Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Prevent loose deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

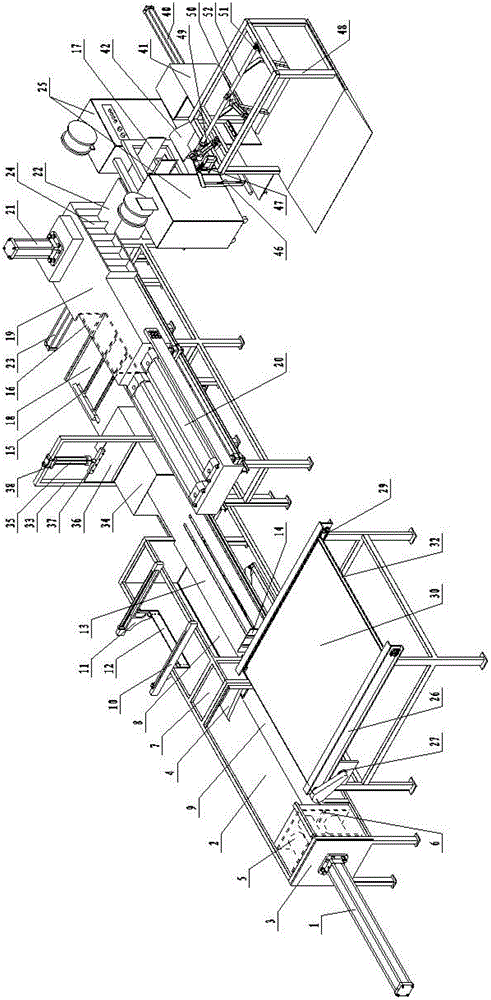

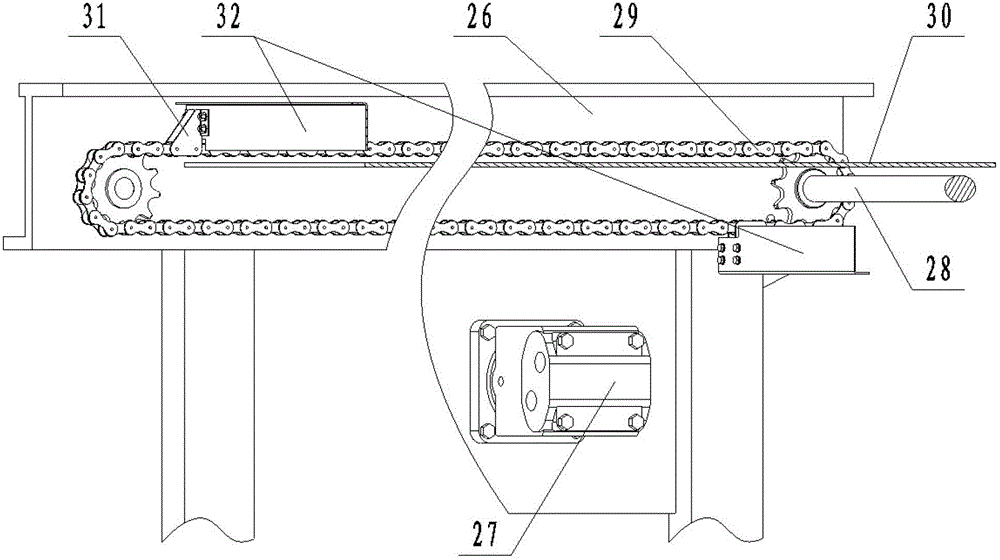

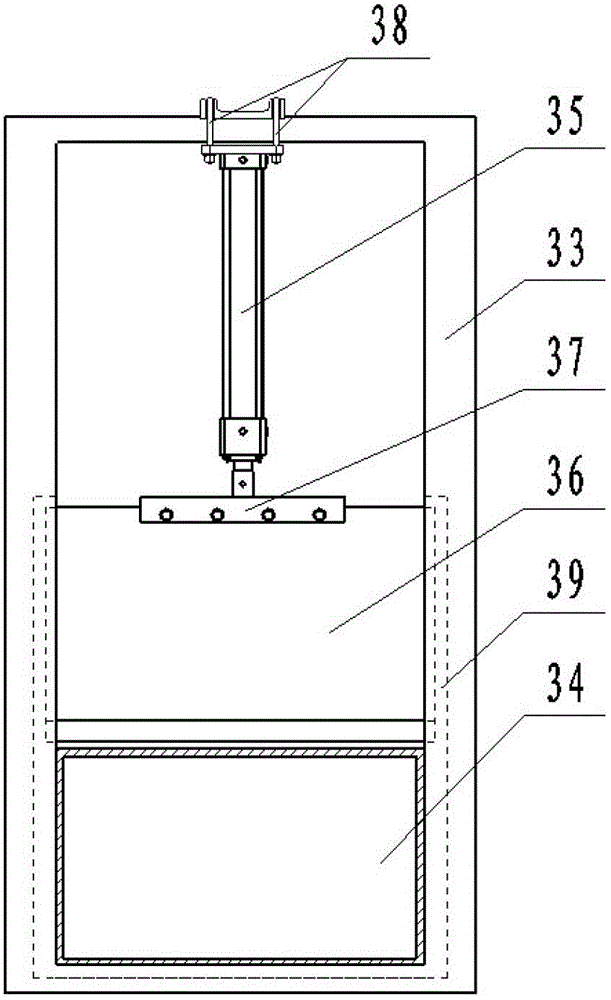

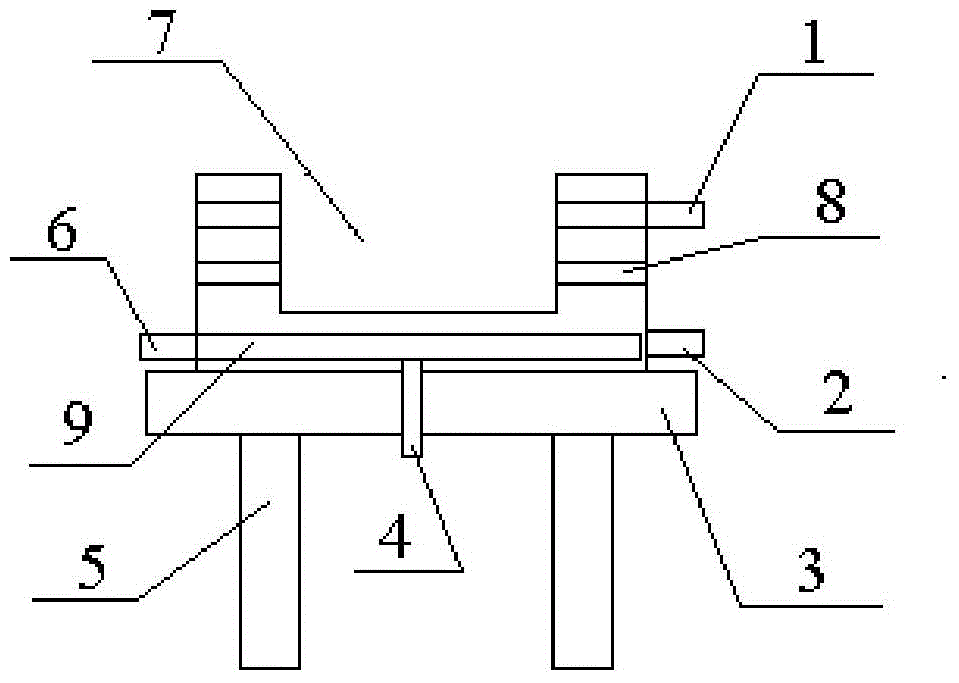

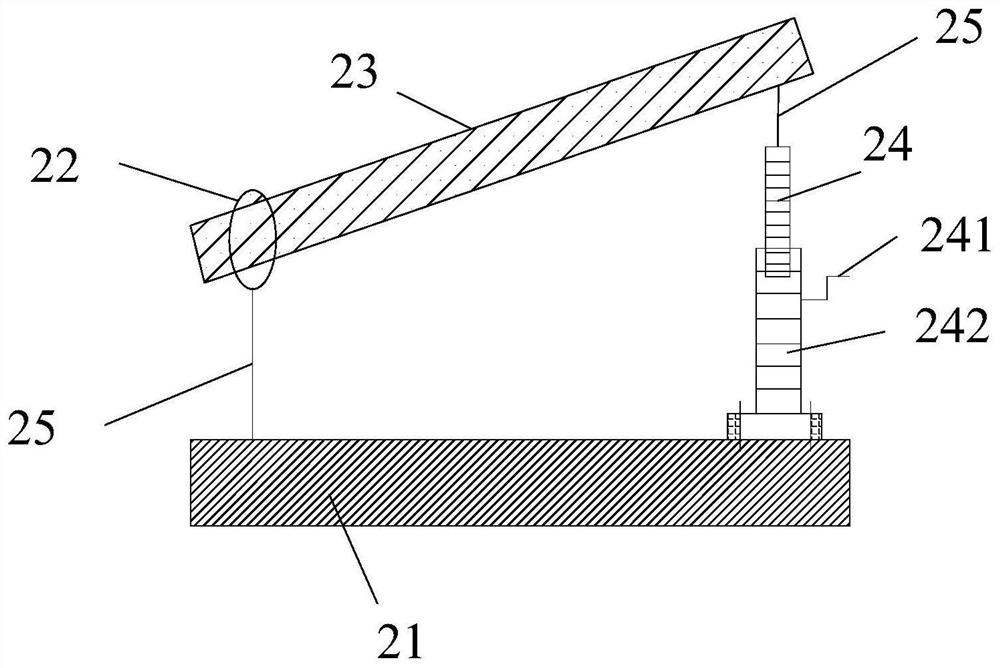

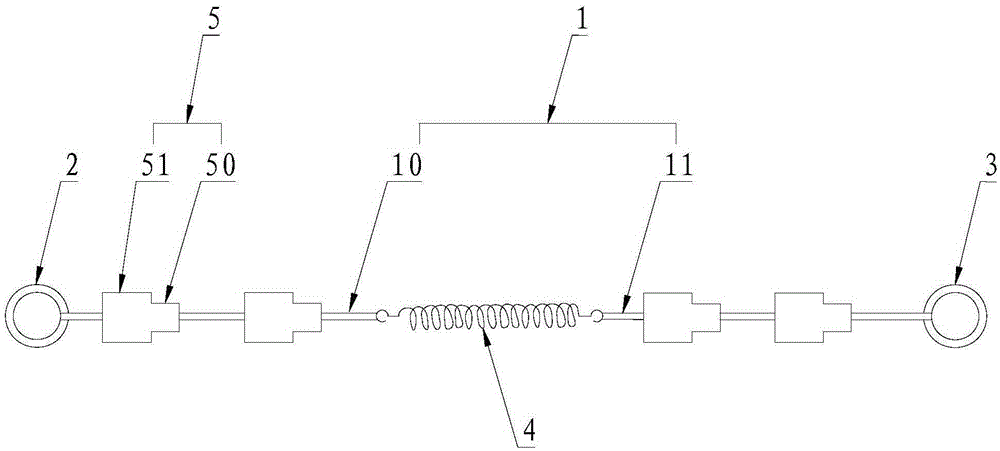

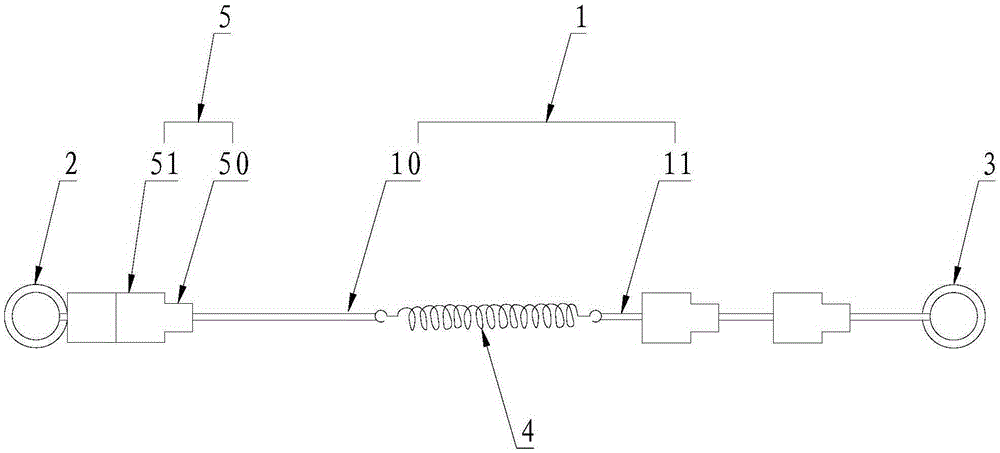

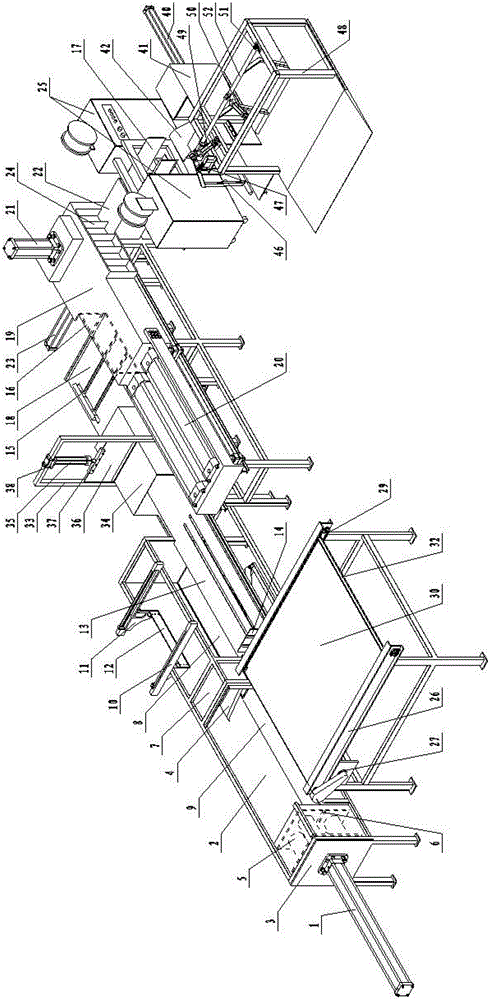

Device and method for processing large square hay bundle into high-density small square hay bundle

