Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Quick wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing technology of butter honey nuts

InactiveCN106174328AImprove uniformityImprove texture firmnessSugar food ingredientsFood coatingAdhesive materialsNutrient

The present invention discloses a processing technology of butter honey nuts. The processing technology specifically consists of the following steps: (1) wrapping liquid preparing; (2) pre-powder and post-powder preparing; (3) spraying and coating; (4) oil-frying and residue removing; (5) oil blowing; (6) cooling and beating; (7) butter spraying; and (8) nut finished product wrapping. The processing technology enriches the fragrant and sweet mouthfeel of the coated butter honey, effectively improves the uniformity of the powder wrapping, improves the texture tightness of the coating, and effectively prevents the falling of the coating, so that the product appearances, physicochemical indicators and other various performance indicators of the butter honey nuts are more stable. The processing technology effectively prevents the losses of the nuts, honey, butter and other nutrients, the low-temperature oil-frying reduces the destruction of the product nutrients, and the processing technology improves the nutritional values of the products, enables the coating to be translucent in appearances and uniform in color and luster, reduces the defective percentage to be 20-30%, improves the yields, and can well separate the adhesive materials. The oil blowing technology is conducive to the rapid drying of the surfaces of the butter honey nuts and prolongs the shelf life of the products.

Owner:青岛果果爸爸食品有限公司

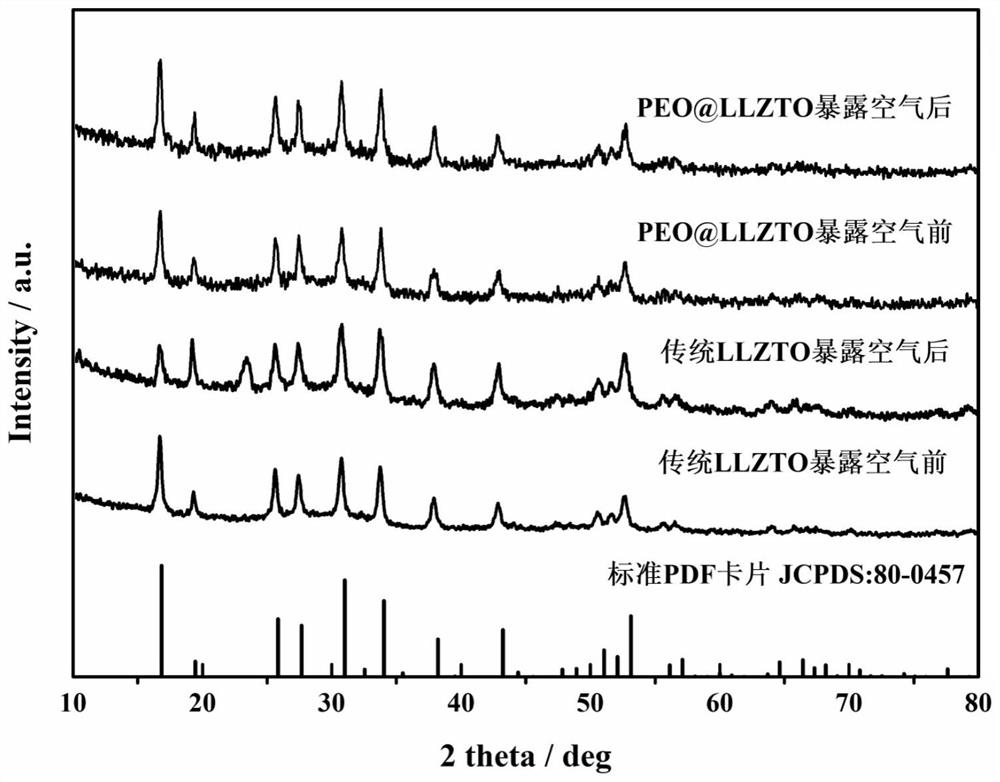

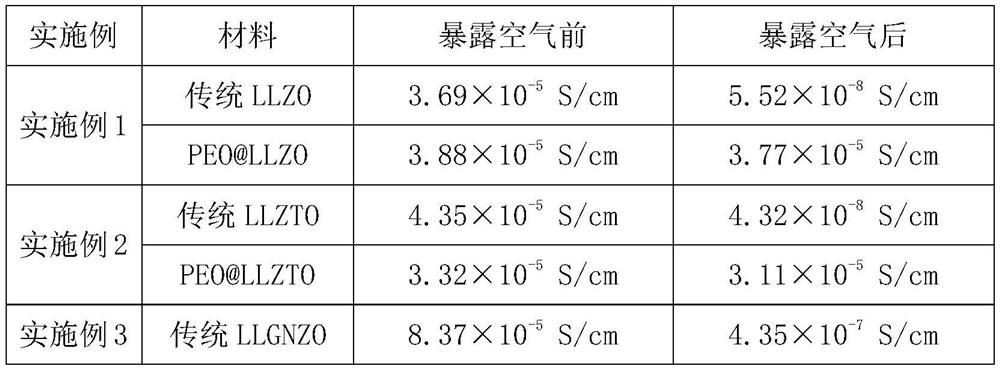

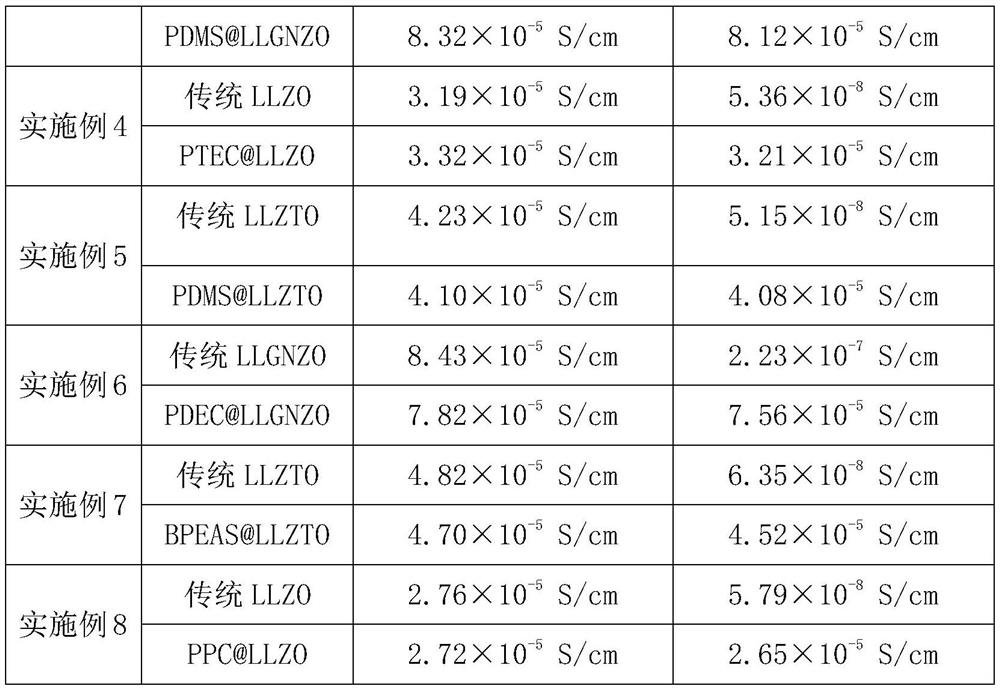

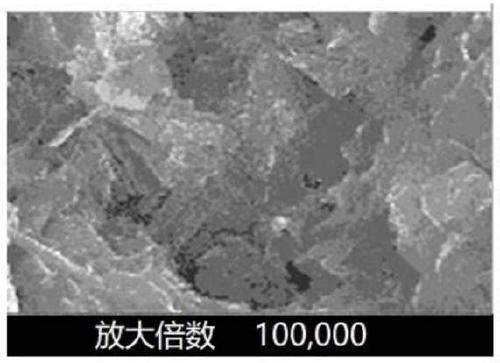

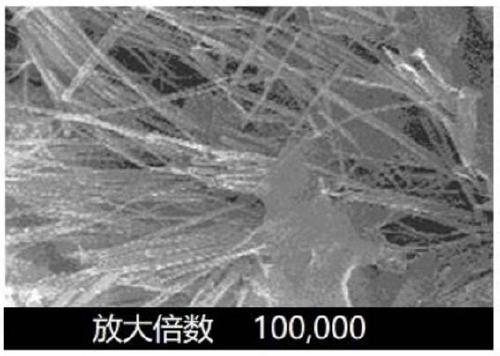

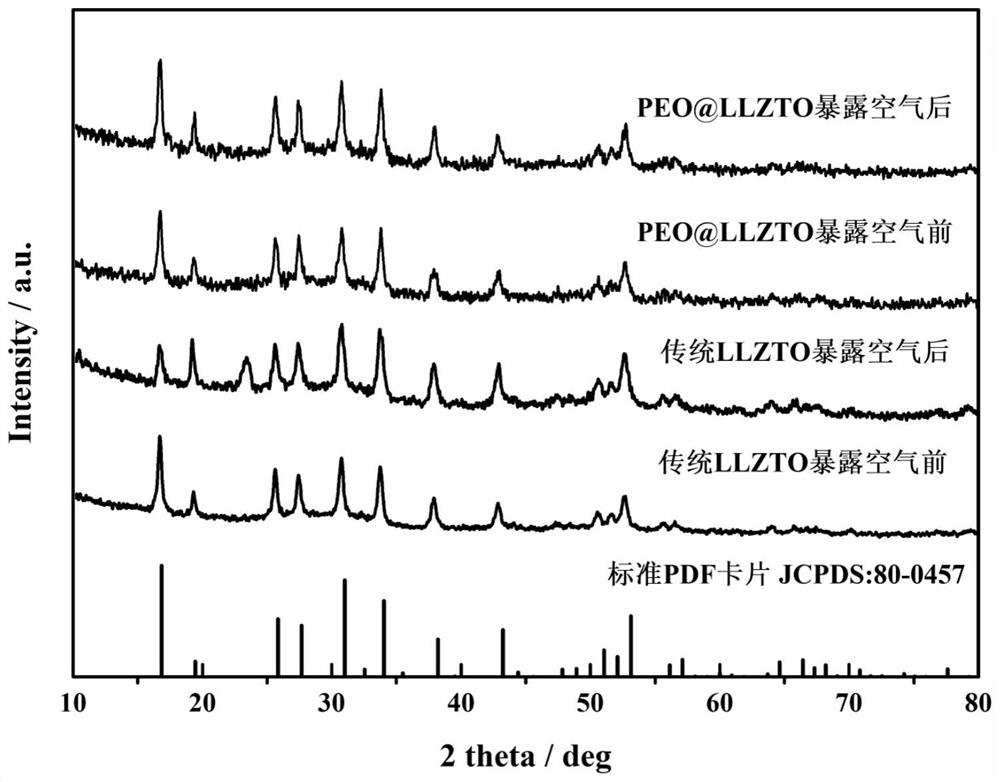

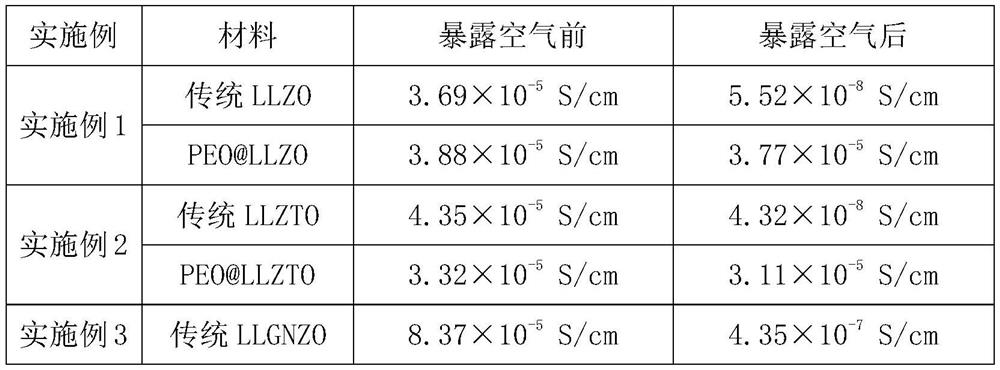

Surface treatment method for garnet type solid electrolyte

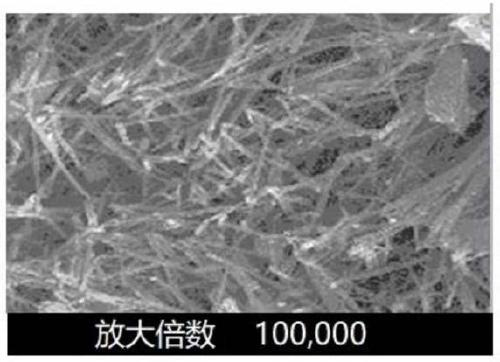

ActiveCN112290082ACoated evenlyWill not introduceElectrolytesLi-accumulatorsSolid state electrolyteConductive polymer

The invention belongs to the technical field of solid electrolyte preparation, and particularly relates to a surface treatment method for a garnet-type solid electrolyte. The method comprises the following steps: pretreating a garnet electrolyte powder material, and forming an ion conductive polymer coating layer with the thickness of 1-50 nm on the surface of the garnet electrolyte powder material by adopting a spray drying technology. According to the method disclosed by the invention, adverse reaction between the garnet solid electrolyte and air is prevented, the generation of surface impurities is inhibited, and meanwhile, the ionic conductivity of the electrolyte is not deteriorated, so that the electrolyte can keep high stability and electrochemical performance in the storage and useprocesses.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

