Mechanical creepage-type chemical mixing device used for atomizing machine

A sprayer and mechanical technology, applied in spraying devices, liquid spraying devices, etc., can solve problems such as the inability to realize the synchronization of dosing amount and plunger pump speed, the inability to solve the problem of conveying low-pressure mixed liquid, and the problem of difficult mixing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

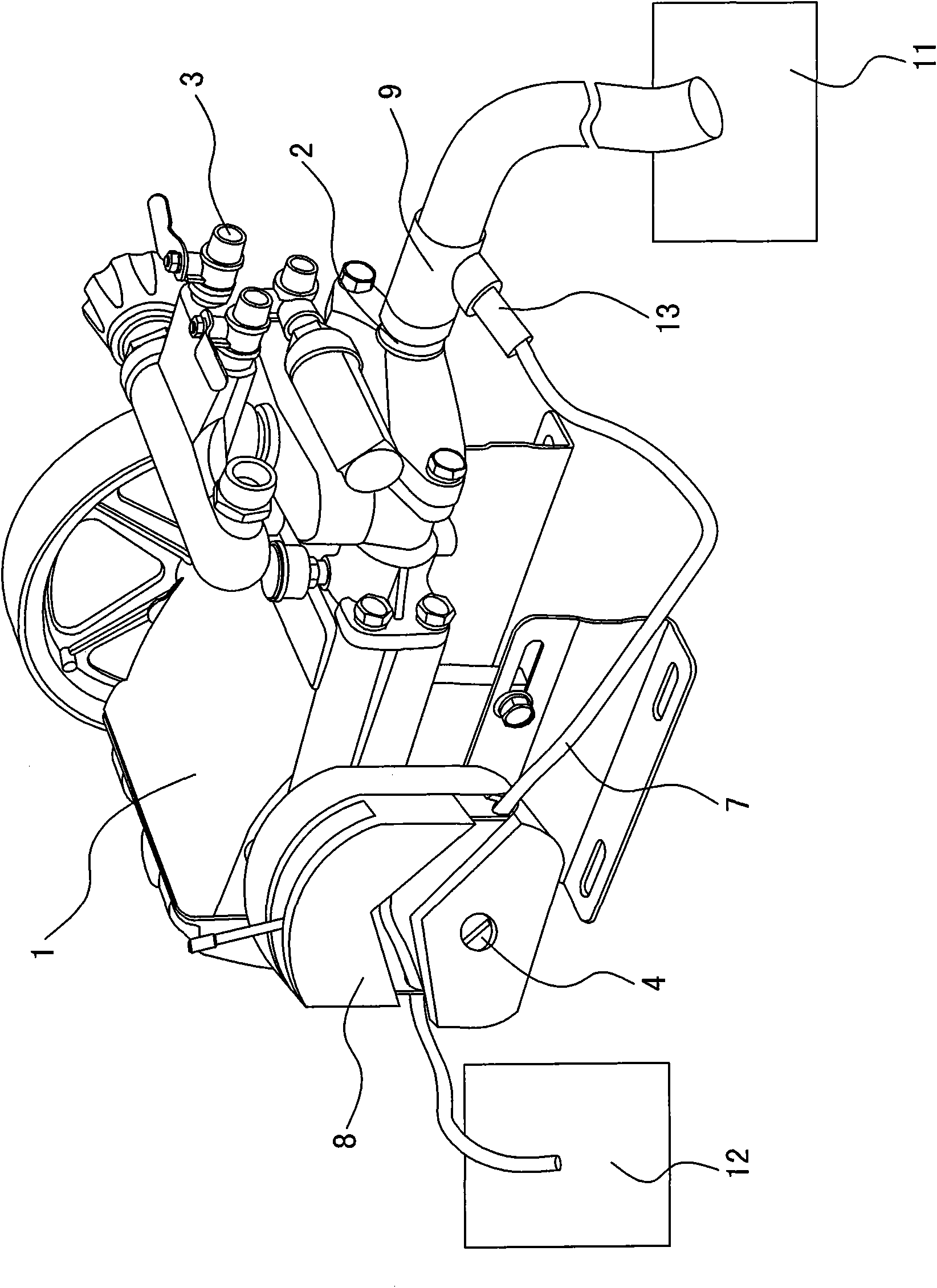

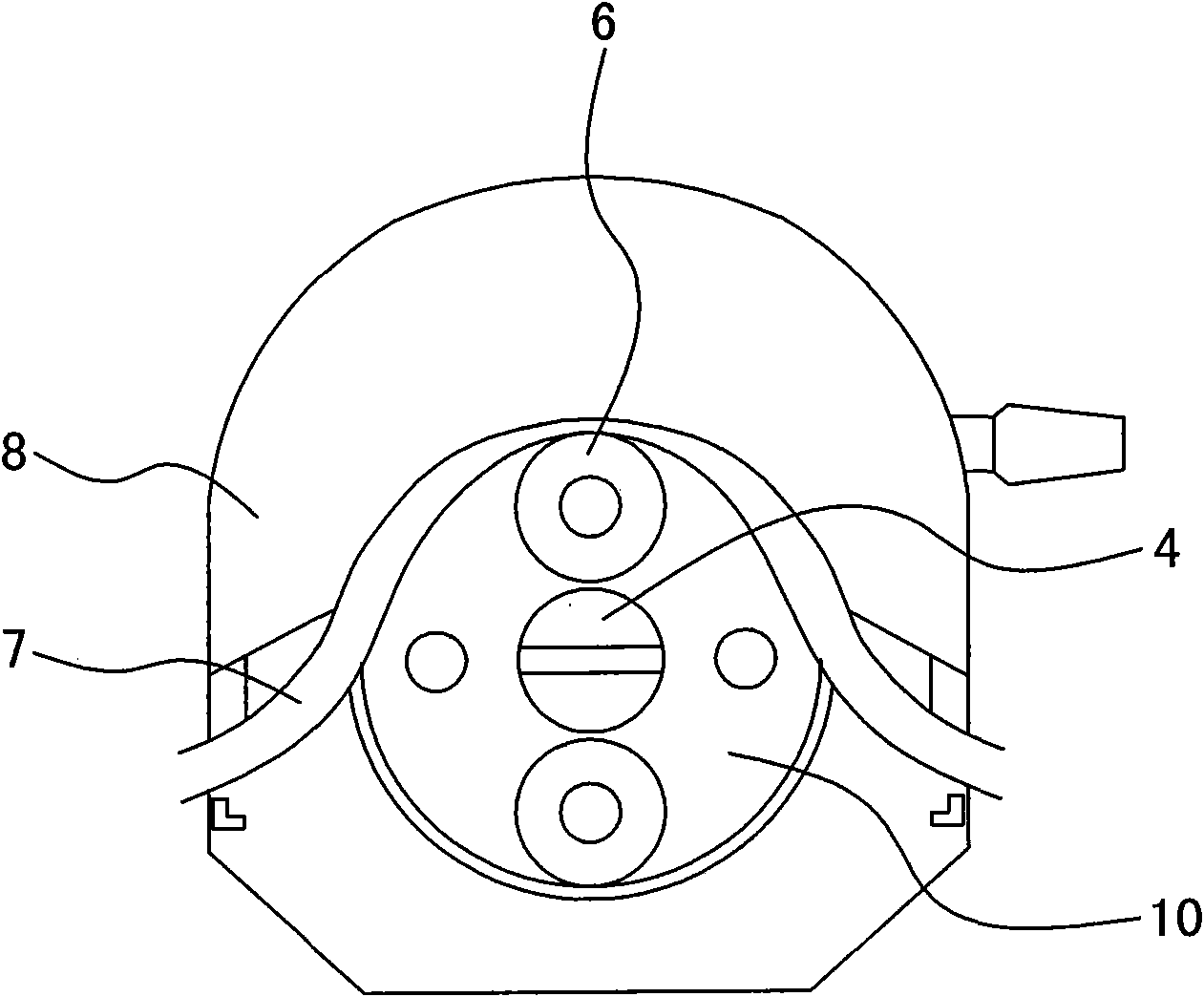

