Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Prevent mutual separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

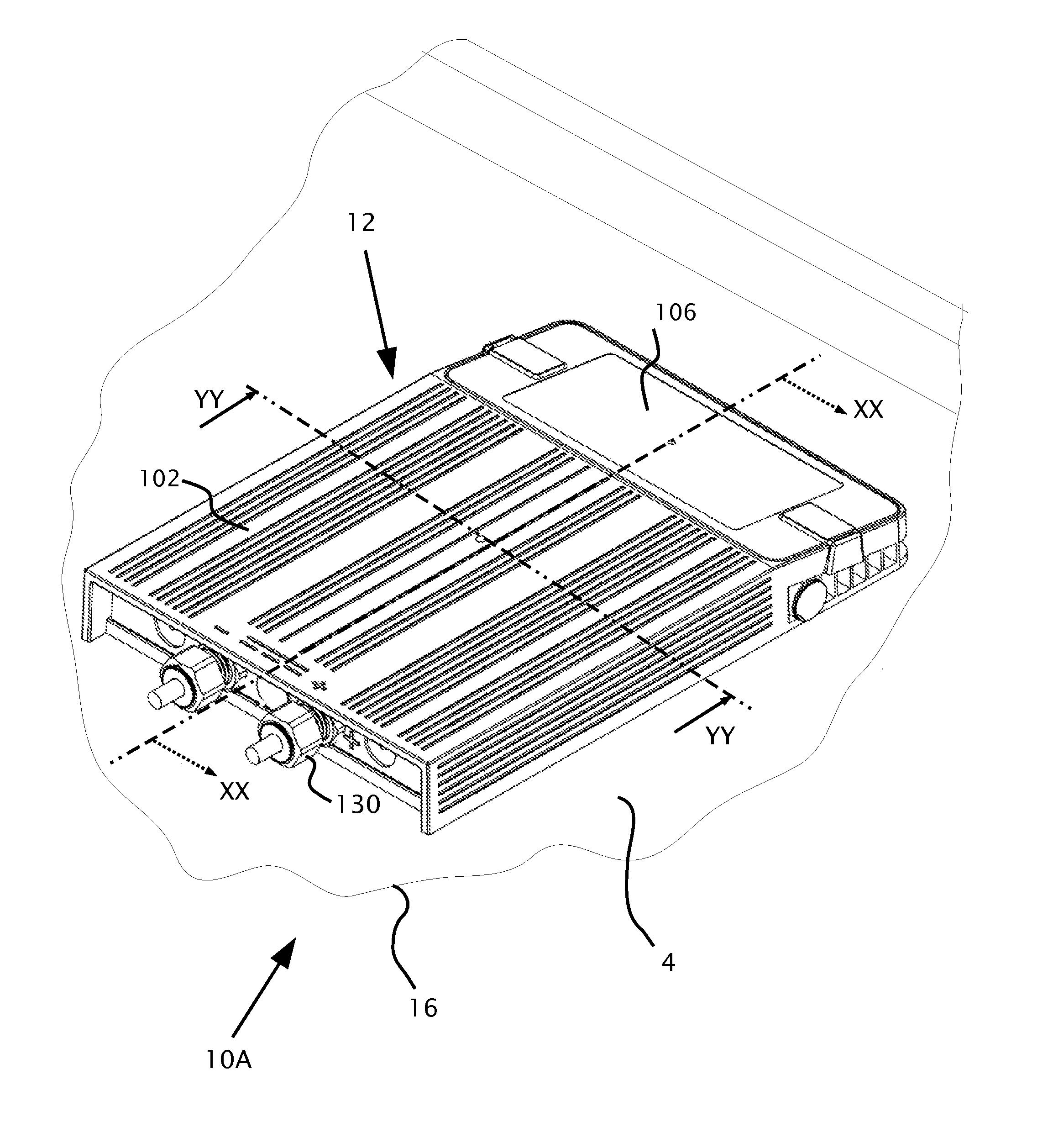

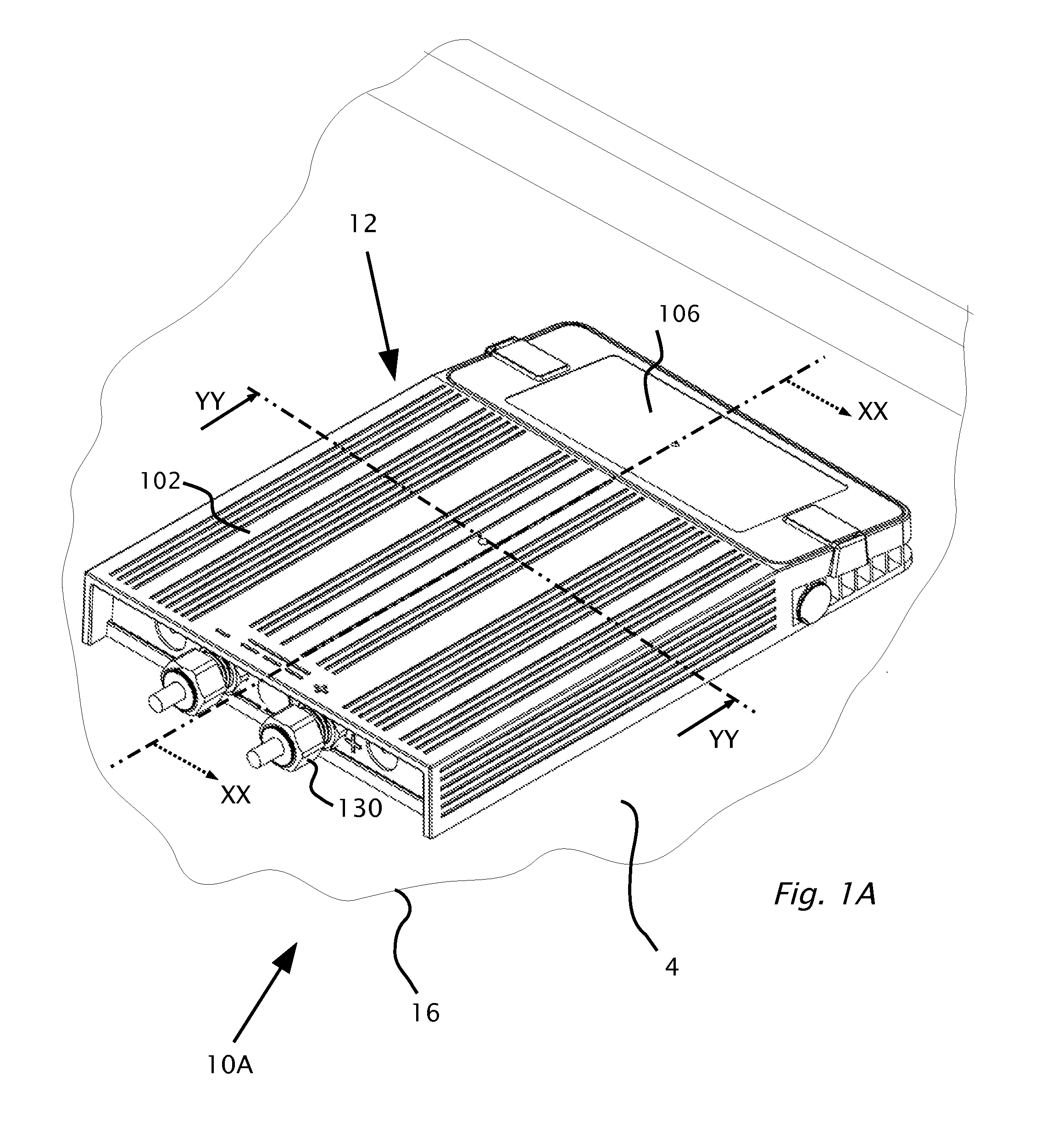

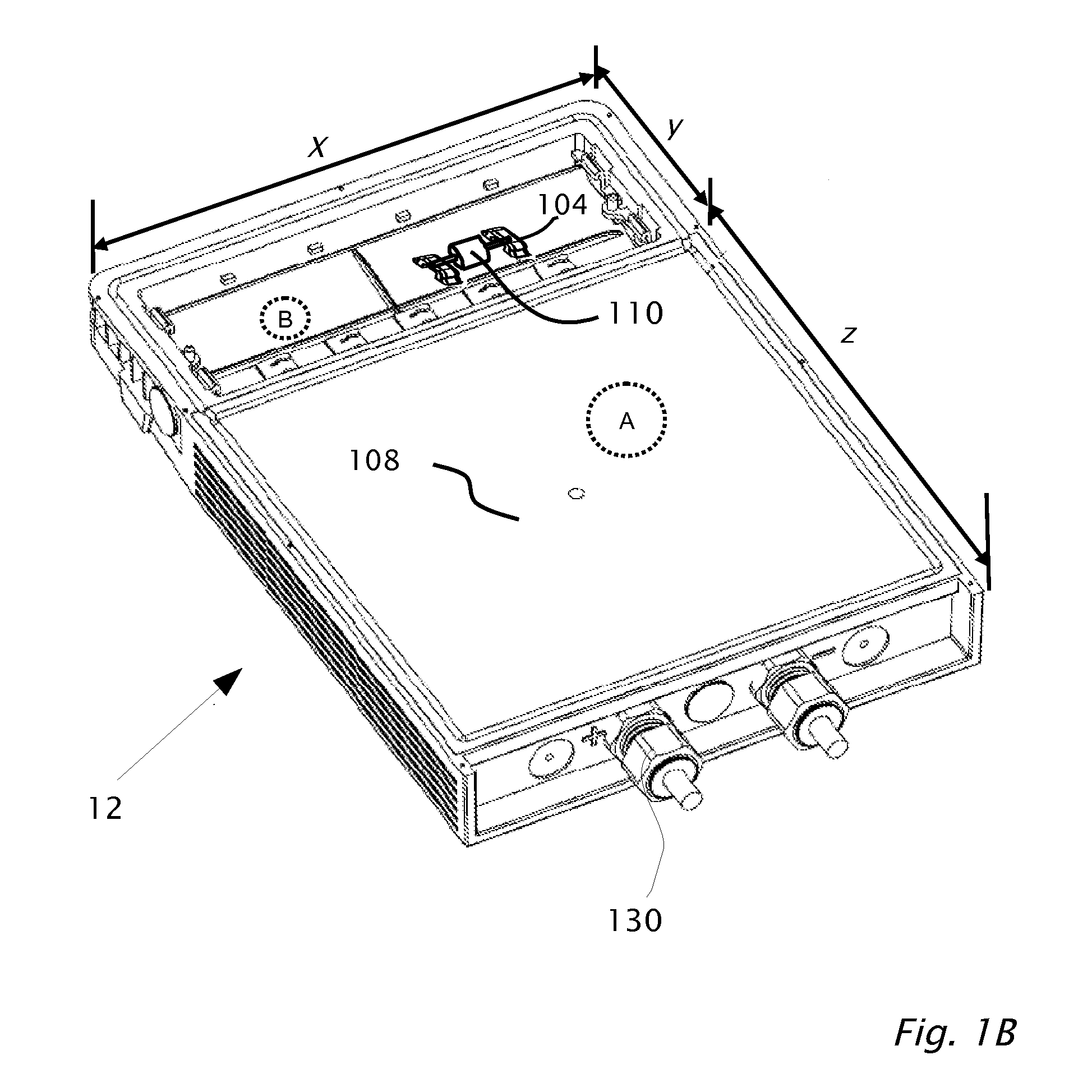

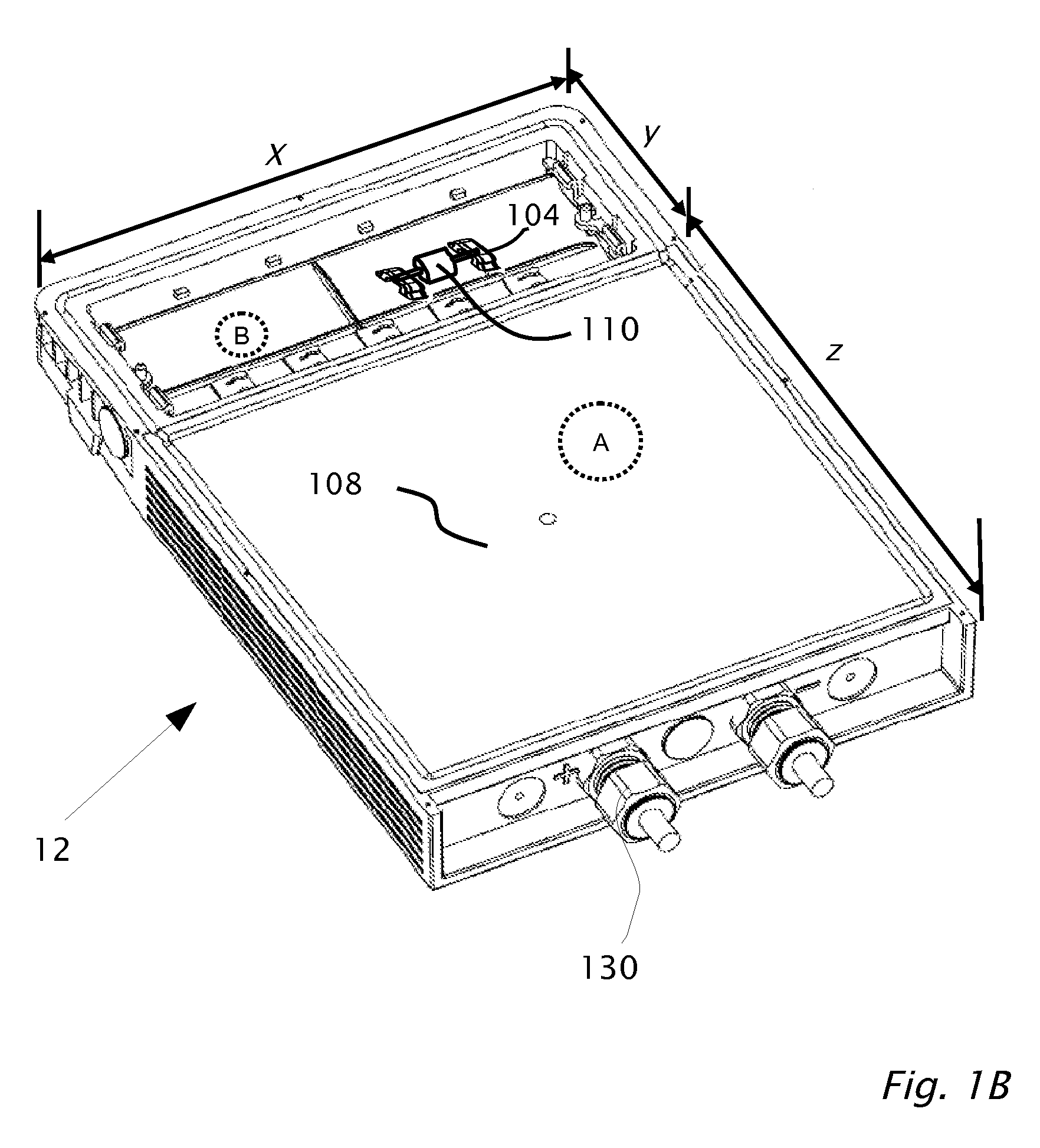

Electrically isolated heat dissipating junction box

ActiveUS20100294528A1Heat dissipationPrevent mutual separationMachine supportsScreening gaskets/sealsElectricityElectrical connection

A junction box used for making electrical connections to a photovoltaic panel. The junction box has two chambers including a first chamber and a second chamber and a wall common to and separating both chambers. The wall may be adapted to have an electrical connection therethrough. The two lids are adapted to seal respectively the two chambers. The two lids are on opposite sides of the junction box relative to the photovoltaic panel. The two lids may be attachable using different sealing processes to a different level of hermeticity. The first chamber may be adapted to receive a circuit board. The junction box may include supports for mounting a printed circuit board in the first chamber. The second chamber is configured for electrical connection to the photovoltaic panel. A metal heat sink may be bonded inside the first chamber. The first chamber is adapted to receive a circuit board for electrical power conversion, and the metal heat sink is adapted to dissipate heat generated by the circuit board.