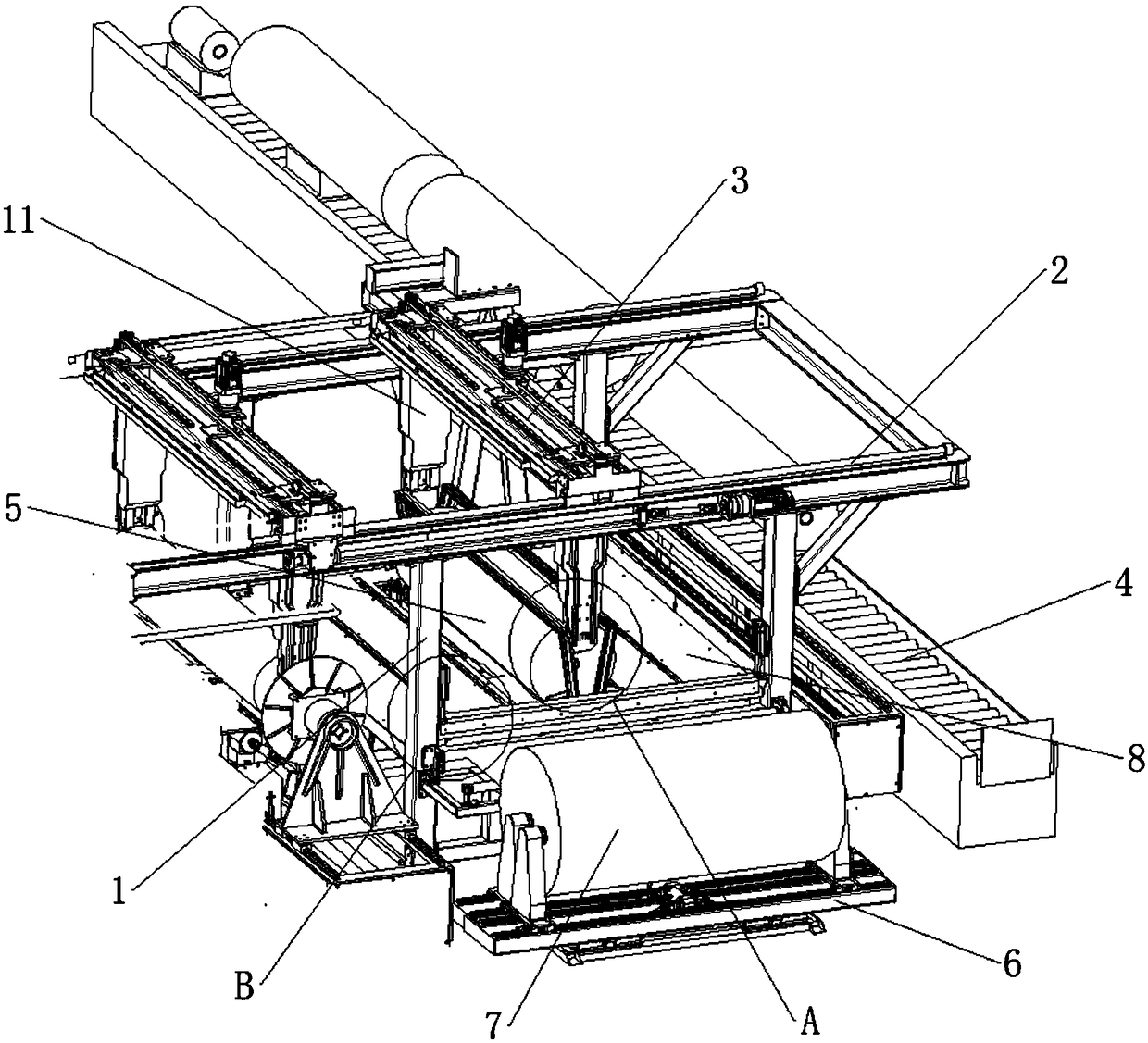

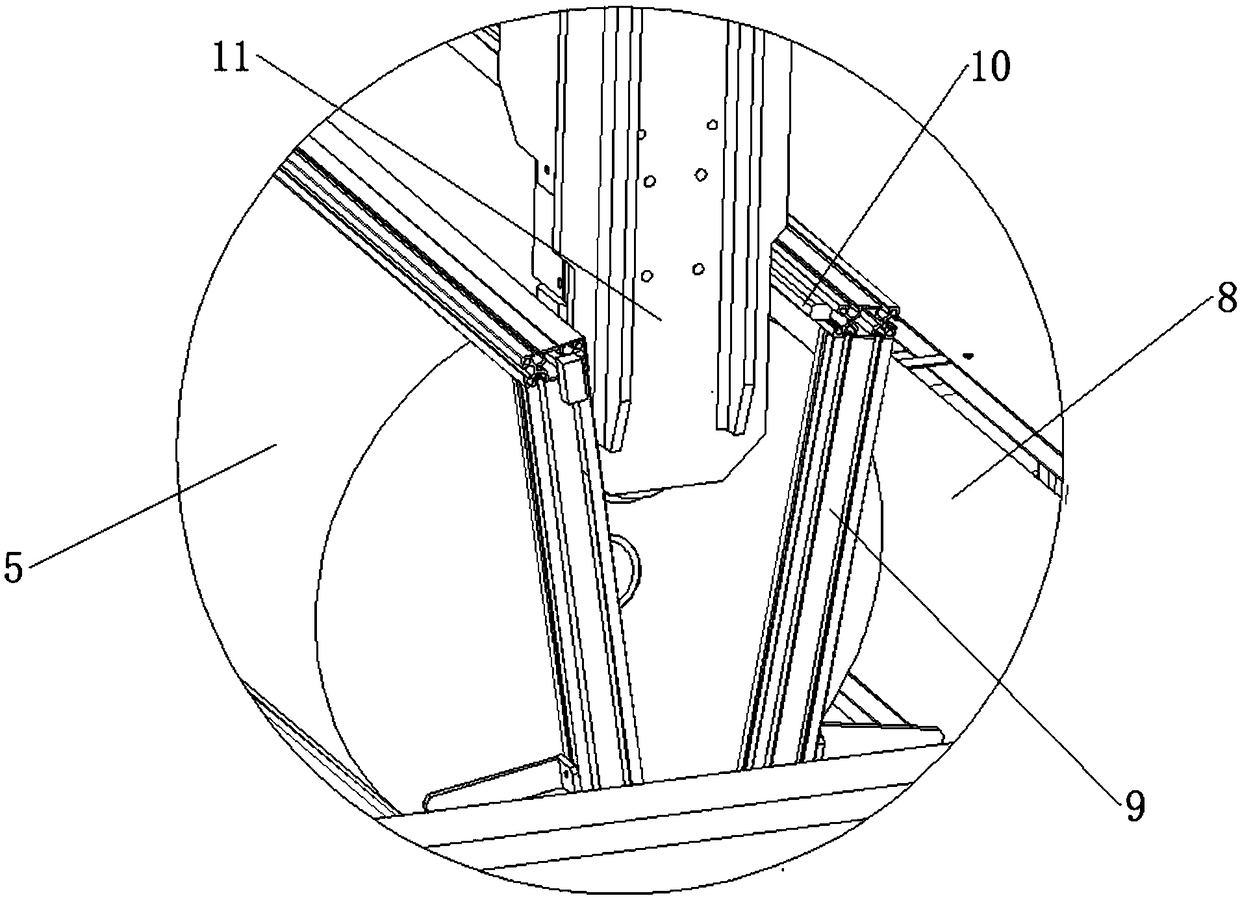

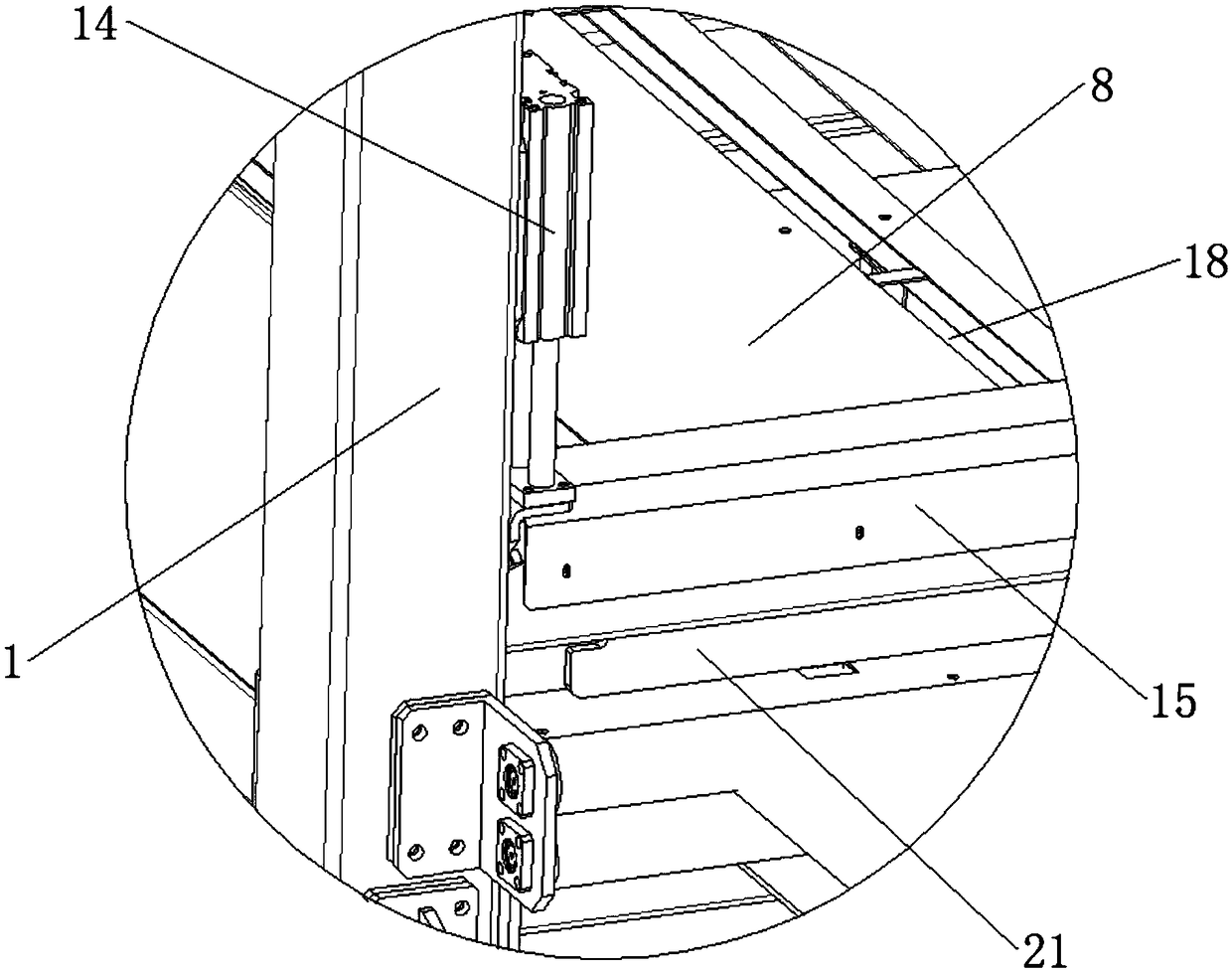

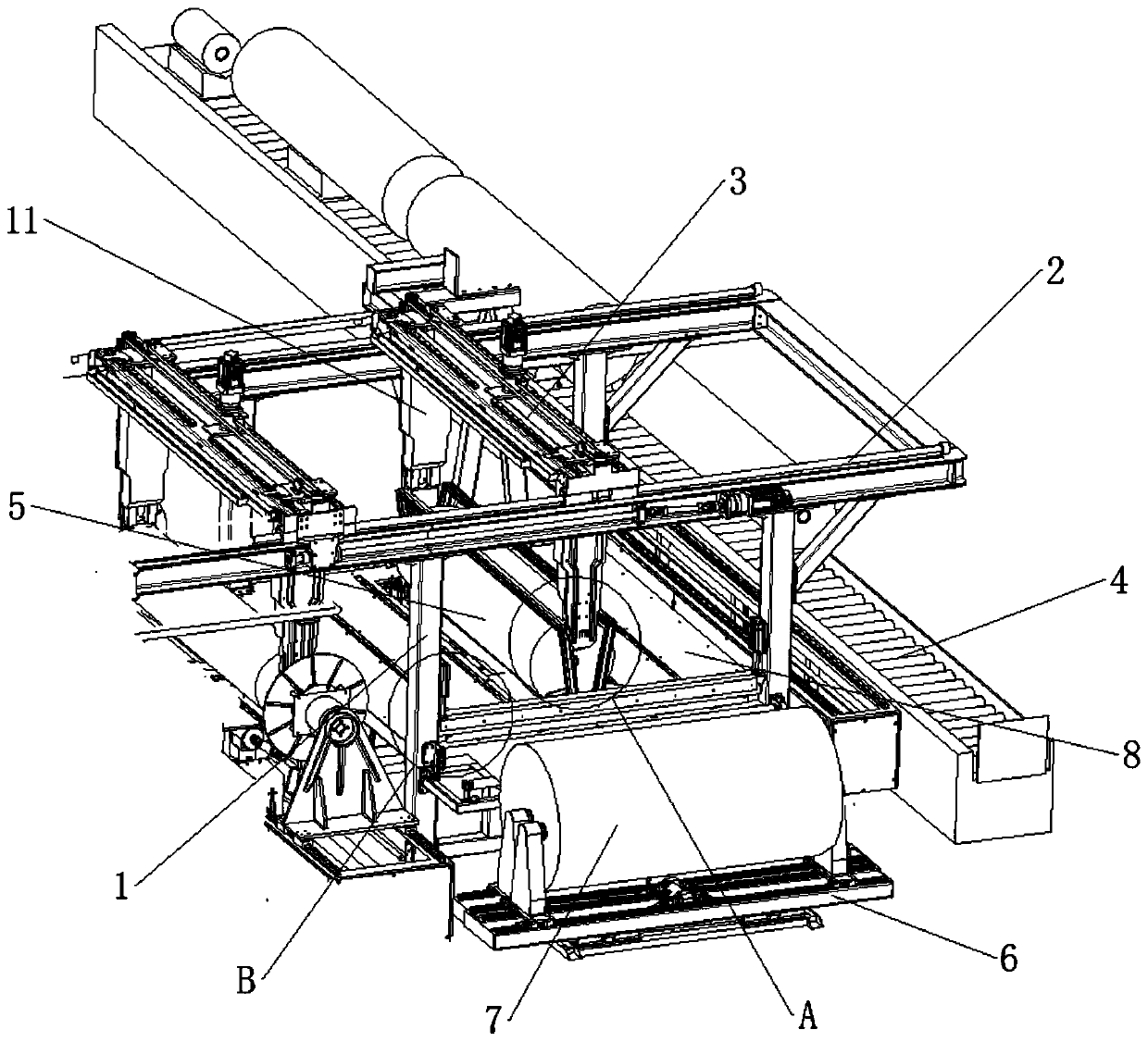

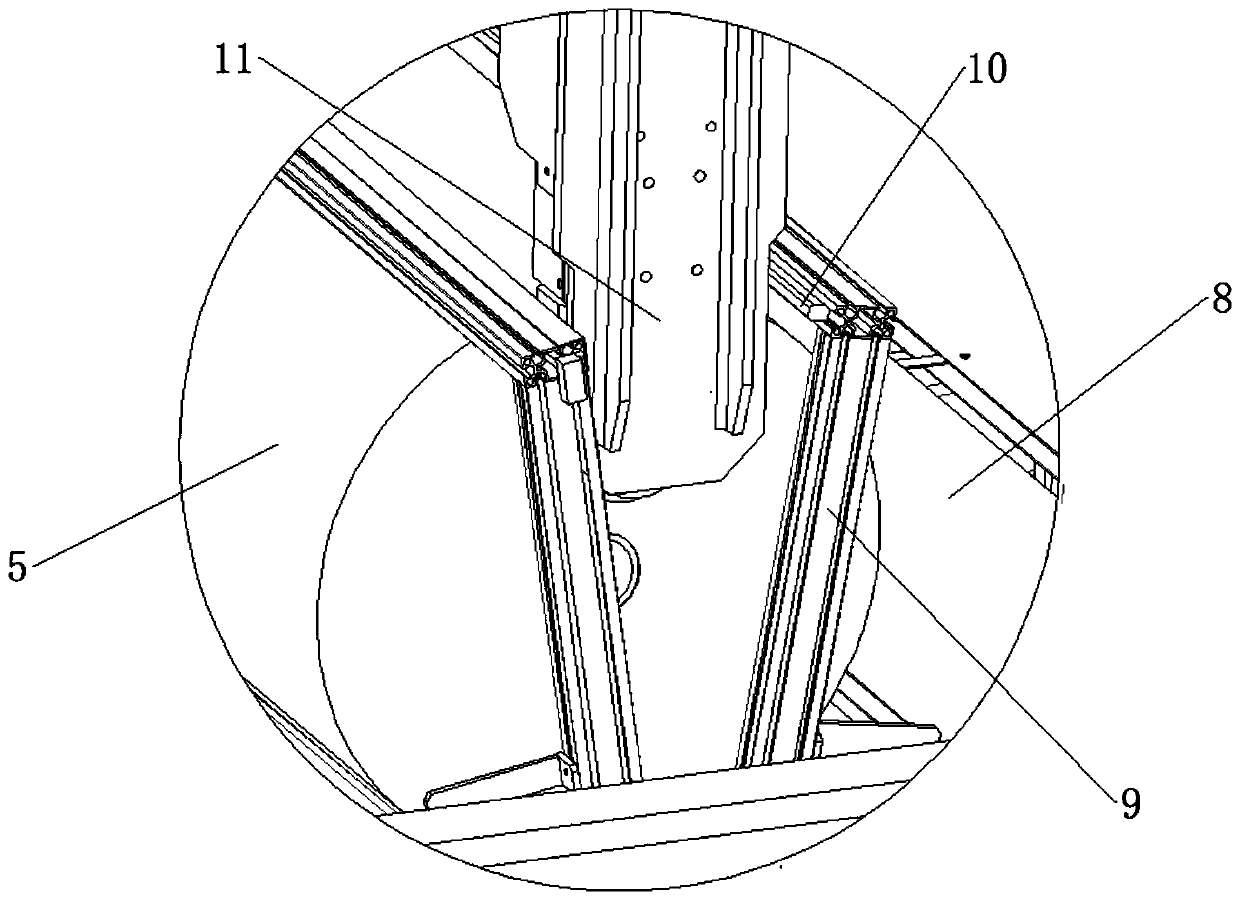

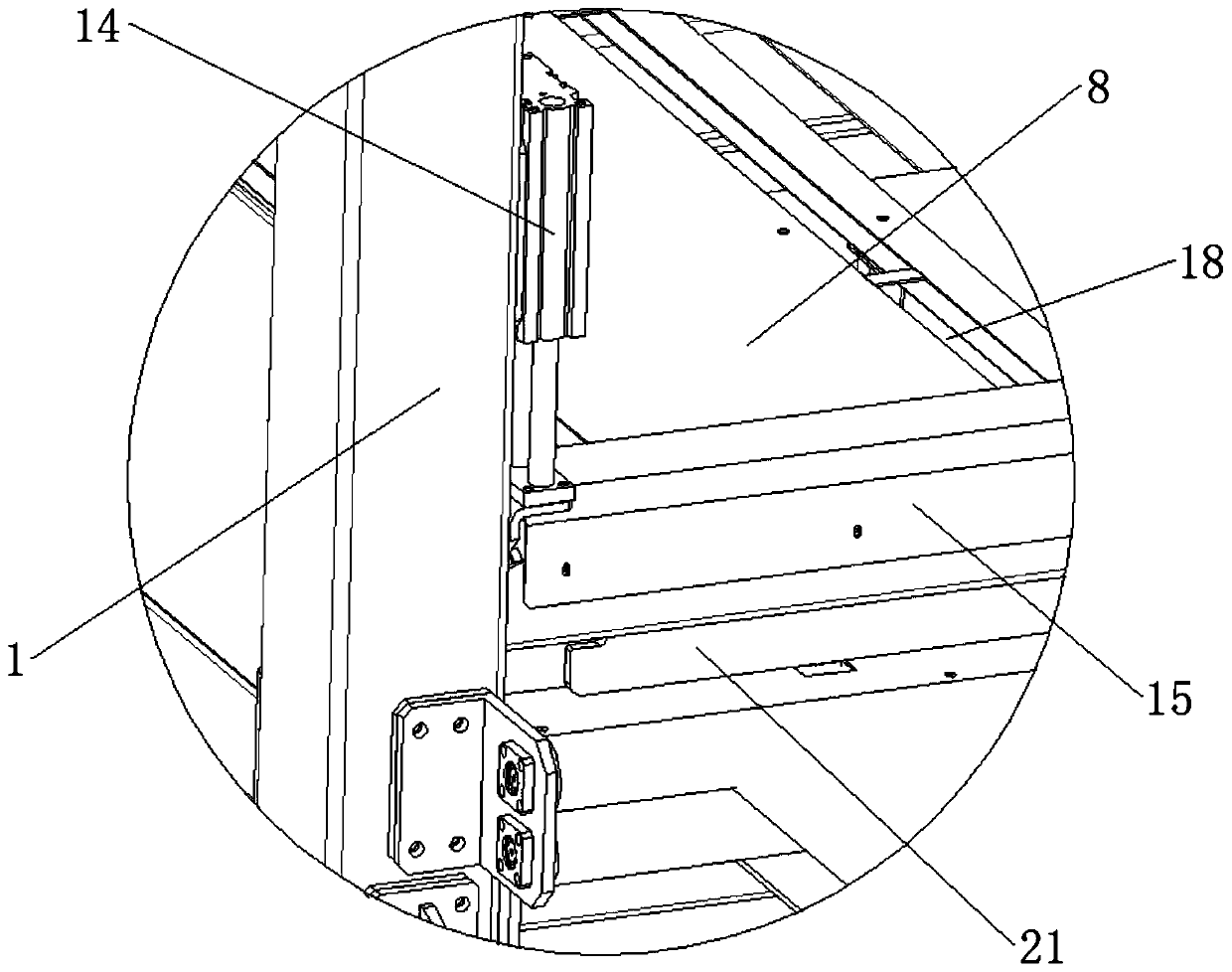

Automatic film-cover and heat-seal device for cylindrical coil

The invention discloses an automatic film-cover and heat-seal device for cylindrical coil and belongs to the technical field of machinery. The automatic film-cover and heat-seal device for cylindricalcoil comprises a main frame; a pair of moving tracks are fixedly connected to an upper end of the main frame; a moving device body is connected to the moving tracks; a pair of lifting mechanical armsare connected to a lower end of the moving device body; a conveying belt is placed at one side of the main frame; a cylindrical thin film roll material body is placed on the conveying belt; an air bubble film coil rack is placed at one side of the main frame; an air bubble film rolling rack is provided with an edge correcting device which can effectively guarantee that the air bubble film is drawn to a table top in the unified direction; It utilizes two lifting and foldable-unfoldable film-cover rods, which are similar to shell opening and closing, and the bubble film is applied from the bottom to the top of the coil surface. When the bubble film reaches to the uppermost end, the heating rod heats the contact surface. By heat sealing the interface of the bubble film, it is possible to quickly cover the bubble film on the end faces of the coils of different diameters for heat sealing.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

Beryllium metal polluted soil repairing agent and preparation method thereof

InactiveCN109504387AEfficient repairImprove economyAgriculture tools and machinesOrganic fertilisersBeryllium MetalMaterials science

The embodiment of the invention provides a beryllium metal polluted soil repairing agent and a preparation method thereof and belongs to the technical field of soil repairing. The repairing agent comprises 80-120 parts of a mineral microcapsule material, 10-40 parts of sepiolite powder and 30-60 parts of hydroxide. The beryllium metal polluted soil repairing agent has the technical fields of efficient soil repairing and high economy.

Owner:浙江中地净土科技有限公司

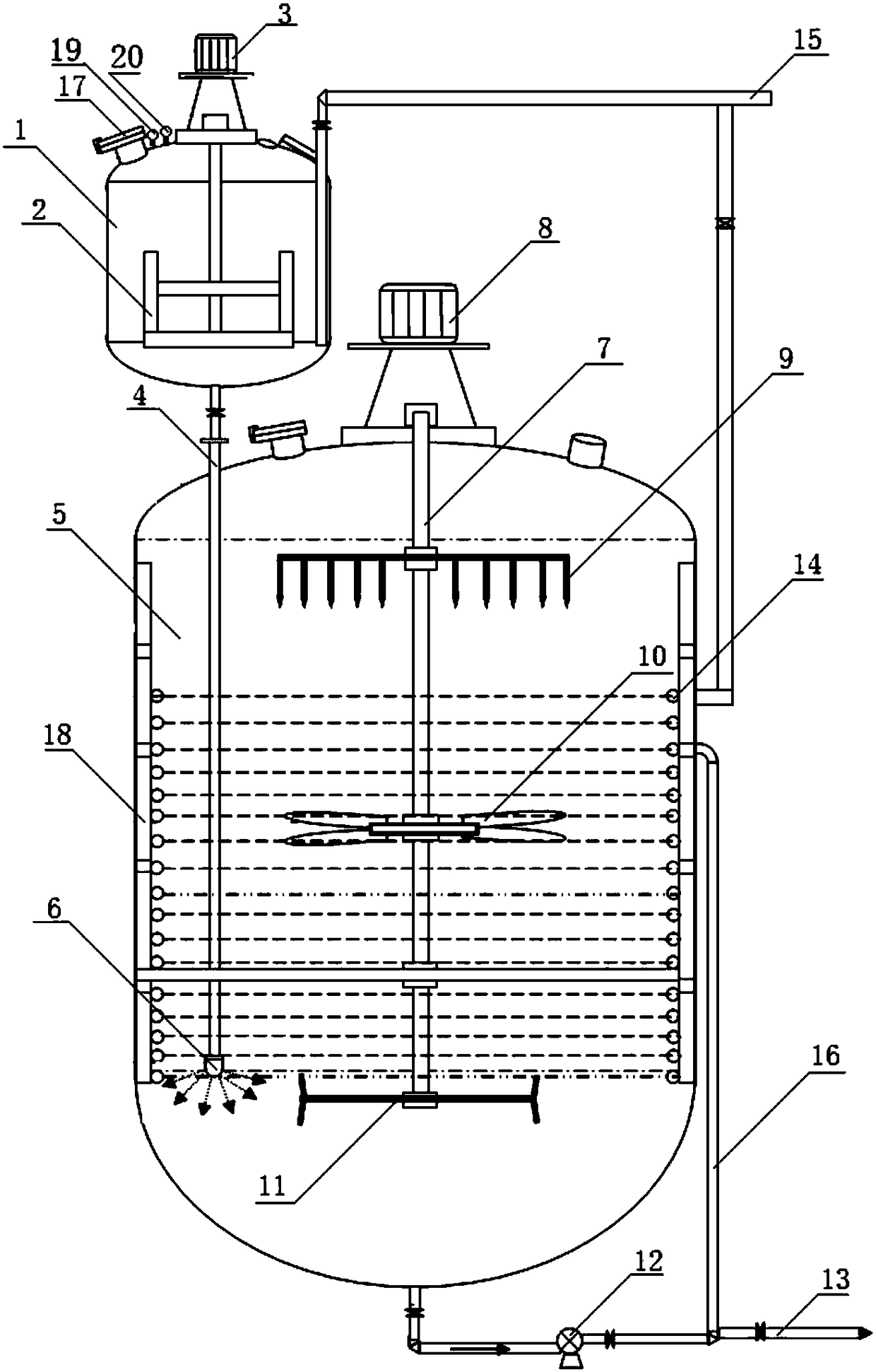

Nano calcium carbonate high pressure saponification wet activation method

ActiveCN107021516BLow oil absorptionUniform adsorptionCalcium/strontium/barium carbonatesMaterial nanotechnologyActivation methodHigh pressure

The invention discloses a method for activating nano calcium carbonate through a high-pressure saponification wet method. According to the method, the following activating devices of a saponification reaction kettle, a saponification stirring device, a saponification discharge pipe, an activating kettle, a spiral nozzle, an activating and stirring device, an emulsifying machine, a circulating pipe and a steam heating device are utilized. The method comprises the specific operation steps: 1, preparing activating agent; 2, feeding nano calcium carbonate; 3, activating the nano calcium carbonate. When the method disclosed by the invention is applied to activating the nano calcium carbonate, particle size refining and medicament dispersion and absorption are facilitated; furthermore, blistering overflow is avoided, an oil absorption value of a nano calcium carbonate product is obviously reduced, and activating rate is 99% or more.

Owner:FUJIAN HONGFENG NANO TECH

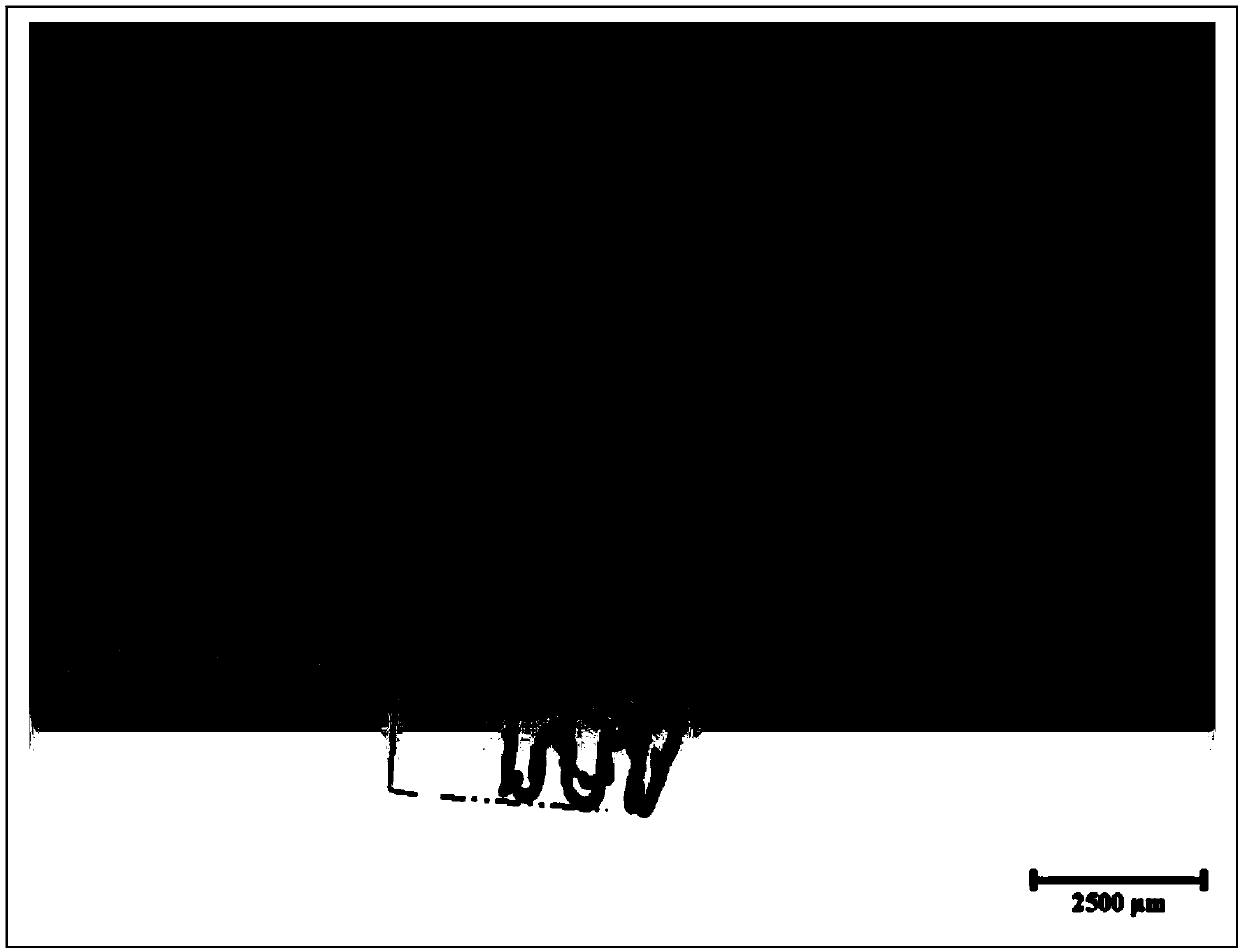

Surface modification method for improving corrosion resistance of magnesium alloy intravascular stent

ActiveCN108014379AImprove corrosion resistanceEasy to captureSurgeryCoatingsEndothelial regenerationStent implantation

The invention relates to the field of interventional medical devices, and especially relates to a surface modification method for improving the corrosion resistance of a magnesium alloy intravascularstent. The method is suitable for a novel dual-drug degradable magnesium alloy intravascular stent for treating intraluminal stenosis, carrying a smooth muscle proliferation inhibitor and promoting endothelialization. The method is characterized in that a drug coating with an endothelialization promoting function is prepared on a magnesium alloy stent to accelerate the endothelialization process after stent implantation and improve the service environment of the stent, so the corrosion resistance of the magnesium alloy intravascular stent is improved. The magnesium alloy intravascular stent carries a drug for inhibiting intimal hypertrophy, and also carries a drug for promoting endothelialization. The stent can realize rapid endothelial regeneration of damaged parts through the action of the drug for promoting endothelialization after being implanted into a diseased blood vessel, so the service environment of the magnesium alloy stent is improved, and the corrosion resistance of the degradable magnesium alloy intravascular stent is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Omni-directional film coating device for carton

The invention discloses a omni-directional film coating device for a carton, and belongs to the technical field of packaging. The invention solves the technical problem that the whole of the carton cannot be covered by film. The omni-directional film coating device for the carton comprises a machine frame, wherein a first film outlet roller is longitudinally rotationally arranged on the machine frame, a driving mechanism for driving the first film outlet roller to move up and down is arranged on the machine frame, a rotating table is rotationally arranged on the machine frame, and a driving mechanism for driving the rotating table to rotate is arranged on the machine frame; a placing table assembly protruding upwards is fixed on the rotating table, and a fixing structure used for fixing the end part of the film is arranged on the rotating table; and a first push rod motor is fixed on the machine frame, a push rod of the first push rod motor is rotatably provided with a rotating pressing piece, and the rotating pressing piece is positioned right above the rotating table. The omni-directional film coating device has the advantages of being capable of completely covering the carton byusing the film.

Owner:嘉兴亿豪新材料股份有限公司

Golden fragrant nut and preparation method thereof

The invention discloses a golden fragrant nut and a preparation method thereof. The preparation method specifically comprises the following steps: (1) performing baking; (2) performing cooling; (3) preparing a coating liquid; (4) preparing a pre-powder; (5) performing coating; (6) performing wrapping with the powder; (5) performing baking; (6) performing cooling; (7) performing scattering; (8) performing vibrating to remove slag; and (9) preparing a golden fragrant nut finished product. According to the golden fragrant nut, the fragrance of a nut raw material is further stimulated, the productis endowed with natural smoking flavor and crispy taste, the smoking flavor and a marinating flavor are naturally fused to form unique golden-fragrant flavor, and the content range of the series of products is expanded. According to the invention, the appearance of the nut coating layer is transparent and bright and uniform in color, the defective rate is reduced by 25-35%, meanwhile, the half-grain rate of the product is reduced by 20%, the yield is increased, the problem of adhesion of the product after being taken out of an oven is solved, the adhered materials can be well separated, a quick cooling process is beneficial to quick drying of the surface of the golden fragrant nut, and the shelf life of the product is prolonged.

Owner:青岛众创味来食品科技有限公司

Antifouling isolation device for yarns

ActiveCN111284740AGood anti-pollution isolation functionQuick fixWrapping with article rotationYarnBall bearing

The invention relates to the technical field of yarn antifouling, and discloses an antifouling isolation device for yarns. The antifouling isolation device comprises a base, wherein a placement cavityis formed in the base; a rotating motor is fixedly connected in the placement cavity; an output shaft at the upper end of the rotating motor penetrates through the upper end of the base and is fixedly connected with a rotating plate; the upper end of the rotating plate is fixedly connected with a fixed cylinder; the inner wall, close to the bottom, of the fixed cylinder is fixedly connected witha transverse plate; the same adjusting screw rod is rotationally connected between the upper end of the transverse plate and the inner wall of the top of the fixed cylinder through a ball bearing; thelower end of the transverse plate is fixedly connected with an adjusting motor; an output shaft at the upper end of the adjusting motor penetrates through the surface of the transverse plate and is fixedly connected to the lower end of the adjusting screw rod; the rod wall of the adjusting screw rod is in threaded connection with a lifting screw ring; and the side wall of the lifting screw ring is uniformly and rotationally connected with a plurality of push-pull rods. The antifouling isolation device for the yarn has the advantages that the yarn can have a good antifouling isolation function, and use is convenient.