InactiveCN102714990AIncrease initial cut-in pressurePrevent loose deformationBalingCuttersHigh densityEngineering

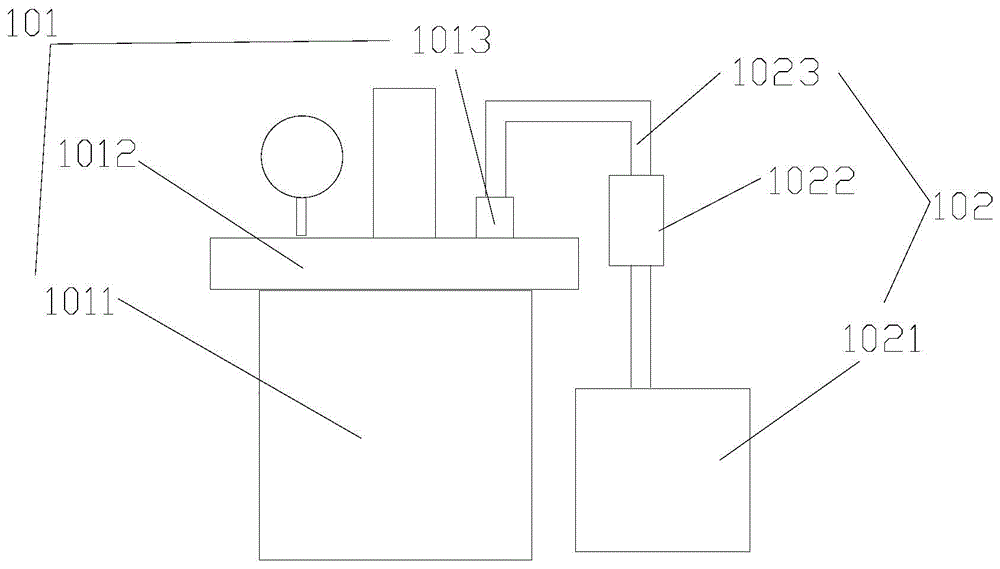

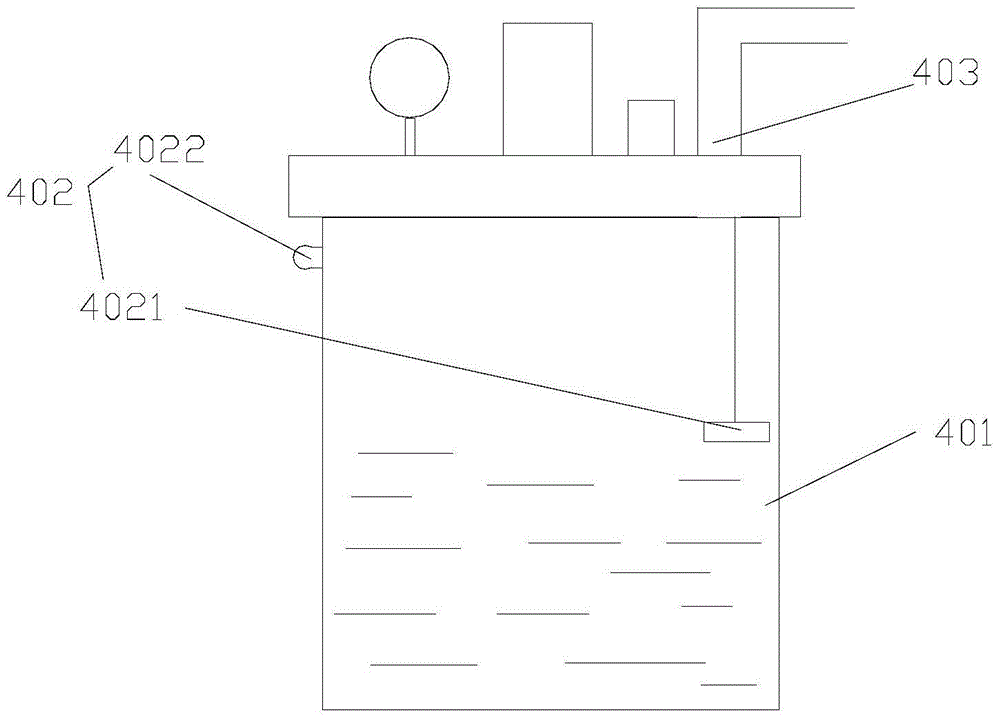

The invention relates to a hay bundle processing machine and a hay bundle processing method, in particular to a device and a method which can be used for cutting a large square hay bundle into hay slices, conducting secondary compression forming after the hay slices are cut into sections and conducting bundling, section cutting and collection operation to the formed hay bundles. A device for processing a large square hay bundle into high-density small square hay bundles comprises a feeding mechanism, a large square hay bundle slicing mechanism, a hay slice separation and conveying mechanism, a hay slice section-cutting mechanism, a secondary compression mechanism, a bundling mechanism, a formed hay bundle section-cutting mechanism and a formed hay bundle collection mechanism. The device and the method have the advantages that the large square hay bundle can be processed into the high-density small square hay bundles, the final products can be tidily collected and the subsequent operation efficiency is improved.

Owner:CHINA AGRI UNIV

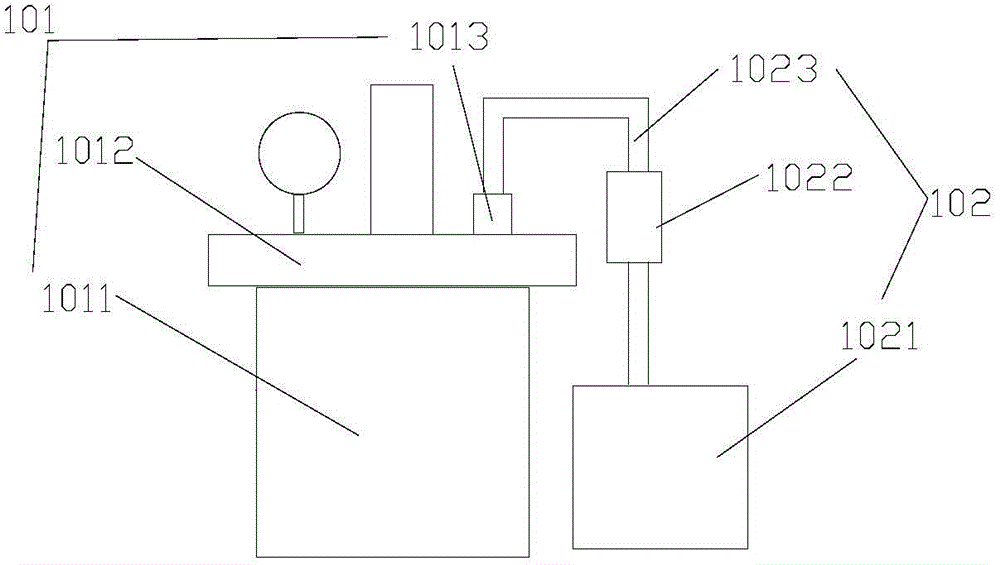

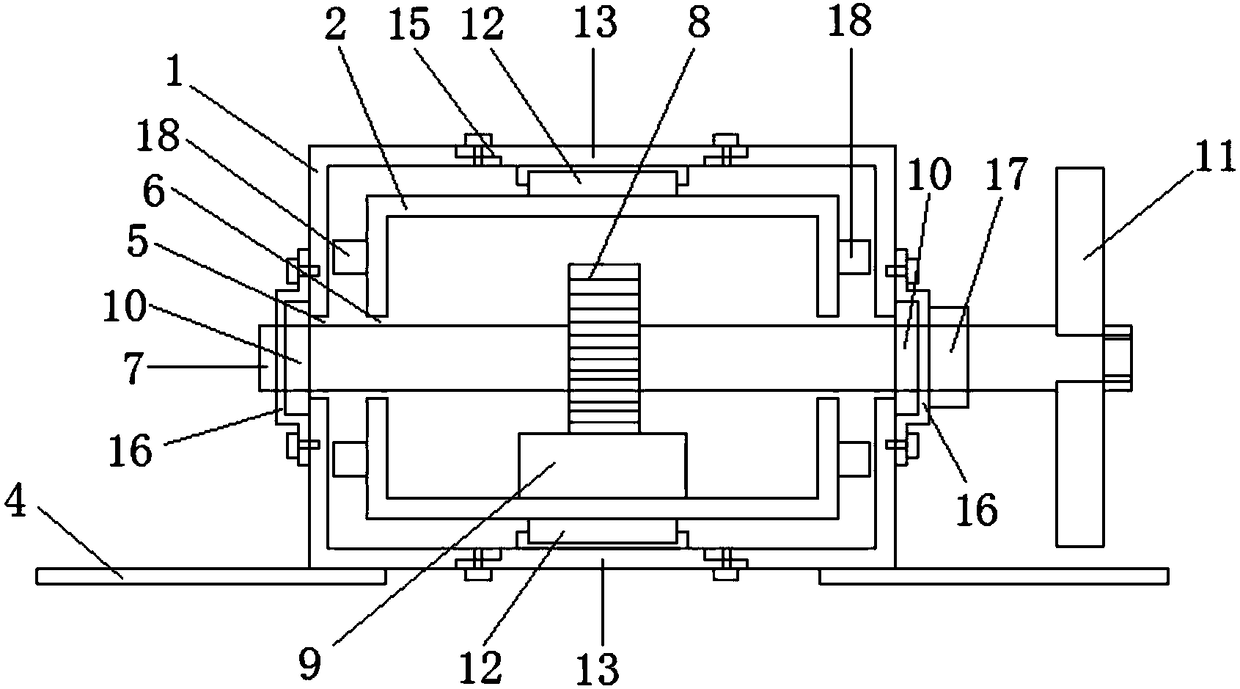

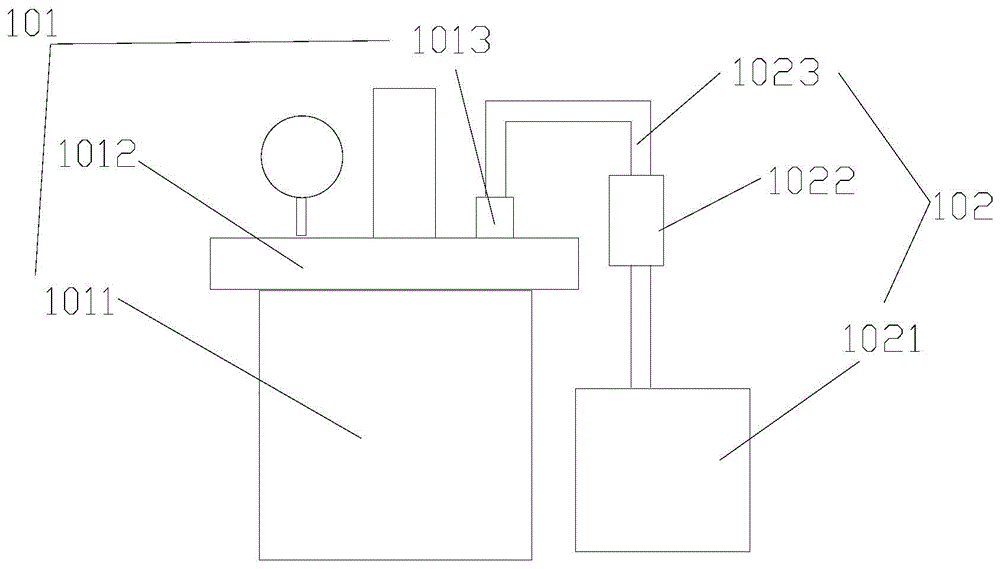

Novel cooling device for automobile accessories

The invention provides a novel cooling device for automobile accessories. The novel cooling device comprises a support, a model groove, a first guide pipe and a second guide pipe. The support is connected with the model groove through a transverse beam, the first guide pipe is arranged on the periphery of the model groove, a first water inlet of the first guide pipe is formed in the lower portion of the right side of the model groove, a first water outlet of the first guide pipe is formed in the upper portion of the right side of the model groove, the second guide pipe is arranged at the bottom of the model groove, a second water inlet of the second guide pipe is formed in the middle of the bottom of the model groove, and a second water outlet of the second guide pipe is formed in the lower portion of the left side of the model groove. The novel cooling device has the advantages that the novel cooling device is reasonable in structure, simple in design and convenient to operate; the model groove is formed to be matched with the accessories to be cooled and achieves the effect of supporting the accessories, and concave-convex shapes are prevented from being loosened and deformed under the gravity effect; as the guide pipes are arranged on the periphery and at the bottom of the model groove, water leading of the guide pipes can be carried out at the same time, the temperature of the accessories is rapidly decreased, cooling shaping is carried out, and the product quality is accordingly guaranteed.