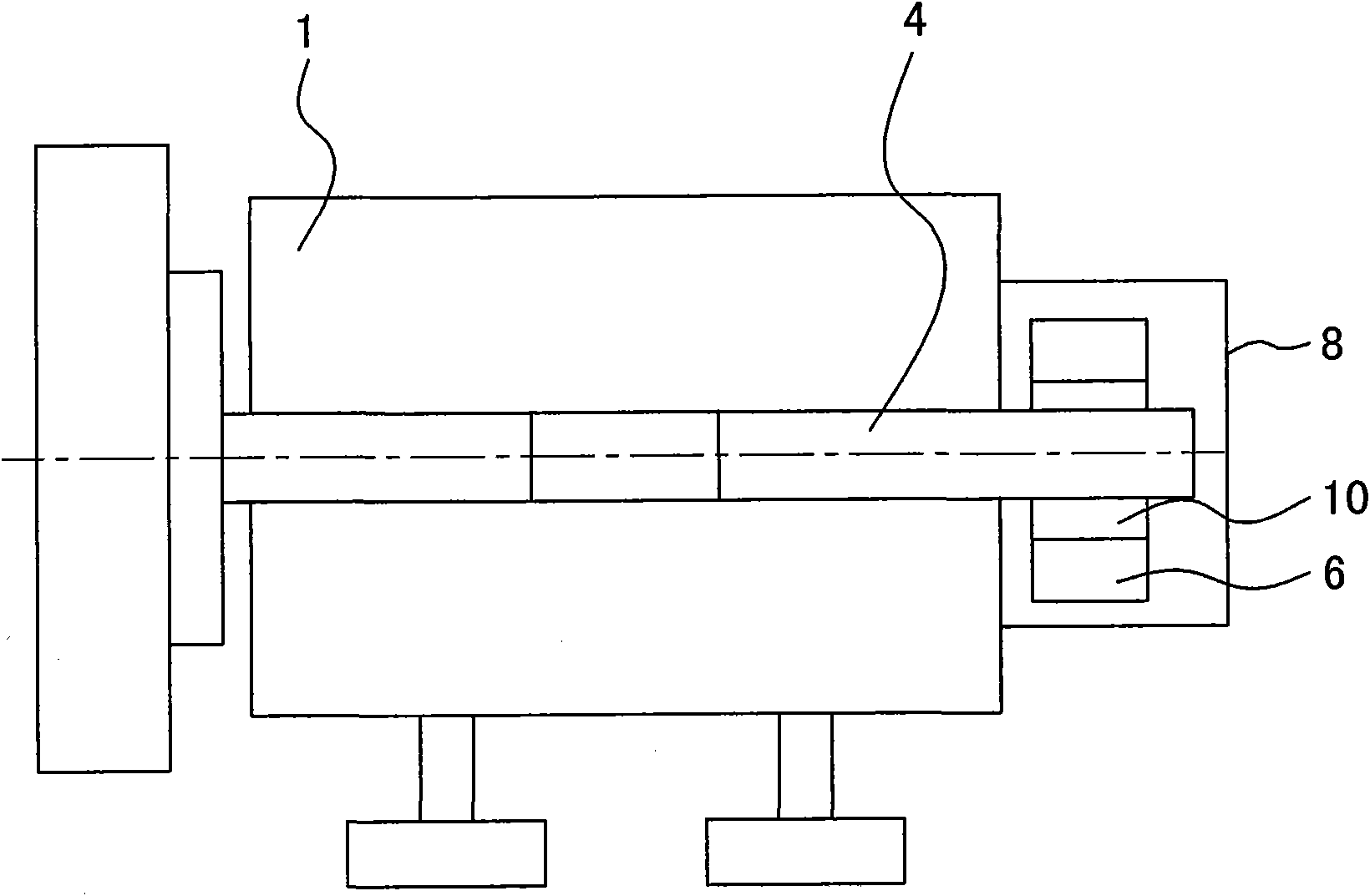

[0013] The invention relates to a peristaltic drug mixing device for a plunger pump of a sprayer, such as Figure 1-Figure 4 As shown, it includes a plunger pump 1. The plunger pump has a water inlet 2 and a water outlet 3. The water inlet is connected to the water container 11, and the water outlet is connected to the spray gun assembly. The plunger of the plunger pump 1 is driven by power through the plunger crankshaft 4. It is characterized in that the other end of the plunger crankshaft 4 is equipped with a cam 10, and more than one roller-shaped pressure roller 6 is embedded on the cam, and a housing 8 is installed outside the pressure roller, and a peristaltic tube 7 is installed between the housing 8 and the pressure roller. When the pressure roller 6 rolls, it presses the peristaltic tube 7 on the inner wall of the housing 8 , one end of the peristaltic tube 7 is connected to the pesticide mother liquid container 12 , and the other end of the peristaltic tube 7 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com