Owner:SOLAREDGE TECH LTD

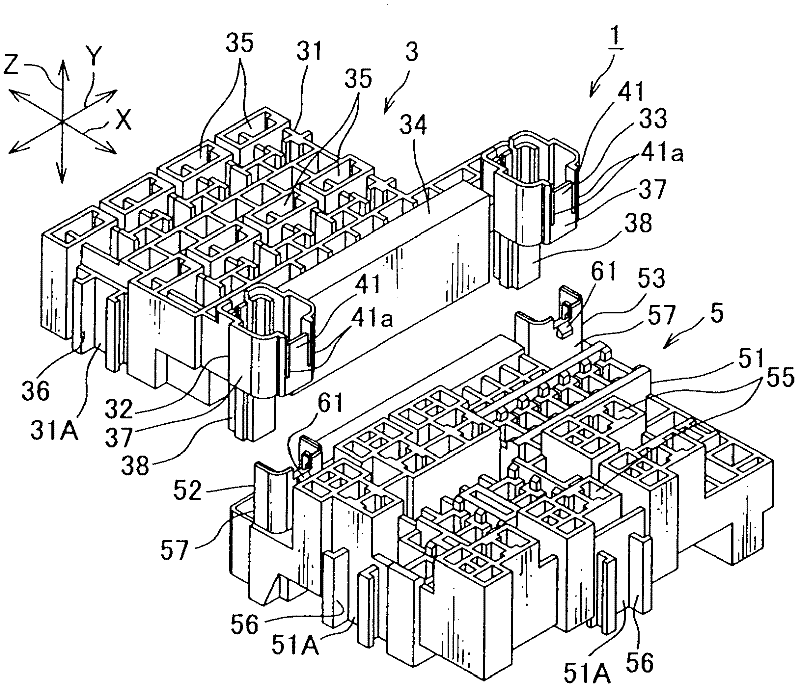

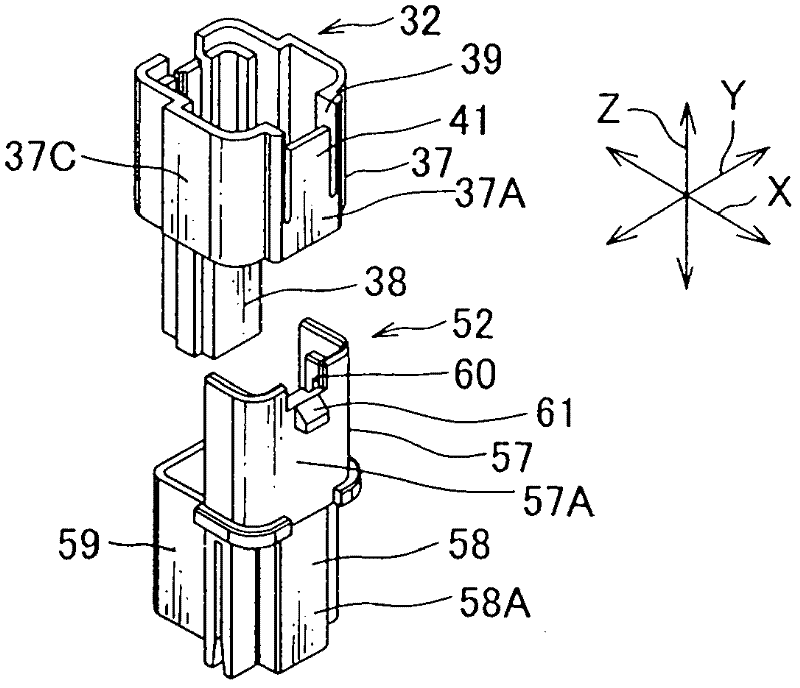

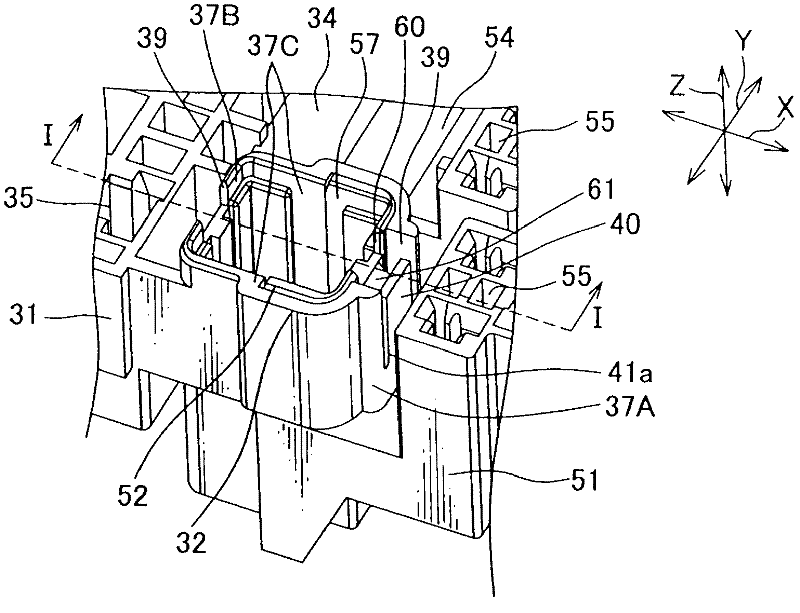

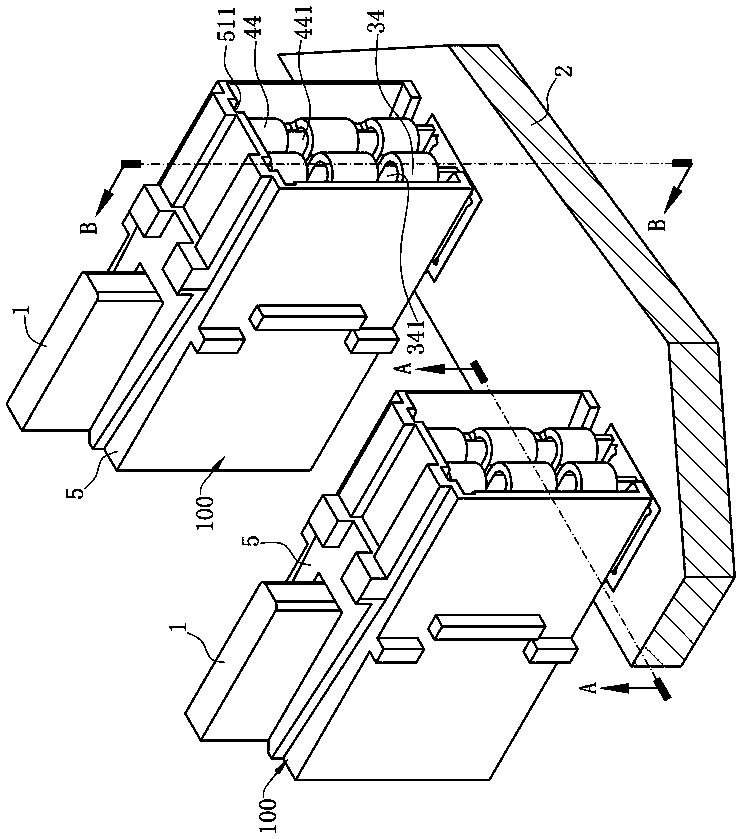

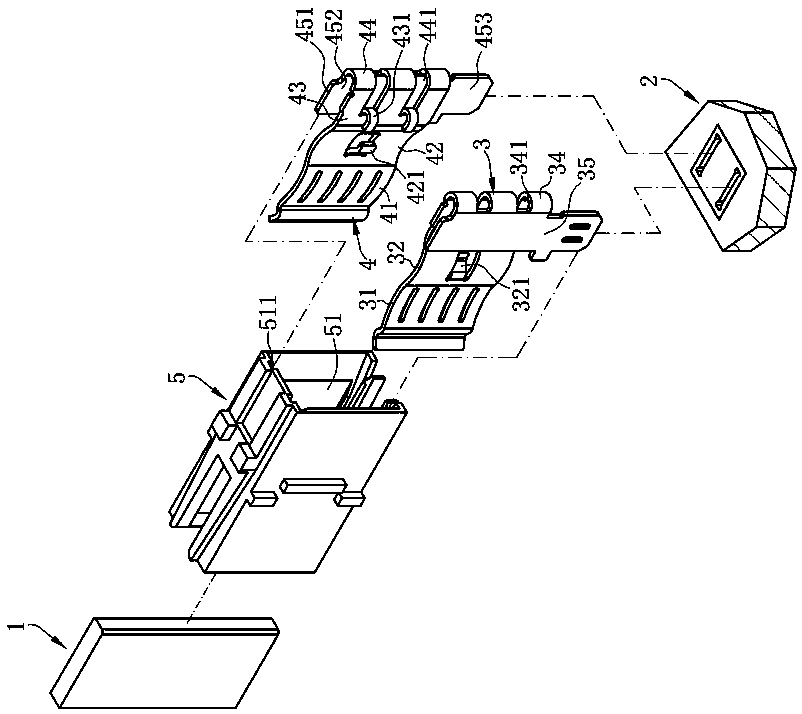

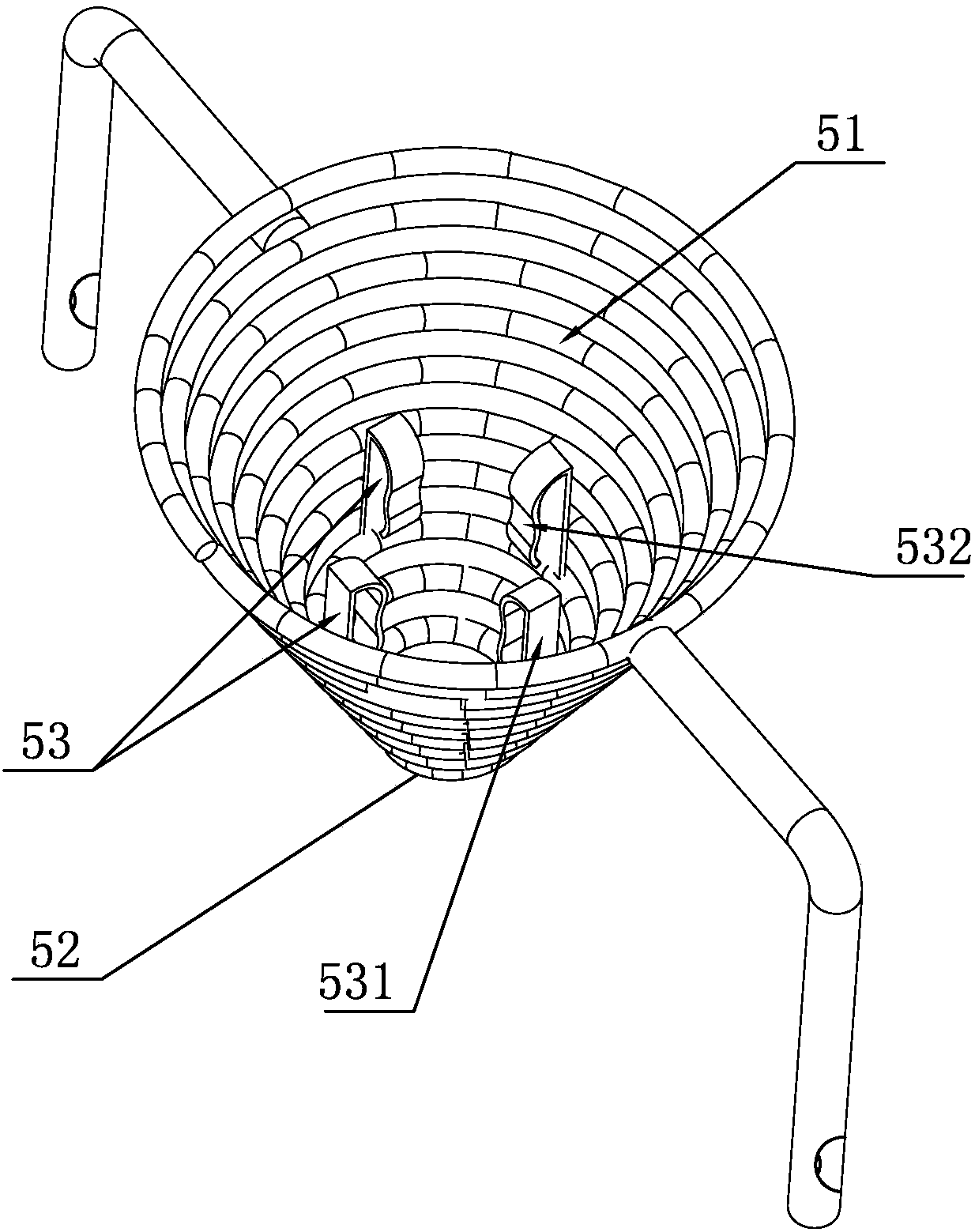

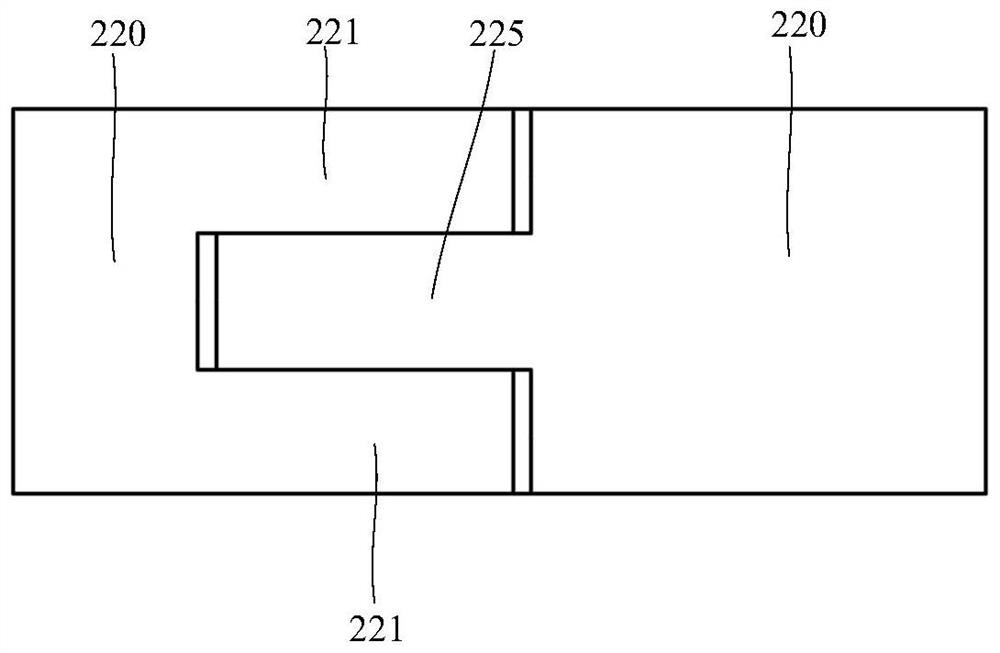

Electrical connection box

ActiveCN102386593ASmall sizeIncrease the number ofMultiple connection subassembliesElectrical connectionBreakout box

There is provided a downsized electrical connection box in which the reliability of the mechanical connection between blocks provided in the electrical connection box is improved. The electrical connection box 1 includes a plurality of electric components, a first block 3 mounted with the electric components and a second block mounted with the electric components. The first block 3 includes a tubular-shaped first member 32, 33 projecting towards the second block 5. The second block 5 includes a second member 52, 53 arranged to be slidably inserted into the first member. The first and the second blocks 3, 5 are coupled to each other by slidably inserting the second member 52, 53 into the first member 32, 33. At least one electric component 8 of the plurality of electric components is received inside the first and the second members 32, 52, 33, 53.

Owner:YAZAKI CORP

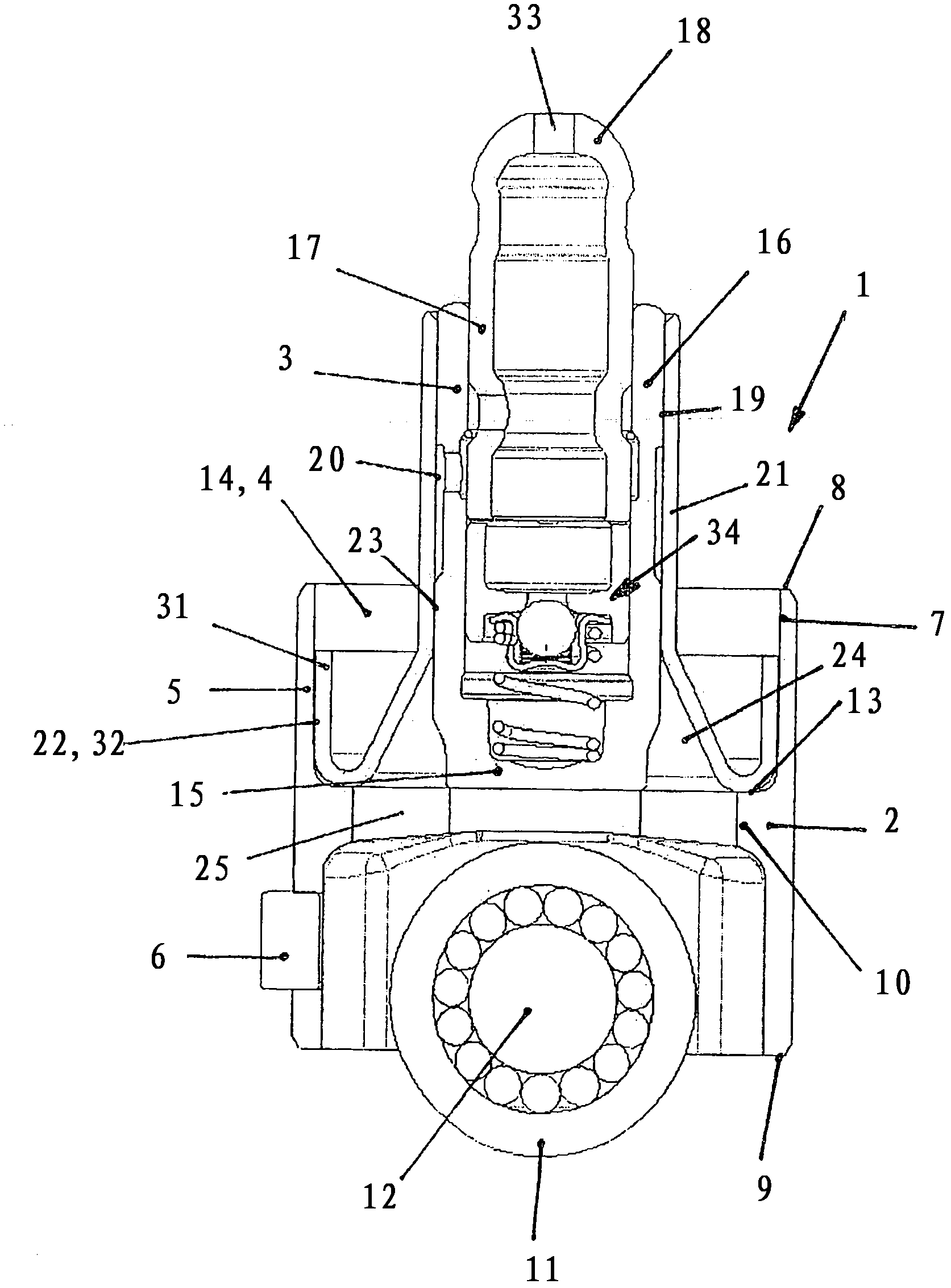

Roller cam follower

InactiveCN102588026ALight in massGuaranteed unchangedValve arrangementsMachines/enginesExternal combustion engineInternal combustion engine

The roller cam follower (1) comprises a hydraulic support unit (3) and a down or lateral cam shaft of an internal combustion engine. The roller cam follower is assembled from a roller shaft (2) for the stroke operation of a piston of a fuel high pressure pump and the hydraulic support unit. An independent claim is also included for a roller shaft has a support unit which is received in sections in a recess.