Owner:微山县泰丰纺织有限公司

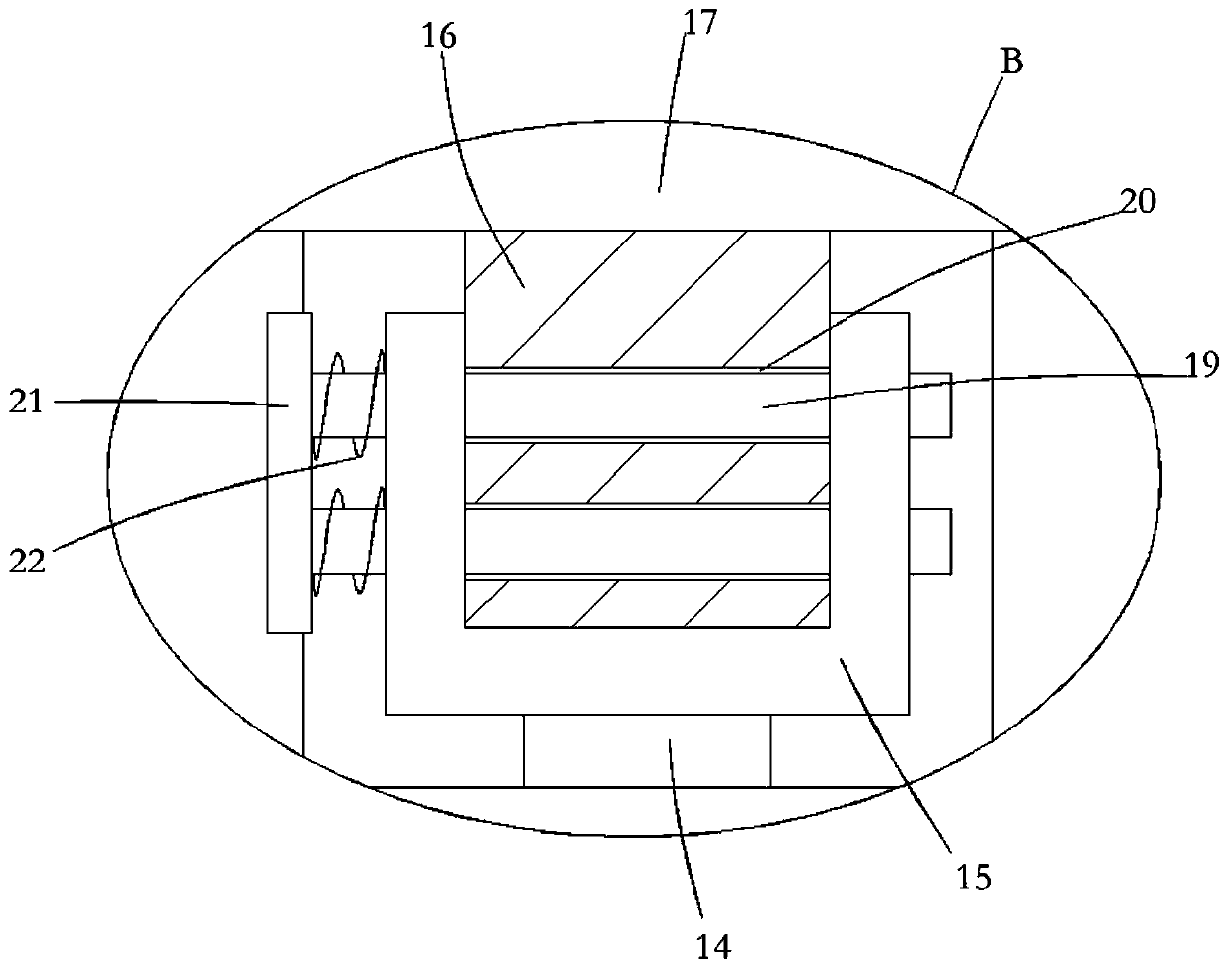

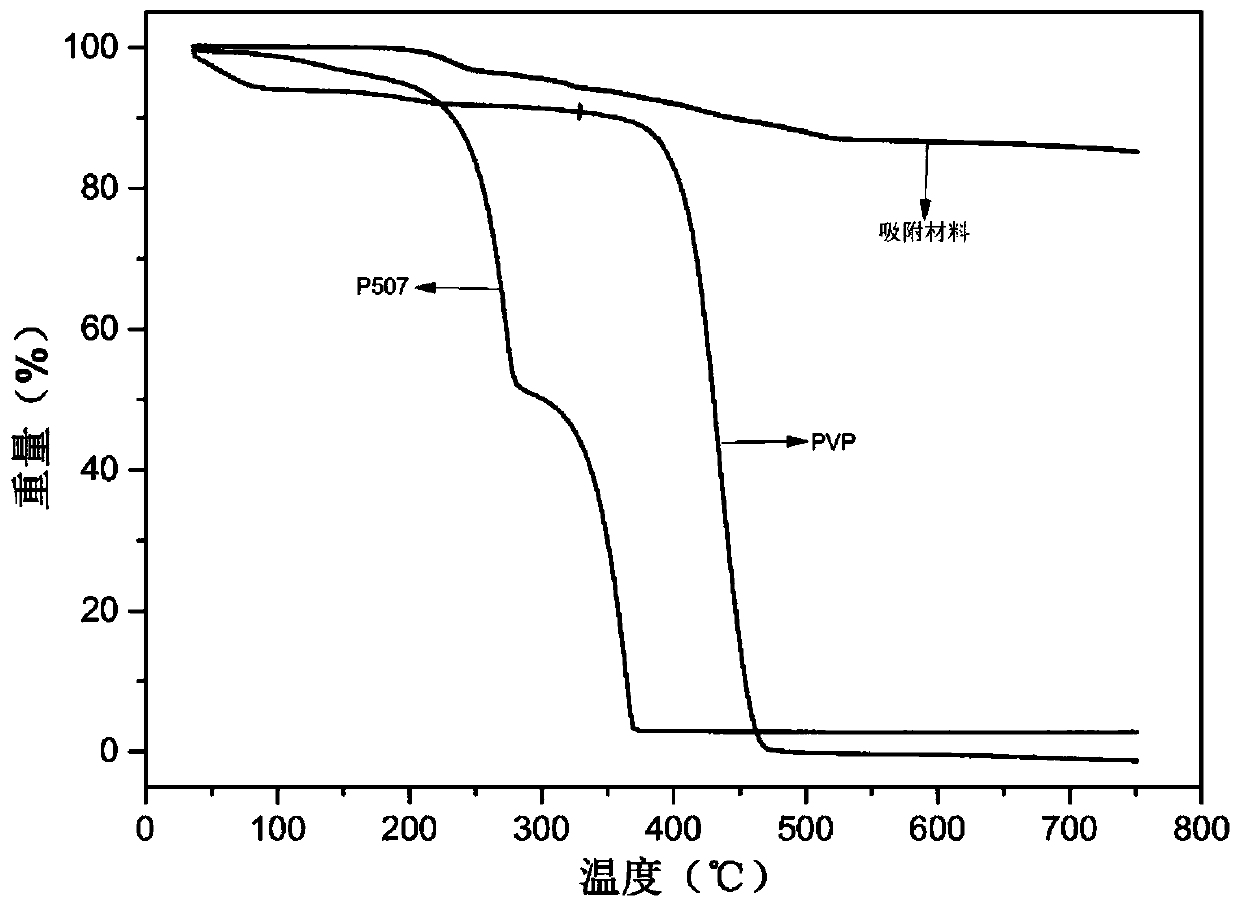

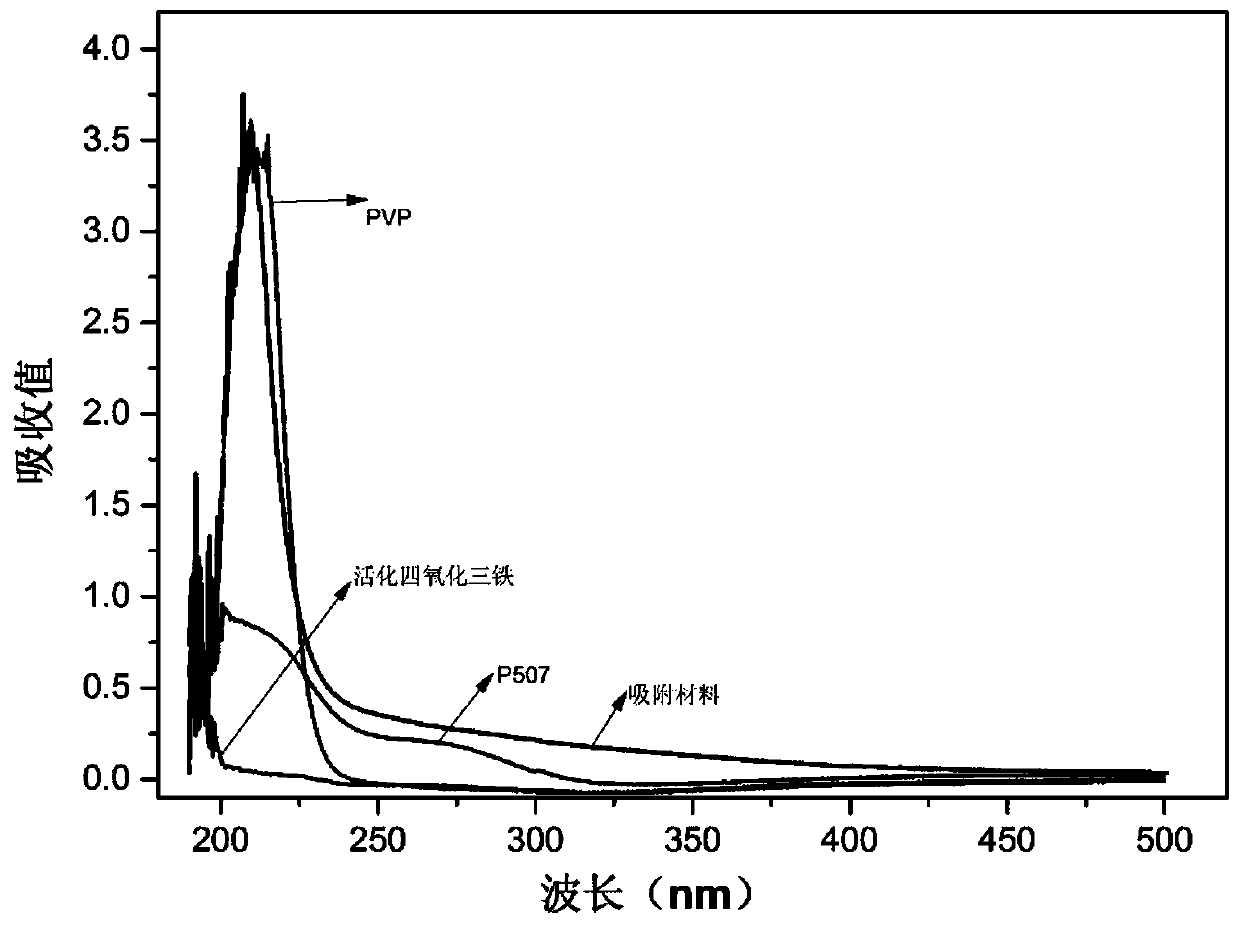

Extractant functionalized magnetic nano adsorption material as well as preparation method and application thereof

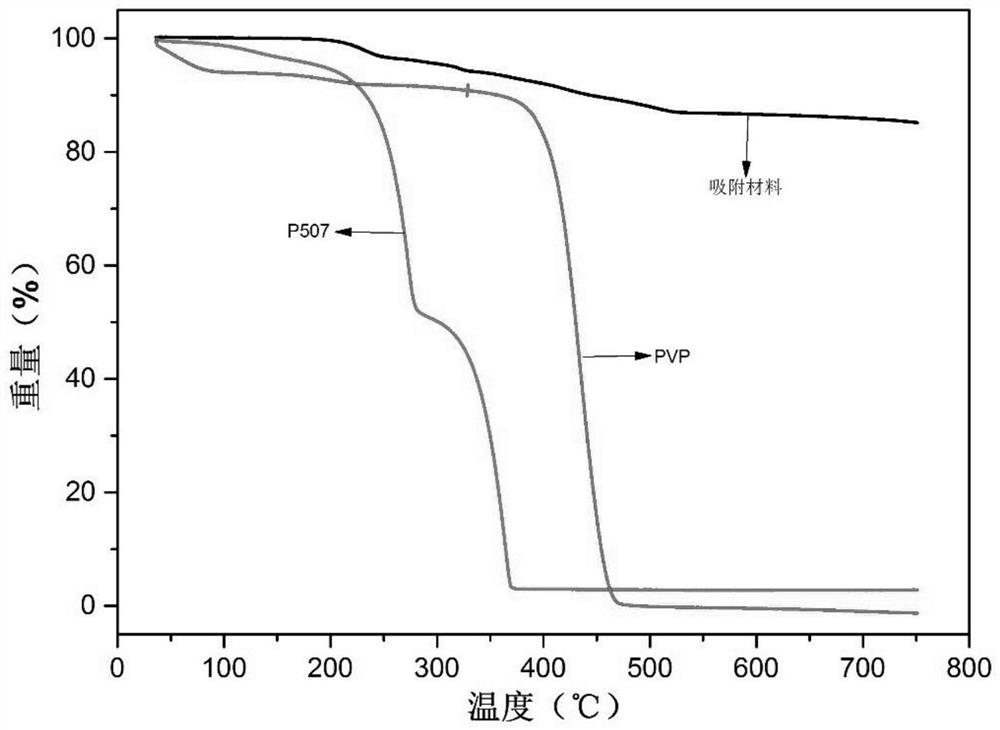

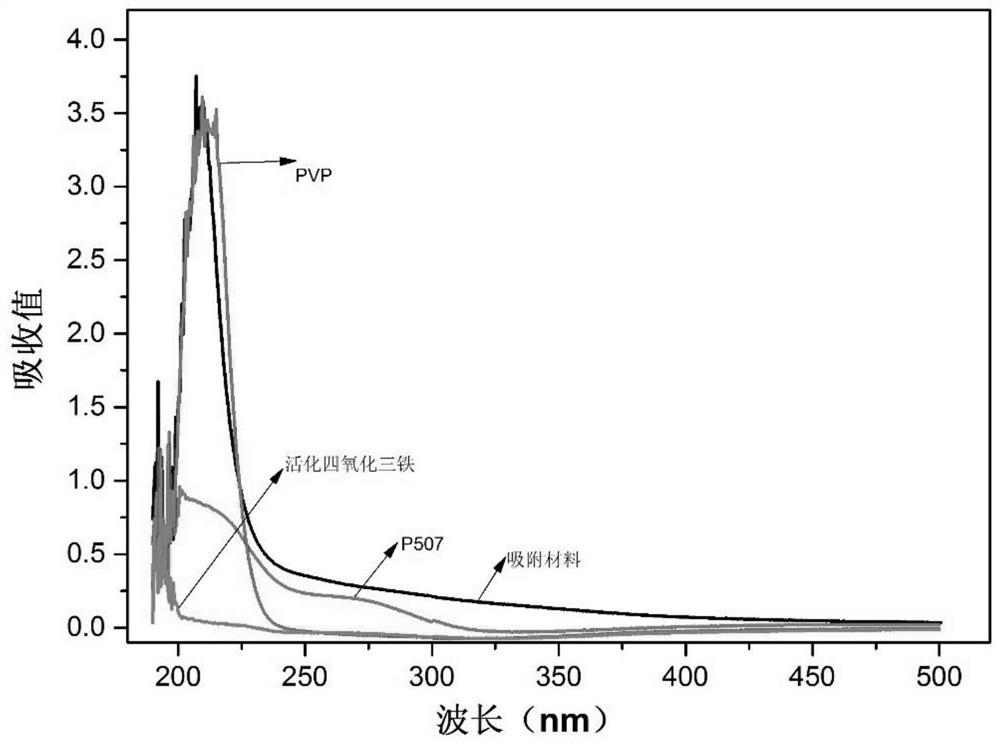

ActiveCN110961086AImprove stabilityImprove production efficiencyIon-exchange process apparatusOther chemical processesAdsorption equilibriumRare earth ions

The invention discloses an extractant functionalized magnetic nano adsorption material as well as a preparation method and application thereof. According to the adsorbing material, magnetic nanoparticles are used as a matrix; by using the good coating performance of polyvinylpyrrolidone, an extraction agent is fixed on the surfaces of the magnetic nanoparticles through the simple chemical method,such that the adsorption material has the adsorption capacity and the magnetism, and can effectively improve the solid-liquid separation efficiency after adsorption equilibrium when the adsorption material is used for adsorbing and separating rare earth ions; besides, the preparation method of the extractant functionalized magnetic nano adsorption material also can overcome the defect that the surface of a magnetic adsorbing material is difficult to modify; by means of the film-forming property of polyvinylpyrrolidone, the surfaces of the magnetic nanoparticles can be rapidly and efficiently coated with different types of extractants, the preparation efficiency of the extractant functionalized magnetic nano adsorption material is improved, the selectable range of the coated extractants isenlarged, and the application of the extractant functionalized magnetic nano adsorption material is enriched.

Owner:JIANGXI UNIV OF SCI & TECH

Winding packaging device for wrapping film packaging

ActiveCN114056633AEasy to holdClamping is easy to achieveWrapping with article rotationWebs handlingElectric machineryEngineering

The invention discloses a winding packaging device for winding film packaging, and the device comprises a base, a motor is fixed to the bottom of the base, and a guide gear ring and a guide gear are both installed in the base in an embedded mode; the device further includes: a transverse rod, which is movably arranged on the side wall of a mounting frame in a penetrating mode, a mounting rod is connected to one end of the transverse rod through a bearing, a guide ball is fixed to the other end of the transverse rod, and a vertical frame is located on the outer side of the mounting frame; a winding film roll assembly, which is mounted at the upper end of the middle part of the base; and a pressure sensor, which is fixed to the outer side of an elastic telescopic rod, wherein a push frame is movably installed in a positioning frame. According to the winding packaging device for winding film packaging, multiple-face film winding treatment of a workpiece is achieved through alternate fixing during revolution and autorotation of the workpiece, wrinkles of the film in the winding process are effectively prevented through stretching of the film and close heating in cooperation, and meanwhile the film is cut off by sensing the number of rotation turns.

