Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Reduce dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

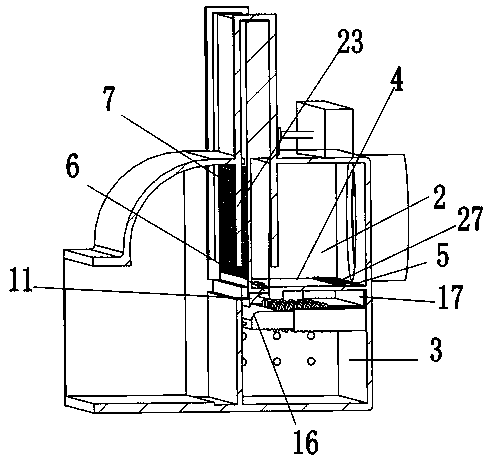

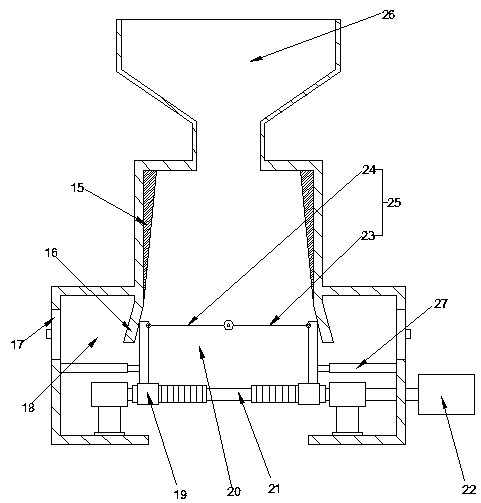

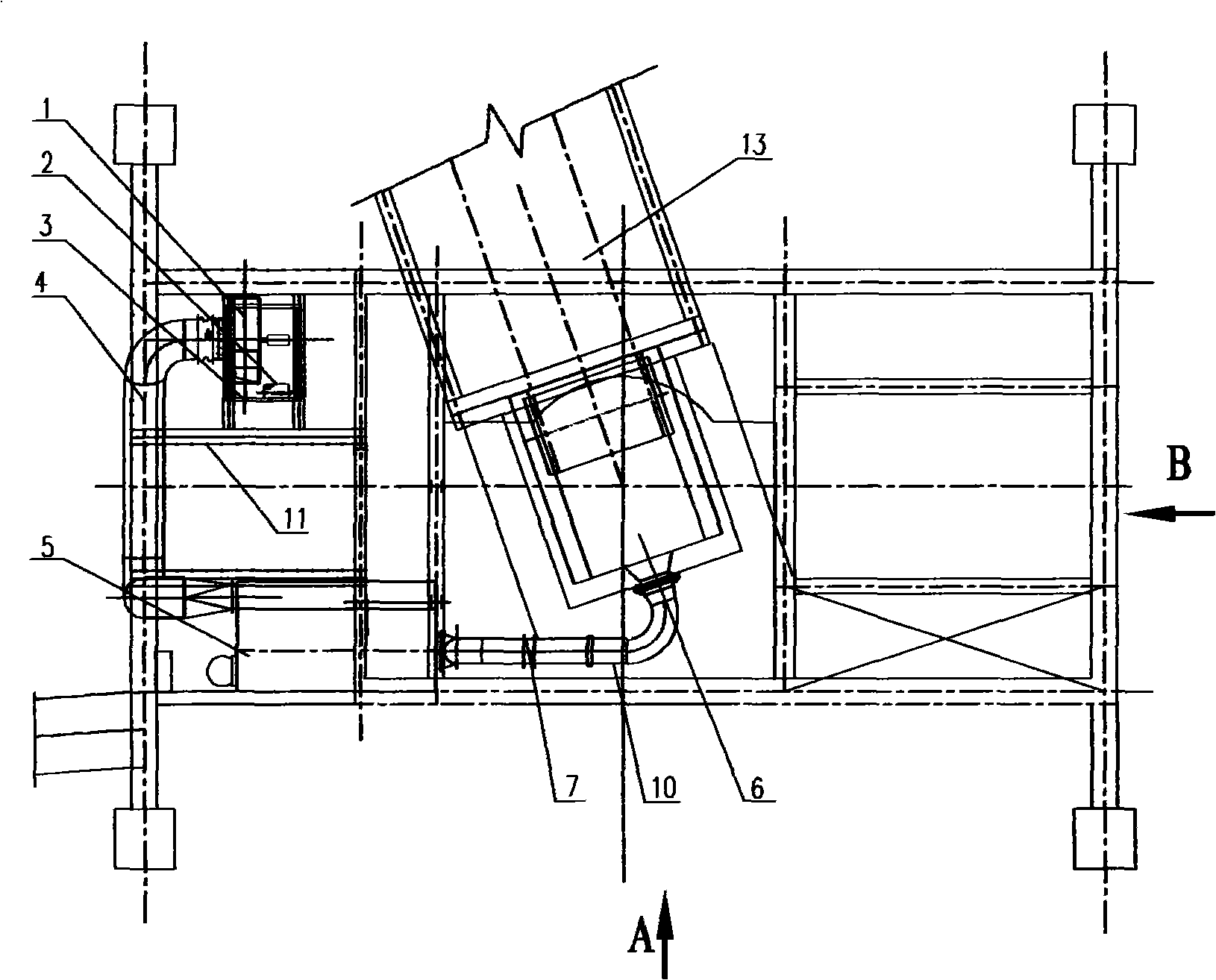

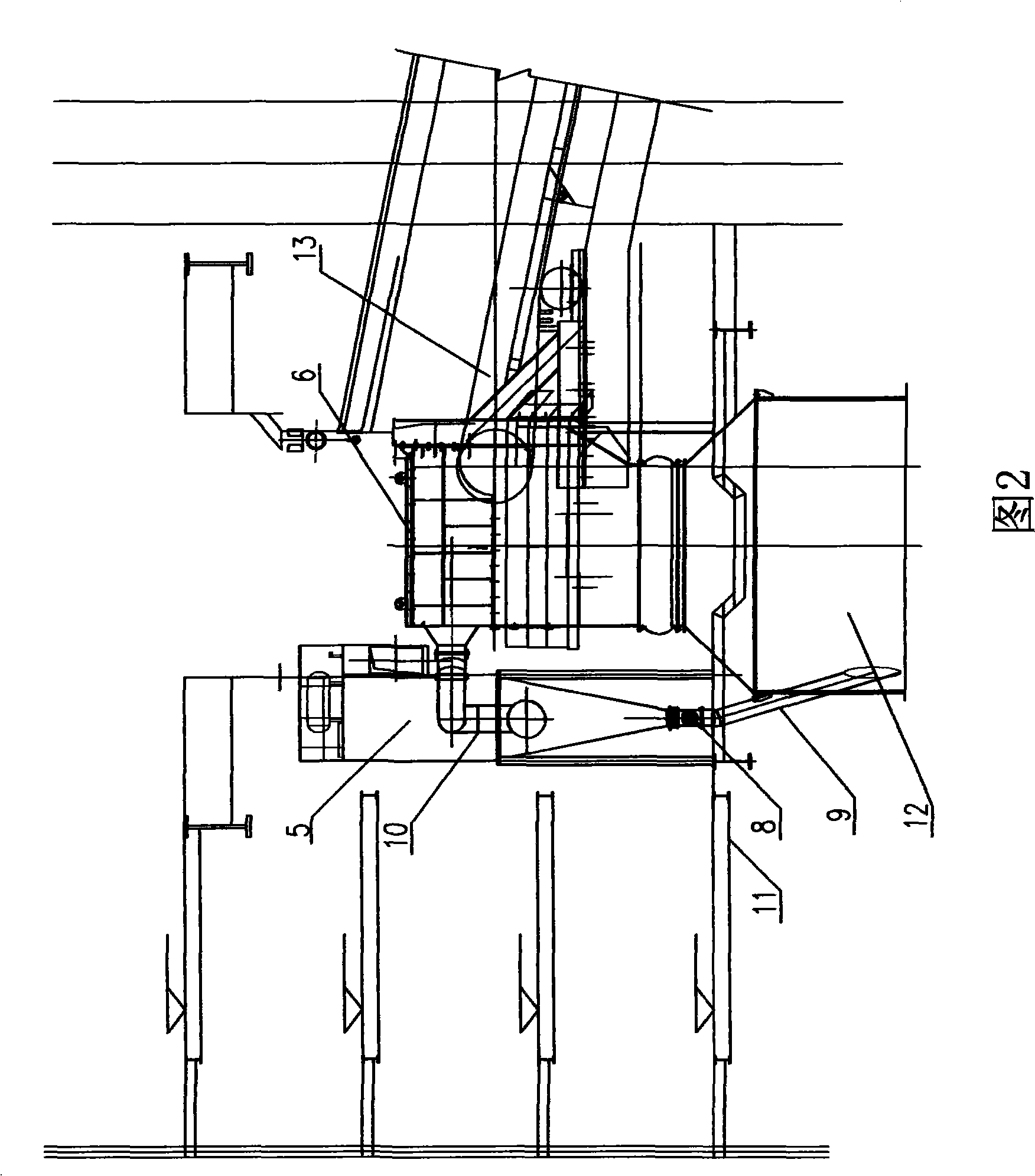

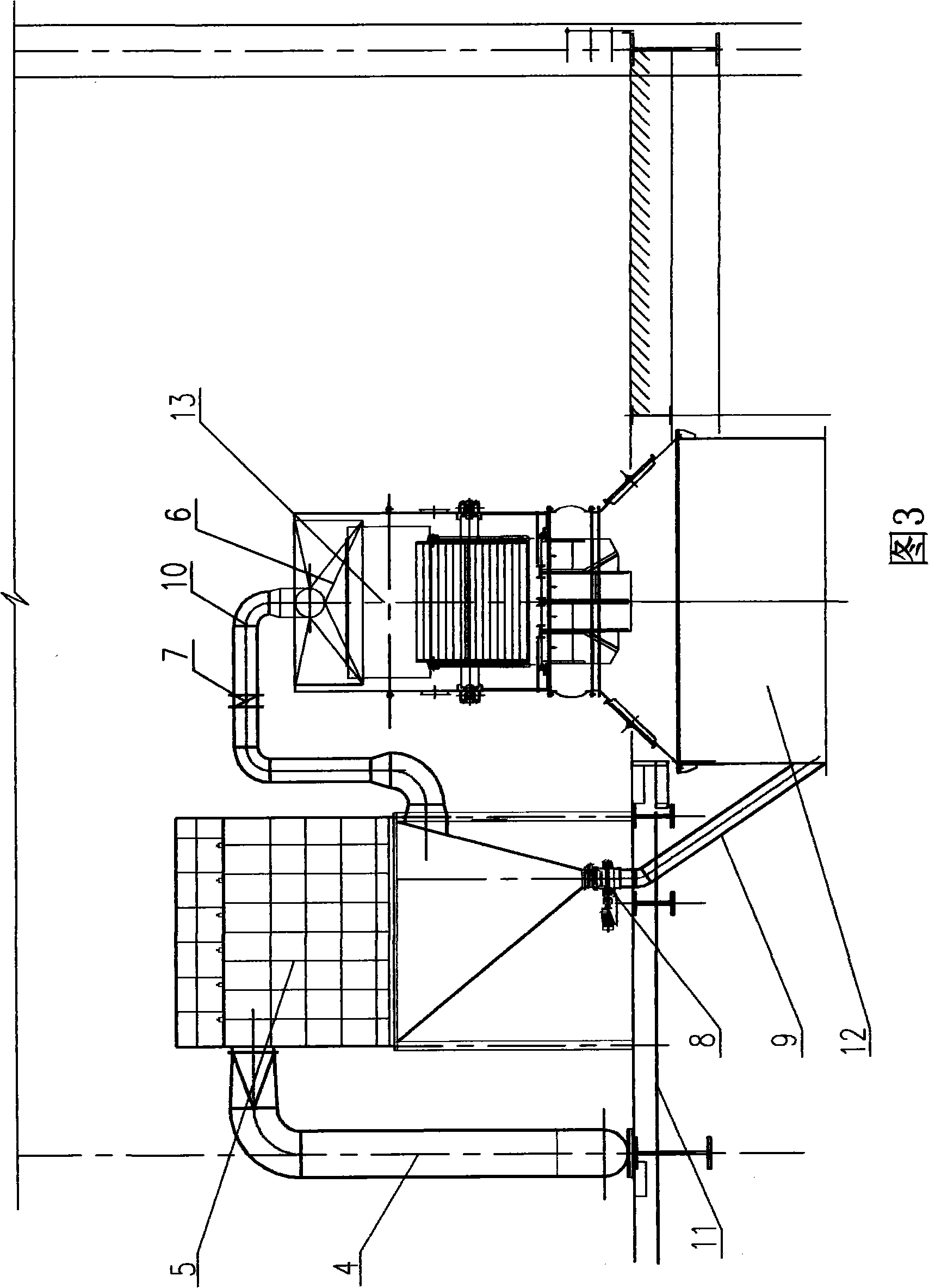

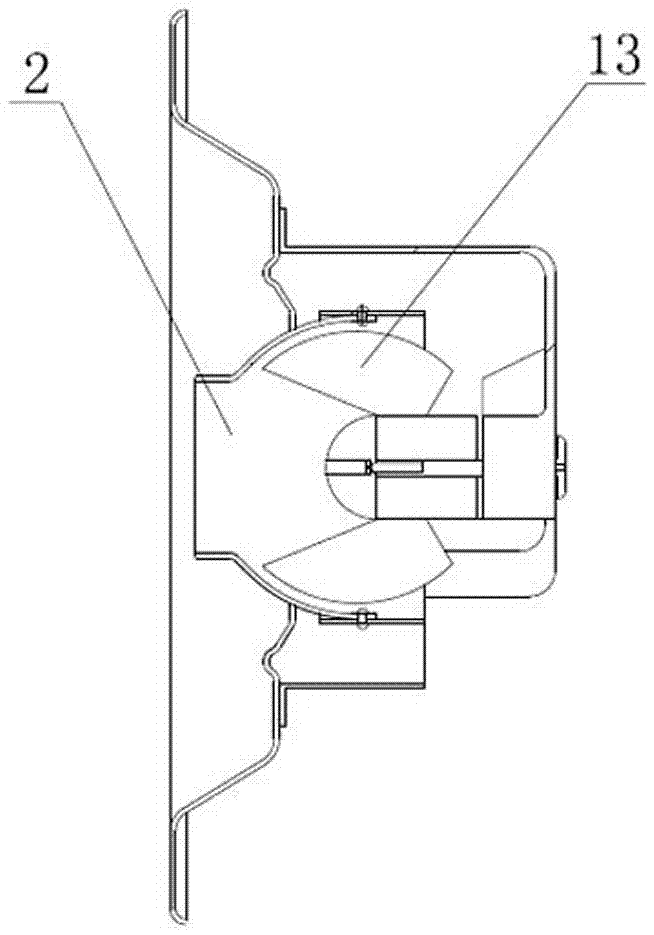

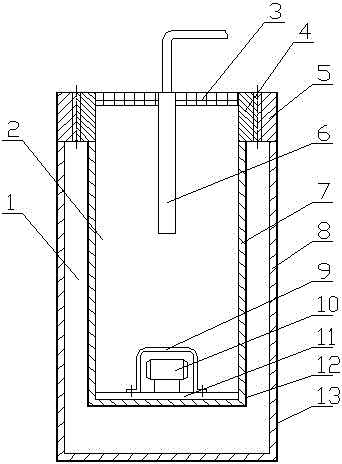

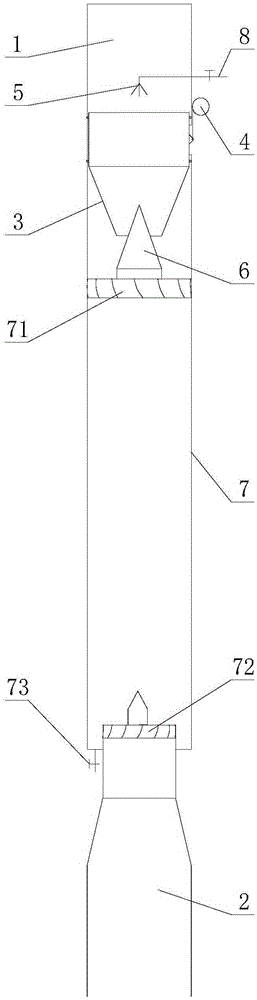

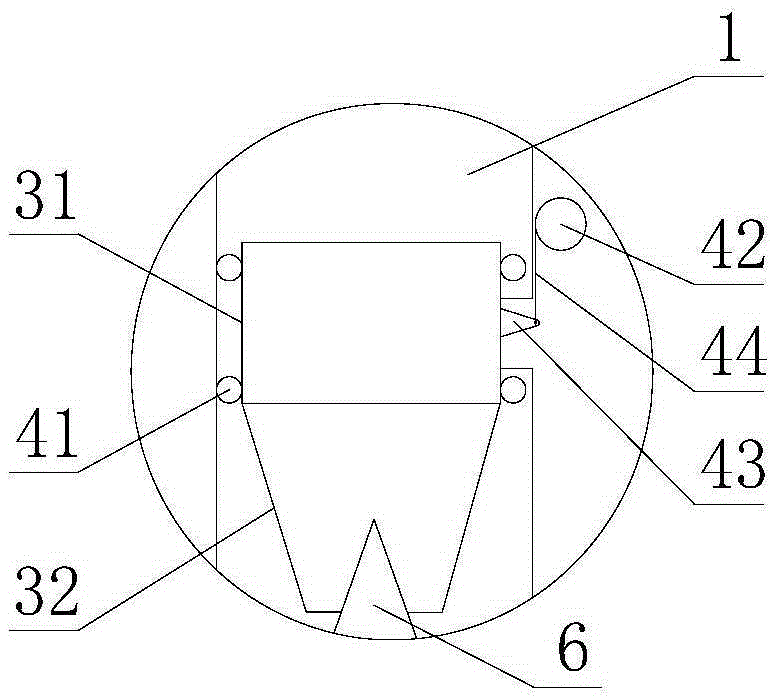

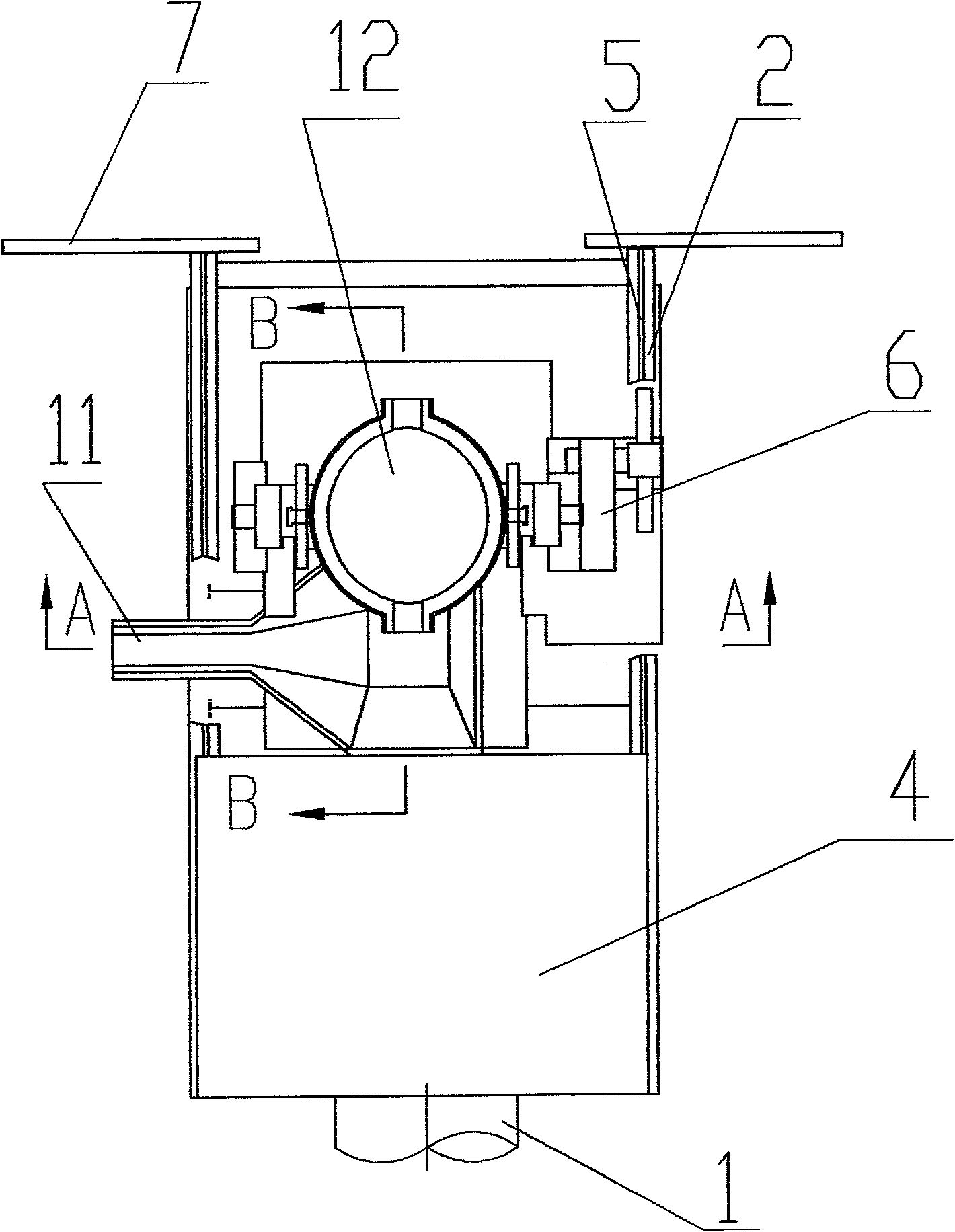

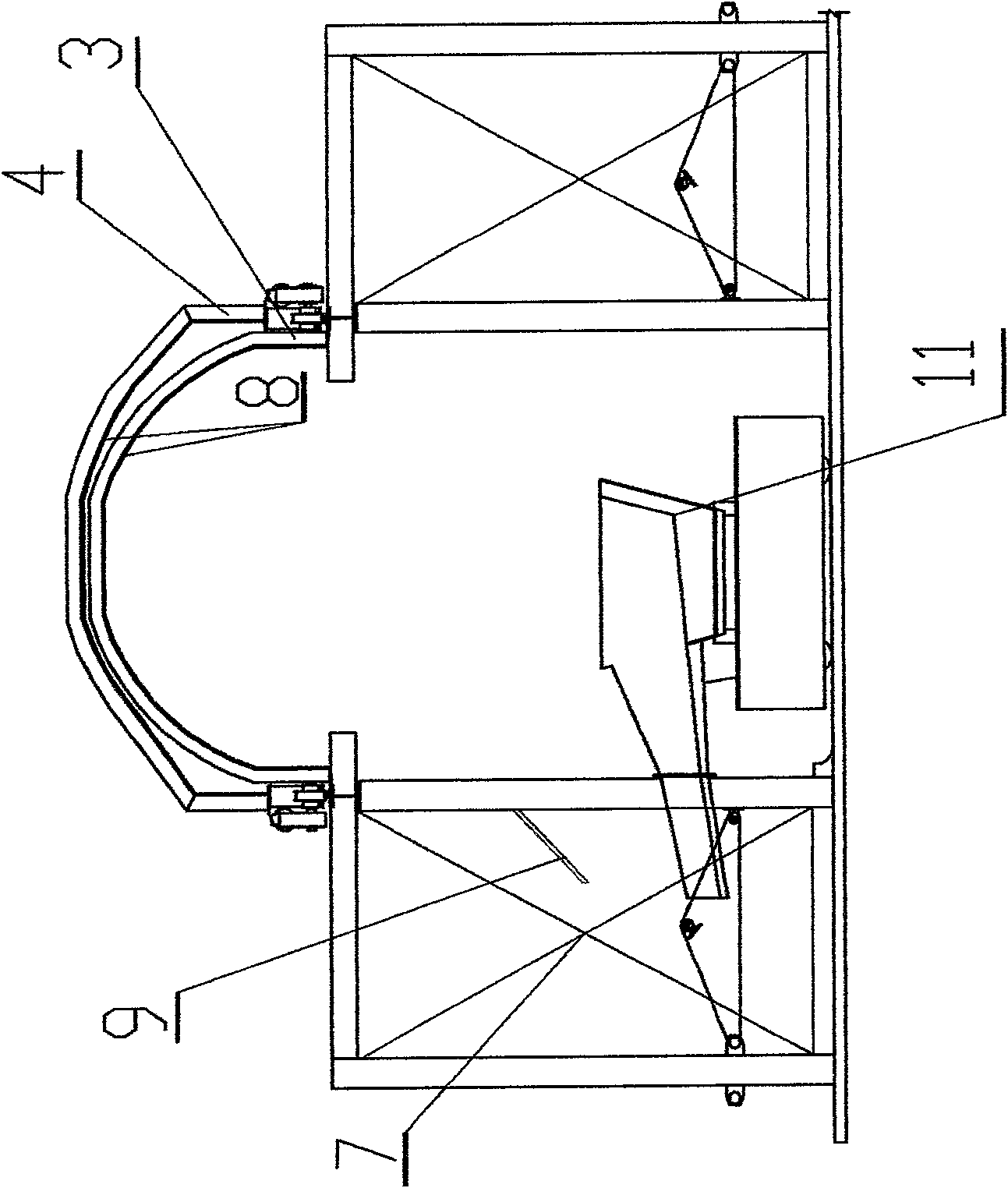

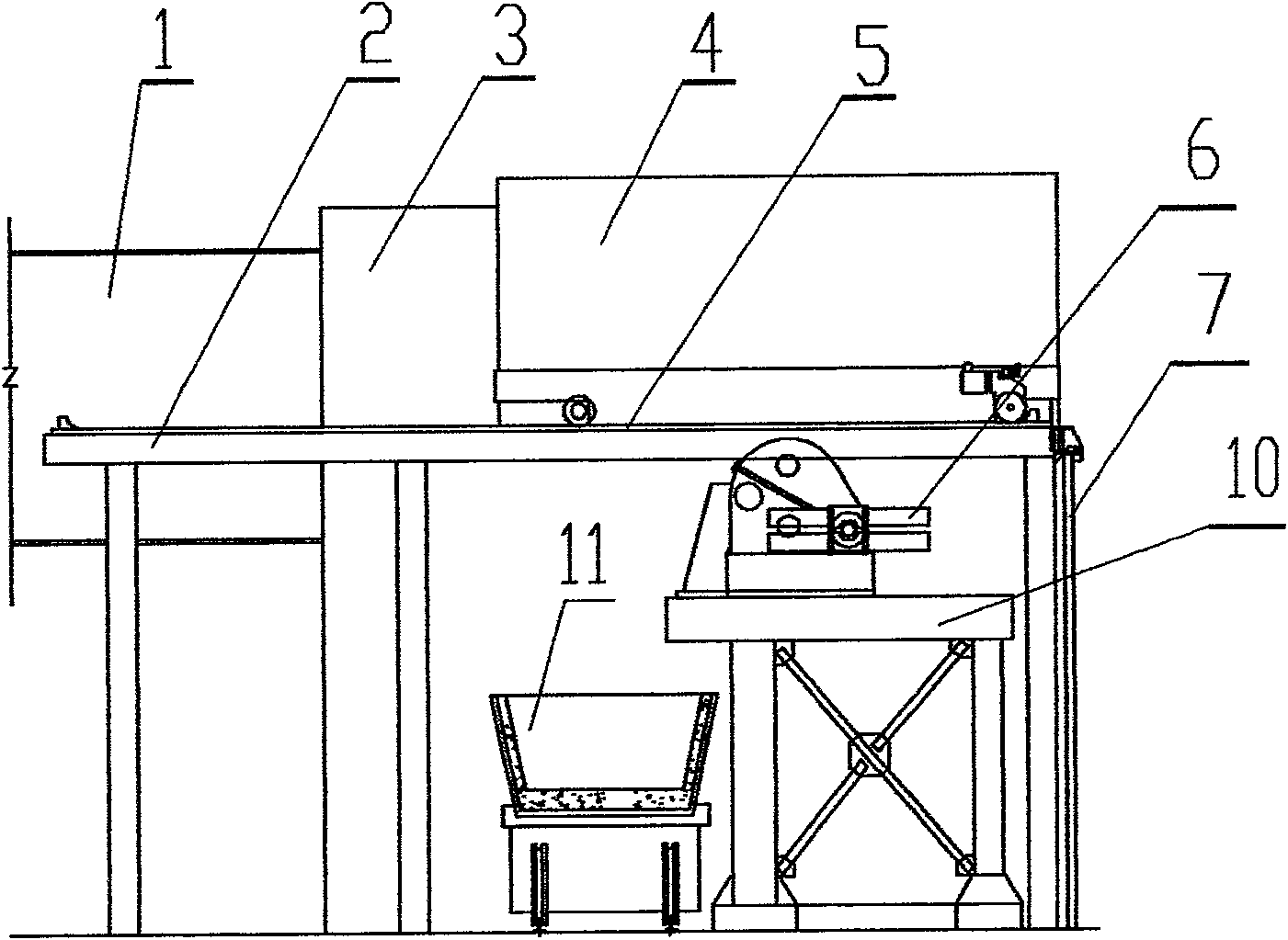

Mobile smoke blast trapping device for furnace mixer

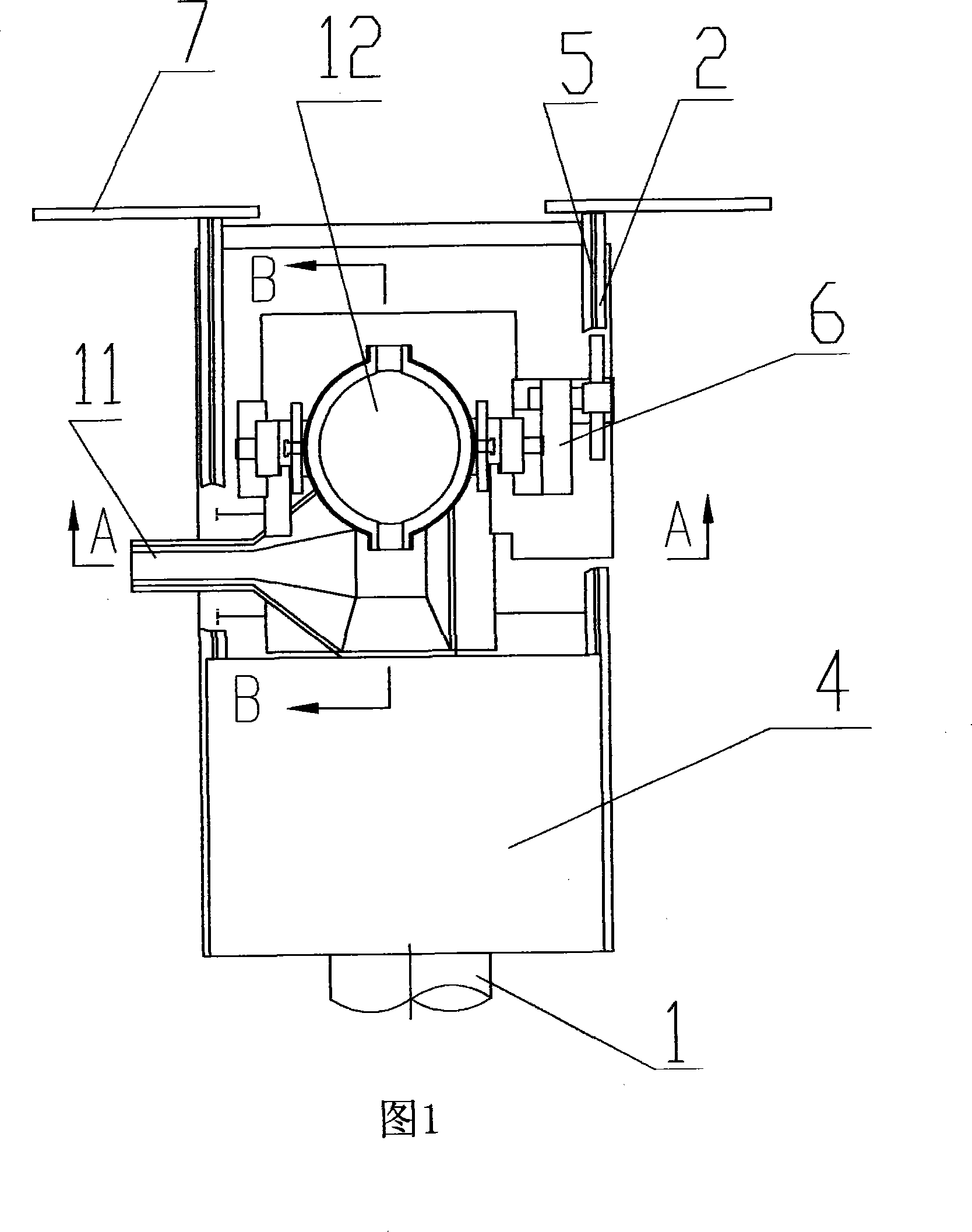

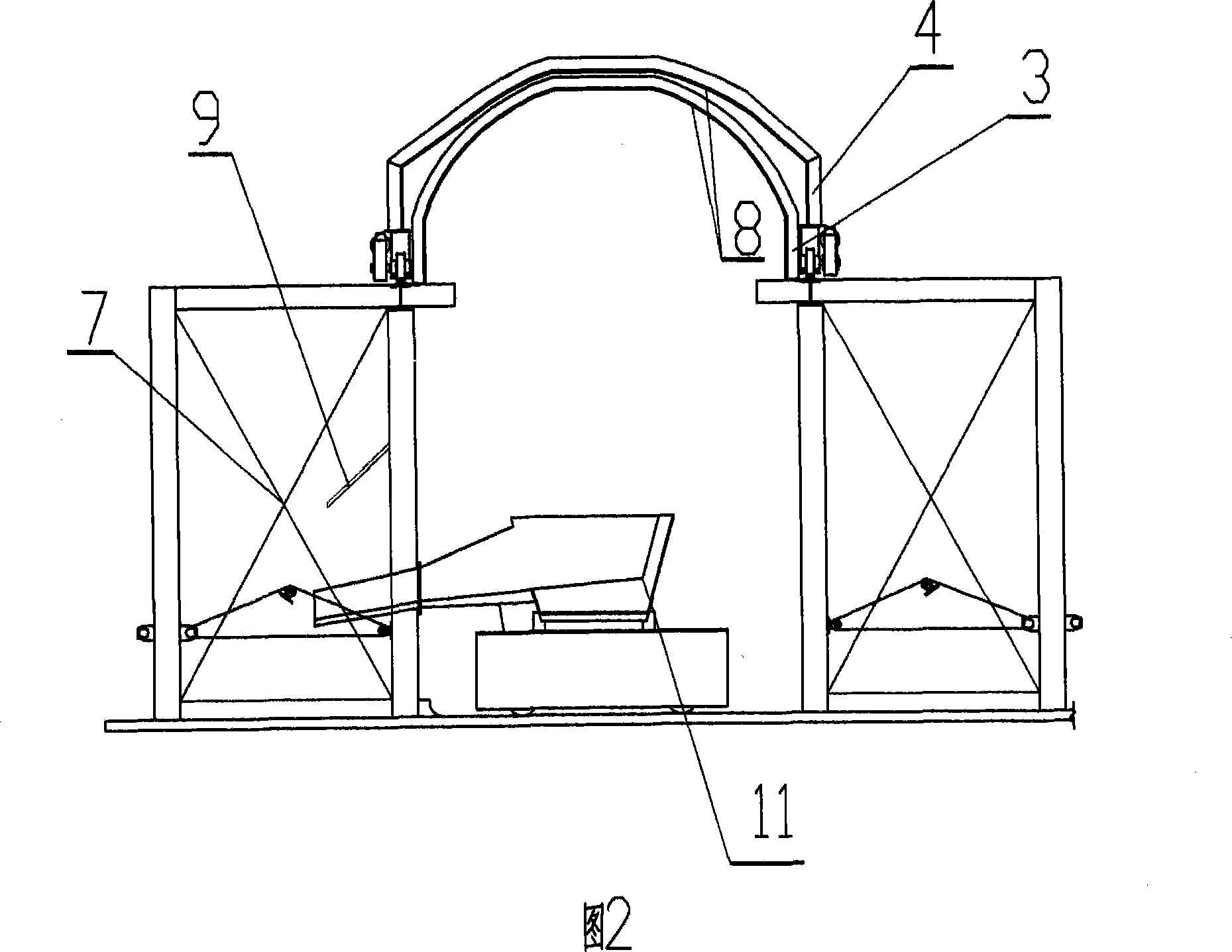

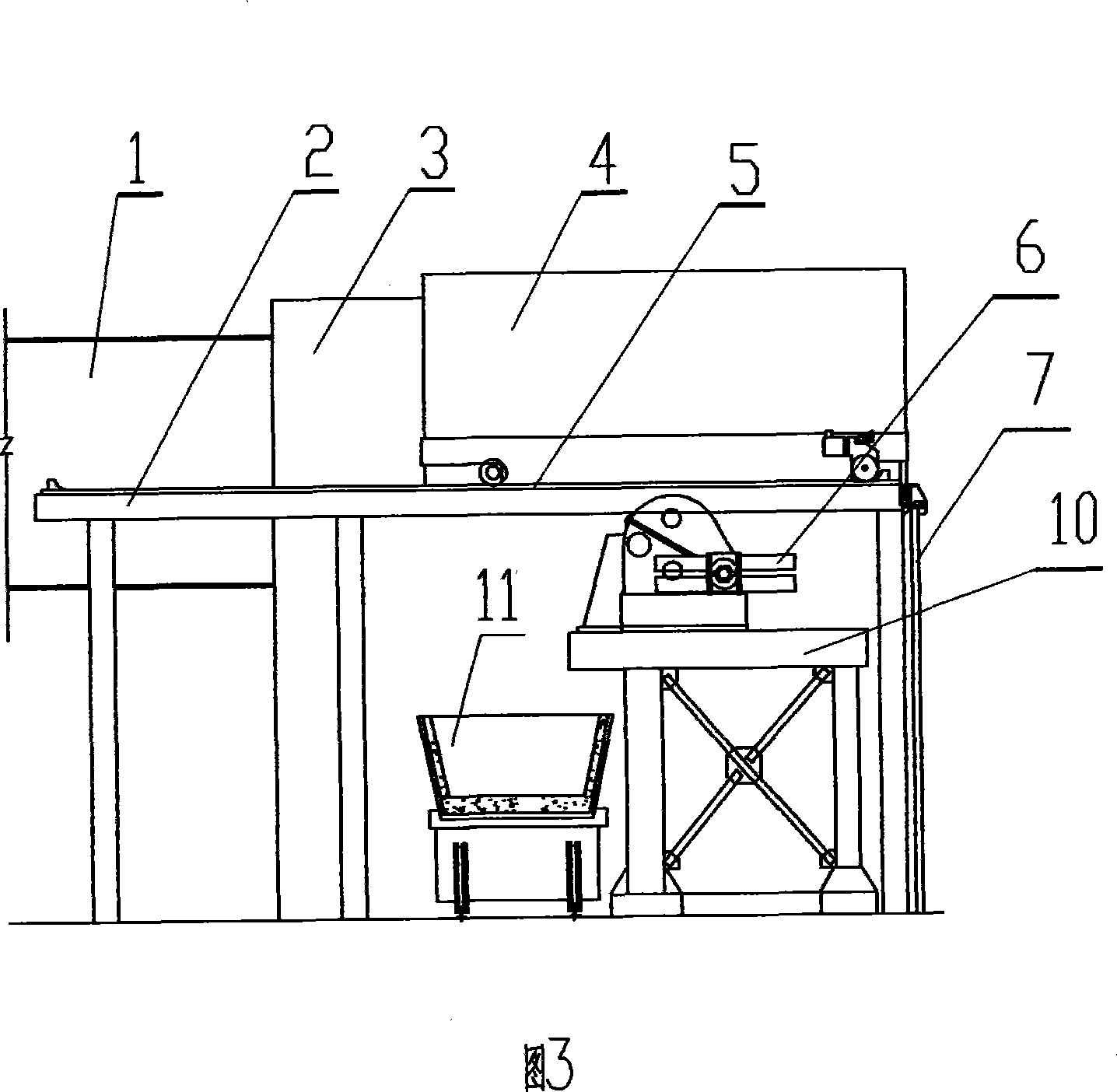

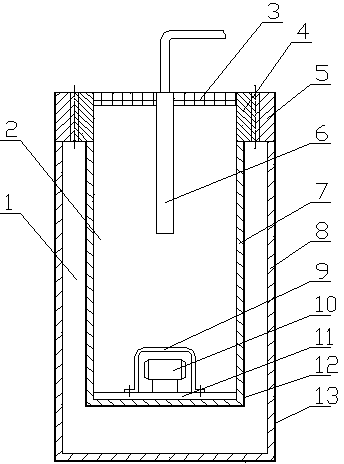

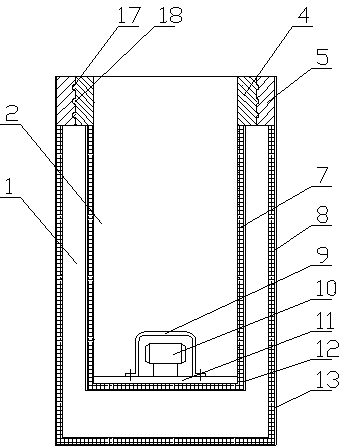

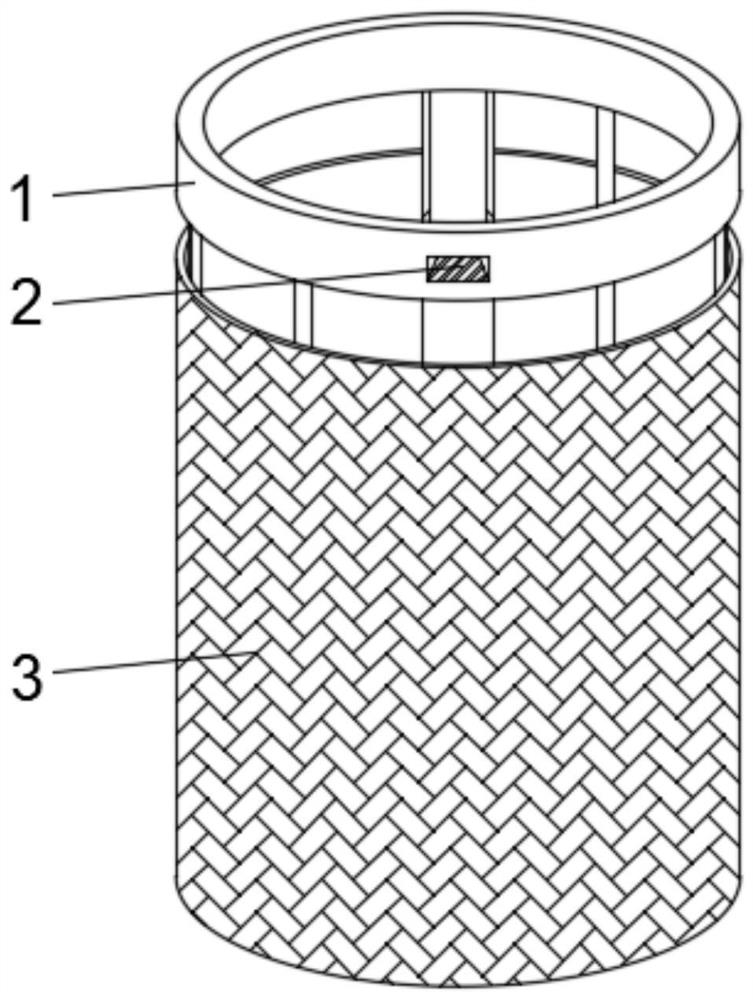

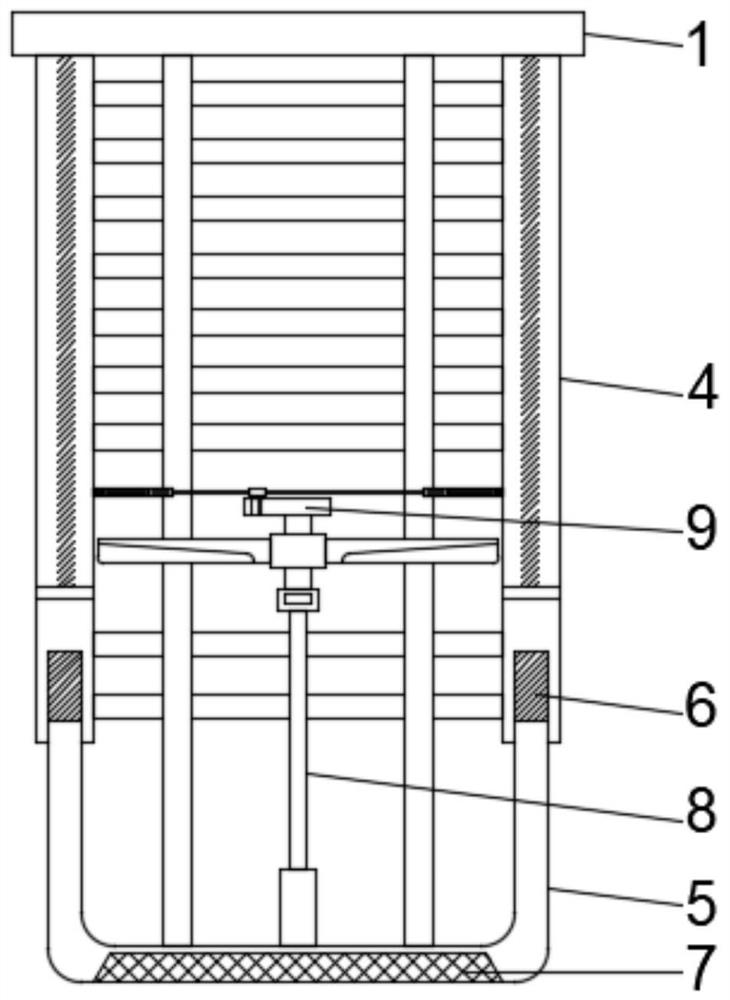

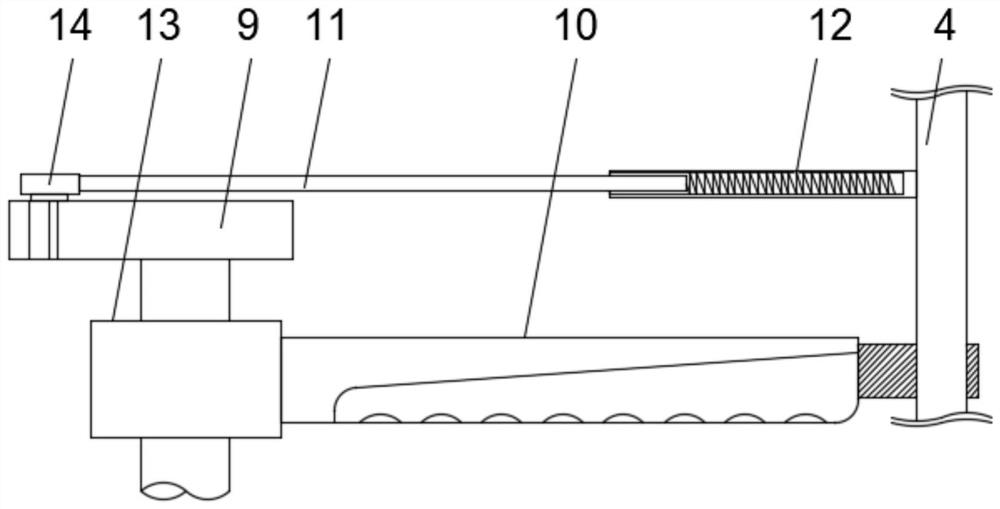

The invention discloses a movable dust arrestment device used for a metal iron mixer, comprising a dedust pipe (1), a support (2), a fixed smoke cover (3) and a movable smoke cover (4). The movable dust arrestment device is characterized in that: the fixed smoke cover (3) and a guide way (5) are arranged on the support (2), and the movable smoke cover (4) can move along the guide way (5), and can be combined with the fixed smoke cover (3) to form a sealed dedust cover; a pig-iron ladle dumping device (6) is arranged on the support (2), and the dedust pipe (1) is arranged on one side of the fixed smoke cover (3). The movable dust arrestment device used for the metal iron mixer has the advantages of convenient usage, ensuring high dust arrestment rate and good dedust effect in the iron receiving process of metal mixer, being energy-saving, reducing running cost, improving the working environment of operating staffs and reducing the operating rate of cranes in workshop.