Owner:SCHAEFFLER TECH AG & CO KG

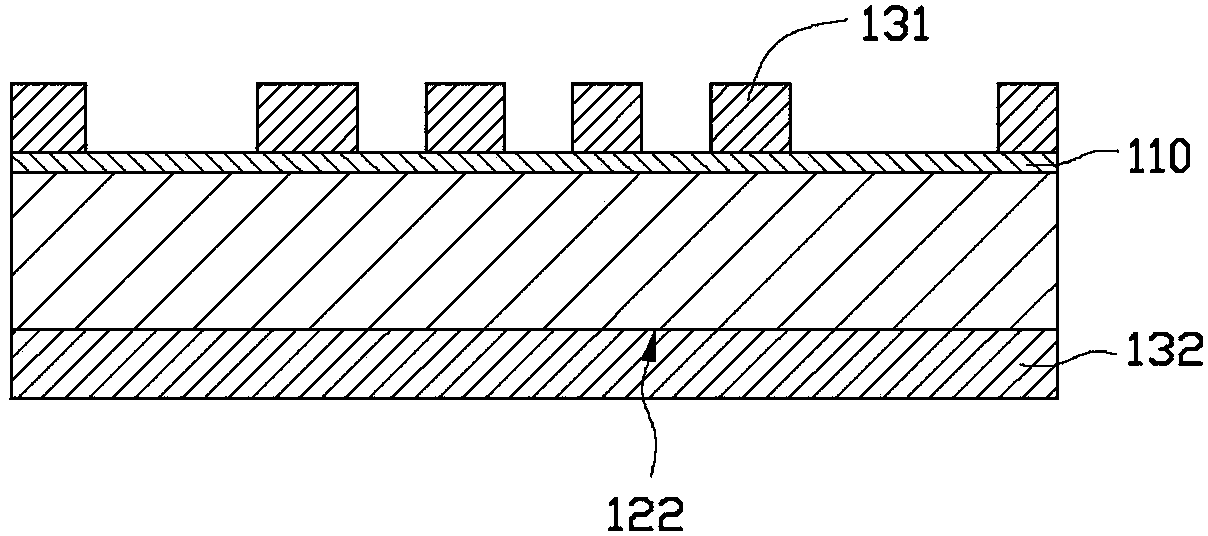

A circuit board and a manufacturing method thereof

InactiveCN104219867AReduce thicknessImprove qualityPrinted circuit detailsConductive material chemical/electrolytical removalEngineeringDielectric layer

The invention provides a circuit board, which comprises a dielectric layer, a first conductive circuit layer and a second conductive circuit layer. The first conductive circuit layer and the second conductive circuit layer are formed on the two opposite sides of the dielectric layer. The first conductive circuit layer is in part embedded in the dielectric layer, and in part protrudes from the dielectric layer, while the second conductive circuit layer is formed on the surface of the dielectric layer. The invention also provides a manufacturing method of the circuit board.

Owner:QI DING TECHNOLOGY QINHUANGDAO CO LTD +1

Key and keyboard with same

ActiveCN103177892AEasy to assembleLimit lateral movementInput/output for user-computer interactionElectric switchesKey pressingEngineering

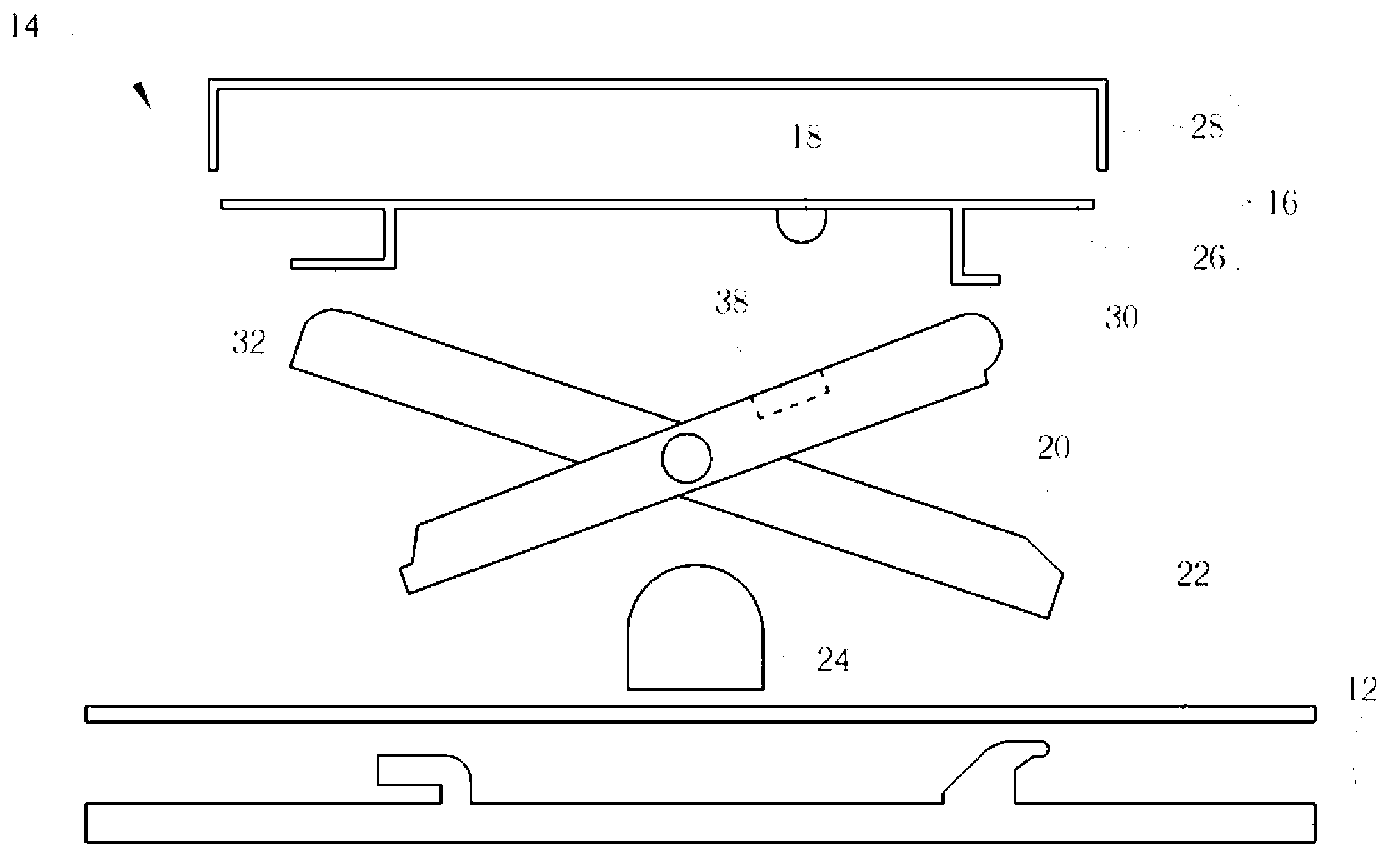

The invention relates to a key and a keyboard with the same. The key comprises a bottom plate, a keycap, a protrusion and a lifting support device. The protrusion is arranged at the bottom of the keycap. The lifting support device is disposed between the bottom plate and the keycap and is provided with a first end, a second end and a recess between the first end and the second end. The first end is opposite to the second end. The first end is movably connected to the keycap. The second end is movably connected to the bottom plate. The protrusion is movably inset in the recess when the keycap moves down through the lifting support device, so that when the keycap moves relative to the bottom plate, the first end leaves the keycap. The key and the keyboard with the same have the advantages of simple structure and easiness in assembly. The transverse movement of the keycap can be limited by effectively utilizing the combination of the protrusion and the recess, so that the keycap is prevented from leaving the lifting support device.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Terminal post sealing cover, upper cover assembly and compressor

PendingCN110854559AEasy to installQuick connectionElectrically conductive connectionsPositive displacement pump componentsStructural engineeringTop cap

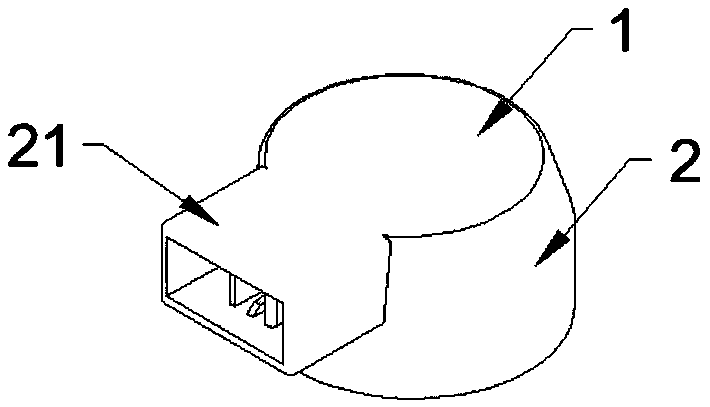

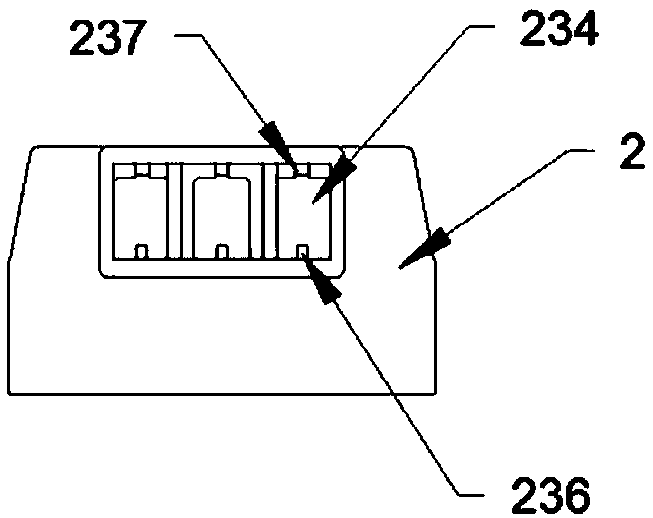

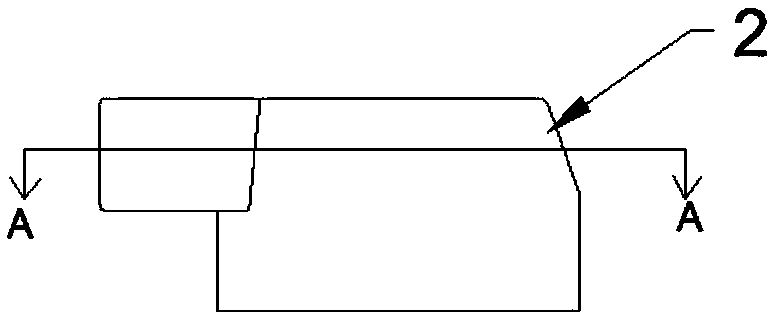

The invention relates to a terminal post sealing cover, an upper cover assembly and a compressor. The terminal post sealing cover comprises a top cover and a side wall extending from the top cover toone end; The side wall comprises a accommodating part for accommodating a connection terminal and a terminal post, and a fixing part for sleeving the outer periphery of the terminal post fixing base and interfering and fixing with the outer periphery of the terminal post fixing base; The accommodating part is provided with a fixing structure for inserting and fixing the connection terminal; The fixing structure is provided with a through hole used for the terminal post to penetrate and enabling the penetrating terminal post to contact and connect with the connection terminal. The fixing part and the terminal post fixing base are interference-fixed so that the installation of the terminal post sealing cover and the terminal post fixing base is facilitated, the sealing between the terminal post sealing cover and the terminal post fixing base is realized, materials are saved, costs are saved and the production efficiency is improved. Besides, the terminal post is enabled to pass through the through hole and contact and connect with the connection terminal in the fixing structure, thus facilitating the rapid connection between the connection terminal and the terminal post and further improving the production efficiency.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

Electrically isolated heat dissipating junction box

ActiveUS8476524B2Heat dissipationPrevent mutual separationMachine supportsScreening gaskets/sealsElectricityElectrical connection

A junction box used for making electrical connections to a photovoltaic panel. The junction box has two chambers including a first chamber and a second chamber and a wall common to and separating both chambers. The wall may be adapted to have an electrical connection therethrough. The two lids are adapted to seal respectively the two chambers. The two lids are on opposite sides of the junction box relative to the photovoltaic panel. The two lids may be attachable using different sealing processes to a different level of hermeticity. The first chamber may be adapted to receive a circuit board. The junction box may include supports for mounting a printed circuit board in the first chamber. The second chamber is configured for electrical connection to the photovoltaic panel. A metal heat sink may be bonded inside the first chamber. The first chamber is adapted to receive a circuit board for electrical power conversion, and the metal heat sink is adapted to dissipate heat generated by the circuit board.

Owner:SOLAREDGE TECH LTD

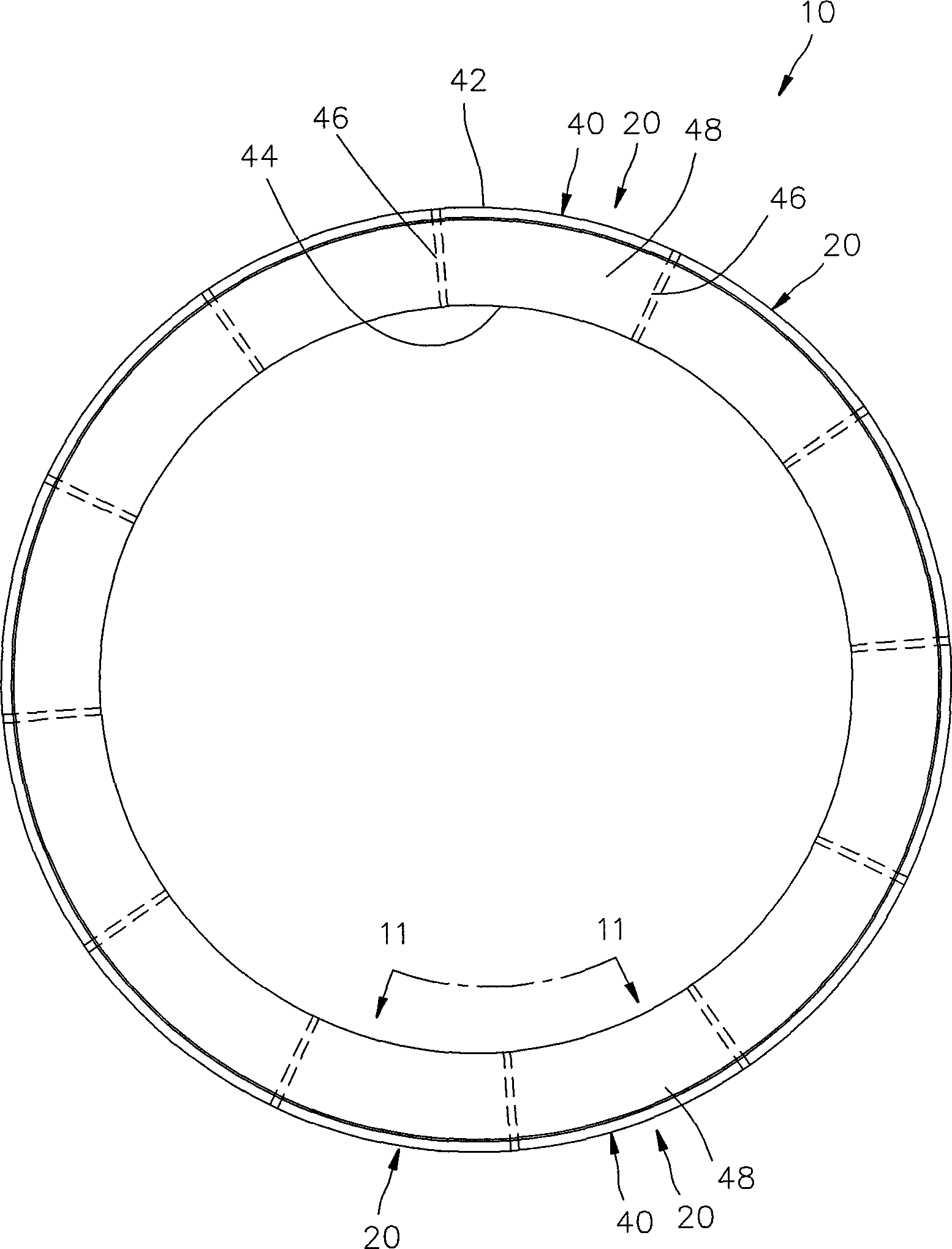

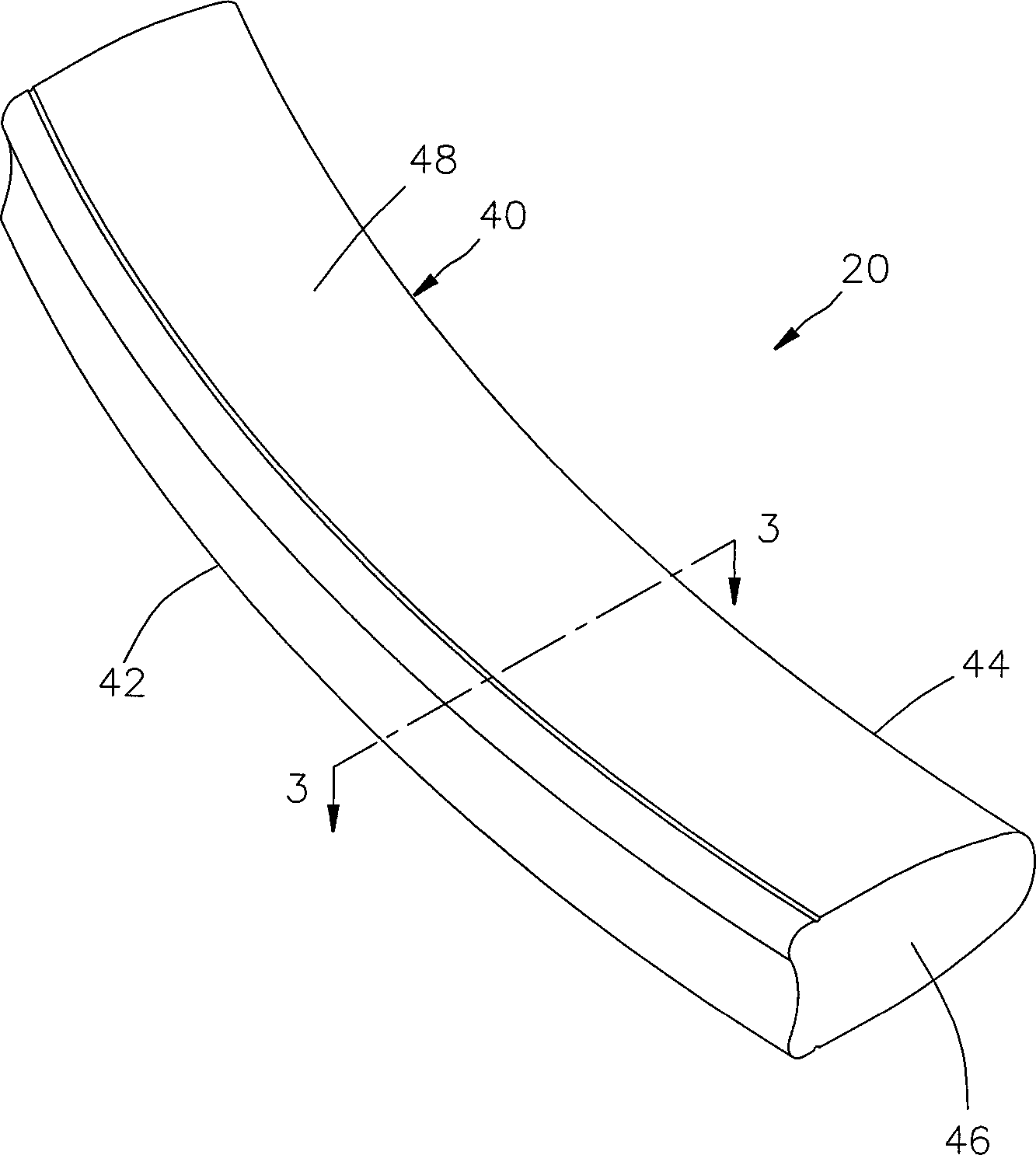

Wheel frame made of fibrous composite

A wheel frame made of a fibrous composite comprises a plurality of arc-shaped frame strips. Each arc-shaped frame strip is provided with a foaming body made of a foaming material, and an outer fibrous composite layer which wraps the foaming body and is made of the fibrous composite. Connection surfaces are respectively formed at the two ends of each arc-shaped frame strip, the arc-shaped frame strips are connected to be annular through the connection surfaces of the outer fibrous composite layers, and a supporting surface is formed on the connection portion of every two adjacent connection surfaces for the arc-shaped frame strips. The wheel frame made of the fibrous composite is light and can not be broken easily.

