Stirring head of stirring curing machine

A mixing head and curing machine technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as insufficient, difficult to achieve uniform mixing, and poor formation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

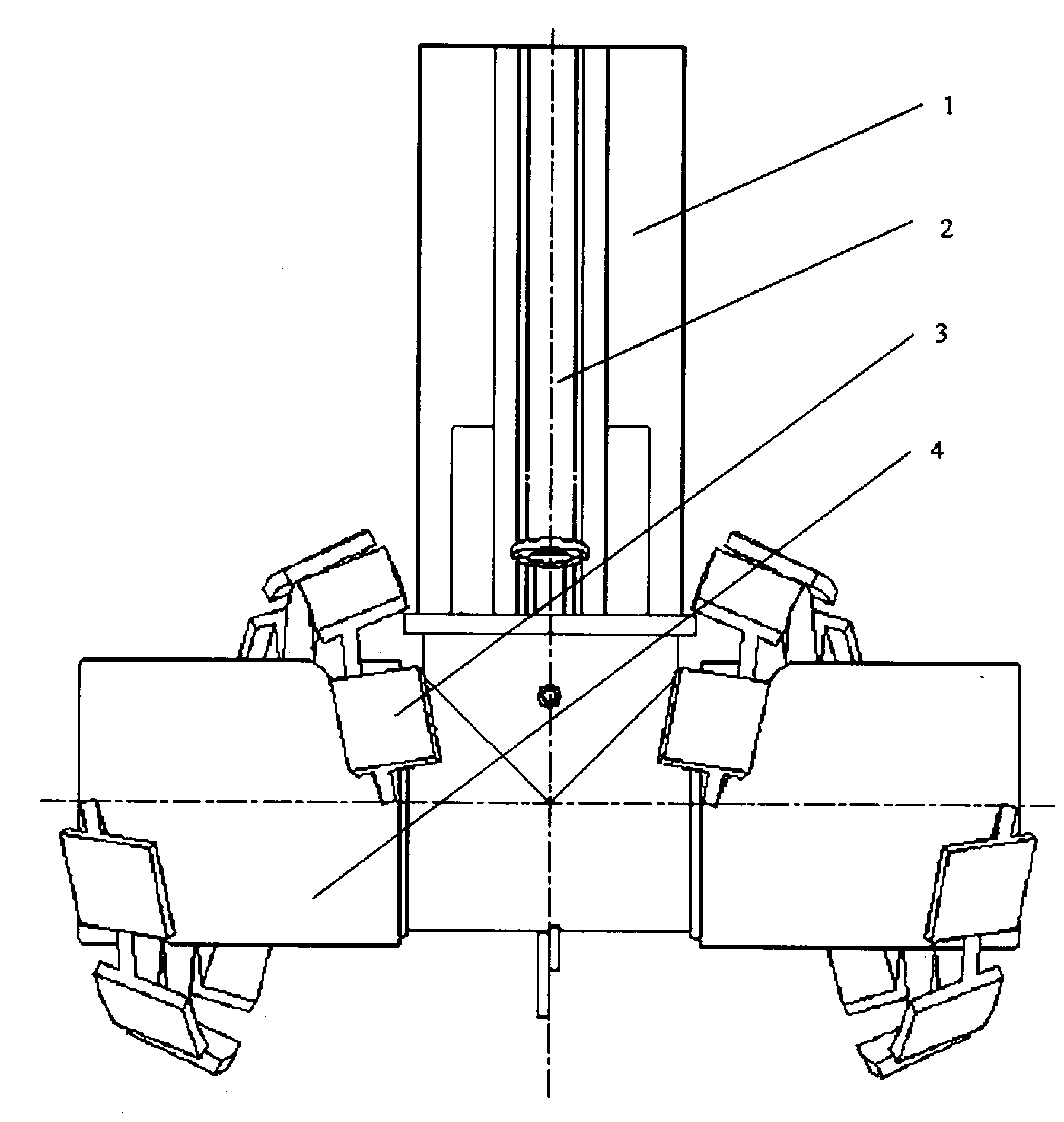

[0024] In order to make the present invention more concise and easy to understand, a preferred example is described in detail below in conjunction with the accompanying drawings.

