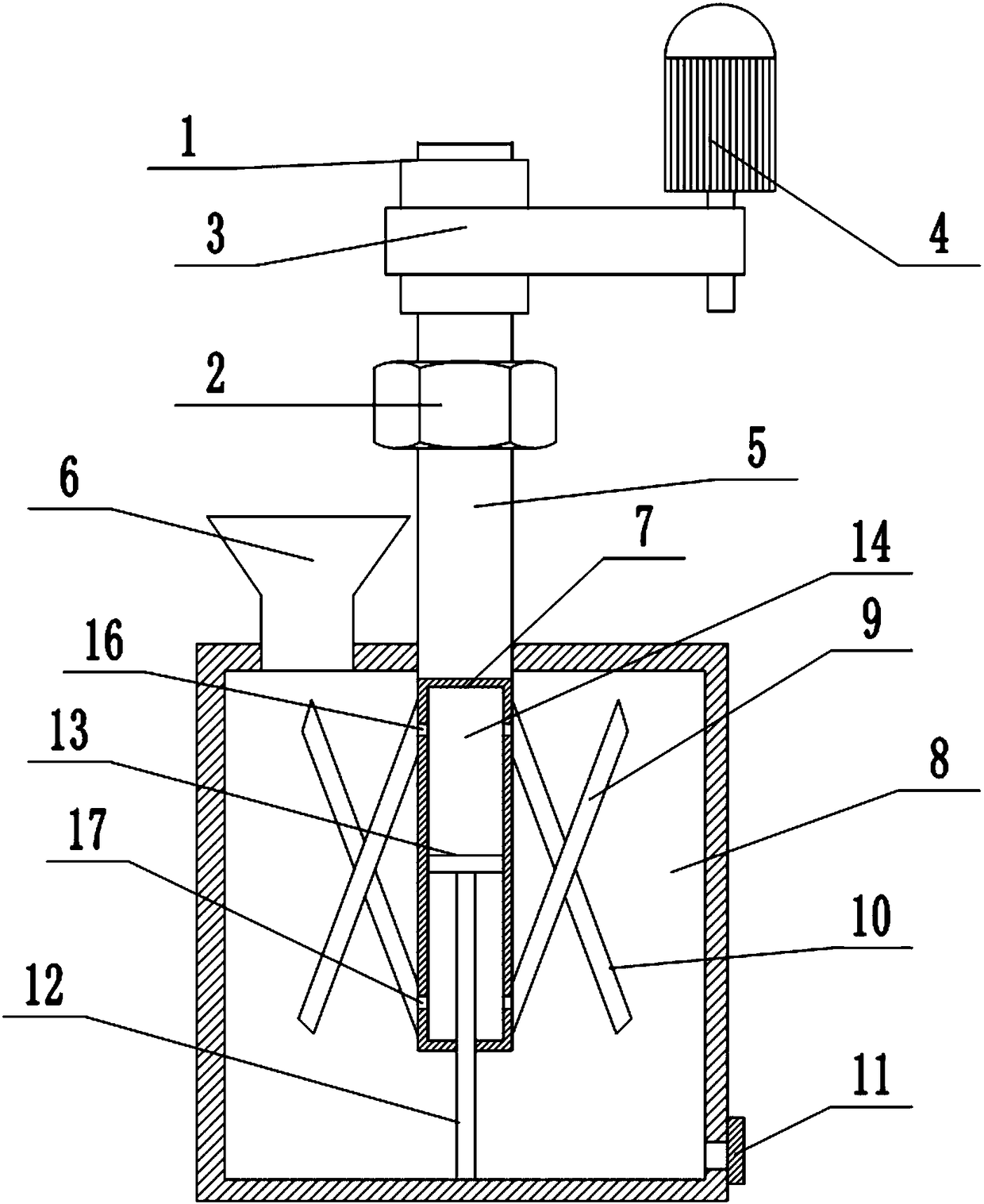

Novel stirrer for building

InactiveCN106799789AReduce stirring dead angleReduce labor intensityHollow article cleaningCement mixing apparatusCircular discEngineering

The invention relates to a novel stirrer for a building. The novel stirrer comprises a support, a barrel body and a barrel cover, wherein a bottom motor is arranged at the bottom end outside the barrel body; a rotary shaft is connected to the top end of the output shaft of the bottom motor; a plurality of stirring rods are arranged on the rotary shaft; a plurality of bottom support rods are connected to the stirring rod located at the bottommost part of the rotary shaft; a charge port is formed in the barrel cover; a discharge port is formed in the bottom of the right side of the barrel body; a cross rod is arranged at the top end in the barrel body; a top vertical rod is connected to the middle of the cross rod; the top vertical rod penetrates upwards through the barrel cover and is rotationally connected with the barrel cover through a bearing; a left scraping rod and a right scraping rod are connected to the left end and the right end of the cross rod separately; the left scraping rod and the right scraping rod are both closely bonded with the vertical inner sidewall of the barrel body; a circular disc is arranged at the top end of the top vertical rod; a handle is arranged at the outer circumference of the circular disc; a thread hole is formed in the circular disc; and a screw rod is further in threaded connection into the thread hole. Through the abovementioned structure, the novel stirrer disclosed by the invention is capable of greatly reducing stirring dead angles during a stirring process, and further greatly lowering the labour intensity during cleaning.