Owner:黄山源点新材料科技有限公司

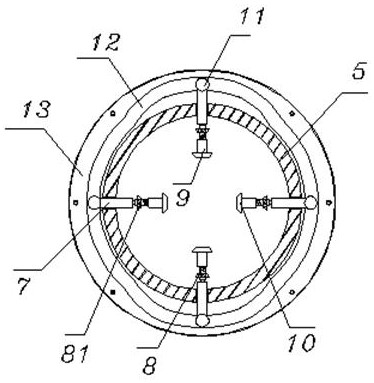

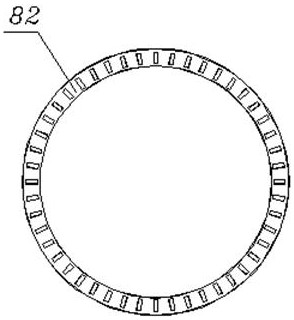

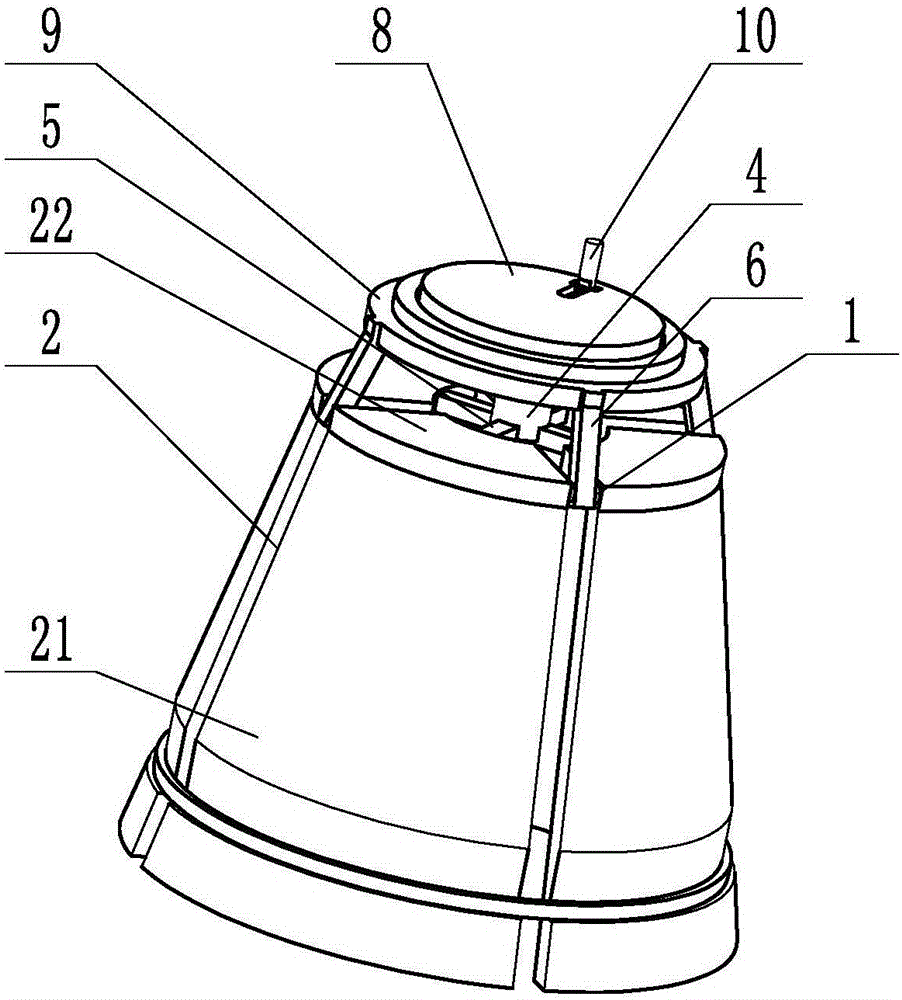

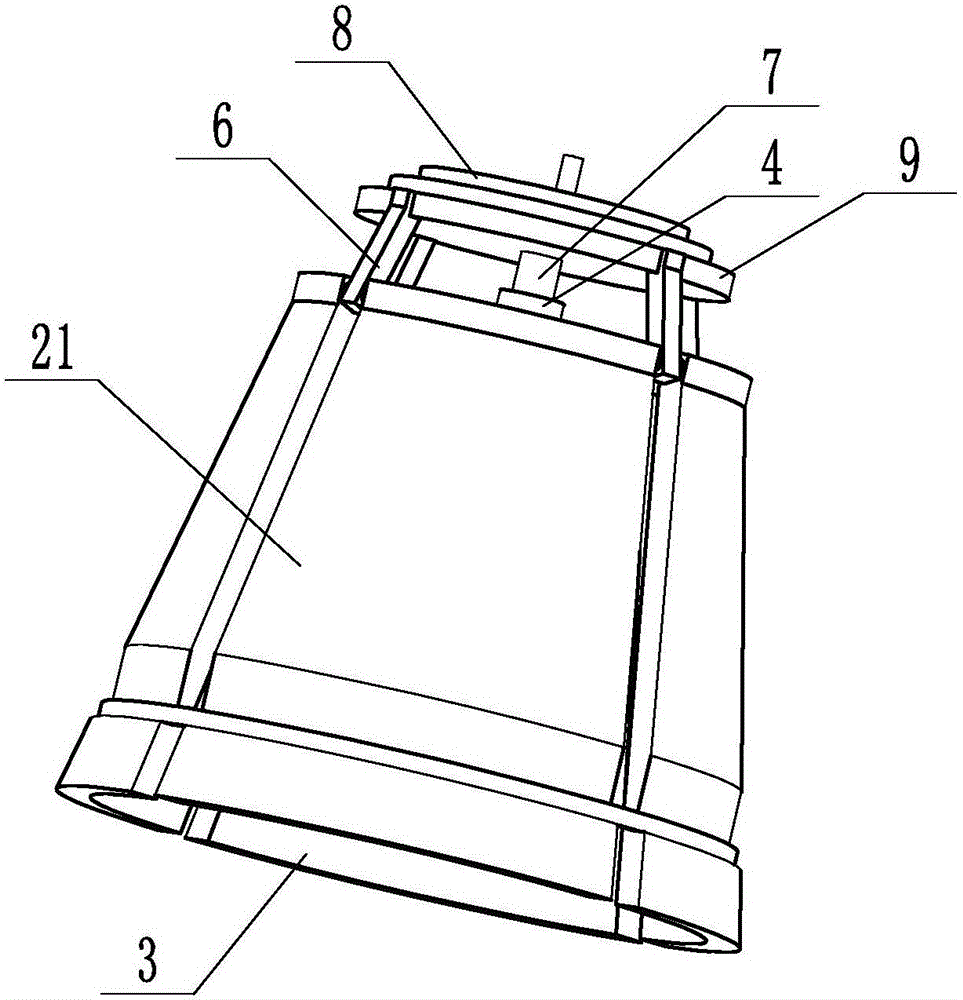

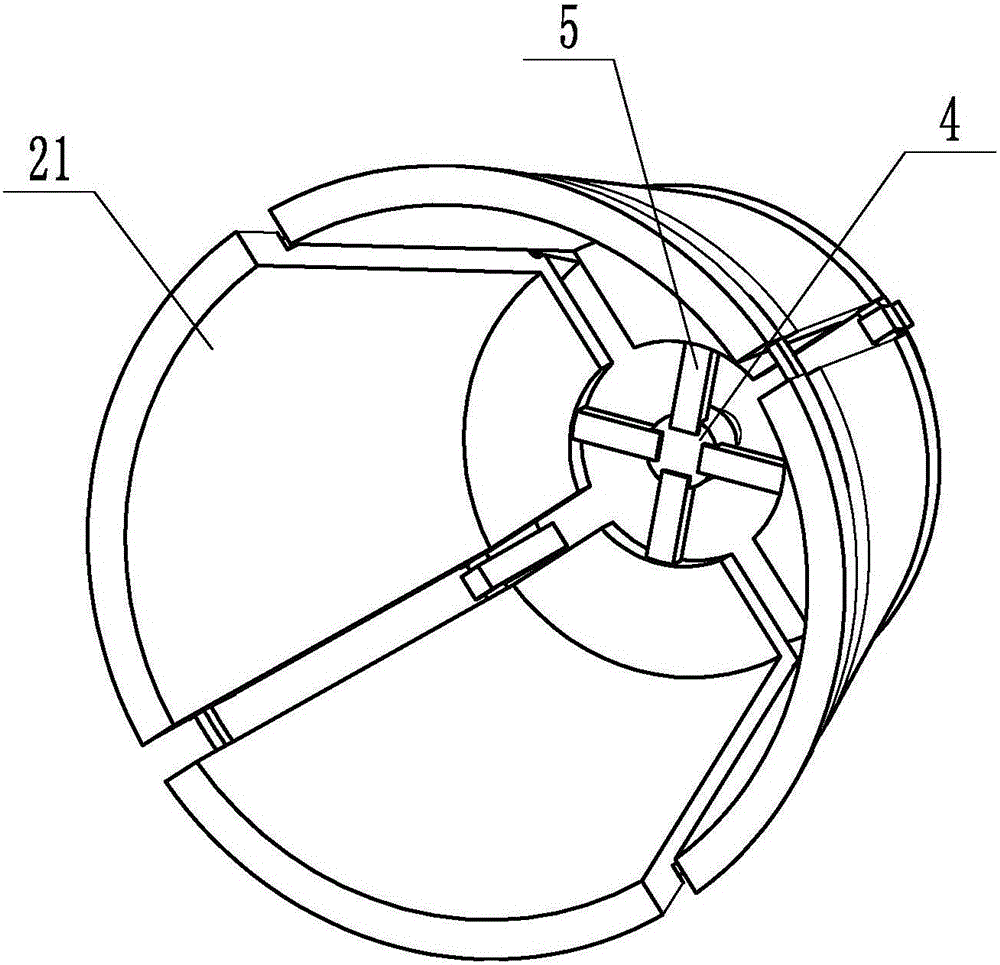

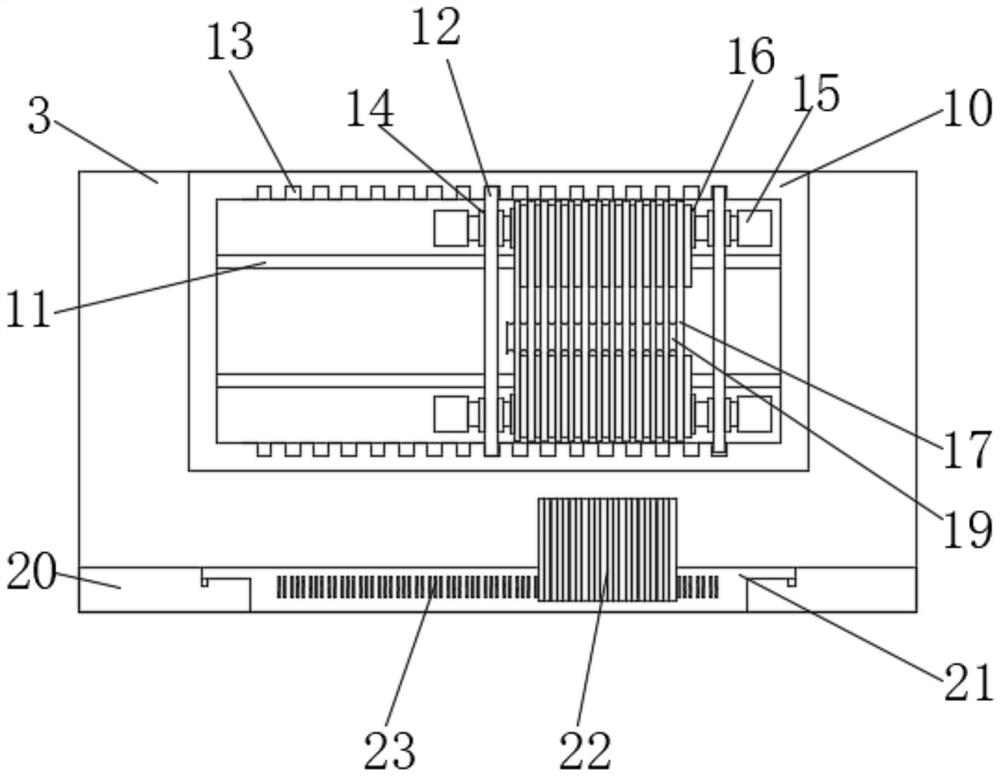

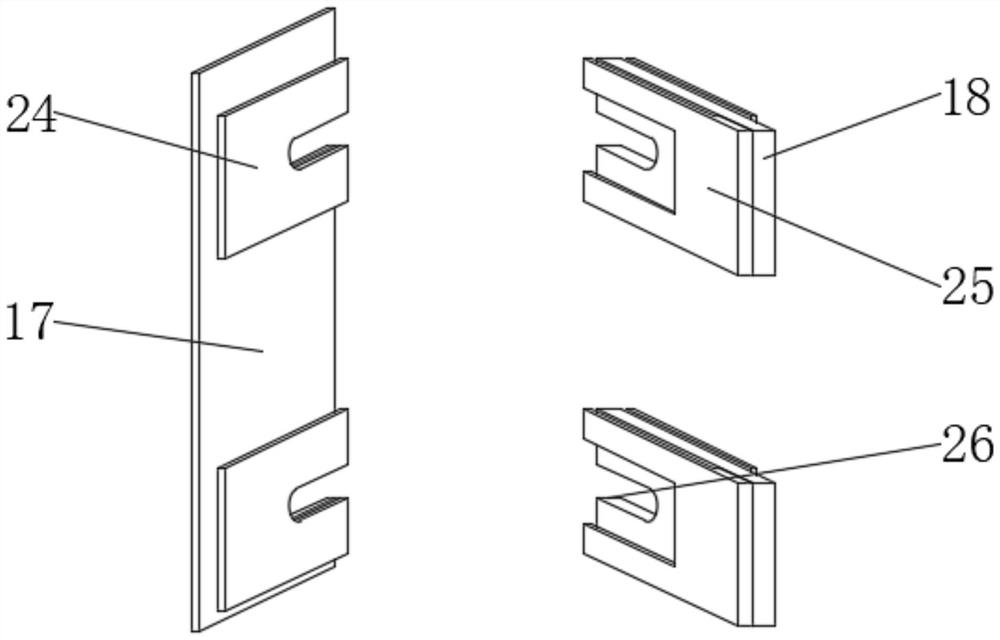

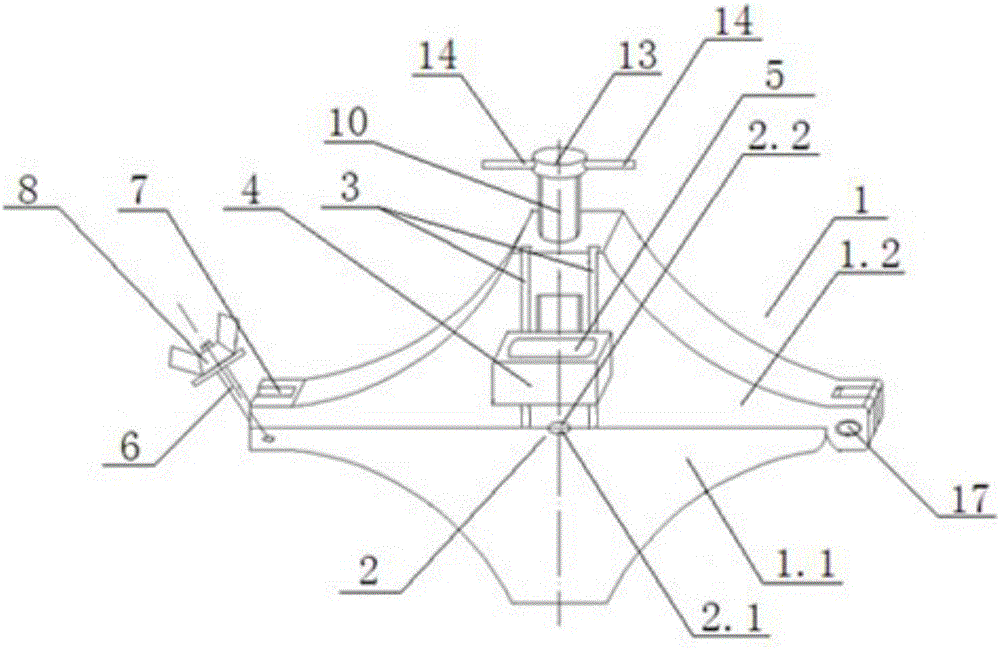

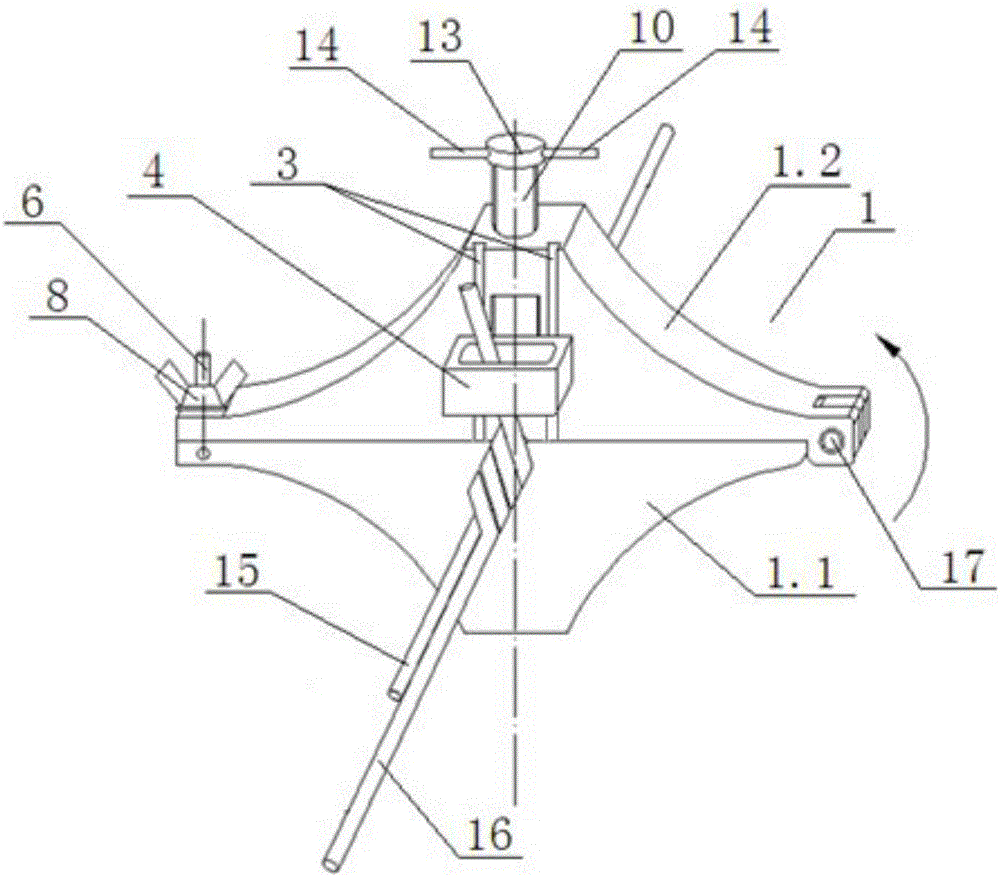

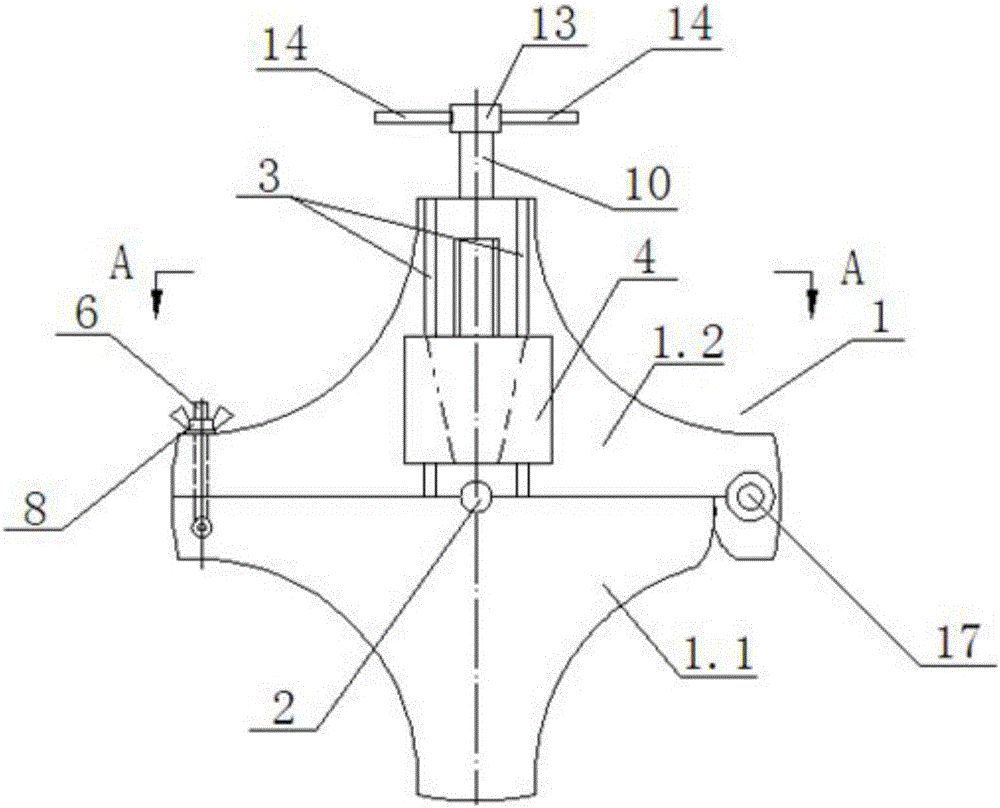

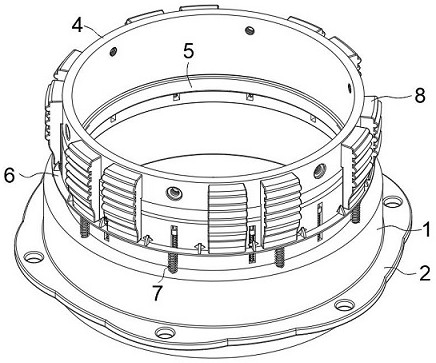

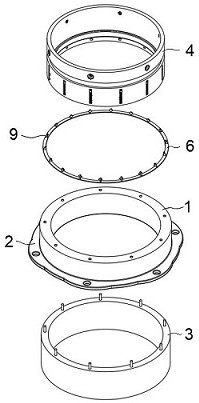

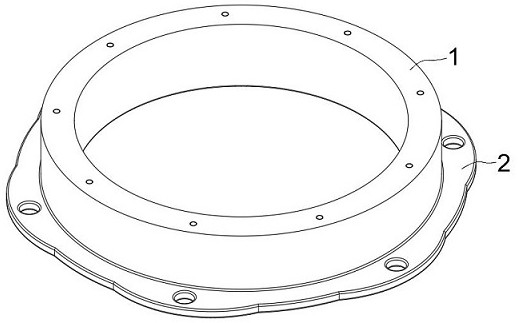

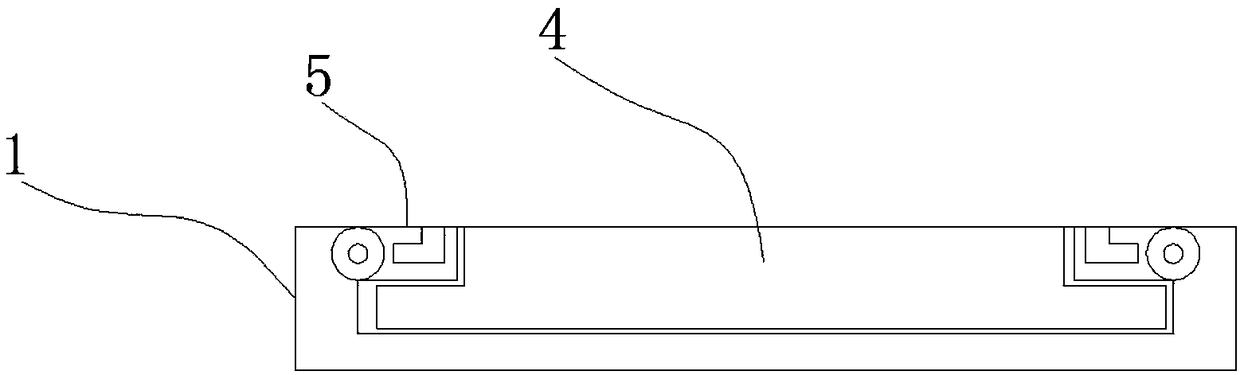

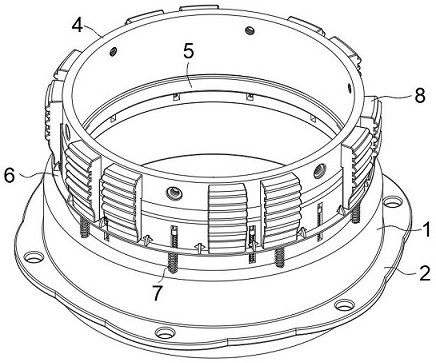

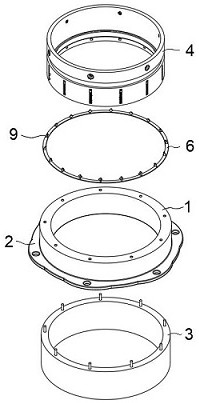

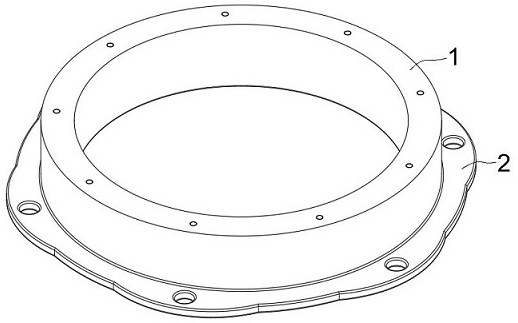

Quick-assembly protective sleeve structure of drilling tool

The invention relates to a quick-assembly protective sleeve structure of a drilling tool. The quick-assembly protective sleeve structure comprises a protective ring, wherein a plurality of protective pieces are arranged in the circumferential direction of the protective ring in a spaced manner; a tapered protective cavity is integrally formed among the protective pieces; the drilling tool is arranged in the protective cavity; the protective pieces comprise wrapping pieces for wrapping the drilling tool, and swinging pieces arranged in the protective ring; the swinging pieces and the wrapping pieces are integrally formed; connection and bending parts between the swinging pieces and the wrapping pieces are rotationally mounted on the protective ring; a regulating sleeve is arranged in the center of a zone defined by the swinging pieces; a connecting rod is connected between the regulating sleeve and one swinging piece correspondingly; one end of one connecting rod is fixedly connected with one swinging piece correspondingly; the other ends of the connecting rods are hinged to the side wall of the regulating sleeve; a fixing plate is mounted at one side of the axial direction of the protective ring, and is fixedly connected with the protective ring through fixing rods; a spiral short column is rotationally mounted in the center of the fixing plate; the inner end of the spiral short column is spirally mounted in the regulating sleeve; an operating panel is mounted at the outer end of the spiral short column; and a handle is mounted at the side surface of the operating panel.

Owner:东莞市瑞佳机电工程有限公司

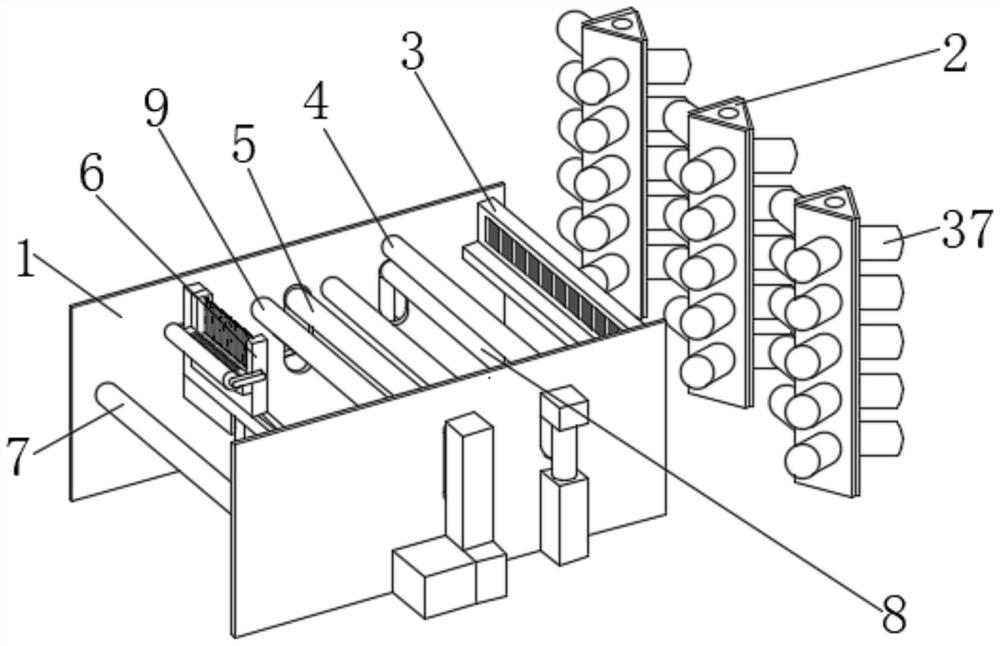

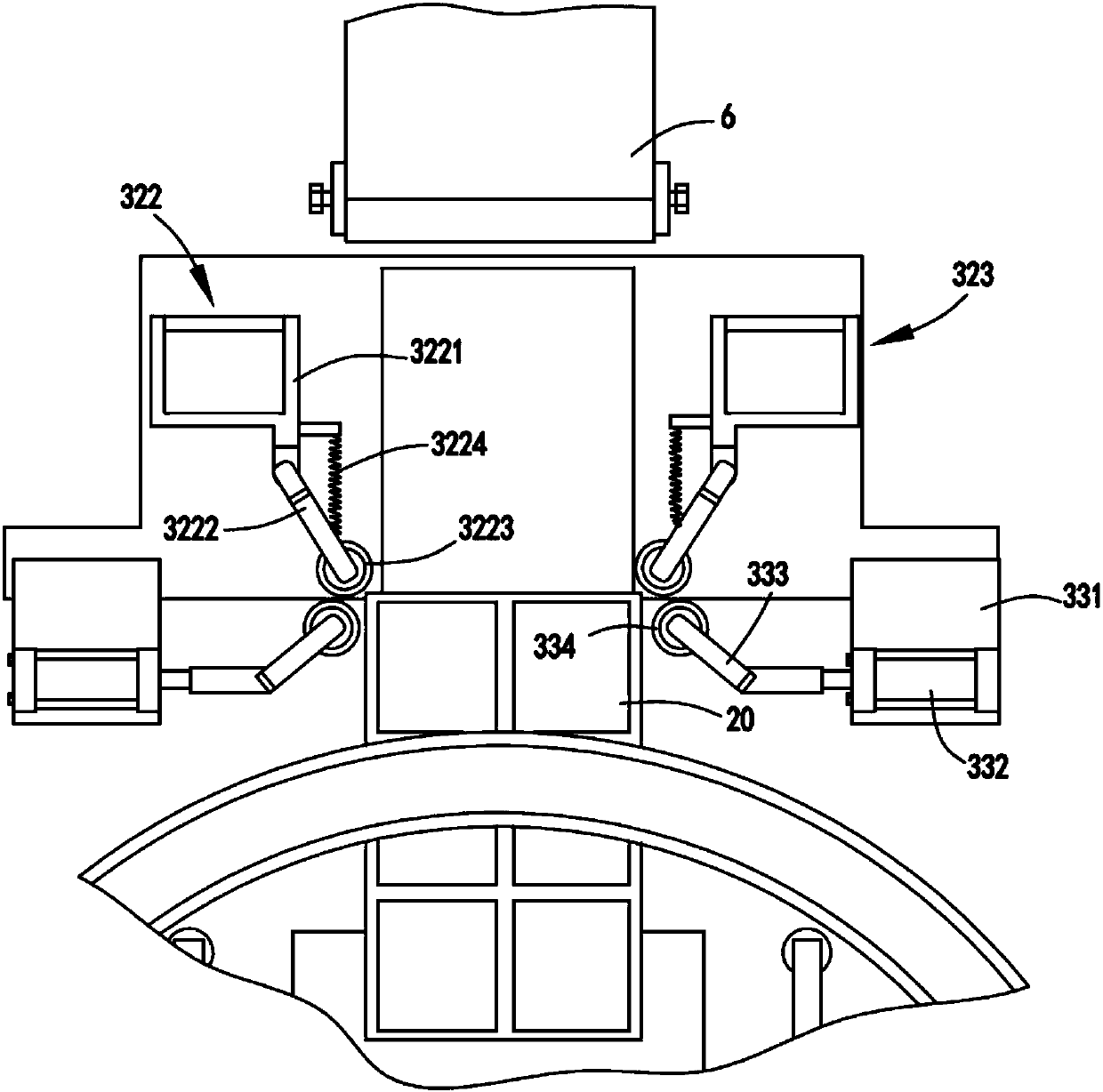

Mussel seedling wrapping device

ActiveCN111264428BQuick wrapImprove work efficiencyWork-feeding meansNeedle severing devicesStructural engineeringConveyor belt

The invention discloses a mussel seedling wrapping device, which solves the problems of low production efficiency and high production cost of manually sewing the wrapping cloth. It is characterized in that: a conveyor belt is provided on the frame, a fabric folding mechanism is provided on both sides of the conveyor belt, a sewing mechanism is provided behind the fabric folding mechanism, and the sewing mechanism is equipped with a shearing mechanism. The wrapped seedling cloth is transported to the fabric folding mechanism through the conveyor belt, and the wrapped seedling cloth is folded through the track of the cloth folding mechanism, and then through the sewing mechanism, the sides and two ends of the seedling-preserving cloth are stitched. After the sewing is completed, the shearing mechanism will sew The thread cutting can quickly wrap the breeding rope tightly, which not only improves the work efficiency, but also reduces the production cost.

