An automatic film-coating heat-sealing device for cylindrical coils

A mobile device and film-covering technology, applied in the mechanical field, can solve the problems of large changes in the diameter and width of the coil, and fail to solve the problems of automatic cutting, so as to achieve the effect of improving shock absorption and protection, and not easy to deviate and dislocate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

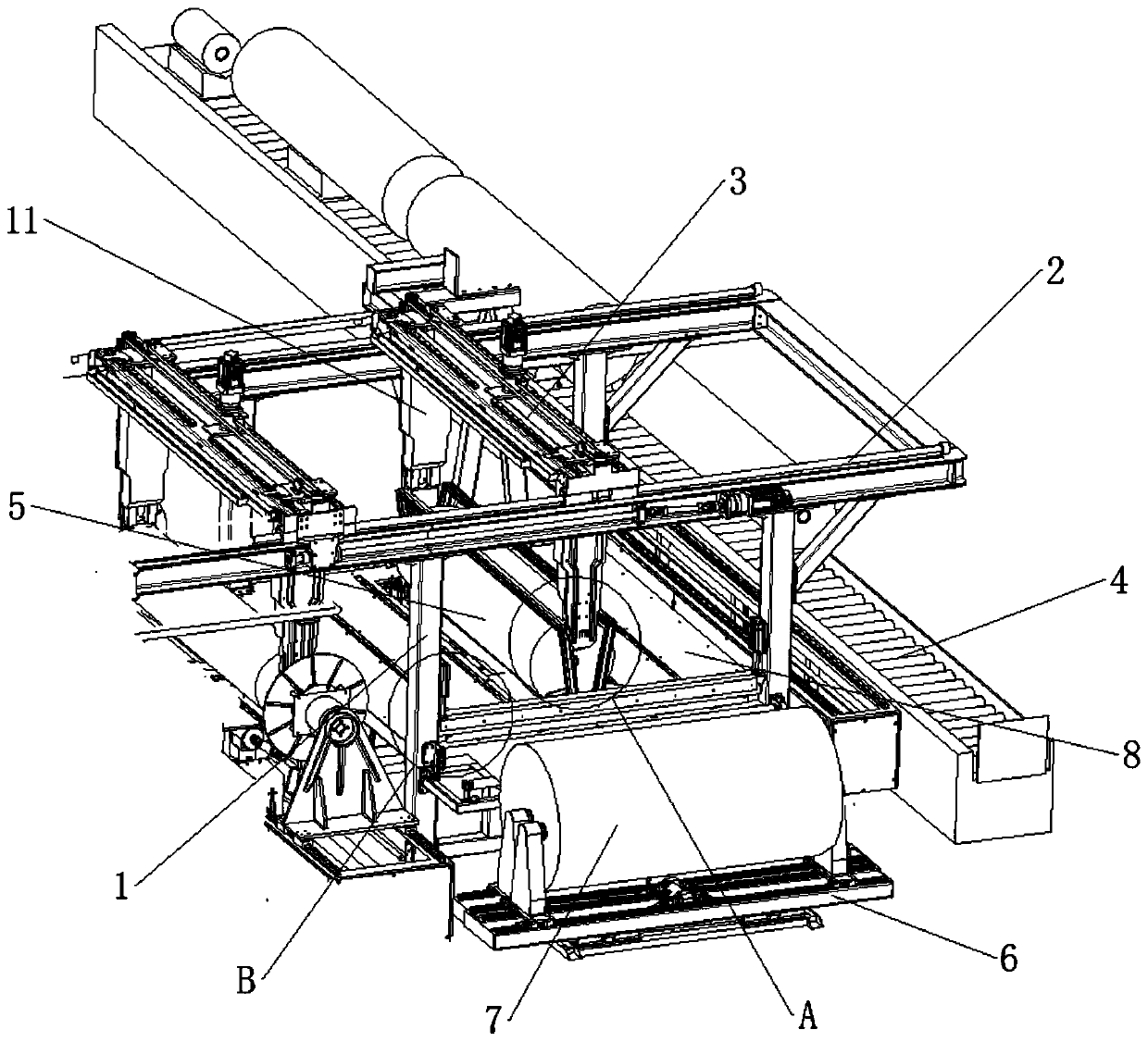

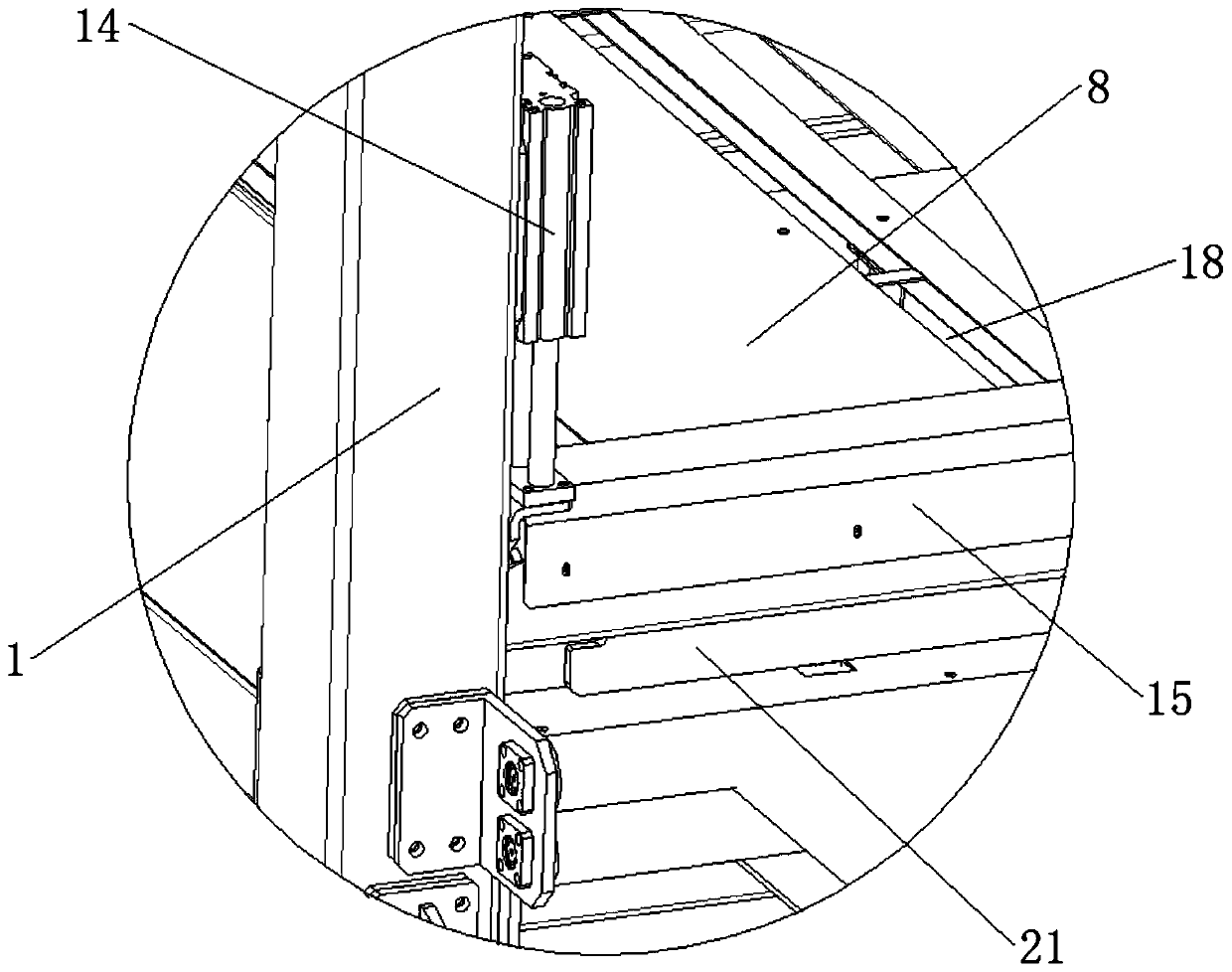

[0044] see Figure 1-5, an automatic film-coating heat-sealing device for cylindrical coils, comprising a main frame 1, a pair of moving rails 2 are fixedly connected to the upper end of the main frame 1, a moving device body 3 is connected to the moving rail 2, and a moving device body 3 is connected to a lower end For the lifting mechanical arm 11, a conveyor belt 4 is placed on one side of the main frame 1, a cylindrical film coil body 5 is placed on the conveyor belt 4, an air bubble film roll holder 6 is placed on one side of the main frame 1, and the air bubble film roll holder 6 is connected with an air bubble film coil 7, and the main frame 1 is fixedly connected with a lamination platform 8. The width of the lamination platform 8 is greater than the width of the cylindrical film coil body 5, and the air bubble film can be smoothly spread. The lamination platform 8 There are four clamping tracks 18 on it.