Owner:HUATIAN ENG & TECH CORP MCC

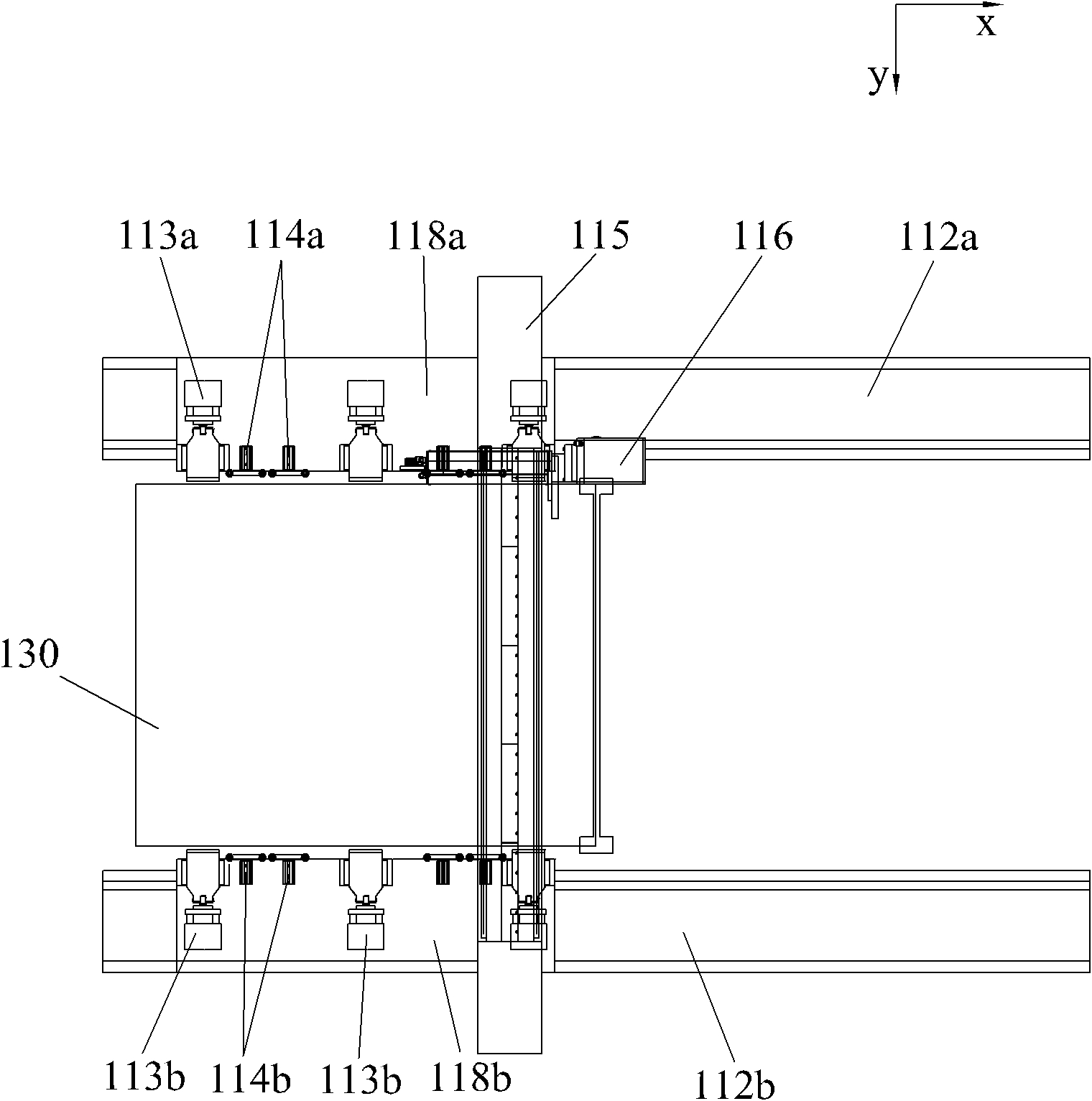

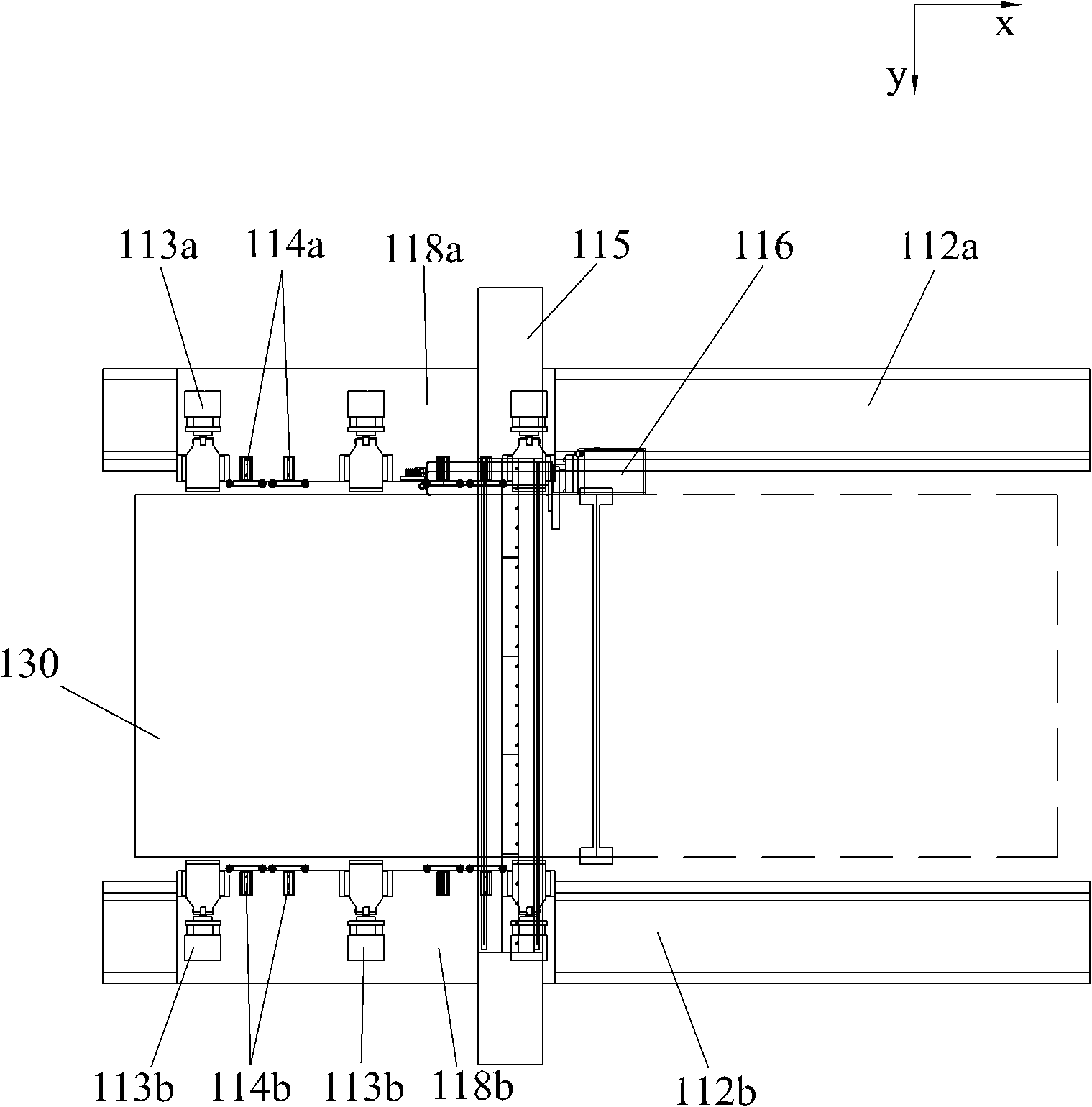

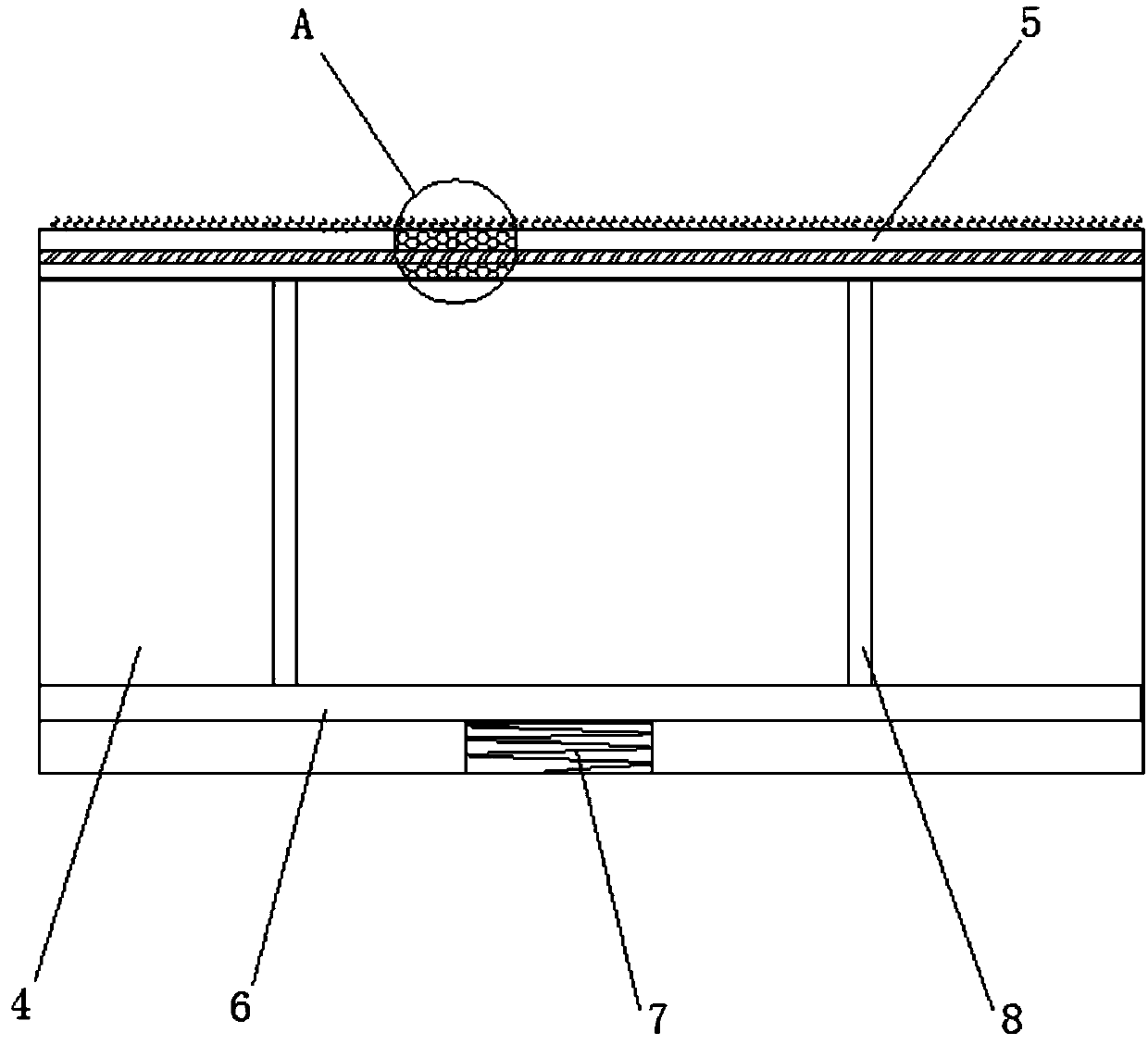

Synchronous dust removing device

InactiveCN102107334AImprove dust removal effectSmall suction areaFinal product manufactureLaser beam welding apparatusEtchingNozzle

The invention discloses a synchronous dust removing device. The device comprises a control unit, a processing unit and a dust removing unit, wherein the processing unit comprises an air floatation platform, a laser track, a laser moving mechanism and a laser generator; an amorphous silicon solar glass substrate is carried above the air flotation platform and a film layer faces downwards; the laser generator is slidably arranged on the laser track; a light outlet hole of the laser generator is positioned above the amorphous silicon solar glass substrate; the dust removing unit comprises a negative pressure dust collector and a synchronous transmission mechanism; the synchronous transmission mechanism is arranged below the air flotation platform; and a negative pressure suction nozzle of the negative pressure dust collector is formed on the synchronous transmission mechanism, is opposite to the light outlet hole of the laser generator, and is driven by the synchronous transmission mechanism to synchronously move together with the light outlet hole of the laser generator, so that the etching and the dust removing of the film layer are synchronized. The device has a better dust removing effect; meanwhile, since the negative pressure suction nozzle is extremely small, and the dust collection area is small, a good dust removing effect can be achieved by a low-power fan.

Owner:东莞宏威薄膜真空技术有限公司

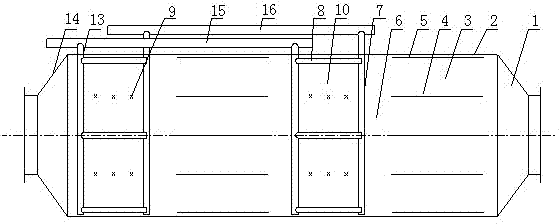

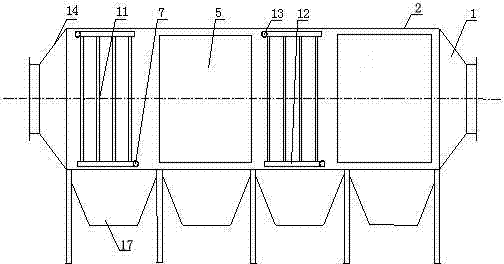

Double-zone multistage electrostatic dust collector with charged cold anode and application method thereof

InactiveCN102872976AReduce the temperatureLower specific resistance valueElectrode constructionsElectrodes cleaningElectricityWire grid

The invention belongs to the technical field of electrostatic dust collectors, and especially relates to a double-zone multistage electrostatic dust collector with a charged cold anode and an application method thereof. According to the double-zone multistage electrostatic dust collector with a charged cold anode of the invention, a dust collecting zone comprises a plate-plate channel formed by an anode plate and a cathode plate disposed face to face; a charged zone comprises an anode tube grid row and a cathode wire grid row; one end of a cold liquid tube of the anode tube grid row is connected with a liquid feeding collector, and the other end is connected with a liquid return collector; each liquid feeding collector is connected with a liquid feeding header; the liquid return collector is connected with a liquid return header; the liquid feeding header is connected with a liquid feeding header tube disposed outside a housing; the liquid return header is connected with a liquid return header tube disposed outside the housing. When the dust collector of the invention operates, cold liquid flowing in the anode grid tubes cools the grid tube surfaces, and thus realizes temperature decrease of a dust layer deposited on the grid tube surfaces, which effectively reduces the specific resistance value of the dust layer, and eliminates the adverse effect that a reverse electric field or back corona caused by the dust layer with a high specific resistance value deposited on the anode surface can charge the dust.

Owner:NORTHEASTERN UNIV

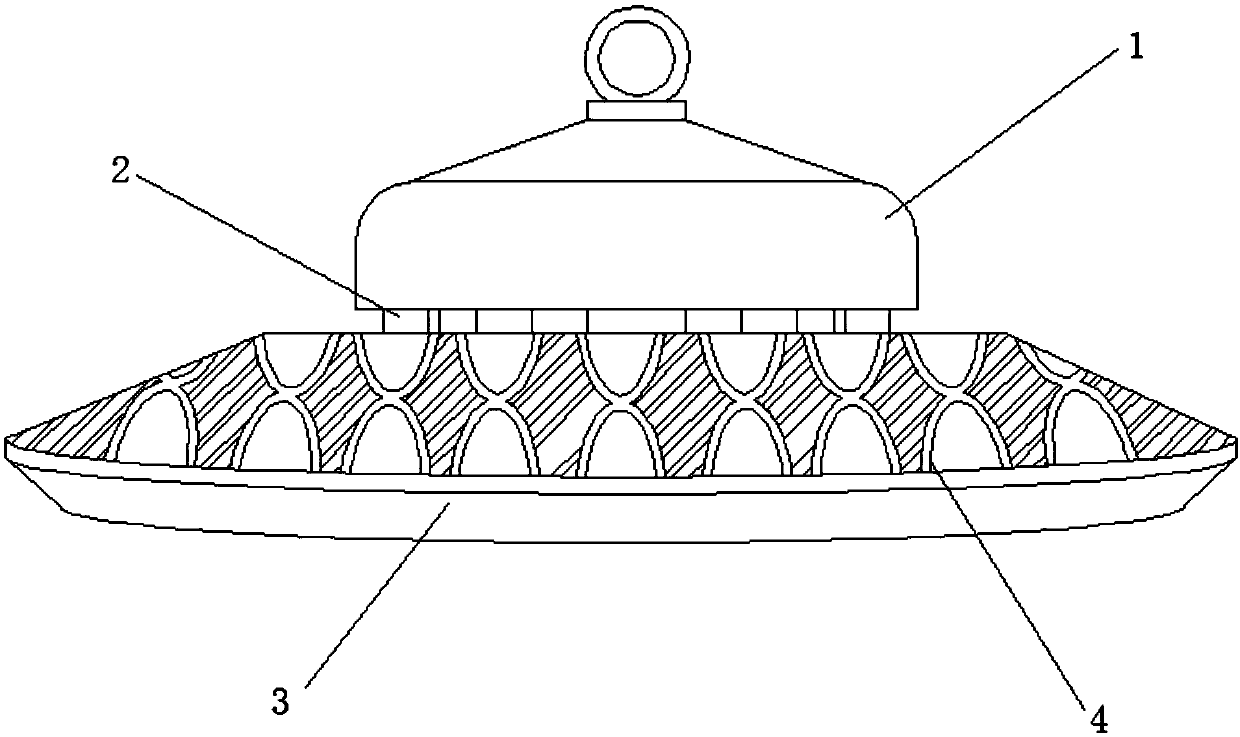

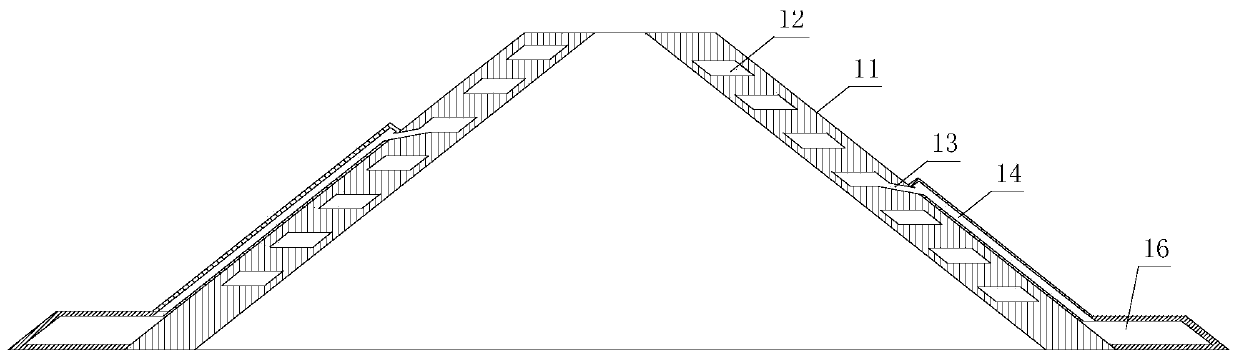

Thread engagement type double-layer combined dedusting cloth bag and production process thereof

InactiveCN104492186AImprove filtering effectReduce impactCombination devicesDispersed particle filtrationElectric machineEngineering

The invention relates to a thread engagement type double-layer combined dedusting cloth bag. The cloth bag comprises an outer bag and an inner bag, wherein the outer bag comprises outer dedusting cloth, an outer frame and an outer retaining ring; the inner bag comprises inner dedusting cloth, an inner frame, an inner retaining ring, a vibrating motor, an electric dedusting grid, a pulse back flushing spray head, a bottom plate, and a motor hood, wherein the electric dedusting grid is arranged at the upper part of the inner bag, the pulse back flushing spray head is arranged in the center of the electric dedusting grid, the bottom plate of the inner bag is arranged on the bottom part of the inner bag, the vibrating motor is arranged on the bottom plate, and the inner bag and the outer bag are connected by using thread engagement. The head engagement type double-layer combined dedusting cloth bag adopts the combined filtering of the double-layer cloth bag and electric dedusting, has the extremely better filtering effect than that of existing dedusting cloth bags, and has the relatively high dedusting capacity due to the combination of pulse air flow and vibration.

Owner:南京市凌湃环保科技有限公司

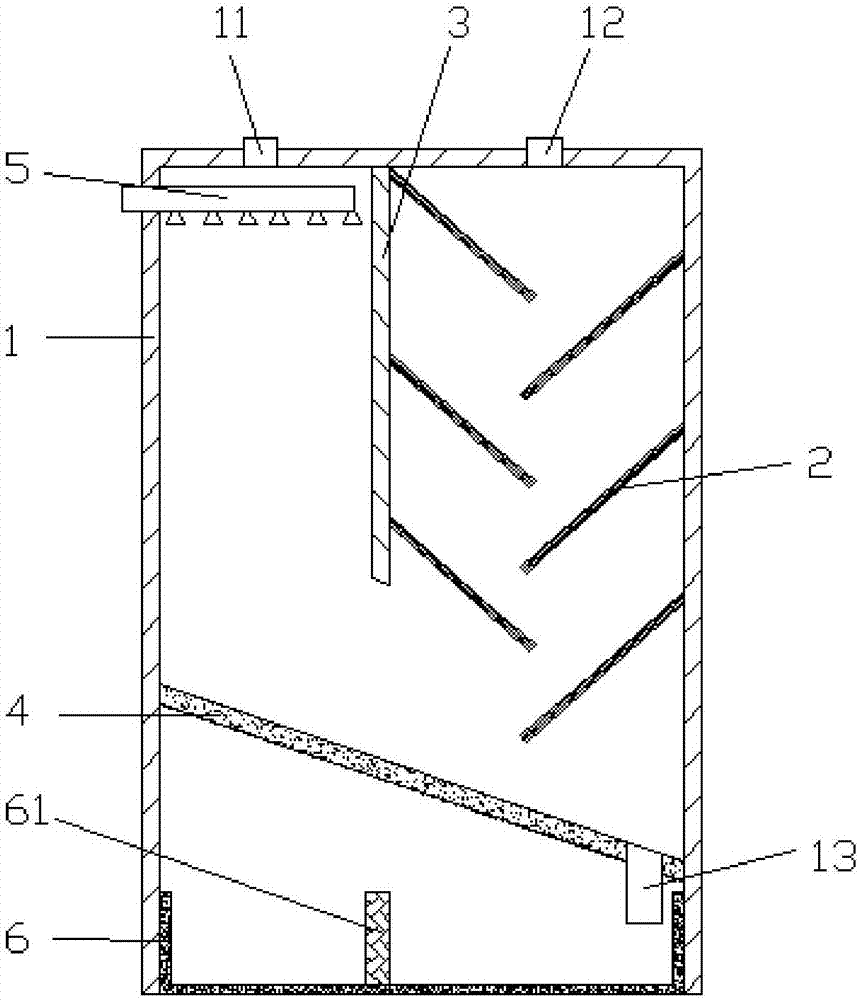

Safe and environment-friendly dust remover

The invention discloses a safe and environment-friendly dust remover. The dust remover comprises a shell and a bottom plate, wherein the shell is internally provided with a vertical division plate which divides the shell into an air inlet cavity and an air outlet cavity, and the bottom plate is arranged below the vertical division plate inside the shell; a lower part of the air inlet cavity is communicated with a lower part of the air outlet cavity to form an air flow channel, the top of the air inlet cavity and the top of the air outlet cavity are respectively provided with an air inlet and an air outlet of the air flow channel; the top of the air inlet cavity is provided with an atomizing device, the air outlet cavity is uniformly and internally provided with slantwise division plates which are arranged in a stagger manner, the high ends of the slantwise division plates are arranged on a side wall or the vertical division plate of the shell, and the low ends of the slantwise division plates are hung in the air and used for elongating the air flow channel; and the bottom plate of the shell has a slantwise shape in design, and one side wall of the shell at the low end of the bottom plate is provided with a sewage draining exit. According to the dust remover, the structure is simple, the use is safe, the requirement for conditions of usage is not high, and the dust removing effect is good.

