Method for preparing ethyl caprate, and stirring apparatus for preparing ethyl caprate

A technology of ethyl decanoate and a stirring device, which is applied in the preparation of carboxylic acid esters, the mixer with a rotating stirring device, the preparation of organic compounds, etc., can solve the problems of low stirring efficiency and low yield, and achieve simple structure, More contact surfaces, improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] The preparation method of ethyl decanoate includes the following steps:

[0023] 1) Add decanoic acid and ethanol to the esterification kettle for stirring, control the temperature to 230°C, the pressure at 5MPa, add the catalyst dropwise, keep the reaction for 3 hours, and collect the crude product of ethyl decanoate;

[0024] 2) Distill the crude ethyl decanoate product in a distillation tower with a temperature of 250°C and a pressure of -5MPa for 8 hours to obtain a finished product of ethyl decanoate.

[0025] The molar ratio of capric acid / ethanol is 1:1.2.

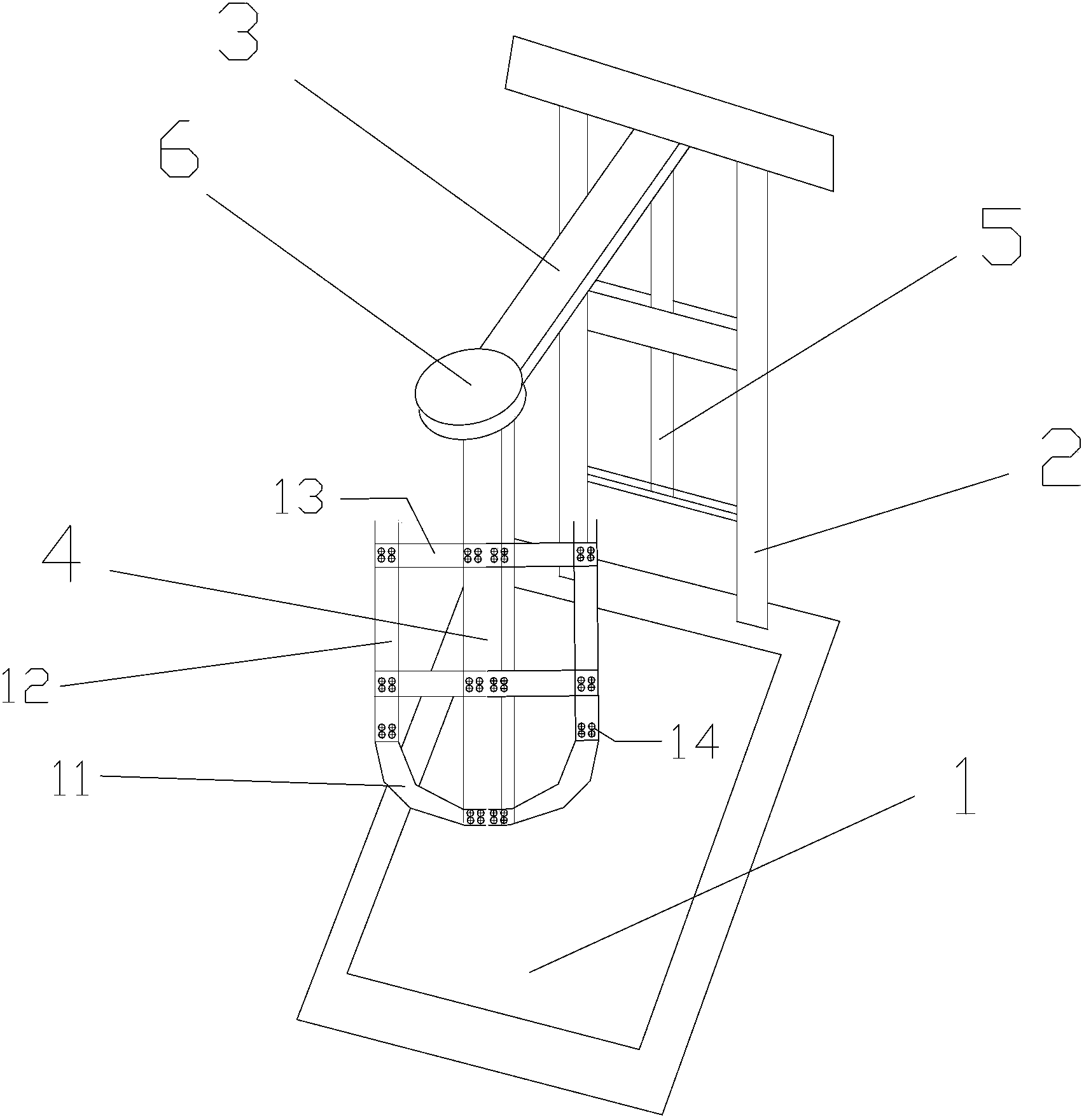

[0026] A stirring device for preparing ethyl decanoate, comprising a base 1, a vertical support 2 and a stirring rod 4. The vertical support 2 is arranged on the base, and the vertical support is connected to the stirring rod 4 through a connecting piece 3. The vertical support 2 A lifting device 5 that can lift the connecting piece 3 is provided on the connecting piece 3, a power device 6 for rotating the stirring r...

Embodiment approach 2

[0028] The difference from Embodiment 1 is:

[0029] The preparation method of ethyl decanoate includes the following steps:

[0030] 1) Add decanoic acid and ethanol to the esterification kettle and stir, control the temperature to 450°C and the pressure to 10MPa, add the catalyst dropwise, keep the reaction for 7 hours, and collect the crude product of ethyl decanoate;

[0031] 2) Distill the crude ethyl decanoate product in a distillation tower with a temperature of 400°C and a pressure of 1 MPa for 10 hours to obtain a finished product of ethyl decanoate.

[0032] 2. The method for preparing ethyl capric acid according to claim 1, wherein the molar ratio of capric acid / ethanol is 1:40.

Embodiment approach 3

[0034] The difference from Embodiments 1 and 2 is:

[0035] The preparation method of ethyl decanoate includes the following steps:

[0036] 1) Add capric acid and ethanol to the esterification kettle and stir, control the temperature to 300°C, the pressure at 8MPa, add the catalyst dropwise, keep the reaction for 5 hours, and collect the crude product of ethyl caprate;

[0037] 2) Distill the crude ethyl decanoate product in a distillation tower with a temperature of 350°C and a pressure of -2MPa for 9 hours to obtain a finished product of ethyl decanoate.

[0038] 2. The method for preparing ethyl capric acid according to claim 1, wherein the molar ratio of capric acid / ethanol is 1:11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com