Owner:ZHOUSHAN SHENGSIHAI GUANGMING ELECTRIC APPLIANCE CO LTD

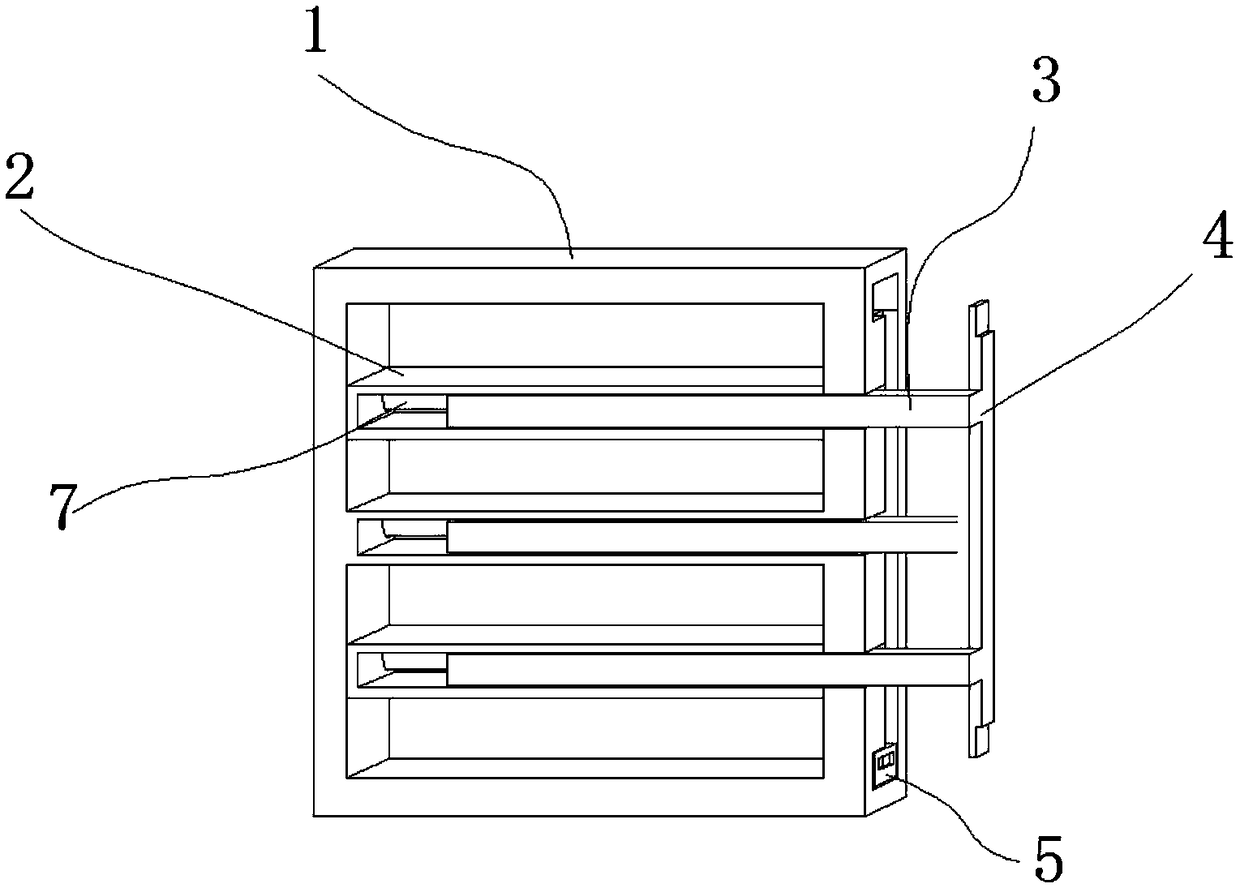

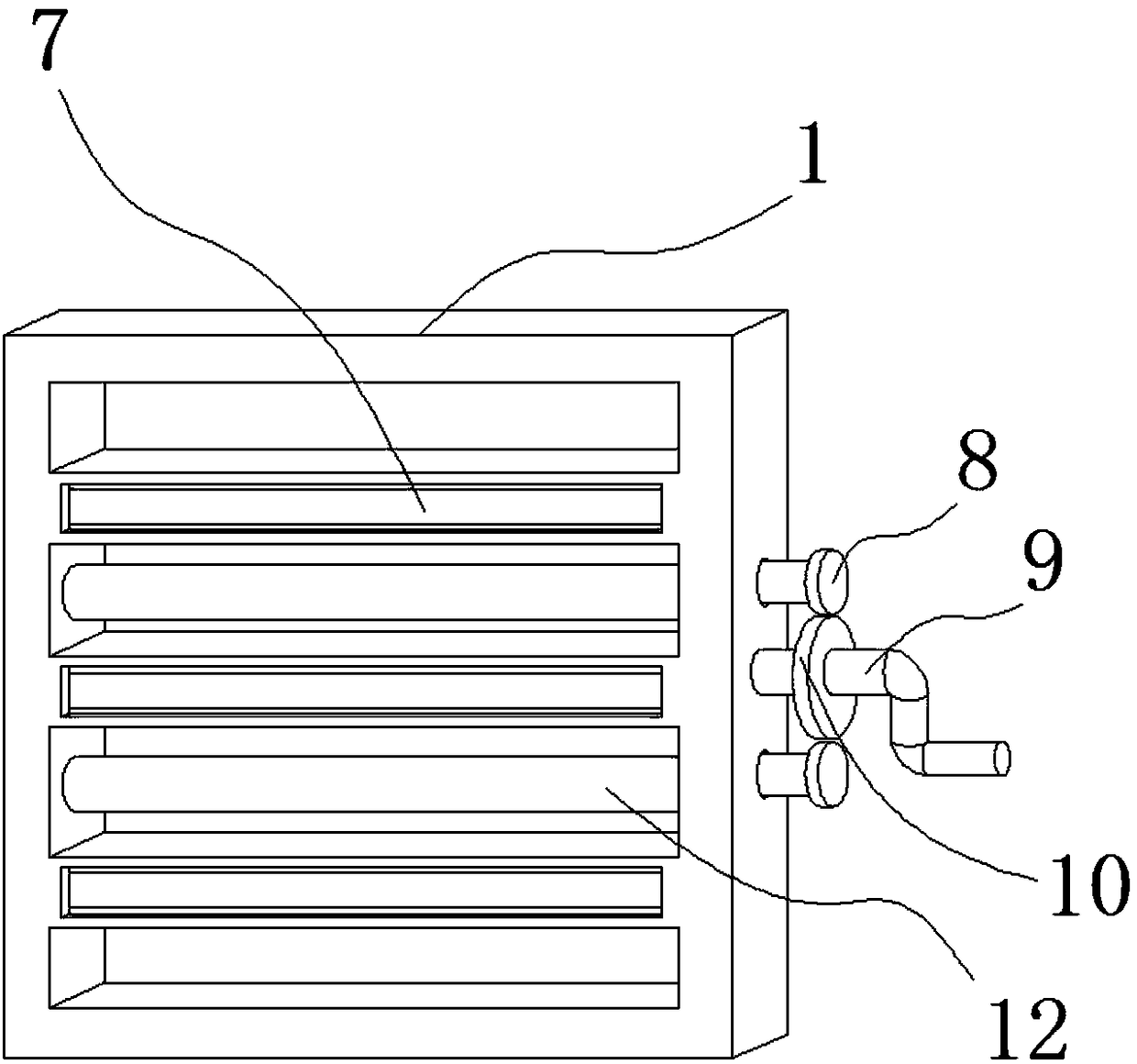

A winding device for fiber cotton processing

The invention discloses a wire winding device used for fiber cotton processing. The wire winding device comprises a frame. The inner side of the frame is connected with multiple fixed plates. A wire winding shaft is arranged between every two fixed plates. A locking block is arranged at one end of each wire winding shaft. Locking openings are formed in one side of the frame. The locking blocks arein threaded connection with the locking openings. A connecting block is arranged at the other end of each wire winding shaft. The side, away from the corresponding wire winding shaft, of each connecting block penetrates the frame and is connected with a driven wheel. The other side of the frame is rotationally connected with a connecting shaft. A driving wheel engaged with the driven wheels is connected to the connecting shaft in a sleeving manner. The wire winding device is convenient to operate and simple in structure; fiber cotton is in winding connection to the wire winding shaft, only ahandle needs to be rotated, and the wire winding shaft can be fast taken out when winding connection is completed; and the fiber cotton can be subjected to heating treatment to a certain degree whilethe wire winding shaft is in winding connection with the fiber cotton, and the effect of fast and efficient winding connection of the fiber cotton can be achieved.

Owner:钟星汉

A kind of surface treatment method of garnet type solid electrolyte

ActiveCN112290082BIsolated from direct contactAvoid generatingElectrolytesLi-accumulatorsSolid state electrolyteConductive polymer

The invention belongs to the technical field of preparation of solid electrolytes, and in particular relates to a surface treatment method for garnet-type solid electrolytes. First, the garnet electrolyte powder material is pretreated, and then spray drying technology is used to form a surface treatment method with a thickness of 1-1. 50nm ion conductive polymer coating layer, the method of the invention prevents adverse reactions between the garnet solid electrolyte and the air, suppresses the generation of surface impurities, and at the same time ensures that the ion conductivity of the electrolyte will not be deteriorated, so that the electrolyte can Maintain a high degree of stability and electrochemical performance during storage and use.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

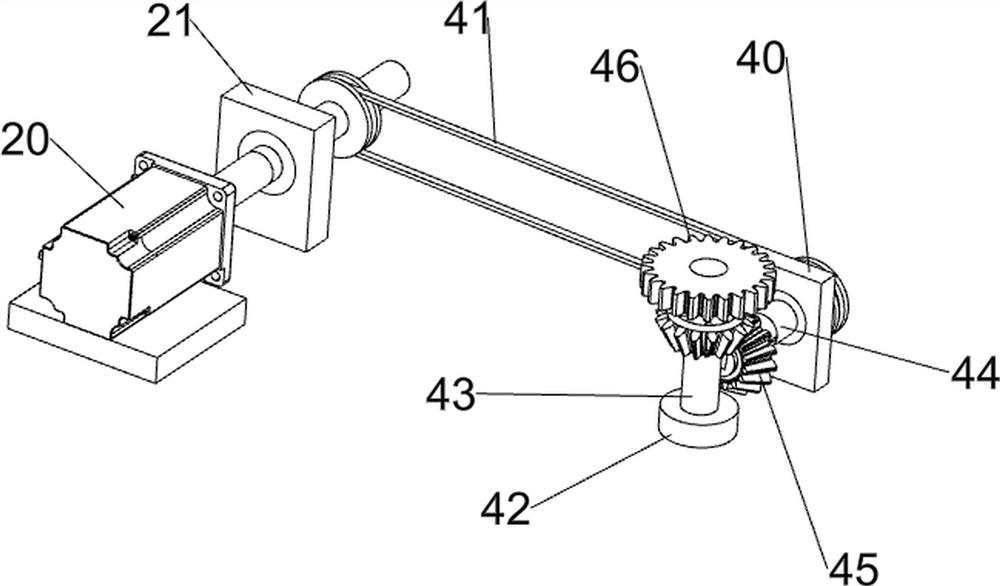

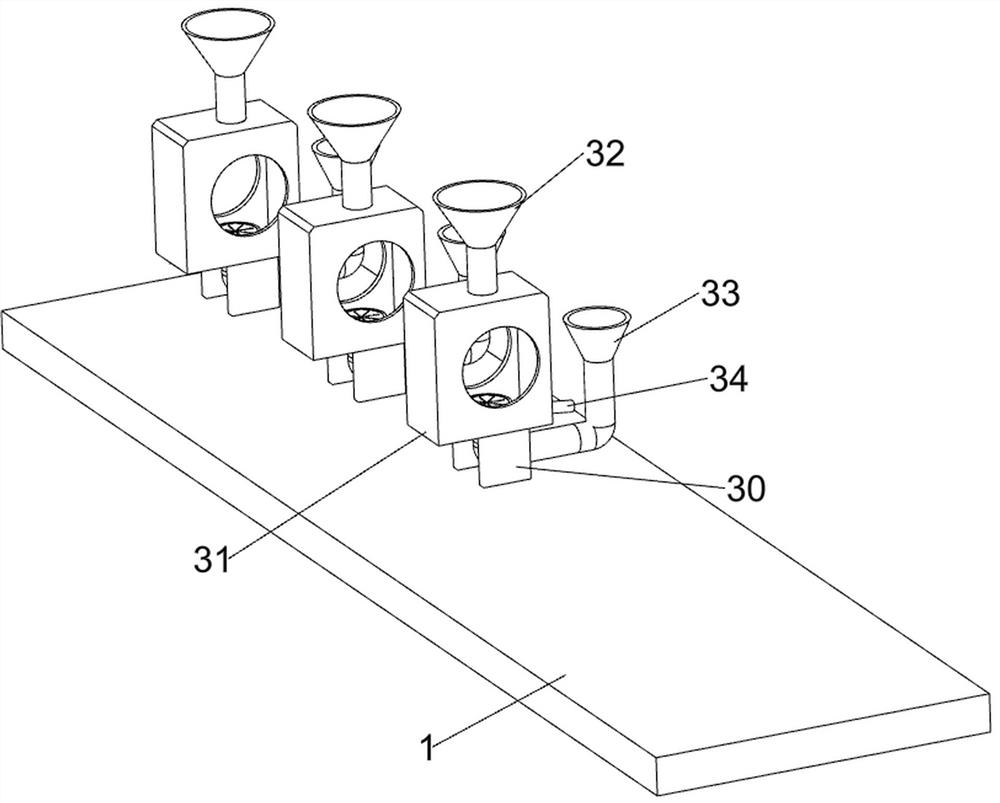

A construction fiberglass oiling and wrapping device

The invention relates to an oiling and wrapping device, in particular to an oiling and wrapping device for architectural FRP. Provided is a construction-type fiberglass oiling and wrapping device that can quickly paint and wrap fiberglass and can automatically push the fiberglass. A construction FRP oiling and wrapping device, including: a base, the base is used to install the whole equipment; a wrapping mechanism, the upper side of the base is equipped with a wrapping mechanism; There is a painting mechanism, and the cloth wrapping mechanism cooperates with the painting mechanism. The present invention can quickly paint and wrap FRP, and can automatically push the FRP. By placing the FRP in the protective frame and the installation frame, the FRP can be painted quickly through the upper nozzle and the lower nozzle. FRP can be wrapped quickly through the adhesive tape on the discharge rod.

Owner:上饶市茗氏达新材料科技有限公司

A quick-loading protective sleeve structure for drilling tools

The invention relates to a quick-assembly protective sleeve structure of a drilling tool. The quick-assembly protective sleeve structure comprises a protective ring, wherein a plurality of protective pieces are arranged in the circumferential direction of the protective ring in a spaced manner; a tapered protective cavity is integrally formed among the protective pieces; the drilling tool is arranged in the protective cavity; the protective pieces comprise wrapping pieces for wrapping the drilling tool, and swinging pieces arranged in the protective ring; the swinging pieces and the wrapping pieces are integrally formed; connection and bending parts between the swinging pieces and the wrapping pieces are rotationally mounted on the protective ring; a regulating sleeve is arranged in the center of a zone defined by the swinging pieces; a connecting rod is connected between the regulating sleeve and one swinging piece correspondingly; one end of one connecting rod is fixedly connected with one swinging piece correspondingly; the other ends of the connecting rods are hinged to the side wall of the regulating sleeve; a fixing plate is mounted at one side of the axial direction of the protective ring, and is fixedly connected with the protective ring through fixing rods; a spiral short column is rotationally mounted in the center of the fixing plate; the inner end of the spiral short column is spirally mounted in the regulating sleeve; an operating panel is mounted at the outer end of the spiral short column; and a handle is mounted at the side surface of the operating panel.

Owner:东莞市瑞佳机电工程有限公司

Hemp rope wrapping and tightening device

ActiveCN111264428AQuick wrapImprove work efficiencyWork-feeding meansNeedle severing devicesStructural engineeringMechanical engineering

The invention discloses a hemp rope wrapping and tightening device, and solves the problems of low production efficiency and high production cost of manual suture of seedling-wrapping cloth. The device is characterized in that the frame is provided with a conveying belt, both sides of the conveying belt are provided with a cloth folding mechanism, the rear of the cloth folding mechanism is provided with a sewing mechanism, and the sewing mechanism is provided with a shearing mechanism. The seedling-wrapping cloth is transported to the cloth folding mechanism through the conveying belt, the seedling-wrapping cloth is folded through the track of the cloth folding mechanism and then passes through the sewing mechanism, the side and both ends of the seedling-wrapping cloth are sewn by the sewing mechanism, and the suture thread is cut by a cutting mechanism after the sewing is completed; and wrapping and tightening of breeding rope can be quickly performed, not only the working efficiencyis improved, but also the production cost is reduced.

Owner:ZHOUSHAN SHENGSIHAI GUANGMING ELECTRIC APPLIANCE CO LTD

Raw material warping device for textile processing

ActiveCN114645359AReduce the probability of breakageAvoid intertwiningCreelsWarping machinesYarnEngineering

The invention relates to a raw material warping device for textile processing, which comprises a warping frame, a plurality of warp cylinders uniformly distributed in an array are arranged on one side of the warping frame, and a plurality of warp cylinders uniformly distributed in an array are mounted on the warp cylinders. A warp dividing frame, a pressing roller, a tensioning roller, a warp guiding frame and a warp winding roller are sequentially installed on the inner side of the warping frame from the side close to the warp cylinder to the side away from the warp cylinder, a lifting roller used for lifting and abutting against the pressing roller is arranged on the lower side of the pressing roller, and guiding rollers symmetrical about the tensioning roller are arranged on the two sides of the tensioning roller. The two ends of the guide roller are fixedly connected with the inner side wall of the warping frame, a plurality of warp dividing pieces which are evenly distributed at equal intervals are installed in the warp dividing frame, tensioning mechanisms used for tensioning the warps are arranged on the portions, located on the periphery of each warp cylinder, of the warp cylinder column, the warps are separated through the warp dividing pieces, the warps are rapidly and accurately wound through the warp winding roller, and the warp winding efficiency is improved. And the warp yarns are prevented from being wound in the whole warping process.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