Owner:成都智宸科技有限公司

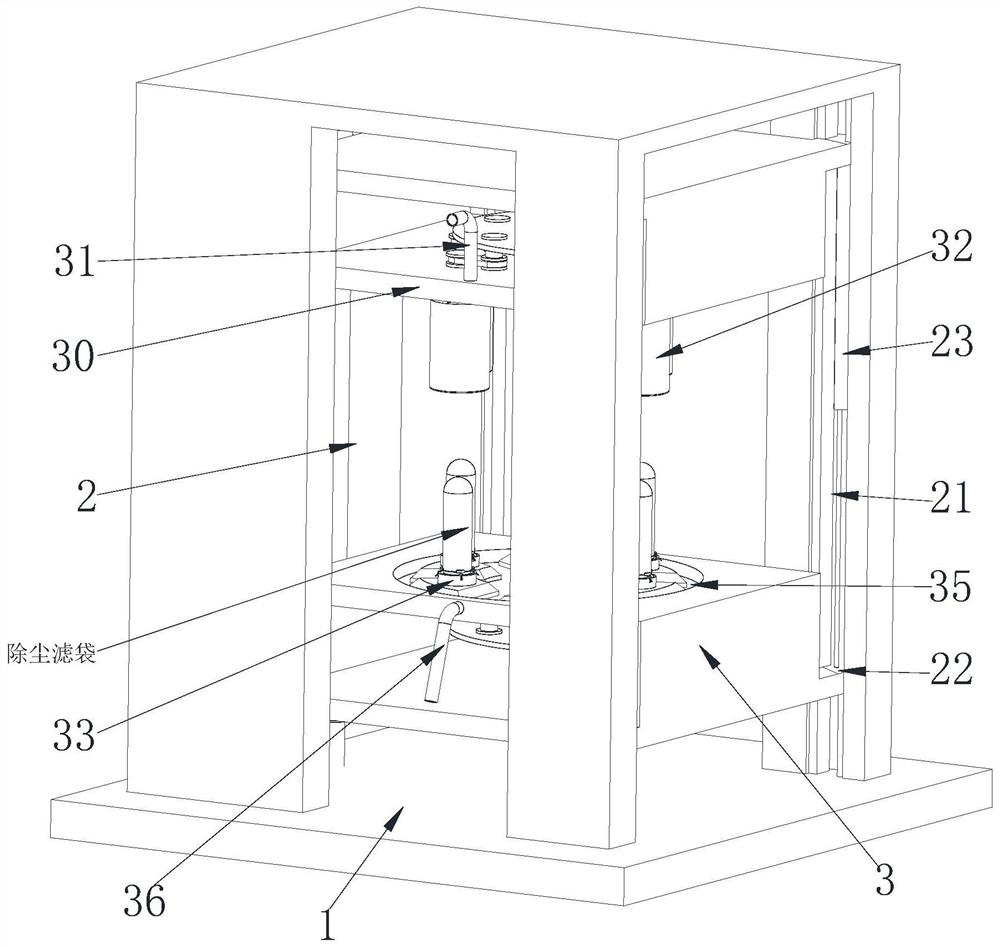

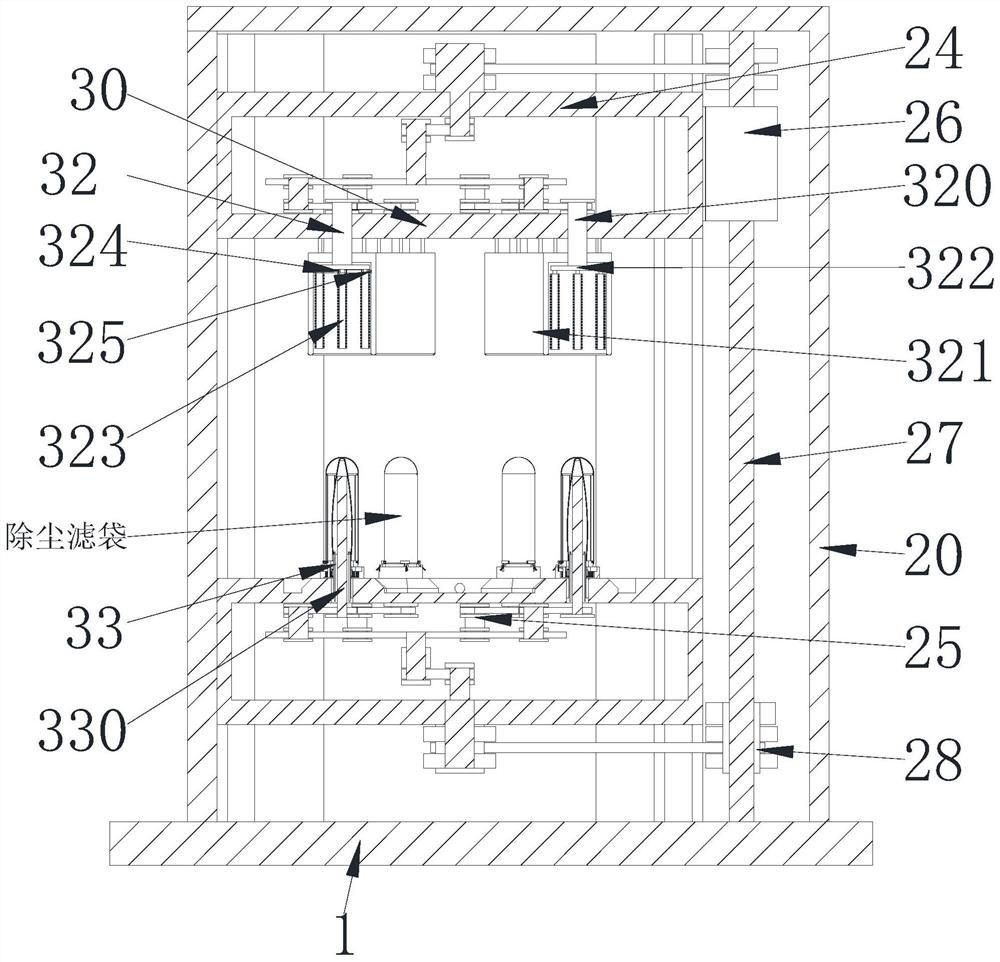

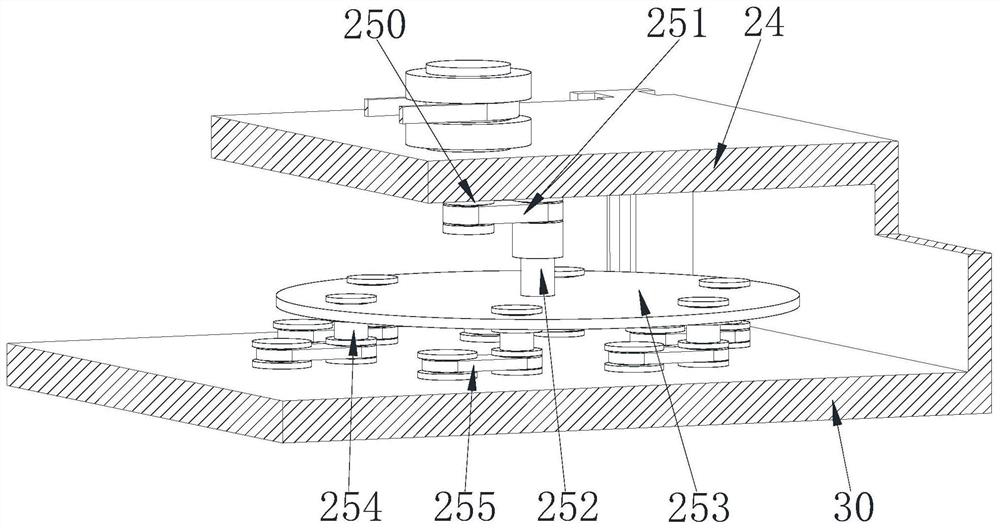

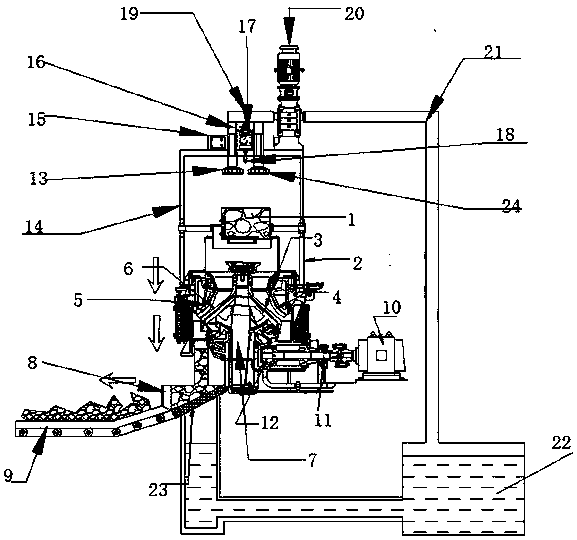

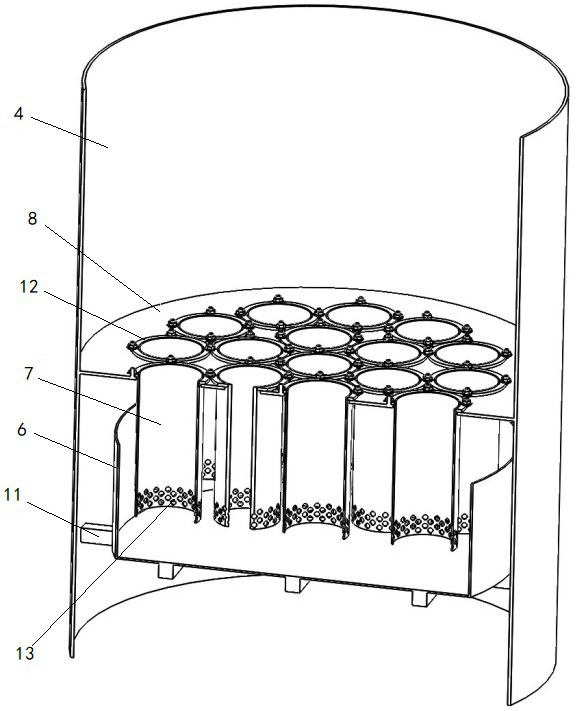

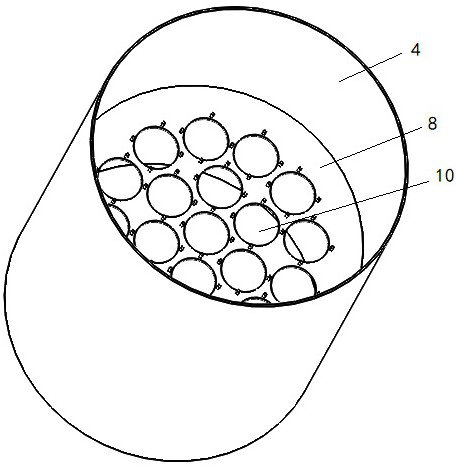

Dedusting filter bag cleaning equipment

ActiveCN112057969AReduce secondary pollutionReduce dust removal effectDispersed particle filtrationPower unitDust control

The invention relates to dedusting filter bag cleaning equipment which comprises a base, a power unit and a cleaning unit, the power unit is arranged on the upper surface of the base, and the cleaningunit is arranged on the power unit. The dedusting filter bag cleaning equipment can solve the problems that when a dust removal filter bag is cleaned at present, high-pressure gas is adopted to blowdust to the dust removal filter bag in an existing dust removal filter bag cleaning mode, due to the cleaning mode, dust on the dust removal filter bag is mixed with harmful substances to be blown toall places, impurities filtered off from through the dust removal filter bag cannot be effectively collected and treated, and due to the structure of the dust removal filter bags, high-pressure gas isused for being aligned with and directly blowing the dust removal filter bag, the dust removal filter bag is expanded, exhaust holes in the dust removal filter bag are enlarged, and thus, the dust removal effect of the cleaned dust removal filter bag can be reduced in the later use process, and the service life of the dust removal filter bag is directly shortened.

Owner:安徽智宇环保滤材有限公司

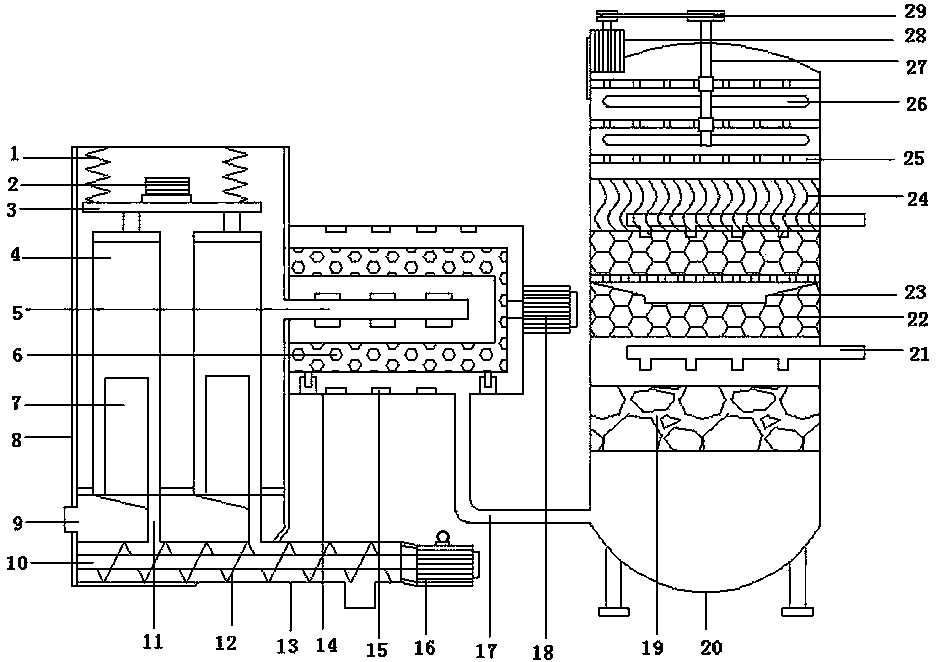

Waste tire treatment tail gas purification system

PendingCN108525413AReduce dust removal effectGood defogging effectGas treatmentDispersed particle filtrationEngineeringExhaust pipe

The invention provides a waste tire treatment tail gas purification system, characterized in that a plurality of cloth bags are arranged on the lower surface of a mounting plate, an inner pipe is arranged at the lower portion of each cloth bag, the lower left of a dust remover is provided with an intake port, the bottom end of the dust remover is provided with a conveyer, a dust removal sleeve isarranged between the inner pipes and the conveyer, an exhaust pipe is arranged in the right middle of the dust remover, the left of a second motor is provided with an interlayer having a plurality ofphotocatalyst spheres, the outer surface of the exhaust pipe and the inner wall of a purifier are provided with a plurality of ultraviolet lamps, the middle of a desulfurizing column is provided witha Pall ring layer, the middle of the Pall ring layer is provided with a liquid collection hood, the upper middle of the desulfurizing column is provided with a plurality of corrugated plates, the upper portion of the desulfurizing column is provided with a plurality of grilles, the left top of the desulfurizing column is provided with a third motor, the top center of the desulfurizing column is provided with a second spindle, a belt is arranged between the second spindle and the third motor, and a plurality of scrapers are arranged on the second spindle. The waste tire treatment tail gas purification system has significant dust removal effect and can treat harmful gas thoroughly.

Owner:曲靖市马龙区天龙橡胶制品有限公司

Textile machine spinning dust collecting device

ActiveCN110270175AAvoid cloggingTo achieve the effect of collecting dustDispersed particle filtrationTransportation and packagingEngineeringSpinning dust

A textile machine spinning dust collecting device comprises a main box, a gas inlet box and a material collecting box. A collecting net and a solid plate are arranged in the main box. A lifting plate is arranged on one side of the solid plate. A rack and a gear are arranged in an inner cavity of the lifting plate. A partition plate is arranged between the gas inlet box and the material collecting box. A ventilating long groove is formed in one side of the partition plate. An upper arc-shaped plate is fixed to the bottom of the collecting net. A fixed sleeve and a squeezing plate are fixed to the inner wall of the material collecting box. A spring is arranged between the outer wall of the squeezing plate and the inner wall of the material collecting box. A lower arc-shaped plate is arranged on the top of the squeezing plate. A material collecting groove is formed in the upper side of the fixed sleeve. An air suction fan is fixed to the side wall of the gas inlet box. A scraper is fixed to the inner wall of the material collecting box. A round hole is formed in the side wall of the material collecting box. By means of the textile machine spinning dust collecting device, spinning dust on the collecting net can be automatically cleaned away in time, and blockage is prevented; meanwhile, the spinning dust can be secondarily collected into a dust collecting cloth bag, secondary contamination during processing is prevented, labor intensity is lowered, and the dust removal effect is improved.

Owner:胡俏俊

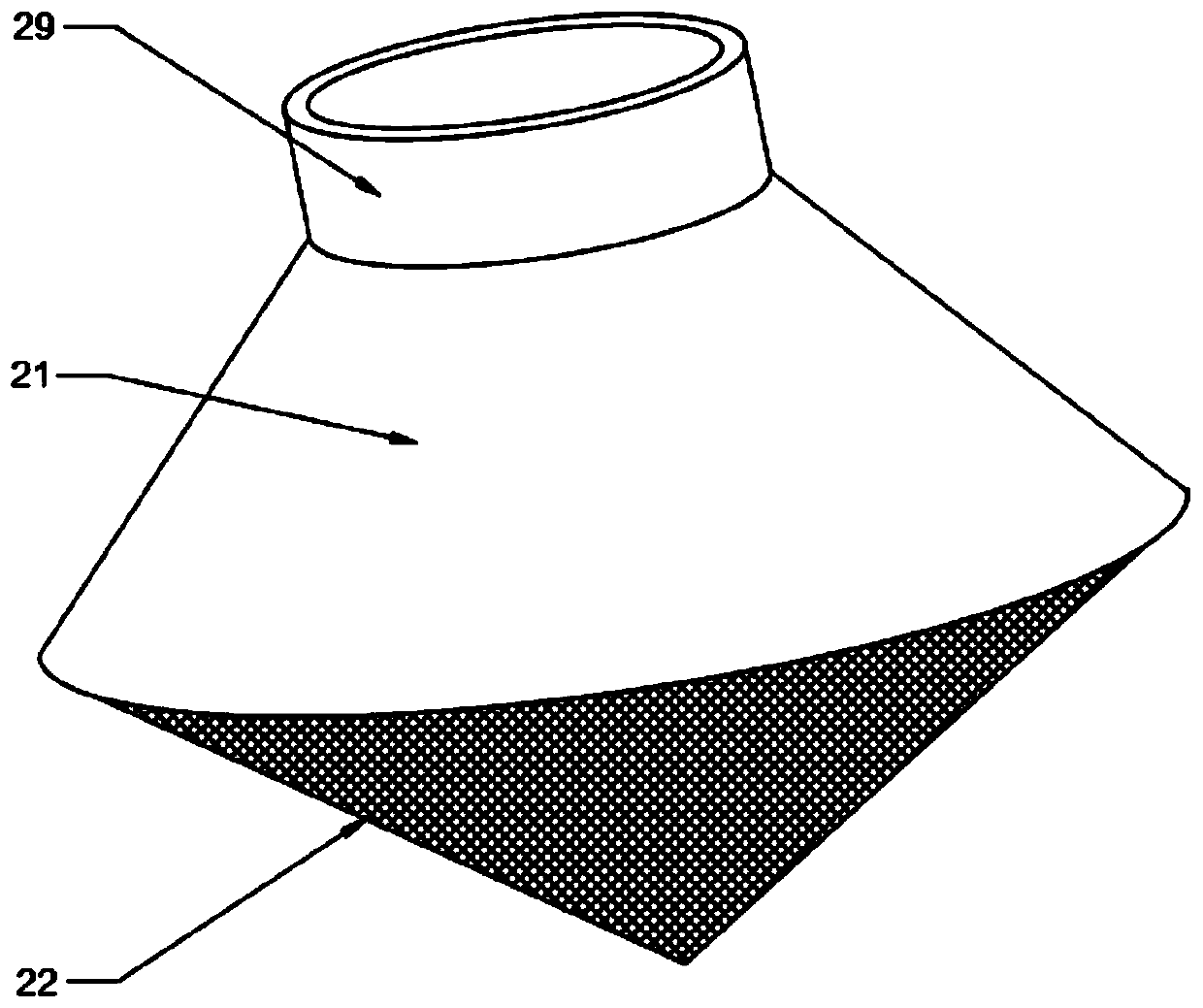

Environment-friendly breaker

InactiveCN107754984AExtended service lifeReduce replacement frequencyUsing liquid separation agentGrain treatmentsGear wheelDrive shaft

The invention relates to an environment-friendly breaker. The environment-friendly breaker comprises a breaking assembly, a power assembly, a dust removing assembly and a filtering assembly, wherein the dust removing assembly is partially arranged at the top end of the breaking assembly, and the filtering assembly is arranged at the lower end and on the right side of the breaking assembly; the power assembly is arranged on the right side of the breaking assembly and is connected with the breaking assembly through a transmission shaft and a bevel gear, and the breaking assembly comprises a feeding opening, a supporting rod, a movable cone, a movable cone bushing, a fixed cone, a fixed cone bushing, an eccentric sleeve, a discharging opening and a conveying belt; the movable cone bushing isarranged on the surface of the movable cone, the eccentric sleeve is arranged in the movable cone, the feeding opening is arranged at the upper part of the movable cone and fixed to the fixed cone bythe support rod, the discharging opening is arranged at the lower end of the left side of the fixed cone, and the conveying belt is arranged under the discharging opening; the power assembly comprisesa motor, a transmission shaft and a bevel gear, the motor is connected with the bevel gear through the transmission shaft, and the bevel gear is partially connected with the movable cone.

Owner:盐城市大丰匀力机械制造厂

LED factory lamp with air channel optimized through fin group applied to normal temperature state

PendingCN109556032AImprove cooling effectGuaranteed cleanlinessLighting heating/cooling arrangementsCleaning using toolsCooling effectEngineering

The invention discloses an LED factory lamp with an air channel optimized through a fin group applied to the normal temperature state, and belongs to the field of LED factory lamps. The LED factory lamp with the air channel optimized through the fin group applied to the normal temperature state comprises a lamp holder connected to the lower end of a mounting base through a connecting post, a lampbead is mounted inside the lamp holder, the air channel is arranged at the upper end of the lamp holder, the air channel comprises cooling fins, temperature variation type dust collecting mechanisms are arranged on two sides of the cooling fins, and each temperature variation type dust collecting mechanism comprises a dust collecting net, a specially-shaped dust collecting movable plate and a temperature variation rod. According to the technical scheme, the surface of the lamp holder is arranged to be the fin group, so that the cooling air channel of the lamp body is optimized, in addition, the temperature variation type dust collecting mechanisms are arranged on the surfaces of the cooling fins in the fin group from, the temperature variation type dust collecting mechanisms can be used for carrying out automatic dust colleting on the surfaces of the cooling fins during the work process of the LED factory lamp, so that the cleanness of the surfaces of the cooling fins is maintained, therefore, the good cooling effect of the cooling fins is guaranteed, and further, the service life of the LED factory lamp is prolonged.