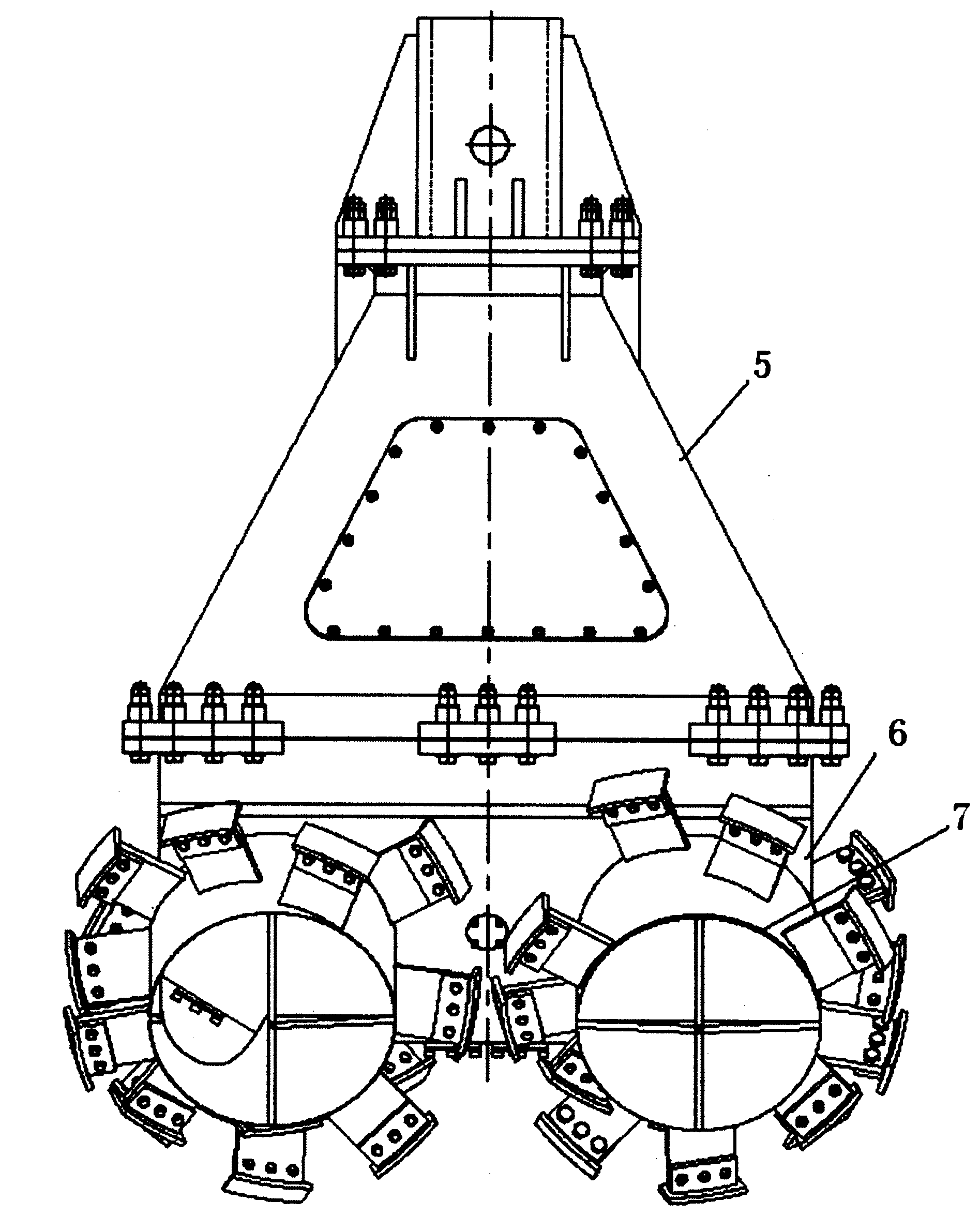

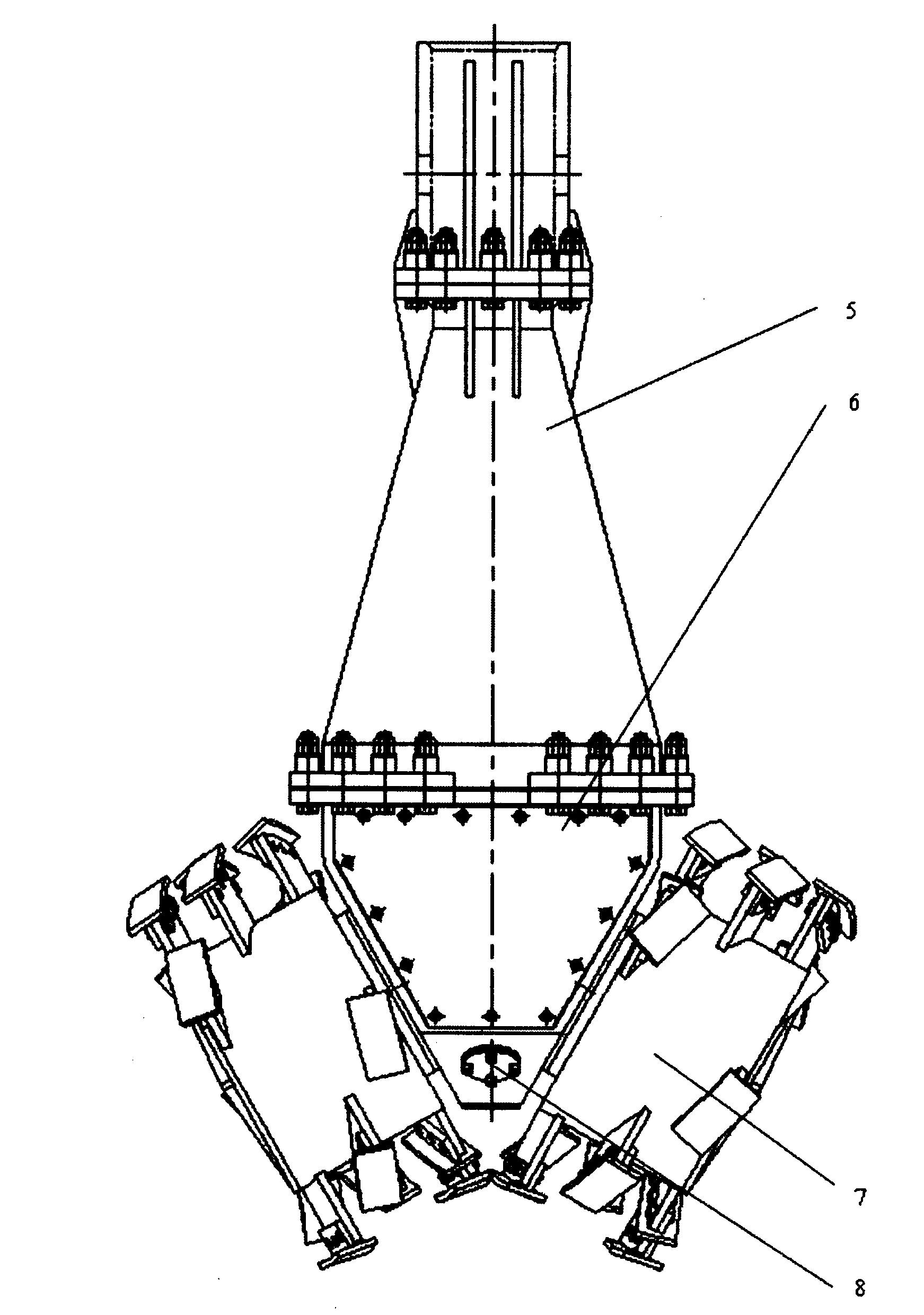

[0025] Such as figure 2 and image 3 As shown, the stirring head of a stirring and curing machine provided by the present invention includes a box body, and the box body is composed of an upper box body 5 and a lower box body 6 connected by bolts. One end of the spray pipe 8 is fixed on the bottom of the lower box body 6, and the other end is connected with another pipe in the box body and is not shown by a flange. On both sides of the bottom of the lower box body 6, an inwardly inclined slope is respectively formed. Stirring wheels 7 are installed on the slopes on both sides of the lower box body 6. In this embodiment, two stirring wheels 7 are installed on one side of the slope.

[0026] The vanes (9) are regularly distributed on the stirring wheel 7, and the vanes 9 have at least three distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com