Owner:CHENGDU JIAMEIJIA SCI & TECH

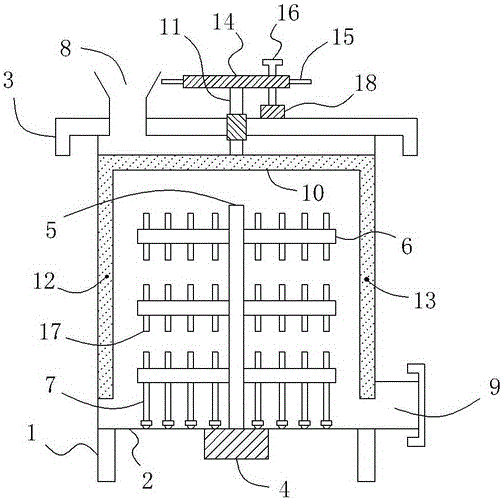

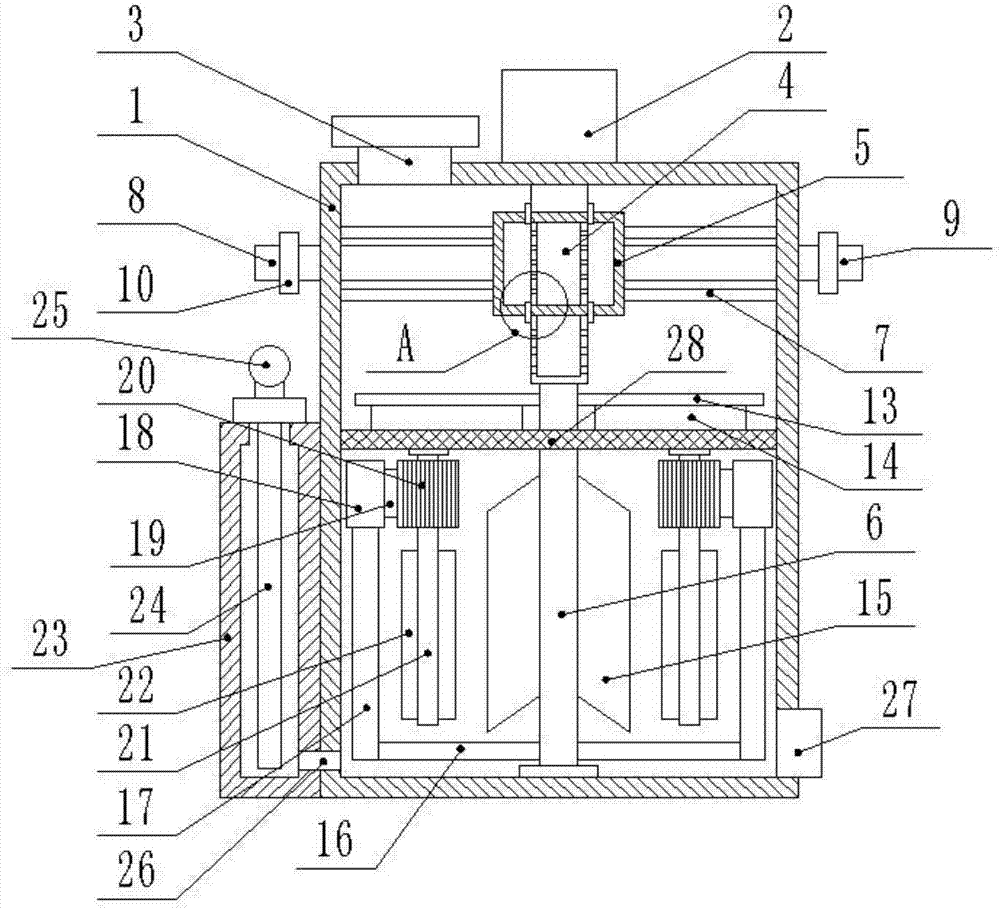

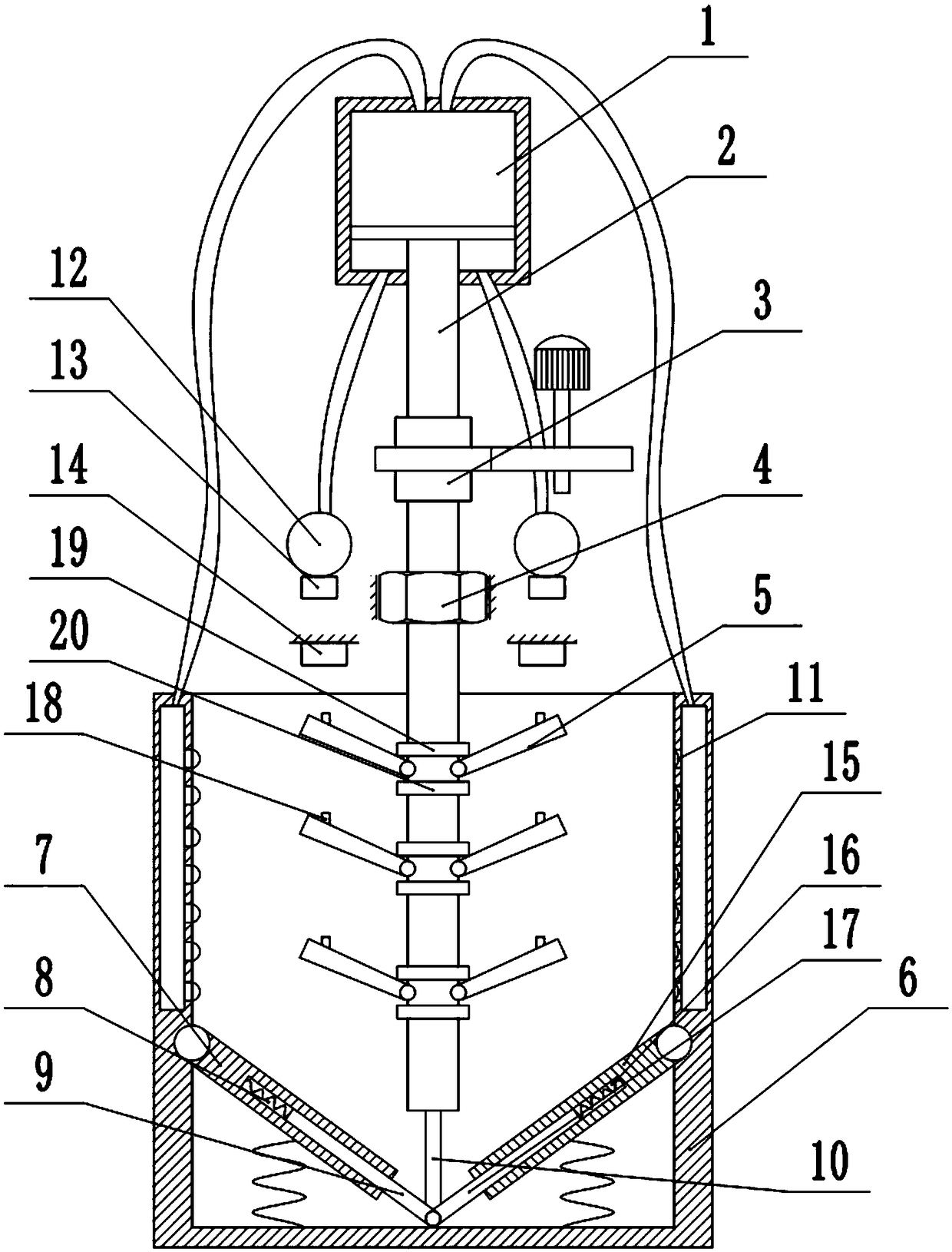

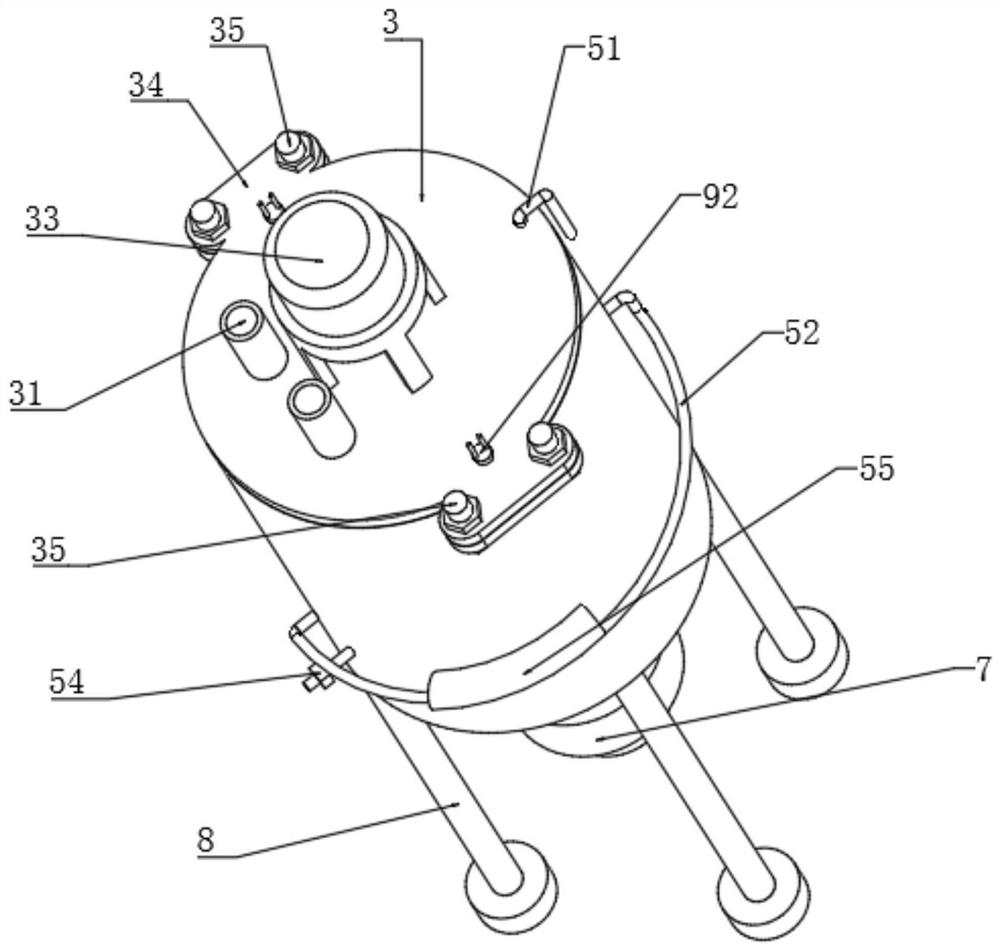

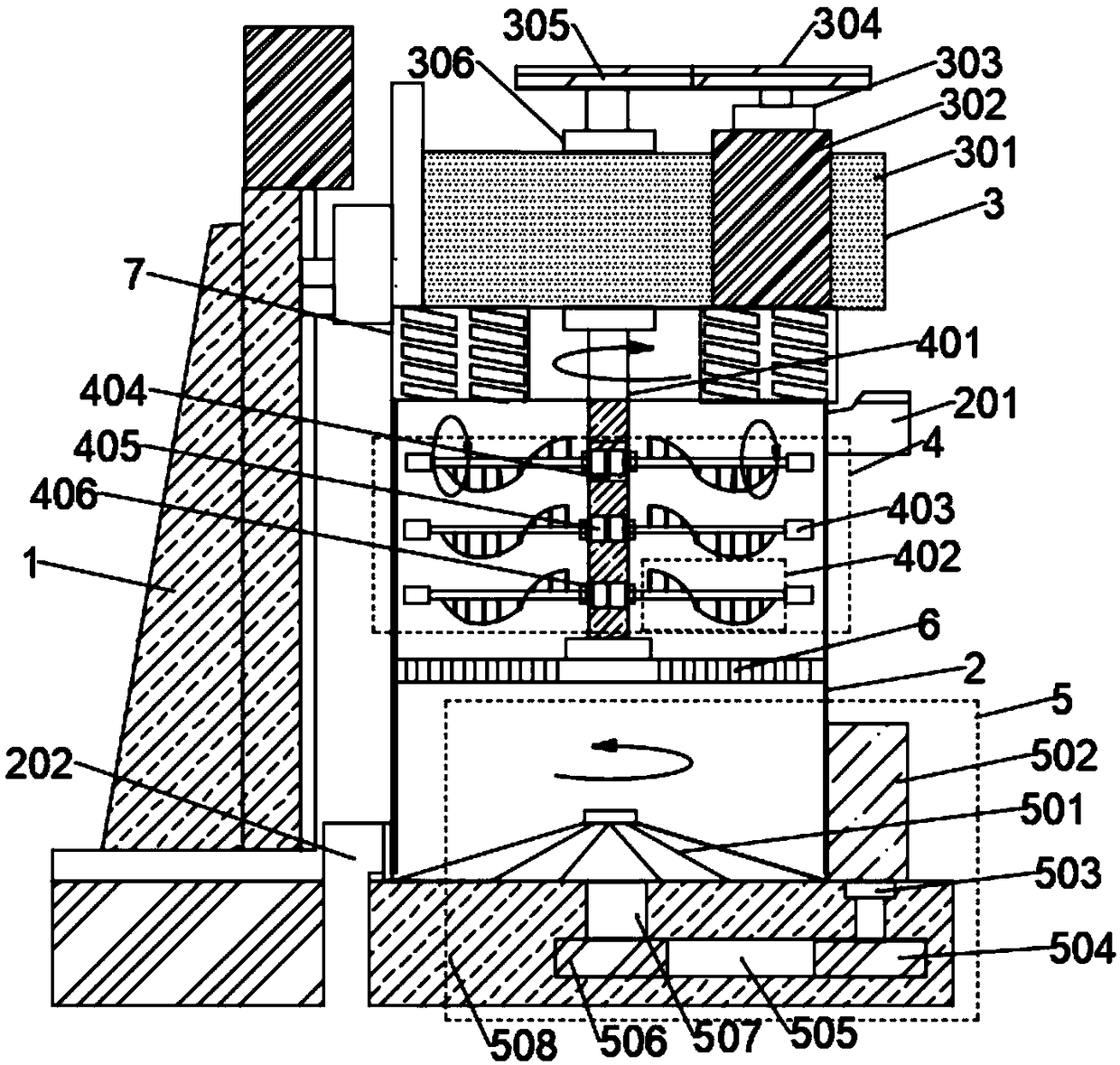

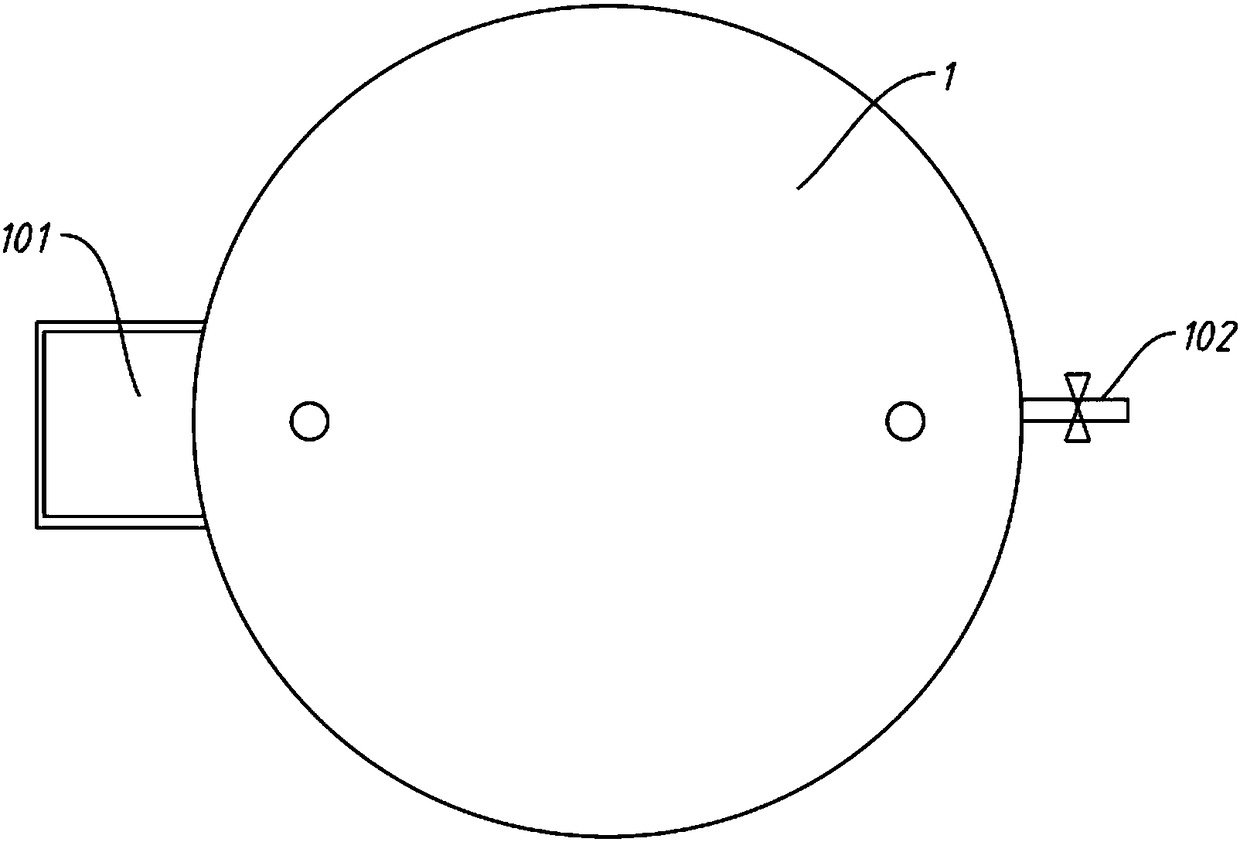

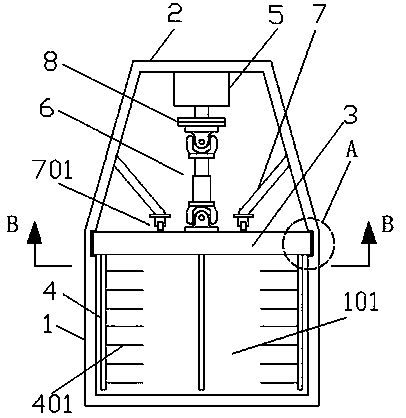

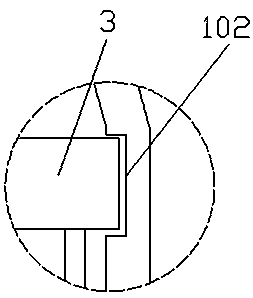

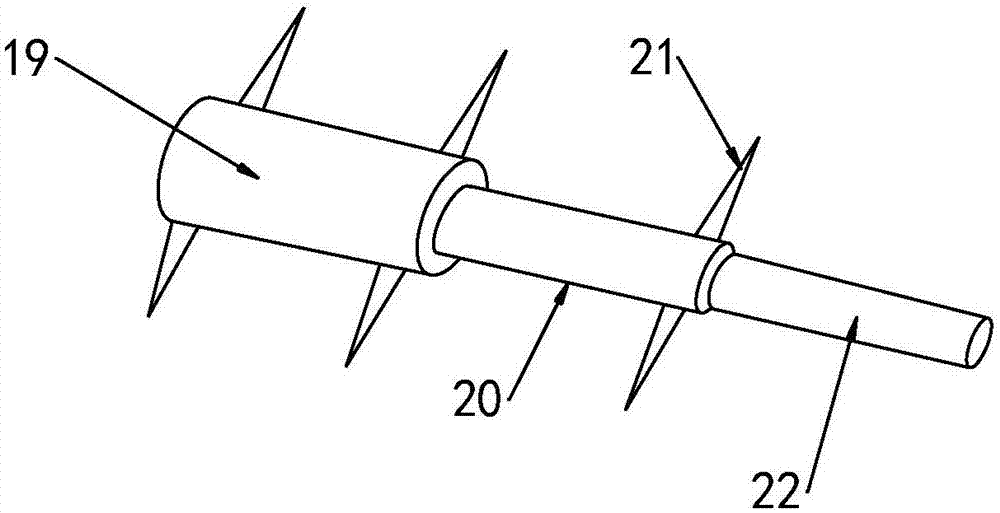

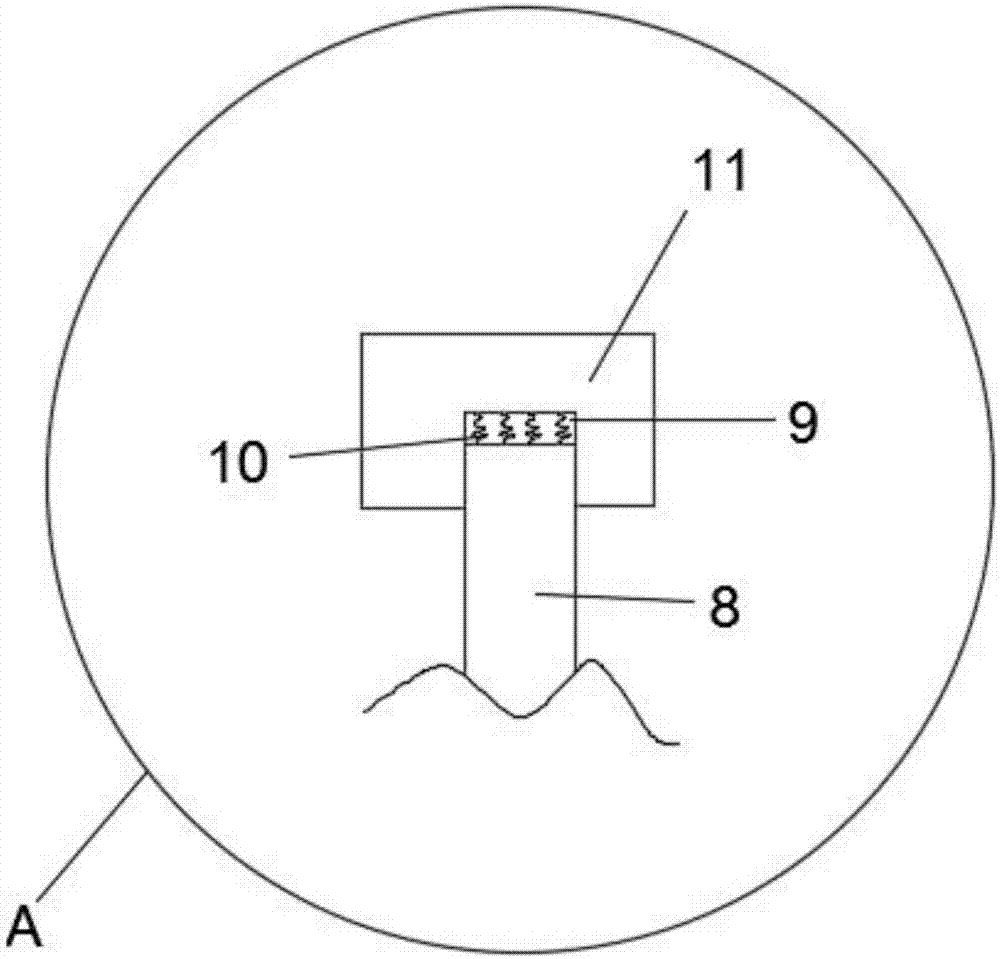

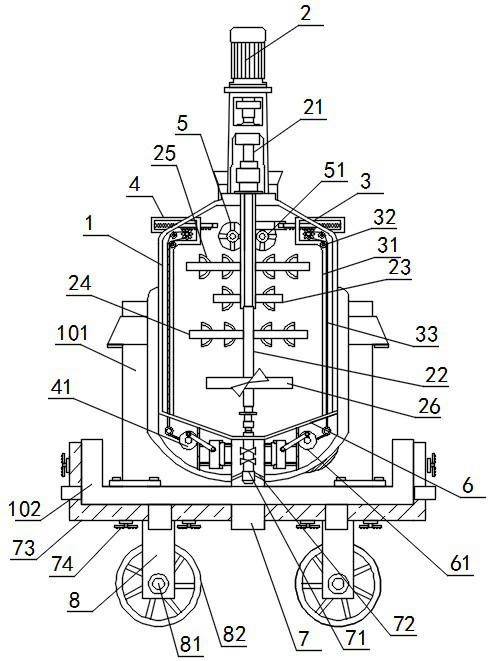

Stirring curing machine

InactiveCN102535437ALower transport heightEasy to transportSoil preservationVehicle frameElectrical control

The invention provides a stirring curing machine. The stirring curing machine comprises an upper vehicle assembly, a lower vehicle assembly connected with the upper vehicle assembly through a rotary support, and a pulp injection system on the upper vehicle assembly. The stirring curing machine is characterized in that one end of a derricking mechanism is connected with the frame of the upper vehicle assembly, and the other end is connected with an upright mast system; an operation device is arranged on the mast system, and can be controlled by a hydraulic system to move on the mast system up and down; a stirring head on the front end of the operation device is driven by the hydraulic system to rotate; and the hydraulic system and an electrical control system are arranged in the upper vehicle assembly. The stirring curing machine provided by the invention has the advantages that the stirring curing machine is specifically used for foundation stabilization, and can reduce stirring dead corners, thereby achieving more uniform stirring. Furthermore, the stirring device in the invention has an enough torque, so that the stirring head can descend into the ground easily when encountering denser soil.