Owner:江苏新西贝机电有限公司

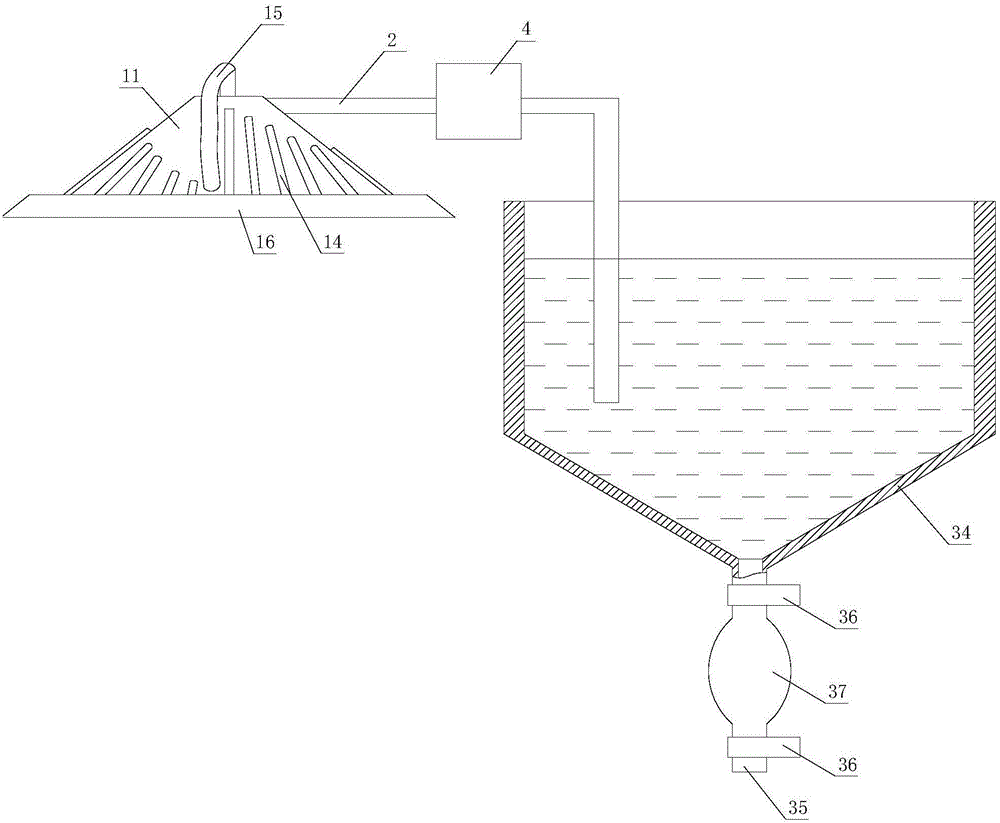

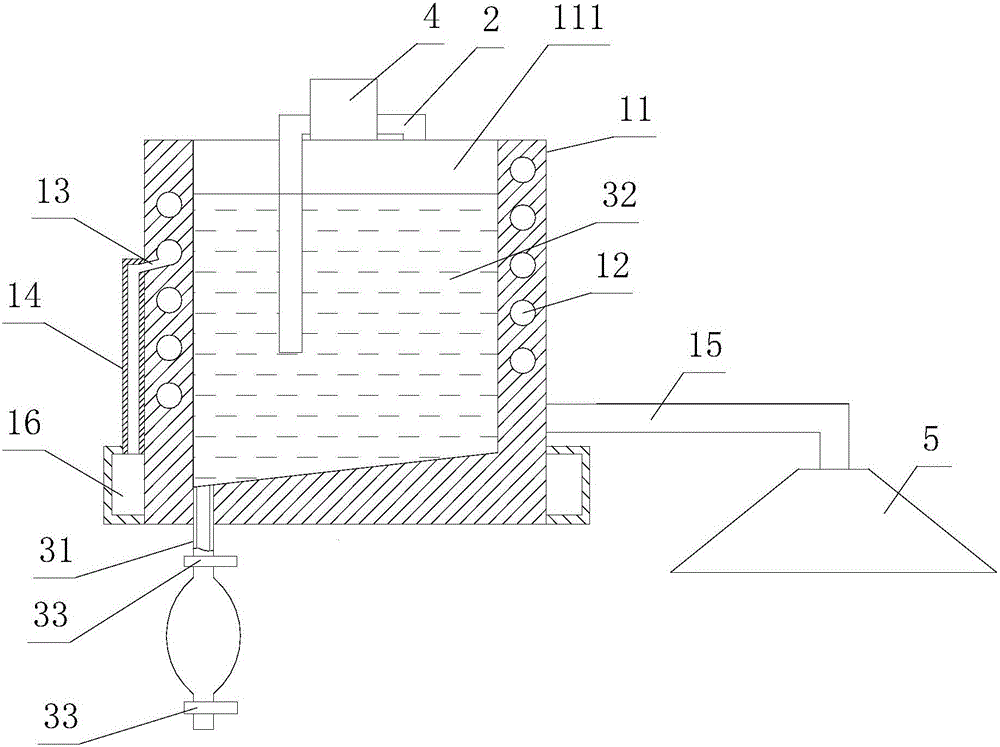

Dust remover for processing sandstone aggregate

ActiveCN112316626ACan be recycledIncrease oxygen contentCombination devicesWaste water treatment from gaseous effluentsDust controlEnvironmental engineering

The invention discloses a dust remover for processing sandstone aggregate. The dust remover comprises a purification water tank and is characterized in that a dust suction pipeline is installed on theleft side of the purification water tank, a dust suction opening is formed in the top of the dust suction pipeline, a dust suction fan is installed in the middle of the dust suction pipeline, an airoutlet is formed in the right side of the purification water tank, the height of the air outlet is higher than that of the dust suction opening, a water tank dust removal device is installed in the purification water tank, dust collection electrodes are evenly installed at the bottom of the water tank dust removal device, each dust collection electrode comprises a dust collection electrode bar, dust collection electrode plates are evenly installed on the surface of each dust collection electrode bar, a rotary dust collection plate is installed at the bottom of the purification water tank, rotary dust collection electrodes are evenly installed in the middle of the rotary dust collection plate, a dust collection box is installed below a switch valve, and a dust collection electrode is installed at the bottom of the dust collection box. The dust remover has the characteristics of being high in practicability and capable of recycling dust.

Owner:JIANGSU JINENGDA ENVIRONMENTAL ENERGY SCI & TECH

Environment-friendly dust removal device for atmospheric control

InactiveCN111544997AEasy to settleEasy to moveCombination devicesStationary filtering element filtersDust controlStructural engineering

The invention discloses an environment-friendly dust removal device for atmospheric control. The environment-friendly dust removal device comprises a base, a dust removal box and a water tank; the dust removal box is arranged at the upper end of the base, a first fan is arranged in the middle of the top end of the dust removal box, and a first ventilation pipe is arranged at the top end of the first fan; a water tank is arranged at the inner bottom of the dust removal box, a first spraying pipe is arranged at the top end of the inner side of the dust removal box, and first nozzles are arrangedat the bottom end of the first spraying pipe; a limiting pipe is mounted at the bottom of the first fan; a second spraying pipe is mounted on the inner side of the limiting pipe; second nozzles are mounted on the outer side of the bottom end of the second spraying pipe; dustproof cloth is arranged between the outer side of the bottom of the limiting pipe and the inner side of the upper end of thewater tank; a first filter screen is arranged on the inner side of the top end of the water tank, a second filter screen is arranged in the middle of the inner side of the water tank, a second ventilation pipe is arranged on the right side of the upper end of the water tank, and a third filter screen and a second fan are arranged on the inner side of the second ventilation pipe. The dust removaldevice is reasonable in structure, dust in air can be conveniently precipitated, dust of different sizes can be conveniently coped with, and the dust removal efficiency is effectively improved.

Owner:GUANGZHOU BAOYUAN ECONOMY ENVIRONMENTAL POLLUTION SCI & TECH CO LTD

Water circulation device used for building construction

InactiveCN110314444AReduce the temperatureReduce dust removal effectFiltration circuitsWater circulationEngineering

The invention discloses a water circulation device used for building construction. The device is characterized by including a separation chamber, a circulation chamber and a water conveying mechanismfor connecting the separation chamber with the circulation chamber, wherein the upper end of the separation chamber is provided with a material inlet and a material distributing opening, the inner side of the separation chamber is provided with a filter screen plate, the material distributing opening is formed below the filter screen plate, the separation chamber includes an upper separation chamber body and a lower separation chamber body, the lower separation chamber body is connected with an air blower, a connecting pipe and an air distribution pipe, the air blower is connected with the airdistribution pipe through the connecting pipe, the pipe wall of the air distribution pipe is evenly provided with a plurality of air outlets, and the lower separation chamber body is provided with asewage outlet. The structure is simple, outside resources can be effectively used, and thus energy is saved.