Owner:天津吉泰空调通风设备有限公司

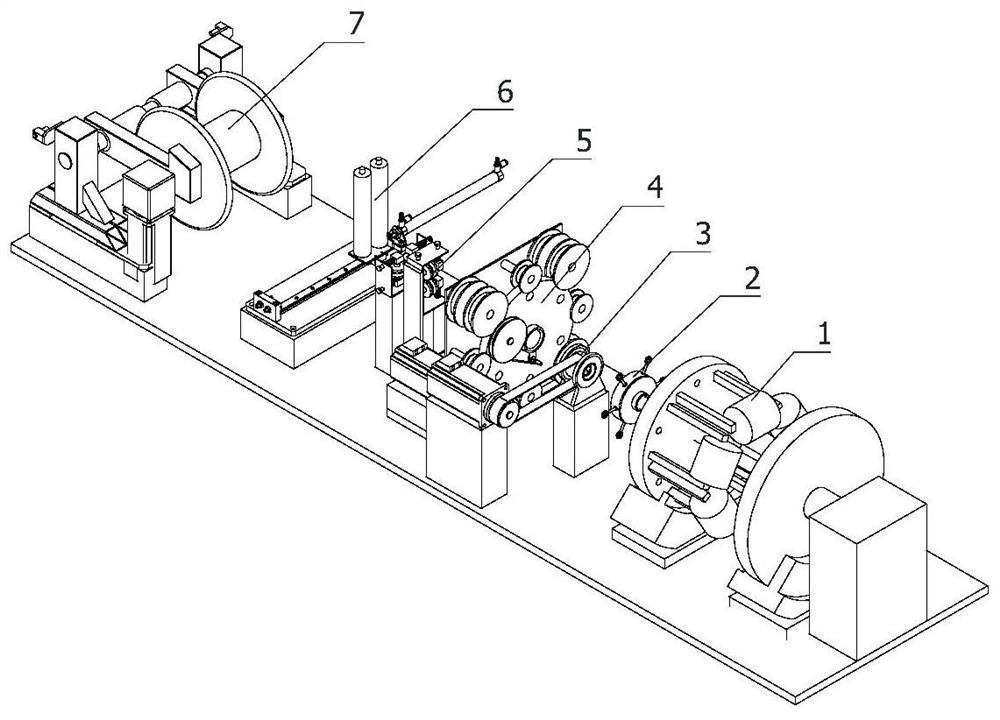

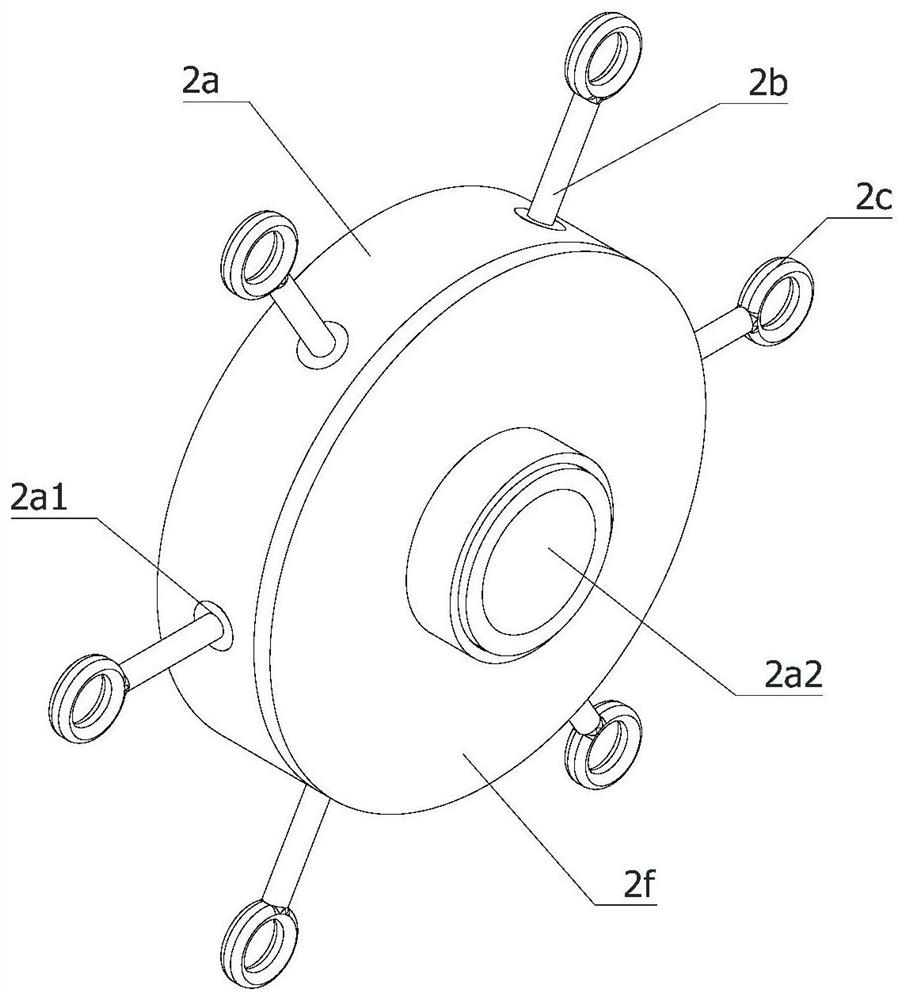

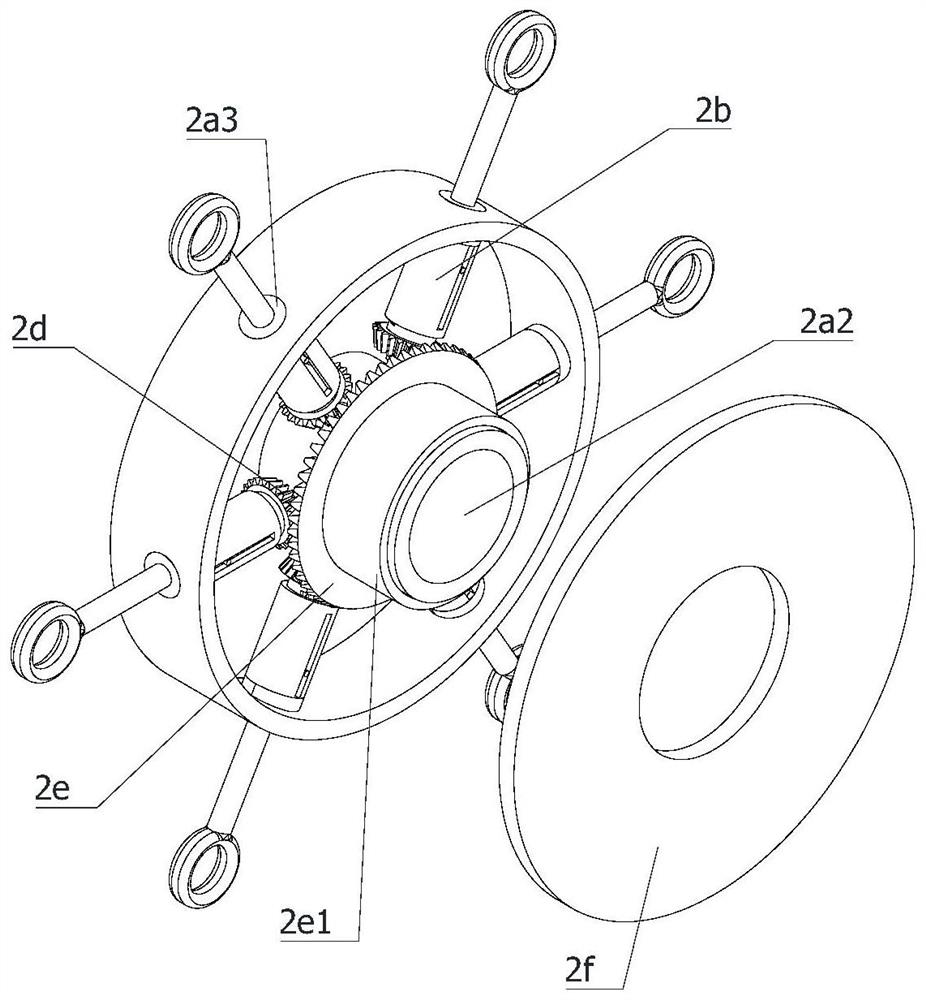

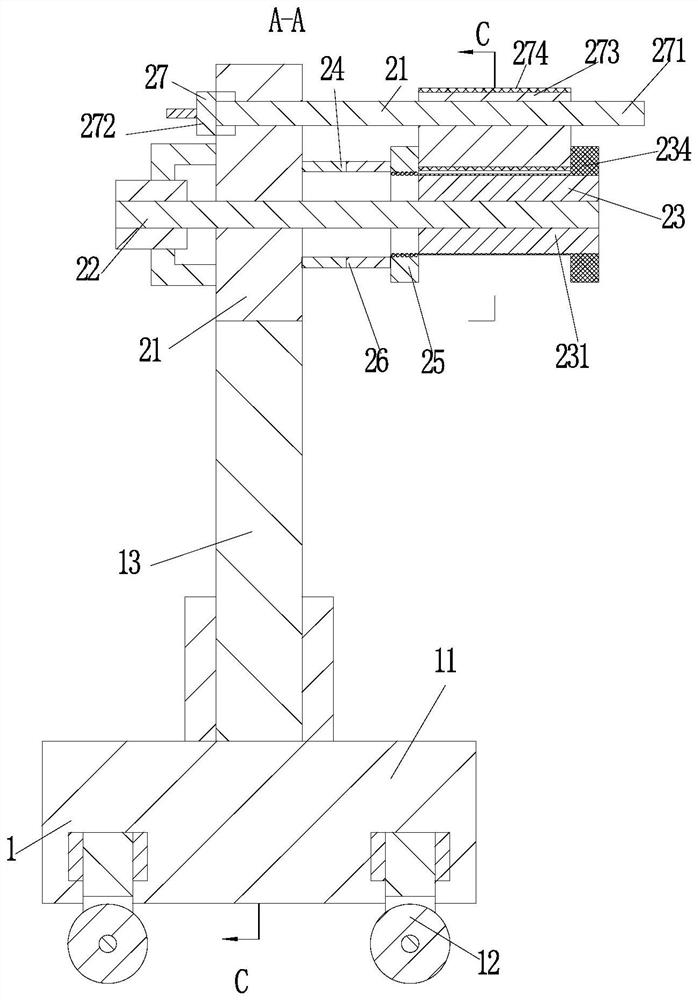

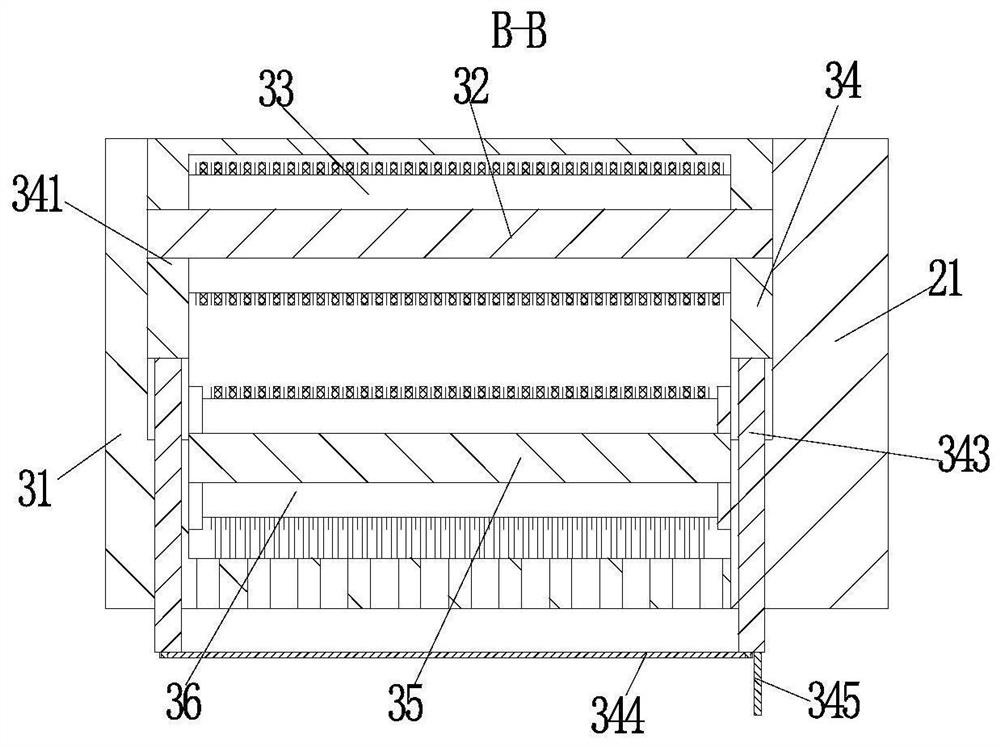

Multi-core cable hinging and synchronous belt winding integrated equipment

PendingCN112209160APrevent loose deformationReduce gapFilament handlingConveyor wrappingWinding machineAdhesive belt

The invention relates to the field of multi-core cable manufacturing equipment, in particular to multi-core cable hinging and synchronous belt winding integrated equipment. The equipment comprises a multi-cable weaving and winding machine, multiple adjusting pay-off devices, a cable reversing and gathering device, a synchronous adhesive tape binding device, an adhesive pressing abutting device anda take-up driving frame, wherein the multiple adjusting pay-off devices are coaxially arranged on a main shaft at the discharge end of the multi-cable weaving and winding machine; the cable reversingand gathering device is coaxially arranged on one side of the multiple adjusting pay-off devices, and in the working state, the cable reversing and gathering device and the multi-cable weaving and winding machine rotate reversely; the working end of the synchronous adhesive tape binding device is coaxially arranged on one side of the cable reversing and gathering device; the adhesive pressing abutting device is arranged on one side of the synchronous adhesive tape binding device, and in the working state, a multi-core cable wrapping adhesive tape coaxially penetrates through the adhesive pressing abutting device to elastically abut against the working end; and the take-up driving frame is arranged on one side of the adhesive pressing abutting device, and a cable leading device used for drawing the cable in a reciprocating mode to facilitate take-up is further arranged between the take-up driving frame and the adhesive pressing abutting device. The equipment facilitates adjustment of the cable winding density and can synchronously wind the adhesive tape on the multi-core cable to prevent the multi-core cable from loosening and deforming.