Owner:ZHONGSHAN FUDA SPORTS EQUIP

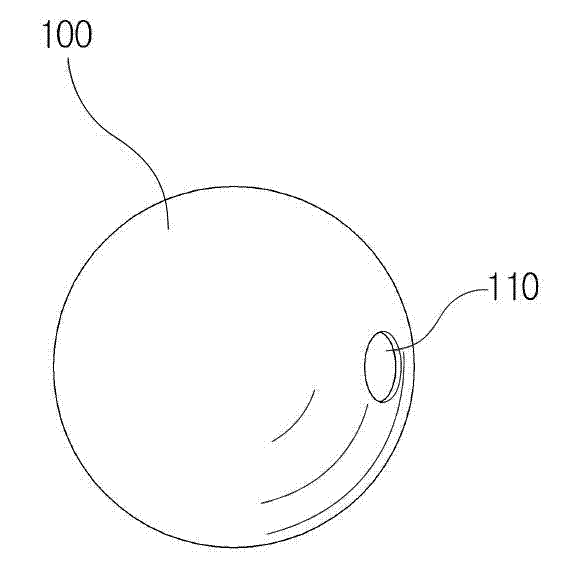

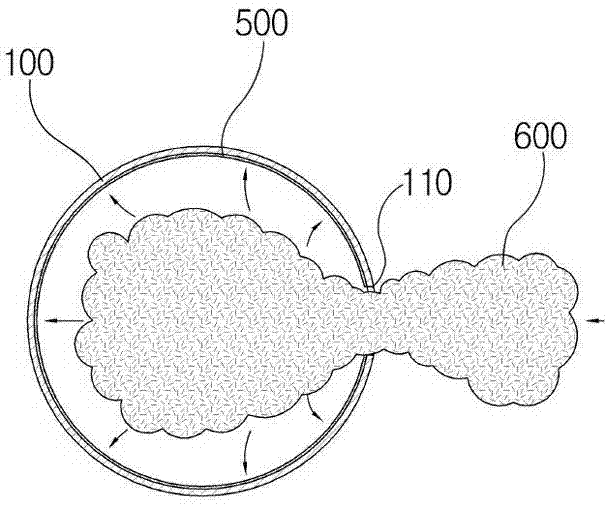

Sports ball and manufacturing method thereof

InactiveCN102258851AGuaranteed uniformityAvoid accumulationHollow inflatable ballsBall soccerManufacturing engineering

The invention discloses a playing ball and a manufacturing method thereof, relates to indoor soccer and or other balls in indoor sports, and aims to reduce elasticity of balls. The technical scheme is that: specially processed fillers are appropriately filled in a ball bag, then the ball bag is sealed, a plurality of knitted reinforcement objects are adhered to the ball bag, and a plurality of polygonal skin slices are adhered to the outer surface of the knitted reinforcement objects. In the playing ball, the ball bag is prevented from being separated from the outer skin, the service life of the ball is prevented, the uniformity of the ball is guaranteed and production efficiency is improved.

Owner:青岛新新体育用品有限公司

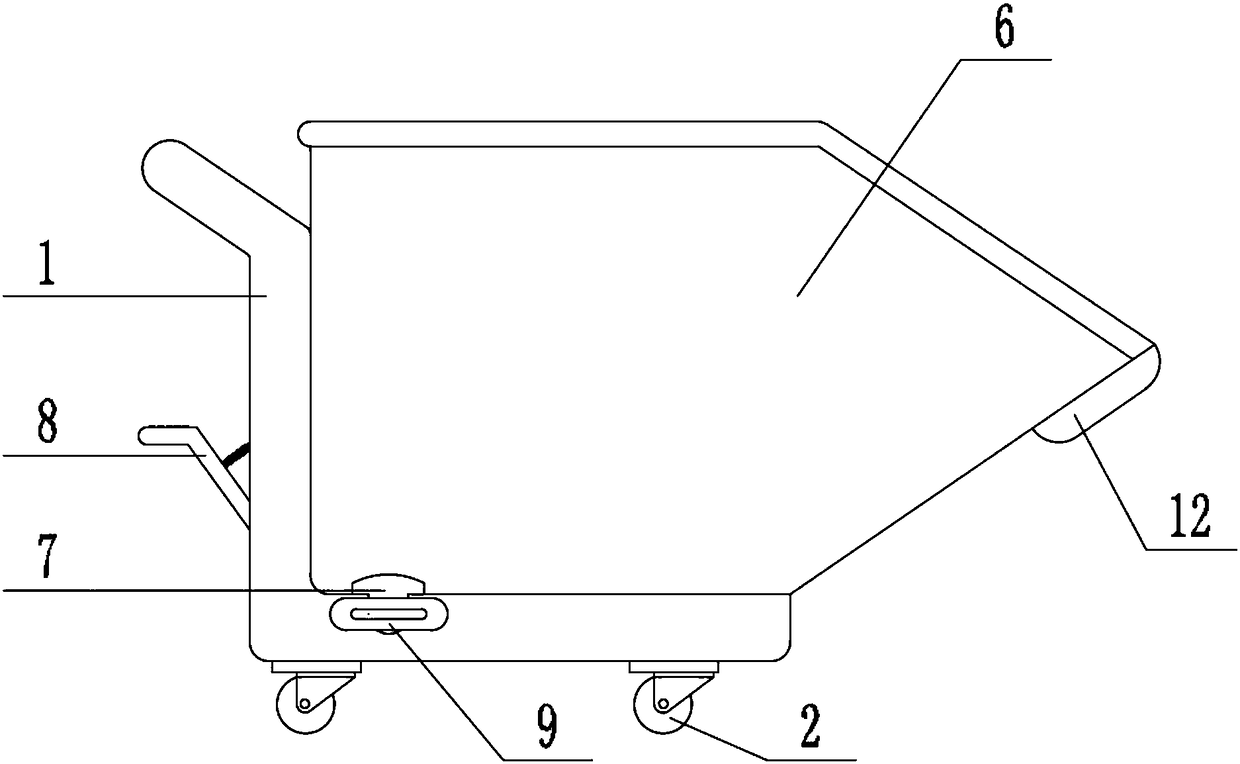

Turnover trolley

InactiveCN108382446AReduce physical exertionQuick and easy flippingHand carts with multiple axesBuffer stripEngineering

The invention provides a turnover trolley comprising a tension spring and a rubber buffer strip. A supporting frame is of an L-shaped frame structure, two magnet attracting holes are formed in the front end face of the supporting frame, and a fixing hole inserted groove is formed in the front end face of the supporting frame; a fixing hole is formed in the fixing hole inserted groove and communicates with an inserting hole; four universal wheels are mounted on the bottom end face of the supporting frame through bolts correspondingly; and a bottom rotary column is mounted in the bottom of the supporting frame. Original manual turnover is changed into foot turnover advantageously, so that physical power consumption generated when personnel turn over is reduced, turnover is further easier, more convenient and rapider, and the labor efficiency is promoted; and through cooperation of setting of the 2:1 proportion of a warping plate, the pressure applied by the feet can be effectively enlarged and is converted into lift force to be transmitted to the bottom of a trolley bucket, so that the trolley bucket is turned over, consumption of strength of the feet of the working personnel is relieved, the trolley bucket is turned over more portably, and the personnel can conveniently use the turnover trolley for a long term.

Owner:卫国锦

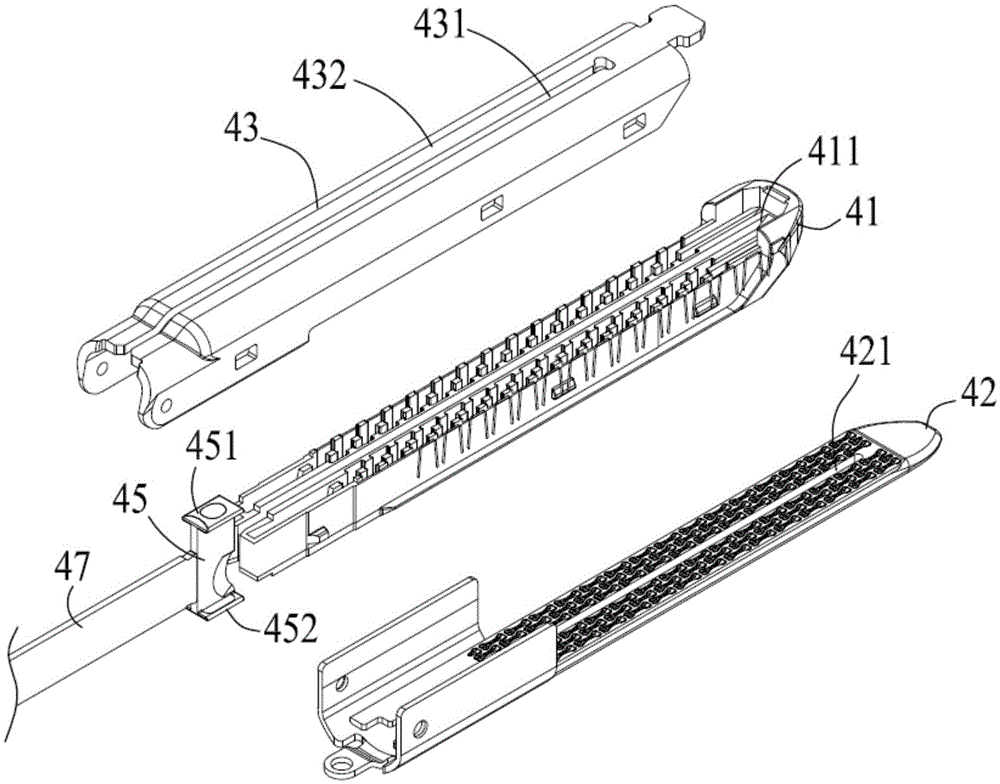

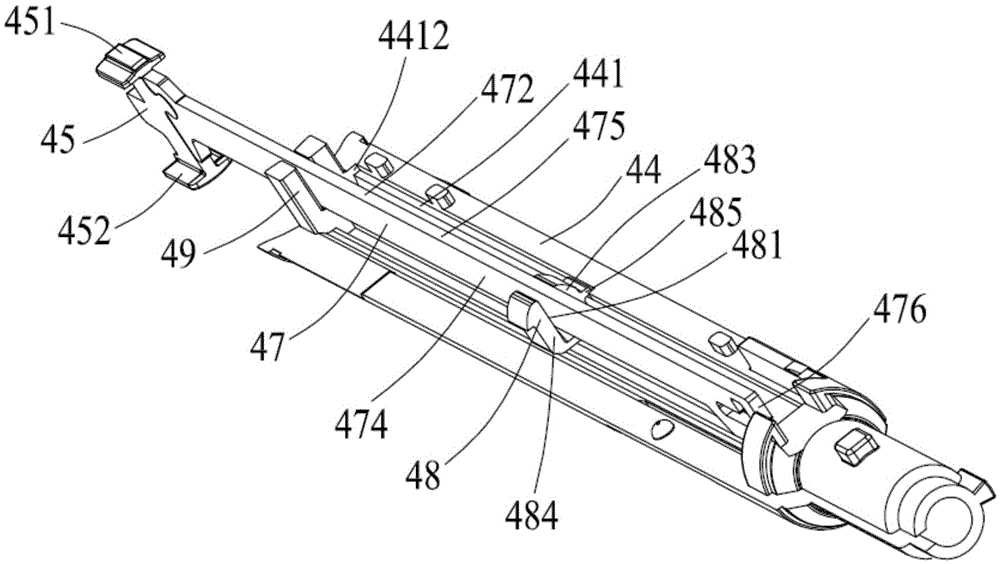

Electric connector

ActiveCN108598739ASimple structureEasy to assembleCoupling contact membersFixed connectionsEngineeringElectrical and Electronics engineering

The invention discloses an electric connector in conduction connection with an electronic card and a circuit board. The electric connector comprises an insulation body, a front end of the insulation body is recessed backwards to form the accommodation space, a first terminal is accommodated in the accommodation space, a second terminal is arranged opposite to the first terminal and is accommodatedin the accommodation space, the second terminal comprises a contact portion abutting the opposite other side of the electronic card, a conduction connection portion arranged at the back of the contact portion, a first elastic portion connected with the contact portion, a second elastic portion connected with the conduction connection portion, and a connection portion connected with the first elastic portion and the second elastic portion, the conduction connection portion is in conduction connection with a circuit board, the connection portion is provided with a pull-holding member, and the first terminal is held by the pull-holding member. The first terminal is held by the pull-holding member, so mutual separation of the first terminal and the second terminal is avoided, the first terminal and the second terminal can be further made to simultaneously swing or move, the structure is simple, assembling is easy, and production cost is reduced.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

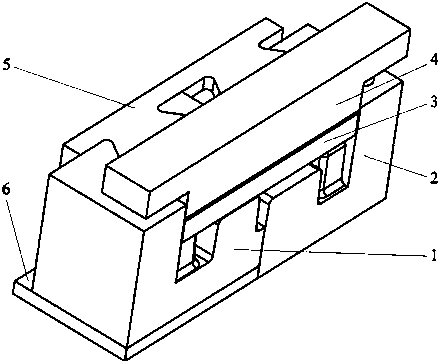

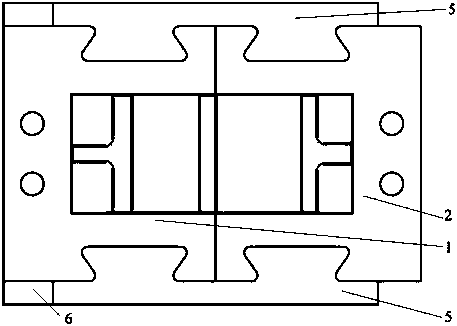

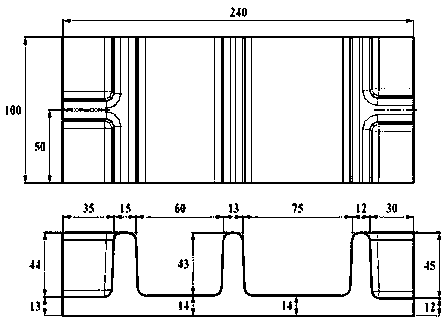

Local loading forming method for single-action press and combined die

InactiveCN110899588AReduce forming loadGood formabilityForging/hammering/pressing machinesIndustrial engineeringMachine press

The invention discloses a local loading forming method for a single-action press machine and a combined die thereof. The forming method comprises the following steps: firstly, a load is applied to anarea, corresponding to a heightened lower die I, in a combined lower die; secondly, a cushion block is removed, the lower die I moves downwards, and then the upper surface of the lower die I and the upper surface of the lower die II are located at the same horizontal position; and finally, a load is applied to an area corresponding to the lower die II. The die comprises a combined lower die, an upper die, a cushion block and a lock catch, wherein the lower die is composed of a lower die I and a lower die II, and the lower die I and the lower die II are connected through the lock catch; the cushion block is placed on the lower surface of the lower die I, so that the upper surface of the lower die I is higher than that of the lower die II. By means of the local loading forming method, the forming load of the overall complex-shaped component can be effectively reduced, and the forming capacity of press equipment in industrial production is improved; fixed connection of combined dies in different loading areas is achieved in the local loading forming process through a lock catch connection method.