Owner:筑邦建设集团股份有限公司

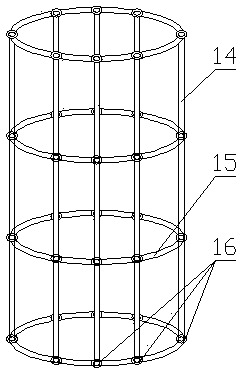

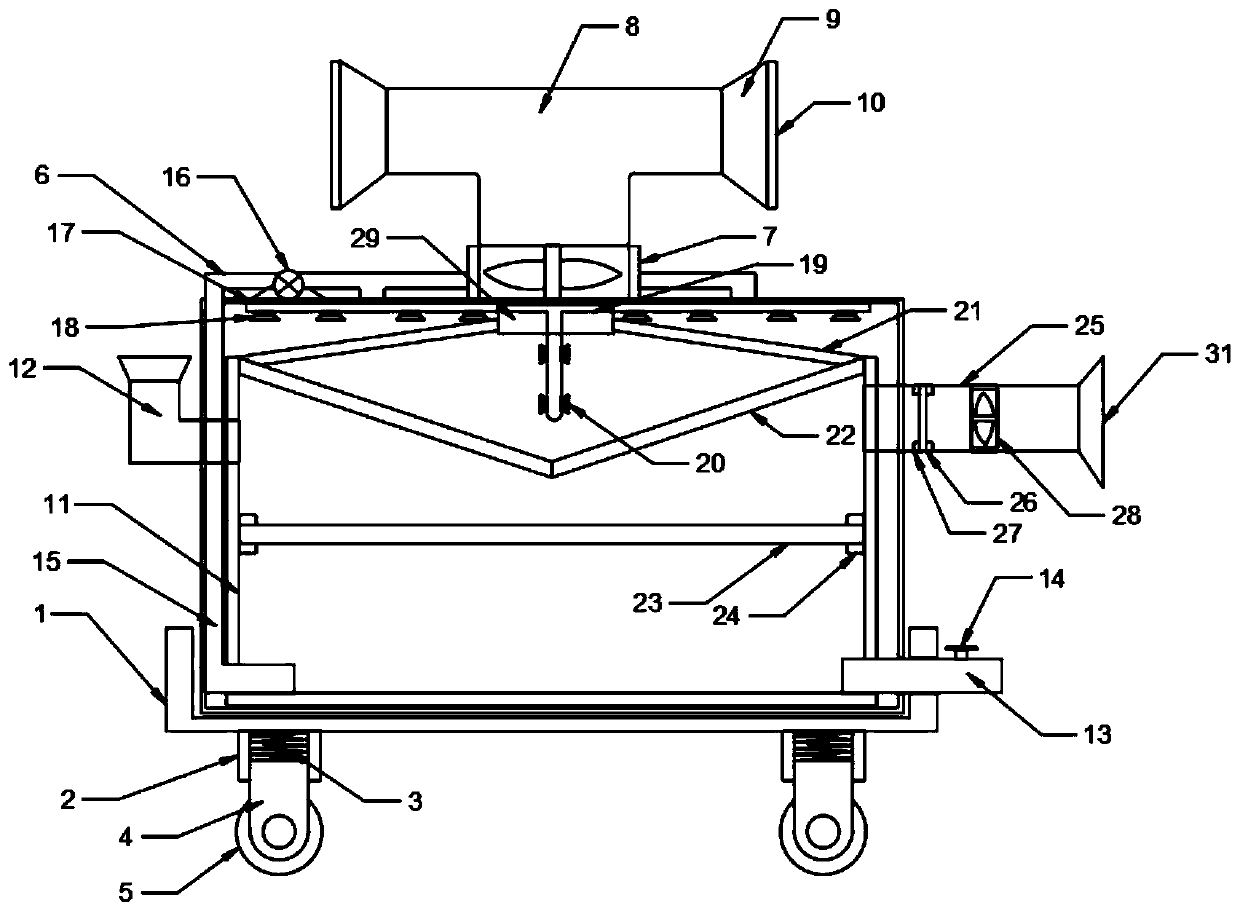

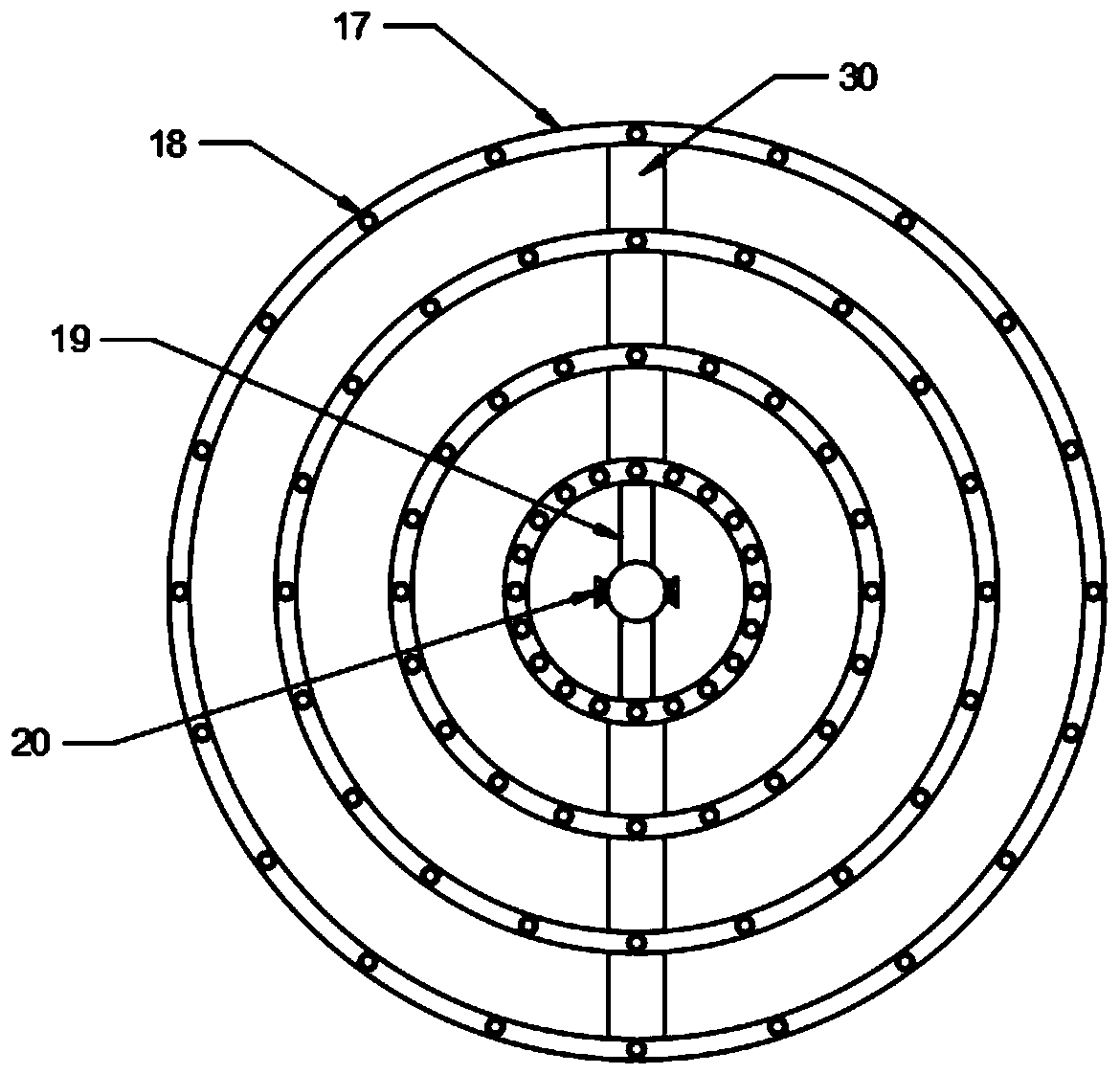

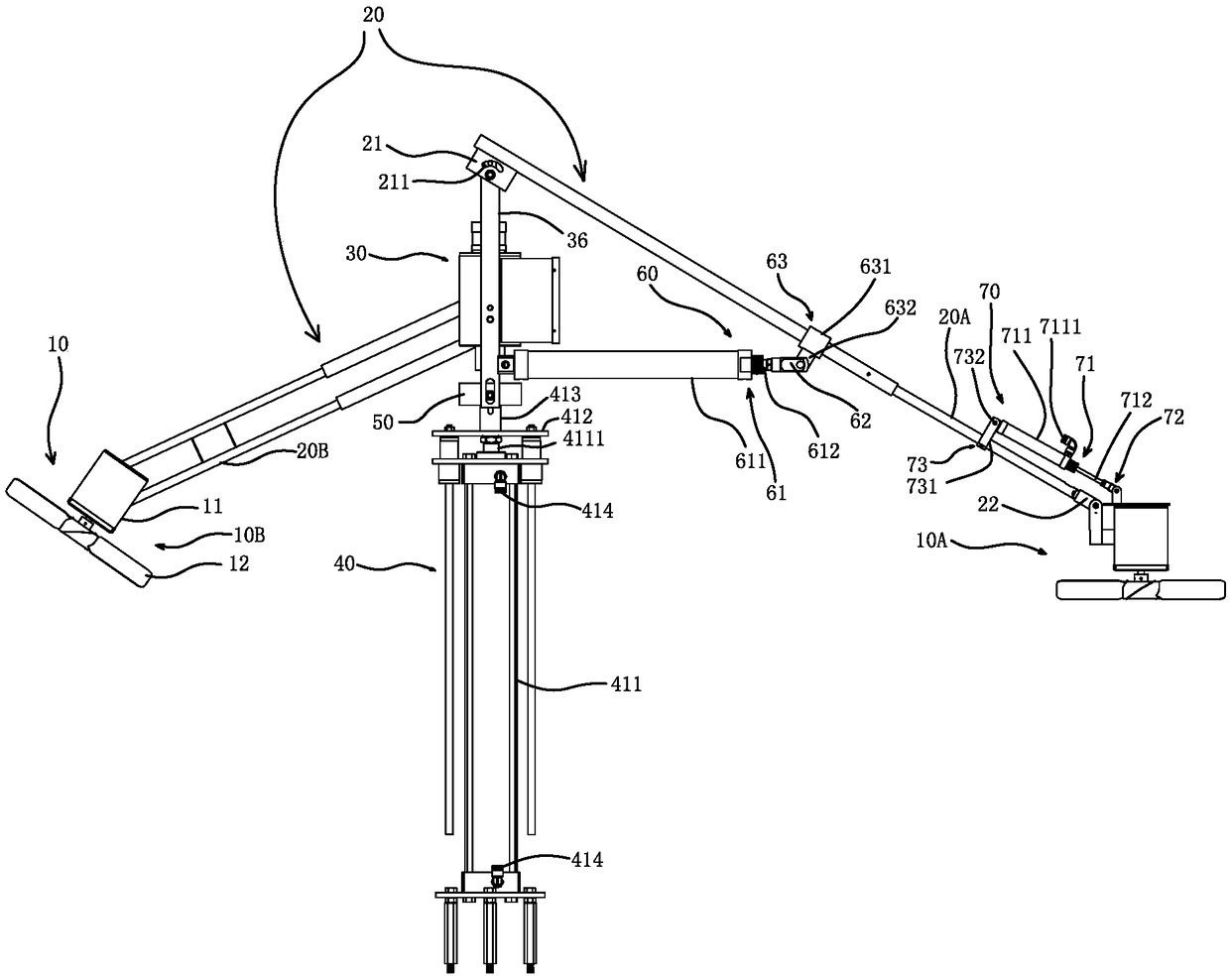

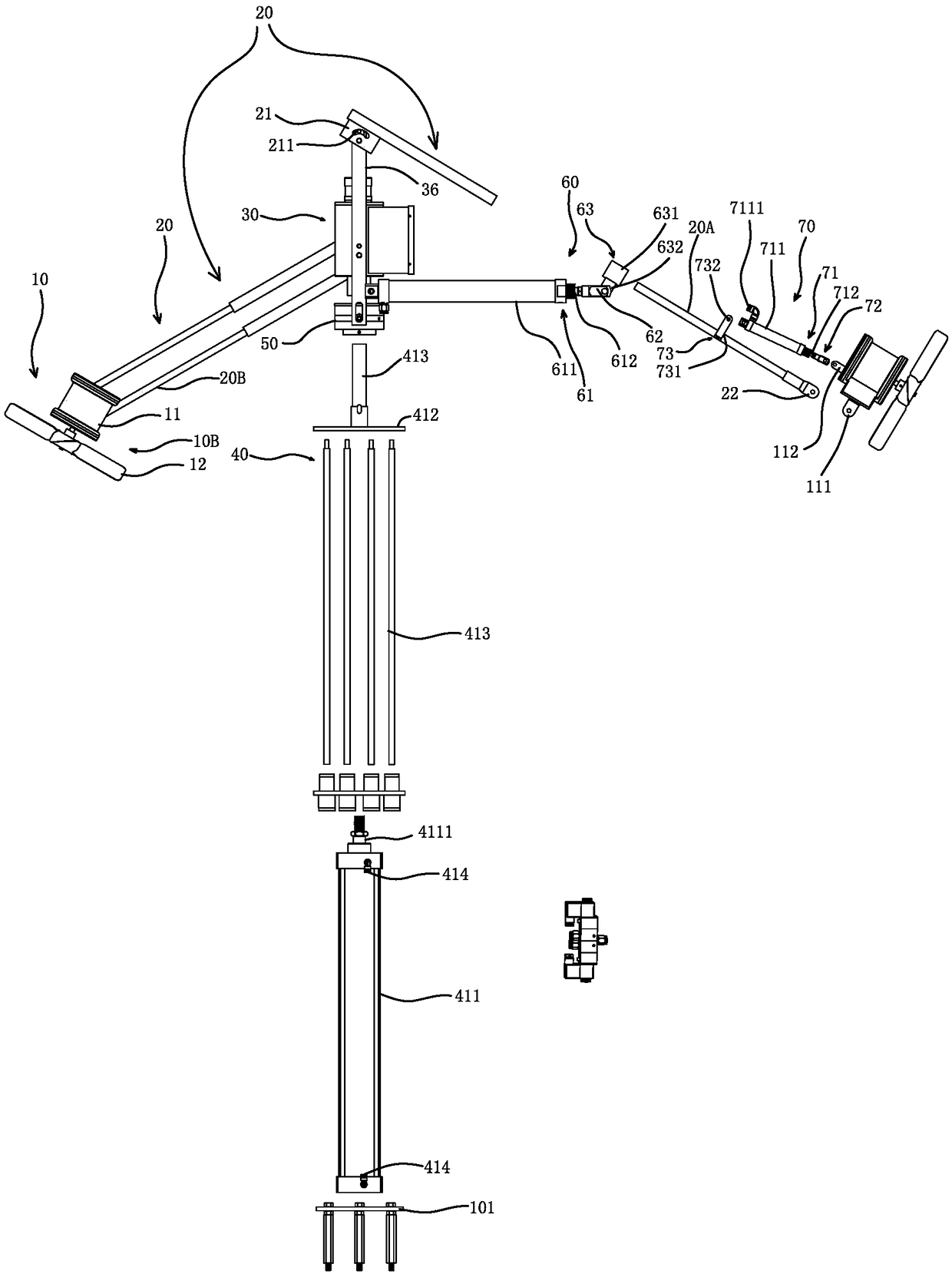

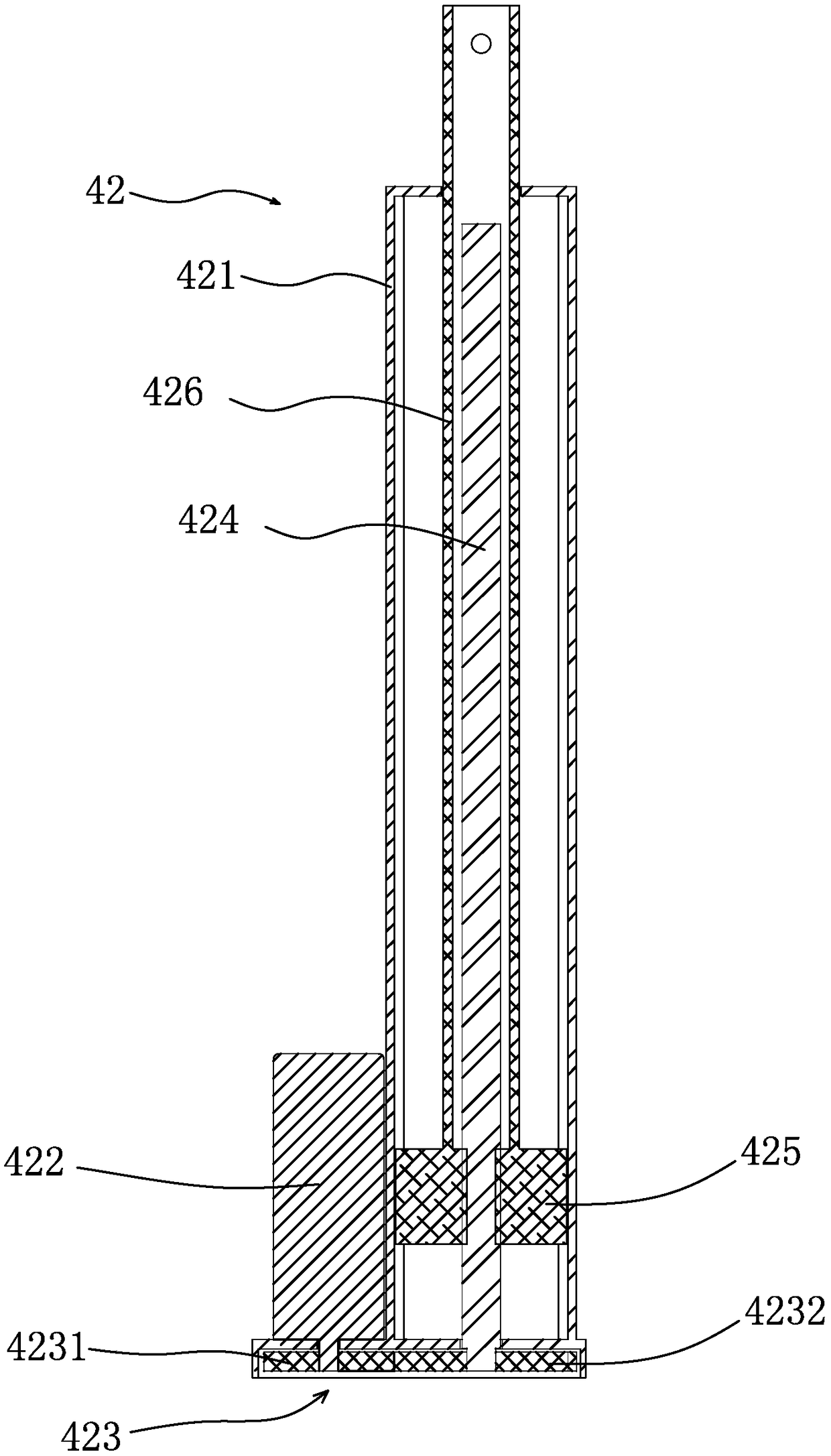

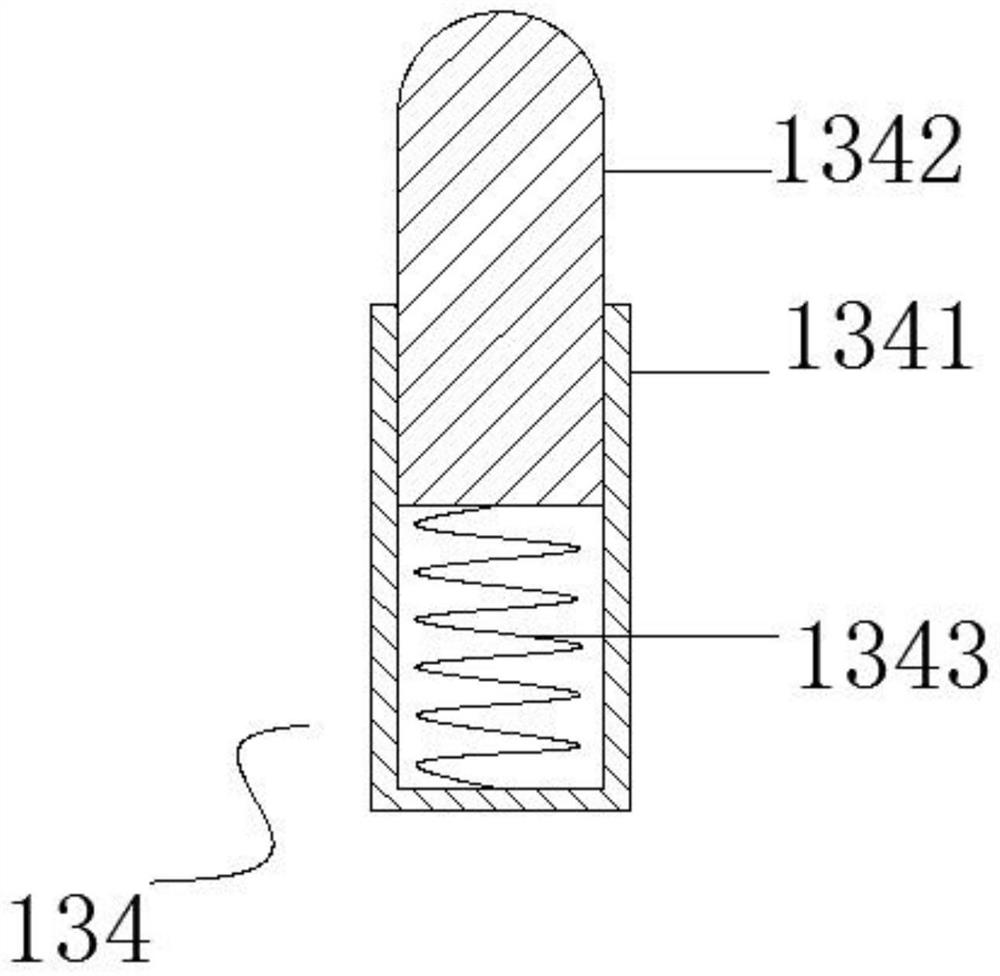

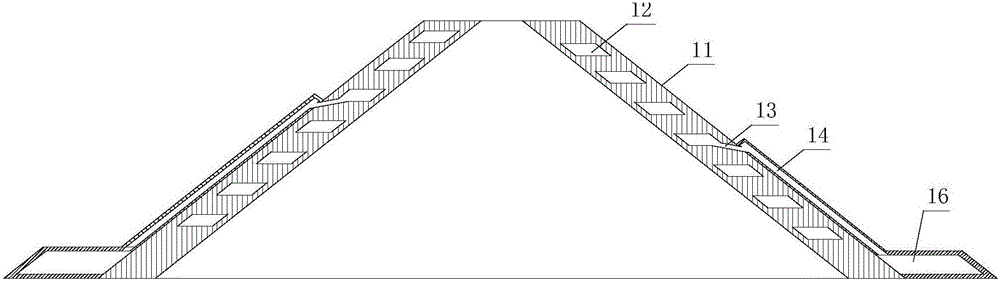

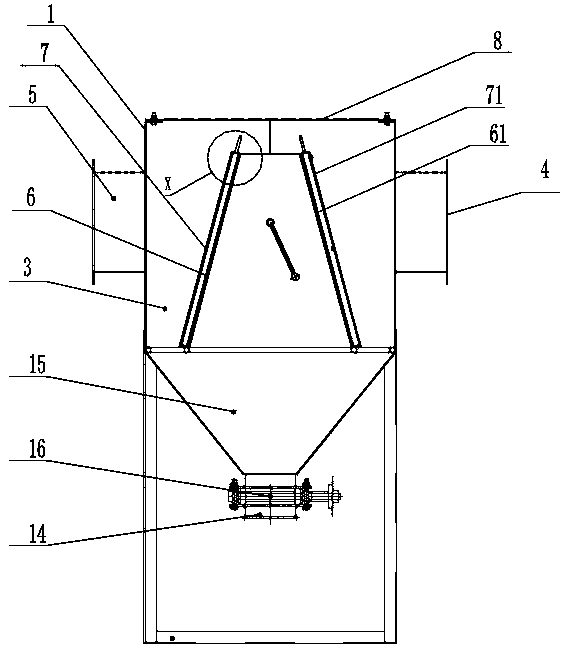

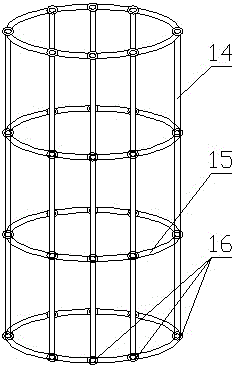

Knitting machine dust removing device capable of lifting and changing rotating angle

The invention relates to a knitting machine dust-removing device capable of lifting and changing the rotating angle, which includes at least one group of dust-removing fans, and the dust-removing fanscan swing up and down by using a central rotating body as a pivot while rotating around the central rotating body along the circumferential direction to adjust the rotating angle to a set rotating angle; a lifting mechanism, wherein the lifting mechanism can push the central rotating body and the dust removing fans to move up and down to different dust removal parts of the knitting machine; an air intake rotating complex, wherein the air intake rotating complex is connected with the central rotating body and the lifting mechanism; a fan connecting rod angle changing mechanism, wherein the fanconnecting rod angle changing mechanism is respectively connected with the fan connecting rod and the air intake rotating complex; a fan angle changing mechanism, wherein the fan angle changing mechanism is respectively connected with the fan connecting rod and the dust removing fans; a control mechanism, wherein the control mechanism is respectively connected with the central rotating body, thelifting mechanism, the air inlet rotating complex, the fan connecting rod angle changing mechanism and the fan angle changing mechanism, so as to control the starting or stopping of the central rotating body, the lifting of the lifting mechanism, and the rotating angles of the fan connecting rod and the dust removing fans.

Owner:YANCHENG WANDALI KNITTING MACHINERY

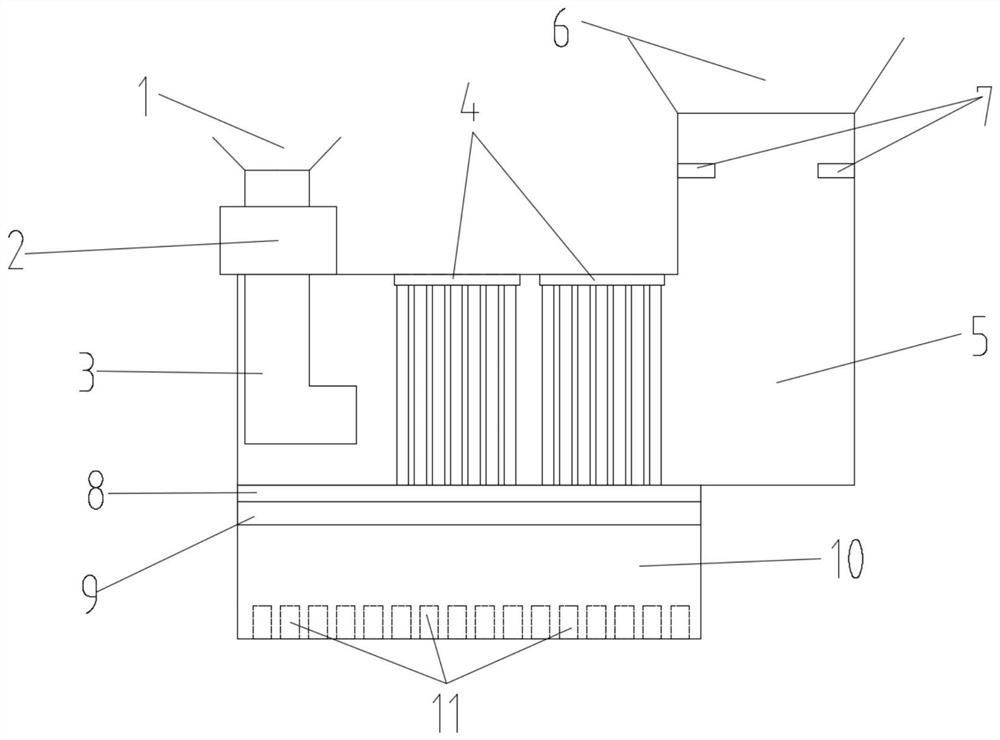

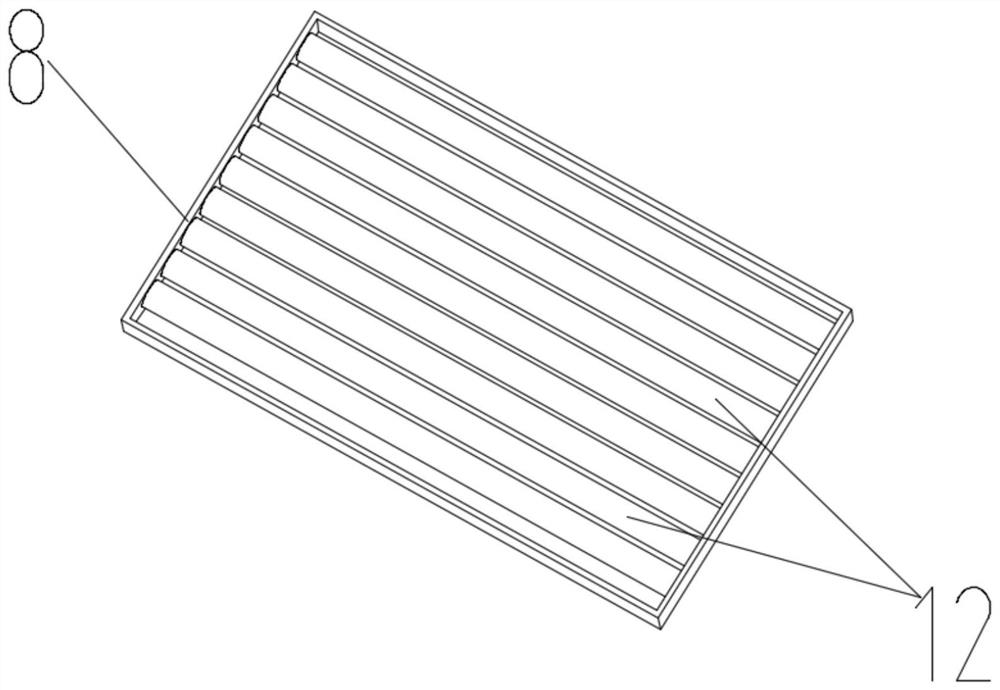

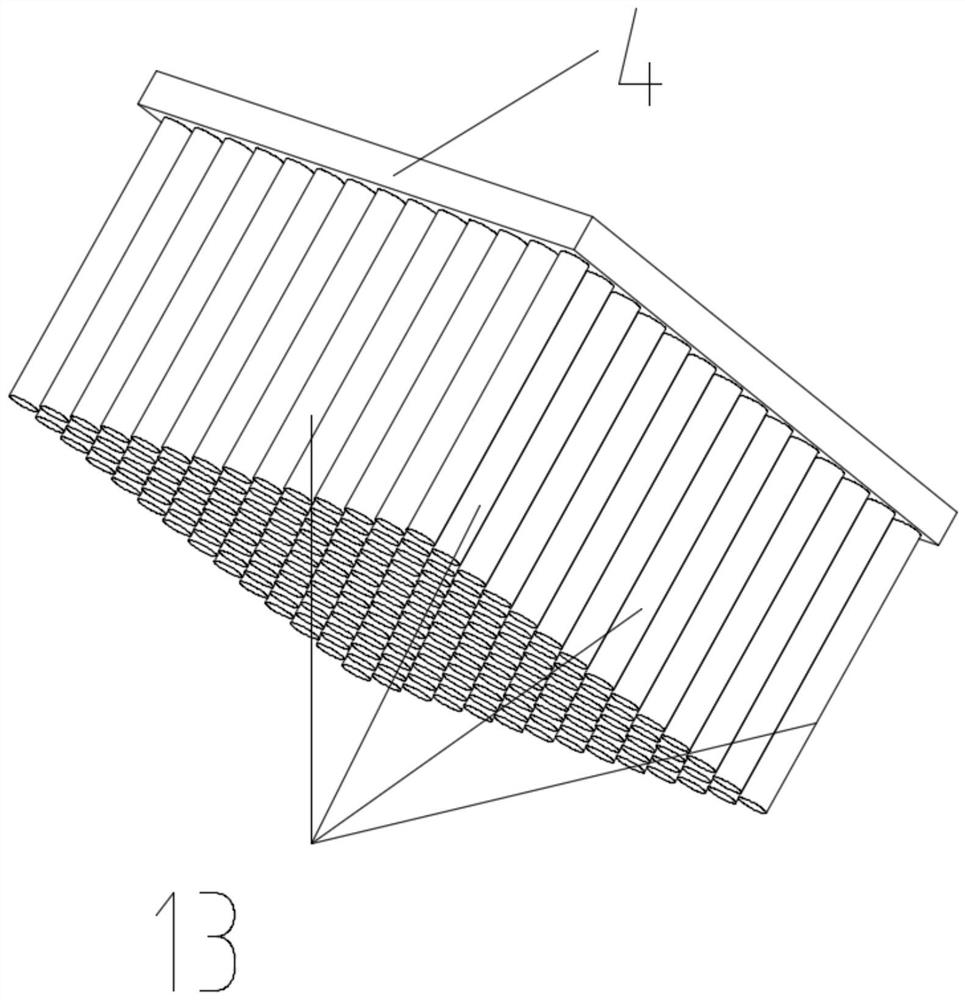

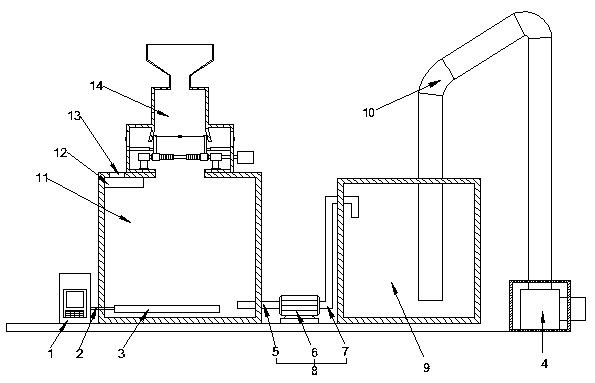

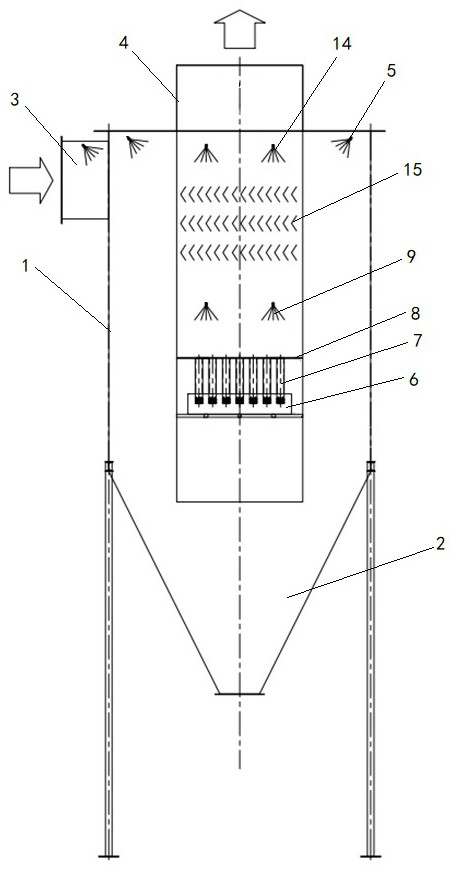

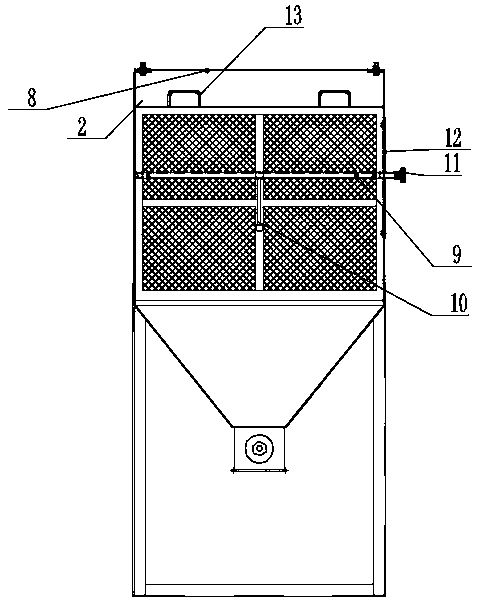

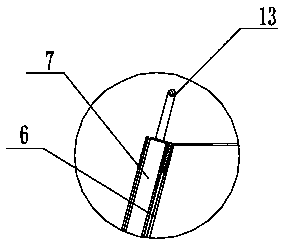

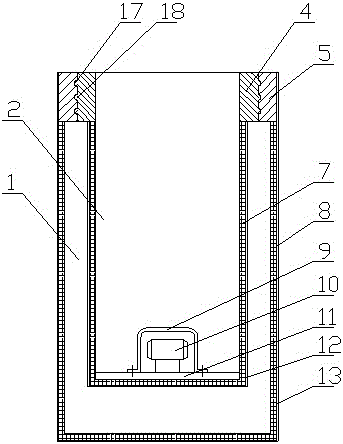

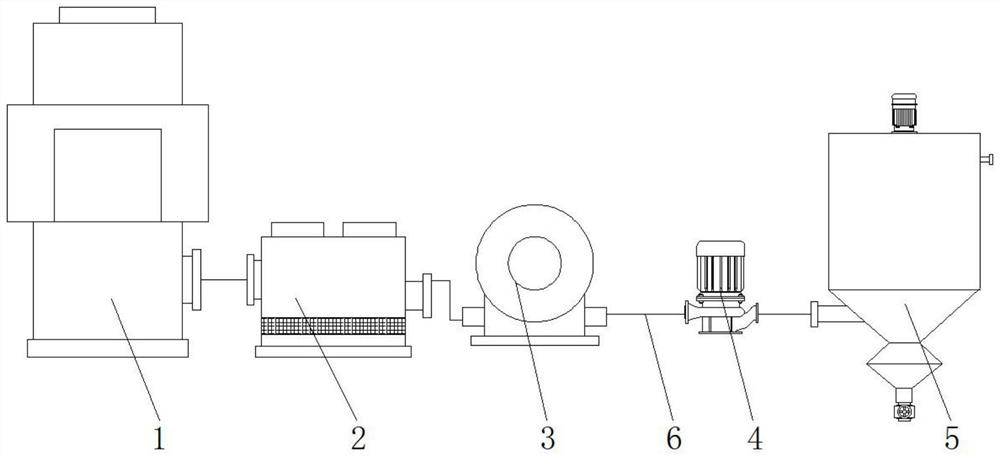

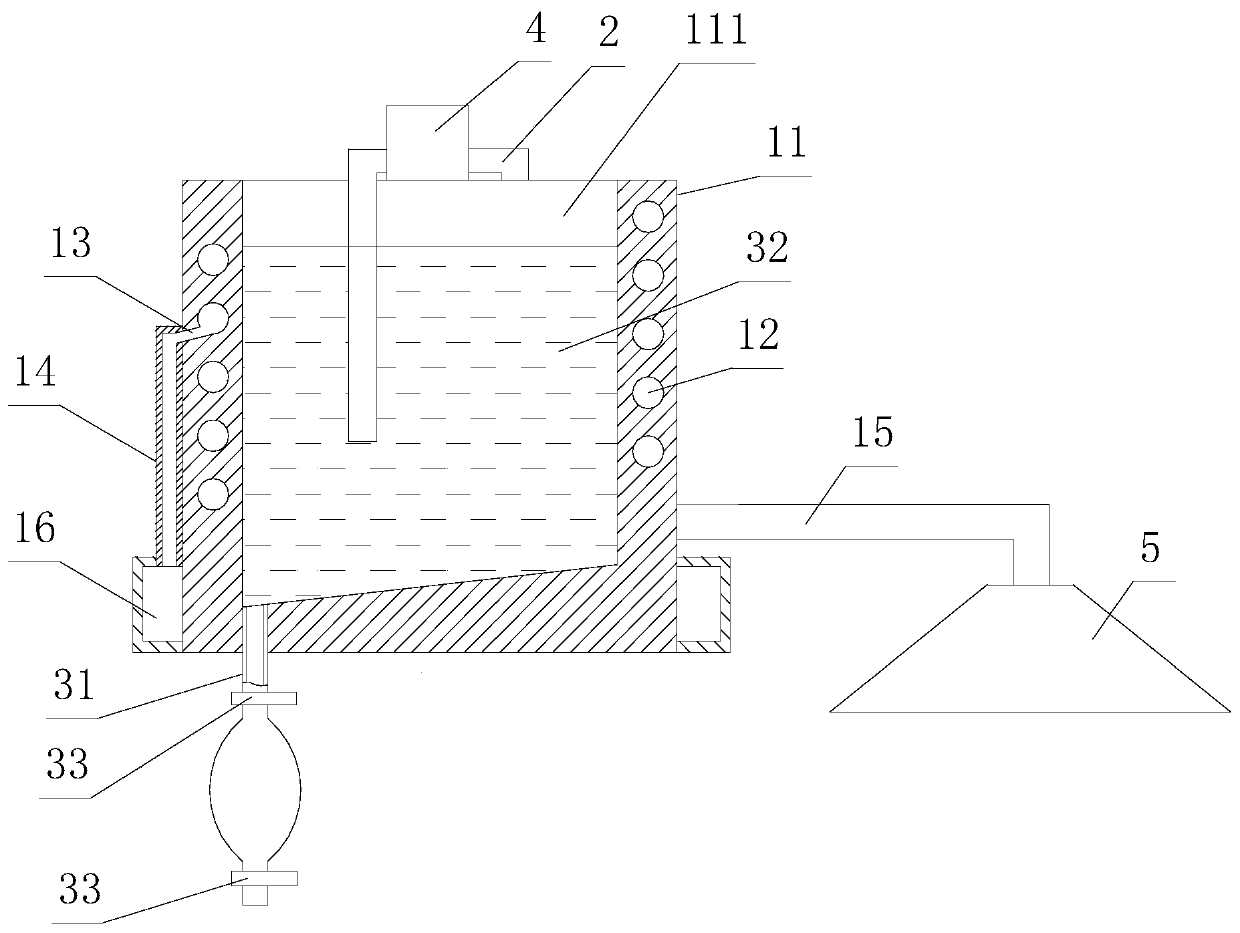

Blast furnace top dust-collecting equipment

ActiveCN101265509ASimple structureReduce energy consumptionDust arrestersEnergy consumptionMechanical engineering

The invention discloses a blast furnace top dust removing plant, which comprises a blower (1), a motor (2), a dust catcher (5) and an obturation exhaust hood (6). The obturation exhaust hood (6) is arranged at the head of an adhesive tape machine (13). The blower (1) is driven by the motor (2). A first pipe (10) is arranged at the outlet of the obturation exhaust hood (6), and the other end of the first pipe (10) is connected with the inlet of the dust catcher (5). The blower (1), the motor (2) and the dust catcher (5) are all arranged on the platform of a blast furnace top (11). A second pipe (4) is arranged between the outlet of the dust catcher (5) and the blower (1). The blast furnace top dust removing plant has the advantages that the structure is simple, the investment is low and the energy consumption is low. At the same time the recycled dust is directly used and the cycled integrated utilization of resources is realized.