Owner:龙工(上海)机械制造有限公司 +1

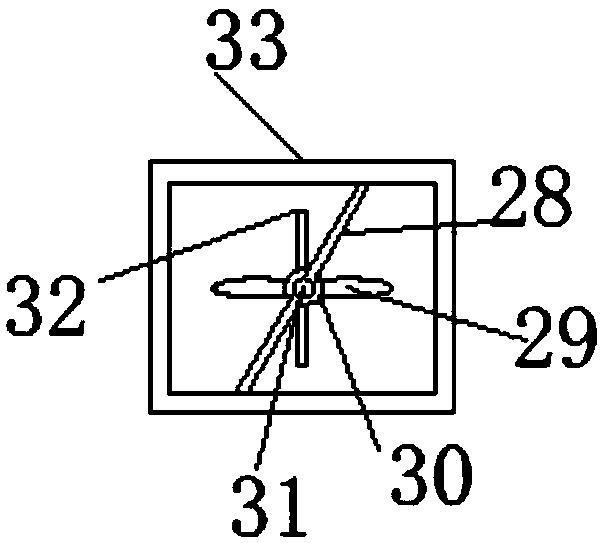

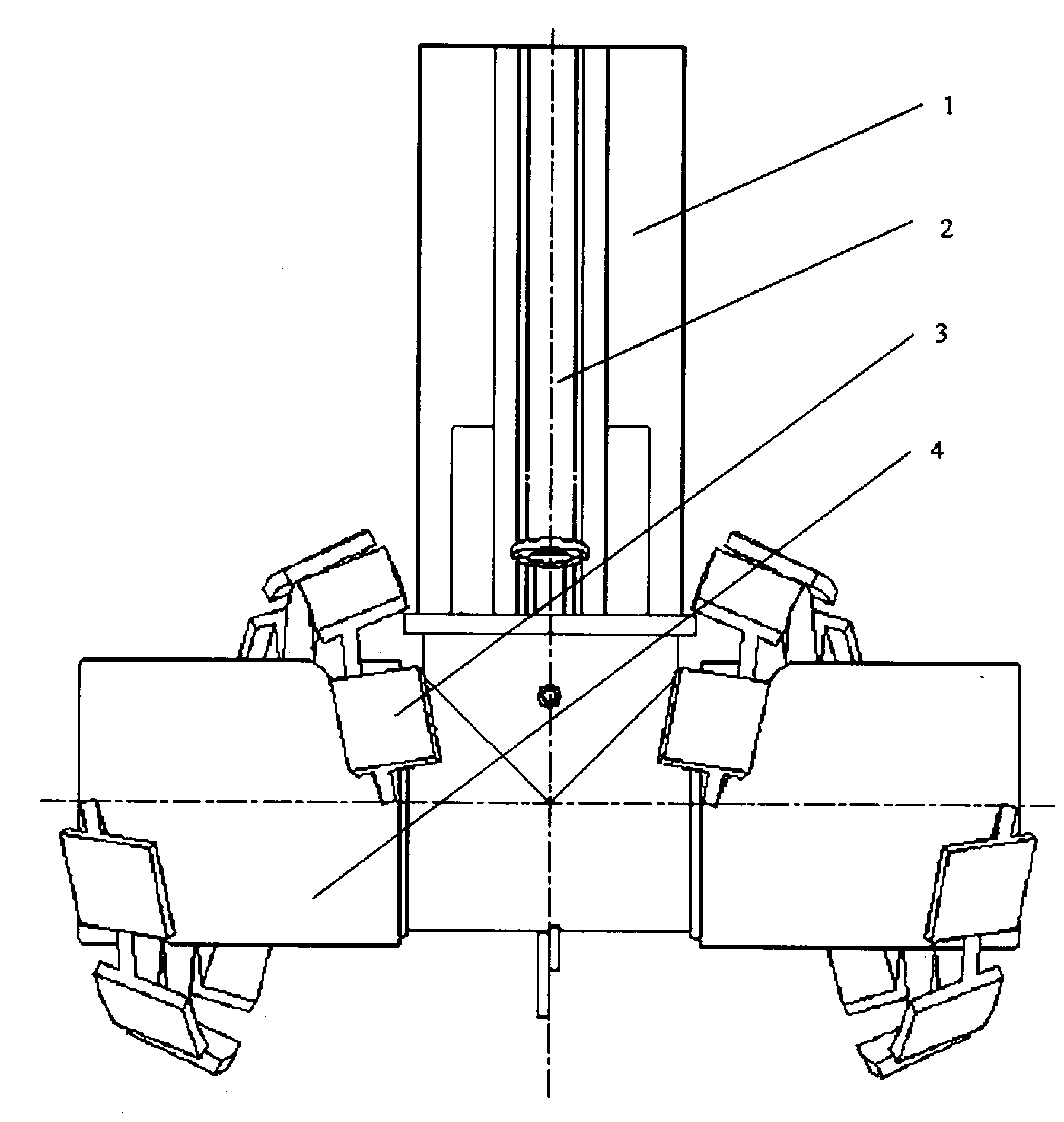

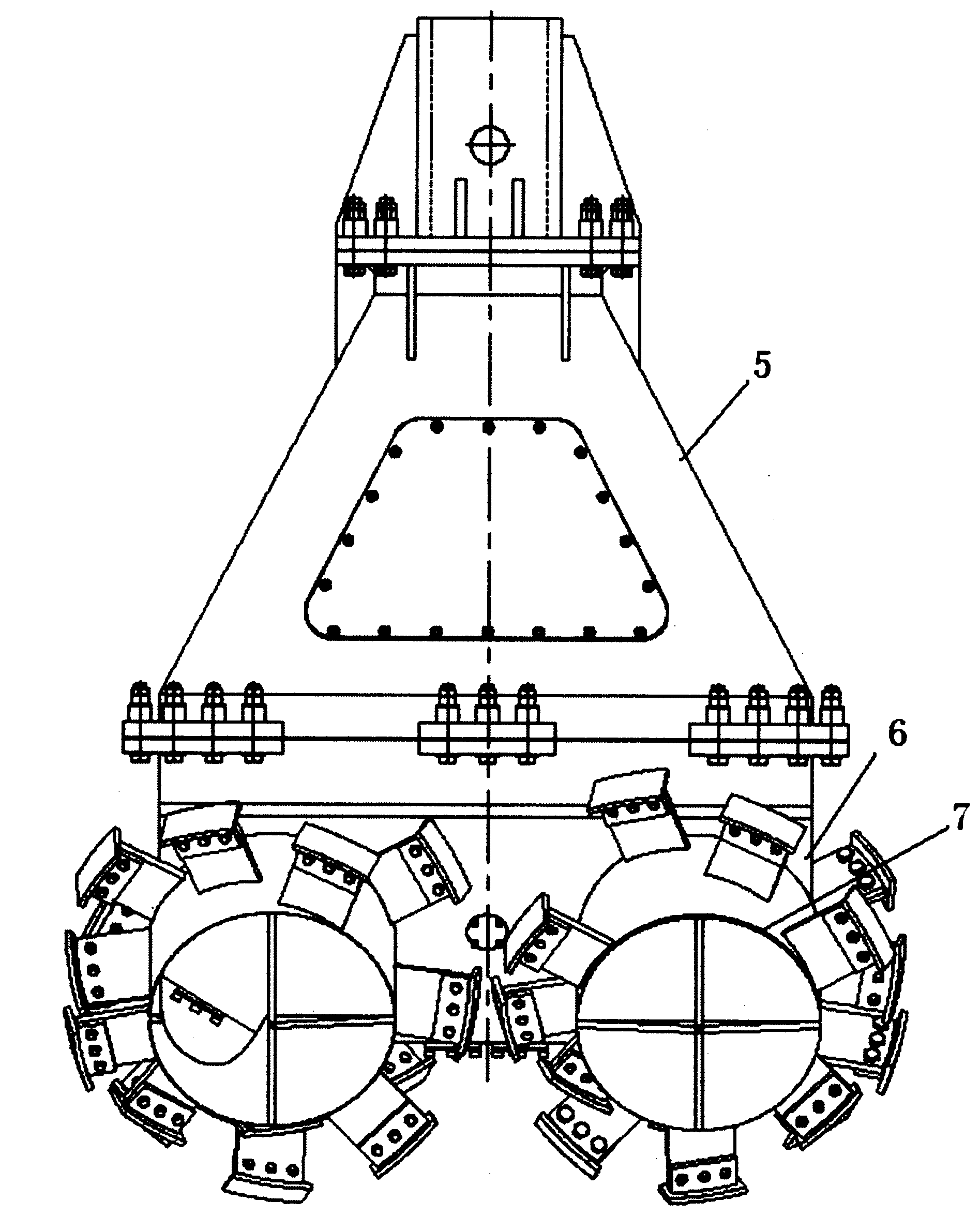

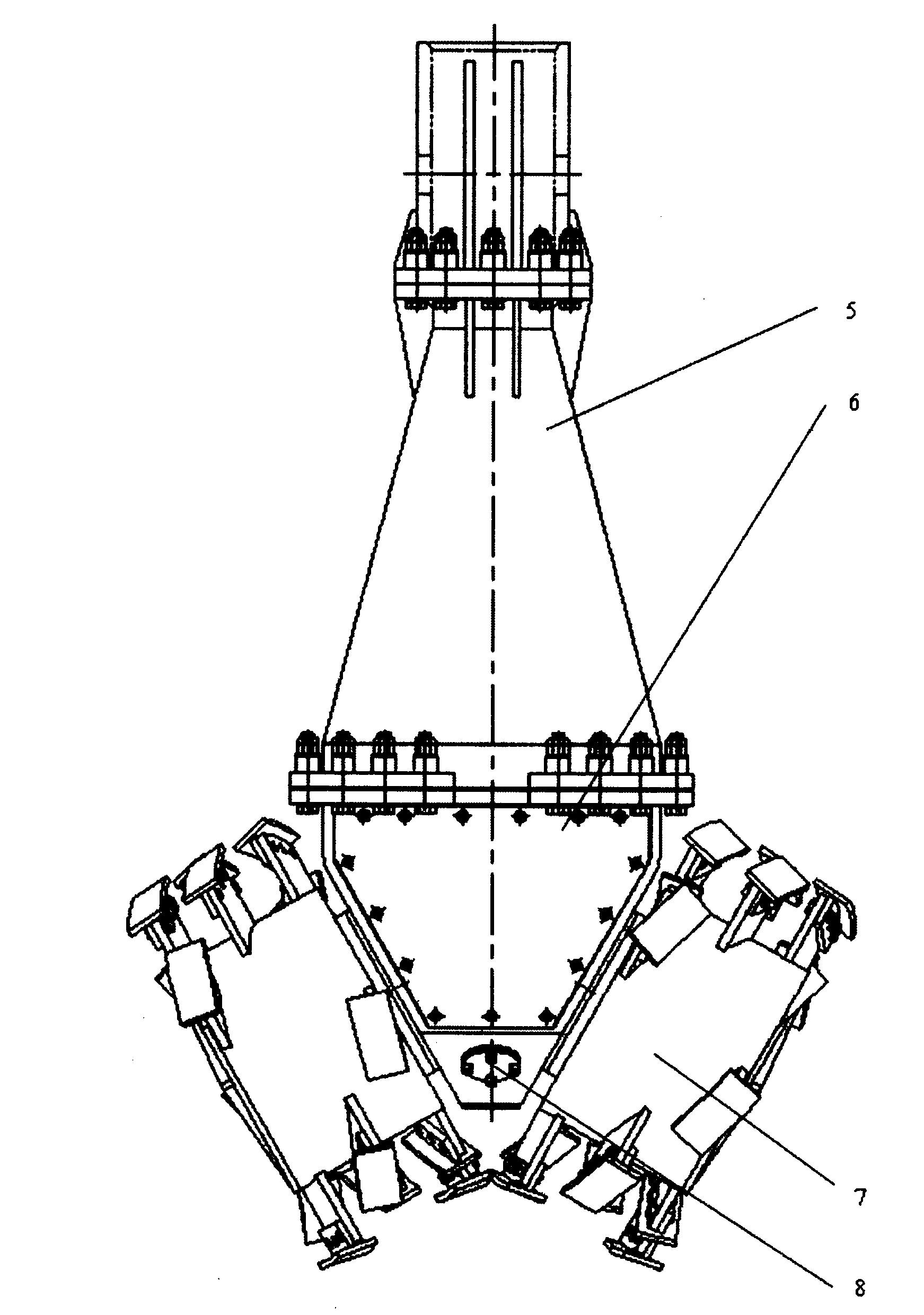

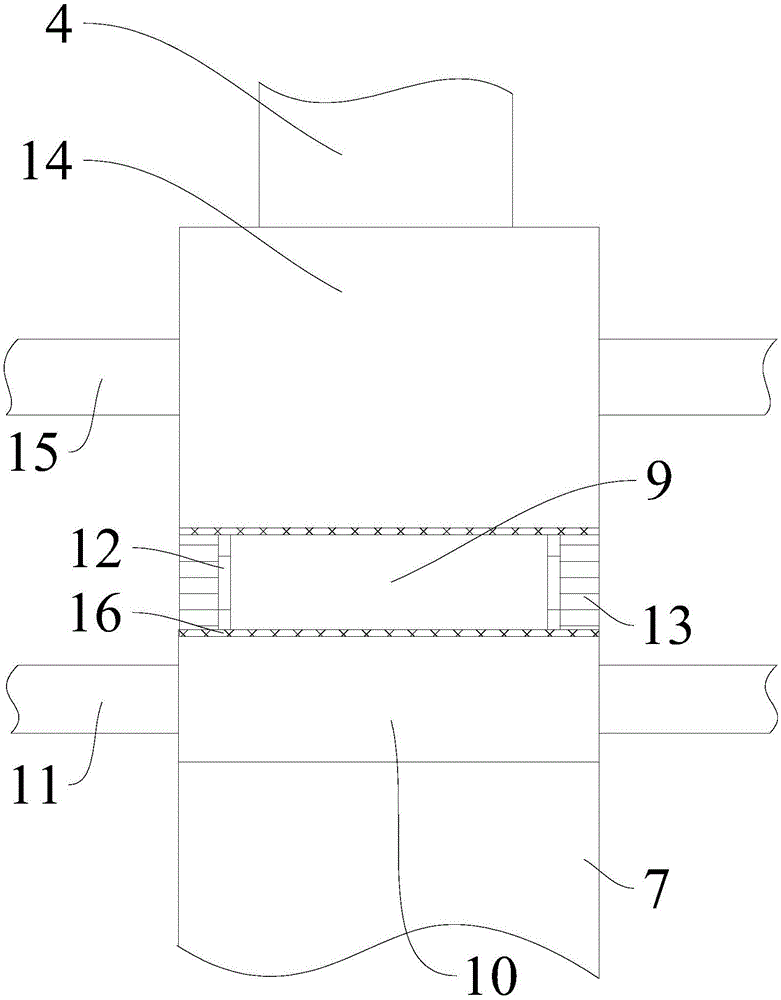

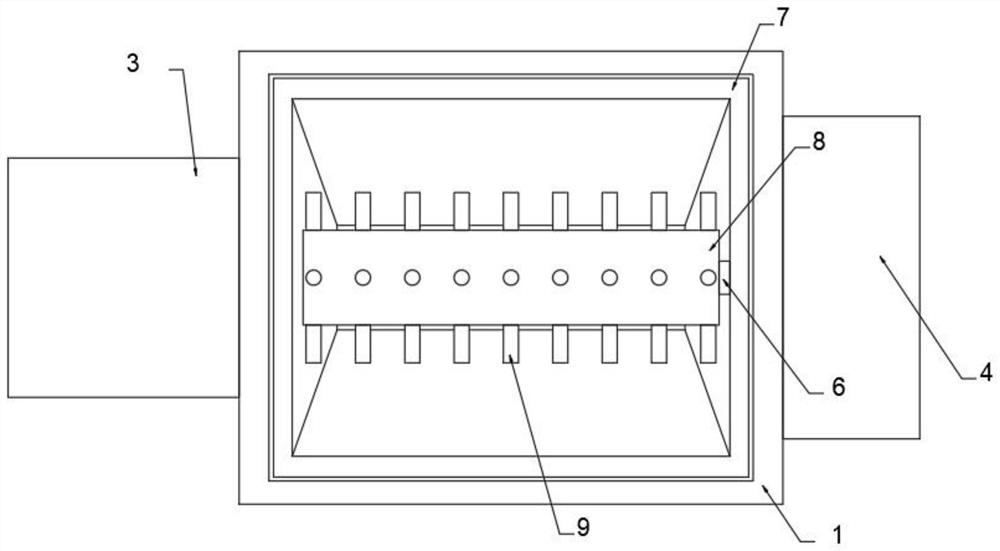

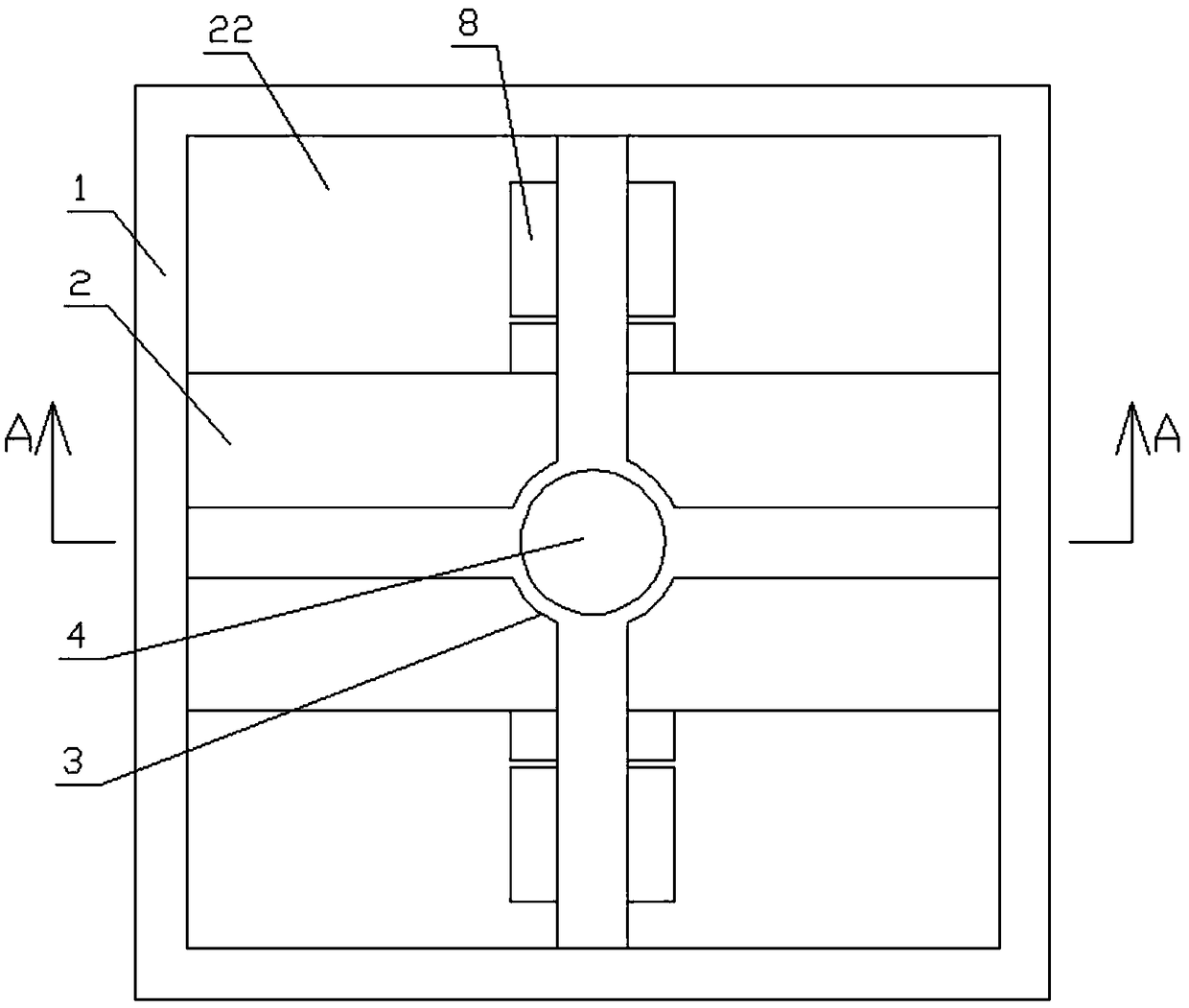

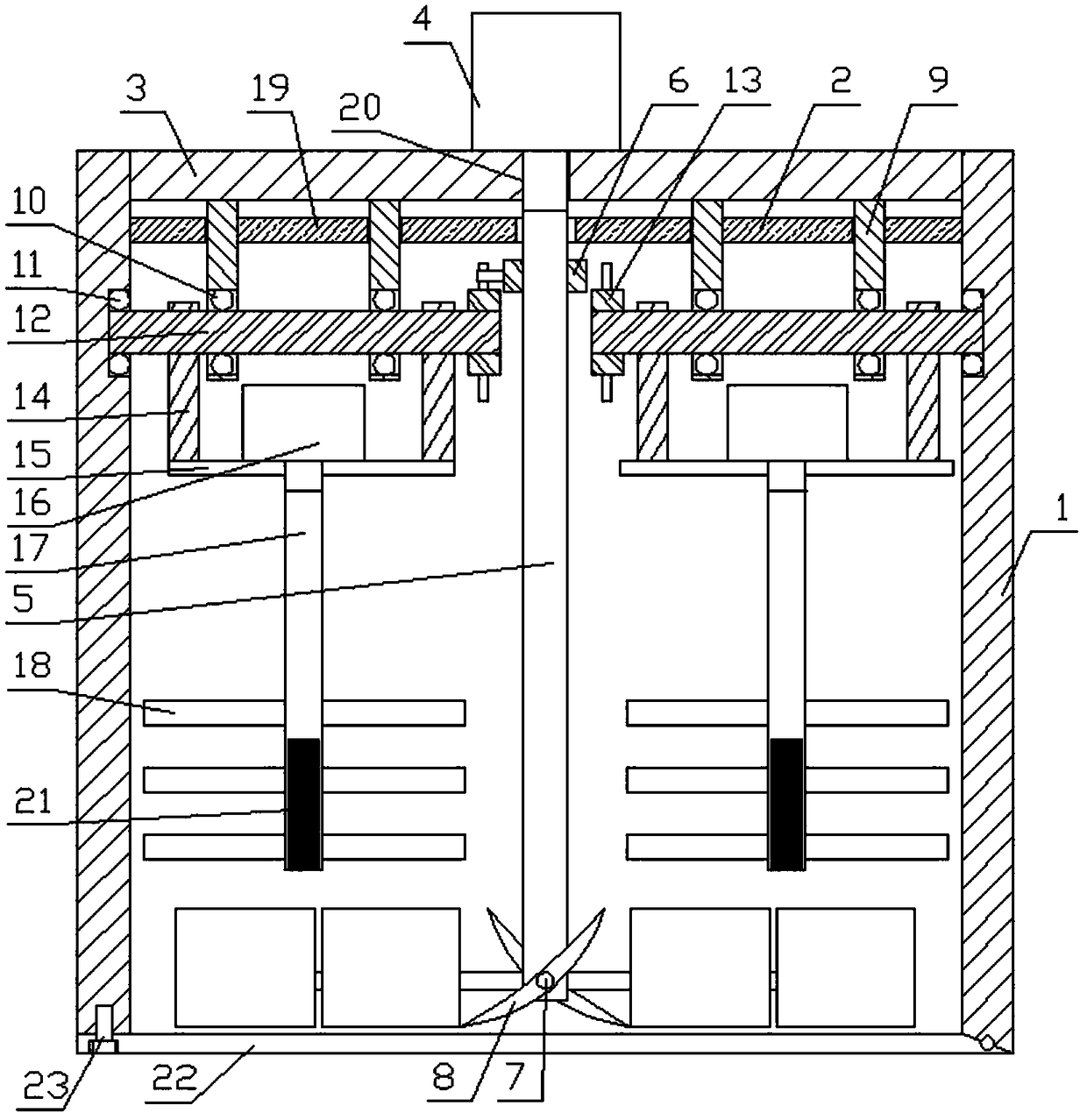

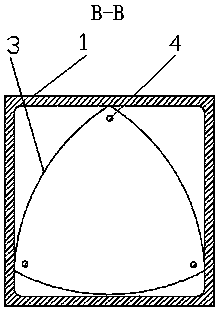

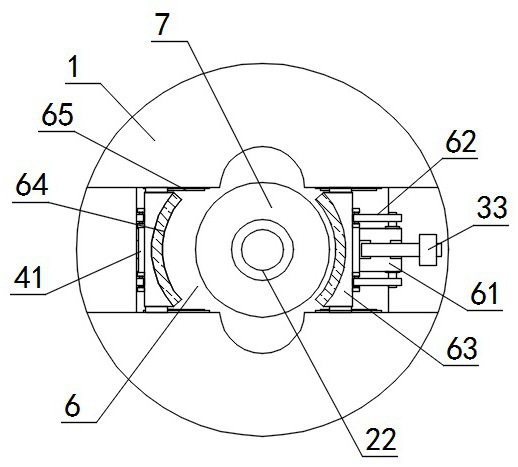

Stirring head of stirring curing machine

The invention provides a stirring head of a stirring curing machine, which is characterized in that the stirring head of the stirring curing machine comprises a box body, wherein an inwards-inclined slope is respectively formed on each of two sides of the bottom of the box body; each slope is respectively provided with at least one stirring device; the stirring device is driven by driving equipment to rotate; and the bottom of the box body is provided with a guniting pipe. The stirring head has the advantages of providing the stirring head which is specially used for the stirring curing machine. According to the stirring head, distance between two adjacent stirring devices is shortened by two inclined slopes, so that a stirring dead corner is reduced, and the material is more evenly stirred. Furthermore, the stirring device disclosed by the invention has enough torque, and the stirring head can easily dive when meeting compact soil texture.

