Omni-directional film coating device for carton

A wrapping device, a comprehensive technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problem of not being able to wrap all cartons, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

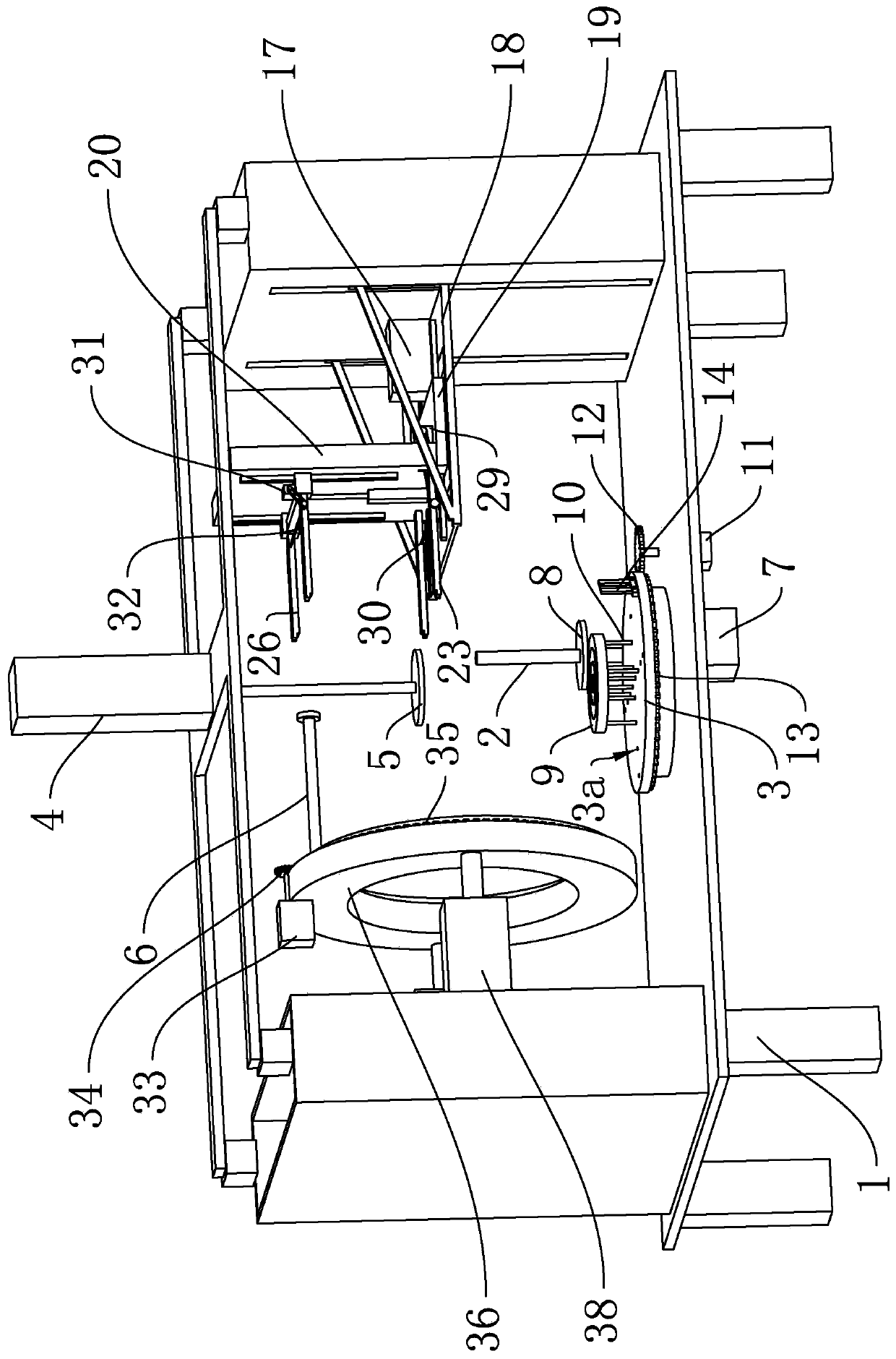

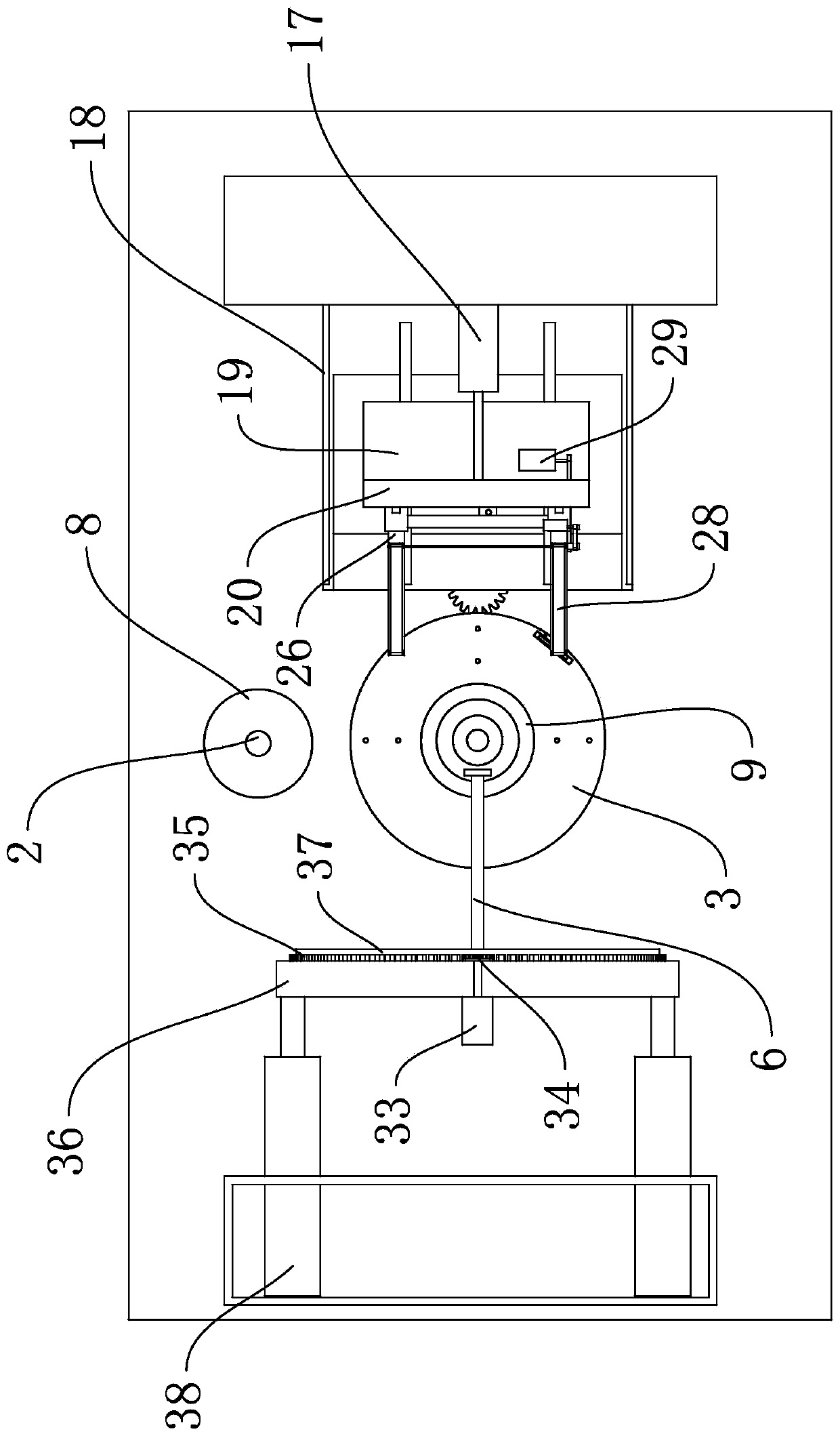

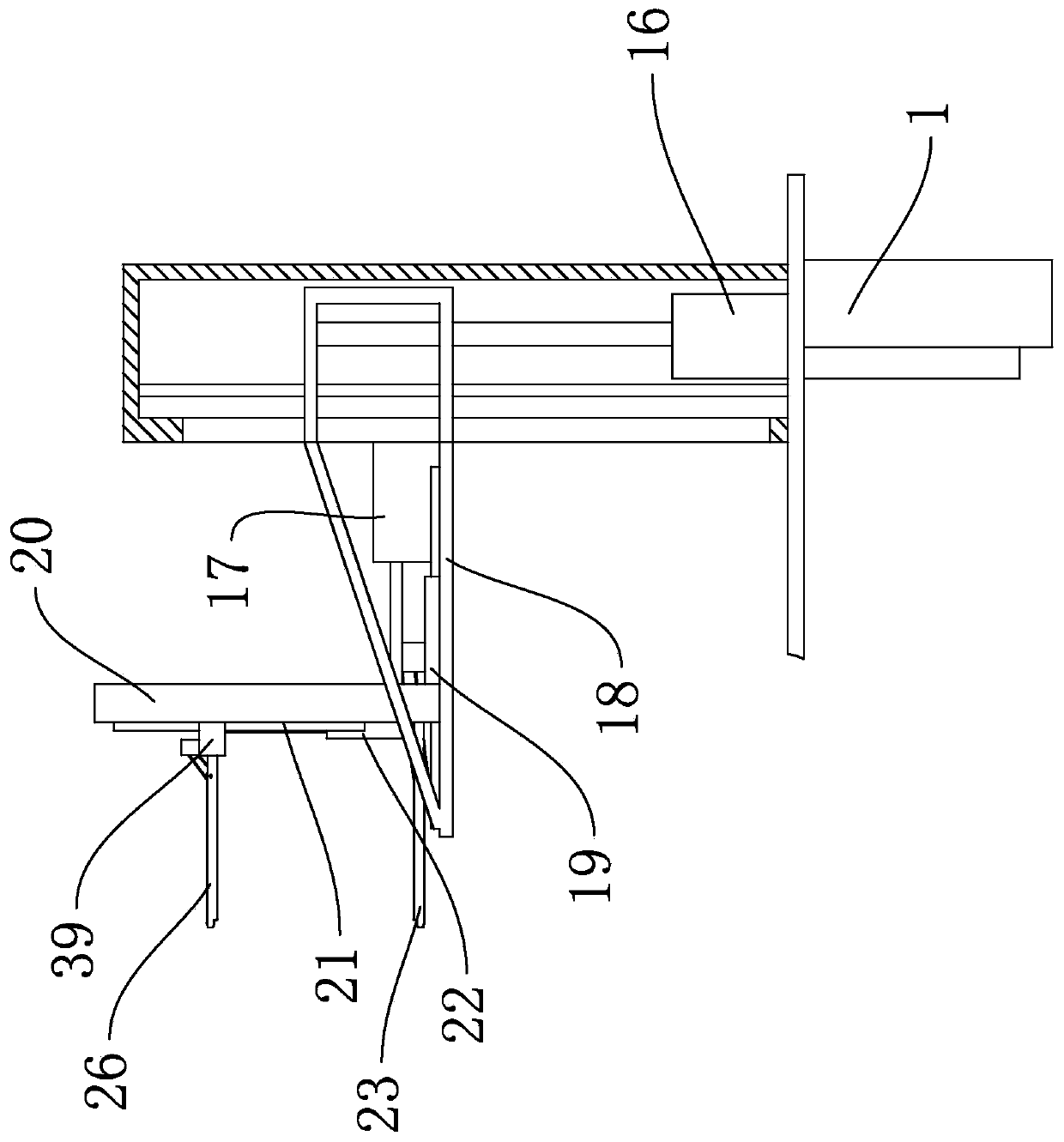

[0027] Such as Figure 1 to Figure 5 As shown, a carton omni-directional film coating device includes a frame 1, the frame 1 is longitudinally rotated and provided with a film-extruding roller 2, and the described frame 1 is provided with a drive film-extruding roller 1 2. A drive mechanism for moving up and down. The frame 1 is provided with a turntable 3 for rotation. The frame 1 is provided with a driving mechanism for driving the turntable 3 to rotate. The turntable 3 is fixed with an upward protruding placement The table assembly, the table assembly is detachable, the rotating table 3 is provided with a fixed structure for fixing the end of the film, the frame 1 is fixed with a push rod motor-4, and the push rod of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com