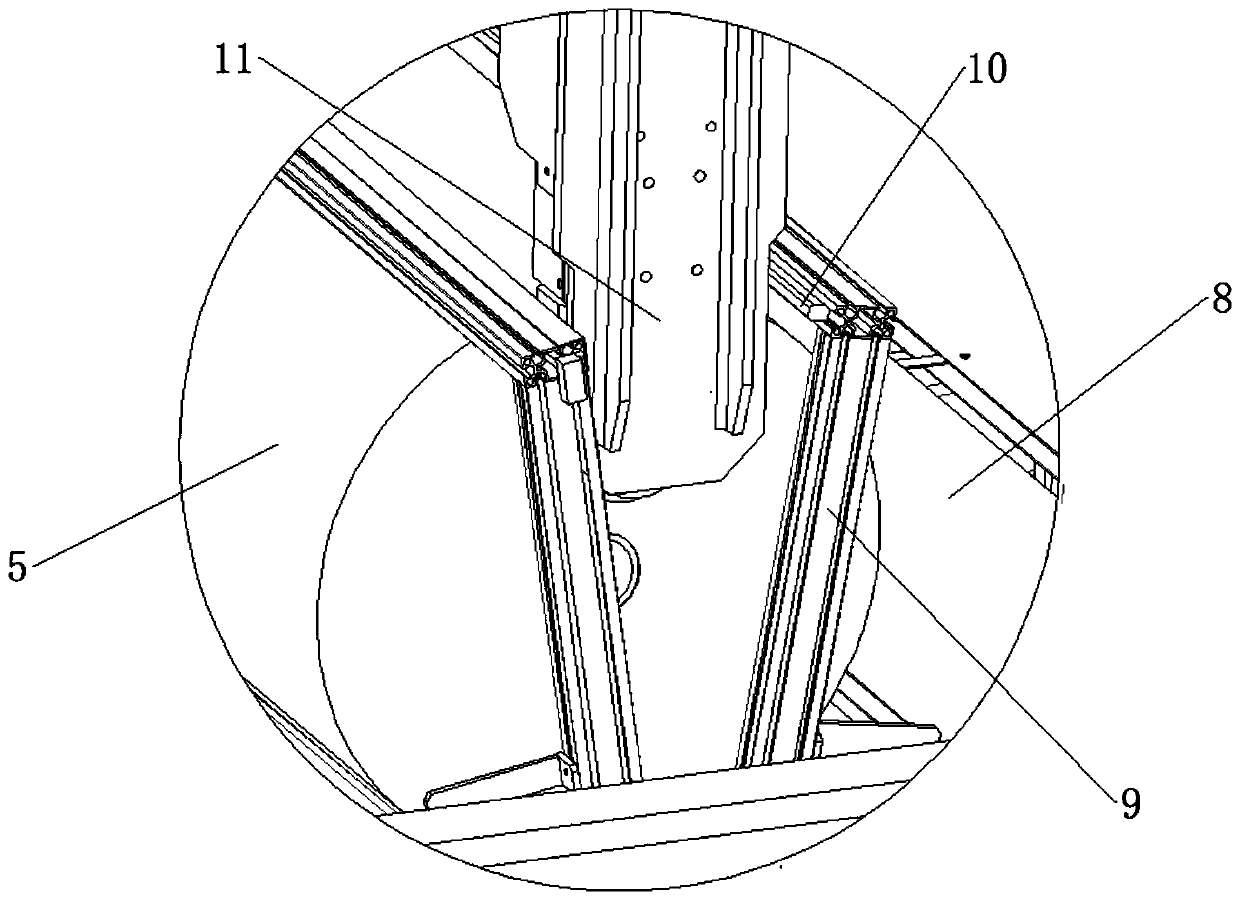

[0045] see figure 2 , Figure 4 and Figure 5 , the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com