Owner:龙工(上海)机械制造有限公司 +1

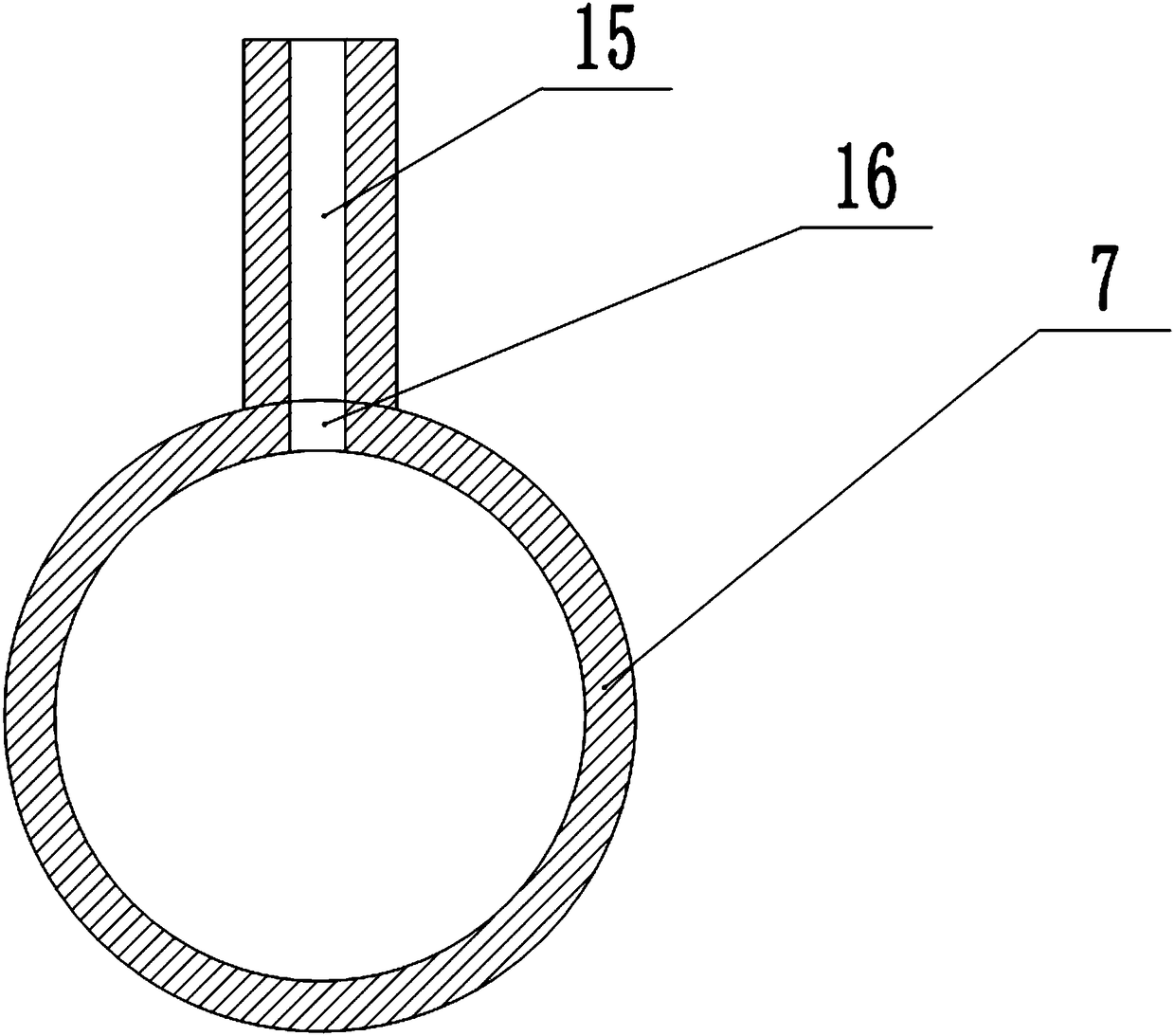

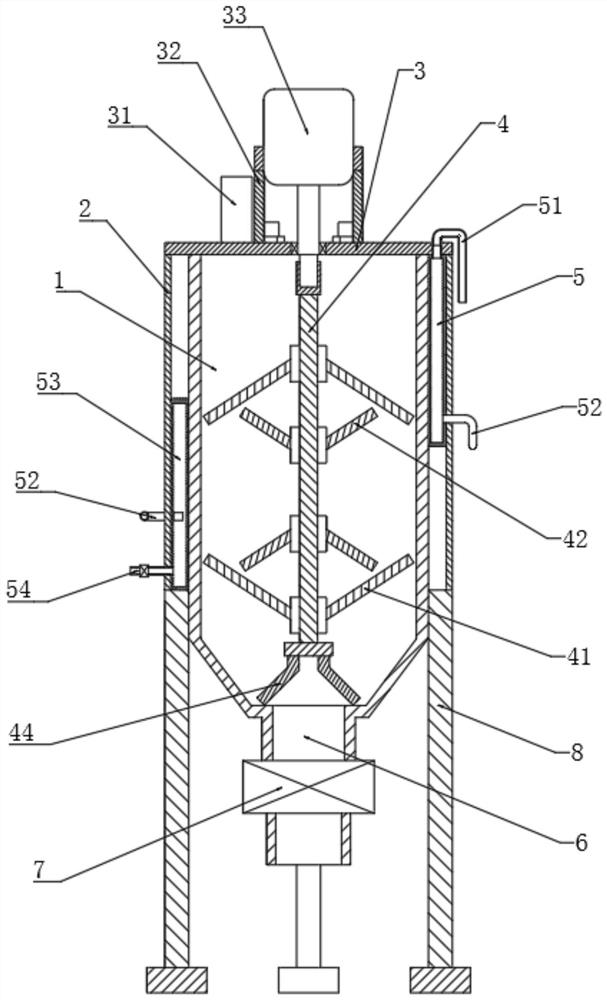

Biological fermenting device with multiple stirring shafts

InactiveCN107325959AWell mixedUniform responseBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention discloses a biological fermentation device with multiple stirring shafts, which comprises a housing, a motor, a feeding port and a sampling chamber; a sealing box is set on the outer side of the dispersing pipe; a horizontal filter screen is fixed in the middle of the housing, The lower end of the dispersing tube is coaxially fixedly connected with a vertical main stirring shaft, and the main stirring blade is fixedly installed on the side wall of the main stirring shaft; a ring rack is installed on the inner side of the ring, and a gear is meshed on the rack. The lower end of the gear is coaxially fixed with an auxiliary stirring shaft, and an auxiliary stirring blade is fixedly arranged on the side wall of the auxiliary stirring shaft; the outer end of the connecting pipe communicates with the sampling chamber. The invention evenly disperses the incoming liquid or gas to the raw materials in the housing through the provided dispersing pipe, so that the added liquid or gas can be evenly mixed with the raw materials, so as to improve the fermentation efficiency and ensure uniform reaction; the main stirring blade is driven by the motor at the same time Rotate with multiple auxiliary stirring blades, and stir the inside at the same time.

Owner:武晓丹

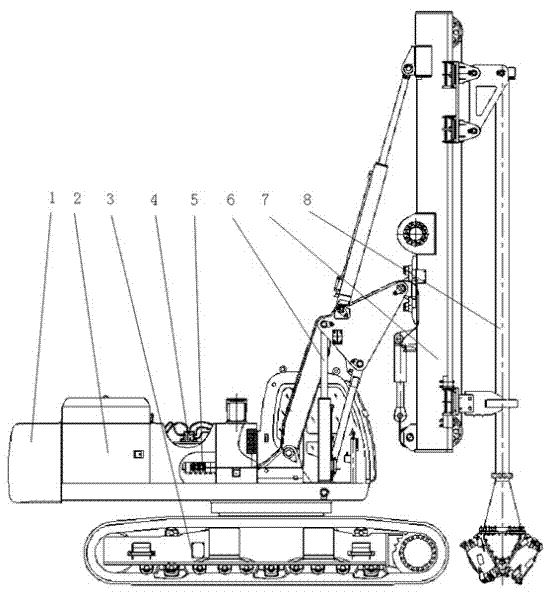

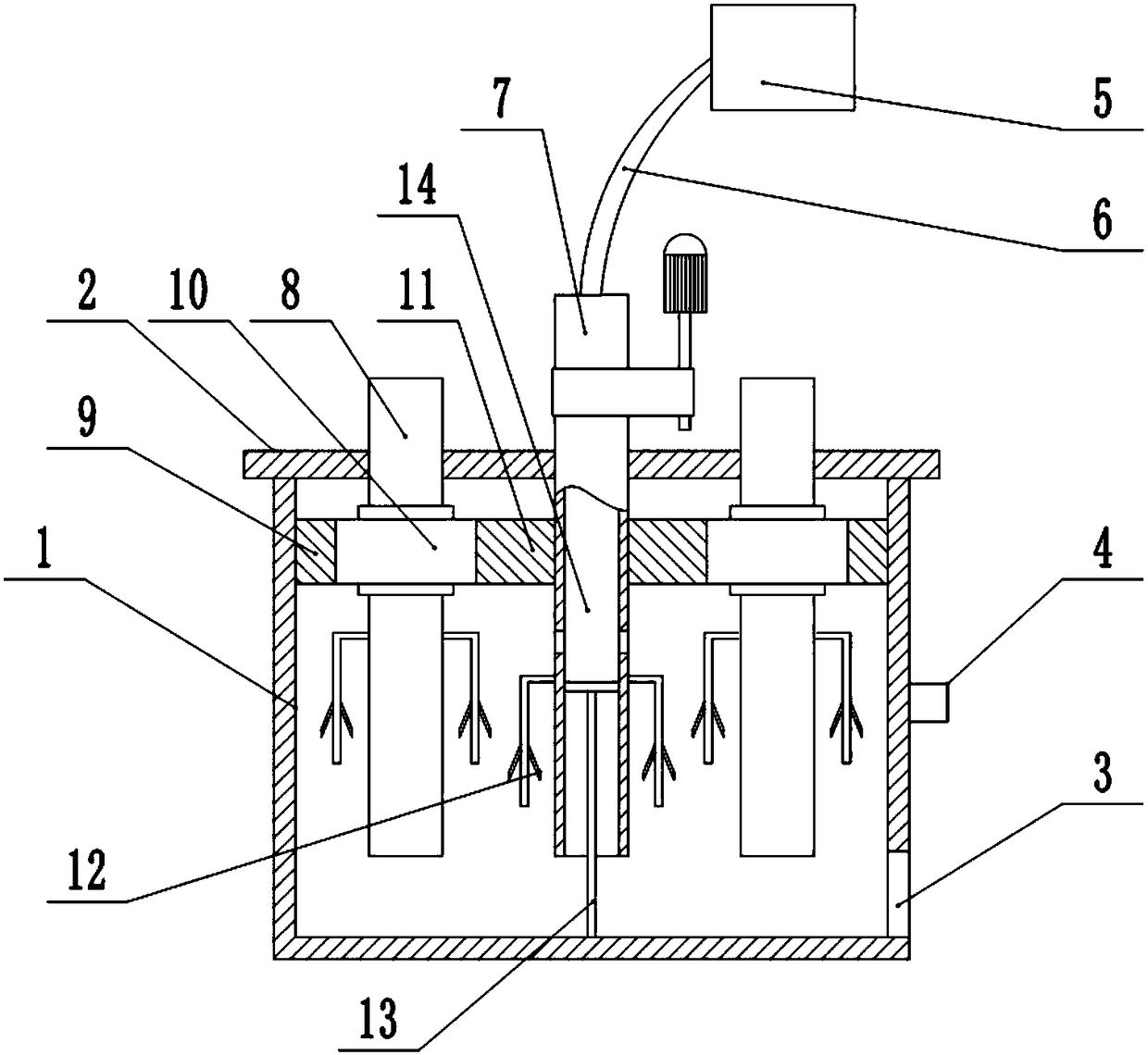

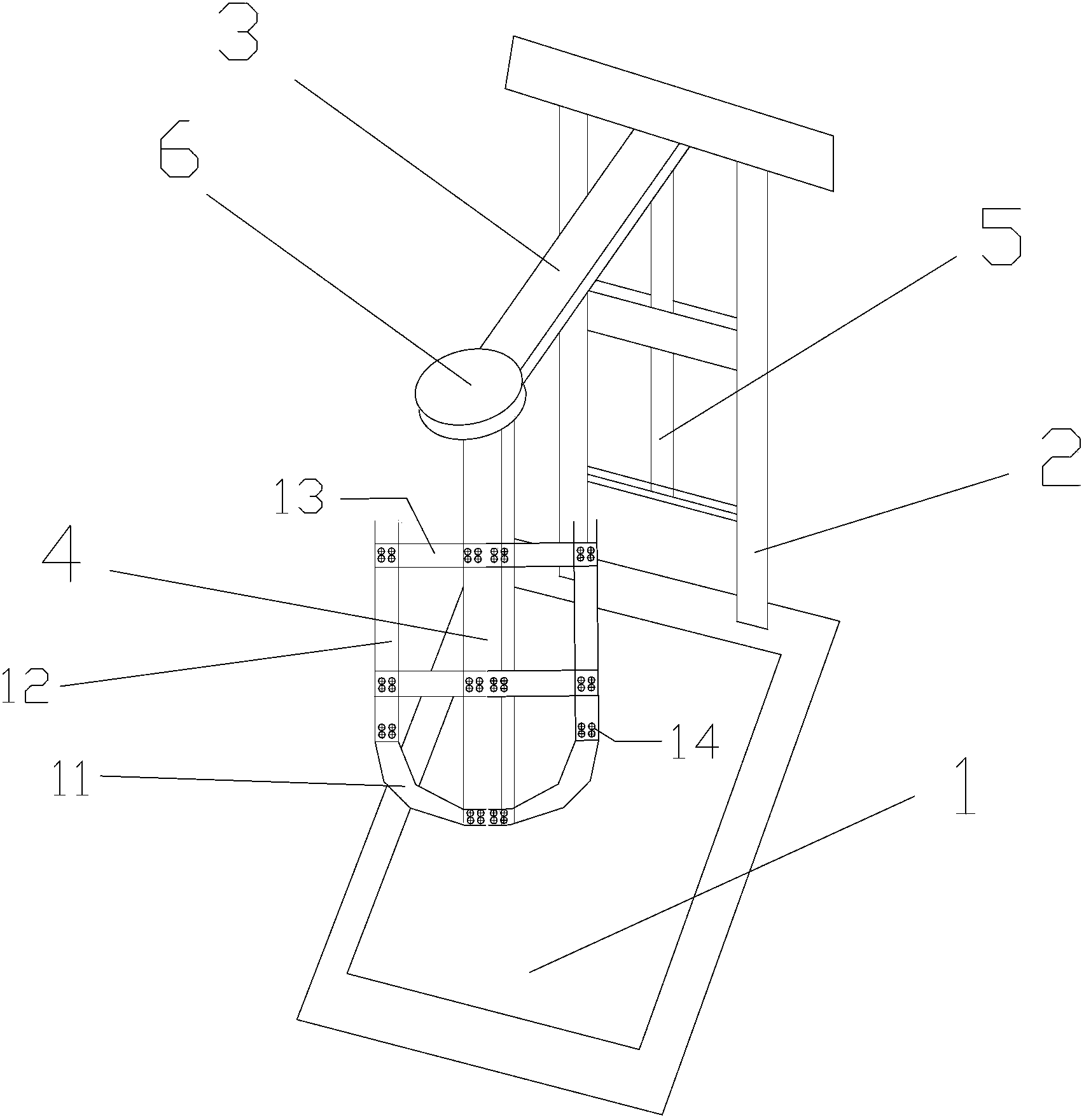

Vertical type animal gastrointestinal bionic digester

ActiveCN105842407AImprove accuracyImprove stabilityEducational modelsMaterial analysisAnimal scienceMedicine

The invention relates to a vertical type animal gastrointestinal bionic digester, which comprises a motor, a connecting shaft sleeve, a heightening transmission rod, a stirring rod and a simulated digestive tract, wherein the connecting shaft sleeve is sleeved on an output shaft of the motor and synchronously rotates along with the motor, and the top end of the heightening transmission rod is fixedly sleeved in a sliding chute below the connecting shaft sleeve by a screw rod, so that the heightening transmission rod can move up and down in the connecting shaft sleeve; a locking nut is arranged on the heightening transmission rod and is used for adjusting the locking degree of the heightening transmission rod and the stirring rod, and the simulated digestive tract is a double-layer hollow vertical glass tube; the stirring rod is arranged in an accommodating cavity of the simulated digestive tract, and the top end of the stirring rod penetrates through a sealing plug at the top of the simulated digestive tract and is connected with the bottom end of the heightening transmission rod. The vertical type animal gastrointestinal bionic digester provided by the invention has the advantages of simple structure, convenience in use, avoidance of leakage of a bionic digestion reaction liquid, high accuracy and good repeatability of digestion simulation, and small errors; the degradation difficulty of cellulose on a dialysis bag in the existing simulated digestive tract in a bionic digestion reaction is effectively solved.

Owner:HUNAN ZHONGBEN INTELLIGENT TECH DEVCO

Novel industrial mixer

InactiveCN106861502AEasy to moveEasy to cleanRotary stirring mixersTransportation and packagingPulp and paper industryIndustrial mixer

The invention discloses a novel industrial mixer and relates to the field of industrial processing. The novel industrial mixer comprises a mixer main body, a glass window, a material inlet, a cover plate, a hinge, a motor, a reduction gearbox, water pipe joints, extension pipes, stirring shafts, stirring blades, a discharge outlet, wheels and openings. The mixer main body is provided with the material inlet. The material inlet is provided with the cover plate. The upper part of the mixer main body is provided with the motor and the reduction gearbox. The motor is connected to a reduction gearbox shaft. The stirring shafts are arranged in the mixer main body and are connected to the reduction gearbox shaft. The stirring shafts comprise three stirring shafts and have hollow structures. The upper part of the stirring shaft is provided with the extension pipe. The end of the extension pipe is provided with the water pipe joint. The surface of the stirring shaft is provided with the opening. The stirring shaft is provided with stirring blades. The mixer main body is provided with the discharge outlet. The lower part of the stirrer main body is provided with the wheels. The three stirring shafts have high stirring efficiency. The hollow stirring shafts are connected to water pipes so that a cleaning function is realized.

Owner:滁州市松园农业科技有限公司

Small swinging concrete mixer

InactiveCN108247837AWell mixedExpand the mixing rangeDischarging apparatusCement mixing apparatusDrive shaftArchitectural engineering

The invention discloses a small swinging concrete mixer. The small swinging concrete mixer comprises a base, support legs, a first motor, a drive shaft and a discharge port, wherein a left fixing plate and a right fixing plate are fixedly connected to the left end and the right end of the upper surface of the base separately; a mixing tank is arranged between the left fixing plate and the right fixing plate; the drive shaft is fixedly connected to a shaft stretching end of the first motor; the lower end of the drive shaft stretches into the mixing tank; a drive gear sleeves the lower end of the drive shaft; a tooth groove is formed in the inner wall of the mixing tank; driven gears are arranged at the left side and the right side of the drive shaft separately; a mixing shaft is fixedly connected to the lower surface of each driven gear; and a second motor is fixedly connected to the upper surface of the base. In a mixing process, the driven gears revolute while driving the mixing shafts to rotate, and concrete is mixed by virtue of a mixing rod, so that the mixing range is expanded, the mixing effect is greatly improved, and the mixing efficiency is increased; and during mixing, the mixing tank swings back and forth to drive concrete slurry to swing in the mixing tank, so that the concrete slurry is much uniformly mixed.

