Powder mixing device

A mixing device and powder technology, applied in mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of raw materials not being stirred, difficult to maintain, affecting industrial production efficiency, etc., to reduce the dead angle of mixing, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

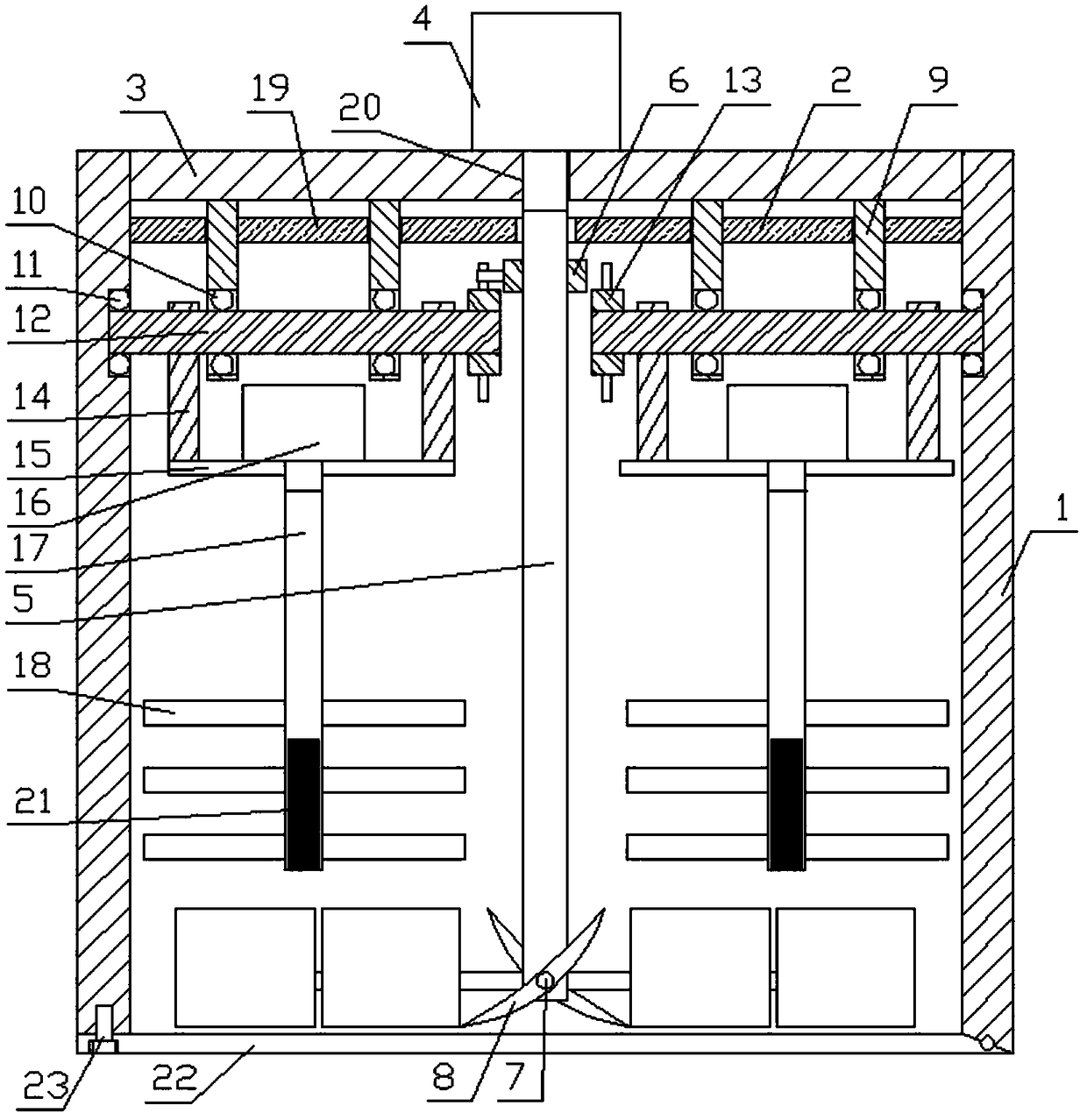