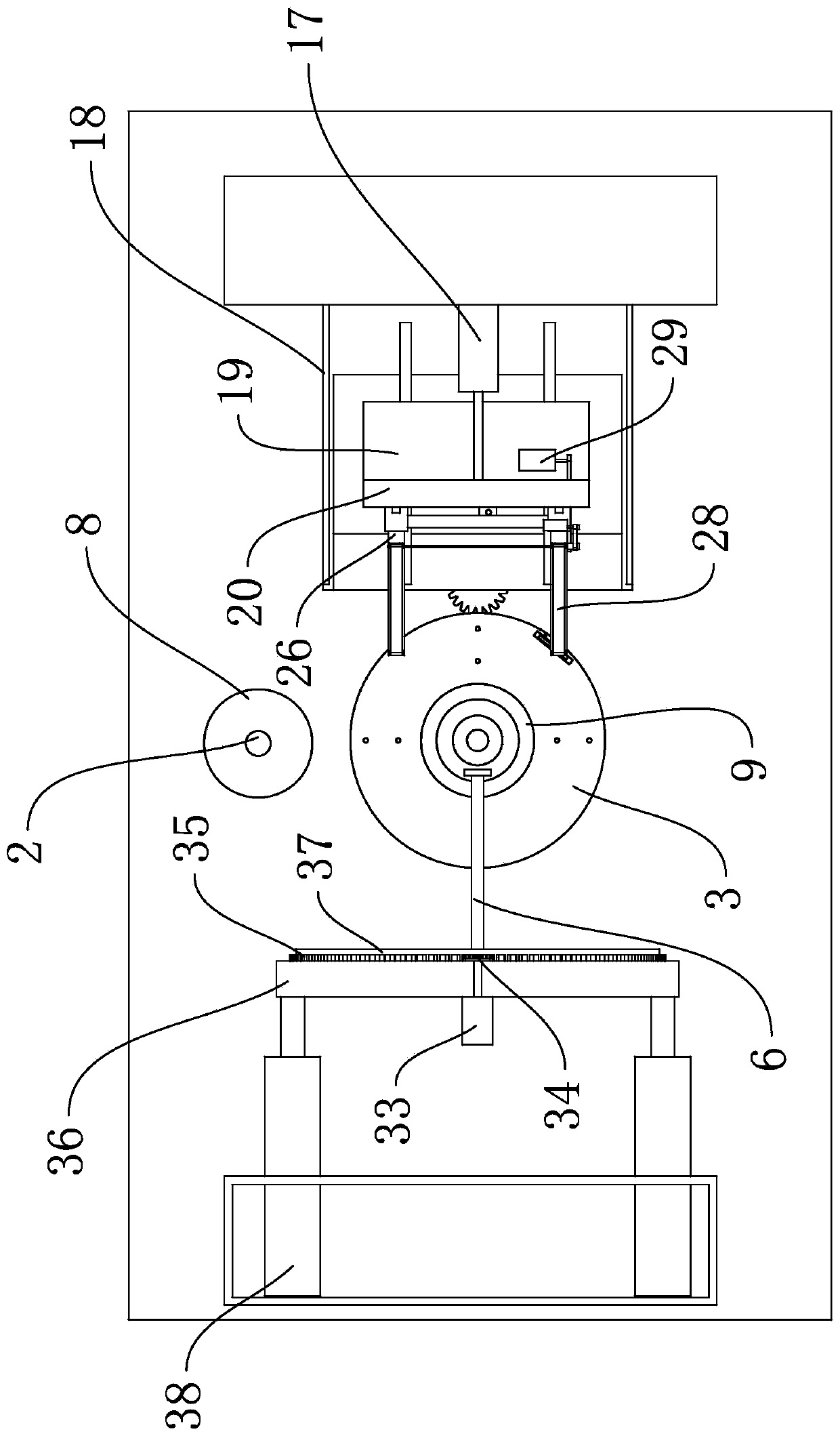

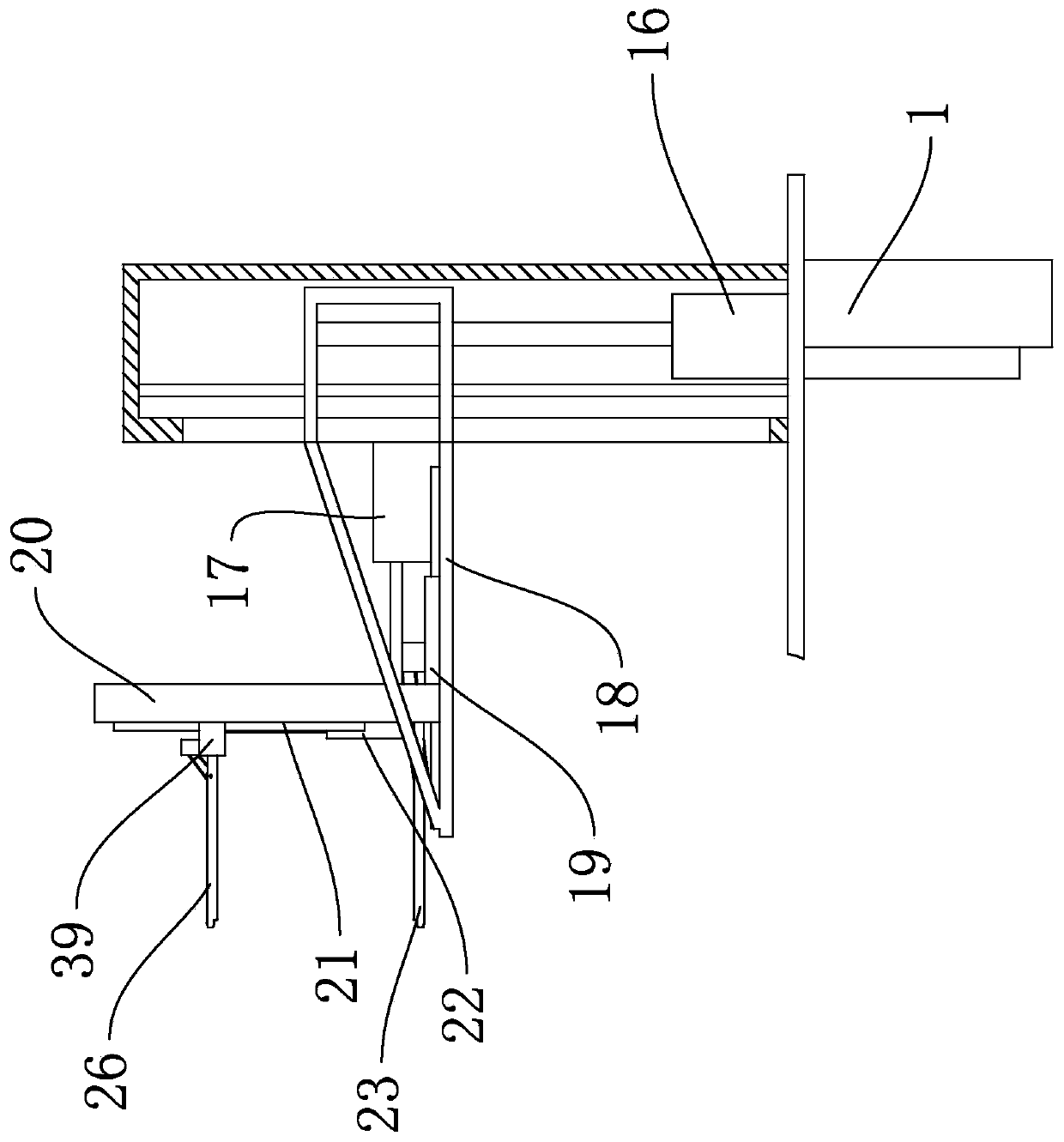

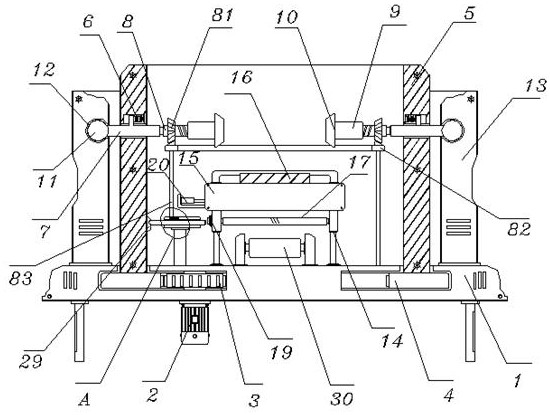

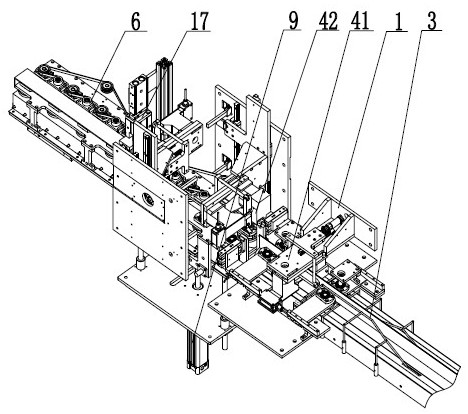

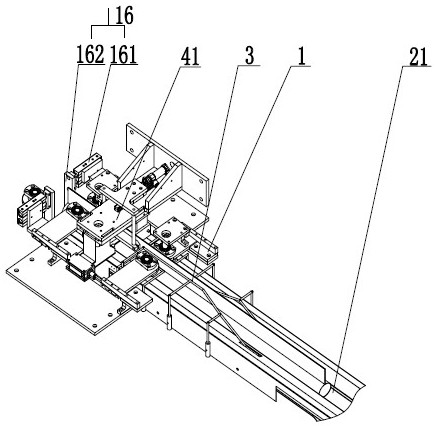

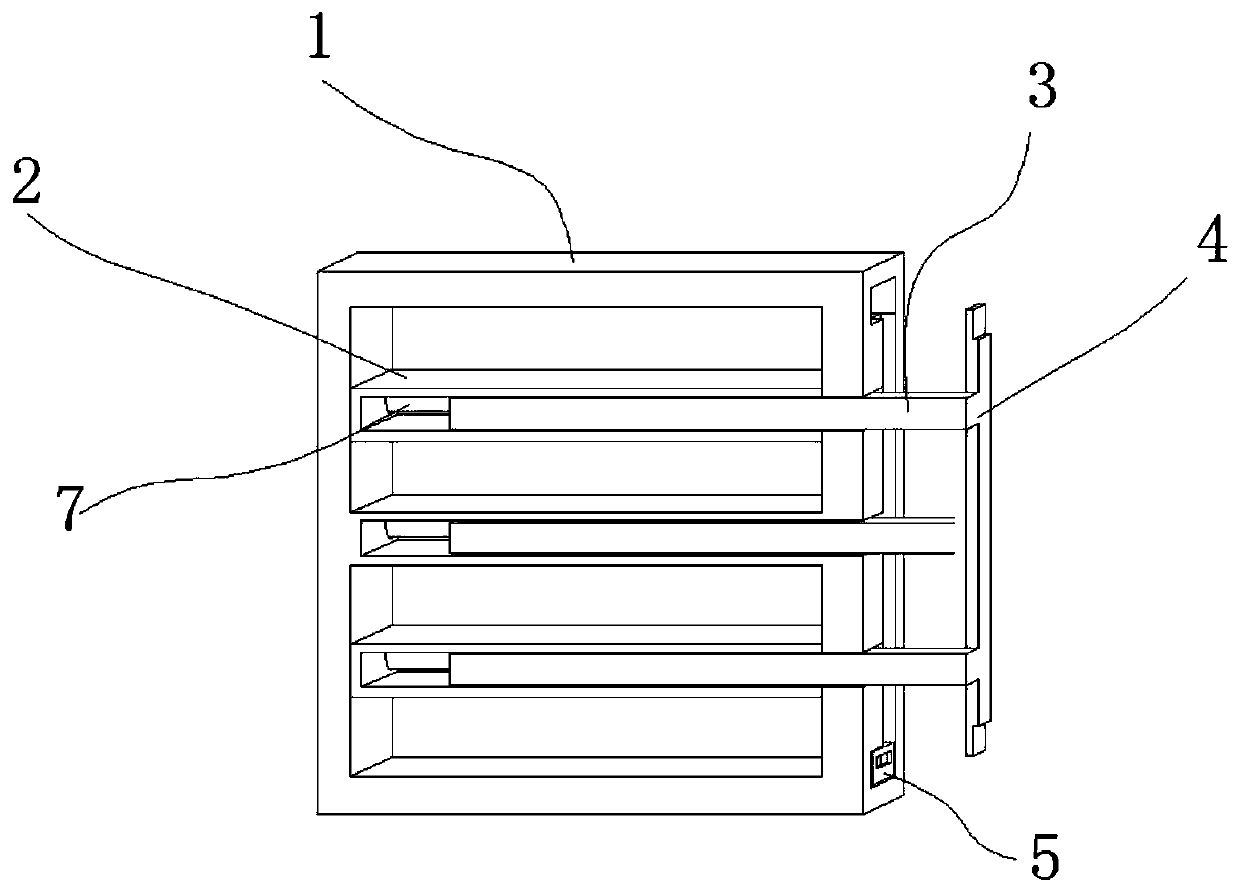

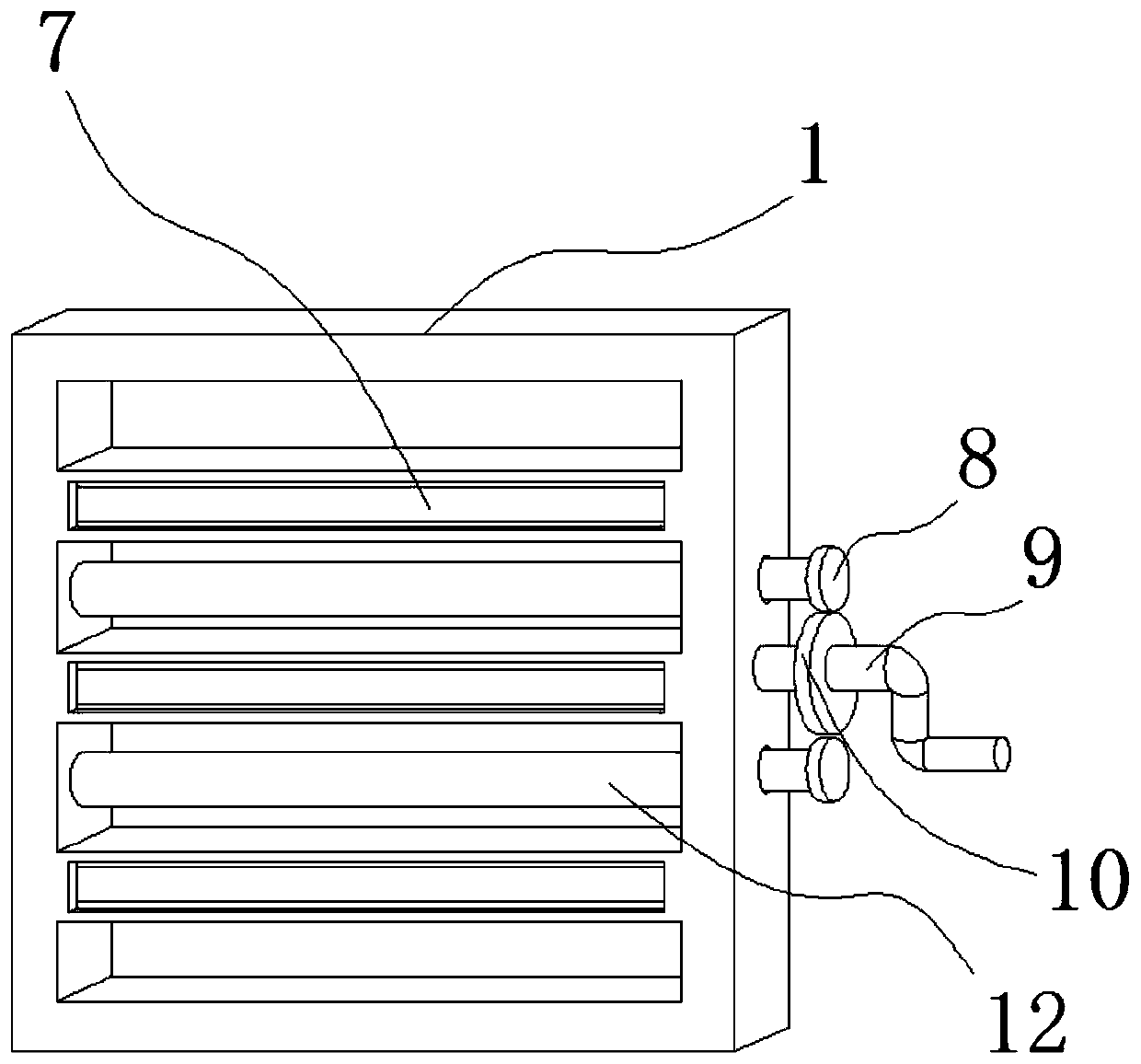

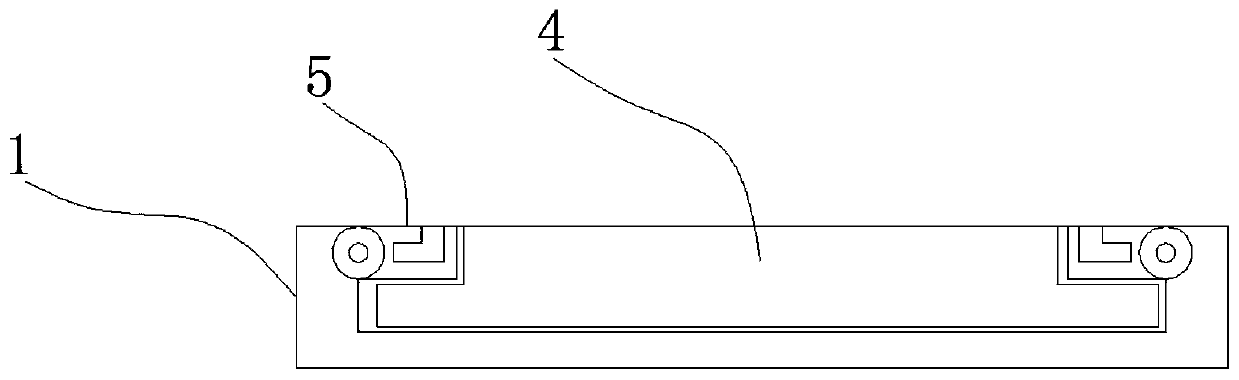

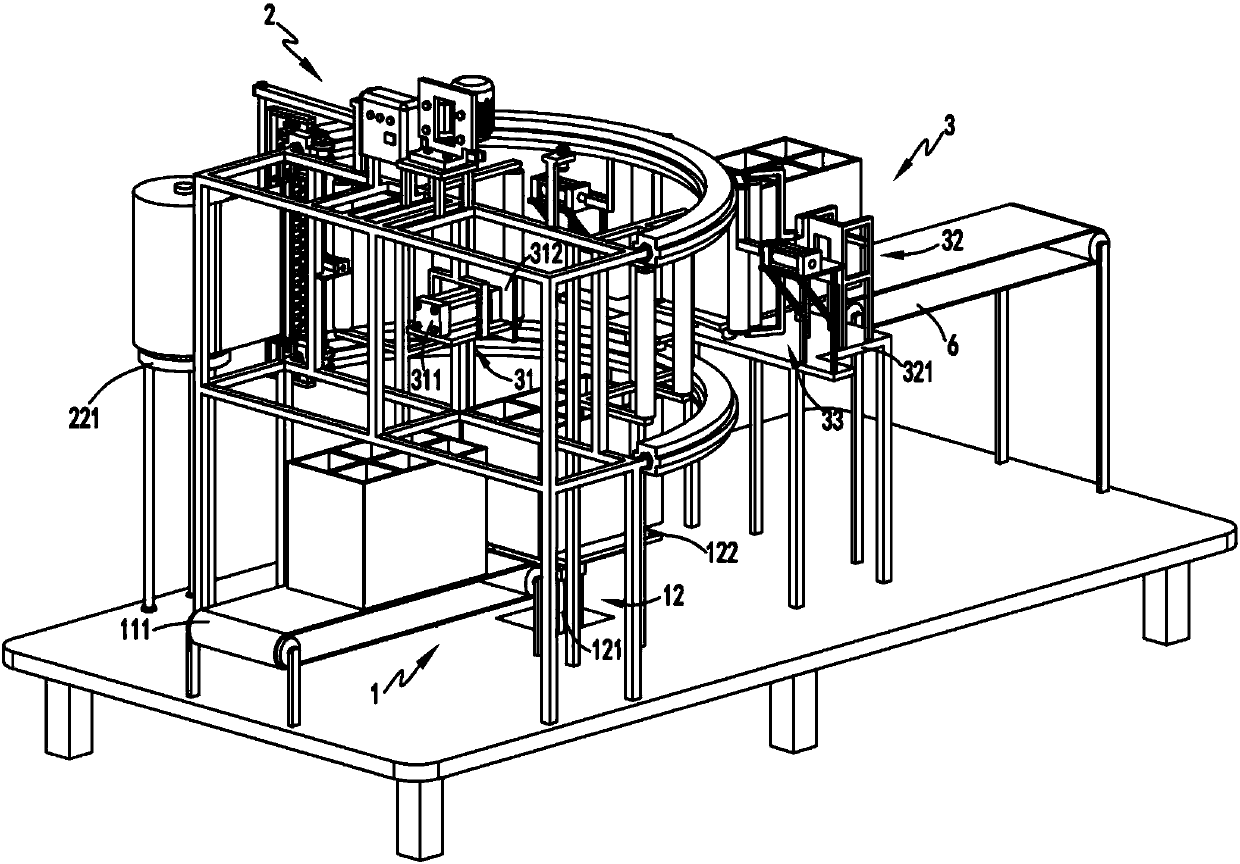

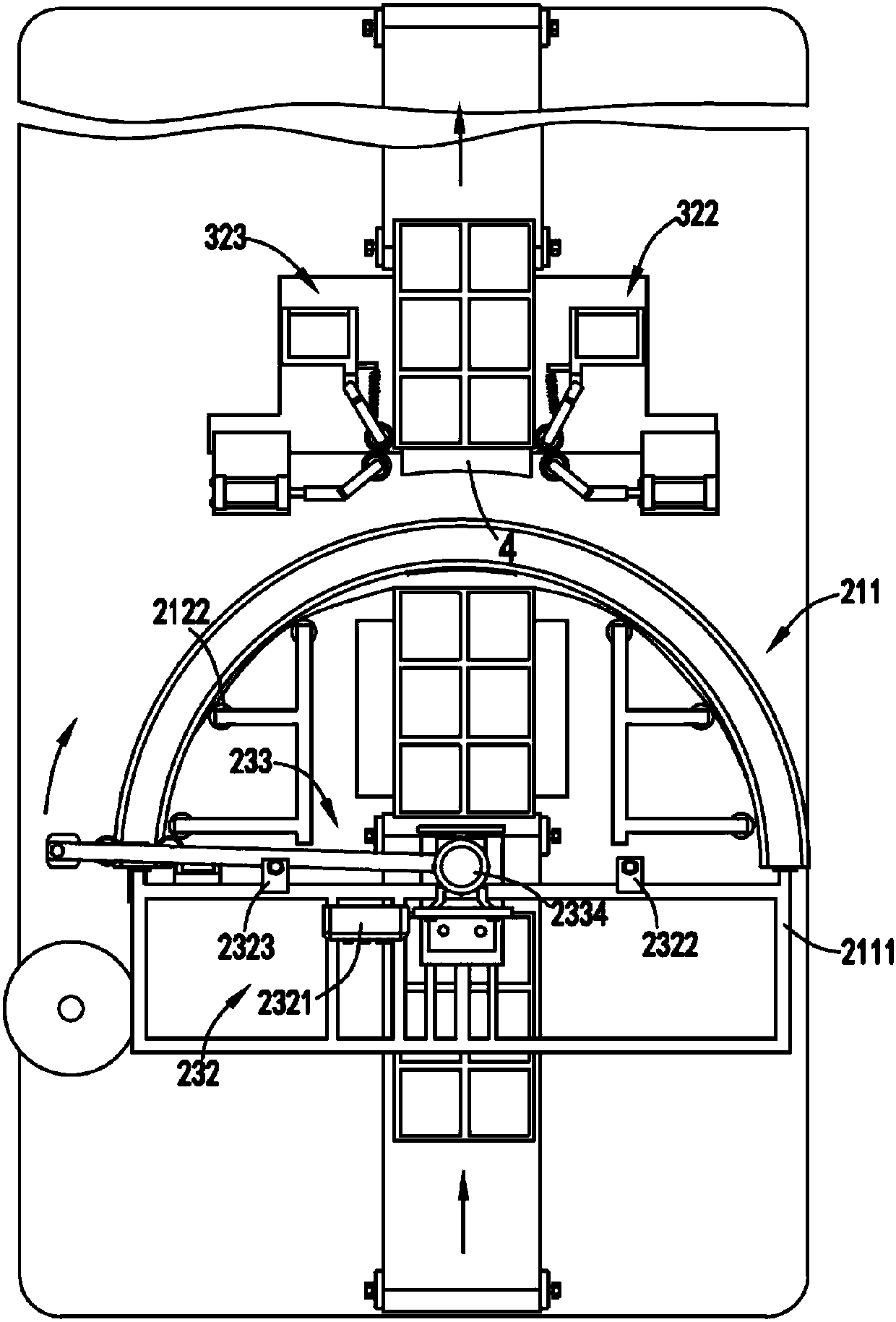

Automatic coating equipment for storage battery case

InactiveCN107819160ARapid Automated DeploymentQuick WrapAssembling battery machinesFinal product manufactureEngineeringAutomation

The invention relates to automatic coating equipment for a storage battery case. The automatic coating equipment comprises a feeding part, a film-drawing part and a coating part, wherein the feeding part comprises a horizontal conveyor and a lifting device arranged at the rear end of the horizontal conveyor; the film-drawing part is arranged at the upper part of the lifting device and comprises aguide device, an unwinding device arranged at one side of the guide device and a film-drawing device arranged on the guide device; the film-drawing device is used for pulling the end part of a thin film on the unwinding device to move to the other end from one end of the guide device; the coating part comprises a pushing device, a rolling device and a pushing and pressing device, wherein the pushing device is used for pushing the case conveyed from the lifting device to move backwards to complete coating of the front side surface of the case; the rolling device is arranged at the rear end of the pushing device and is used for being matched with the pushing device to complete coating of two side surfaces of the case; and the pushing and pressing device is arranged at one side of the rollingdevice and is used for completing coating of the rear side surface of the case. According to the automatic coating equipment, the problems that relatively high automation cannot be achieved and the coating effect is poor due to low coating efficiency for the battery case are solved.