Owner:宜昌益智建材有限责任公司

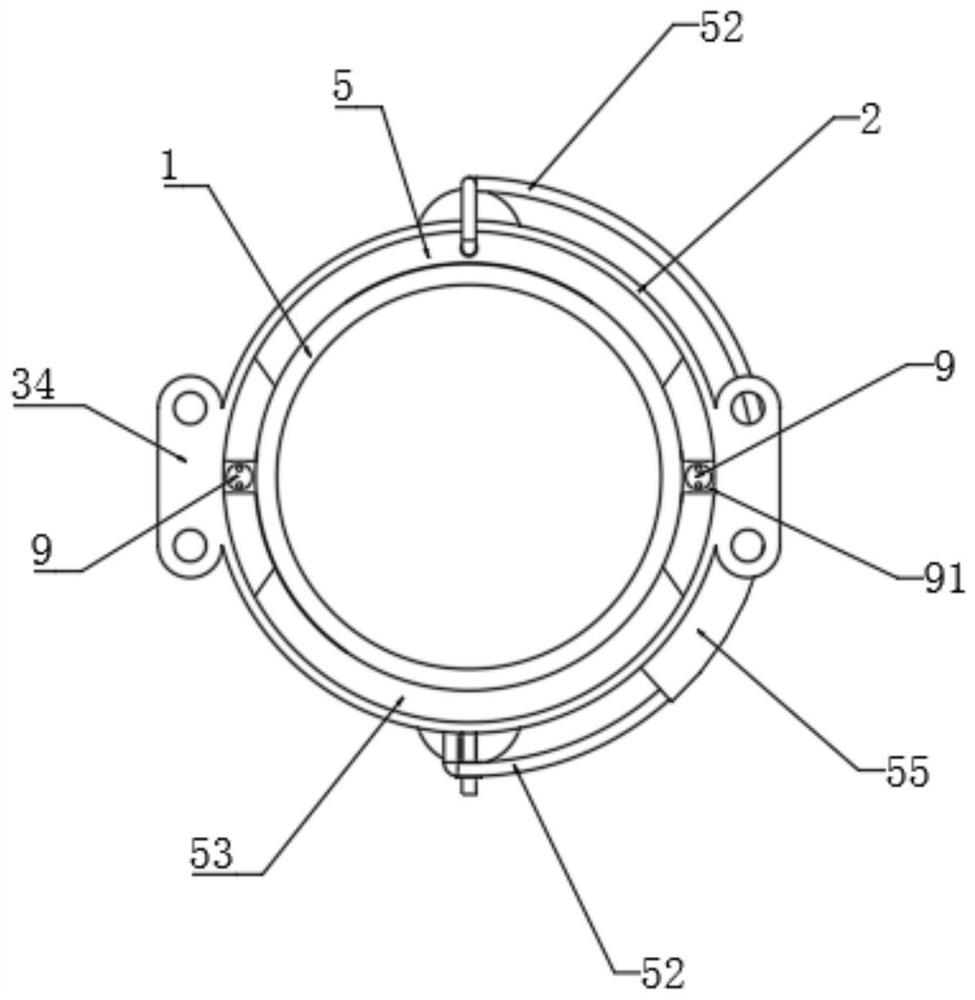

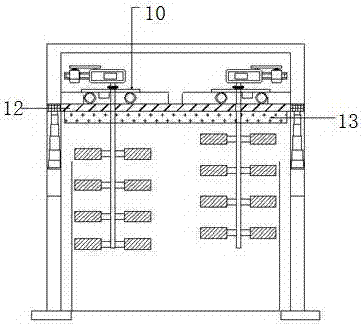

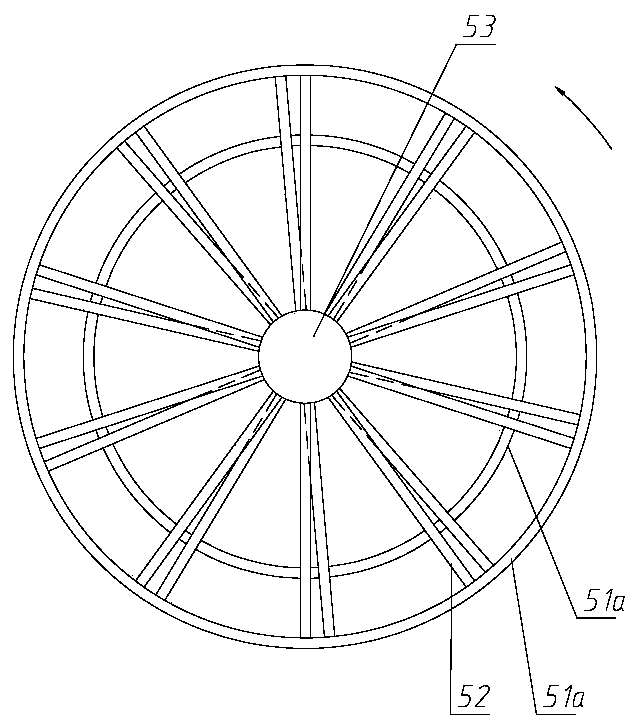

Bidirectional mixing chelating device for feed production

InactiveCN106423031AQuality improvementReduce stirring dead angleFeeding-stuffRotary stirring mixersEngineeringMixing effect

The invention relates to the technical field of feed production equipment, and particularly relates to a bidirectional mixing chelating device for feed production. The chelating device comprises a main shell and a high-speed motor which is positioned at the upper end of the main shell, wherein two feeding pipes are fixed at the upper end of the main shell and are respectively positioned on two sides of the high-speed motor; and a main rotating shaft is longitudinally arranged inside the main shell and is axially and fixedly connected with the rotating shaft at the lower end of the high-speed motor. According to the bidirectional mixing chelating device for feed production, a bottom support is fixed at the bottom in the main shell, and is in transmission connection with a driving ring on the main rotating shaft by utilizing a transmission mechanism and a transmission gear on the bottom support, so that an inner mixing support and an outer mixing support rotate in opposite directions inside the main shell; and the chelating device has a small mixing dead angle, a rich material flowing track and an ideal mixing effect, is used for primarily grinding a material by utilizing a top grinding blade so as to greatly improve the efficiency of chelating reaction, has a better integral reaction effect, and enables the feed quality to be greatly improved.