Owner:NANCHANG HANGKONG UNIVERSITY

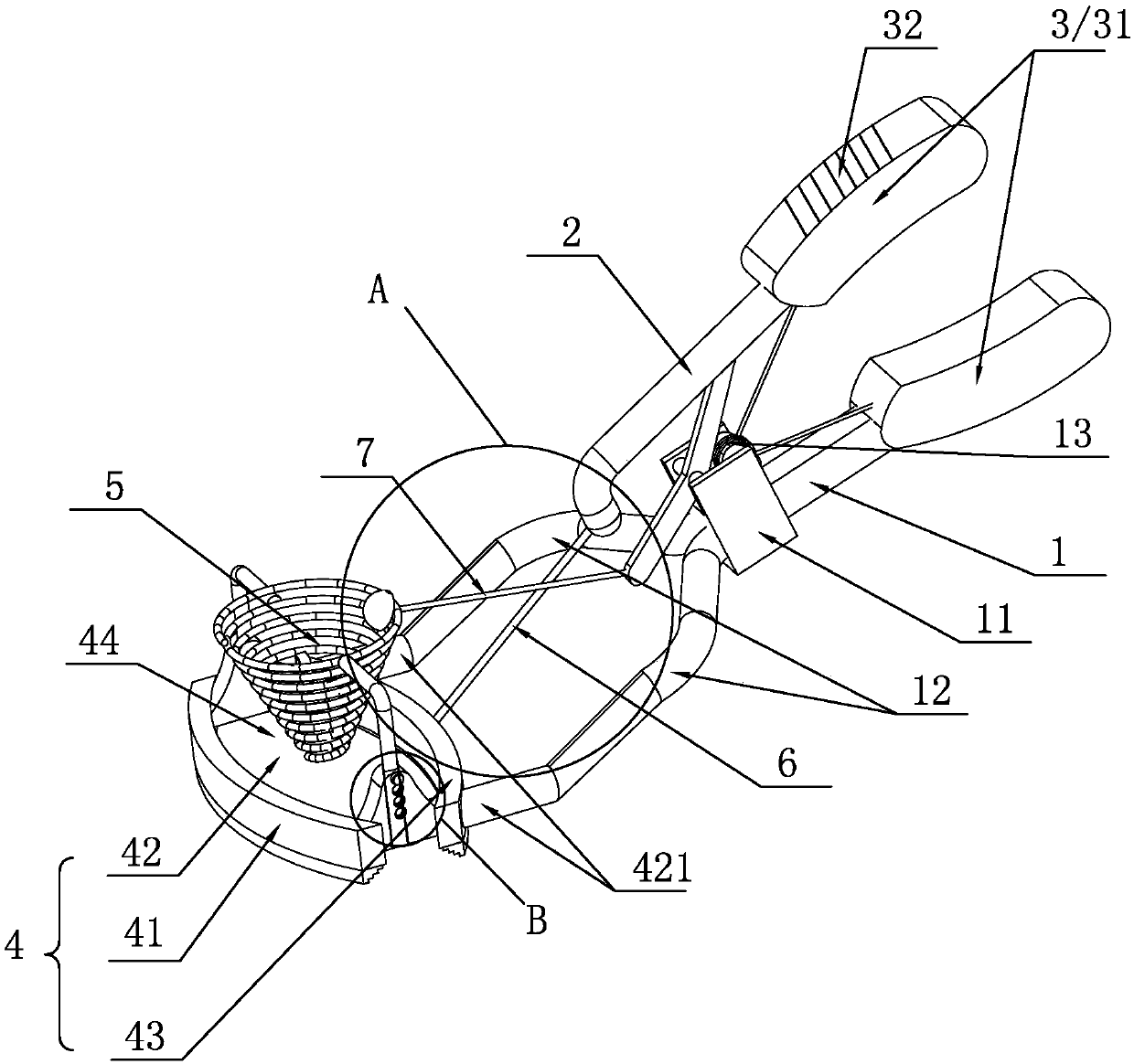

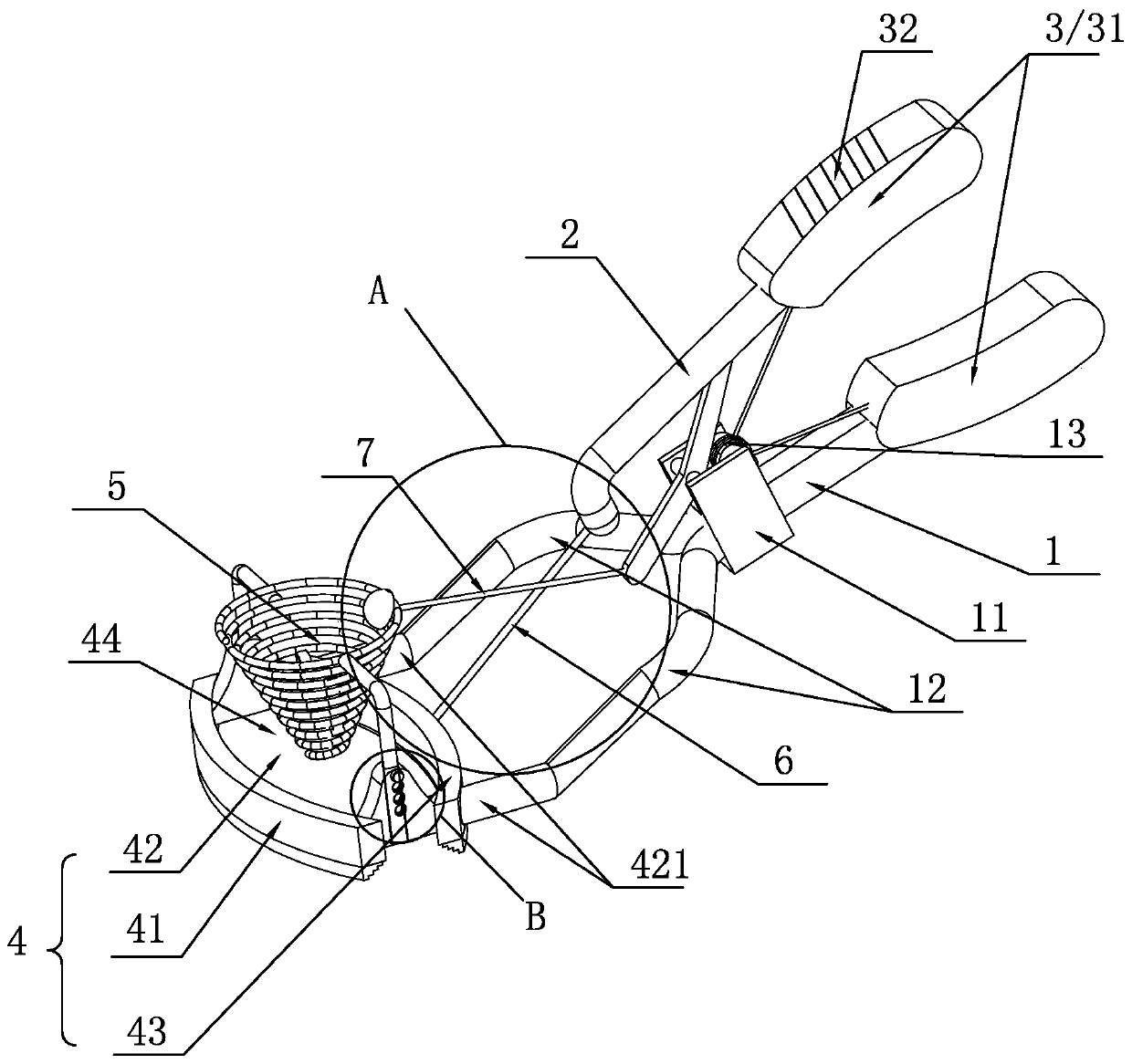

Eye drops device

ActiveCN107669397AStimulus signal decreasesEasy to dripPharmaceutical containersMedical packagingEyelidEye/ear drops

The invention relates to an eye drops device. The eye drops device comprises an upper frame body and a lower frame body; the upper frame body and the lower frame body are connected in a hinged mode and provided with an operating handle respectively, a separating mechanism is arranged on the lower frame body, the separating mechanism comprises a locating plate, a sliding track and a propping-up plate, the propping-up plate is arranged on the sliding track in a sliding mode, the locating plate and the propping-up plate form an eye drops area, an installation post is fixedly arranged on the upperside of the eye drops area, and a linkage rod is arranged between the upper frame body and the propping-up plate in a linkage mode; when operating handles approach each other, the linkage rod drivesthe propping-up plate away from the locating plate, an extrusion piece for squeezing the external wall of an eye drops bottle is arranged on the upper frame body in a rotating mode, when the operatinghandles approach each other, the extrusion piece moves toward the side wall of the eye drops bottle, and a reserved spacing is arranged between the most front end of the extrusion piece facing towardthe side wall of eye drops and the side wall of the eye drops. The above scheme provides the eye drops device which can separate the upper and lower eyelids and carry out accurate and automatic eye drops operations after the separation from each other.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

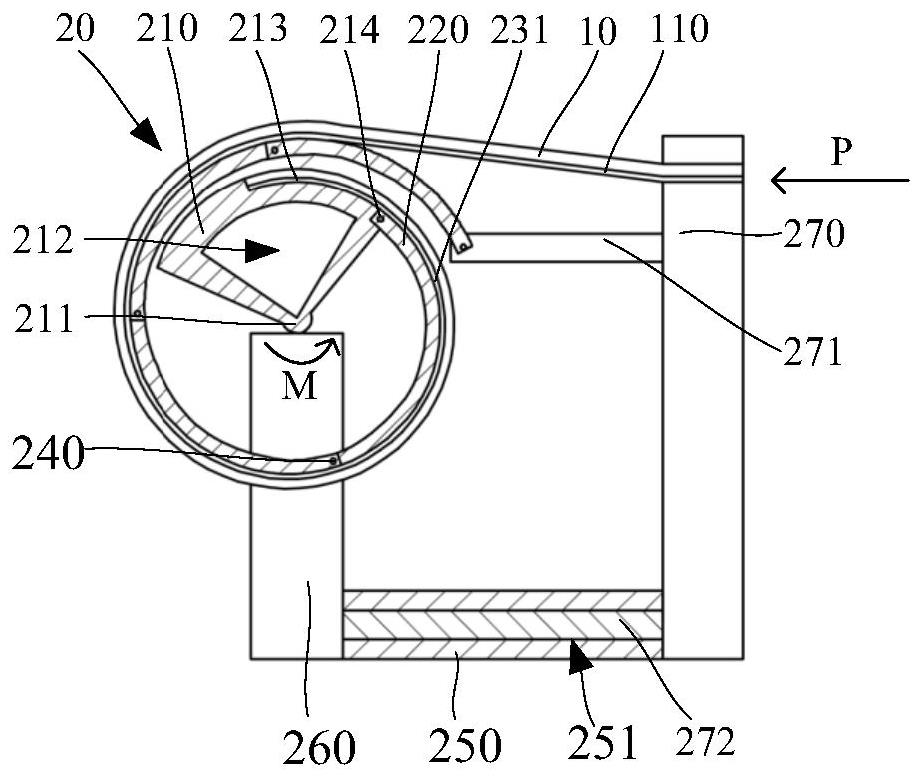

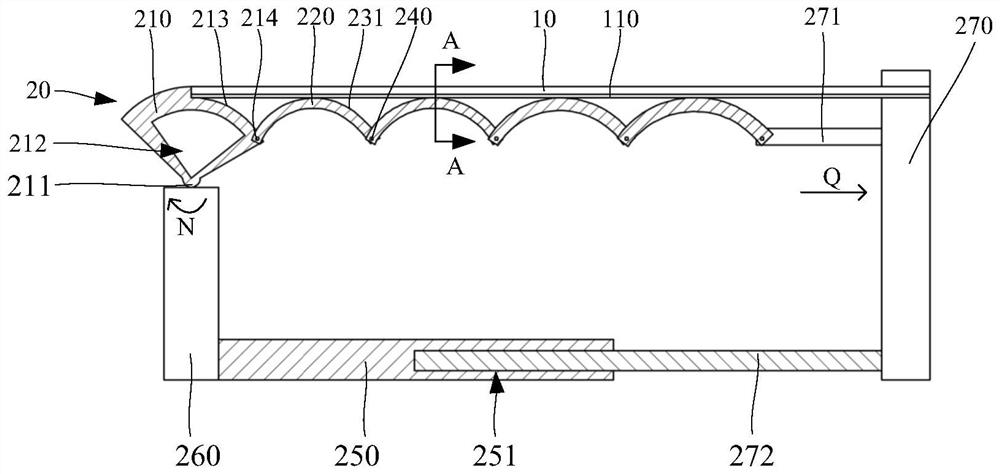

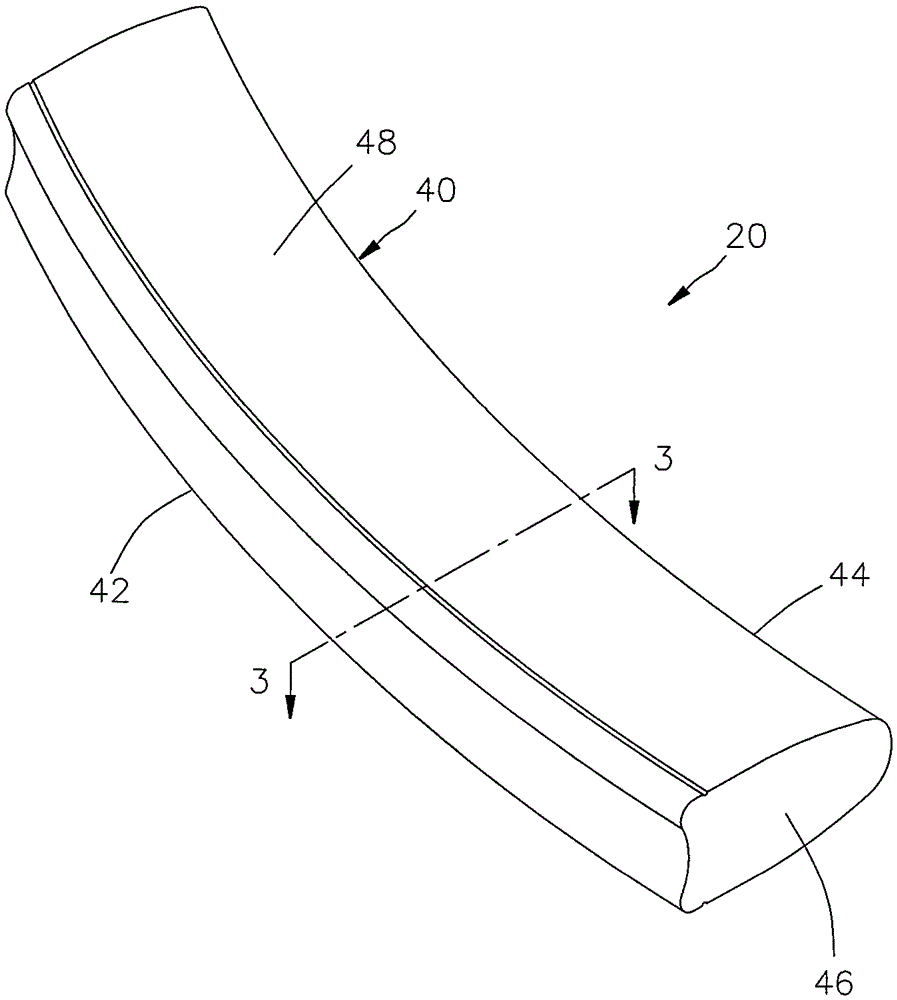

Flexible display device and mobile terminal

PendingCN114220354AGuaranteed display effectReduce the chance of curlingIdentification meansEngineeringFlexible display

The embodiment of the invention relates to a flexible display device and a mobile terminal, and belongs to the technical field of display. The embodiment of the invention aims to solve the problem that an inorganic layer of a flexible screen is easy to break or film layers in the flexible screen are separated from one another in the prior art. The flexible display device comprises a flexible screen and a supporting mechanism, the supporting mechanism comprises a reel and a plurality of arc-shaped supporting plates hinged in sequence, and one arc-shaped supporting plate at one end of the arc-shaped supporting plates hinged in sequence is hinged to the reel; one end of the flexible screen is fixedly connected with the reel; the plurality of arc-shaped supporting plates which are hinged in sequence are configured to form a spiral supporting piece surrounding the reel when the flexible screen is curled around the reel; when the flexible screen is unfolded, a wave-shaped supporting piece is formed, and all wave crests of the wave-shaped supporting piece are coplanar. According to the flexible display device provided by the embodiment of the invention, breakage of the inorganic layer of the flexible screen and / or mutual separation of film layers in the flexible screen can be avoided.

Owner:HEFEI VISIONOX TECH CO LTD

Wear-resistant and oil stain-proof book cover packing paper

The invention mainly relates to the technical field of packaging material processing, and discloses a wear-resistant and oil stain-proof book cover packing paper. The wear-resistant and oil stain-proof book cover packing paper comprises an outer protective layer and an inner folded layer; the protective layer comprises, by weight, 28-30 parts of natural latex, 17-19 parts of an epoxy resin modified styrene-acrylic emulsion, 3.2-3.4 parts of nanometer titanium dioxide, 2.1-2.3 parts of nano-alumina and 0.5-0.7 part of negative ion powder; and the folded layer comprises, by weight, 41-43 parts of paper fibers, 17-19 parts of cotton fibers, 14-16 parts of bamboo fibers and 6-8 parts of activated carbon fibers. The book cover packing paper has the advantages of high strength, good wear resistance, easiness in folding, softness, comfortableness, avoiding of scratches of corners to skins, good oil-proof and waterproof property, avoiding of oil and water from contaminating the packing paper and then penetrating books, and good book protection effect; and the book cover packing paper is composed of the outer protective layer and the inner folded layer, and the protective layer can preventthe oil and water from penetrating in order to improve the wear resistance of the book cover packing paper.

Owner:安徽省汉甲机电设备科技有限公司

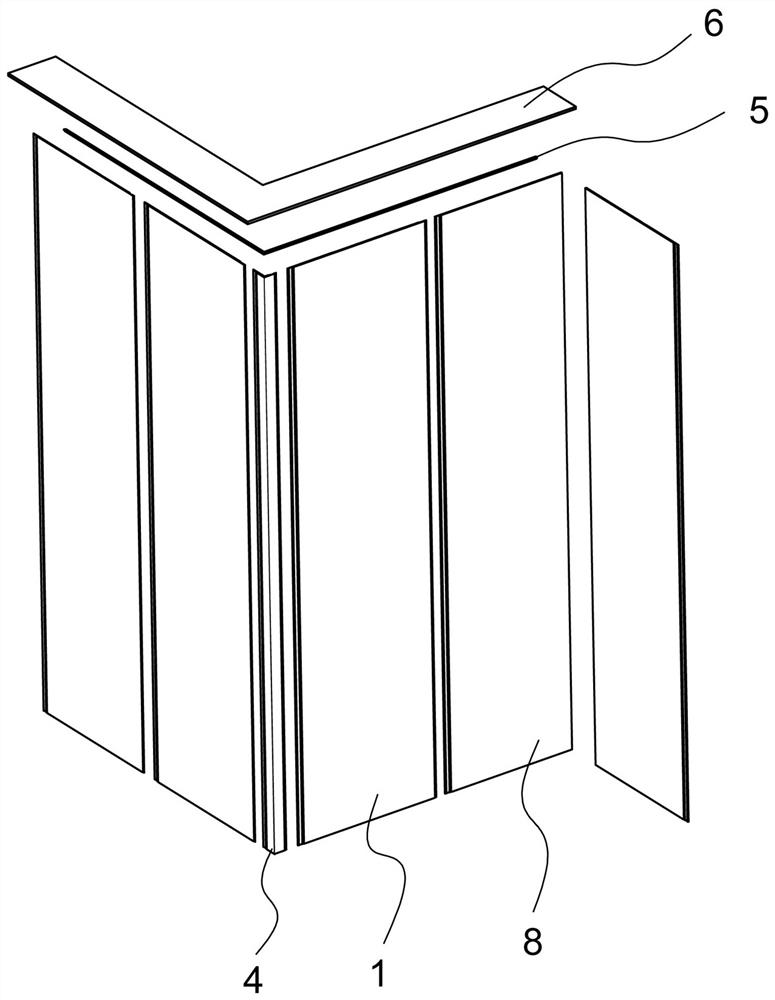

Plug-in buckle type ultrathin hollow stone-plastic wallboard assembly and mounting method

PendingCN112554467AAchieve installationEasy to installCovering/liningsMechanical engineeringDropped ceiling

The invention provides a plug-in buckle type ultrathin hollow stone-plastic wallboard assembly and a mounting method, and belongs to the technical field of indoor wall decoration. The plug-in buckle type ultrathin hollow stone-plastic wallboard assembly comprises a suspended ceiling board, a wallboard unit and closing-up lines. The fixing ends of two first internal corner plates abut against eachother at the internal corner of the wall, the two first internal corner plates are fixed to the two ends of the internal corner of the wall correspondingly, installation of the wallboard at the internal corner of the wall is achieved, the first clamping structures of the first wallboard are clamped to the second clamping structures of the first internal corner plates at the two ends of the flush joint of the wall correspondingly, the first wallboard, fixing the first wallboard are sequentially mounted at the wall flush joint, the third clamping structure of an external corner plate is clampedto the second clamping structure of the first wallboard at one end of the wall flush joint, the fourth clamping structure of the external corner plate is clamped to the first clamping structure of thefirst wallboard at the other end of the wall flush joint at a wall external corner, installation of the external corners of the wall is achieved, and the wall is provided with the closing-up lines.