Owner:HUATIAN ENG & TECH CORP MCC

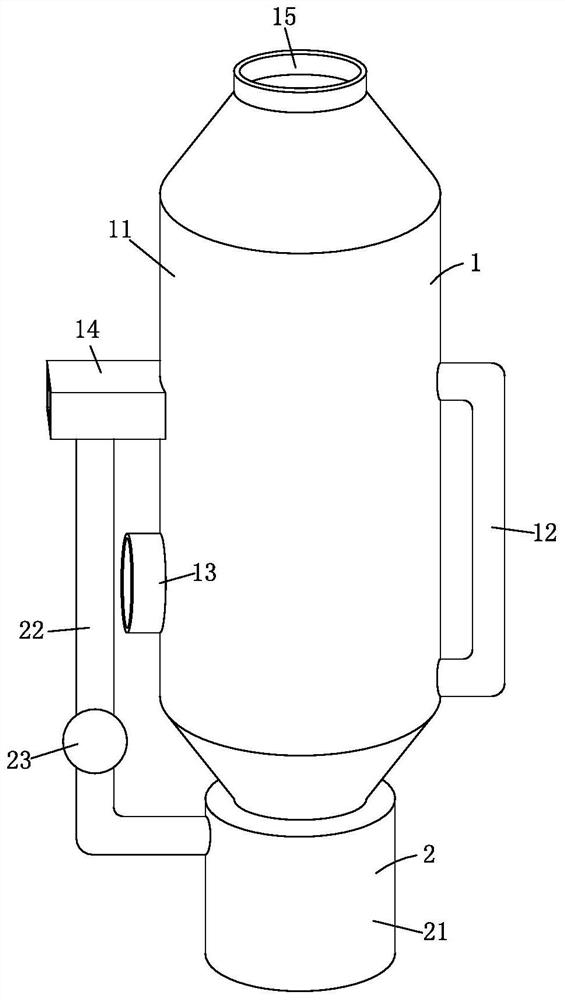

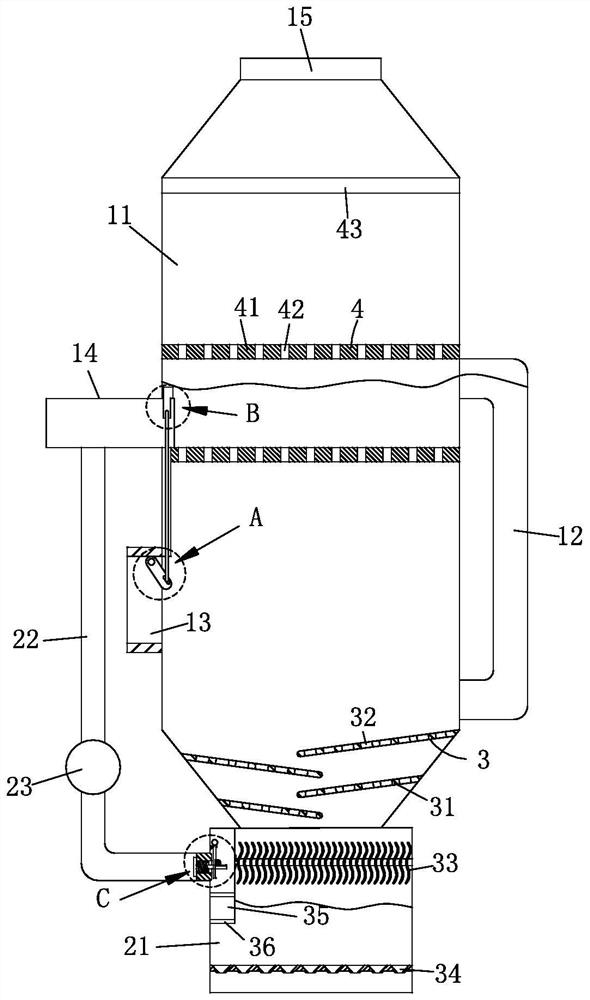

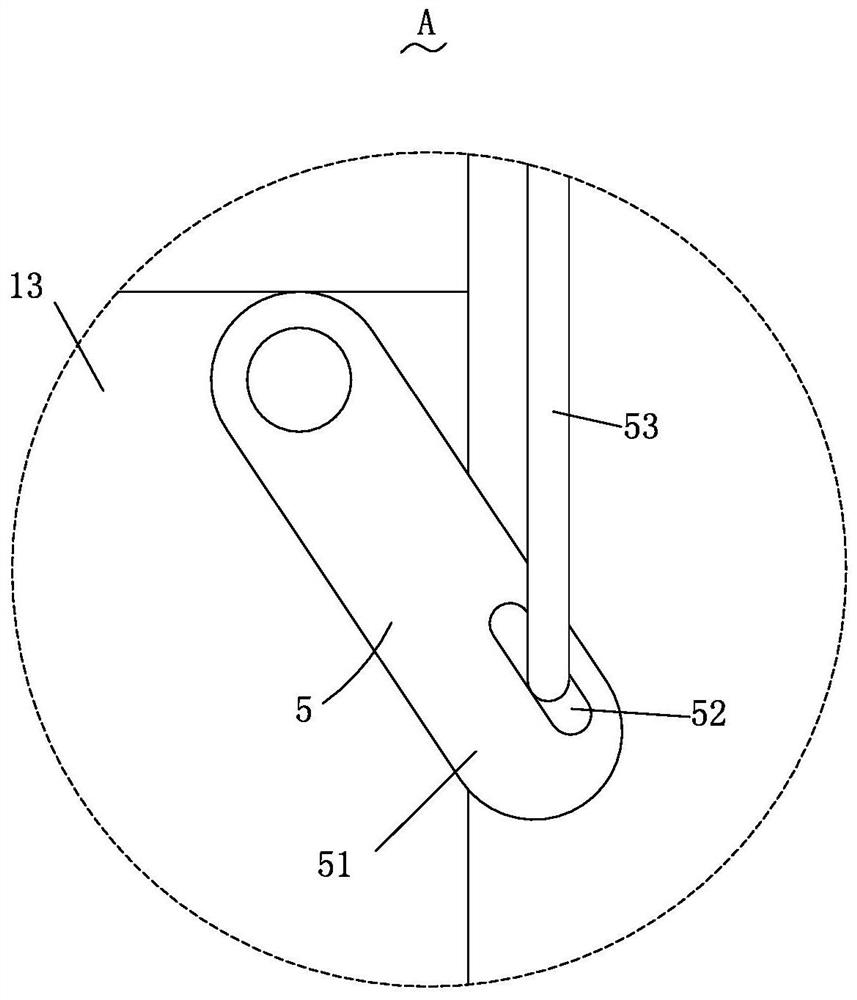

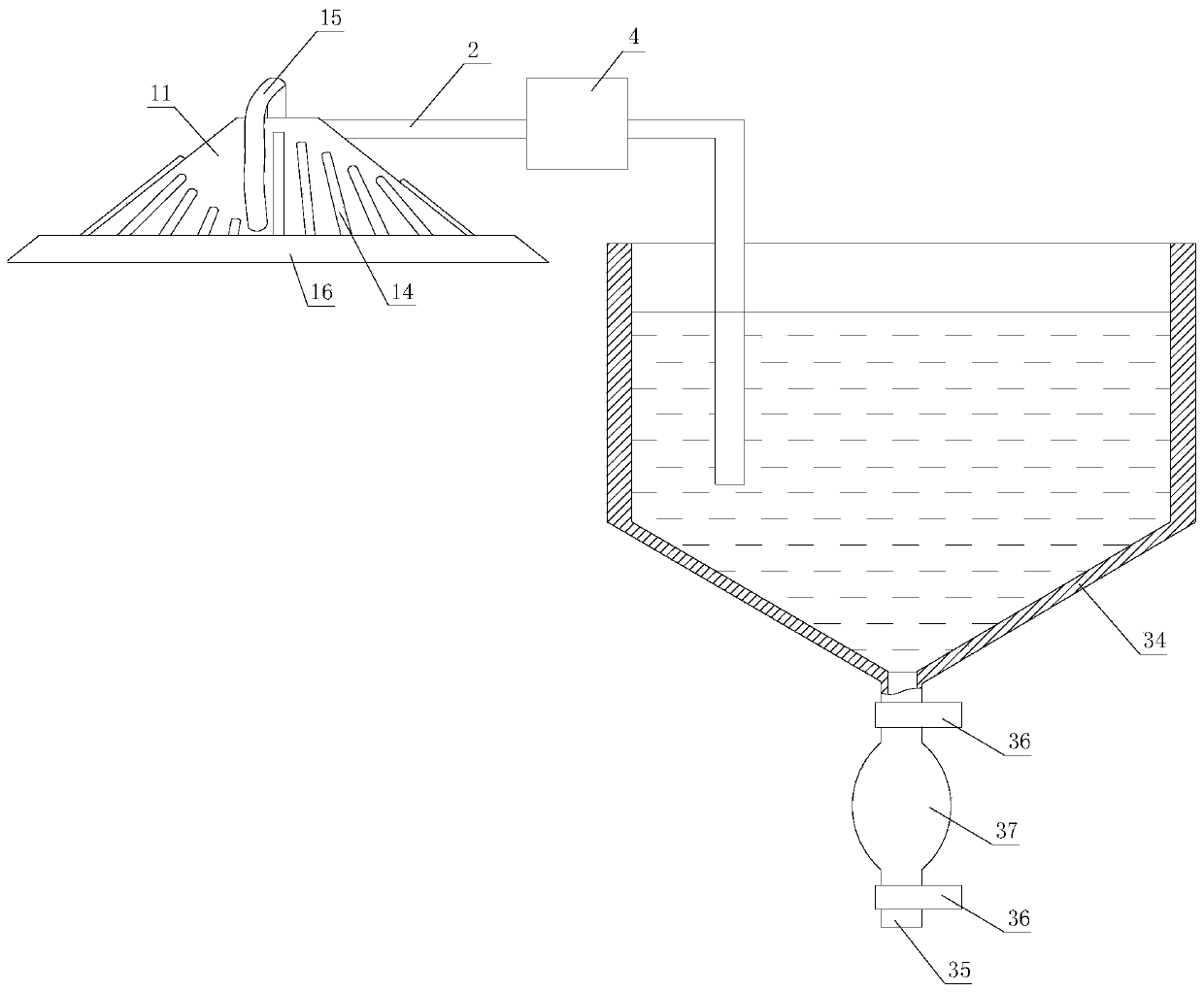

Integrated water bath wet cyclone dust collector

PendingCN114797347AIncrease flow rateReduce areaCombination devicesHuman health protectionEngineeringEnvironmental geology

The invention discloses an integrated water bath wet cyclone dust collector which comprises a cyclone cylinder, a tangential air inlet is formed in the side wall of the cyclone cylinder, an air guide pipe is arranged in the middle of the cyclone cylinder, the air guide pipe extends out of the top of the cyclone cylinder, a water bath module is arranged in the air guide pipe, and the tangential air inlet is formed in the side wall of the cyclone cylinder. The water bath module comprises a water bath pool, a water bath pipe and a partition plate, the partition plate is fixedly connected with the inner wall of the air guide pipe, the space in the air guide pipe is divided into an upper pipe part and a lower pipe part by the partition plate, a plurality of through holes are formed in the partition plate, and the water bath pool is fixed in the lower pipe part of the air guide pipe; an air flow channel is reserved between the water bath pool and the inner wall of the air guide pipe, the top of the water bath pipe is fixedly connected with the partition plate and is aligned to the through hole, the bottom of the water bath pipe is arranged in the water bath pool, and the upper pipe part of the air guide pipe is provided with a water bath spraying pipe for spraying towards the partition plate. The device is small in occupied area, and the dust removal efficiency is effectively improved.

Owner:JIANGSU XINHUANENG ENVIRONMENTAL ENG CO LTD

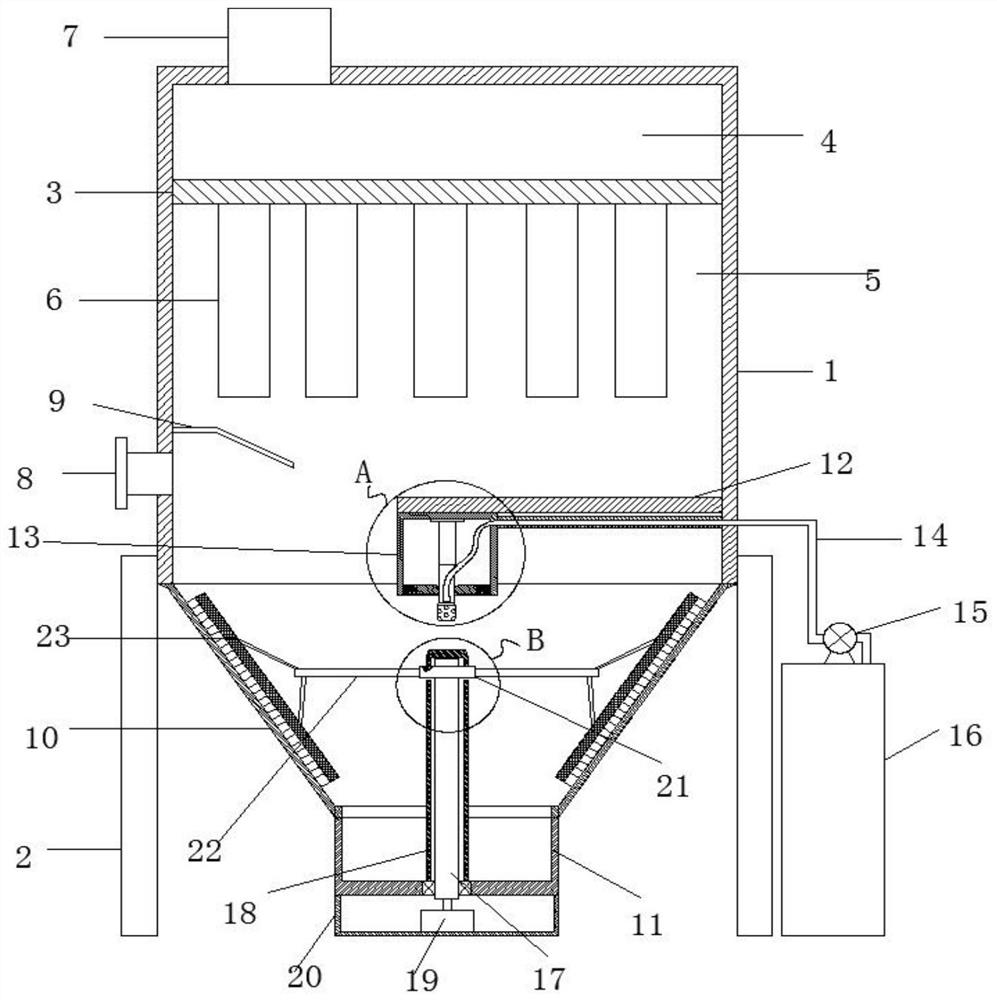

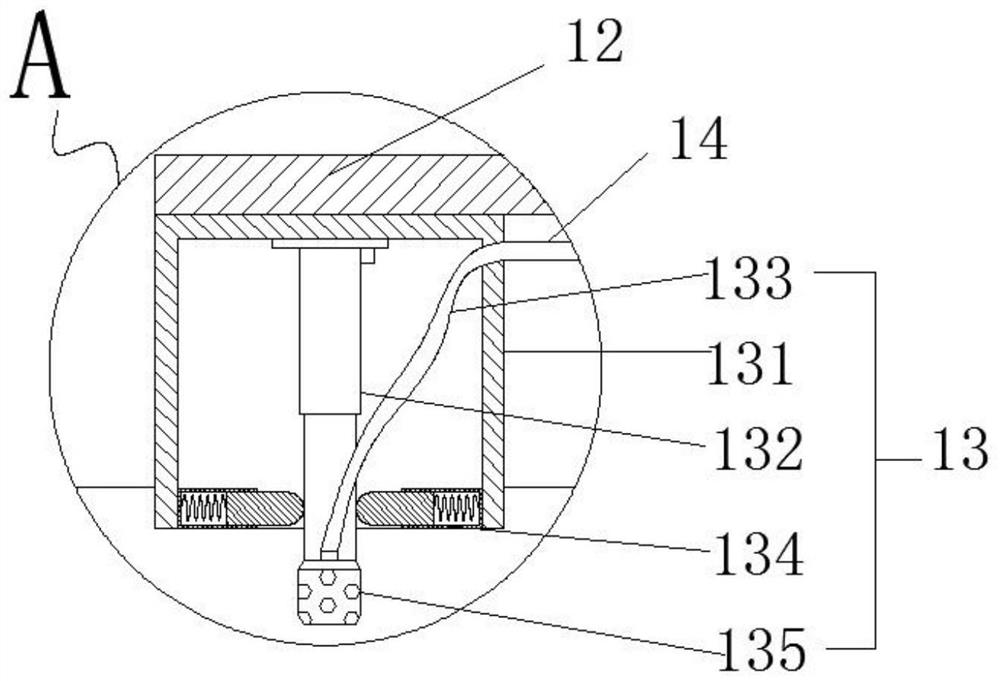

A filter cartridge dust collector equipped with an ash hopper sprinkler

ActiveCN109289381BImprove dust removal effectReduce dust removal effectDispersed particle filtrationMembrane filtersDust controlEnvironmental engineering

The invention discloses a filter cartridge dust collector equipped with an ash hopper cleaning device in the technical field of waste gas dedusting. , the flower plate divides the inner cavity of the box into a dust filter chamber and a clean air chamber, and the bottom of the flower plate is uniformly provided with a filter cartridge, and the present invention can clean the inner wall of the ash hopper by brushing through the provided rotating brush plate structure, and at the same time through The set sprinkler structure sprays water or washing liquid to greatly improve the dust removal effect of the brush plate, so that the inner wall of the ash hopper can be cleaned regularly to avoid the reduction of the dust removal effect of the equipment. The structure of the contact nozzle can avoid the problem that the nozzle is blocked by dust and the water spray effect is not good. The dust-proof sleeve device can greatly reduce the dust in contact with the rotating shaft and reduce the cleaning force of the device.

Owner:郭庆平

Concrete curing bag and manufacturing technology thereof

InactiveCN108452615AImprove filtering effectReduce impactCombination devicesDispersed particle filtrationSpray nozzleAirflow

The invention relates to a concrete curing bag and a manufacturing technology thereof. The concrete curing bag is formed by an outer bag and an inner bag, the outer bag comprises an outer dedusting cloth, an outer skeleton and an outer check ring, the inner bag comprises an inner dedusting cloth, an inner skeleton, an inner check ring, a vibrating motor, an electric dedusting barrier, an impulse backflush spray nozzle, a base plate and a motor cover, the electric dedusting barrier is arranged at the upper part of the inner bag, the impulse backflush spray nozzle is arranged at the center of the electric dedusting barrier, the base plate is arranged at the bottom of the inner bag, the vibrating motor is arranged on the base plate, and the inner bag is in threaded connection with the outer bag. The concrete curing bag combining pulse airflow with vibration has strong cleaning and curing ability.

Owner:长沙水能量新材料有限公司

Dust collection device for pyrophyllite breaking system

The invention provides a dust collection device for a pyrophyllite breaking system with an aim to solve the problem that air quality is affected by dust generated in the process of pyrophyllite breaking in the prior art. The dust collection device comprises a dust collector, an escape pipe, a draught fan and a water dust collector; the dust collector comprises a body, dust collection grooves and a connecting pipe, spiral channels are arranged in the body, dust collection channels are arrayed in inner bottoms of the channels, each dust collection channel is connected with a dust collection pipe at the lower end, each dust collection pipe is connected with one dust collection groove at the lower end, and the lower outer lateral wall of the body is encircled with the dust collection grooves. Under the action of centrifugal force, dust particles larger than air in density are thrown to side walls of the channels; under the action of the lateral-wall friction resistance, dust falls upon the bottoms of the channels and falls into the dust collection channels when moving slowly to the dust collection channels along the bottoms of the channels, the dust falling into the dust collection channels falls into the dust collection grooves via the dust collection pipes, and dusty air is treated through the dust collection channels and purified.

Owner:邵阳市东昇超硬材料有限公司

Dust removal cloth bag structure for industrial cloth bag dust removal device

InactiveCN112915666AFall assistRealize the isolation functionDispersed particle filtrationTransportation and packagingSuction forceDust control

The invention provides a dedusting cloth bag structure for an industrial cloth bag dedusting device, and relates to the field of industrial dedusting. The dedusting cloth bag structure comprises a locking ring, the outer side of the locking ring is provided with a plurality of groups of clamping bolts, the bottom end of the locking ring is provided with a shaping frame, and the outer side of the shaping frame is provided with an isolation cloth bag; the inner side of the isolation cloth bag is movably connected with a locking ring through a clamping bolt, a bottom frame is installed at the bottom end of the shaping frame, the bottom frame is movably connected with the inner side of the bottom end of the shaping frame, a chassis base is installed at the bottom end of the bottom frame, and a clamping groove is formed in the side penetrating through a driving clamping ring. The problems that in the using process of the dust collecting bag, too much dust and sundries with high adhesiveness adhere to the outer side of the bag, so the dust collecting effect is reduced due to the fact that suction force is reduced, and the utilization rate and the service life of the cloth bag are relatively low due to the fact that the static dust collecting bag is prone to causing height loss of part of the position and lack of use of part of the position are effectively solved.

Owner:程正文

Cremation machine tail gas spark blocking device and method

PendingCN110841388AReduced dust removal efficiencyReduce use costDispersed particle filtrationTransportation and packagingEngineeringDust control

The invention relates to a cremation machine tail gas spark blocking device and method. The device comprises an upper box body, the upper box body comprises a left side plate, a right side plate, a front side plate and a rear side plate, the left side plate and the right side plate are respectively provided with an air inlet and an air outlet, a first sliding rail is fixedly connected to the innerwall of the front side plate, a second sliding rail corresponding to the first sliding rail of the front side plate is arranged on the rear side plate, a first stainless steel net is connected between the first sliding rail and the second sliding rail in a sliding mode, and the line-face included angle between the first stainless steel net and the axis of the air inlet is larger than or equal to45 degrees and smaller than or equal to 90 degrees. By arranging the vibrating mechanism, dust with sparks in the tail gas of the cremation machine is blocked by the two stainless steel nets, so thatthe dust with sparks is prevented from burning a cloth bag of the bag-type dust remover in a tail gas treatment system, it is avoided that the dust removal efficiency of the bag-type dust remover is reduced or even lost, the tail gas treatment effect is not influenced, and the use cost of parts is saved.