Owner:阜阳市金亮涂料有限公司

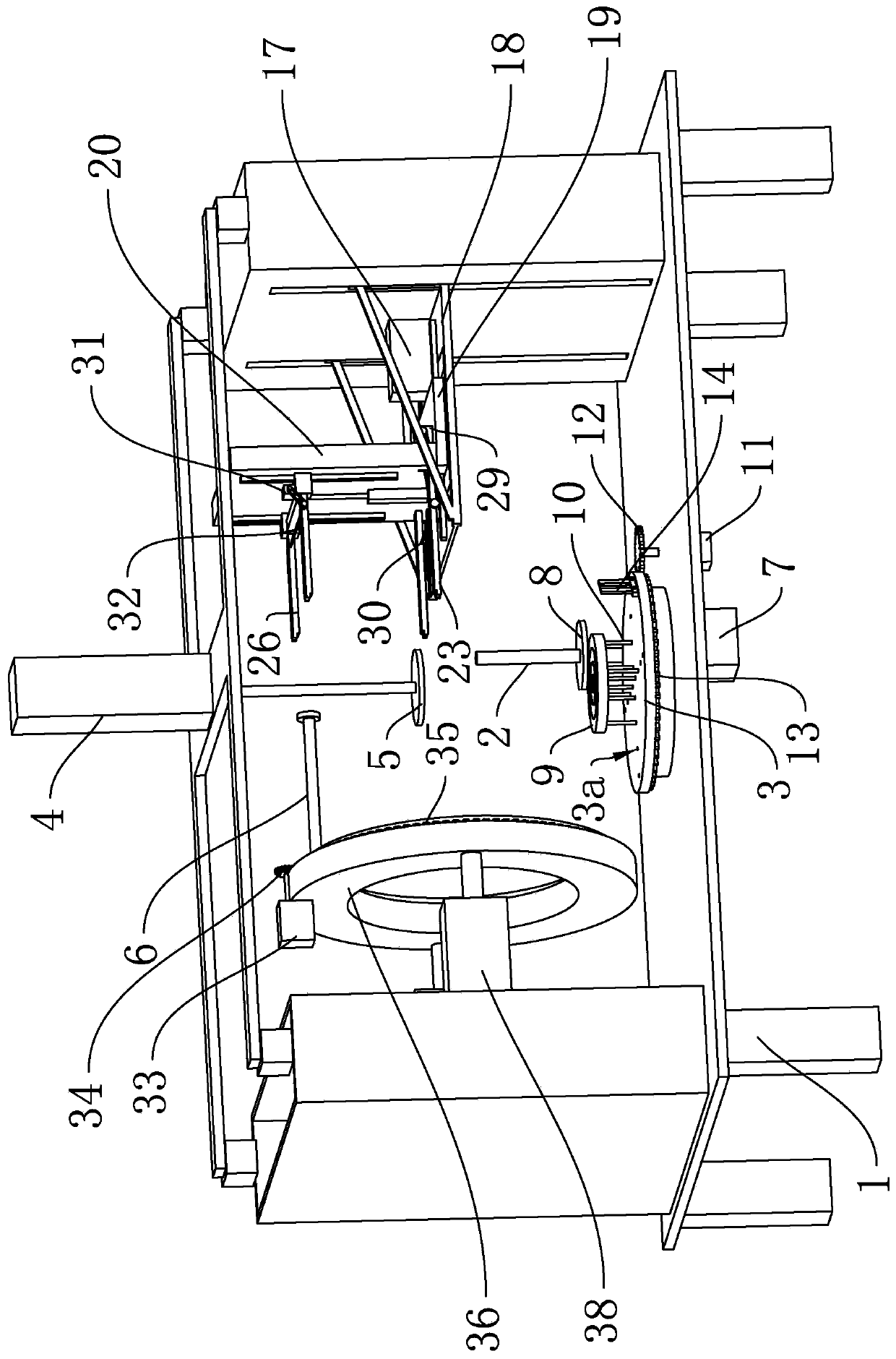

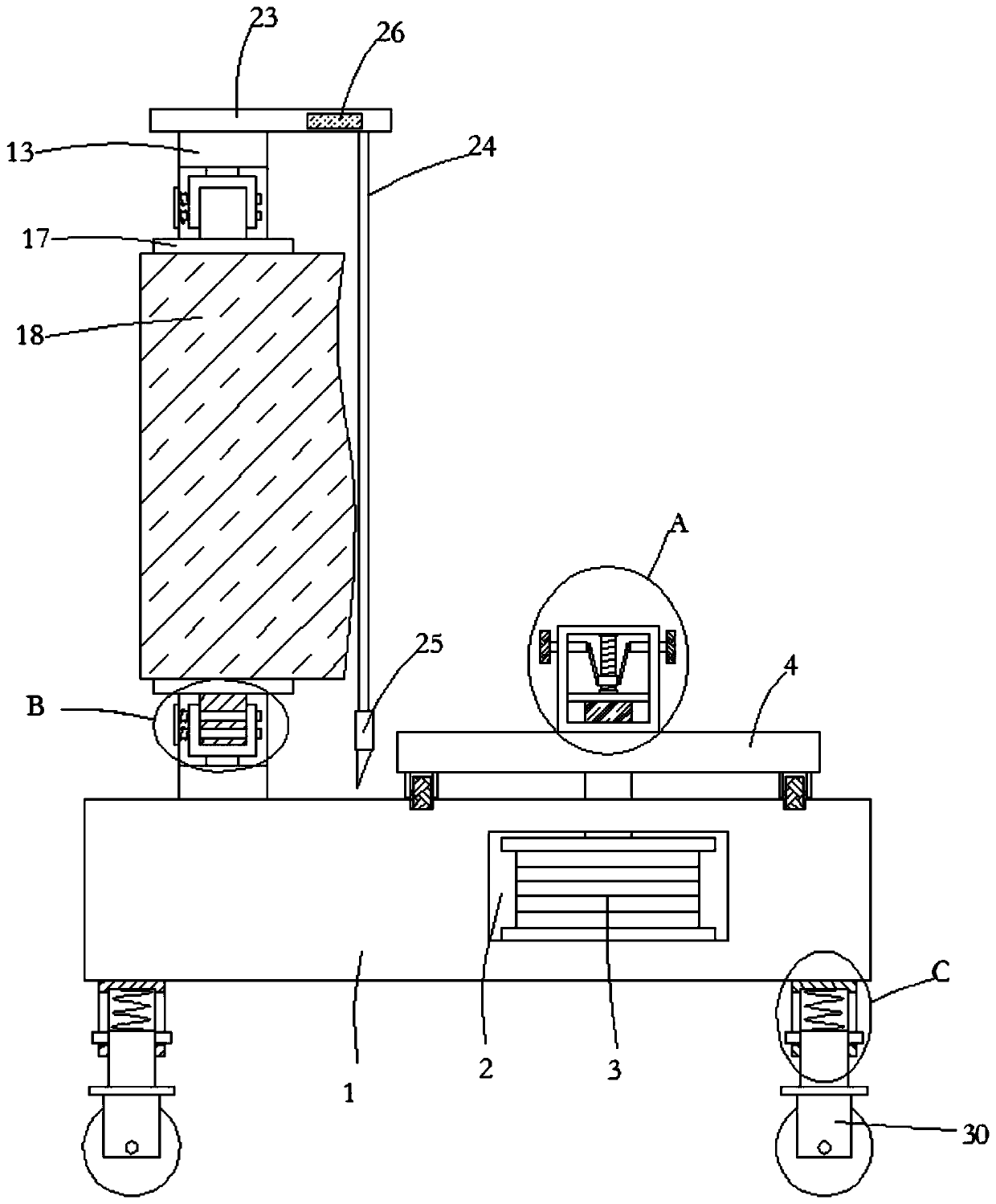

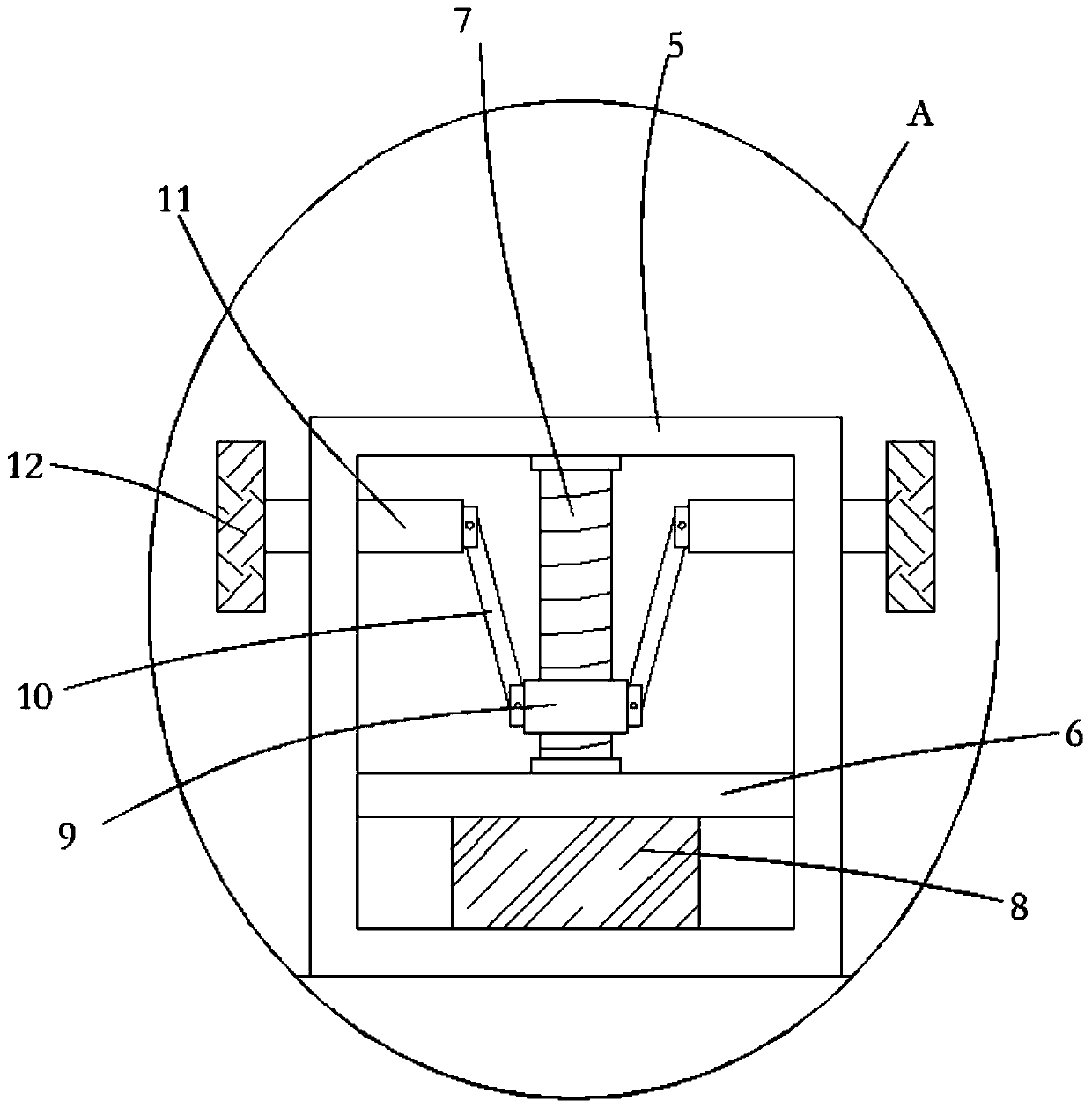

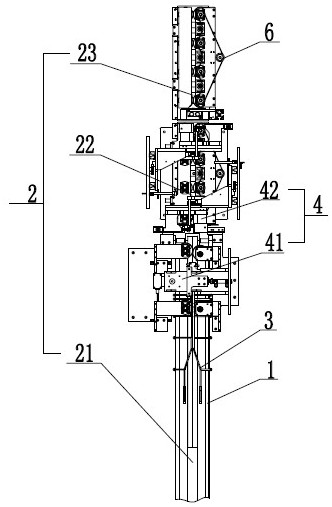

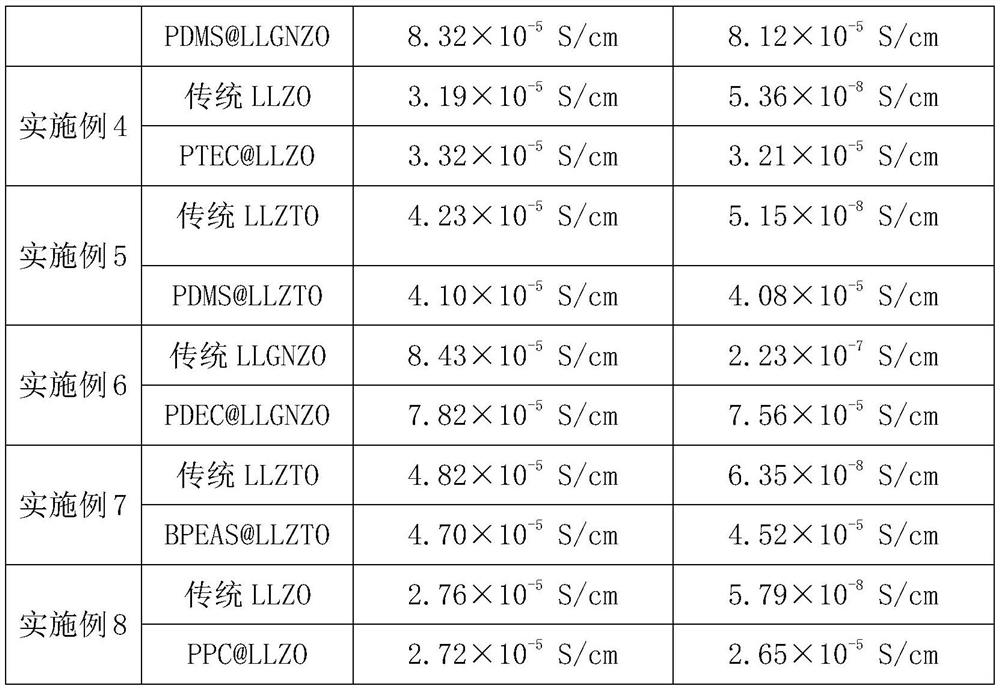

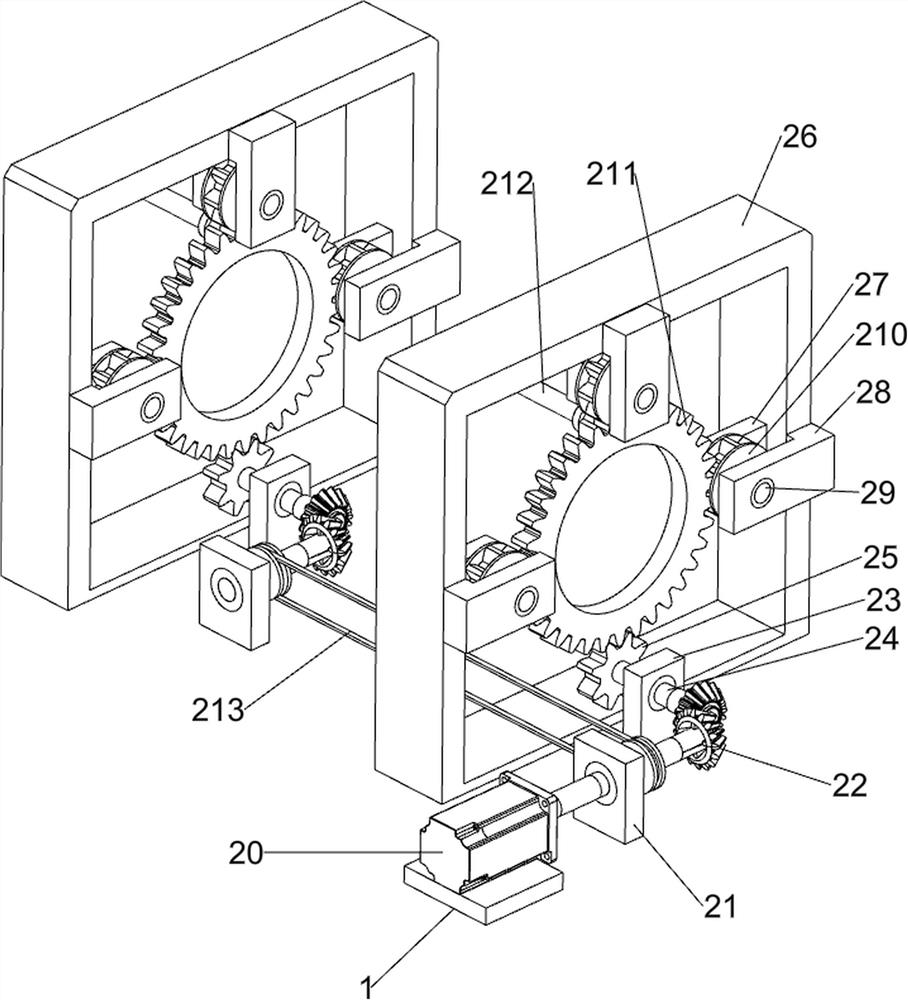

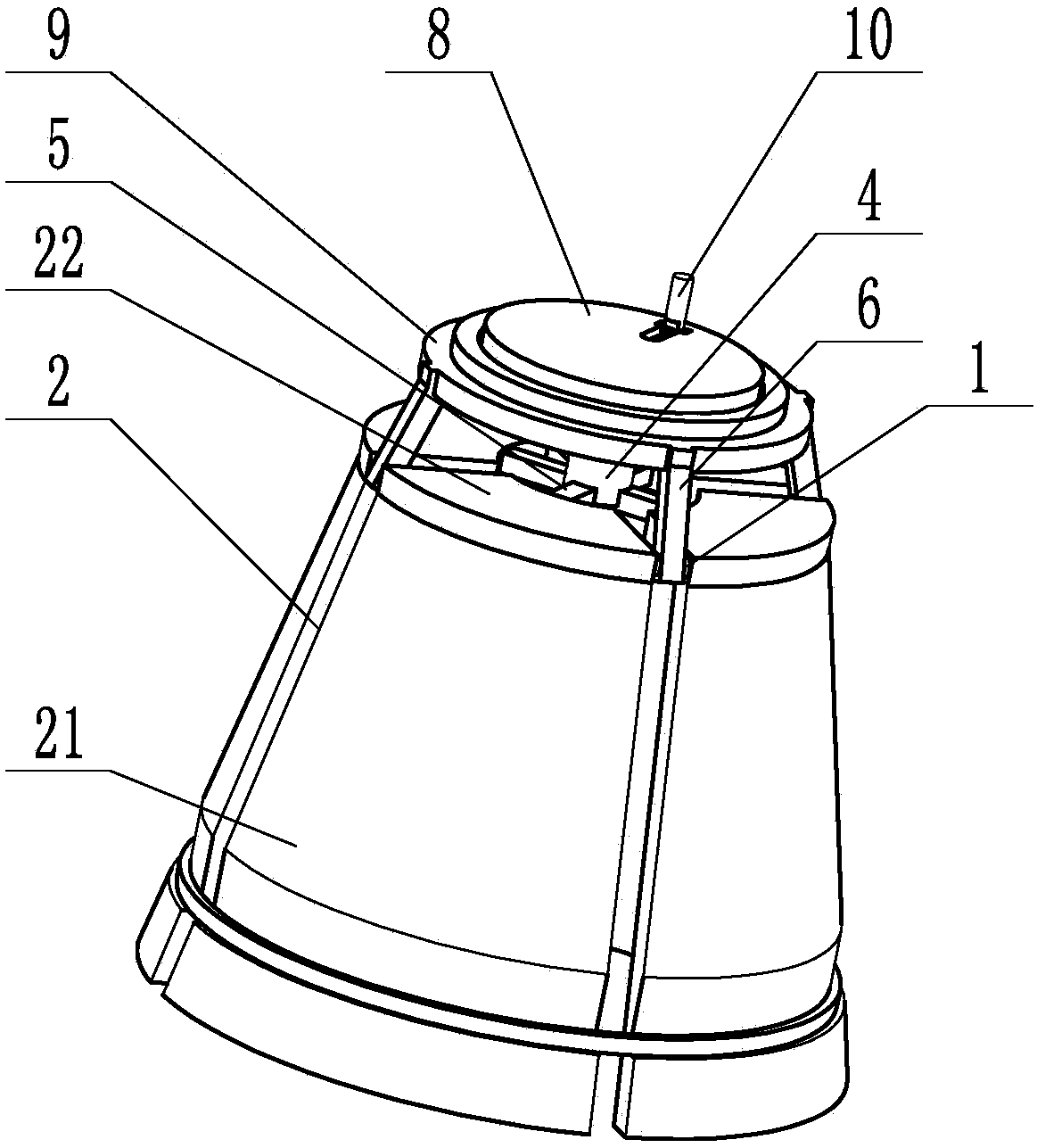

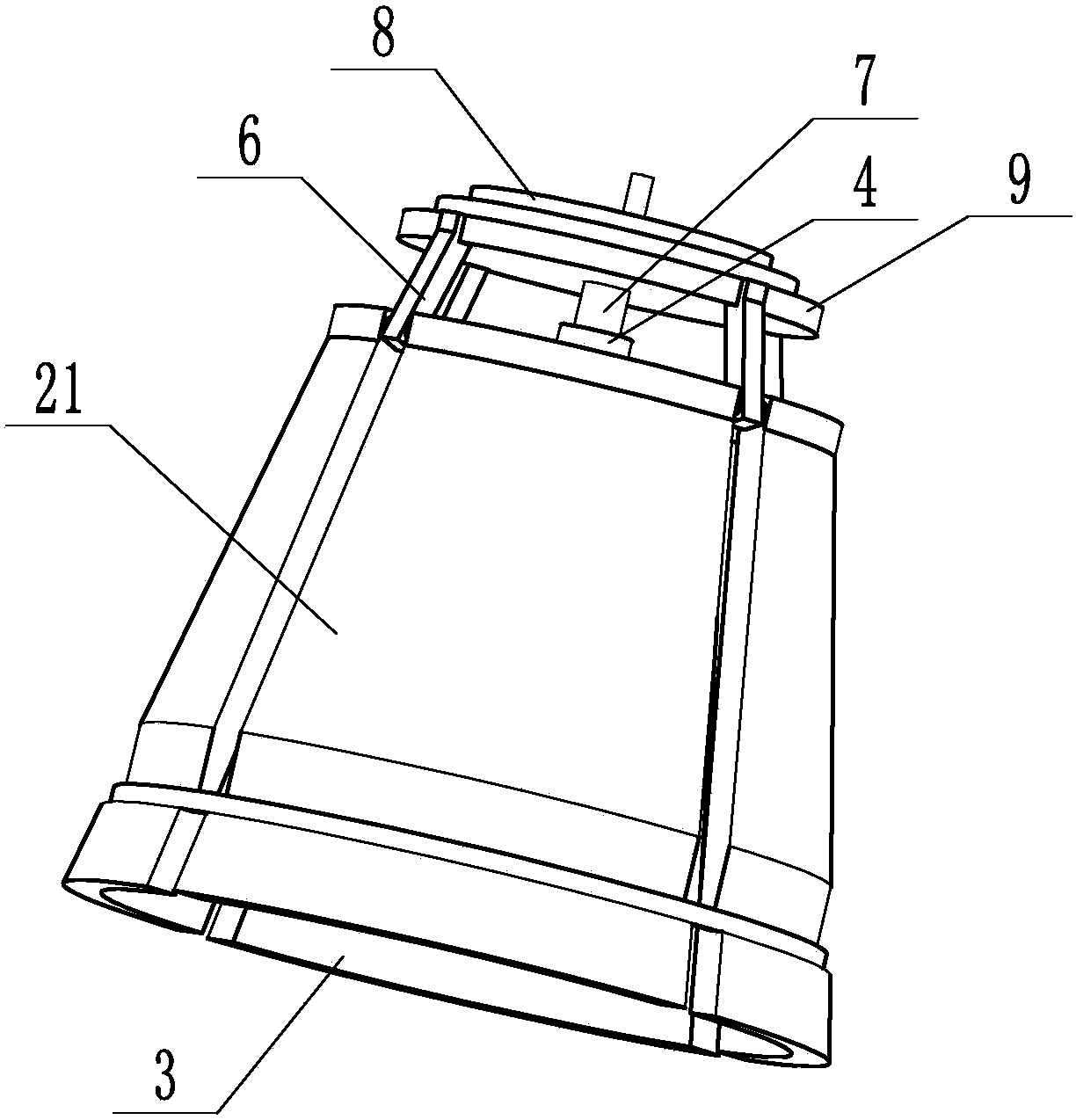

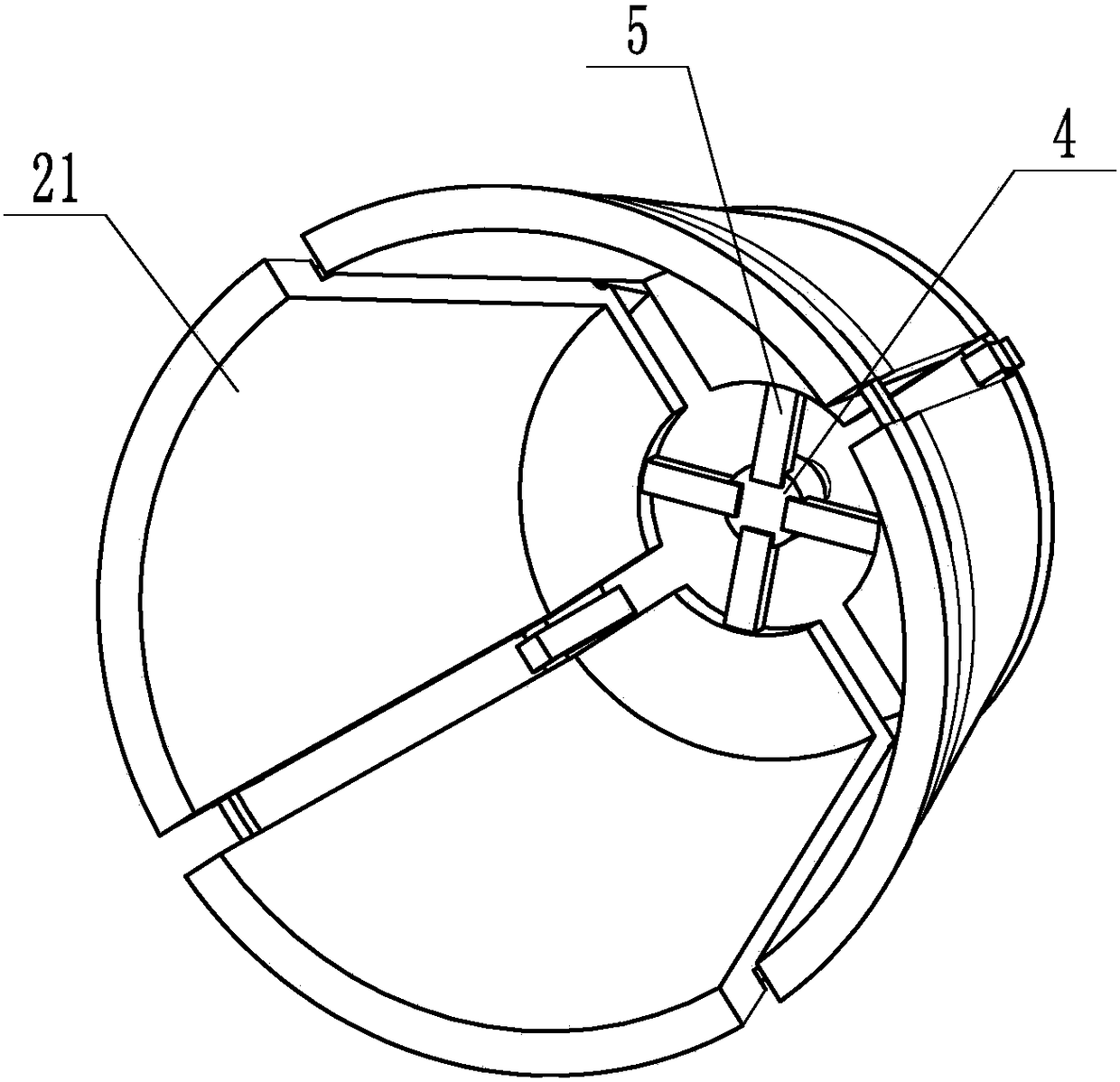

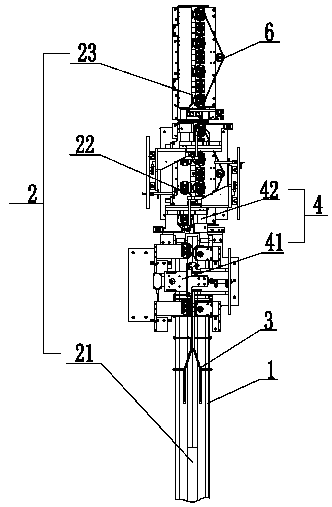

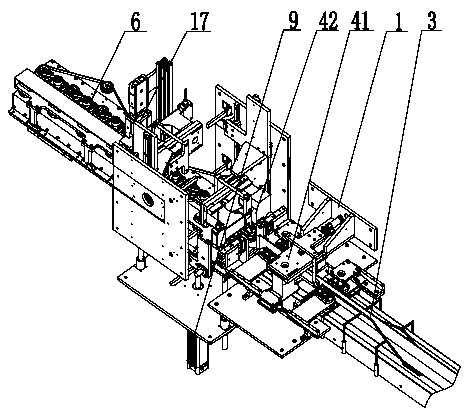

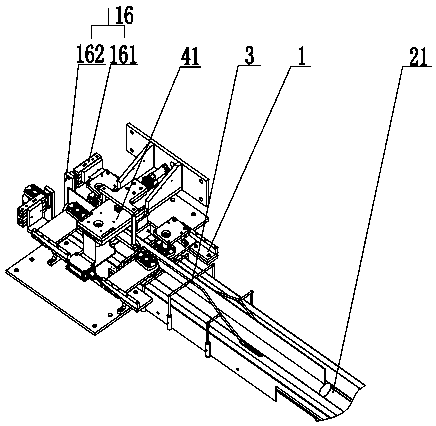

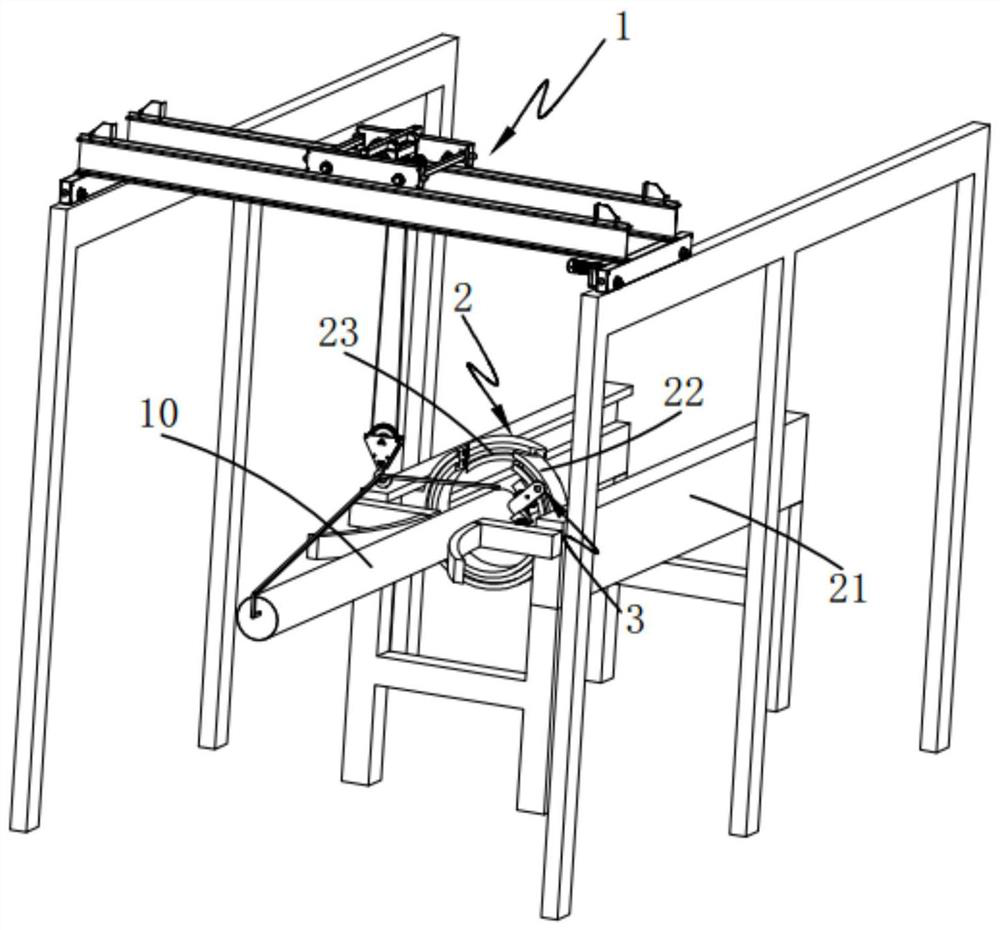

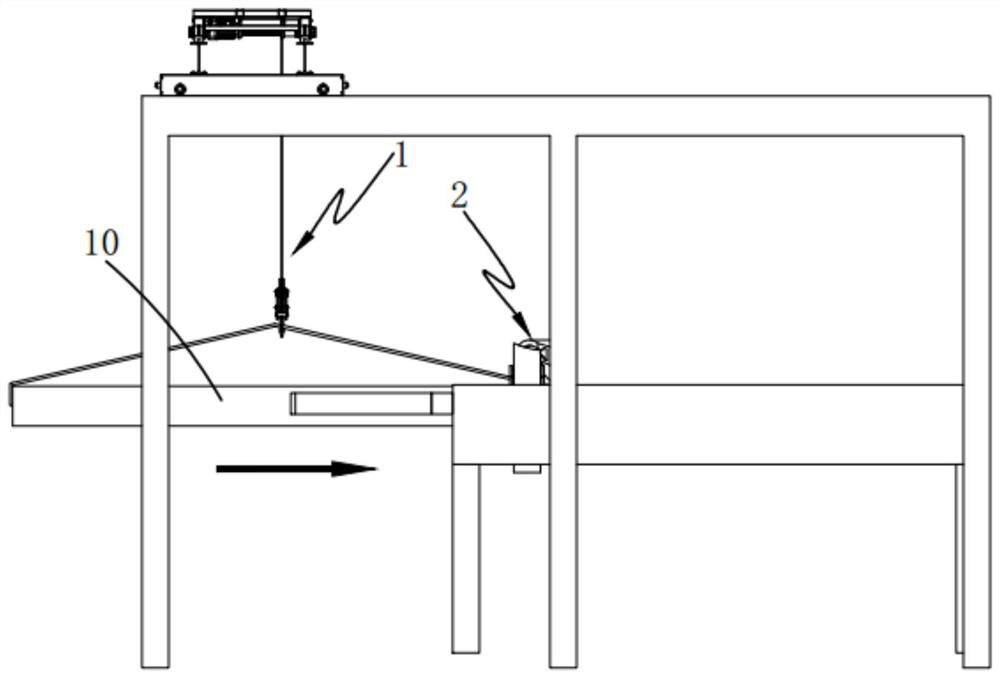

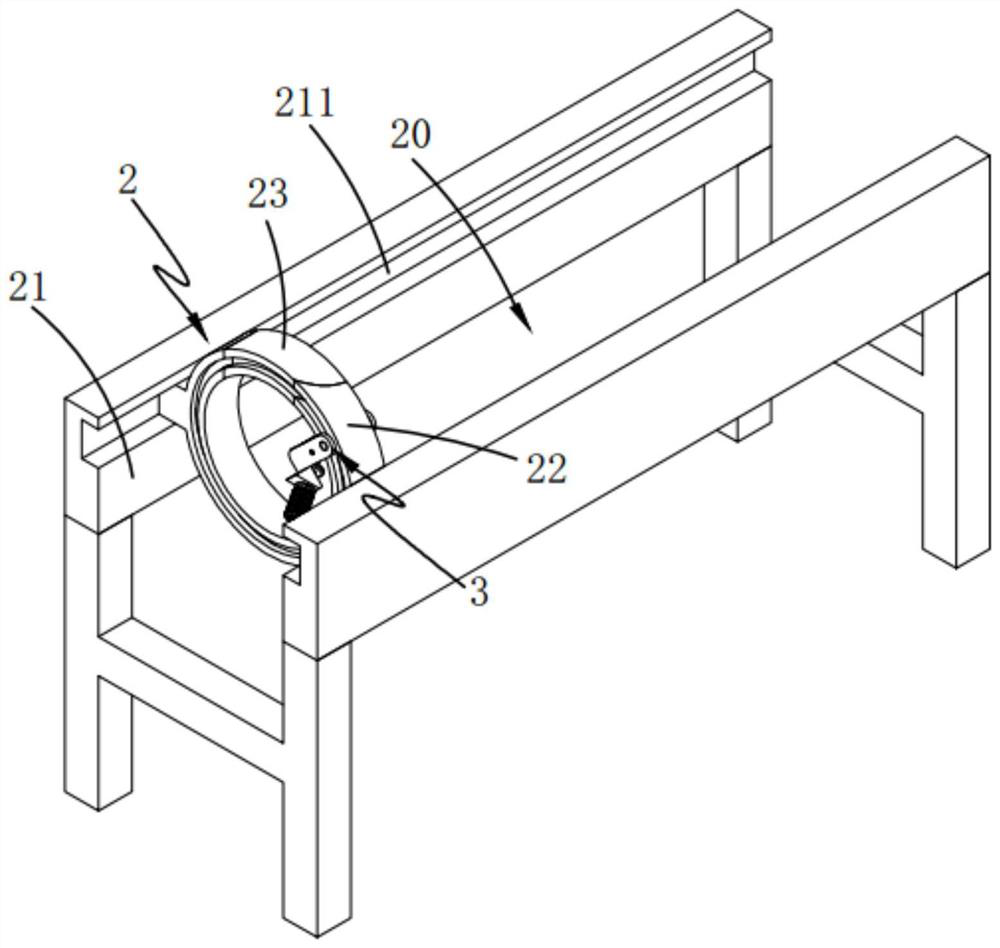

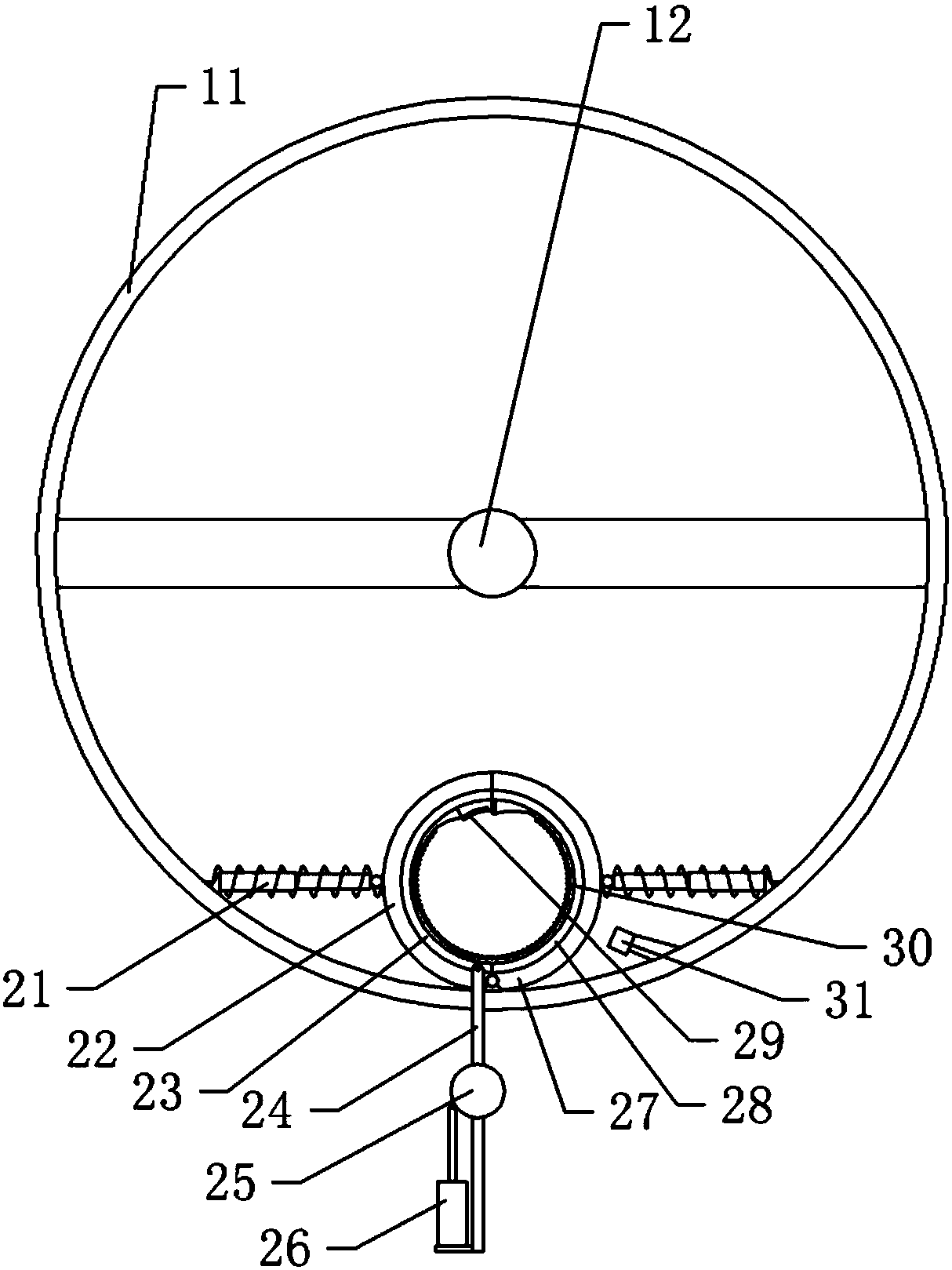

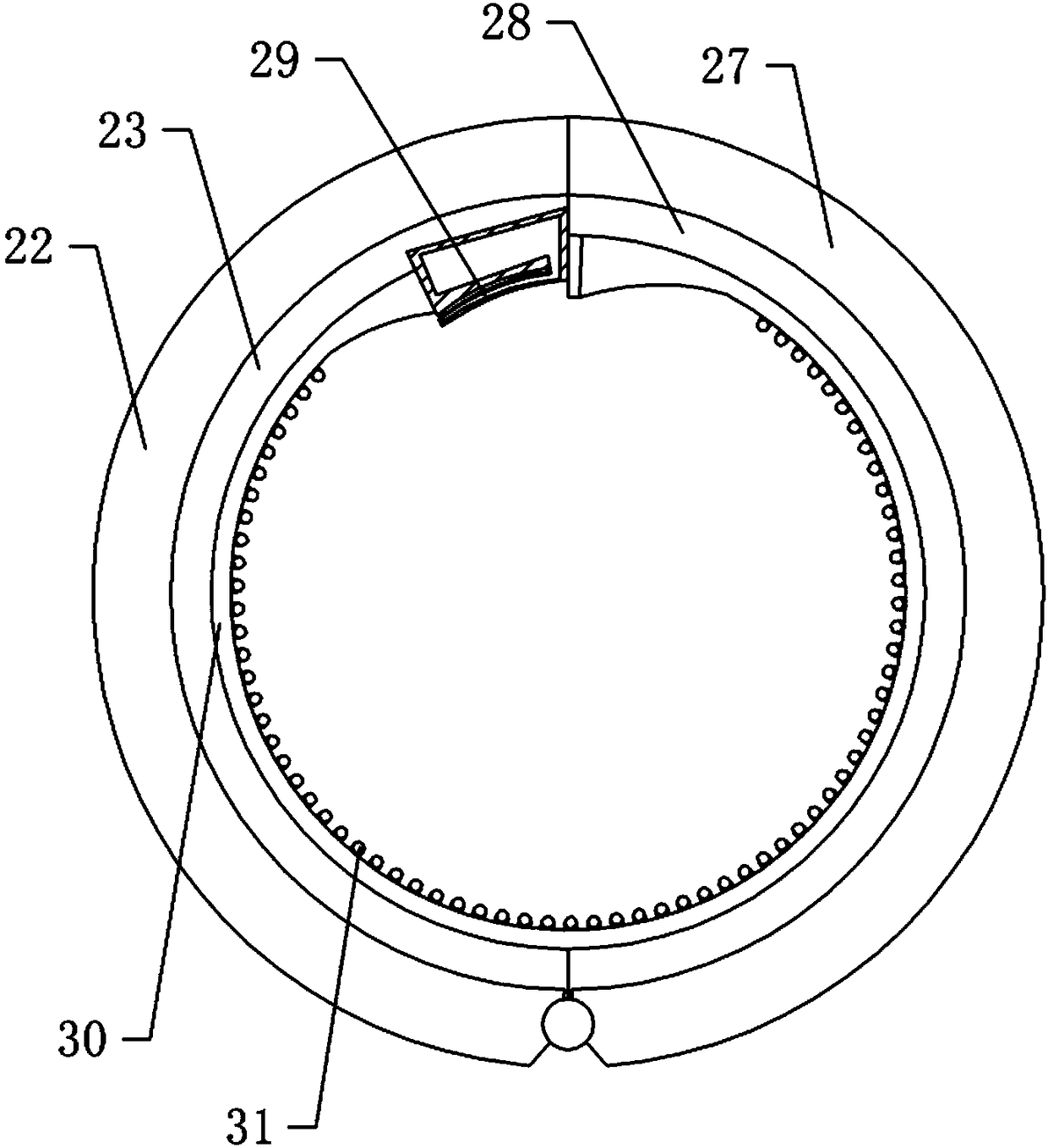

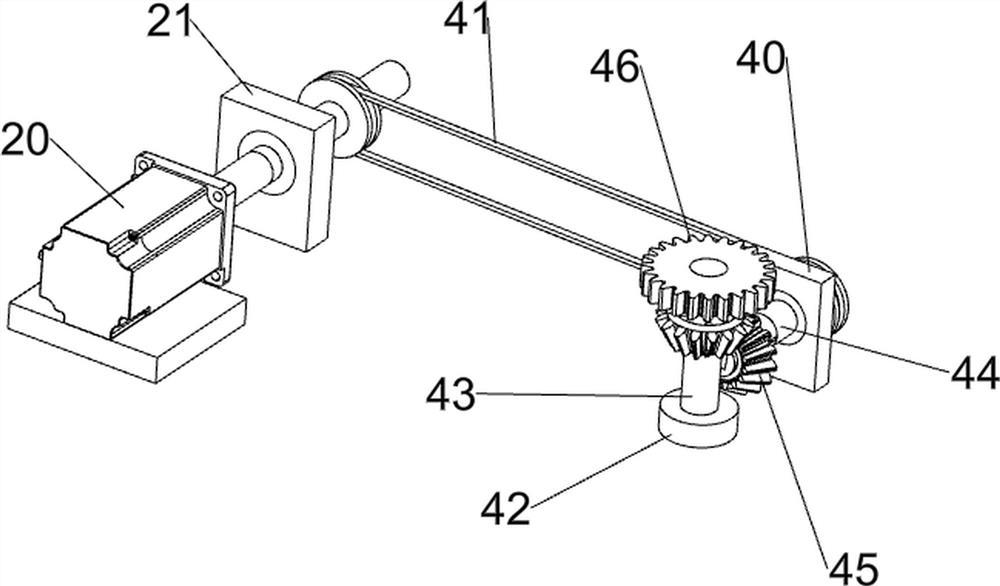

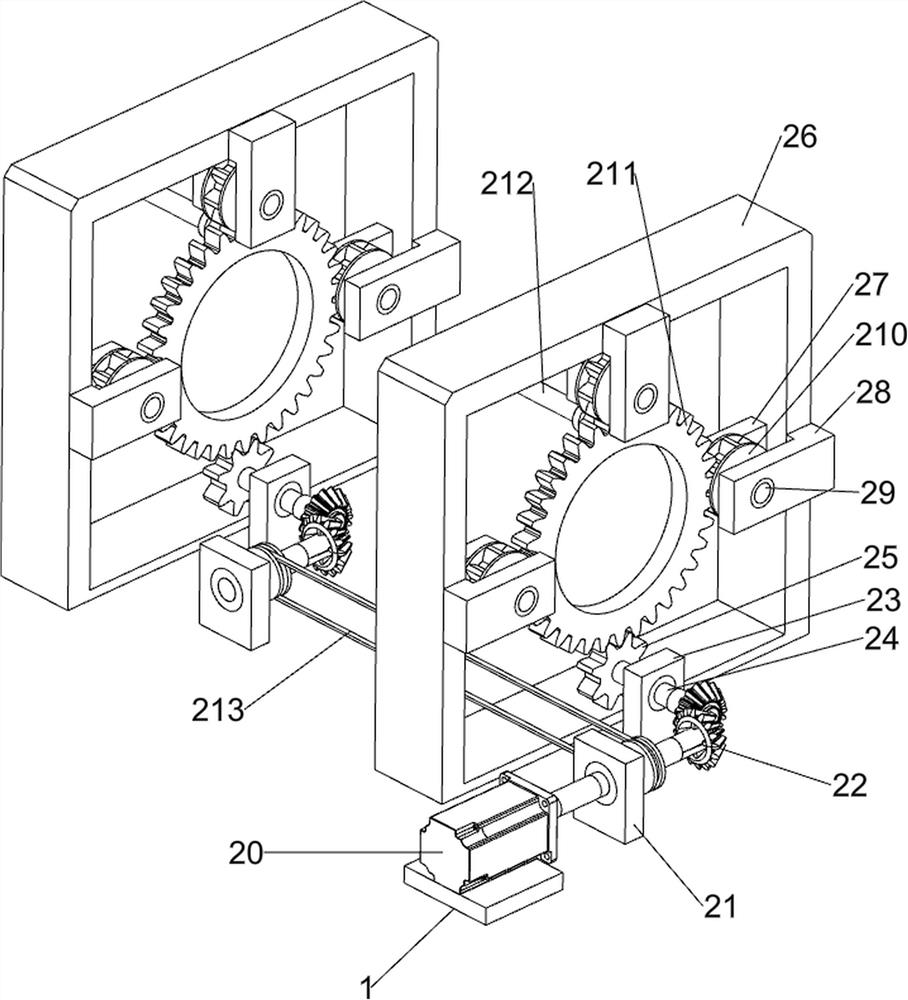

A post-processing equipment for the production of traffic signs

ActiveCN109941481BImprove work efficiencyQuick wrapWrapping with article rotationStructural engineeringMechanical engineering

The invention provides traffic sign production post-processing equipment which comprises a sign rod lifting device, a transverse moving device and a rotary cloth winding device. The transverse movingdevice is arranged below one side of the sign rod lifting device and comprises a limiting support, a sign rod limiting ring and an intermittent opening and closing component; and the rotary cloth winding device is rotationally arranged in the circumferential direction of the sign rod limiting ring and comprises a cloth winding revolution component and a rotation component. By arranging the transverse moving device, when the sign rod lifting device lifts a sign rod to the position of the transverse moving device, opening and closing of the intermittent opening and closing assembly are controlled, and the sign rod limiting ring is arranged on the outer circumference of the sign rod in a sleeving mode, d meanwhile, with rotation of the rotary cloth winding device, horizontal displacement in the axial direction while the circumferential cloth winding of the sign rod is realized, quick cloth winding on the surface of the sign rod is realized, and the technical problems that manual cloth winding is time-consuming, labor-consuming and low in cloth winding efficiency in the prior art are solved.

Owner:HUZHOU COLLEGE

A kind of extraction agent functionalized magnetic nano-adsorption material and its preparation method and application

ActiveCN110961086BImprove stabilityImprove production efficiencyIon-exchange process apparatusOther chemical processesAdsorption equilibriumRare earth ions

The invention discloses an extraction agent functionalized magnetic nano-adsorption material and its preparation method and application. The adsorption material uses magnetic nano-particles as a matrix, utilizes the good coating performance of polyvinylpyrrolidone, and extracts the extraction agent through a simple chemical method. Fixed on the surface of magnetic nanoparticles, so that the adsorption material has adsorption capacity and also has magnetism. When the adsorption material is used for adsorption and separation of rare earth ions, the solid-liquid separation efficiency after adsorption equilibrium can be effectively improved; in addition, the present invention The preparation method of the above-mentioned adsorption material also overcomes the disadvantage of difficult surface modification of the magnetic adsorption material. With the help of the film-forming property of polyvinylpyrrolidone, different types of extraction agents can be quickly and efficiently coated on the surface of the magnetic nanoparticles, which improves the surface of the magnetic nano-particles. The preparation efficiency of the adsorption material expands the optional range of the coated extractant and enriches the use of the adsorption material.

Owner:JIANGXI UNIV OF SCI & TECH

Fine dried noodle packaging machine

ActiveCN108423225AQuick wrapRealize automatic glue applicationWrappingWrapper twisting/gatheringEngineeringAirbag

The invention relates to the technical field of fine dried noodle packaging equipment, in particular to a fine dried noodle packaging machine which comprises a frame. A rotating ring is rotatably connected onto the frame, a clamping mechanism is eccentrically arranged at the inner bottom of the rotating ring and comprises a positioning cylinder, the positioning cylinder comprises two splicing cylinders with semicircular cross sections, the inner side of the positioning cylinder is rotatably connected with a supporting cylinder, the supporting cylinder comprises a first half supporting cylinderwith a semicircular cross section and a second half supporting cylinder with a semicircular cross section, a gluing block is arranged on the inner side of the upper end of the first half supporting cylinder, the inner sides of the first half supporting cylinder and the second half supporting cylinder are fixedly connected with arc-shaped elastic airbags, a plurality of carrier roller mechanisms are arranged on the inner sides of the elastic airbags, carrier rollers are connected onto the elastic airbags through one-way bearings, a guide rod is hinged to the lower end of the first half supporting cylinder, a swing ball and a cylinder are arranged on the guide rod, and a limit block for limiting 45-degree anticlockwise rotation of the swing ball is fixedly arranged on the rotating ring. Thefine dried noodle packaging machine solves the problem of high labor intensity of workers in fine dried noodle packaging in the prior art.

Owner:ZUNYI TONGZI YUQIANG AGRI PROD DEV CO LTD

Building glass fiber reinforced plastic oiling and cloth winding device

The invention relates to an oiling and cloth winding device, in particular to a building glass fiber reinforced plastic oiling and cloth winding device. The building glass fiber reinforced plastic oiling and cloth winding device can quickly paint and wind cloth on glass fiber reinforced plastics and can automatically push the glass fiber reinforced plastics. The building glass fiber reinforced plastic oiling and cloth winding device comprises a base used for installing the whole device; a cloth winding mechanism arranged on one side of the upper portion of the base; and a paint spraying mechanism arranged on the side, close to the cloth winding mechanism, of the upper portion of the base and matched with the cloth winding mechanism. According to the building glass fiber reinforced plasticoiling and cloth winding device provided by the invention, the effects that the glass fiber reinforced plastics can be rapidly painted and wound, and the glass fiber reinforced plastics can be automatically pushed are achieved, the glass fiber reinforced plastics are placed in a protection frame and a mounting frame, rapid paint spraying can be conducted on the glass fiber reinforced plastics through an upper spraying pipe and a lower spraying pipe, and rapid winding can be conducted on the glass fiber reinforced plastics through an adhesive tape on a discharging rod.

Owner:张宏辉

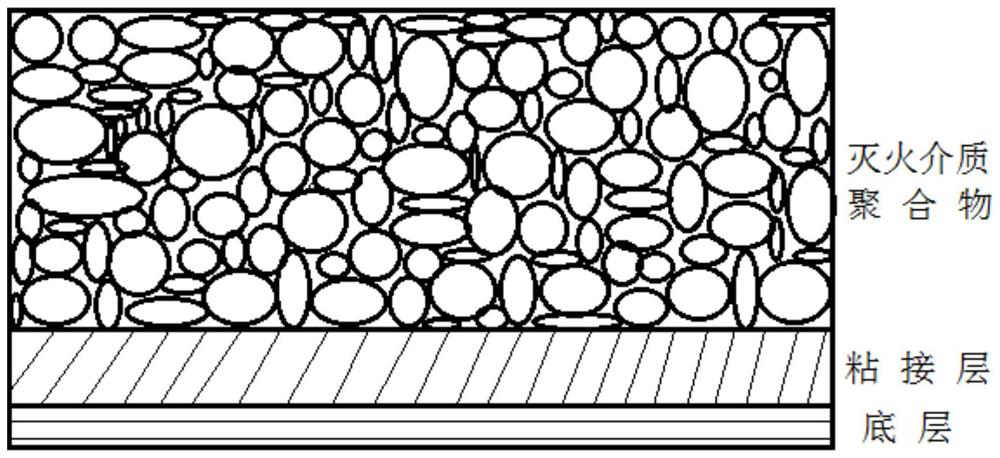

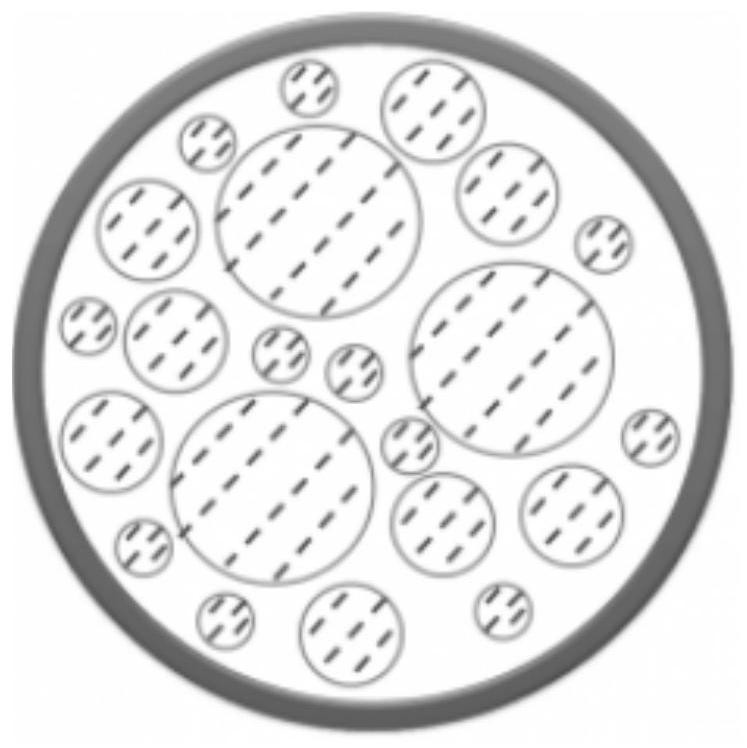

Microcapsule fire extinguishing material and preparation method thereof

ActiveCN110025916BWith temperature sensing self-starting functionImprove fire extinguishing efficiencyFilm/foil adhesivesMicroballoon preparationPolyolMeth-

The invention discloses a microcapsule fire extinguishing material and a preparation method thereof. The microcapsule fire extinguishing material comprises a capsule wall and a capsule core fire-extinguishing medium coated by the capsule wall, the capsule wall is formed by polymerizing a water phase medium and an oil phase medium, and the microcapsule fire extinguishing material comprises the following components in percentage by mass: 70%-90% of capsule core fire-extinguishing medium, 5%-15% of water phase medium and 5%-15% of oil phase medium, wherein the capsule core fire-extinguishing medium is dodecafluoro-2-methyl-3-pentanone or a homologue of dodecafluoro-2-methyl-3-pentanone, the water phase medium is polyol or polyamine, and the oil phase medium is polyacyl chloride. Compared withthe prior art, the material is simple and easy to install, detection starting is accurate and reliable, fire extinguishing is fast and fire extinguishing efficiency is high.

