Fully hydraulically driven multi-stirring wheel synchronization device for stirring curer

A technology of synchronous device and curing machine, which is applied in the direction of soil protection, excavation, sheet pile wall, etc., which can solve the problems that the speed synchronization cannot be guaranteed, achieve the effect of speed synchronization and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

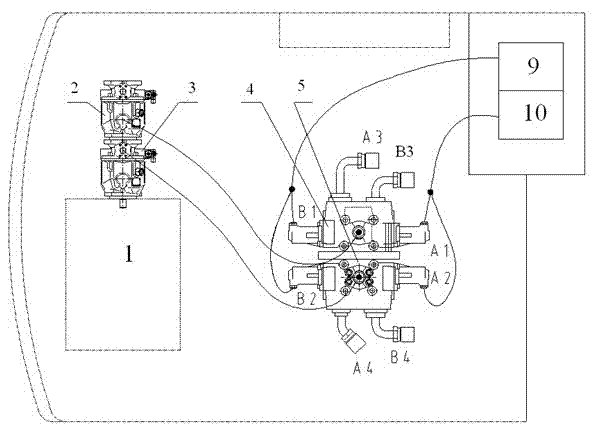

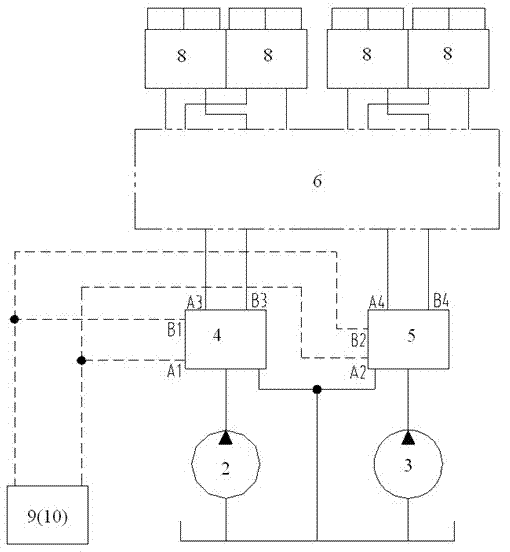

[0016] Such as figure 1 and figure 2 As shown, the multi-wheel synchronizing device of the agitating wheel of a fully hydraulically driven stirring and curing machine provided in this embodiment includes a first hydraulic pump 2 and a second hydraulic pump 3, and the first hydraulic pump 2 and the second hydraulic pump 3 are driven by the engine. 1 provides power and is installed on the chassis together with engine 1. The first main valve 4 and the second main valve 5 are installed on the chassis. The first handle 9 and the second handle 10 are fixed in the cab.

[0017] The first hydraulic pump 2 is connected to the first main valve 4 through a hose and a joint, and the second hydraulic pump 3 is connected to the second main valve 5 through a hose and a joint. The dual pumps provide a maximum working flow of 220L / min×2 and a maximum working pressure of 32MPa High-pressure hydraulic oil is referred to as high-pressure oil. The main oil port A3 and the main oil port B3 in ...

Embodiment 2

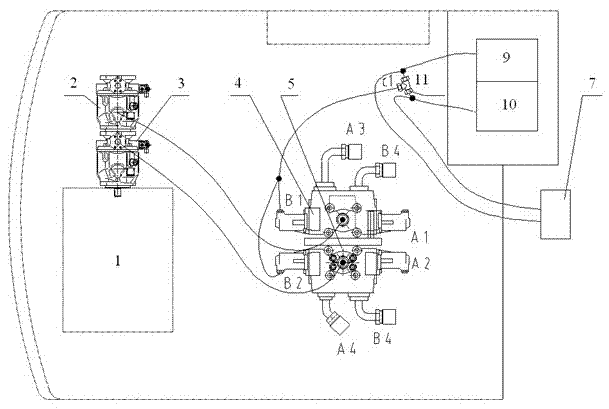

[0021] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the first handle oil port 9 and the second handle oil port 10 are connected to the diverter valve 7 through the shuttle valve 11 . The pilot pressure port c1 of the shuttle valve 11 is respectively connected in series with the pilot oil port B1 of the first main valve 4 and the pilot oil port B2 of the second main valve 5 through a hose and a joint. The main oil port A3 of the first main valve 4 (the main oil port A4 of the second main valve 5 is connected to the oil inlet port of the diverter valve 7 through the rubber hose, and the oil outlet of the diverter valve 7 is respectively connected to the four stirring wheels through the rubber hose and joints .

[0022] The low-pressure pilot oil from the first handle oil port 9 and the second handle oil port 10 obtains a relatively high pressure through the shuttle valve 7, and the low-pressure pilot control o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com