Owner:吴麒麟

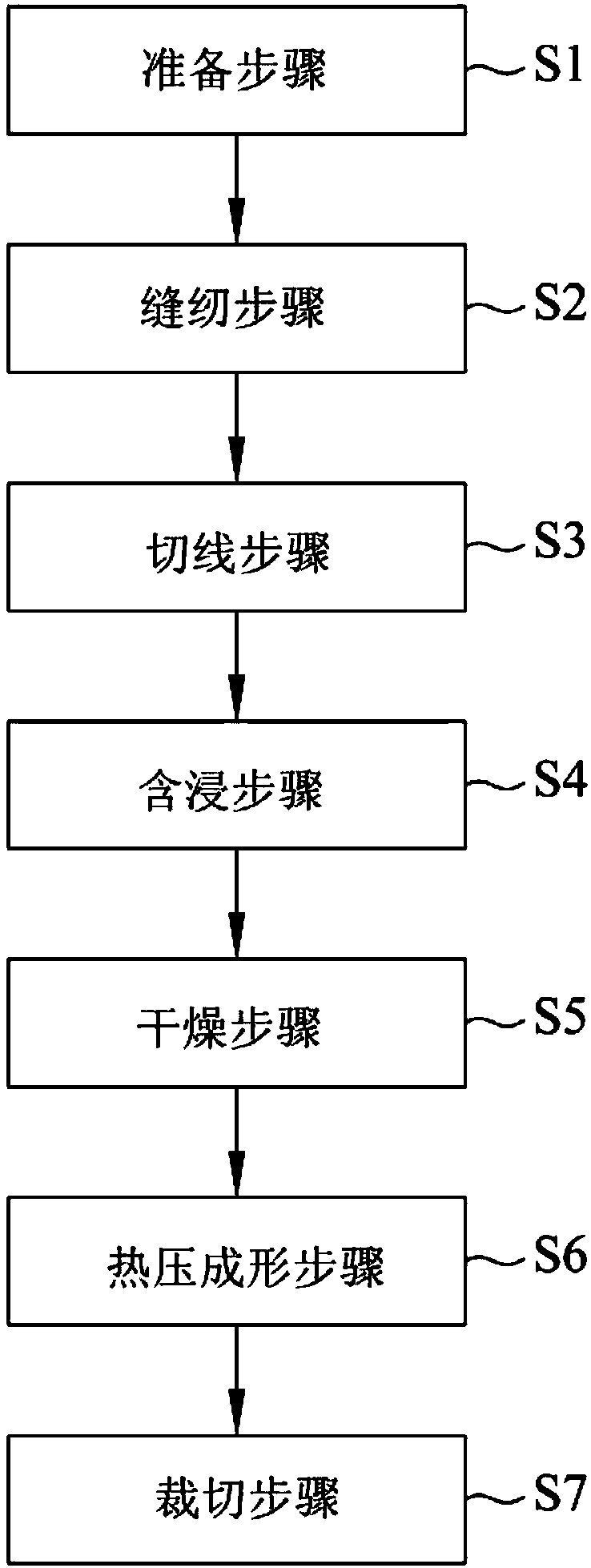

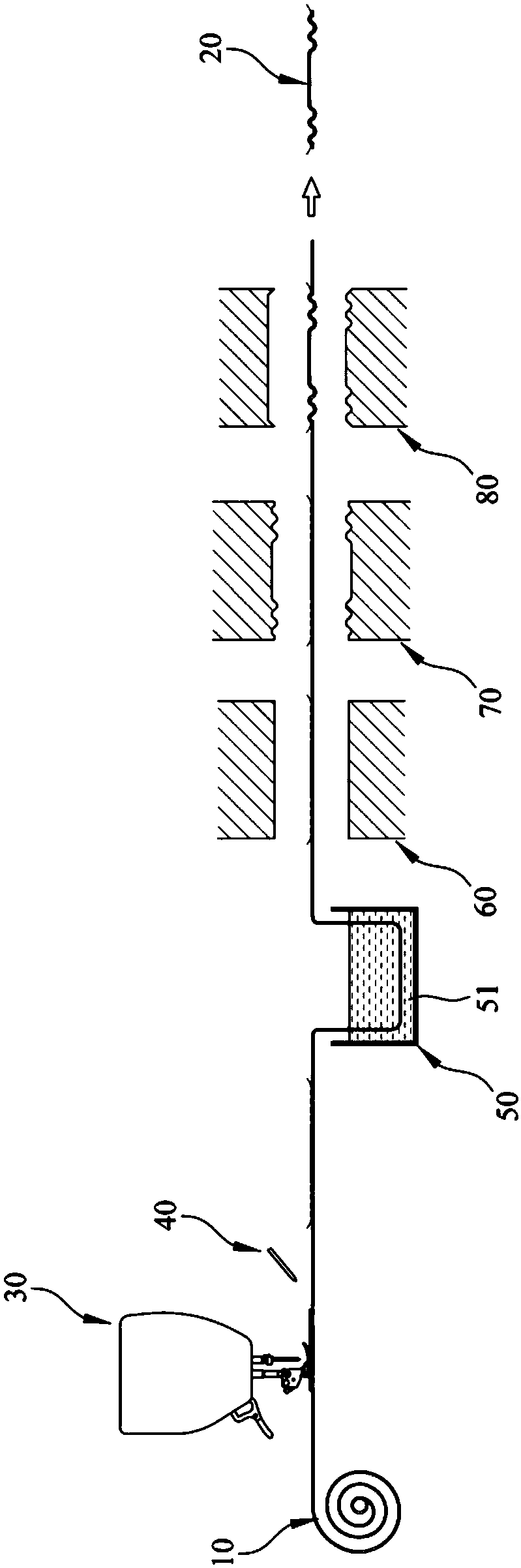

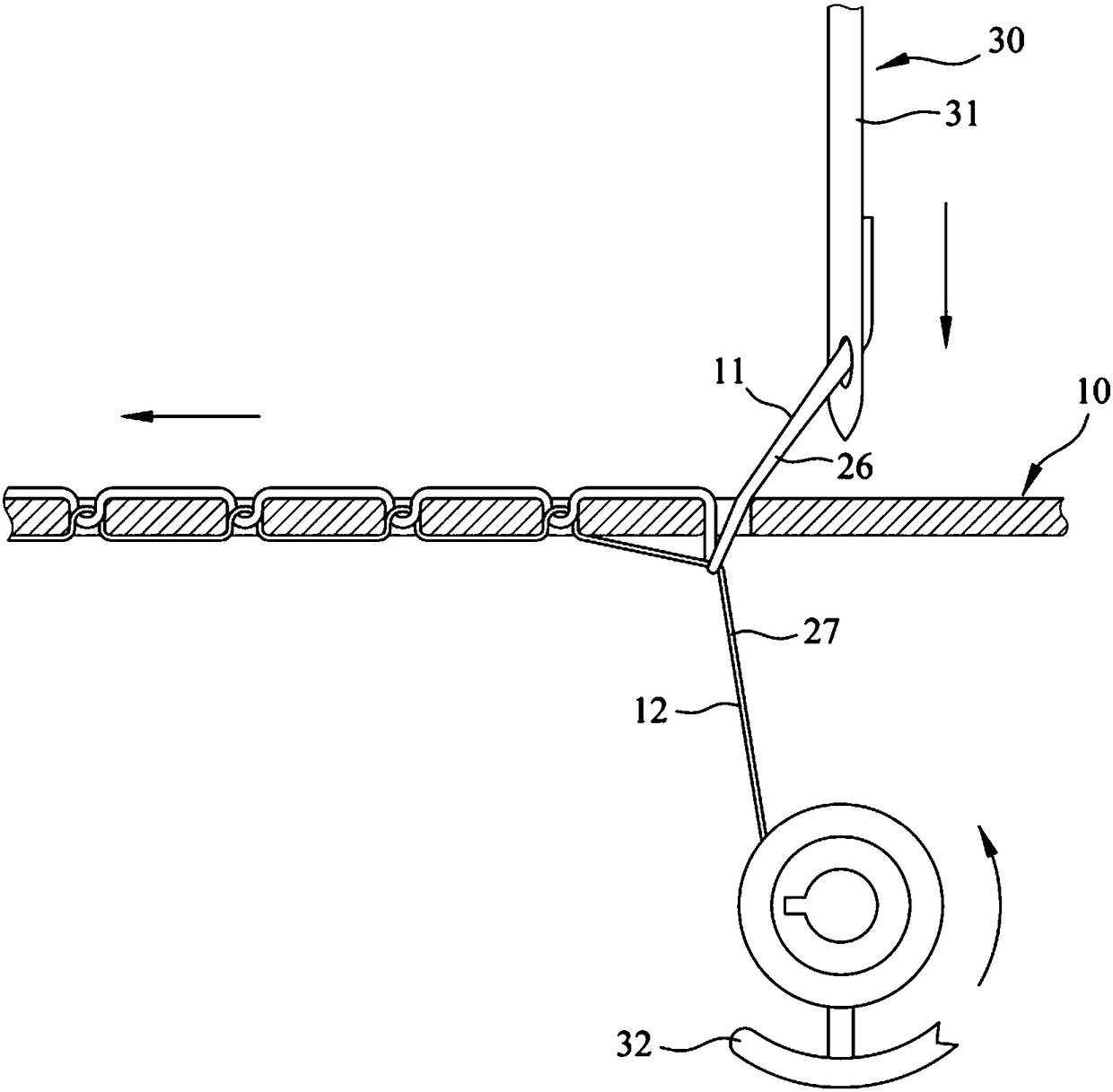

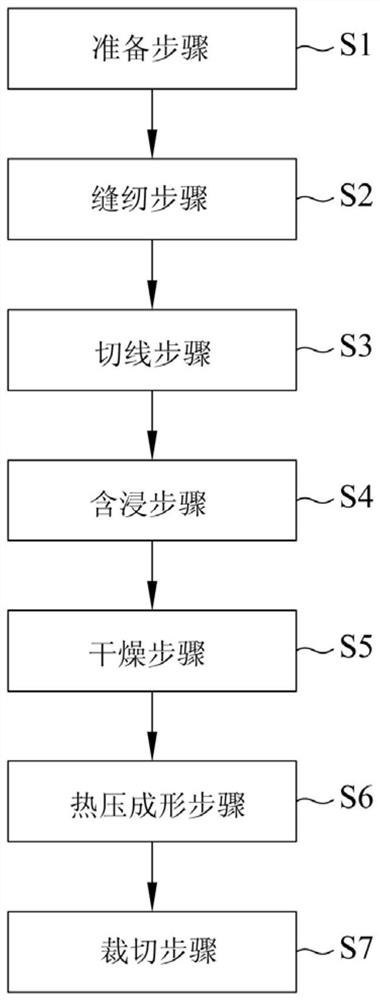

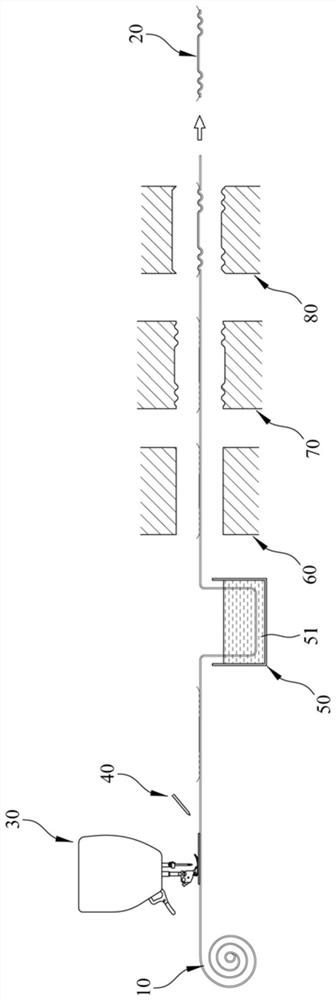

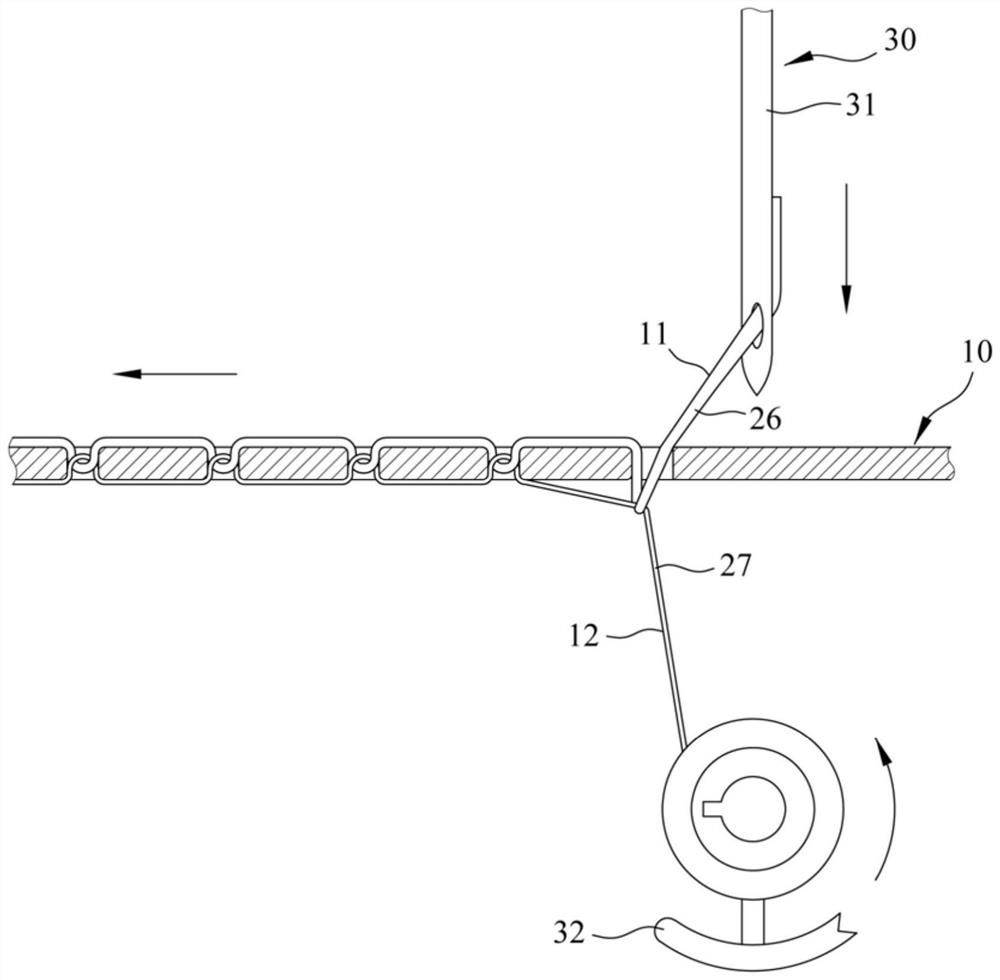

Horn vibrating reed sewn into wire and method for sewing wire into horn vibrating reed