Owner:湖北博大生物股份有限公司

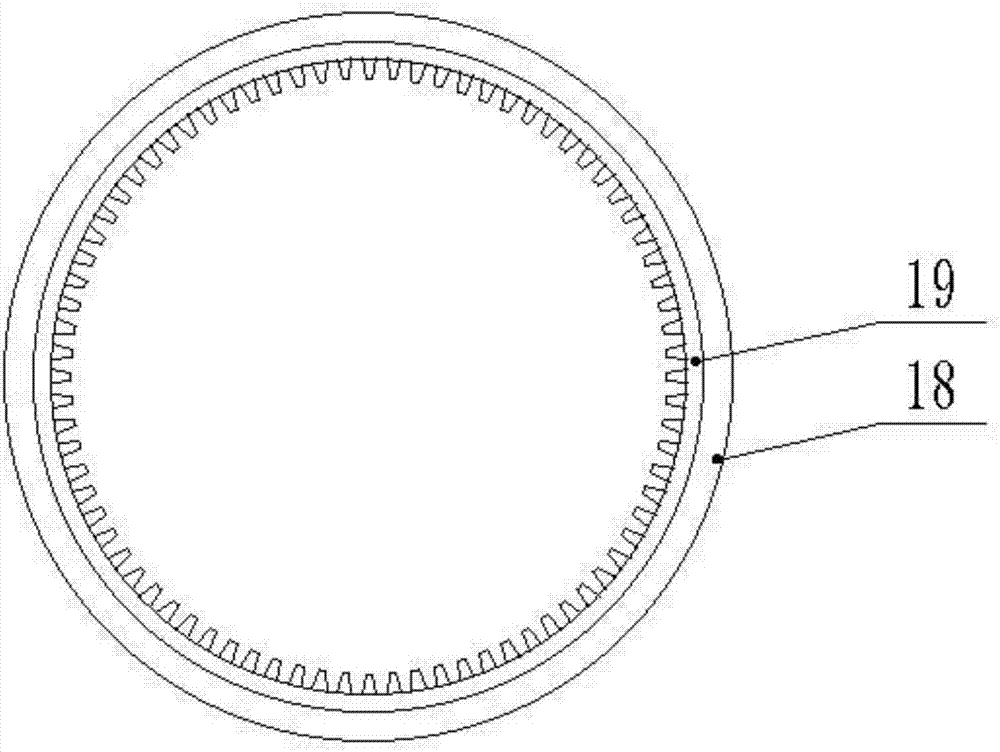

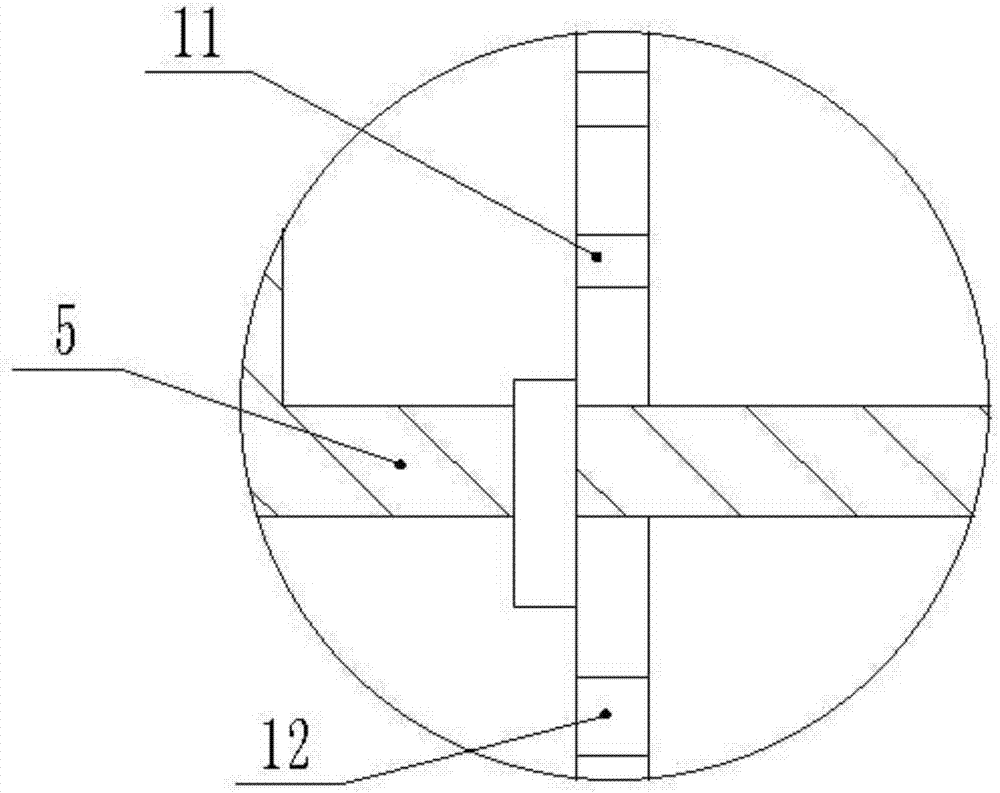

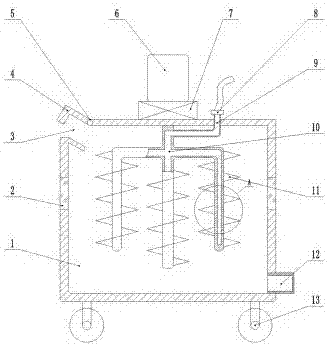

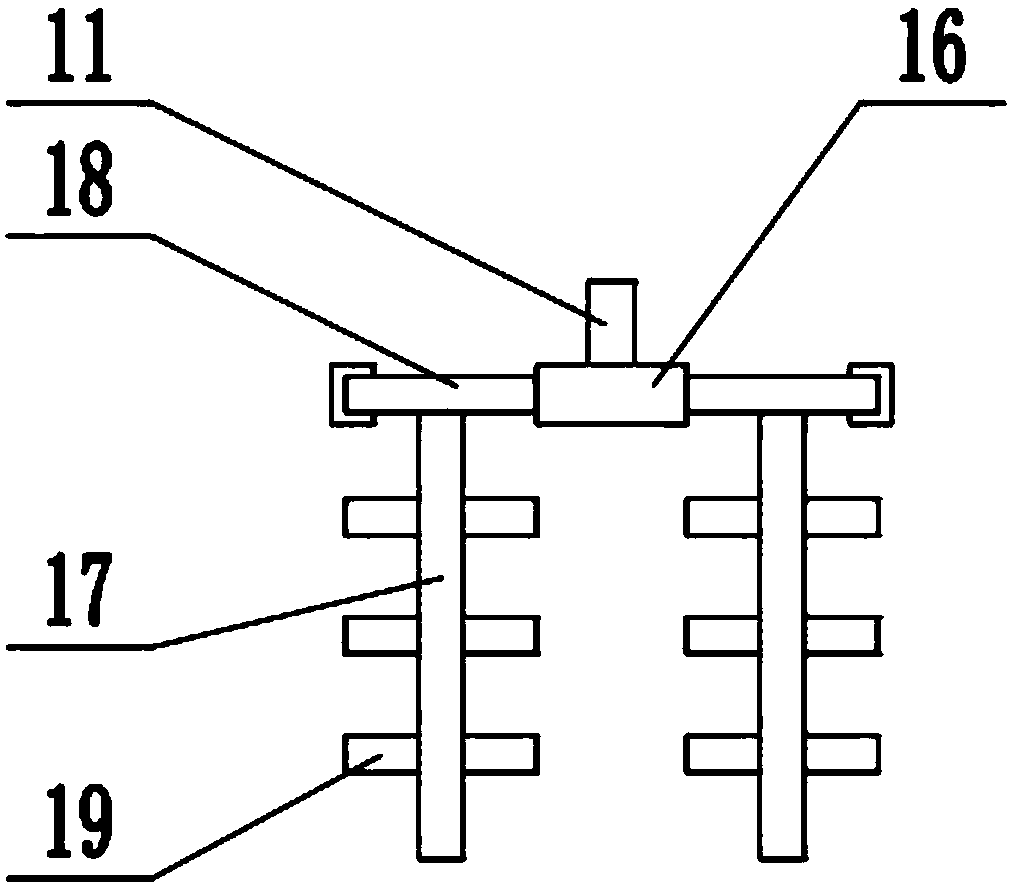

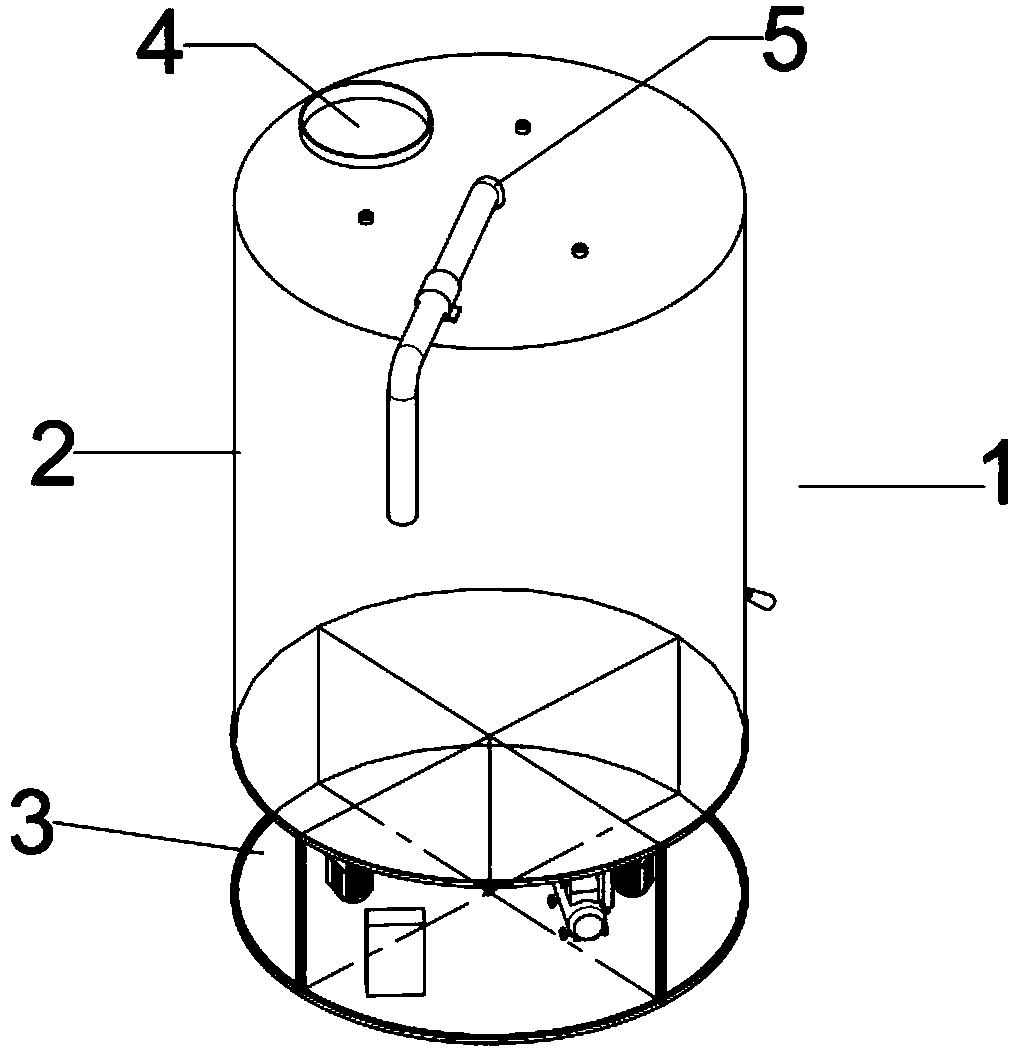

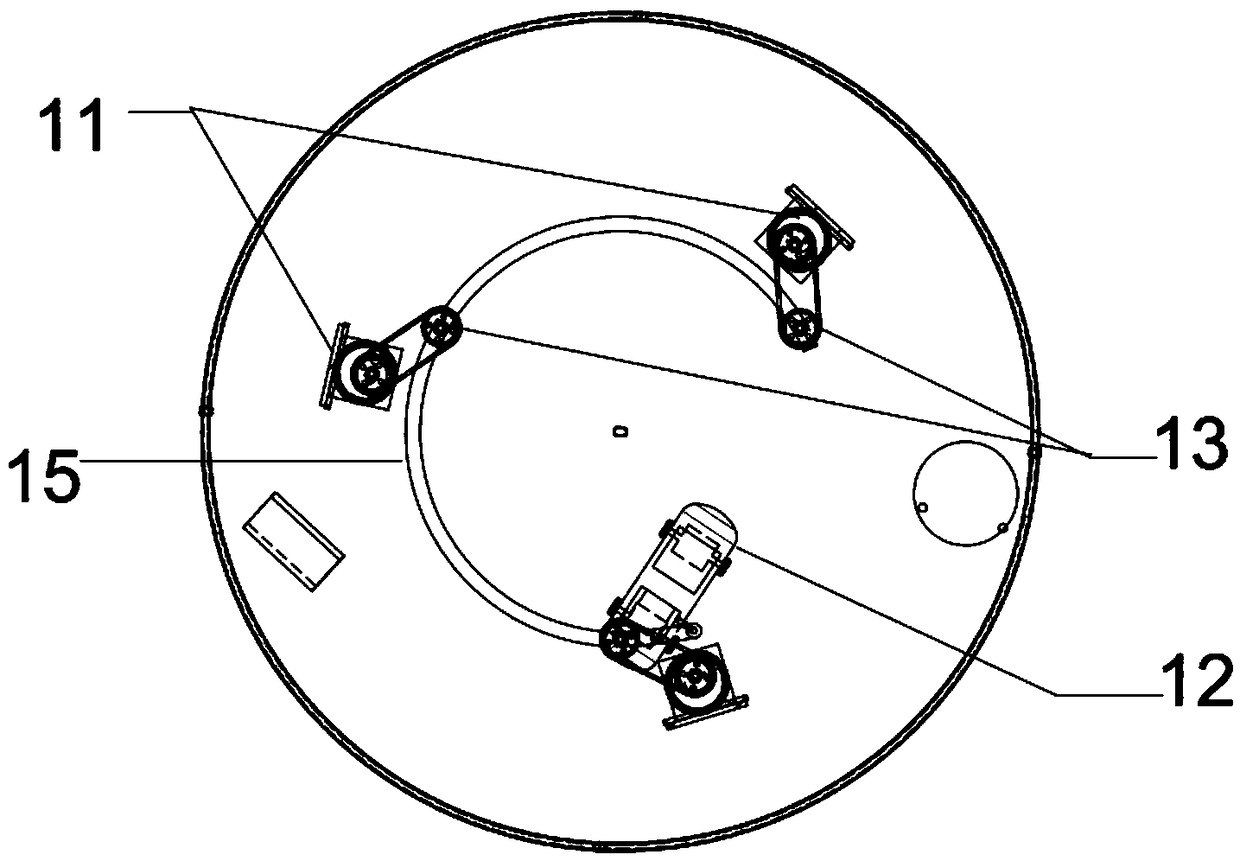

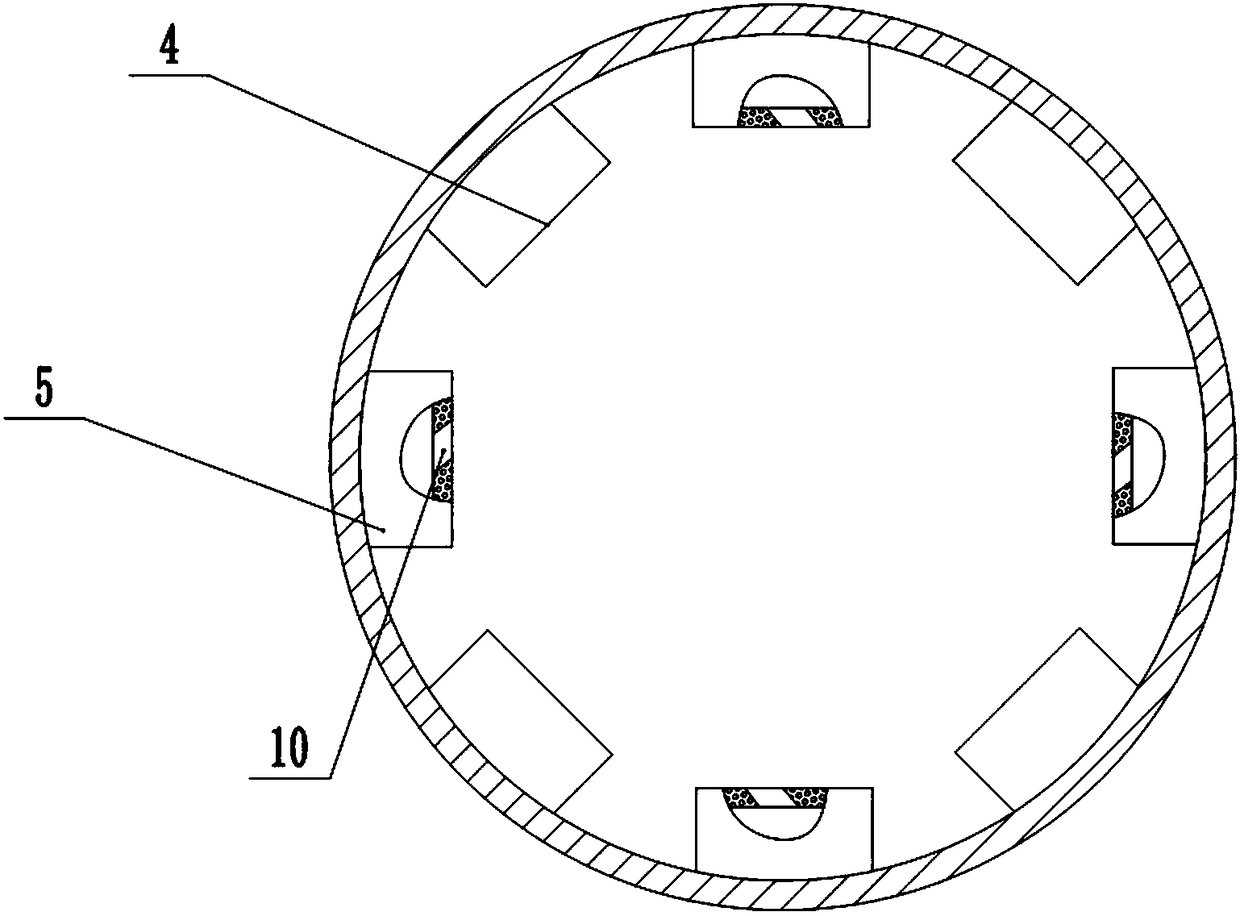

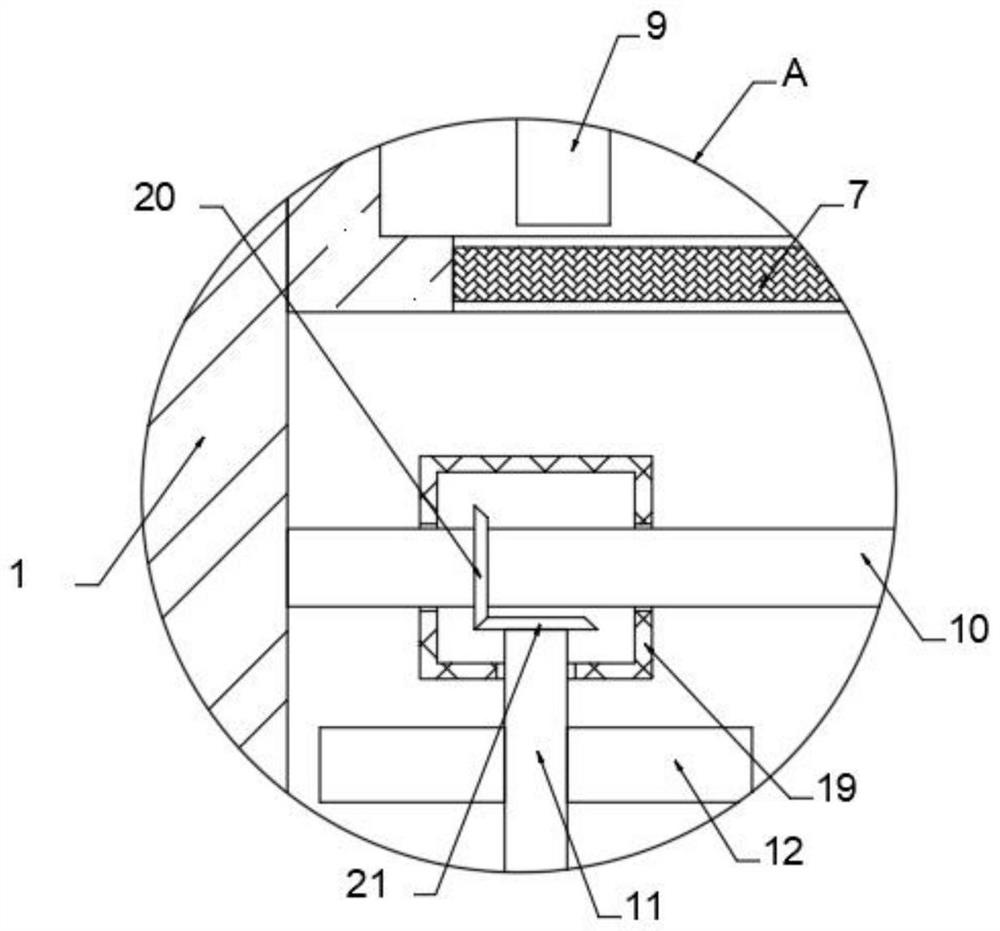

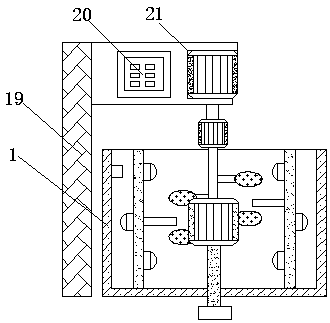

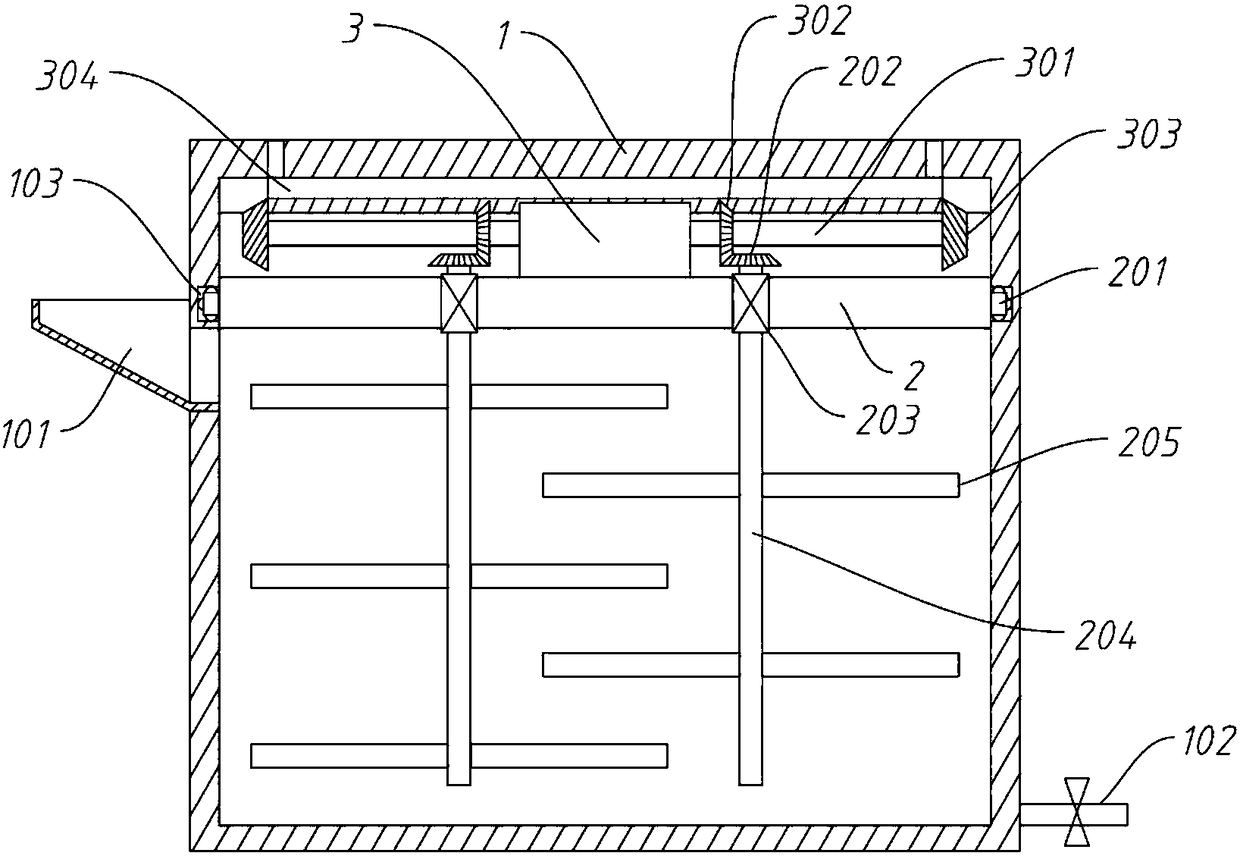

Composting reactor for quickly, efficiently and harmlessly treating livestock manure

PendingCN109232027AShorten the lengthAvoid CatonClimate change adaptationExcrement fertilisersMotor driveFeces

The invention relates to a compost reactor for quickly, efficiently and harmlessly treating livestock manure, comprising a cylindrical fermenter which is divided into an upper fermentation chamber anda lower equipment chamber, wherein a feed port and a gas outlet are formed in the top of the fermentation chamber, a discharge port and a discharge valve are formed in the side face of the fermentation chamber, a heating coil tube surrounding the inner wall of the fermentation chamber is arranged on the inner wall, a liquid inlet end and a liquid outlet end of the coil tube are connected to a high temperature circulating oil bath tank located in an equipment chamber, three stirring motors and air pump are arranged in the equipment chamber, the three stirring motors drive three stirring rods to rotate, the three stirring rods are distributed in an equilateral triangle, each stirring rod is provided with a plurality of layers of stirring blades, three stirring blades are arranged on each layer, an angle of 120 degrees is formed between the stirring blades of the same layer, the stirring blade layers of the three stirring rods are distributed in a staggered manner, the stirring rods andthe stirring blades both are of hollow structures and communicated with each other, and an air outlet of the air pump is communicated to the bottoms of the three stirring rods by the air outlet, and aplurality of air outlet holes are formed in the stirring blades.

Owner:中国农业大学烟台研究院

Processing equipment of pig feed

InactiveCN108851145APrevent affecting operationChange the mixing rangeShaking/oscillating/vibrating mixersFeeding-stuffSlide plateEngineering

The invention belongs to the field of feed processing, and particularly discloses processing equipment of pig feed. A stirring box is fixed to a rack, the lower portion of the inner wall of the stirring box is slidingly connected with a connecting rod, a first baffle is hinged to the inner wall of the left side of the stirring box, a first sliding plate is slidingly connected into a first slidinggroove, and the right end of the first sliding plate is hinged to a connecting rod. A second baffle is hinged to the inner wall of the right side of the stirring box, a second sliding plate is slidingly connected into a second sliding groove, and the left end of the second sliding plate is hinged to the connecting rod. Reset springs are fixed between the lower end of the first baffle and the rackand between the lower end of the second baffle and the rack. A stirring shaft is arranged on the rack, and comprises a spline section, a thread section and a stirring section which are sequentially arranged from top to bottom. The spline section is in spline connection with a spline sleeve, and the thread section is in threaded connection with a nut. A piston barrel is fixed to the portion, located above the stirring shaft, of the rack, and a cavity is formed in the side wall of the stirring box. By the adoption of the scheme, the problem that in the stirring process, raw materials easily adhere to the inner wall of the stirring box is solved.

Owner:桐梓县惠农畜牧养殖专业合作社

Soil layer sampling device for geological exploration

ActiveCN110907218AAvoid cakingWell mixedWithdrawing sample devicesPreparing sample for investigationSpiral bladeStructural engineering

The invention belongs to the field of geological prospecting, and particularly discloses a soil layer sampling device for geological prospecting. The device comprises a sampling barrel. A rotating shaft is rotatably connected in the sampling barrel, a plurality of groups of stirring assemblies are arranged on the rotating shaft from top to bottom, and a plurality of groups of sampling assemblies are arranged on the outer wall of the sampling barrel from top to bottom. The stirring assembly comprises a stirring rod rotationally connected to the rotating shaft and transversely arranged and stirring blades hinged to the rotating shaft and located below the stirring rod. Driving bevel gears are fixed to the portions, located above the stirring rod, of the rotating shaft, and a connecting rod is rotationally connected to the inner wall of the sampling barrel. A driven bevel gear meshed with the driving bevel gear is fixed to the connecting rod, a through hole allowing the connecting rod toextend out is formed in the sampling barrel and located in the connecting rod, and the inner diameter of the through hole is larger than the outer diameter of the connecting rod. Spiral blades are fixed at the part, outside the sampling barrel, of the connecting rod. By the adoption of the scheme, the problem that it is troublesome to complete sampling of soil layers of different depths through multiple times of sampling of a sampler can be solved.

Owner:LIUPANSHUI NORMAL UNIV

Tea leaf enzyme deactivation device

The invention belongs to the field of tea processing, and particularly discloses a tea leaf enzyme deactivation device. The device comprises a frame; an enzyme deactivation barrel is fixed on the frame; first air bags and second air bags are staggered on the inner wall of the enzyme deactivation barrel; the upper part of each first air bag is provided with a first projection; a first spring is fixedly arranged between the two inner side walls at each first projection and in each first air bag; each first projection is provided with a first magnetic block; the inner wall of the upper end of each first air bag is provided with a first air inlet hole; the outer wall of the upper end of each first air bag is provided with a first air outlet hole; the outer wall of the lower end of each secondair bag is provided with a second air inlet hole; the outer wall of the lower end of each second air bag is provided with a second air outlet hole; a stirring shaft is rotatably connected onto the frame; the stirring shaft is provided with some supporting rods which are close to the first projections and the second projections and are uniformly distributed in circumferential direction; and one ends, far from the stirring shaft, of the supporting rods are fixedly connected to an electromagnet for repelling first magnetic blocks and second magnetic blocks. The adopted scheme of the invention solves the problem that the tea leaves are easy to heap up during the enzyme deactivation process.

Owner:湖北小稀藤生物科技有限公司

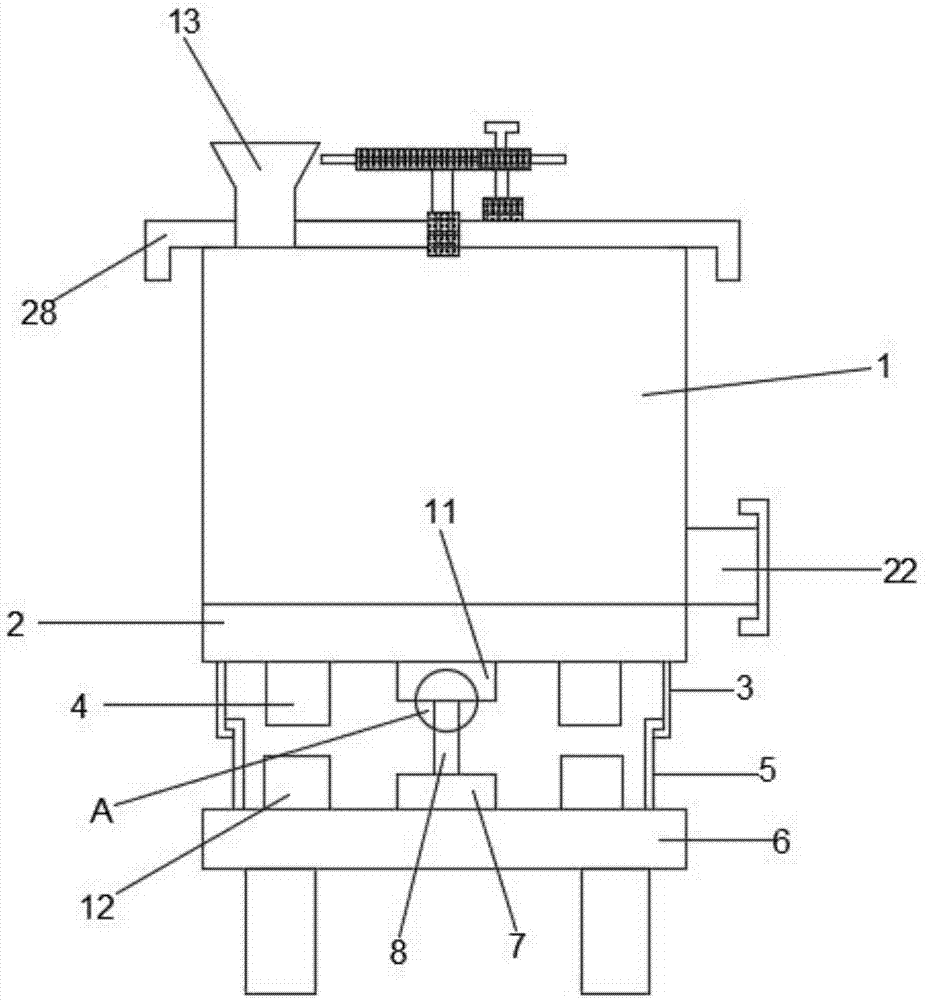

Biochar and fertilizer mixing device and process for improving soil environment

InactiveCN114367236AWell mixedEasy to useTransportation and packagingRotary stirring mixersElectric machineryStructural engineering