Owner:WEIHAI LUYUAN ENVIRONMENTAL PROTECTION EQUIP SCI & TECH

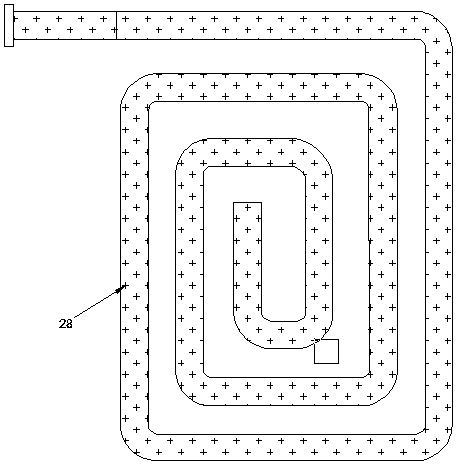

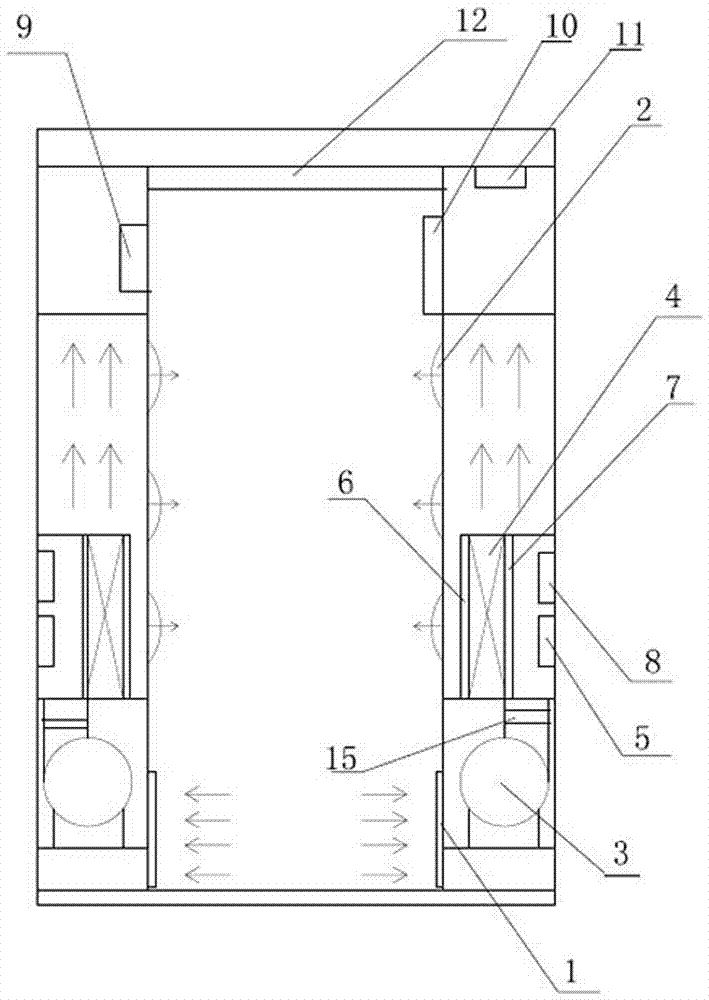

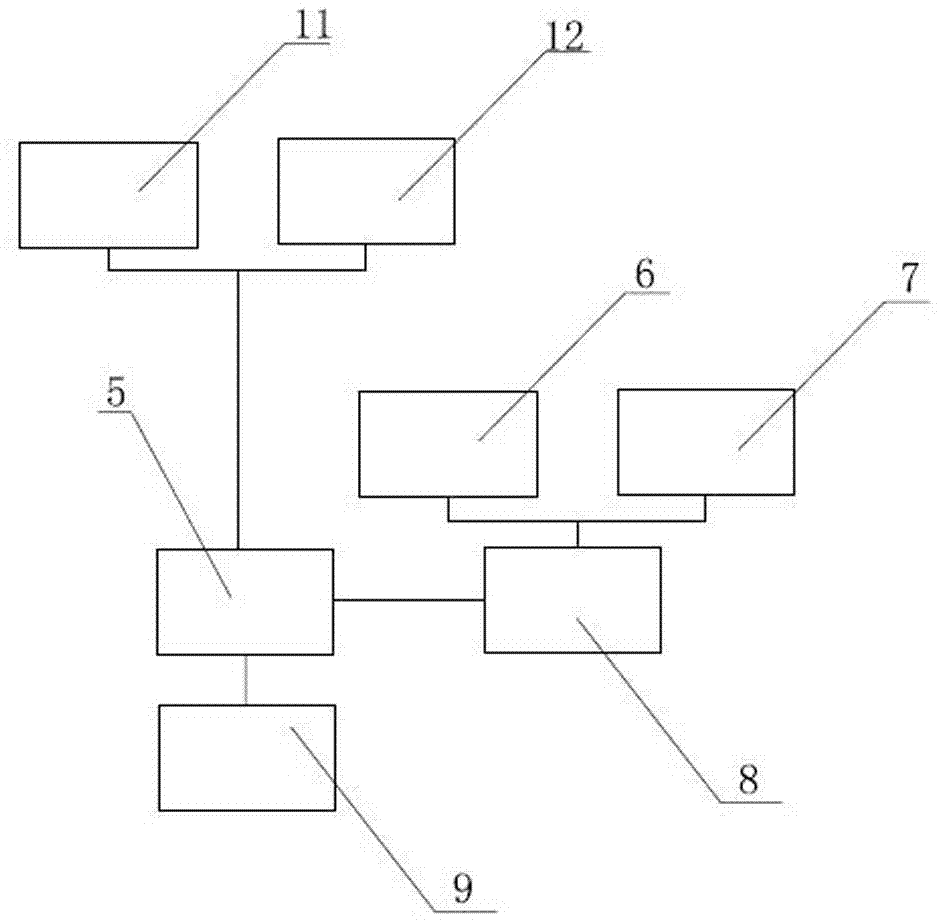

Air shower and control method

ActiveCN105457946BReduce dust removal effectImprove dust removal effectCleaning using gasesProgramme control in sequence/logic controllersElectricityProgrammable logic controller

The invention discloses an air shower fan and a control method thereof. According to the technical scheme, an air shower chamber comprises an air inlet, an air outlet, the air shower fan, an efficient filter and a programmable logic controller (PLC) control circuit. The air shower fan and the efficient filter are connected to an air channel between the air inlet and the air outlet in series. The PLC control circuit is electrically connected with the air shower fan. The air shower chamber further comprises a first pressure sensor, a second pressure sensor, an analog quantity input and output module and an alarm module. The first pressure sensor and the second pressure sensor are installed in front of and behind filter paper of the efficient filter respectively and electrically connected with the input end of the analog quantity input and output module. The output end of the analog quantity input and output module is electrically connected with the PLC control circuit and the alarm module.

Owner:无锡一净净化设备有限公司

Spin-on double-layer mixed dust bag and its manufacturing process

InactiveCN104492186BImprove filtering effectReduce impactCombination devicesDispersed particle filtrationEngineeringFilter effect

The invention relates to a thread engagement type double-layer combined dedusting cloth bag. The cloth bag comprises an outer bag and an inner bag, wherein the outer bag comprises outer dedusting cloth, an outer frame and an outer retaining ring; the inner bag comprises inner dedusting cloth, an inner frame, an inner retaining ring, a vibrating motor, an electric dedusting grid, a pulse back flushing spray head, a bottom plate, and a motor hood, wherein the electric dedusting grid is arranged at the upper part of the inner bag, the pulse back flushing spray head is arranged in the center of the electric dedusting grid, the bottom plate of the inner bag is arranged on the bottom part of the inner bag, the vibrating motor is arranged on the bottom plate, and the inner bag and the outer bag are connected by using thread engagement. The head engagement type double-layer combined dedusting cloth bag adopts the combined filtering of the double-layer cloth bag and electric dedusting, has the extremely better filtering effect than that of existing dedusting cloth bags, and has the relatively high dedusting capacity due to the combination of pulse air flow and vibration.

Owner:南京市凌湃环保科技有限公司

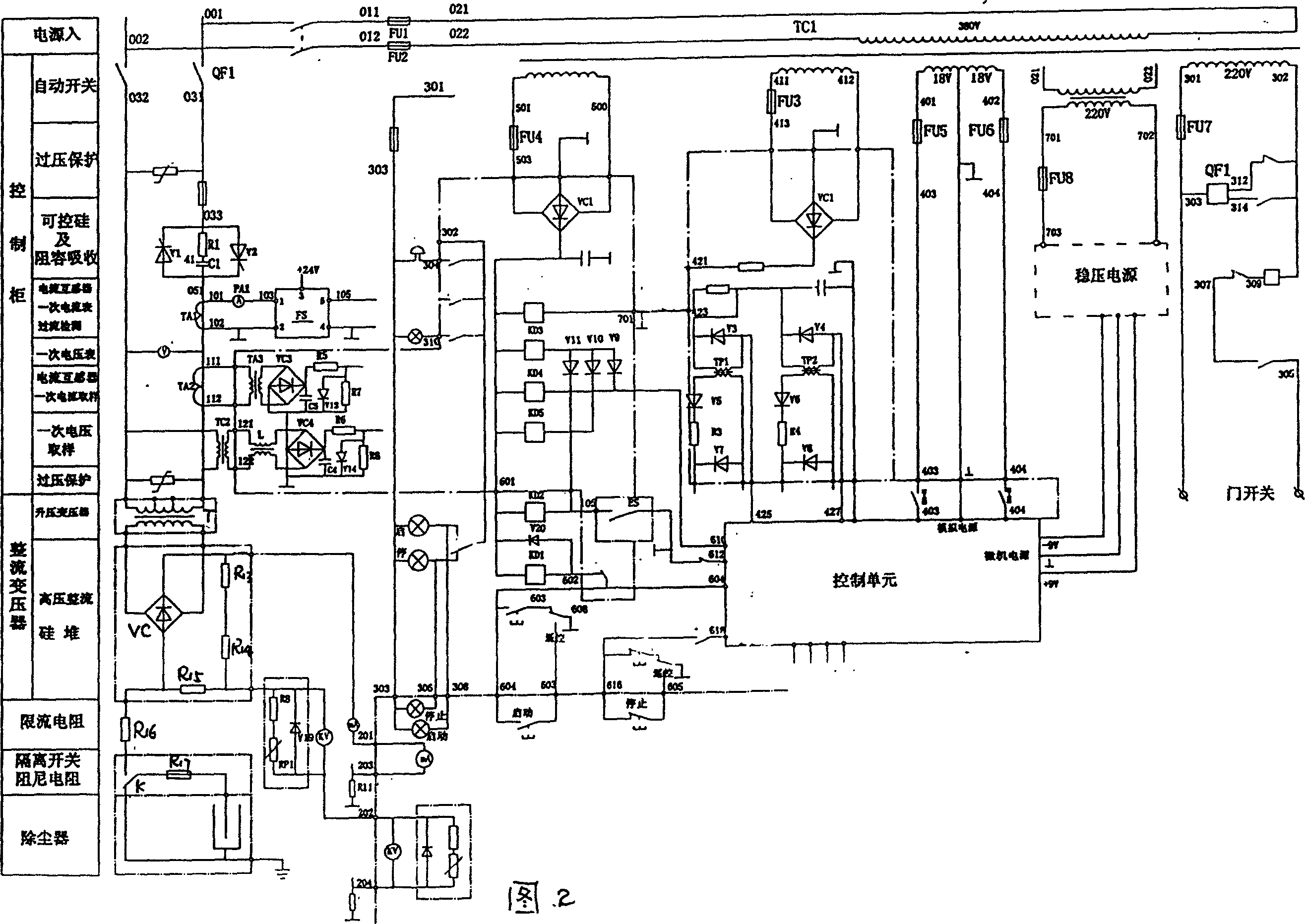

Industrial electric dust removing device purifying system

ActiveCN1291794CReasonable structureImprove dust removal effectExternal electric electrostatic seperatorElectric supply techniquesLow voltageEngineering

The present invention relates to industrial electrically dusting purification system comprising electric duster, high voltage DC power supply and low voltage PLC control system. The purification system is provided with high voltage SCR power supply, upper computer communication interface for communication with upper computer, and low voltage control system with programmable PLC controller to control the pulse shaker, heater and discharge unit of the electric duster. The present invention adopts live showing clean technology to spray atomized water to clean dust collecting electrode and discharge electrode for optimized electric field cleaning effect and lowered operation cost; and has also electromagnetic shaker. The present invention has reasonable structure, high dusting effect and low cost.

Owner:高国纯

Integrated adjustable Venturi cyclone exhaust gas scrubber

The invention discloses a one-piece adjustable venturi cyclone exhaust gas scrubbing tower which comprises a tower body, wherein an air inlet pipeline is arranged at one end of the tower body, and an exhaust pipeline is arranged at the other end of the tower body; the air inlet pipeline extends into the tower body, and a throat pipe is arranged at the opening of the air inlet pipeline in a sleeving manner; a spray pipe is arranged at the connecting position between the air inlet pipeline and the throat pipe, and a nozzle is arranged on the spray pipe; the position, close to the throat pipe, of the side wall of the tower body is connected with a throat pipe adjusting device, and the other end of the throat pipe is connected with a wind scooper; a gas liquid separation section is arranged at the other end of the wind scooper. The one-piece adjustable venturi cyclone exhaust gas scrubbing tower has the advantages of simple structure, reasonable design, convenience in operation, good dust removal effect and small occupied area. The diameter of the tower body is similar to that of an exhaust gas pipeline, the tower can be horizontally or vertically mounted in an exhaust gas pipeline system, and the mounting position is largely saved. Meanwhile, the energy consumption of the system is reduced.

Owner:南通辰丰自动化设备制造有限公司

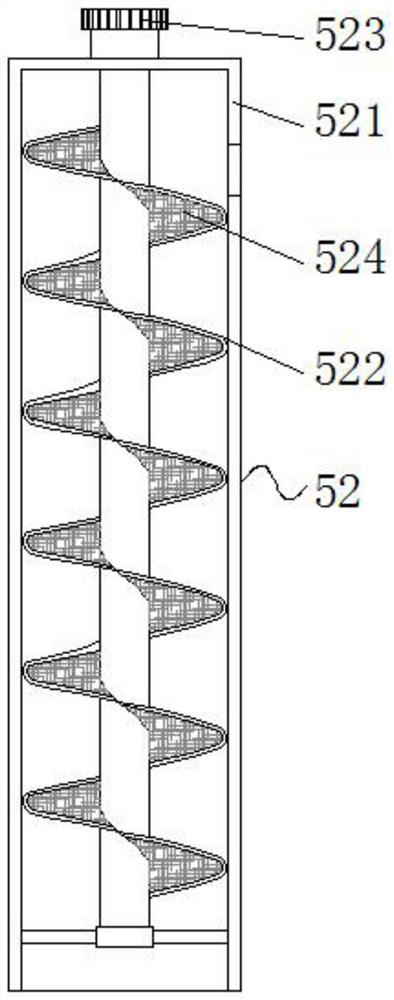

Calcining furnace tail gas purification treatment device and process

PendingCN114471121AQuality improvementEfficient removalGas treatmentDispersed particle filtrationExhaust fumesDust control

The invention discloses a calcining furnace tail gas purification treatment device and process, the calcining furnace tail gas purification treatment device comprises a calcining furnace, a boiler, a heat exchanger, an air blower and purification equipment, the purification equipment comprises a purification tank, a dust removal component and a purification component are arranged in the purification tank, and the dust removal component comprises multiple sets of dust removal cylinders and spiral blades. According to the calcining furnace tail gas purification treatment device and process, dust residues in waste gas are isolated and discharged to the dust collection box through rotation of the spiral blades and the filter cloth, the gas is upwards discharged through the filter cloth and enters the purification barrel through the dust removal exhaust pipe, and liquid in the alkaline water tank is pumped through the water pump and sprayed through the atomization spray head; the waste gas entering the purification cylinder is in contact with vaporific alkali liquor to neutralize sulfide and alkaline water, so that the waste gas is purified, foreign gas in organisms is effectively removed, the waste gas purification quality is better improved, and the influence of the waste gas on the surrounding environment is reduced.

Owner:湖北中颐和环境工程有限公司

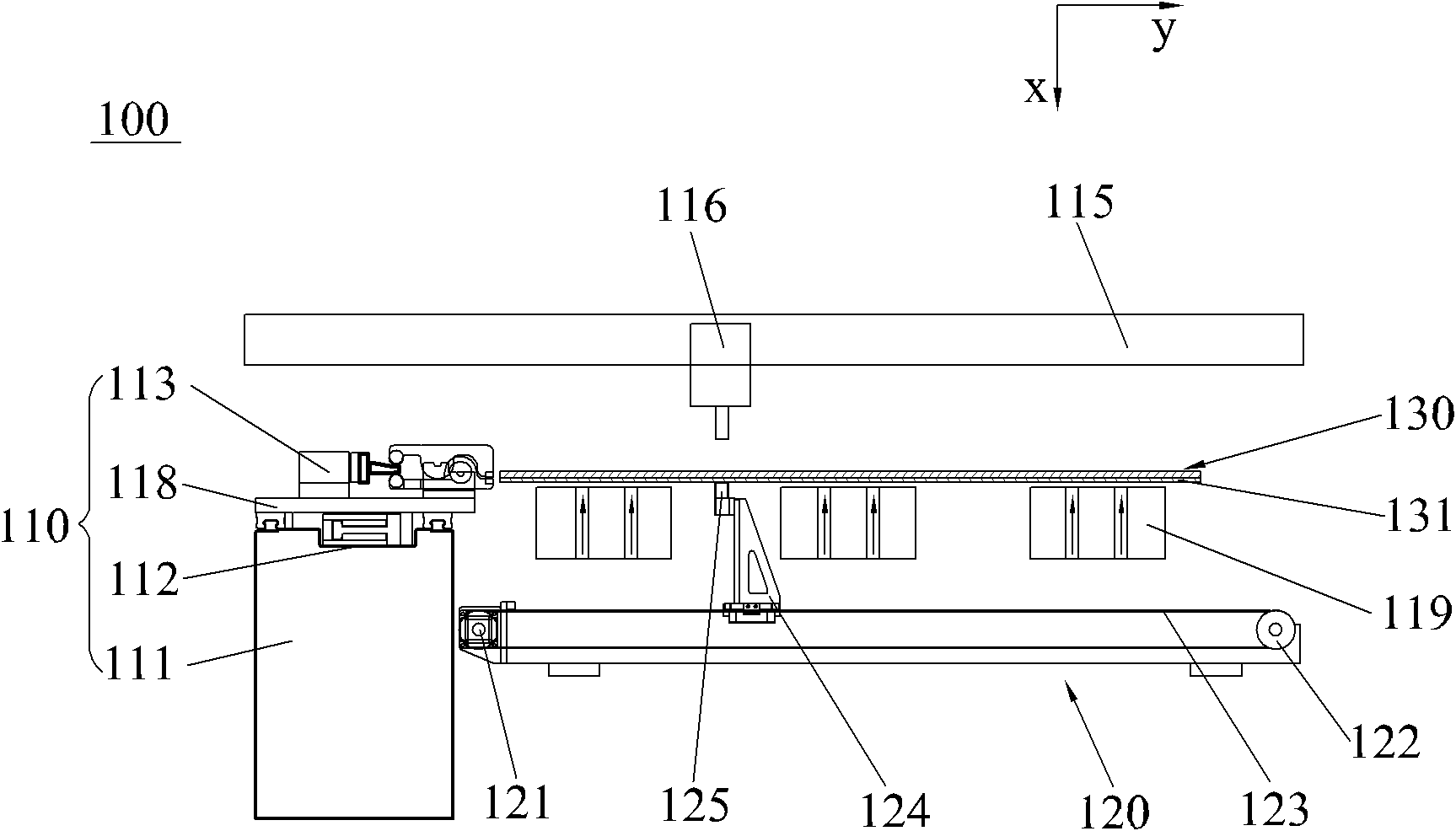

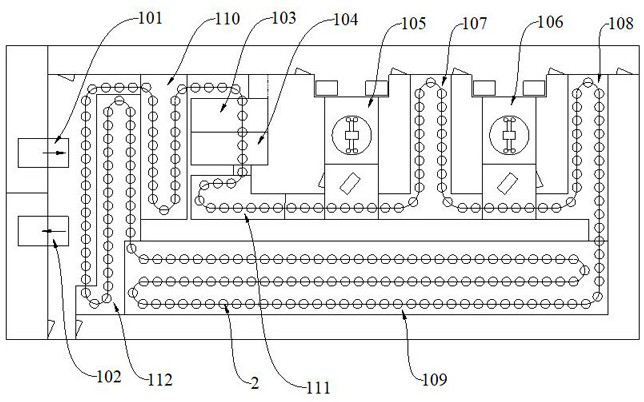

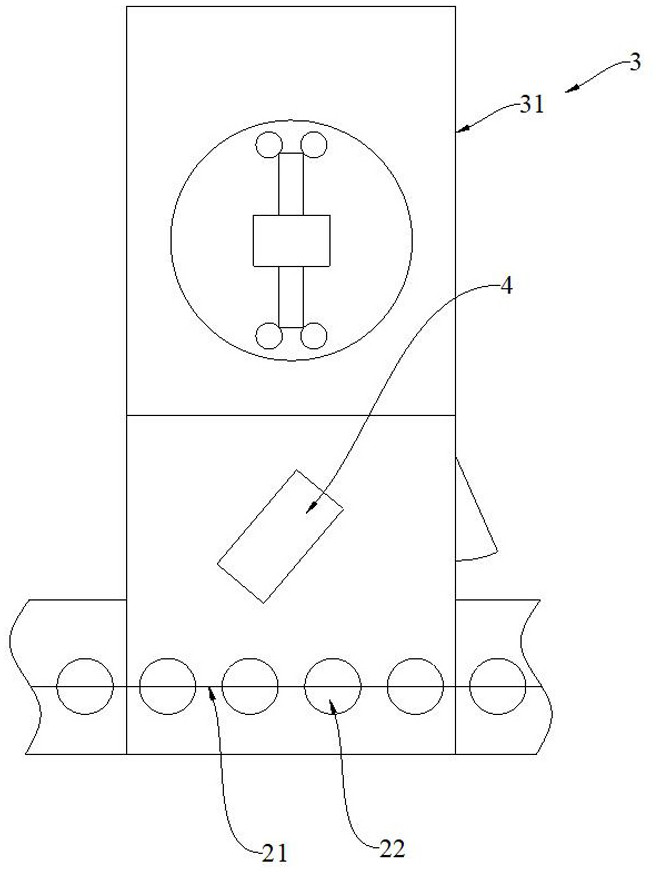

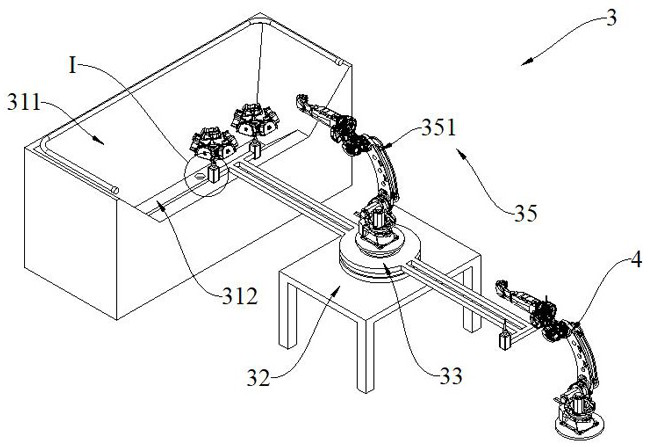

A flexible automatic intelligent coating line

ActiveCN114100937BHigh degree of automationEasy to control spray qualitySpray boothsRobot handDust control

The application discloses a flexible automatic intelligent coating line, which includes a circulation conveying system, a material loading area, a material unloading area, a cleaning area, a dust removal area, a first spraying area, a second spraying area, a first leveling area, a second flow Flat area and drying area; the circular conveyor system includes a circular conveyor belt and multiple trays, and multiple trays are arranged at intervals along the conveying direction; the trays are detachable and rotatably connected to the circular conveyor belt, and multiple brackets are detachable on the trays. A plurality of brackets are arranged at intervals along the circumferential direction of the tray; spraying devices and grabbing manipulators are provided in the first spraying area and the second spraying area; when the tray moves to the cleaning area and dust removal area, the tray rotates to Multiple workpieces are cleaned and dust-removed; when the pallet conveyor belt moves to the first spraying area and the second spraying area, the corresponding grabbing manipulator clamps the pallet to the corresponding spraying device to spray multiple workpieces on the pallet . It has high degree of automation, high work efficiency and good spraying quality.

Owner:NINGBO SHUANGLIN MOULD CO LTD

Spraying foam desulfurization dust remover

InactiveCN111874973AReduce flow rateAffect the effect of sedimentationUsing liquid separation agentTreatment involving filtrationSpray foamsDust abatement

The invention relates to the field of desulfurization and dust removal, in particular to a spraying foam desulfurization and dust remover, which comprises a tank body structure, a water treatment structure, a filtering structure, a dust removal structure, a flow limiting structure and a foam blocking structure. In the dust remover, the filtering structure can be used for storing and precipitatingsewage discharged by the dust removal structure, impurities in the sewage are precipitated and filtered to be changed into reusable water again to be used by the dust removal structure, so that use ofthe water by the dust removal structure is effectively reduced, meanwhile, the filtering structure can reduce the flow speed of the sewage discharged by the dust removal structure, which facilitatesfiltration and precipitation of the sewage; furthermore, due to the foam blocking structure, residual foam is prevented from entering a pipeline of the water treatment structure to cause unclean ascending water, so that the dust removal effect of the dust removal structure is reduced, and meanwhile, the foam blocking structure can delay the flow speed of the water to enable the water to be settledmore completely in the filtering structure; in addition, by using the flow limiting structure, the water inlet amount can be automatically adjusted by controlling the flow speed of the entering gas,so that the dust removal effect of the dust removal structure is better.

Owner:沈春丰

Dust removal device for pyrophyllite crushing system

Owner:邵阳市东昇超硬材料有限公司

Mobile smoke blast trapping device for furnace mixer

Owner:HUATIAN ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com