Owner:ZHEJIANG YASHA DECORATION

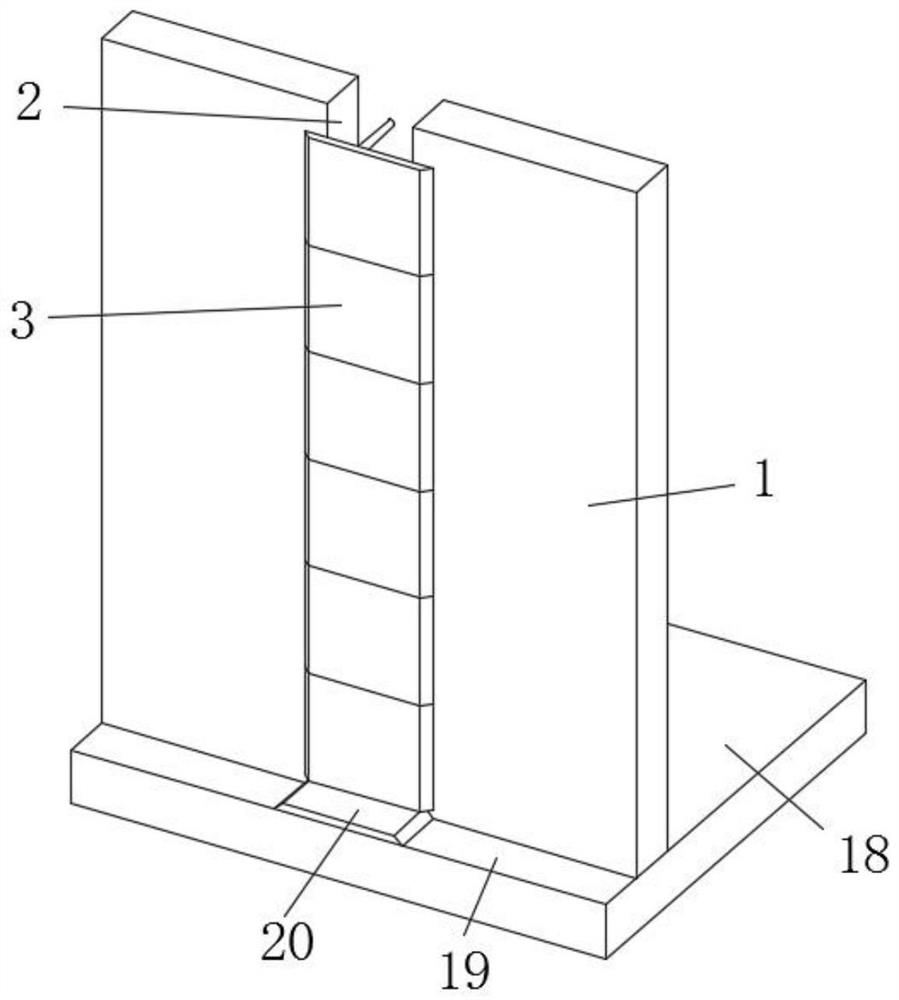

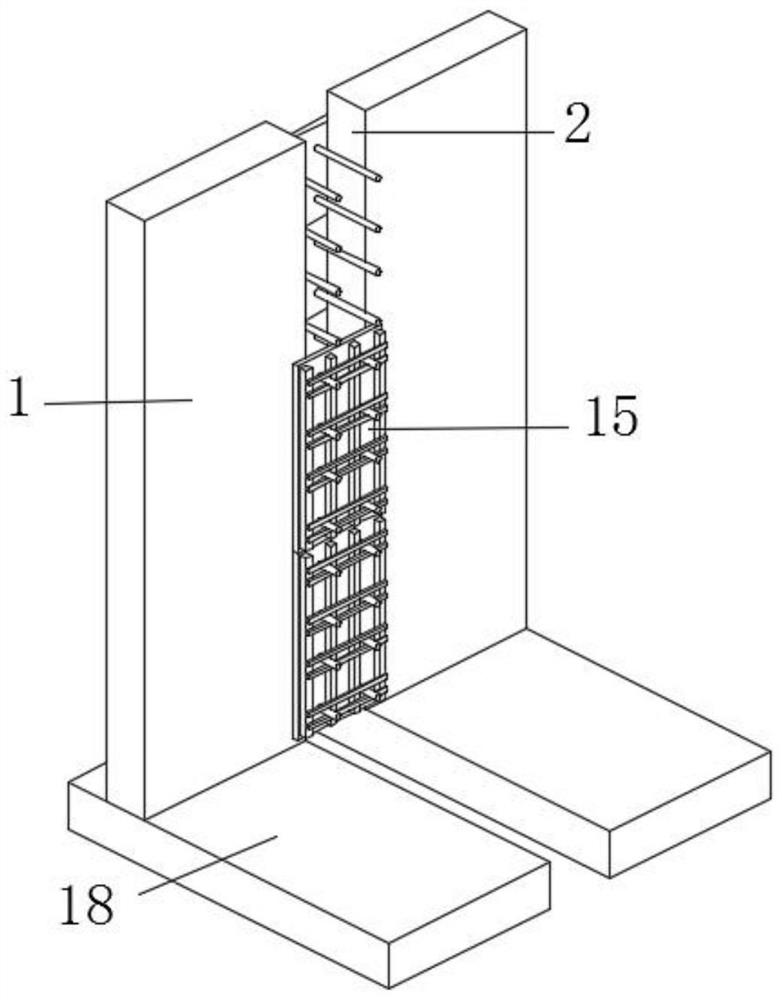

Building pouring formwork support and construction method thereof

InactiveCN114856181AImprove structural strengthQuality improvementArtificial islandsProtective foundationBasementArchitectural engineering

The invention relates to the technical field of post-cast strip pouring formworks, in particular to a building pouring formwork support and a construction method thereof.The building pouring formwork support comprises a basement outer wall, and an outer wall post-cast strip is arranged in the middle of the basement outer wall; the prefabricated splice plate is attached to the middle of the outer side wall of the basement outer wall and covers one side of the outer wall post-cast strip, the side face of the fixed baffle is fixedly connected with an L-shaped elastic metal plate, the side face of the positioning protruding plate is fixedly connected with a wedge-shaped block, and the end of the positioning protruding plate is matched with the inner side of the elastic metal plate; the prefabricated splicing structure has the beneficial effects that the multiple prefabricated splicing plates are arranged, every two adjacent prefabricated splicing plates are assembled and spliced through the positioning protruding plates, the fixing baffles and the elastic metal plates, the split bolts are arranged on the prefabricated splicing plates and used for being connected with the inner side formwork, and the prefabricated splicing plates are spliced in an assembled mode and can be installed according to site requirements; the construction process is more flexible, and the application range is wider.

Owner:蚌埠凡达建筑工程有限公司

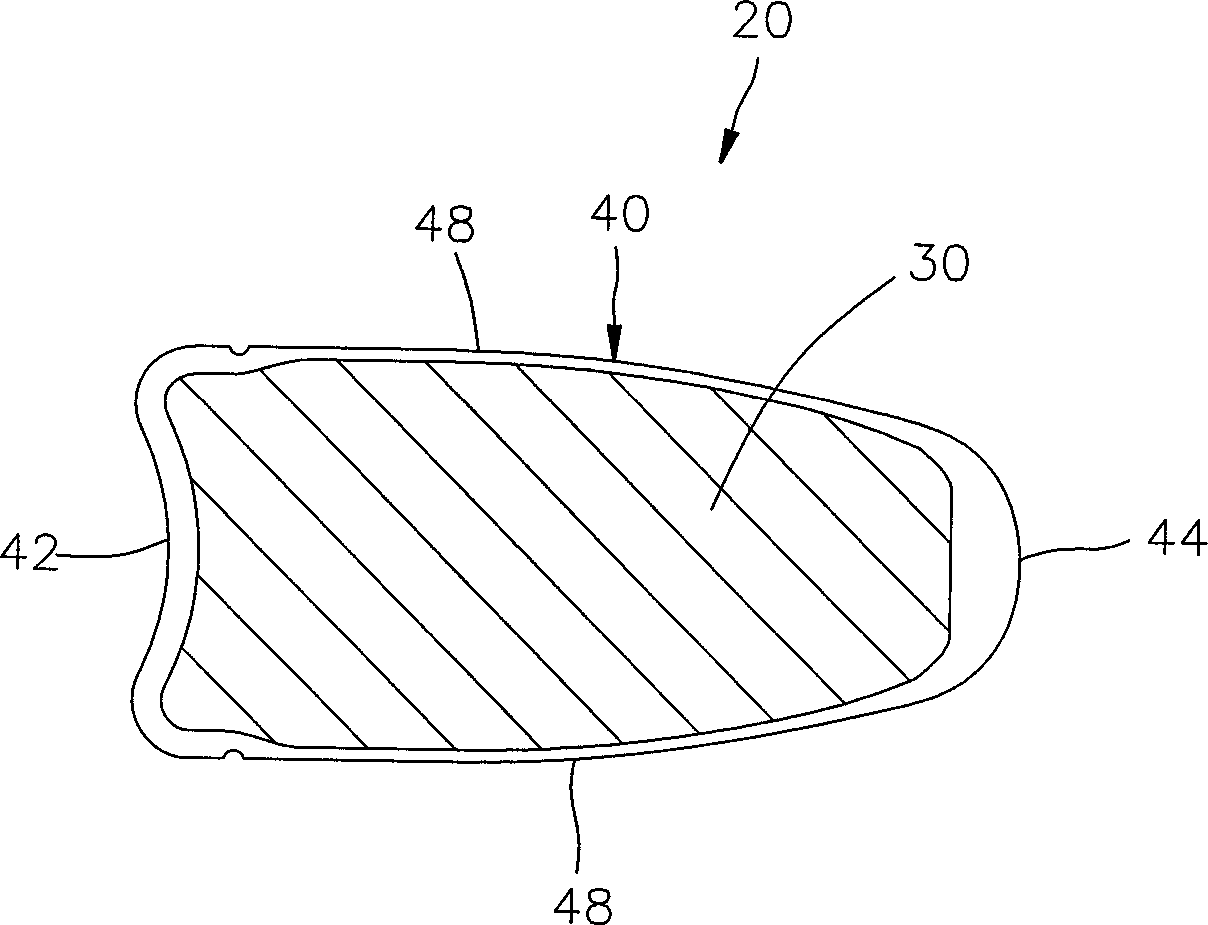

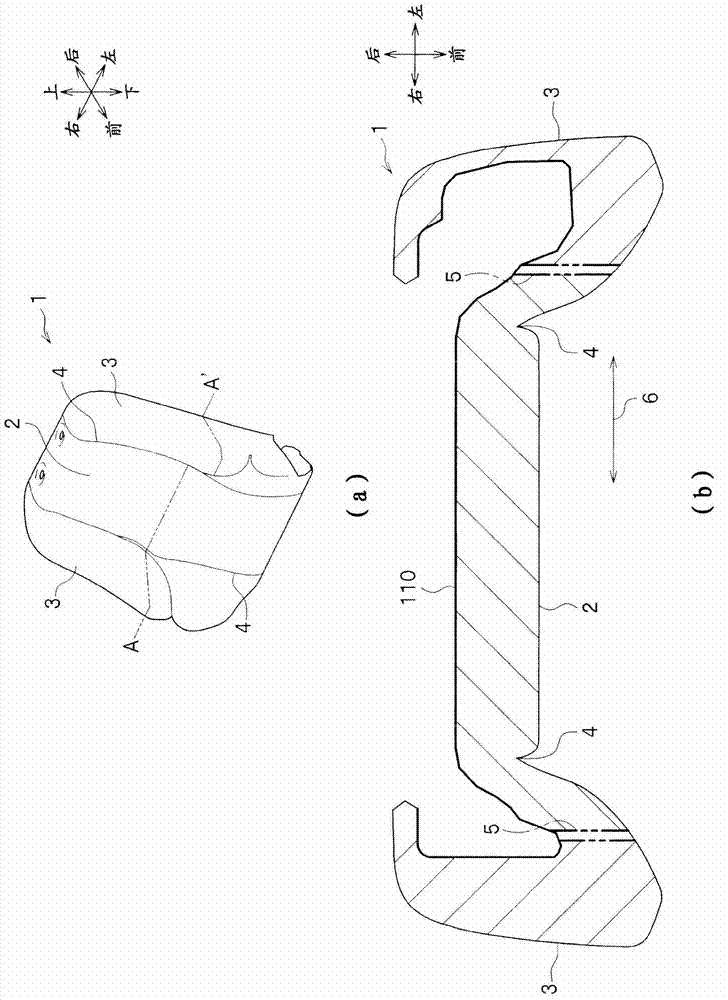

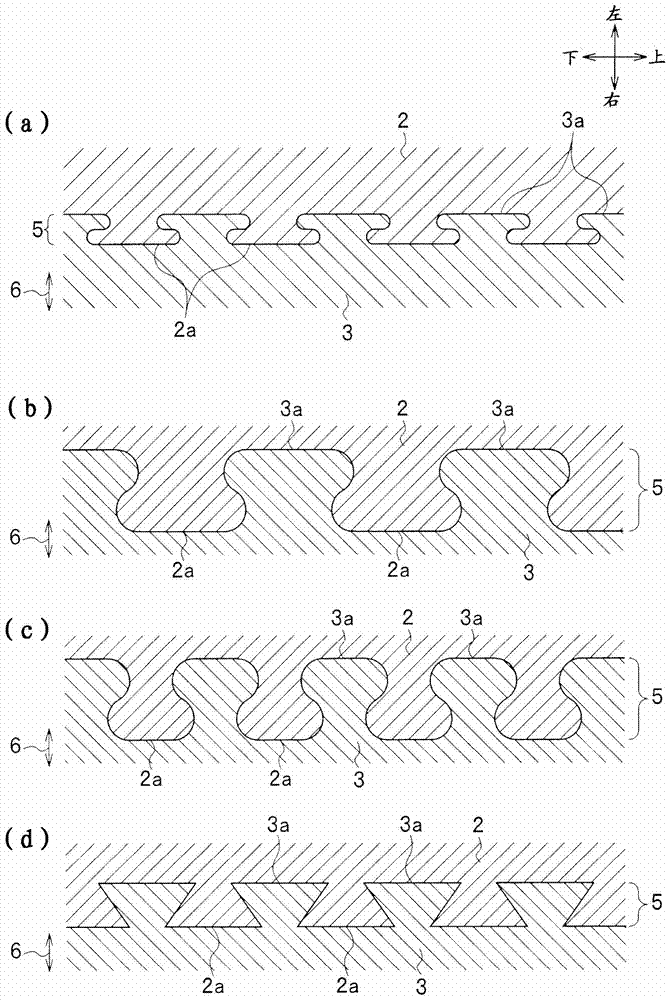

Molded body, method of manufacturing the same, seat material for vehicles, and method of manufacturing the same

ActiveCN104511997APrevent mutual separationFully supportedBack restsDomestic articlesEngineeringMechanical engineering

There is provided a molded body including a main portion and a bank portion each of which is formed by foaming and molding a foam material. The main portion is made of urethane material which is softer than the material for the bank portion. At a boundary portion between the main and bank portions, the main portion is formed in a continuous interlocking profile and the bank portion is also formed in another continuous interlocking profile. The interlocking profile and the another interlocking profile are mated to each other so as to prevent separation between the main portion and the bank portion in a direction of an arrow (vehicle width direction). The boundary portion is provided by partitioning the cavity in a single mold with a weir, introducing different foam materials into both sides of the weir and foaming the introduced materials.