[0018] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

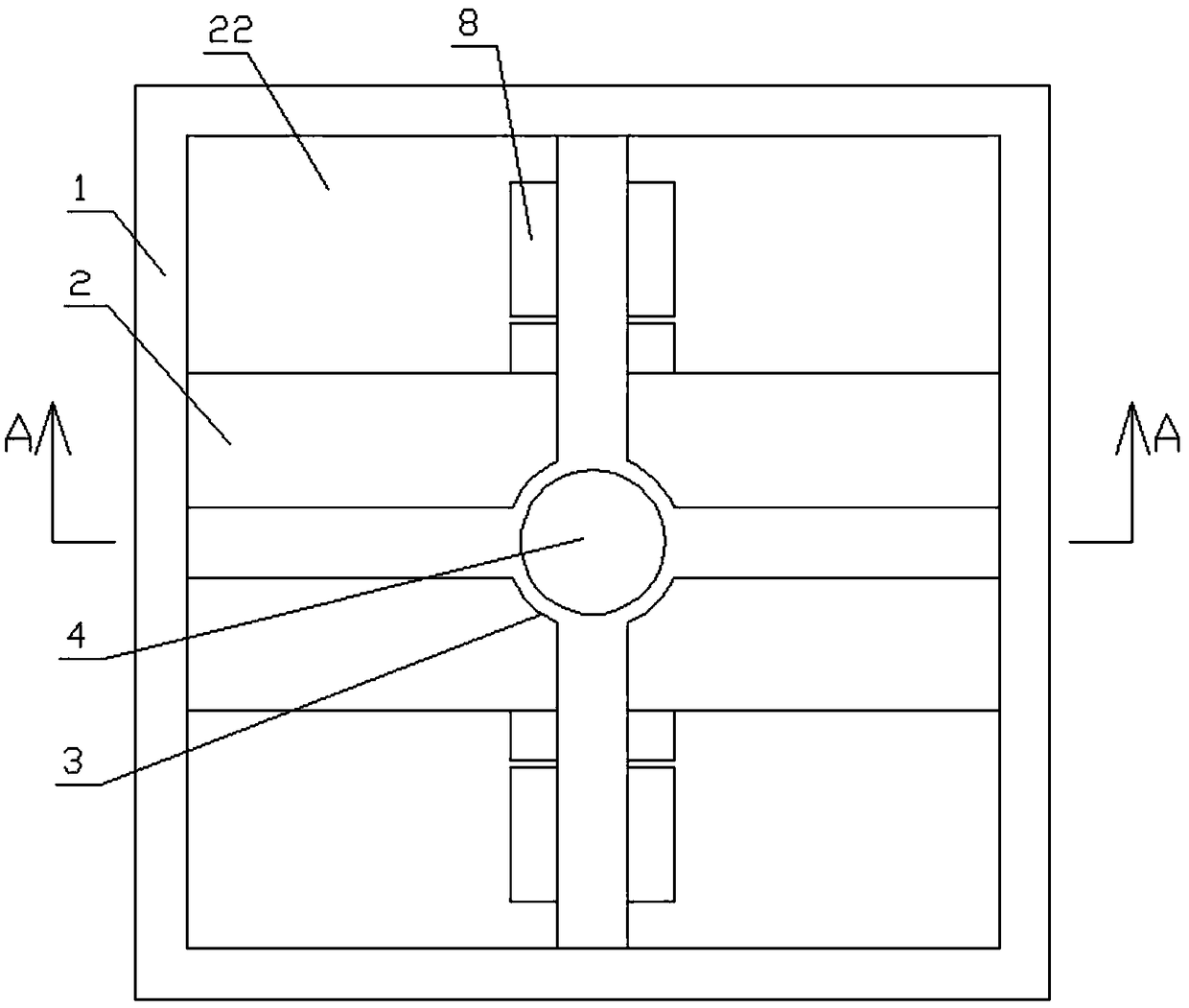

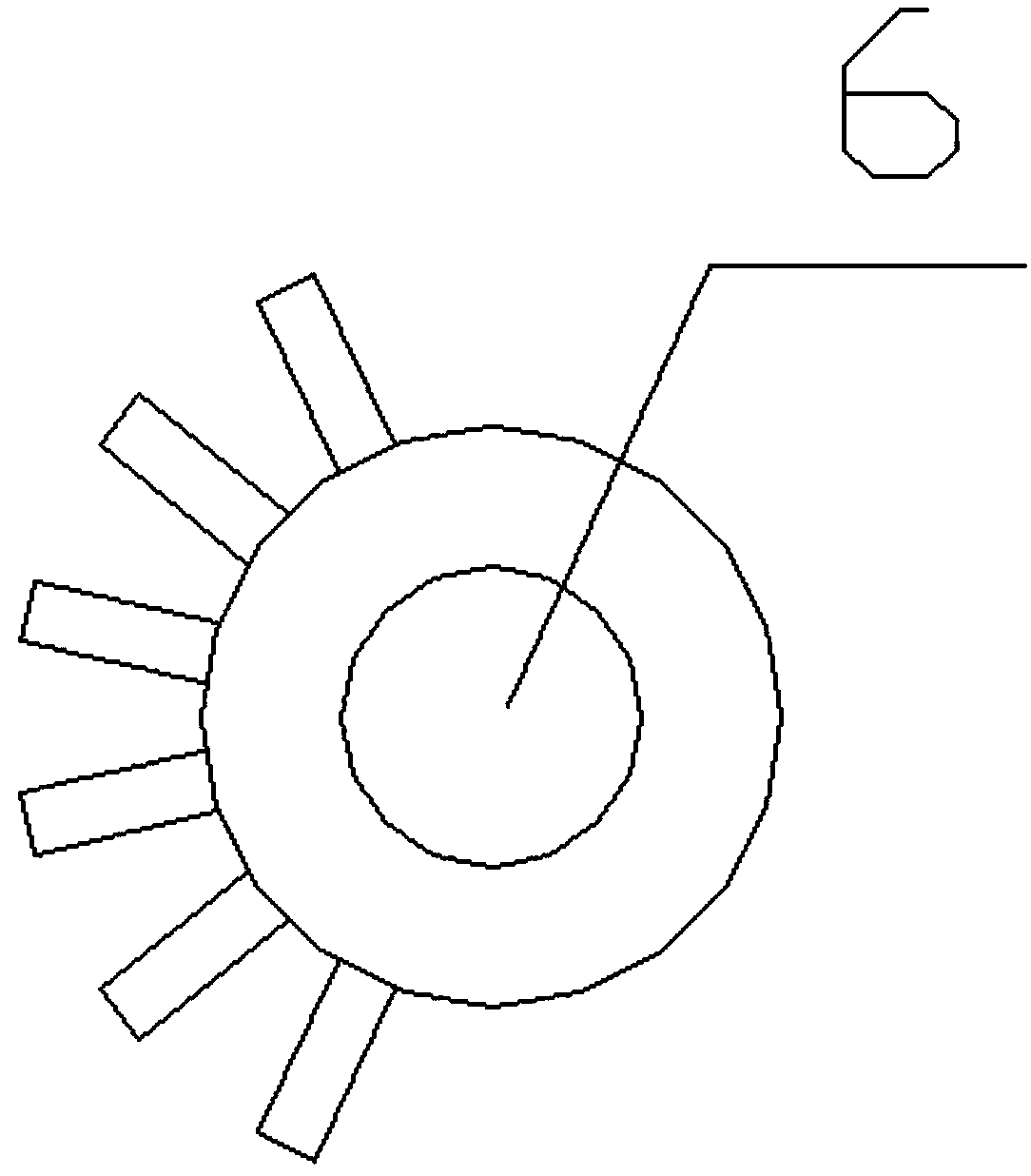

[0019] Such as Figure 1 to Figure 6 As shown, the present invention is a powder mixing device, comprising a rectangular mixing box 1, a rising stirring device, a swinging stirring device and a masking plate 2, the upper end of the rectangular mixing box 1 is fixed with a cross support frame 3, and the cross The center of the support frame 3 is provided with a main rotating motor 4, the output shaft of the main rotating motor 4 passes through the cross support frame 3, and the lower end of the output shaft is fixedly connected with the first rotating shaft 5, and the first rotating shaft 5 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com