The invention discloses a biochar and fertilizer mixing device for improving the soil environment and a mixing technology.The mixing device comprises a mixing box, the bottom of the mixing box is connected with a discharging box through a fixing plate, a communicating assembly is arranged between the mixing box and the discharging box, the inner side wall of the discharging box is fixedly connected with a feeding hopper, and the inner side wall of the discharging box is fixedly connected with a discharging hopper; a driving motor is connected to the outer side wall of the mixing box through a connecting plate, a driving rod is fixedly connected to the output end of the driving motor, and the end, away from the driving motor, of the driving rod penetrates through the mixing box and the feeding hopper and is fixedly connected with a mounting cylinder. According to the material crushing device, through mutual cooperation of the driving motor, the driving rod, the feeding hopper, the mounting barrel and the crushing rod, during feeding, the driving motor drives the mounting barrel to rotate through the driving rod, the mounting barrel drives the crushing rod to rotate, and during feeding, the crushing rod strikes materials to crush the materials; and the situation that the materials cannot be well mixed due to the large size of the materials is effectively avoided, so that the subsequent using effect of the materials is improved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Preparation method and equipment of magnetic nanocomposite material

ActiveCN111790288AReduce resistanceImprove stirring efficiencyRotary stirring mixersTransportation and packagingElectric machineCooling effect

The invention discloses a preparation method and equipment of a magnetic nanocomposite material, belonging to the technical field of magnetic nanomaterial preparation. The equipment comprises an agitating tank, wherein a heating cavity is formed in the outer wall of the upper part of the agitating tank; a feeding pipe is arranged on the upper end surface of the upper cover; the middle part of theupper end surface of the upper cover is fixedly connected with a stirring motor through a mounting frame; the output shaft end of the stirring motor is fixedly connected with a stirring shaft; the lower part of the stirring shaft is fixedly connected with long stirring blades and short stirring blades respectively; a first cooling cavity and a second cooling cavity are formed in an inner cavity ofthe heating cavity; and irradiation heating devices are symmetrically arranged in the inner cavity of the heating cavity. According to the invention, the problems that existing magnetic nanocompositematerial preparation equipment is low in liquid raw material and powder mixing efficiency and poor in heating and cooling effect, and consequently the whole magnetic nanomaterial production efficiency is not high are solved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

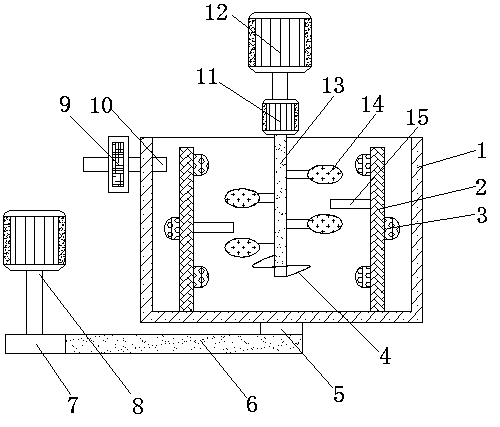

Efficient water stirring device for mixing

InactiveCN108479481AIncrease the effective mixing areaImprove efficiencyTransportation and packagingRotary stirring mixersEngineeringUltraviolet germicidal light

The invention discloses an efficient water stirring device for mixing. The efficient stirring device comprises a stirring box without a cover, a mounting rack, a water pump and a second motor, whereinvertically arranged connecting rods are fixed on the inner wall of the bottom of the stirring box through bolts, and are distributed on the inner wall of the bottom of the stirring box at equal intervals; ultraviolet germicidal lamps which are distributed at equal intervals are fixed on the outer wall of one side of each connecting rod through bolts; a horizontally arranged transverse plate is welded with the outer wall of one side of the connecting rod; a vertically arranged first transmission rod is welded to the outer wall of the bottom of the stirring box, and is positioned in the centerof the outer wall of the bottom of the stirring box; a horizontally arranged second transmission rod is welded to the outer wall of the bottom of the first transmission rod. The efficient stirring device has the advantages that the operation direction and the stirring direction of the stirring box are different, the effective stirring area of liquid is increased during stirring of the device, thehigh efficiency of the stirring device is improved, and the stirring device can move longitudinally, reduces the stirring dead angles when performing stirring in different positions, and improves theadjustability.

Owner:云和县东泽阀门有限公司

Double-shaft adjustable stirrer

PendingCN106890588AReduce overrunningAvoid overrunningRotary stirring mixersTransportation and packagingDrive shaftPulp and paper industry

The invention relates to a double-shaft adjustable stirrer which comprises a stirring tank, stirring components, a supporting component and a power component. The stirring components are positioned in the stirring tank, the power component is positioned on the supporting component and connected with the stirring components through stirring transmission shafts, each stirring component comprises stirring blades, one transmission shaft and blade connecting rods, each stirring blade is connected with the corresponding transmission shaft through the corresponding blade connecting rod, and the supporting component comprises a supporting frame, a hydraulic rod and a portal bridge frame; the supporting frame is fixed on a supporting frame foundation, one end of the hydraulic rod is fixed on the supporting frame while the other end of the same is connected with the portal bridge frame, and angle ranges of the stirring blades and the blade connecting rods are 20-70 degrees.

Owner:张惠琴

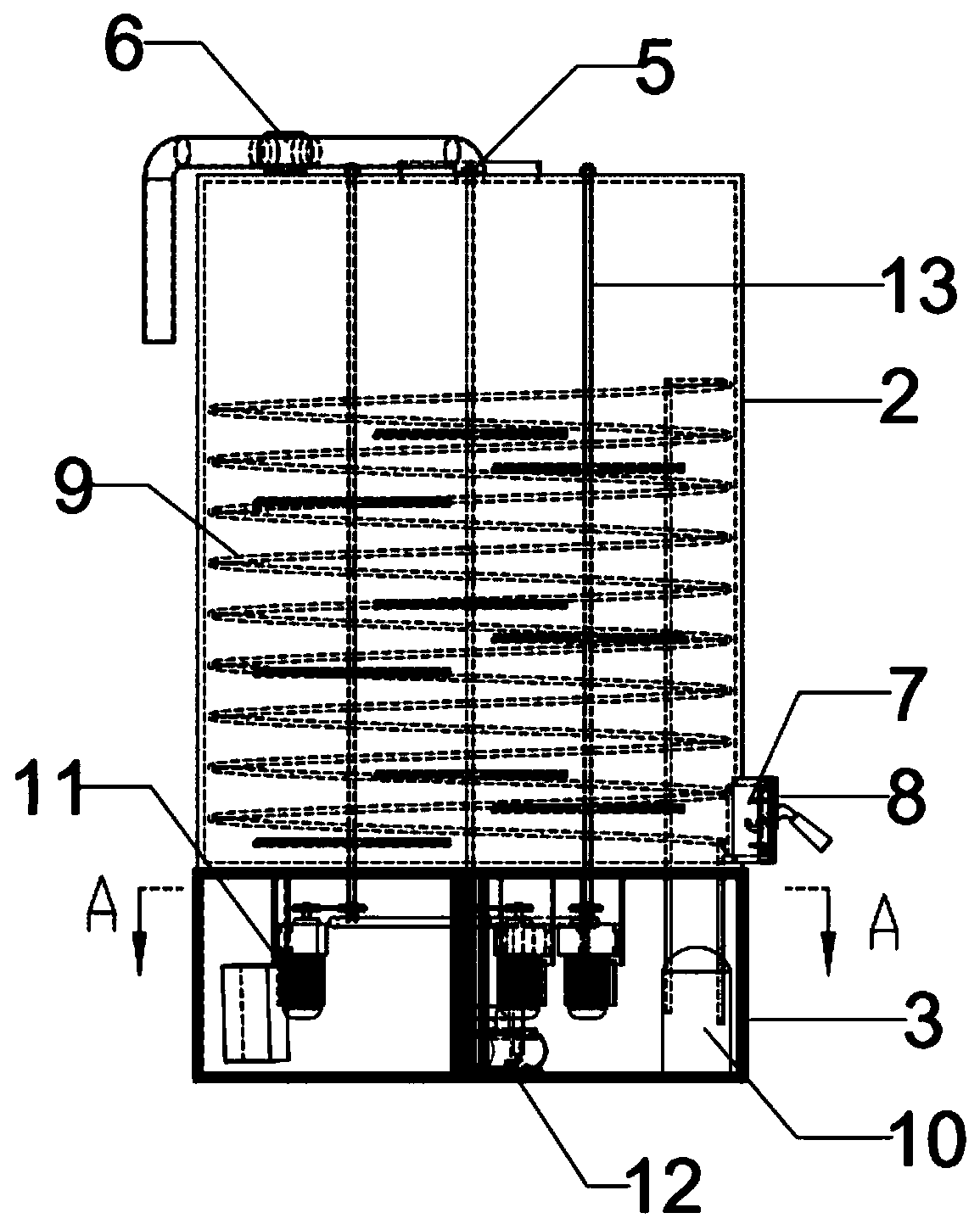

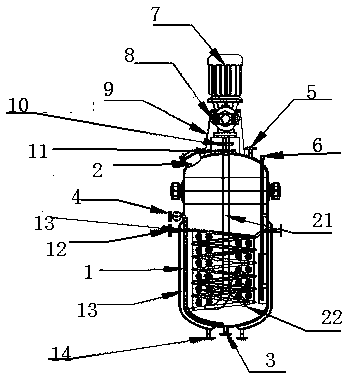

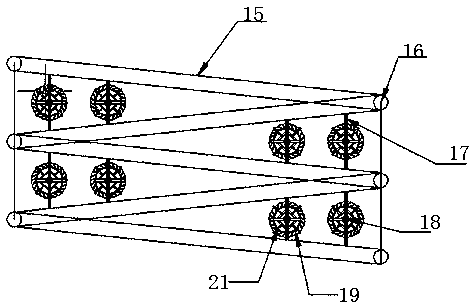

Efficient spiral coil reaction device

InactiveCN107638859AThe overall structure is ingeniously designedLow costChemical/physical/physico-chemical stationary reactorsSpiral coilPower component

The invention relates to an efficient spiral coil reaction device. The efficient spiral coil reaction device is characterized in that the efficient spiral coil reaction device comprises a tank component, a power component, a heat exchanger assembly and a stirring component, wherein the power component is installed above the tank component; part of the heat exchange assembly is installed on the outer wall of the tank component, and the other part of the heat exchange assembly is installed in a tank; the stirring component is installed in the tank component, and the top of the stirring componentis connected with the power component; the heat exchange assembly comprises a steam inlet, a clamp sleeve, a heating coil pipe and a condensate outlet; the steam outlet is formed in the upper end ofthe clamp sleeve; the clamp sleeve is installed at the two sides of the outer wall of the tank; the condensate outlet is formed in the bottom of the clamp sleeve; the heating coil pipe is installed inthe tank, the upper end of the heating coil pipe is connected with the steam inlet, and the lower end of the heating coil pipe is connected with the clamp sleeve.

Owner:盐城市大丰匀力机械制造厂

Building-material stirring equipment

InactiveCN108568900AAchieving stirringSave time and costDischarging apparatusCement mixing apparatusGear wheelPulp and paper industry

The invention belongs to the field of building processing and particularly discloses building-material stirring equipment. The building-material stirring equipment comprises a stirring barrel, whereina guide block is arranged on the outer wall of the stirring barrel, and a spiral groove is formed in a rack; the rack is also rotatably connected with a stirring shaft and rotary shafts; the lower ends of the stirring shaft and the rotary shafts extend into the stirring barrel respectively, and stirring blades are respectively arranged on the stirring shaft and the rotary shafts along the peripheral direction; a driving gear is arranged on the stirring shaft, the rotary shafts are provided with driven gears meshed with the driving gear, and inner gear rings meshed with the driven gears are arranged on the inner wall of the stirring barrel; a water discharging groove is formed in the bottom part of the stirring shaft and is internally provided with a piston in a sliding and connecting manner, a piston rod is fixedly connected to the lower side of the piston, and the lower end of the piston rod is fixed at the bottom part of a piston barrel; a water inlet is formed in the top part of the stirring shaft, a water outlet is formed in the side wall of the stirring shaft, a water feeding pipe is rotatably connected with the water inlet, a water barrel is also arranged on the rack, and one end, which is far from the stirring shaft, of the water feeding pipe is communicated with the water barrel. The building-material stirring equipment disclosed by the invention has the beneficial effect that by adoption of the scheme, the requirement of automatically filling water in the stirring process is met.

Owner:苏州相城埭辰科技产业发展有限公司

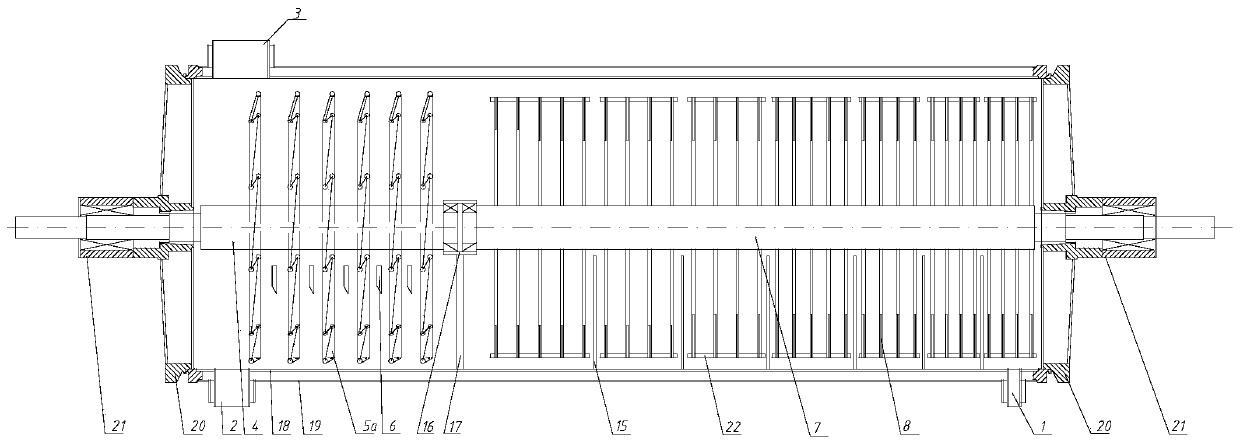

Production method for continuously producing high-viscosity polymer

ActiveCN111560116AHigh intrinsic viscosityShort residence time at high temperatureChemical/physical/physico-chemical stationary reactorsPolymer scienceIntrinsic viscosity

The invention relates to the field of polymer production, and discloses a production method for continuously producing a high-viscosity polymer. The method comprises the following steps: continuouslyfeeding a prepolymer melt with the intrinsic viscosity of 0.10 to 0.45 dL / g into a final polycondensation reactor; reacting and standing for 30 to 250 min under the conditions that the temperature is220 to 295 DEG C and the absolute pressure is 20 to 2000 Pa so as to prepare the high-viscosity polymer with the intrinsic viscosity of 0.7 to 1.15 dL / g, wherein in the final polycondensation reactor,the prepolymer melt is sequentially treated by a first stirrer and a second stirrer with different rotating speeds. Two stirrers with different rotating speeds and different structures are arranged in the same polycondensation reactor, so a liquid film can still be efficiently updated when the viscosity of the polymer is high, the mixing and mass transfer effects during high viscosity are effectively improved, the intrinsic viscosity of the polymer at the outlet of the reactor can be effectively improved, and the production capacity and the product range of the polycondensation reactor are effectively improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Building decorative coating stirring uniform mixing device

InactiveCN108927030AReduce stirring dead angleAct as agitatorRotary stirring mixersTransportation and packagingDistortionTransverse plane

The invention discloses a building decorative coating stirring uniform mixing device. The building decorative coating stirring uniform mixing device comprises a longitudinal adjusting device; the right side of the longitudinal adjusting device is provided with a stirring barrel; the upper end of the stirring barrel is provided with a stirring power assembly connected with the longitudinal adjusting device; a vertical omnidirectional stirring paddle is arranged in the stirring barrel; the lower end of the vertical omnidirectional stirring paddle is connected with an uniform sieve; a paint raising device is arranged right below the uniform sieve; the connection part of the stirring power assembly with the stirring barrel is provided with a damping connecting piece. In application, self rotation of a distortion paddle rod is driven, cutting of coating blocks is realized, and then stirring effect of coating in a vertical plane is achieved, coating transverse plane longitudinal plane three-dimensional stirring is realized, the rotating direction of a rotating vertical shaft and the rotating direction of a rotating bottom shaft are opposite, in-time stirring of raised coating is ensured,raising of stirred coating after precipitation is achieved, a virtuous circle is achieved, and stirring efficiency is increased greatly.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Powder mixing device

InactiveCN108854652AWell mixedSimple structureRotary stirring mixersTransportation and packagingEngineering

The invention discloses a powder mixing device, which comprises a rectangular mixing box, a rising stirring device, a swing stirring device and a powder cover plate, wherein the upper end of the rectangular mixing box is provided with a cross support frame, a main rotating motor is arranged on the center of the cross support frame, the lower end of an output shaft is fixedly connected with a firstrotating shaft, an incomplete toothed disk is fixedly arranged on the first rotating shaft, the lower end array thereof is provided with four mounting horizontal columns, the mounting horizontal columns are provided with a plurality of crescent-shaped scrapers, the lower end face of the cross support frame is provided with two pairs of hanging blocks symmetrically around the first rotating shaft,the hanging blocks are provided with bearings, bearing pedestals and the bearings are provided with a second rotating shaft, the inner end thereof is provided with a complete toothed disk, the secondrotating shaft is fixed with a pair of connecting rods, a support plate is fixedly arranged on the lower ends of the connecting rods, a secondary rotating motor is arranged on the support plate, theoutput shaft of the secondary rotating motor penetrates through the support plate, the lower end thereof is fixedly provided with a third rotating shaft, and the third rotating shaft is provided witha plurality of agitation sticks. According to the invention, the bulk pharmaceutical chemical powder in the device can be mixed evenly.