ActiveCN109391879AImprove bindingPrevent loose deformationNon-planar diaphragms/conesDiaphragm extensionsPunchingWire cutting

The present invention provides a horn vibrating reed sewn into a wire and a method for sewing a wire into a horn vibrating reed. The method comprises a preparation step a sewing step, a wire cutting step, a hot compacting step and a cutting step. The method produces a plurality of horn vibrating reed sewn into wires through the steps, each horn vibrating reed comprises: one body, wherein the center position of the body is provided with a punching hole, and the body is provided with a wave portion; at least one metal wire continuously sewn at the wave portion of the elastic wave body; and at least one sewing thread continuously sewn at the wave portion of the elastic wave body and connected in an interweaving mode with the metal wire to form a plurality of fixed structures. Therefore, the horn vibrating reed sewn into the wire and the method for sewing the wire into the horn vibrating reed can effectively avoid the conditions of deformation, loosening or cracking of the metal wire afterlong-term vibration and can avoid the condition of unbalance vibration due to malposition when the metal wire and the horn vibrating reed are combined.

Owner:大原博

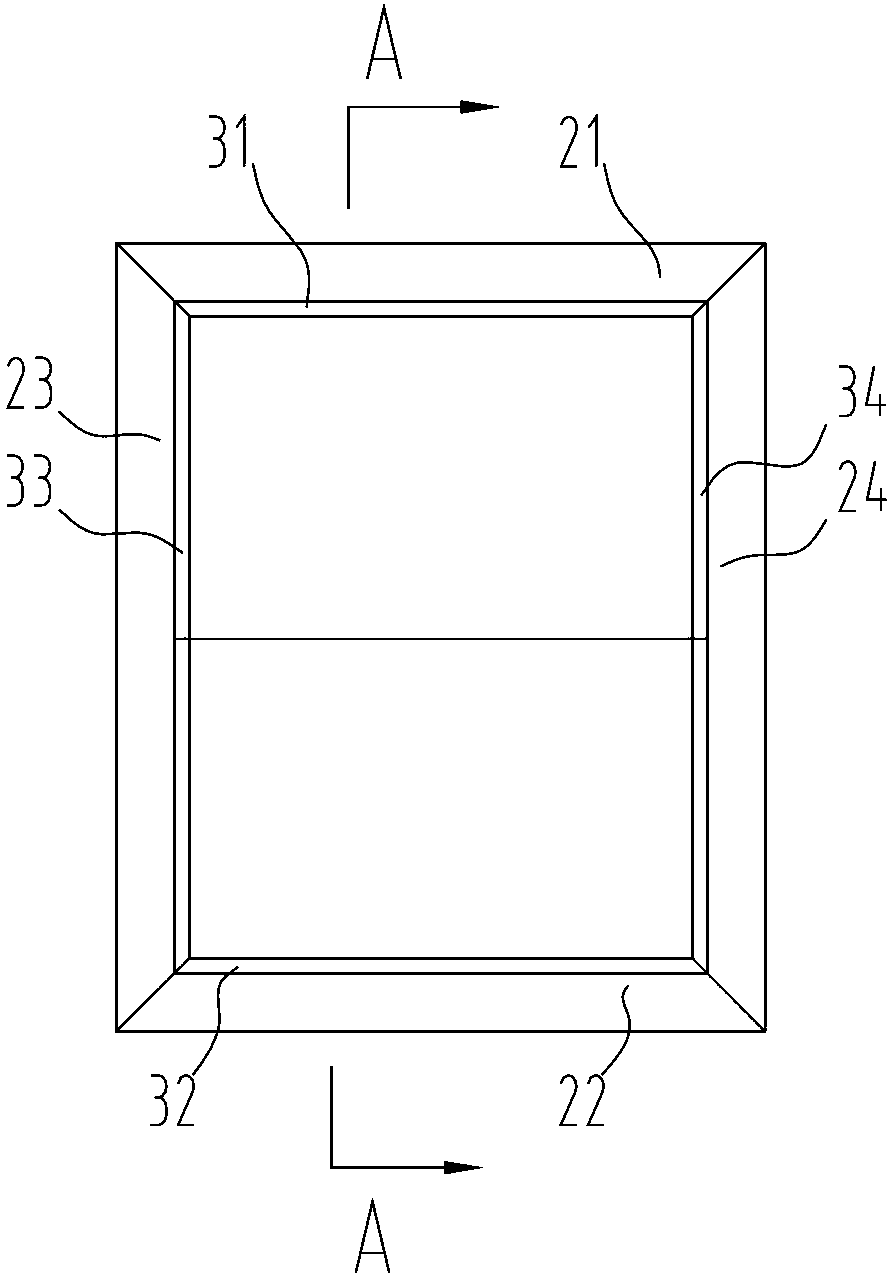

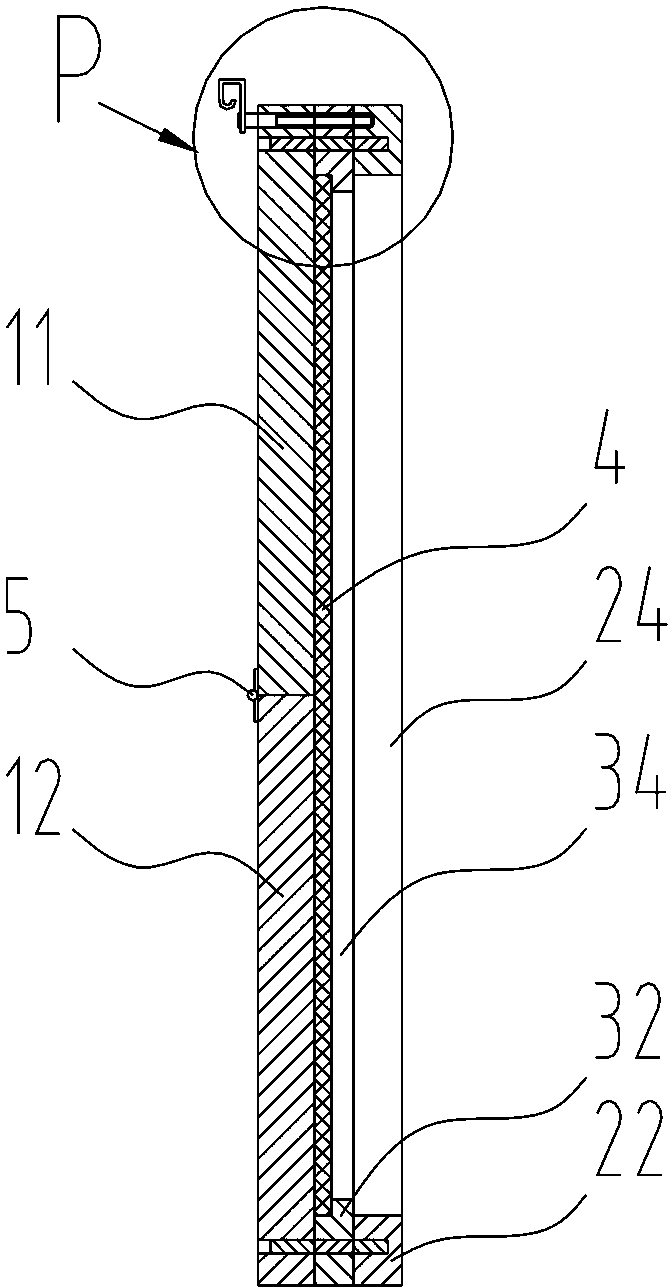

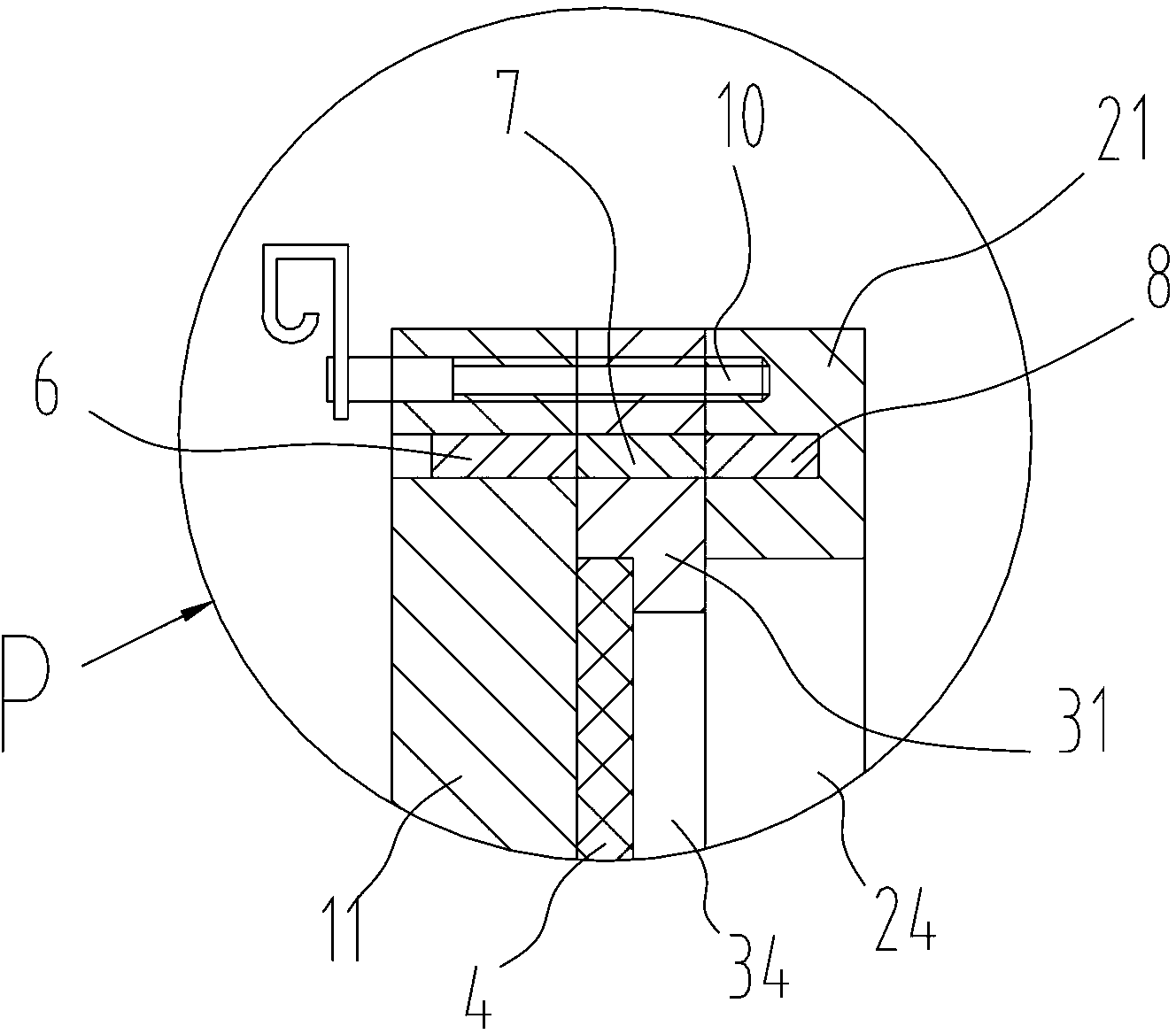

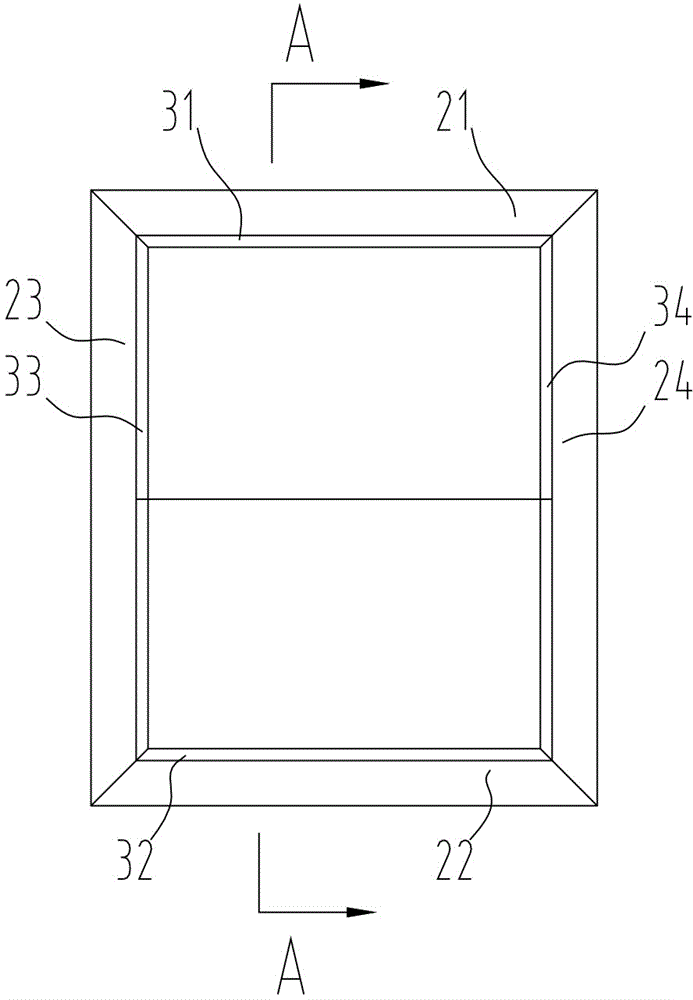

Picture frame convenient to disassemble, assemble and transport

The invention provides a picture frame convenient to disassemble, assemble and transport. The picture frame convenient to disassemble, assemble and transport comprises a rectangular bottom plate, a border assembly and a frame pressing assembly which is located between the bottom plate and the border assembly, and a first magnet set is arranged on the periphery of the surface of the bottom plate; the frame pressing assembly comprises four independent pressing plates, each pressing plate is provided with a second magnet set, and the four pressing plates are in magnetic connection with the bottom plate by attraction force between the second magnet sets and the first magnet set; the border assembly comprises four independent borders, and the four pressing plates are pressed by the four borders respectively. According to the picture frame convenient to disassemble, assemble and transport, calligraphy and painting mounting can be achieved rapidly, and by means of the magnetic attraction force of the first magnet set and the second magnet sets, position locating of each pressing plate on the bottom plate can be completed automatically; during disassembly, the pressing plates are manually removed only, no tool is needed, and disassembly is facilitated greatly. The border assembly comprises the four independent borders, and therefore during transportation, the four borders and the four pressing plates are convenient to transport.

