Novel stirrer for building

A construction and mixer technology, which is applied to cement mixing devices, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of large mixing dead angle, affecting the mixing effect, insufficient and uniform mixing, etc., to reduce the mixing dead angle, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

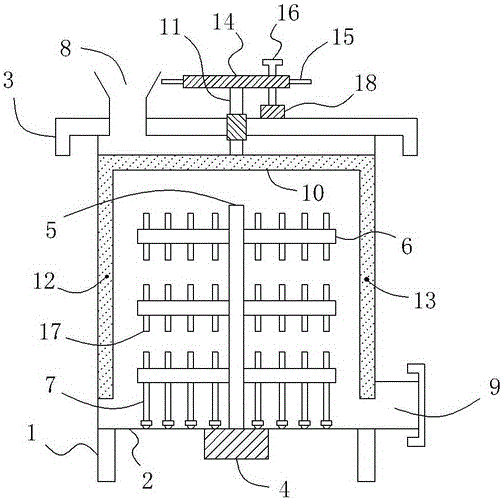

[0014] Such as figure 1 As shown, a new construction mixer includes a bracket 1 and a cylinder 2 arranged on the bracket 1, a cylinder cover 3 is provided on the top of the cylinder 2, and a bottom motor is also provided at the outer bottom of the cylinder 2. 4. The output shaft of the bottom motor 4 is set vertically upwards and extends to the inside of the barrel 2, and the top of the output shaft of the bottom motor 4 is also connected to a vertically upwardly extending shaft 5, which is also from top to bottom on the shaft 5 There are a plurality of horizontally arranged stirring rods 6; on the stirring rod 6 at the bottom of the rotating shaft 5, a plurality of bottom struts 7 extending vertically downwards are fixedly connected, so that between the stirring rods 6 and the bottom struts 7 Under the action of stirring, the building materials can be fully and evenly stirred, and the dead angle of stirring at the inner bottom of the cylinder 2 is greatly reduced. There is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com