Owner:HONDA MOTOR CO LTD

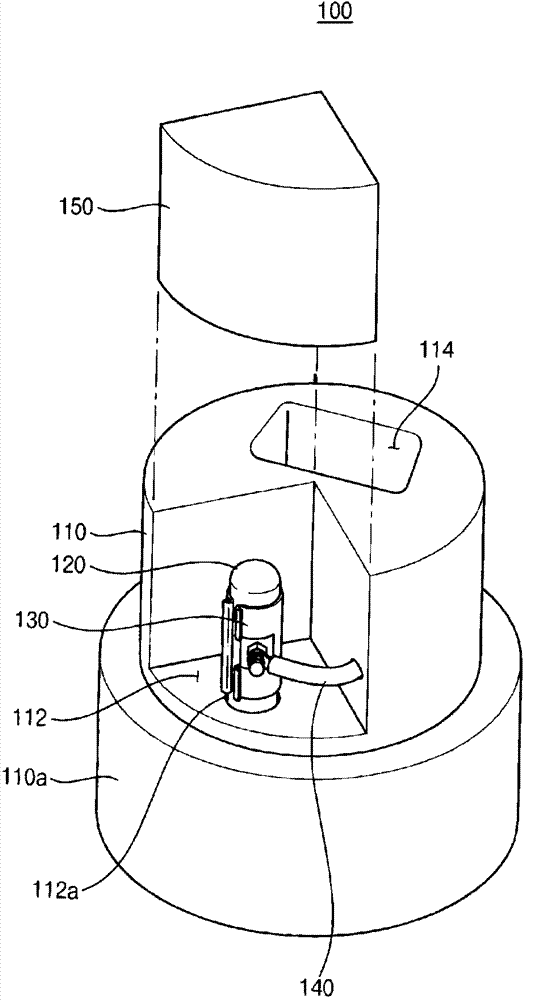

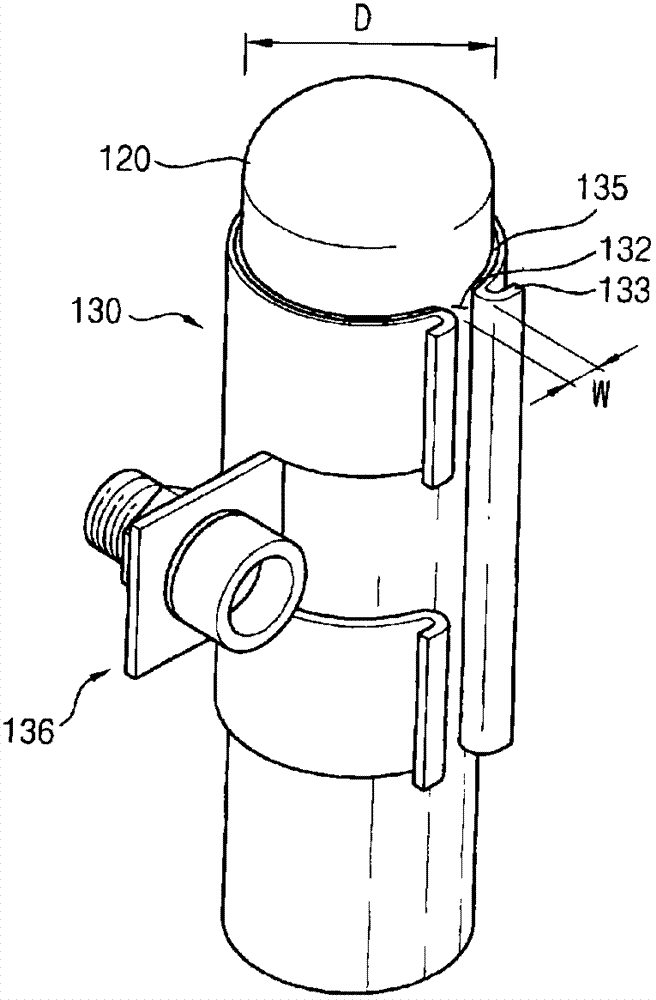

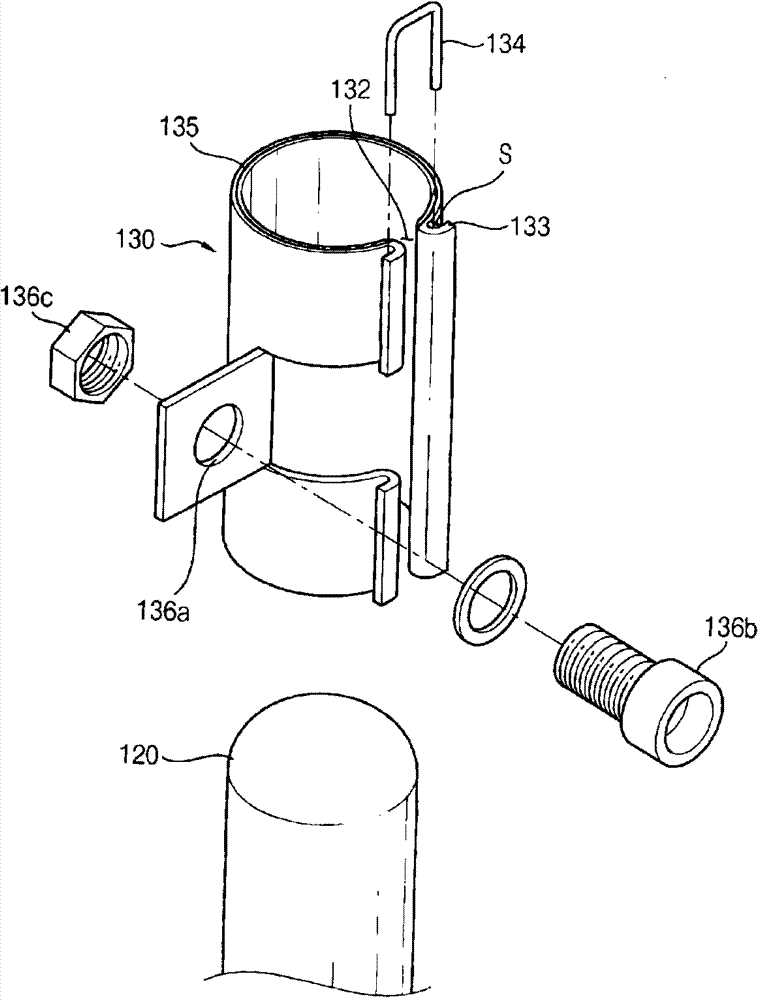

Grounding structure, and heater and chemical vapor deposition apparatus having the same

InactiveCN102792421AAvoid damagePrevent mutual separationElectrically conductive connectionsSemiconductor/solid-state device manufacturingEngineeringChemical vapor deposition

The present invention relates to a grounding structure, and a heater and a chemical vapor deposition apparatus having the same. The grounding structure comprises: a grounding mount having a housing for receiving a grounding connector that serves to guide a ground current to a ground receiver; a grounding clamp located at the housing, the grounding clamp having a cylindrical form with an open portion to communicate inside and outside and holding a grounding connector in such a manner as to bring the surface and inner surface of the grounding connector into contact with each other; a pair of jaws protruding from the outer surface close to the open portion and extending in parallel with the outer surface, while keeping a distance from each other as much as the width of the open portion; an interference reinforcing member fastened to the jaws, for reinforcing the bonding force between the grounding clamp and the grounding connector; and a ground wire for connecting the outer surface of the grounding clamp with the grounding mount to transfer the ground current to the grounding mount. By increasing the bonding force between the grounding clamp and the grounding connector, it is possible to restrain the formation of a clearance and thus prevent the damage on the grounding connector due to arcing.

Owner:KOMICO

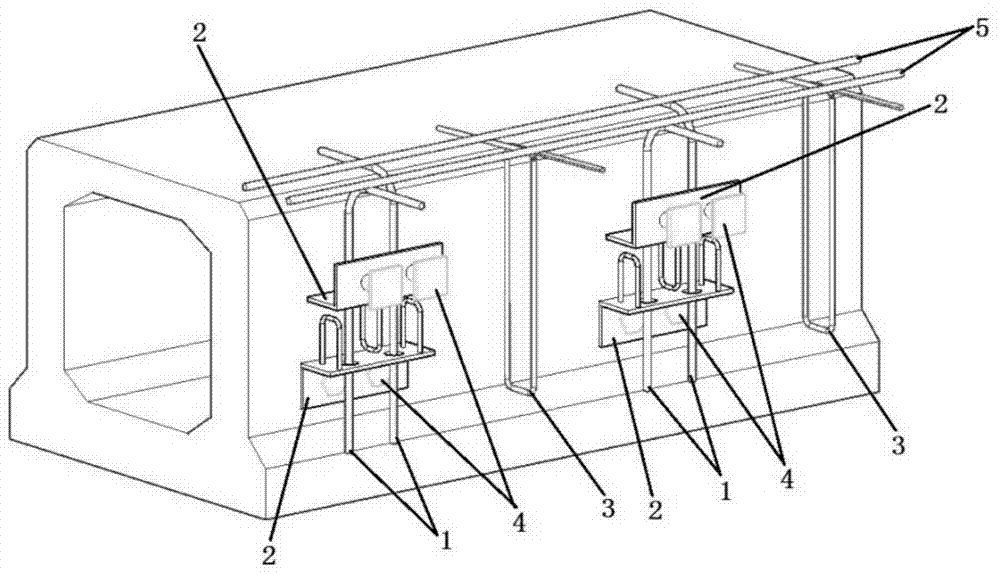

Reinforcing steel bar structure of hinge joint

The invention discloses a reinforcing steel bar structure of a hinge joint. The reinforcing steel bar structure comprises a plurality of restraining structures, stirrups and straight reinforcing steel bars, wherein the restraining structures, the stirrups and the straight reinforcing steel bars are fixed into a gap of the hinge joint, and the height direction is defined to be the y axis. Each restraining structure comprises M restraining reinforcing steel bars and N pairs of folding plates, each pair of folding plates are fixed to the wall faces of two adjacent concrete beams through fastening pieces respectively, L restraining reinforcing steel bar holes are formed on the folding faces of the folding plates, the central axes of all opposite restraining reinforcing steel bar holes of the folding plates are located in a straight line parallel to the y axis, one end of each restraining reinforcing steel bar penetrates through the corresponding restraining reinforcing steel bar hole with the central axis located in the straight line parallel to the y axis, the other end of each restraining reinforcing steel bar is bent and is attached to the top face of the corresponding concrete beam, the hoops are arranged between every two adjacent restraining structures, and all the hoops and all the bent ends of the restraining reinforcing steel bars are bound with the straight reinforcing steel bars to form a reinforcing steel bar net. The reinforcing steel bar structure of the hinge joint solves the problem that safety of a bridge is affected due to the fact that a reinforcing steel bar structure of an existing hinge joint is poor in shearing resistance performance and poor in tensile property and the hinge joint can be easily damaged.

Owner:SOUTHEAST UNIV

eye drop device

ActiveCN107669397BAvoid painReliable friction fixationPharmaceutical containersMedical packagingEyelidEye/ear drops

The invention relates to an eye drops device. The eye drops device comprises an upper frame body and a lower frame body; the upper frame body and the lower frame body are connected in a hinged mode and provided with an operating handle respectively, a separating mechanism is arranged on the lower frame body, the separating mechanism comprises a locating plate, a sliding track and a propping-up plate, the propping-up plate is arranged on the sliding track in a sliding mode, the locating plate and the propping-up plate form an eye drops area, an installation post is fixedly arranged on the upperside of the eye drops area, and a linkage rod is arranged between the upper frame body and the propping-up plate in a linkage mode; when operating handles approach each other, the linkage rod drivesthe propping-up plate away from the locating plate, an extrusion piece for squeezing the external wall of an eye drops bottle is arranged on the upper frame body in a rotating mode, when the operatinghandles approach each other, the extrusion piece moves toward the side wall of the eye drops bottle, and a reserved spacing is arranged between the most front end of the extrusion piece facing towardthe side wall of eye drops and the side wall of the eye drops. The above scheme provides the eye drops device which can separate the upper and lower eyelids and carry out accurate and automatic eye drops operations after the separation from each other.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

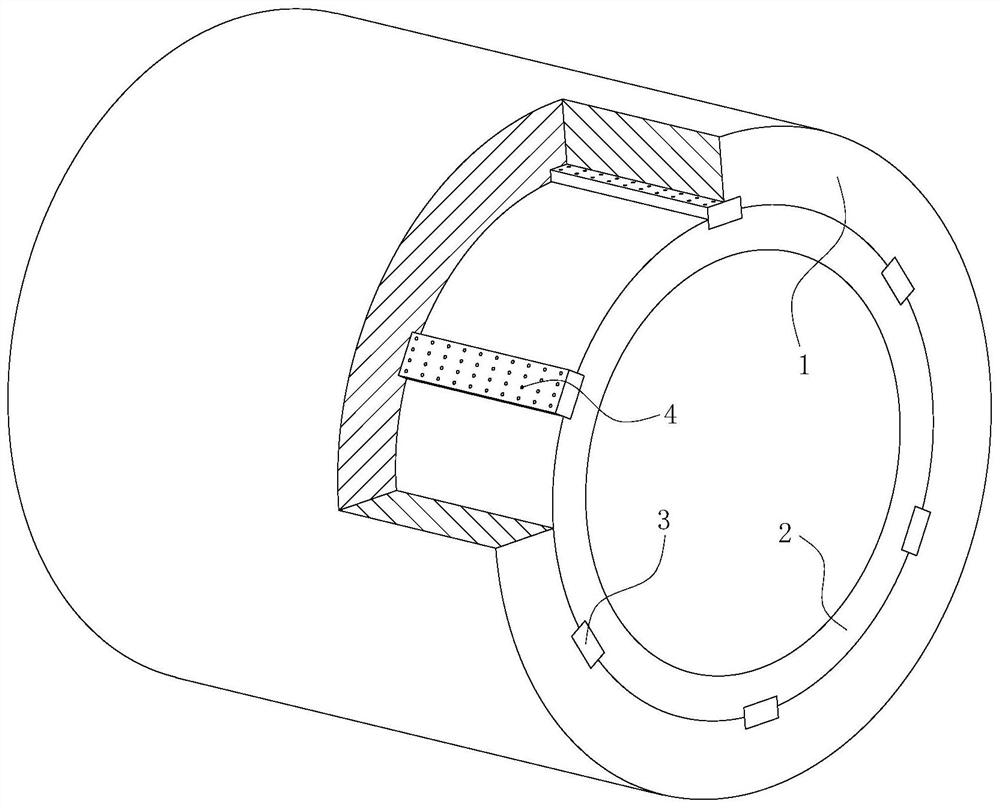

Motor

ActiveCN111313592APrevent looseningEnsure fit stabilitySupports/enclosures/casingsInterference fitElectric machine

The invention provides a motor. The motor comprises a shell which comprises a seam allowance and an end cover for sealing the seam allowance; a first fixing assembly which comprises a first part and asecond part which are located on the end cover and the shell respectively and matched with each other, wherein the first part abuts against the second part so that the first part and the second partcan be relatively static in the first direction, the first direction is parallel to the center axis of the shell, and the first direction points to the end cover from the shell; and a second fixing assembly which comprises a first split body and a second split body which are located on the end cover and the shell respectively and matched with each other, the first split body and the second split body abut against each other, the first split body and the second split body are relatively static in the second direction, and the second direction is parallel to the rotating direction of the rotor in the shell. Even if the interference fit assembly mode is not adopted, the matching stability of the shell and the end cover in the operation process of the motor can be ensured so that the problem of easiness in damage in disassembly due to interference fit is solved.

Owner:ZHUHAI KAIBANG MOTOR MFR +1

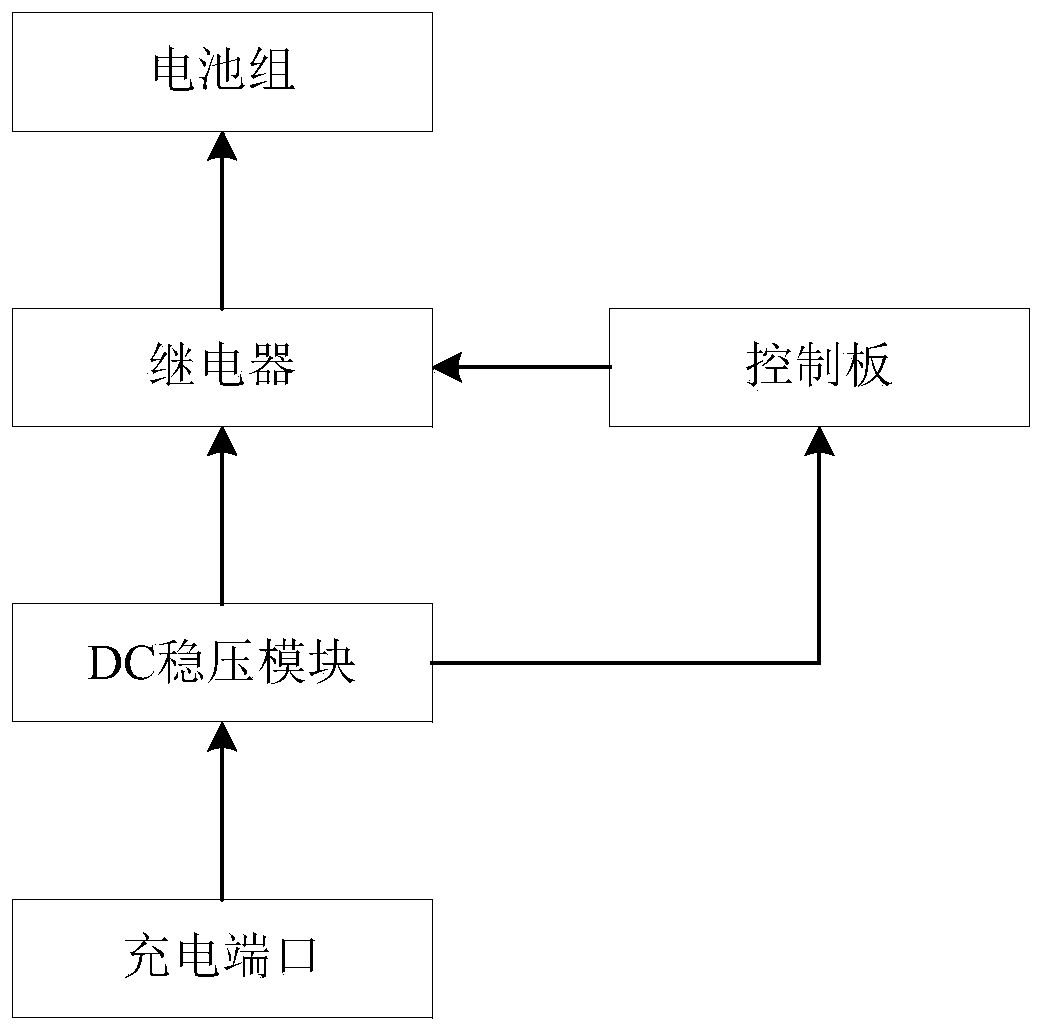

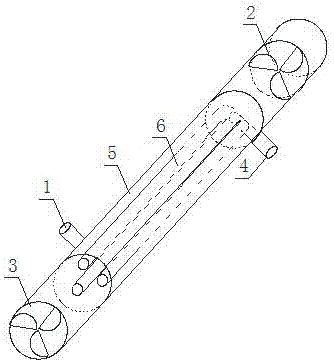

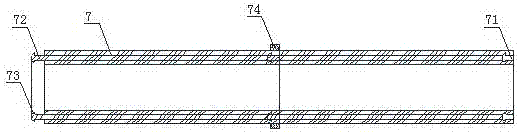

Direct-drive-type track walking device based on photoelectric detection type charging circuit

ActiveCN110966505AGuaranteed uptimeSimple structureBatteries circuit arrangementsStands/trestlesSimulationControl theory

The invention discloses a direct-drive-type track walking device based on a photoelectric detection type charging circuit. The device comprises a track and a walking trolley. The direct-drive-type track walking device further comprises a photoelectric detection type charging circuit; the photoelectric detection type charging circuit comprises a control panel, a photoelectric detection module, a relay, a battery pack and a charging port; the input control end of the relay is connected with the driving output end of the control panel; the photoelectric detection module is used for detecting whether to-be-charged equipment is connected to the charging port or not; and the output end of the photoelectric detection module is connected with the input end of the control panel. The direct-drive-type track walking device of the invention is applied to a track inspection robot and can meet the walking requirements of various types of curve tracks. With the device of the invention adopted, the robot will not deviate from the track even if bearing a transverse force. Compared with an existing inspection robot walking trolley, the device of the invention has the advantages of wide application range and more stable operation.