Owner:周巧

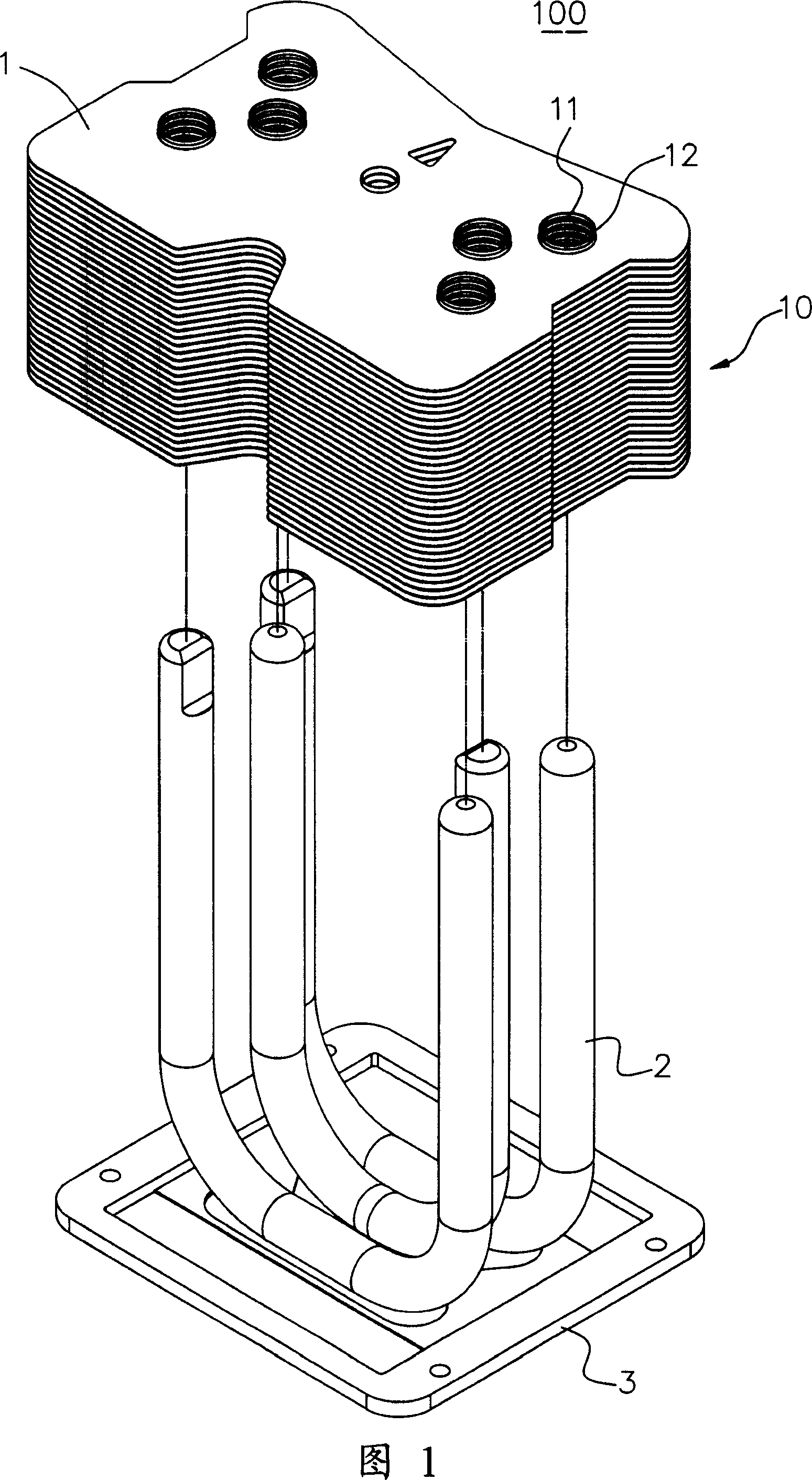

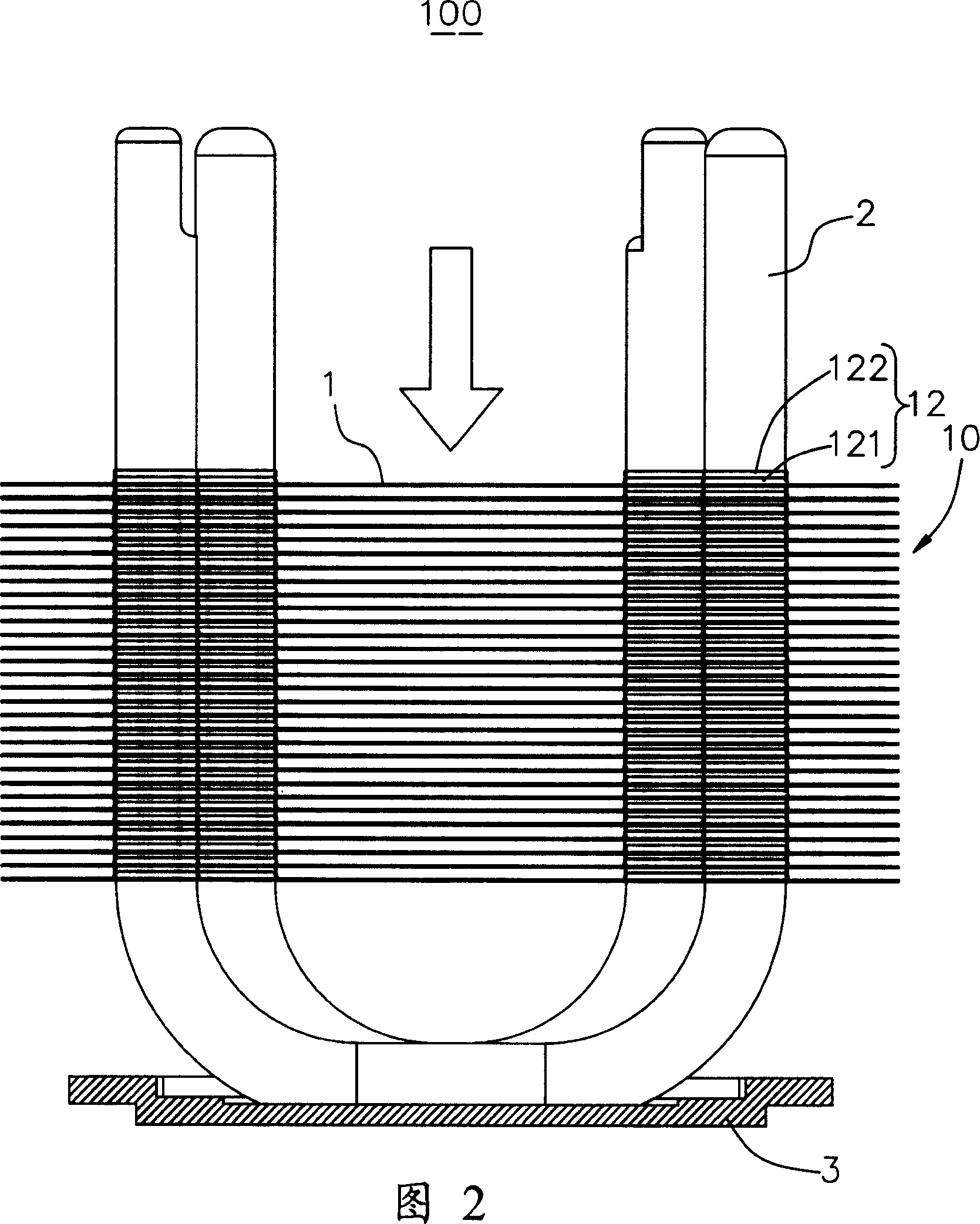

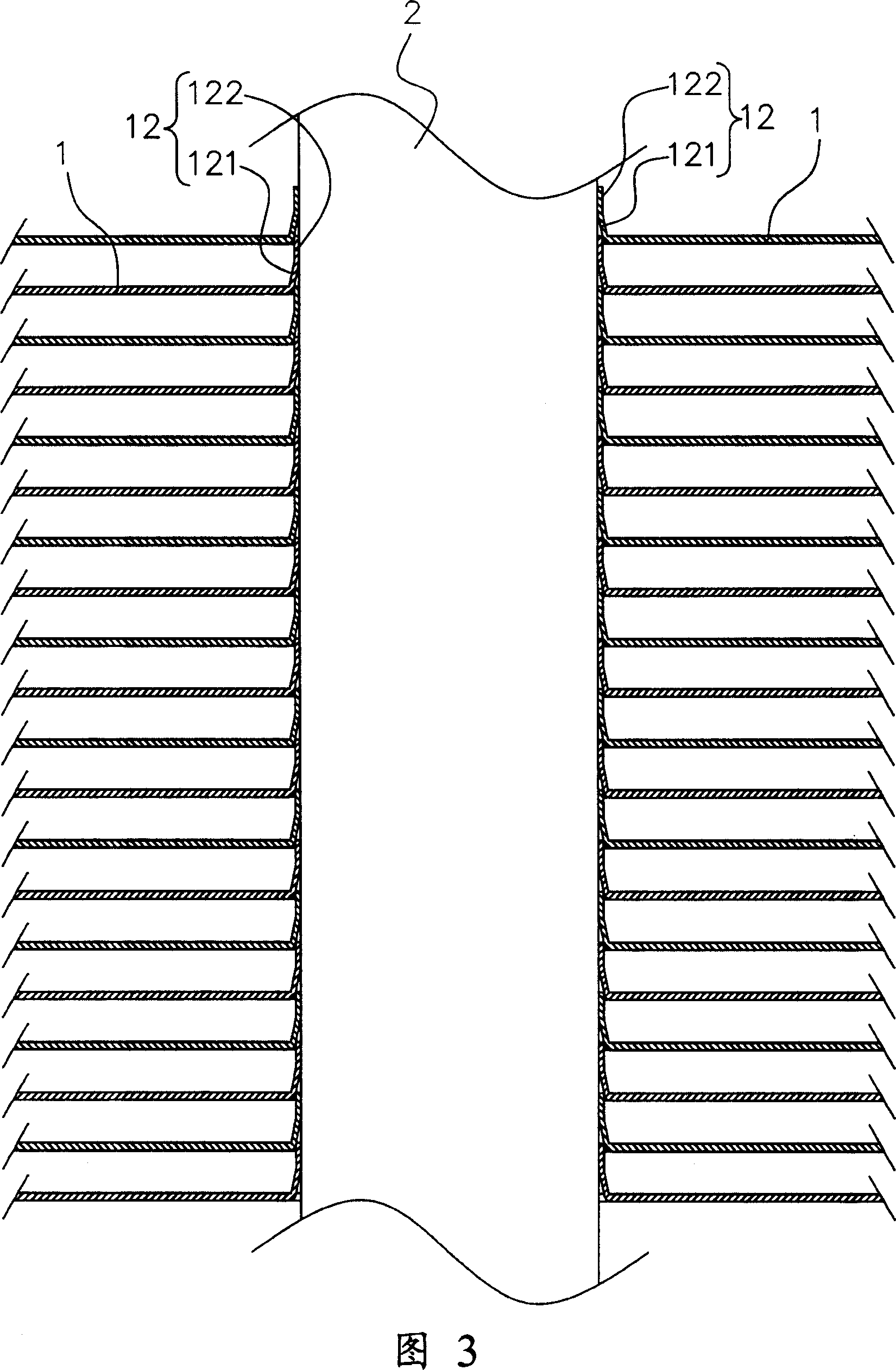

Method of molding radiator, and locative structure

InactiveCN1958218APrevent loose deformationImprove cooling efficiencyAssembly machinesWork holdersHeat conductingEngineering

A technology for forming a heat sink consisting of at least one heat conducting tube and multiple groups of heat-sinking finned sheets includes such steps as passing a heat conducting tube through a laminated first group of finned sheets, attaching a locating plate for applying a pressure down to the group of finned sheets, making said heat conducting tube pass through the second group of heat-sinking finned sheets, and attaching a pressing plate to the top finned sheet. It has high heat sinking efficiency. Its locating structure is also disclosed.