Owner:SHENZHEN HONGHAISHENG SPECIAL FIRE TECH CO LTD

Metal Wire Winder

ActiveCN104269268BQuick wrapSimple structureLine/current collector detailsCoils manufactureLocking mechanismEngineering

The invention discloses a metal wire winding device, which comprises a wire core positioning plate, and the center of the wire core positioning plate is provided with a wound wire positioning hole corresponding to the wound wire; the wire core positioning plate includes an upper wire core positioning plate and a lower wire positioning plate. Core positioning plate, one end of the lower thread core positioning plate is hingedly connected with one end of the upper thread core positioning plate, and the other end of the lower thread core positioning plate and the other end of the upper thread core positioning plate are provided so that the lower thread core positioning plate and the upper thread core positioning plate are pressed against each other. Tight locking structure; the winding positioning hole is composed of the winding positioning upper half hole opened in the middle of the upper core positioning plate and the winding positioning lower half hole opening in the lower core positioning plate; the upper core positioning plate The middle part is provided with a threading block, and the middle part of the threading block is provided with a winding positioning hole corresponding to the winding. The winding device has the advantages of simple structure, convenient operation, low cost and good practicability.

Owner:JIANGHAN UNIVERSITY

An automatic film-coating heat-sealing device for cylindrical coils

The invention discloses an automatic film-cover and heat-seal device for cylindrical coil and belongs to the technical field of machinery. The automatic film-cover and heat-seal device for cylindricalcoil comprises a main frame; a pair of moving tracks are fixedly connected to an upper end of the main frame; a moving device body is connected to the moving tracks; a pair of lifting mechanical armsare connected to a lower end of the moving device body; a conveying belt is placed at one side of the main frame; a cylindrical thin film roll material body is placed on the conveying belt; an air bubble film coil rack is placed at one side of the main frame; an air bubble film rolling rack is provided with an edge correcting device which can effectively guarantee that the air bubble film is drawn to a table top in the unified direction; It utilizes two lifting and foldable-unfoldable film-cover rods, which are similar to shell opening and closing, and the bubble film is applied from the bottom to the top of the coil surface. When the bubble film reaches to the uppermost end, the heating rod heats the contact surface. By heat sealing the interface of the bubble film, it is possible to quickly cover the bubble film on the end faces of the coils of different diameters for heat sealing.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

A shock absorption device for electric vacuum pump of new energy vehicle

ActiveCN114017464BQuick WrapAvoid damageHybrid vehiclesBraking action transmissionNew energyEngineering

The invention relates to the technical field of shock absorption for new energy vehicles, in particular to a shock absorption device for an electric vacuum pump of a new energy vehicle. The shock absorbing device of the electric vacuum pump of the new energy vehicle includes an annular sleeve, a fixed flange is fixedly sleeved on the pipe wall, and a through cavity is arranged in the annular sleeve to penetrate the bottom of the pipe body; the protection part is located in the annular sleeve a through cavity opened at the bottom of the sleeve, and the protection component includes a protection tube, the bottom of the protection tube is fixedly fitted in the through cavity opened by the annular sleeve, and an organ-shaped elastic airbag and a decomposition agent are installed in the protection tube ; The buffer part is located on the upper surface of the annular sleeve. The shock absorbing device of the electric vacuum pump of the new energy vehicle provided by the present invention has a built-in protective component that makes the organ-shaped elastic airbag rapidly expand and can quickly cover the shell of the electric vacuum pump, effectively protecting the electric vacuum pump and reducing the collision caused by the electric vacuum pump. Or the problem that the casing is damaged due to severe vibration.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Wire winding device used for fiber cotton processing

The invention discloses a wire winding device used for fiber cotton processing. The wire winding device comprises a frame. The inner side of the frame is connected with multiple fixed plates. A wire winding shaft is arranged between every two fixed plates. A locking block is arranged at one end of each wire winding shaft. Locking openings are formed in one side of the frame. The locking blocks arein threaded connection with the locking openings. A connecting block is arranged at the other end of each wire winding shaft. The side, away from the corresponding wire winding shaft, of each connecting block penetrates the frame and is connected with a driven wheel. The other side of the frame is rotationally connected with a connecting shaft. A driving wheel engaged with the driven wheels is connected to the connecting shaft in a sleeving manner. The wire winding device is convenient to operate and simple in structure; fiber cotton is in winding connection to the wire winding shaft, only ahandle needs to be rotated, and the wire winding shaft can be fast taken out when winding connection is completed; and the fiber cotton can be subjected to heating treatment to a certain degree whilethe wire winding shaft is in winding connection with the fiber cotton, and the effect of fast and efficient winding connection of the fiber cotton can be achieved.

Owner:钟星汉

Damping device for electric vacuum pump of new energy vehicle

ActiveCN114017464AQuick WrapAvoid damageHybrid vehiclesBraking action transmissionNew energyVacuum pump

The invention belongs to the technical field of new energy vehicle damping and relates to a damping device of an electric vacuum pump of a new energy vehicle. The damping device of the electric vacuum pump of the new energy vehicle comprises an annular casing pipe, a protection component and a buffer component; the pipe wall of the annular casing pipe is fixedly sleeved with a fixing flange, and a through cavity penetrating through the bottom of a pipe body is formed in the annular casing pipe; the protection component is located in the through cavity formed in the bottom of the annular casing pipe, the protection component comprises a protection pipe, the bottom of the protection pipe is fixedly embedded in the through cavity formed in the annular casing pipe, and an organ-shaped elastic air bag and a decomposing agent are installed in the protection pipe; and the buffer component is positioned on the upper pipe surface of the annular casing pipe. According to the damping device of the electric vacuum pump of the new energy vehicle, the organ-shaped elastic air bag is rapidly expanded through the internally-arranged protection component, the shell of the electric vacuum pump can be rapidly wrapped, the electric vacuum pump is effectively protected, and the problem that the shell is damaged due to collision or violent vibration of the electric vacuum pump is solved.

Owner:HANGZHOU SAIQI MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com