Owner:WUHU KANGQI PHARMA

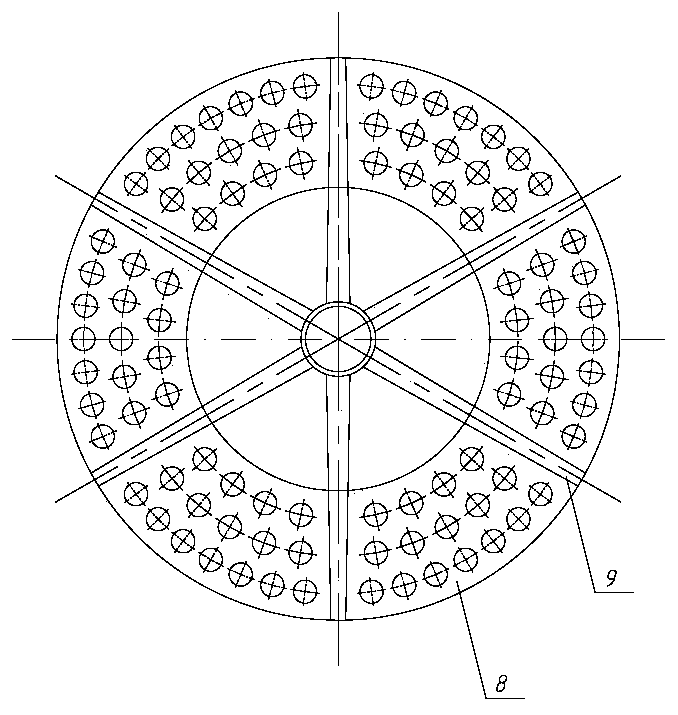

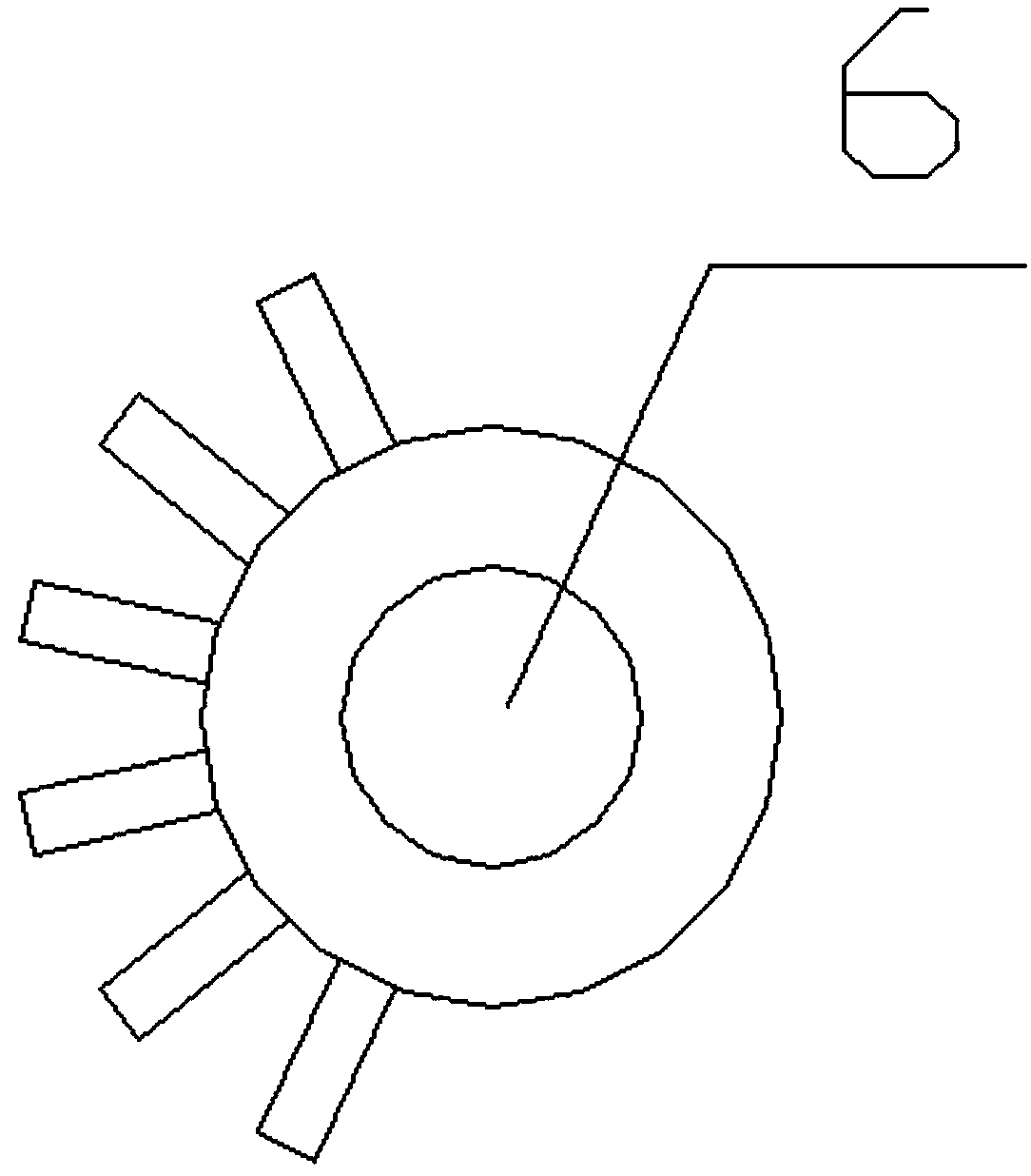

Glaze mixing device for ceramic

InactiveCN108543473AReduce stirring dead angleIncreased turbulenceTransportation and packagingRotary stirring mixersDrive shaftEngineering

The invention relates to the technical field of ceramic production, and concretely relates to a glaze slurry mixing device for ceramic. The glaze slurry mixing device for ceramic comprises a tank body. A double-head motor is adopted to drive a driving shaft to rotate, and a driving bevel gear cooperates with a driven bevel gear to realize the autoroatation of driven shafts, so stirring rods are driven to stir; and a mobile spiral bevel gear cooperates with a static spiral bevel gear to realize the rotation of a turntable in order to drive the driven shafts to rotate with the central axis of the tank as a center, so the stirring dead angle is reduced, turbulence flow is enhanced, and the stirring effect is improved.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

Material mixing device

PendingCN111013433AImprove effective utilizationReduce stirring dead angleRotary stirring mixersTransportation and packagingSquare cross sectionEngineering

The invention discloses a material mixing device, and belongs to the technical field of material processing equipment. The material mixing device is provided with a main body structure which is used for stirring and mixing, wherein the main body structure is of a rectangular tank body with a square cross section; compared with a traditional cylindrical stirring barrel, the material mixing device is larger in volume and single-time stirring amount when the occupied area with the same length and width is occupied; in order to stir the interior of the material mixing device more comprehensively,and avoid stirring blind angles, a Wankel rotor is arranged at the top of the rectangular tank body in a movably manner; the Wankel rotor can perform eccentric rotary motion in a square sliding groovewith the same shape of the rectangular tank body at the top of the rectangular tank body; therefore, the three corners can slide around the edge of a rectangular stirring and mixing chamber; stirringrods arranged at the three corners of the rectangular stirring and mixing chamber can be driven to slide in a square surrounding mode, the problems, that the stirring rods cannot be contacted with the four right-angle inner walls of the rectangular stirring and mixing chamber, and stirring blind angles are generated, are solved, and the stirring and mixing effect is still considerable while the space effective utilization rate is increased.

Owner:广州市浩恒建材科技有限公司

Assistant precipitation preventing device for textile engineering

InactiveCN107875916ATo achieve the effect of positive and negative stirringPrevent precipitationTransportation and packagingRotary stirring mixersArchitectural engineeringPush pull

The invention discloses an assistant precipitation preventing device for textile engineering. The assistant precipitation preventing device comprises a tank body, a base, a supporting platform, a right wheel disk, a toothed plate, an annular gear, a left wheel disk and stirring parts; the outer end surface of the right wheel disk is fixedly provided with a right guide post; the outer circumferenceof the right guide post is slidably sleeved with a right sleeve plate; the outer end surface of the left wheel disk is fixedly provided with a left guide post; the outer circumference the left guidepost is slidably sleeved with a left sleeve plate; each of two ends of the toothed plate is fixedly connected with the right sleeve plate and the left sleeve plate by a push-pull rod; the middle partof an inner cavity of the tank body is rotatably provided with a rotating rod in a bearing connecting way; the outer circumference of the bottom of the rotating rod is fixedly provided with the annular gear; and the outer circumference surface of the rotating rod in the inner cavity of the tank body is symmetrically and fixedly provided with the plurality of stirring parts. The assistant precipitation preventing device is simple in structure, convenient to use and capable of effectively reducing the possibility that stirring dead angles appear and solving the problem that a textile assistant easily generates substance separation under the action of a centrifugal force so as to be suitable for popularization and application.

Owner:广西东创智能科技有限公司

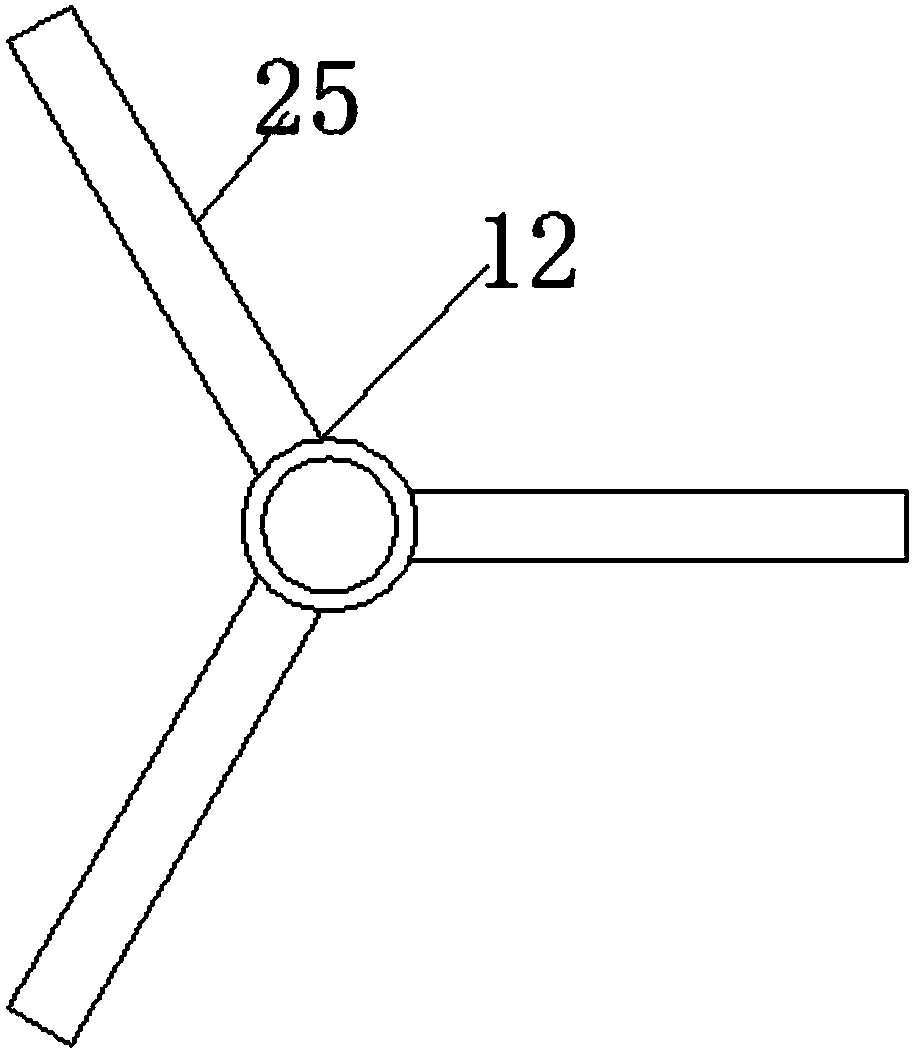

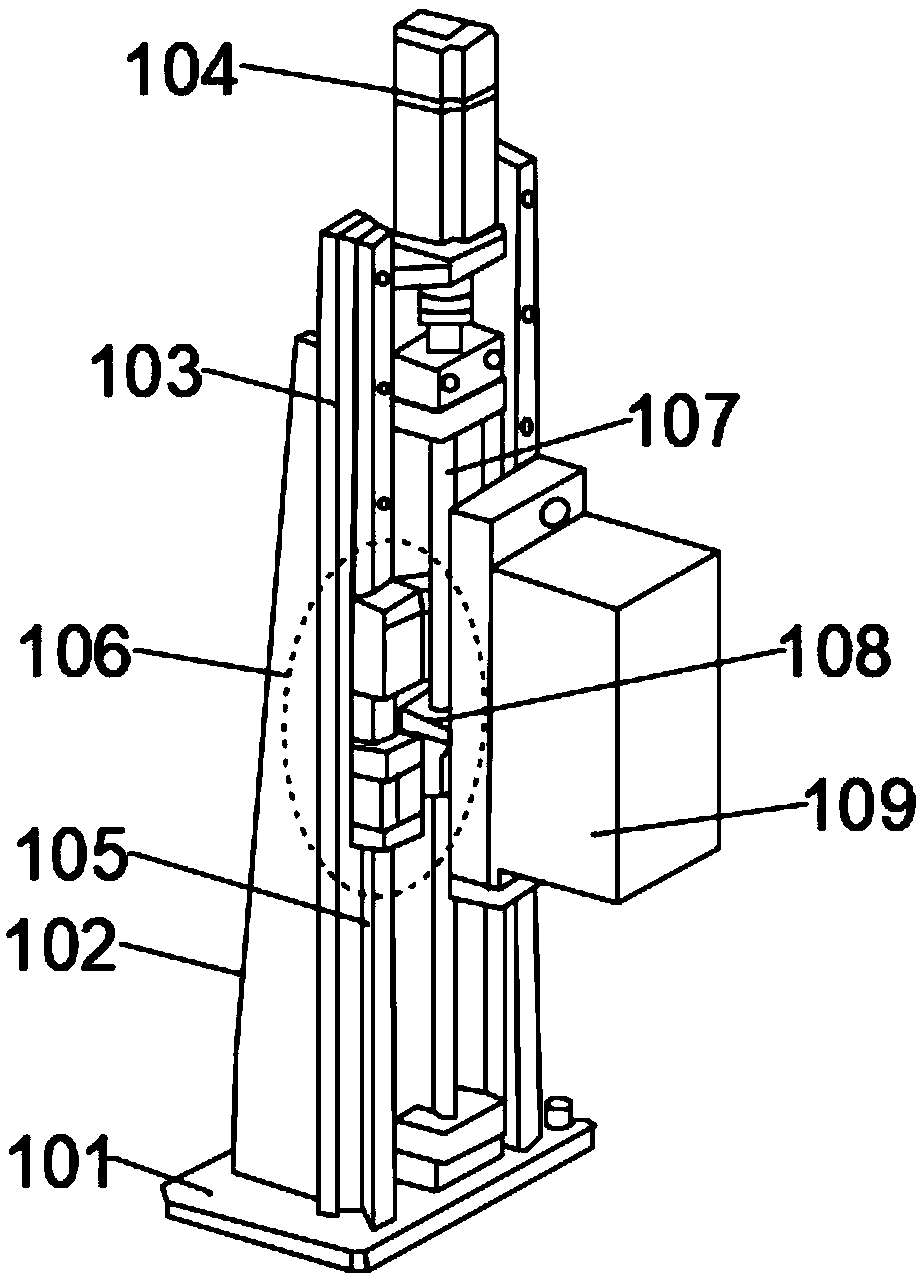

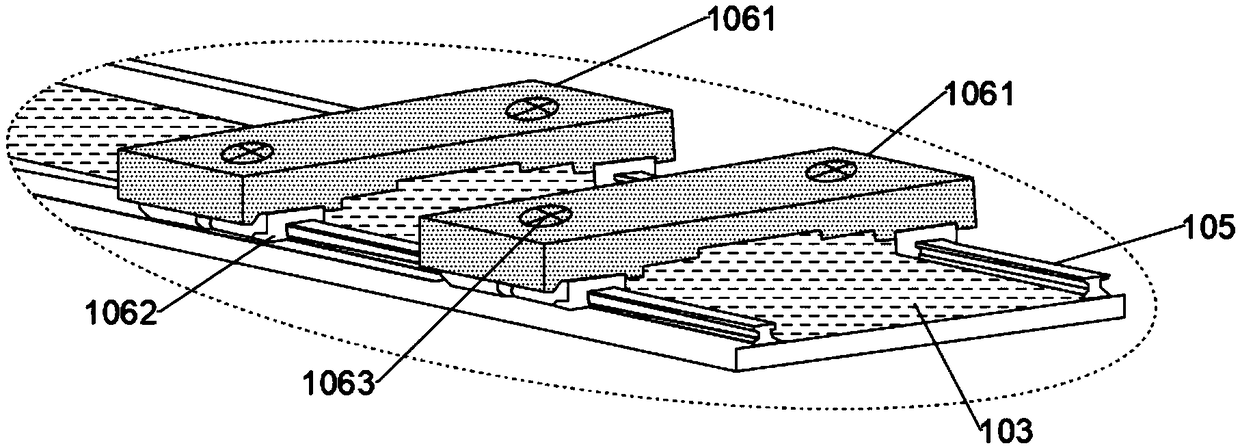

Method for preparing ethyl caprate, and stirring apparatus for preparing ethyl caprate

InactiveCN104341302ASimple structureOperational securityOrganic compound preparationRotary stirring mixersEngineeringOperation safety

The invention discloses a method for preparing ethyl caprate, and a stirring apparatus for preparing ethyl caprate. The structure of the apparatus comprises a pedestal, a vertical bracket and a stirring rod, the vertical bracket is arranged on the pedestal, the vertical bracket is connected with the stirring rod through a connecting piece, the vertical bracket is provided with a lifting device for lifting the connecting piece, the connecting piece is provided with a power device for making the stirring rod rotate, the stirring rod is provided with three blades, the three blades are uniformly distributed on the stirring rod in a circumferential manner, and the blades comprise a first blade and second blades connected with the first blade. At least one reinforcing rib is arranged between adjacent second blades, and components are connected through screws and fixed through nuts. The stirring position of the apparatus can be adjusted, so it is in favor of fully stirring a material; and the blades have the characteristics of simple structure, operation safety and large surface of contact with the material, so the material mixing uniformity can be effectively improved, and the stirring efficiency is improved, thereby the yield of ethyl caprate is improved.

Owner:常州市松盛香料有限公司

Buffered mixer for construction

PendingCN107399007AExtended service lifePlay a repelling roleCement mixing apparatusEngineeringMagnet

The invention discloses a buffered mixer for construction. The buffered mixer comprises a box body which is internally provided with a mixing mechanism, and the lower end of the box body is fixedly provided with a cushion block; the lower surface of the cushion block is provided with an upper buckle, an upper magnet and an upper lug from outside to inside in sequence, and a base is provided with a lower buckle, a lower magnet and a lower lug; the centers of the front sides of the upper lug and the lower lug are provide with slots, and the two groups of the slots are provided with connecting rods in a run-through manner; the ends of the connecting rods are welded with four groups of springs; and the mixing mechanism is composed of a feed port, a top vertical rod, a screw rod, mixing arms, a cross rod, a right scraping rod, a discharge port, a bottom motor, a rotating shaft, a bottom support rod, a left scraping rod, an ejector rod and a box cover. The buffered mixer is rational in structural design, and plays a role in buffering, and the pressure is reduced; the service life of the base is prolonged; and at the same time, the mixing blind angle in the mixing process and the labor intensity during cleaning can be reduced greatly.

Owner:ZHENGZHOU UNIV

Soil remediation kettle capable of automatically moving and automatically discharging remediation liquid during mixing

InactiveCN113908715ASpeed up emissionsImprove practicalityRotary stirring mixersTransportation and packagingSoil remediationElectric machine

The invention discloses a soil remediation kettle capable of automatically moving and automatically discharging remediation liquid during mixing. The soil remediation kettle comprises a kettle body which is a main outer frame structure, a stirring motor and a first shell, wherein a fixing frame is arranged on the outer surface of the kettle body, and a bottom support is arranged at the bottom end of the fixing frame; the stirring motor is located at the top end of the kettle body, the bottom end of the stirring motor is connected with a mechanical sealing piece, the output end of the stirring motor is connected with a stirring shaft, and one end of the stirring shaft penetrates through the mechanical sealing piece; the first shell is located at the right upper end of the kettle body, one end of the first shell is connected with a connecting plate, one end of the connecting plate penetrates through the interior of the kettle body, and a transmission roller and a rotating shaft are arranged on the inner surface of the connecting plate. According to the soil remediation kettle capable of automatically moving and automatically discharging the remediation liquid during mixing, when rotating, the soil remediation kettle is matched with an internal stirring paddle, materials can rotate in a hourglass shape, stirring dead angles are reduced, the mixing effect of remediation liquid and raw materials is improved, and therefore the overall practicability is improved.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com