Owner:AMA PRECISION INC

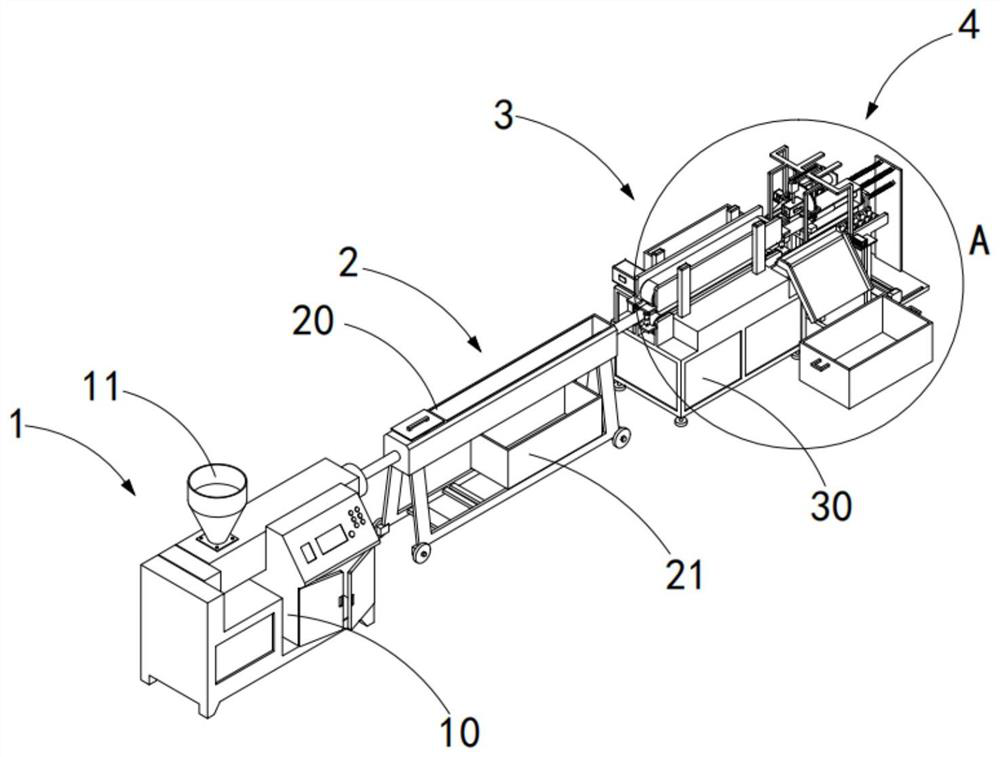

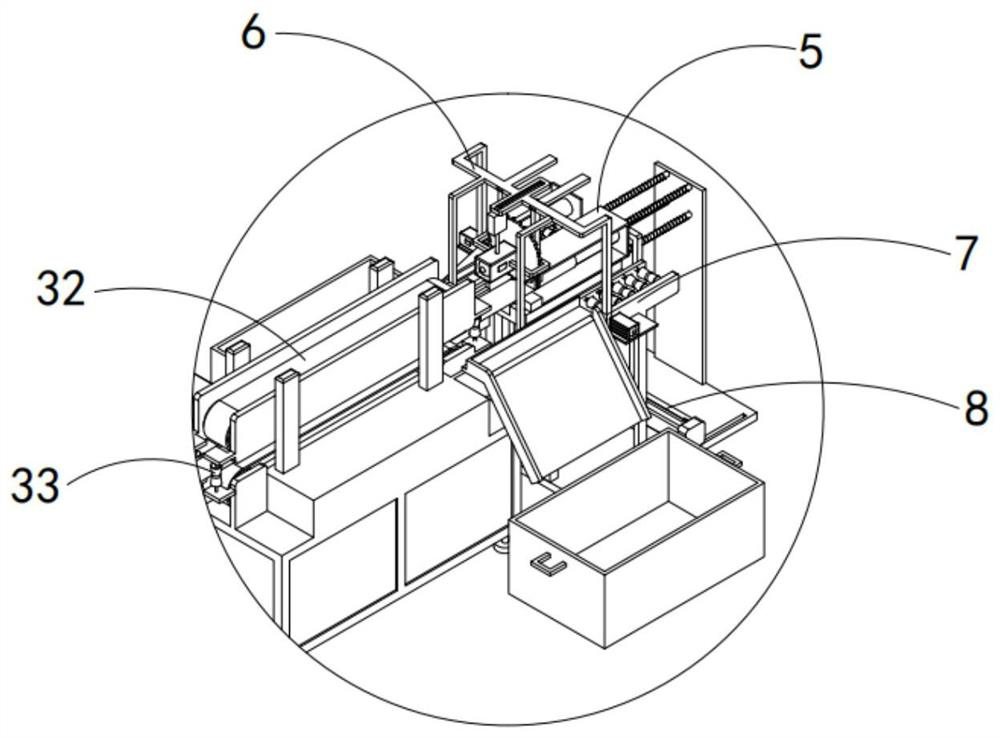

Cutting equipment for producing PVC pipes

PendingCN113400384ASolve production inefficienciesStable deliveryMetal working apparatusEngineeringTransfer mechanism

The invention relates to cutting equipment for producing PVC pipes. The cutting equipment comprises an extrusion device, a shaping device and a dragging device, wherein a cutting device is arranged at the tail end of the dragging device and comprises a bearing mechanism, a cutting mechanism arranged at the front end of the bearing mechanism, a transferring mechanism arranged at the tail end of the bearing mechanism and blanking mechanisms arranged on two sides of the bearing mechanism; the bearing mechanisms are used for bearing the PVC pipes conveyed on the dragging device; the cutting mechanism comprises a guide rail and a saw blade; the transferring mechanism comprises a baffle a and a baffle b; the PVC pipes abuts against the baffle a and the baffle b in the conveying process to drive the bearing mechanisms to move backwards, and meanwhile, the bearing mechanisms drive the saw blade to move backwards along the guide rail to cut the PVC pipes; the transferring mechanism is used for transferring the cut PVC pipes to the blanking mechanism in a translation manner; and the blanking mechanism is used for stroking the cut PVC pipes down from the transferring mechanism. Through the cutting equipment for producing the PVC pipes, the problems that machined notches are uneven, the cutting efficiency is low and the labor cost is high are solved.

