Processing equipment of pig feed

A processing equipment and pig feed technology, applied in feed, mixer, food science, etc., can solve the problem that raw materials are easy to adhere to the inner wall of the mixing box, and achieve the effect of changing the mixing range and reducing the dead angle of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

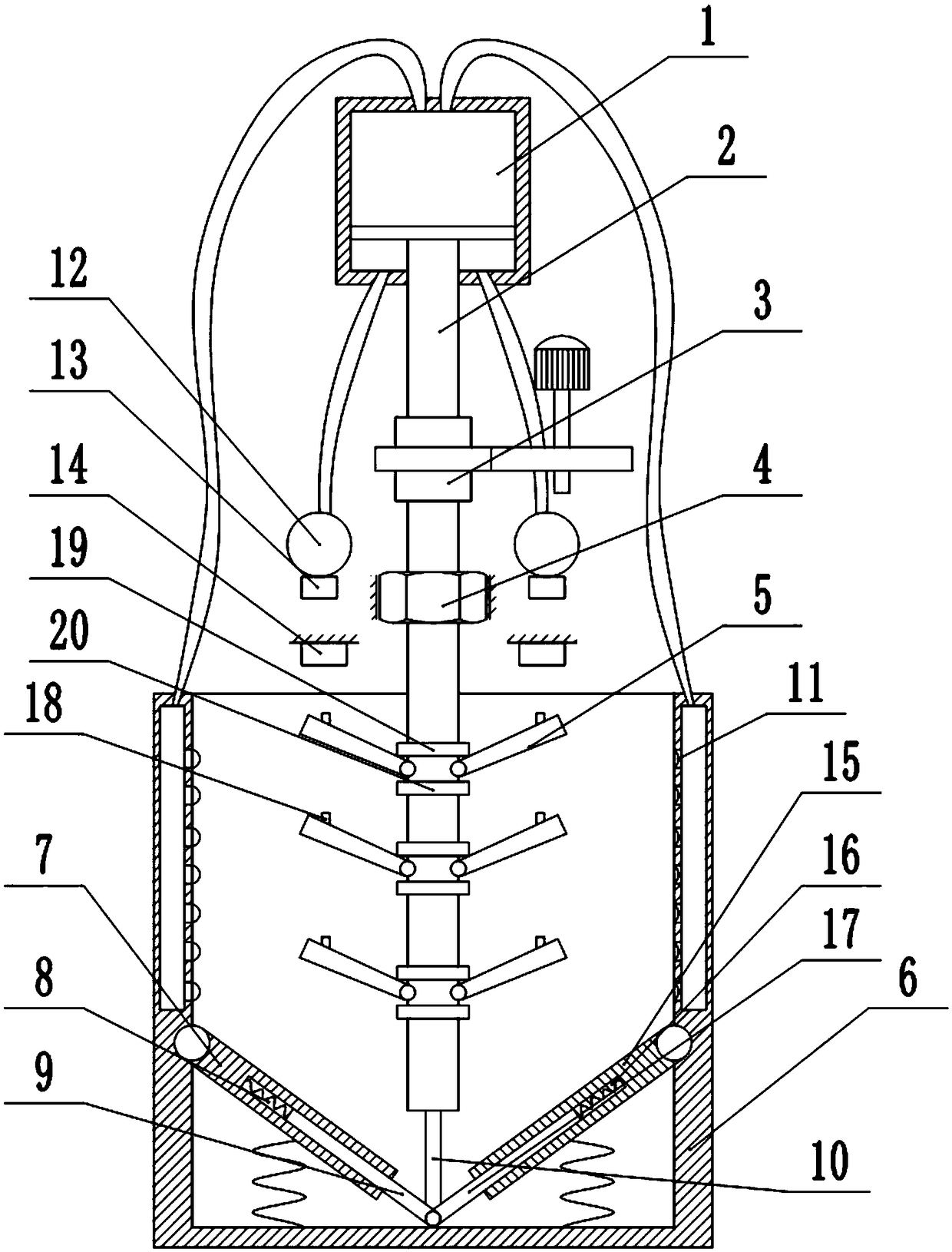

[0025] The reference signs in the drawings of the description include: piston barrel 1, stirring shaft 2, spline sleeve 3, nut 4, stirring blade 5, stirring box 6, first baffle plate 7, first chute 8, first slide plate 9 , connecting rod 10, film 11, air bag 12, limit switch 13, electromagnet 14, second baffle plate 15, second chute 16, second slide plate 17, magnetic block 18, upper limit ring 19, lower limit ring 20 .

[0026] Such as figure 1 As shown, the pig feed processing equipment includes a frame on which a mixing box 6 is fixed, the side wall of the mixing box 6 is provided with cavities, and the inner wall of the mixing box 6 is provided with several through holes communicating with the cavities. Both are provided with a film 11, the size of which is equal to the aperture of the through hole, and the edge of the film 11 is fixed on the inner wall of the through hole.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com