Owner:成都蓉视通科技有限公司

Heat exchange device

PendingCN107166622APrevent mutual separationReduce energy consumptionMechanical apparatusLighting and heating apparatusHazardous substanceEngineering

The invention discloses a heat exchange device which comprises a shell and further comprises an outdoor air inlet, a fresh air outlet, a dirty air inlet and a dirty air outlet which are formed in the shell. A heat exchange box communicated with the outdoor air inlet and the fresh air outlet is arranged inside the shell, a heat exchange pipe is arranged in the heat exchange box, an ultraviolet ray transmitting component is arranged on the outer surface of the heat exchange pipe, the outer surface of the heat exchange pipe is coated with a photocatalyst sterilization layer, and the two ends of the heat exchange pipe are communicated with the dirty air inlet and the dirty air outlet correspondingly; and the fresh air outlet is connected with a gas pipe, an annular groove is formed in the end face of one end of the gas pipe, an annular protrusion is arranged at the position, on the end face of the other end of the gas pipe, of the end face of the fresh air outlet, limiting rings are arranged on the inner and outer side walls of the protrusion, and the groove is matched with the protrusion. The outer wall of the heat exchange pipe is coated with the photocatalyst sterilization layer, and a light source is arranged, so that hazardous substances such as various germs and viruses in fresh air are killed. Compared with the manner that a single photocatalyst sterilization layer is arranged, the purification effect of the heat exchange device is better.

Owner:SICHUAN JIANYUAN ENERGY SAVING TECH CO LTD

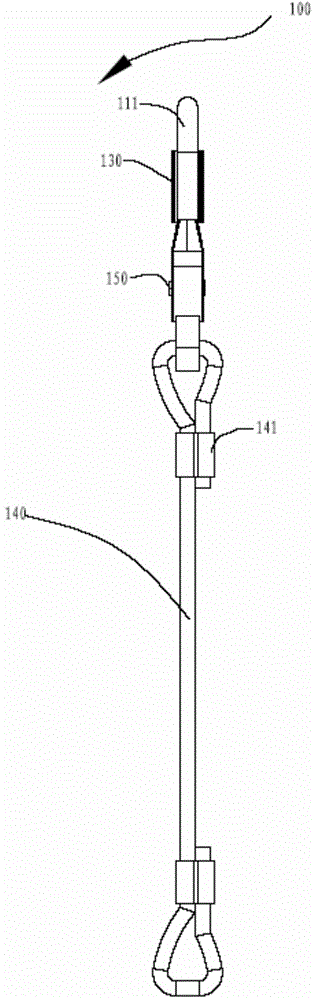

Hanging structure

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

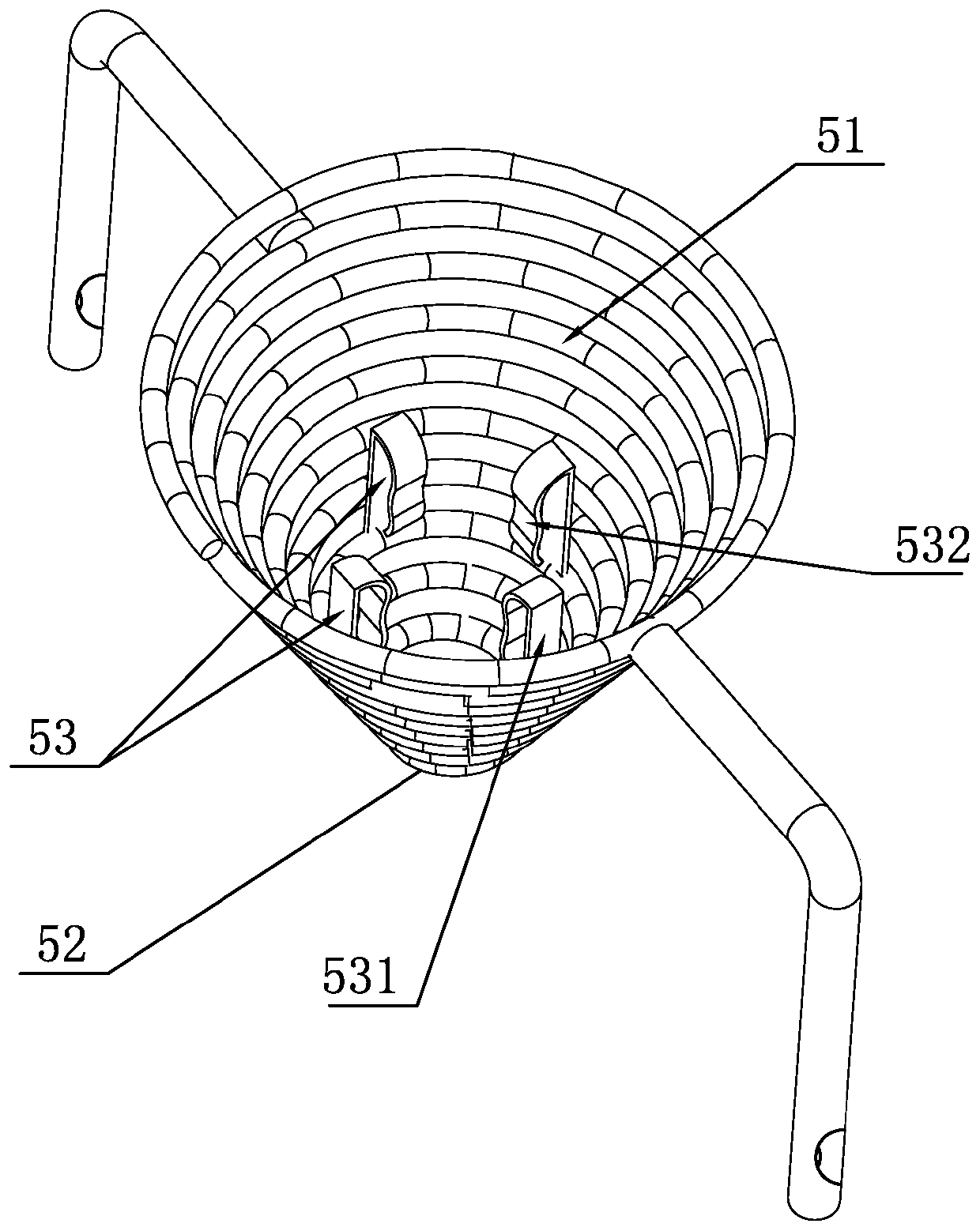

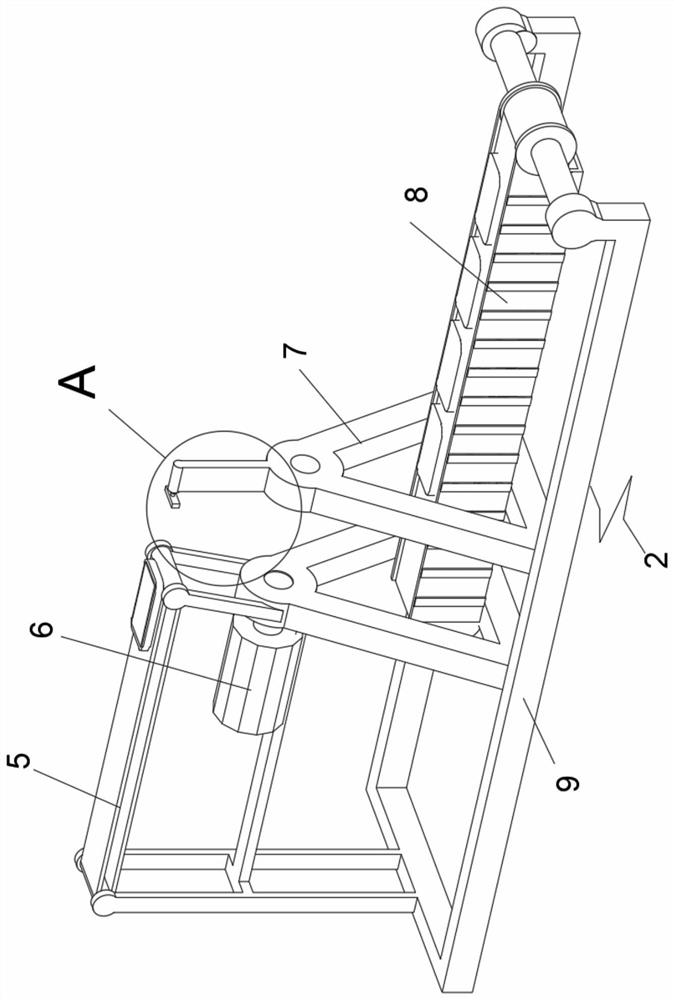

Staple cartridge component and medical anastomat using staple cartridge

The invention provides a staple cartridge component and a medical anastomat using the staple cartridge component, wherein the staple cartridge component comprises a staple cartridge connecting piece and a knife pushing rod, and further comprises a limiting block which is accommodated inside the staple cartridge connecting piece so as to limit the plurality of the thin sheets from mutually separating in the overlapping direction of the plurality of the thin sheets; the knife pushing rod is formed by overlapping a plurality of thin sheets; and in a process of triggering the knife pushing rod, the limiting block, following the knife pushing rod, moves towards the far end of the staple cartridge component from the near end of the staple cartridge component and constantly limits the plurality of the thin sheets from mutually separating in the overlapping direction of the plurality of the thin sheets. The staple cartridge component disclosed by the invention has the beneficial effects that the staple cartridge component is provided with the limiting block, and the limiting block moves along with the knife pushing rod at least in the process of triggering the knife pushing rod so as to constantly limit the plurality of the thin sheets; therefore, the plurality of the thin sheets of the knife pushing rod are prevented from mutually separating in the overlapping direction.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

Function testing device for electronic product

InactiveCN112798891AEasy to disengageEasy to holdElectrical testingMeasurement instrument housingTest efficiencyFunctional testing

Owner:EASTERN LIAONING UNIV

fiber composite wheel frame

A wheel frame made of a fibrous composite comprises a plurality of arc-shaped frame strips. Each arc-shaped frame strip is provided with a foaming body made of a foaming material, and an outer fibrous composite layer which wraps the foaming body and is made of the fibrous composite. Connection surfaces are respectively formed at the two ends of each arc-shaped frame strip, the arc-shaped frame strips are connected to be annular through the connection surfaces of the outer fibrous composite layers, and a supporting surface is formed on the connection portion of every two adjacent connection surfaces for the arc-shaped frame strips. The wheel frame made of the fibrous composite is light and can not be broken easily.

Owner:ZHONGSHAN FUDA SPORTS EQUIP

Automatic processing process of stainless steel seamless steel pipe

The invention belongs to the technical field of metal processing, and particularly relates to an automatic processing process of a stainless steel seamless steel pipe. The automatic processing process comprises the following steps: S1, the surface of round steel is cleaned and derusted, and the round steel is cut off to obtain steel sections; S2, on the basis of the step S1, a perforating machine is used for perforating the steel sections, and tubular billets are obtained; S3, on the basis of the step S2, the tubular billets are subjected to cold rolling, and structural pipes are obtained; S4, on the basis of the step S3, pipe blanks are subjected to cold expanding treatment, and composite pipes are obtained; S5, on the basis of the step S4, the composite pipes are subjected to bright solution treatment, then the surfaces of the composite pipes are subjected to anti-oxidation and anti-corrosion treatment, and the finished seamless steel pipes are obtained; and S6, on the basis of the step S5, the finished seamless steel pipes are straightened, then the finished seamless steel pipes are detected, and the finished seamless steel pipes which are detected to be qualified are packaged and warehoused after the surfaces are marked. The prepared steel pipes are high in strength, good in quality, stable in structure performance and high in practicability.

Owner:孟祥平

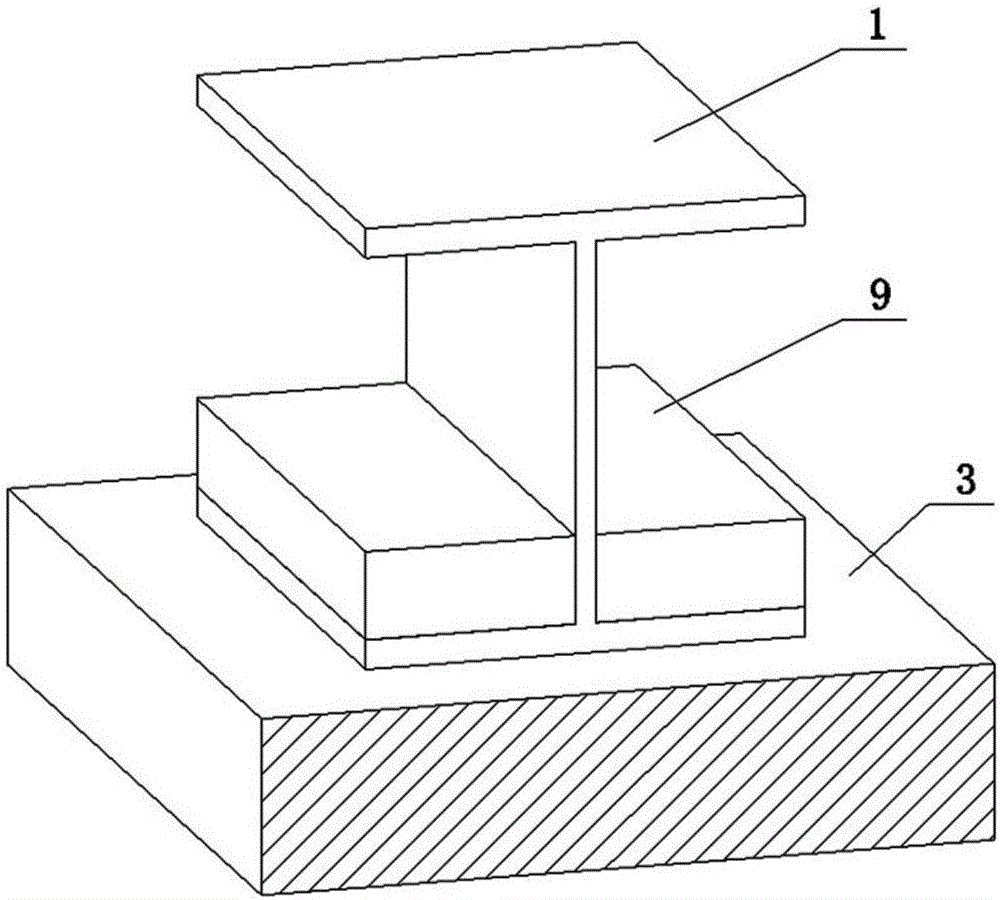

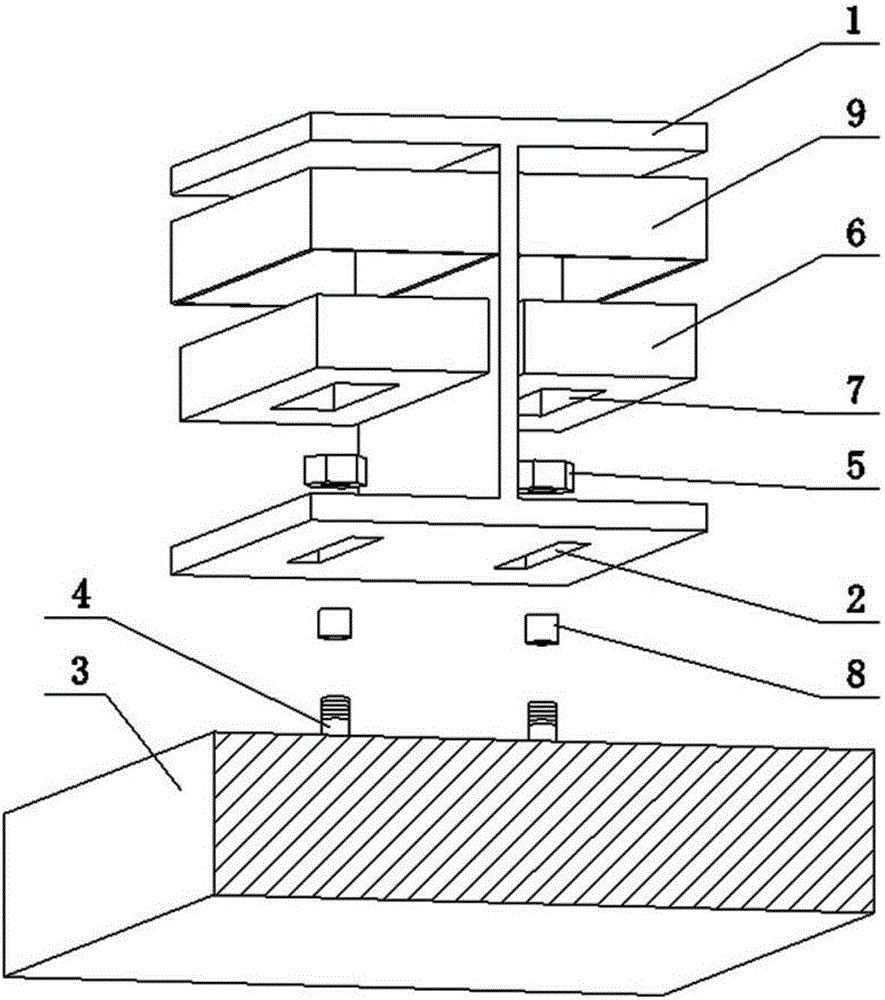

Sliding connecting piece between steel member and concrete

InactiveCN106368331APrevent concrete from crackingPrevent deformation or damageBuilding constructionsEngineeringStructural engineering

The invention discloses a sliding connecting piece between a steel member and concrete. The sliding connecting piece is composed of a connecting piece body, wherein the connecting piece body comprise an anchoring part fixed in a concrete body, at least one strip-shaped hole is formed in a base of the anchoring part, a bolt fixed to the steel member and a nut matched with the bolt are arranged in each strip-shaped hole, each strip-shaped hole is provided with a protective cover, and a cavity corresponding to the strip-shaped holes and containing the nuts and the bolts is formed in the lower portion of the protective cover. The sliding connecting piece permits that certain relative sliding between the steel member and the concrete under the condition that relative separation does not occur between the steel member and the concrete, and the problem of concrete cracking caused by the fact that a concrete member is pulled is avoided.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com