Owner:浙江都达新材料科技有限公司

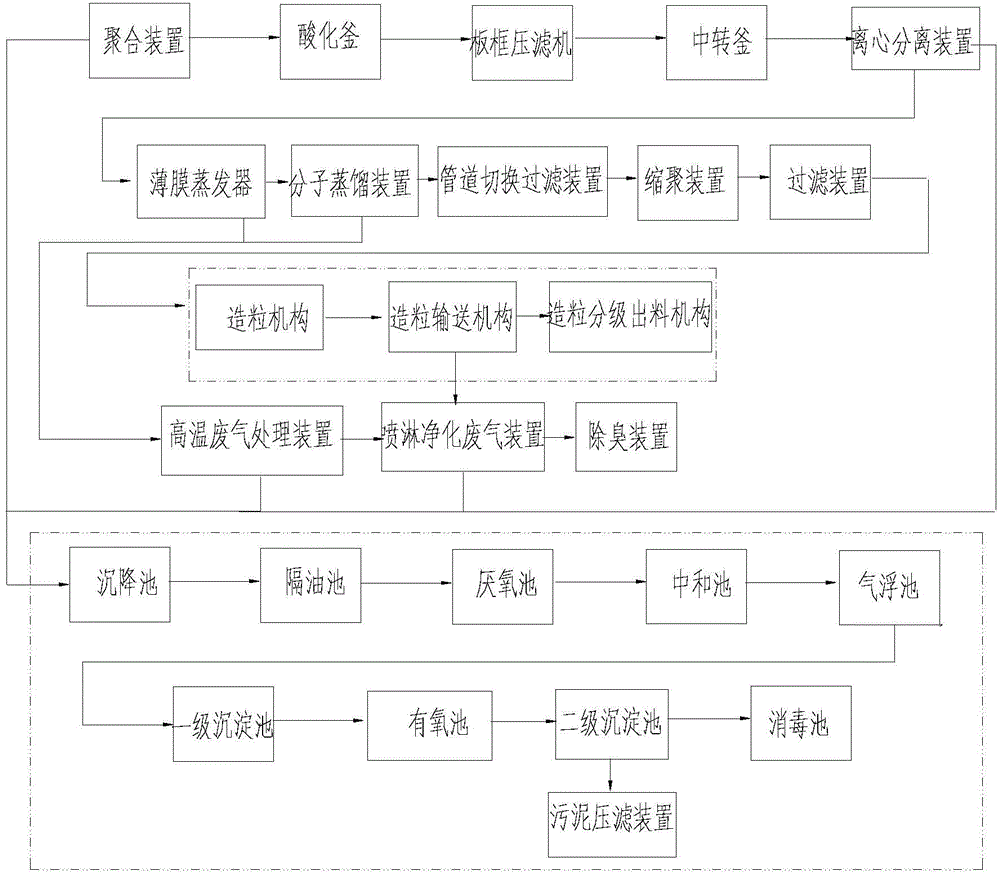

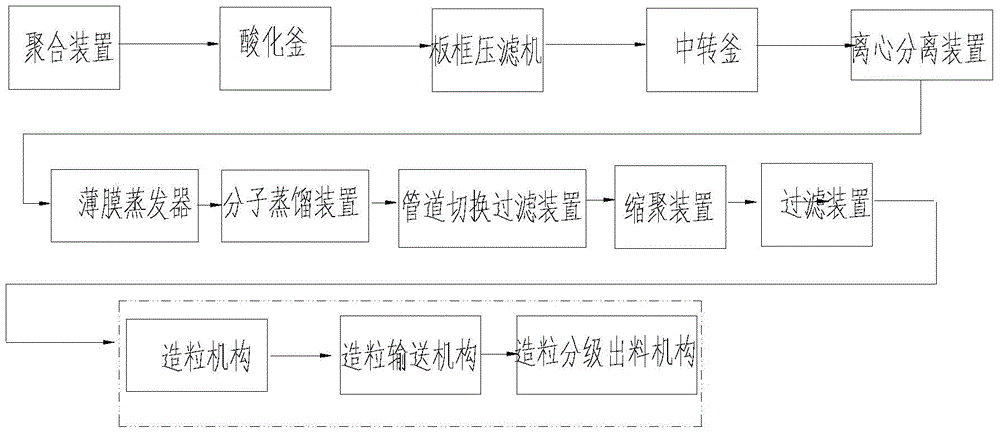

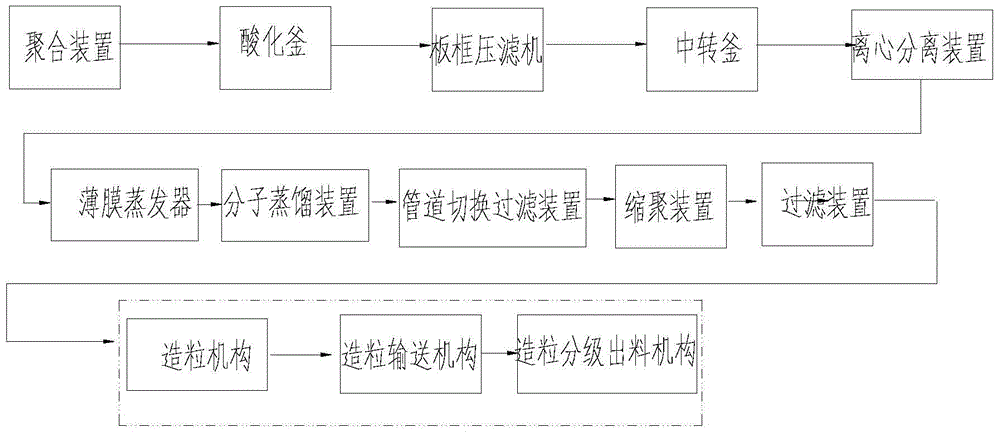

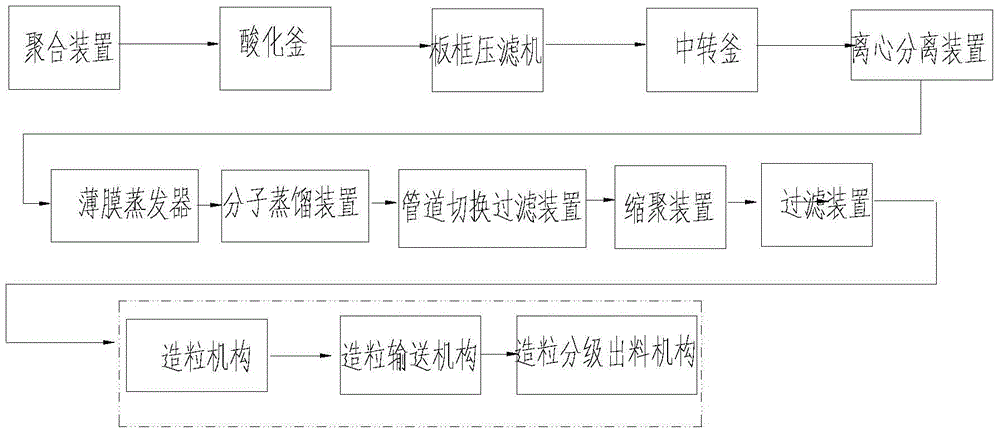

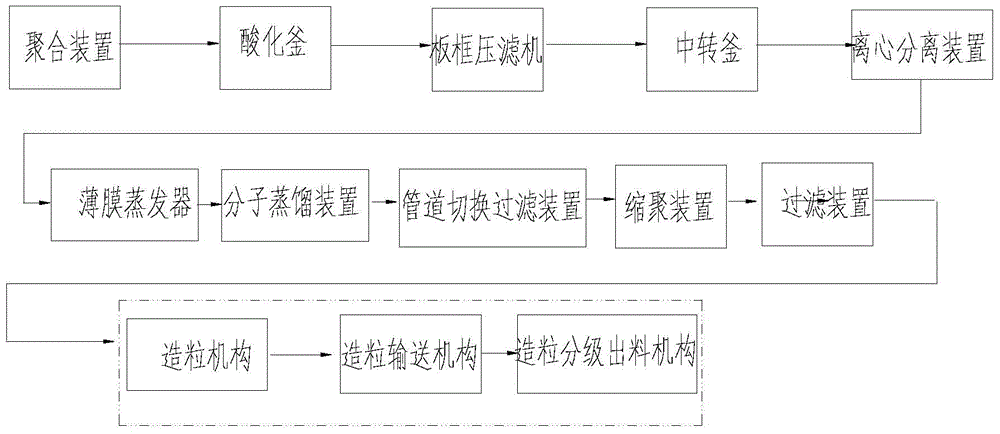

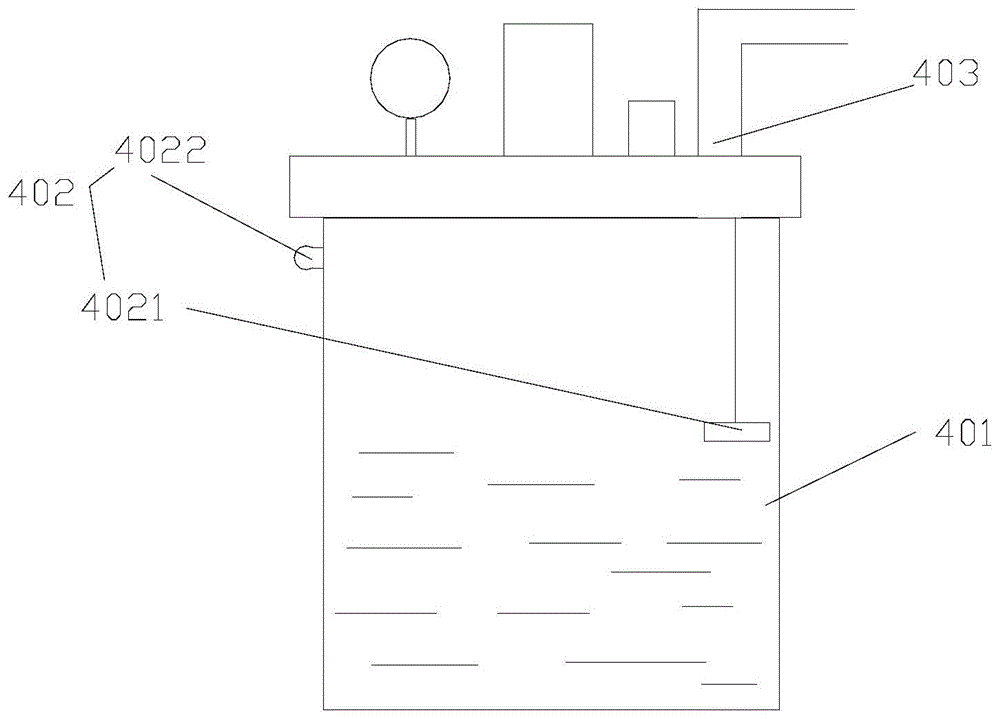

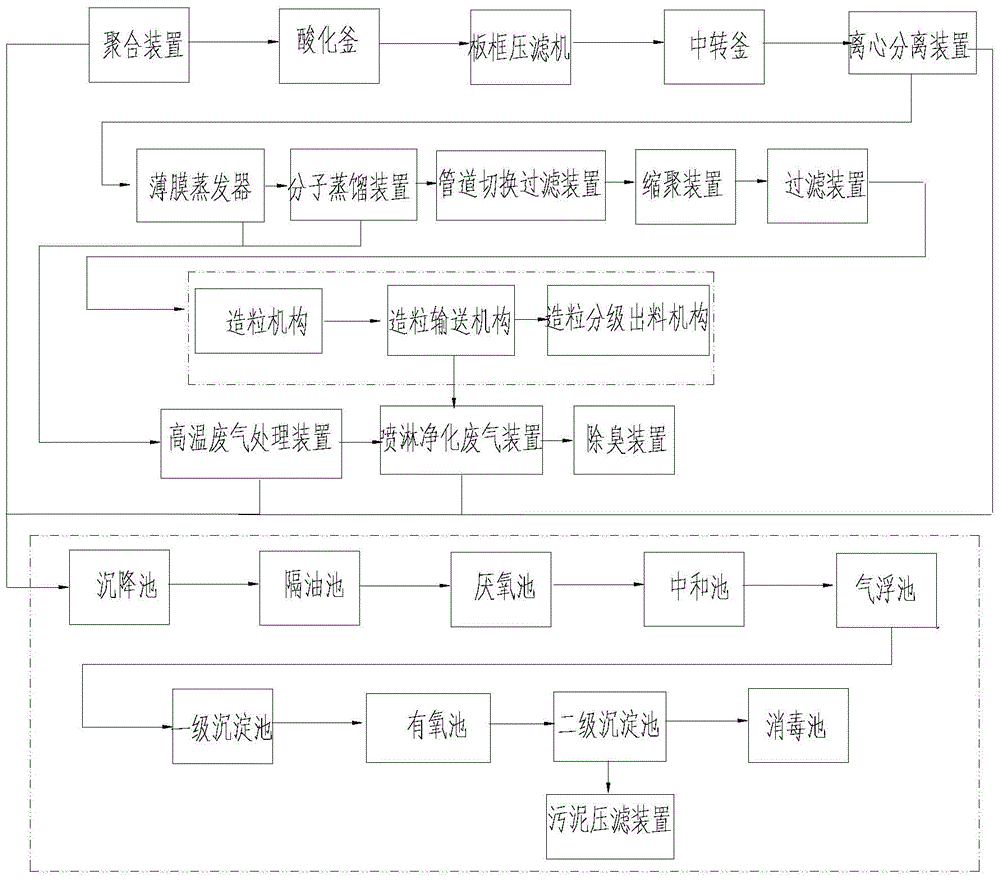

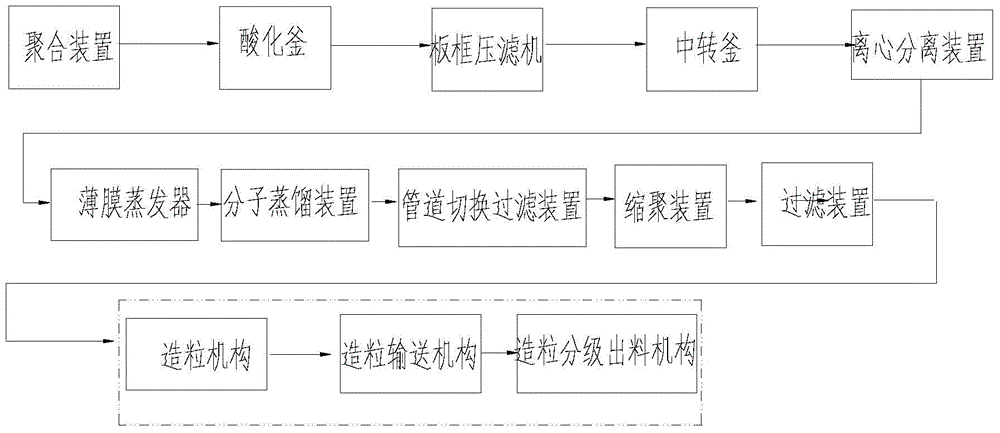

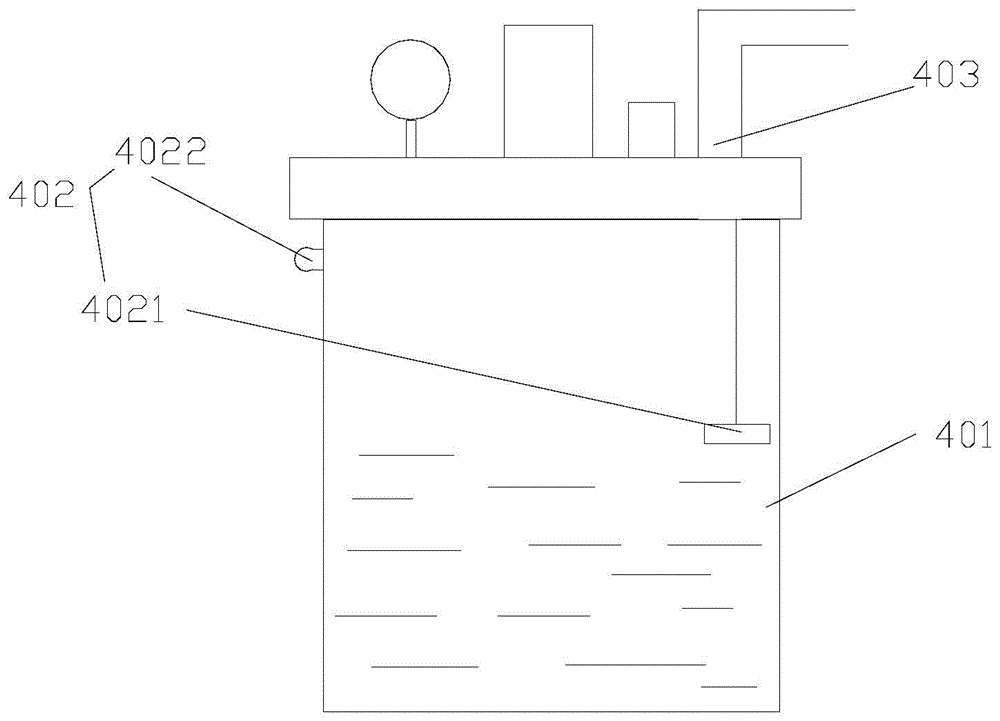

Polyamide production system and polyamide production method

The invention discloses a polyamide production system. The polyamide production system comprises a polymerization plant, an acidification kettle, a plate-and-frame filter press, a transferring kettle, a centrifugal separation device, a film evaporator, a molecular distillation device, a pipeline switching and filtering device, a polycondensation device, a filtering device and a pelleting system sequentially from front to back according to a technical process, and further comprises a waste gas treating device and a waste water treating system. The waste gas treating device is used for subjecting waste gas produced in a production process to decomposition and sedimentation treatment. The waste water treating system is used for subjecting waste water produced in the production process to purification treatment. The invention further discloses a polyamide production method for the polyamide production system. The polyamide production system and the polyamide production method have the advantages of high processing efficiency, high processing safety, low product impurity rate and capabilities of treating the waste water and the waste gas produced in the production process, and are mainly applied to the technical field of polyamide production.

Owner:安徽虹泰新材料股份有限公司

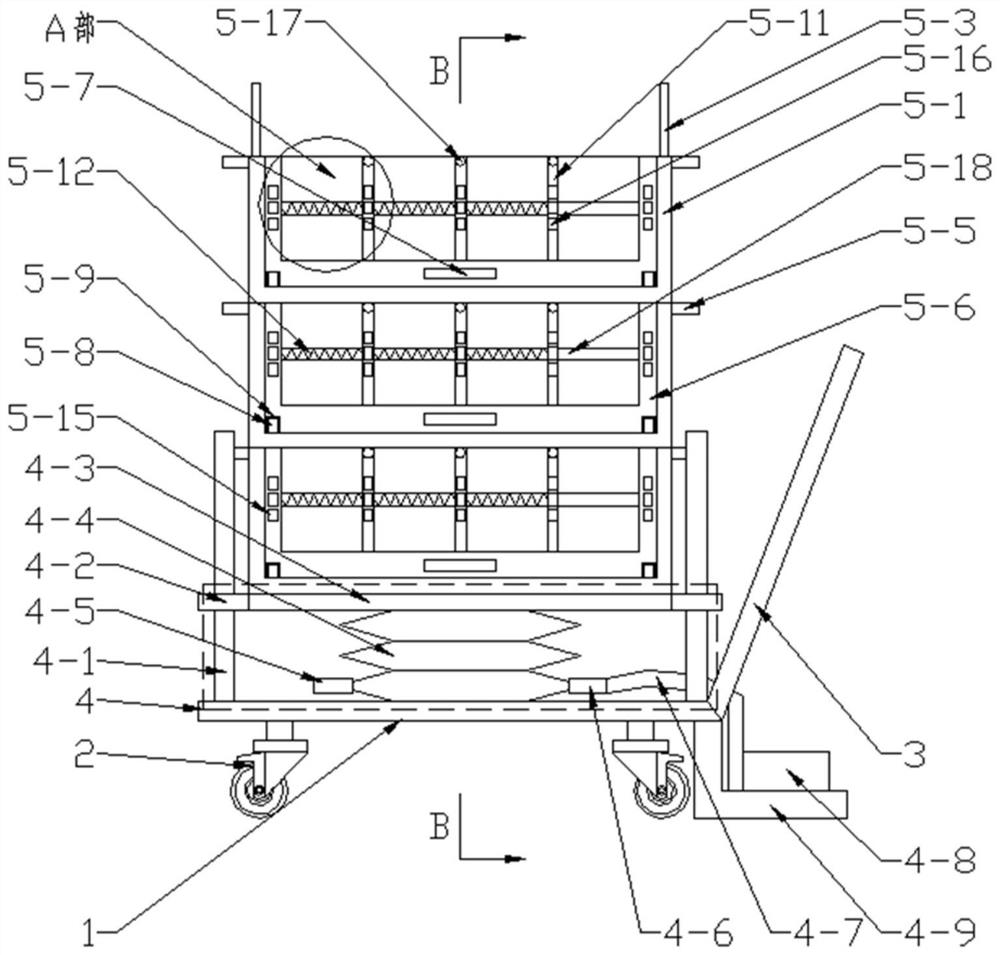

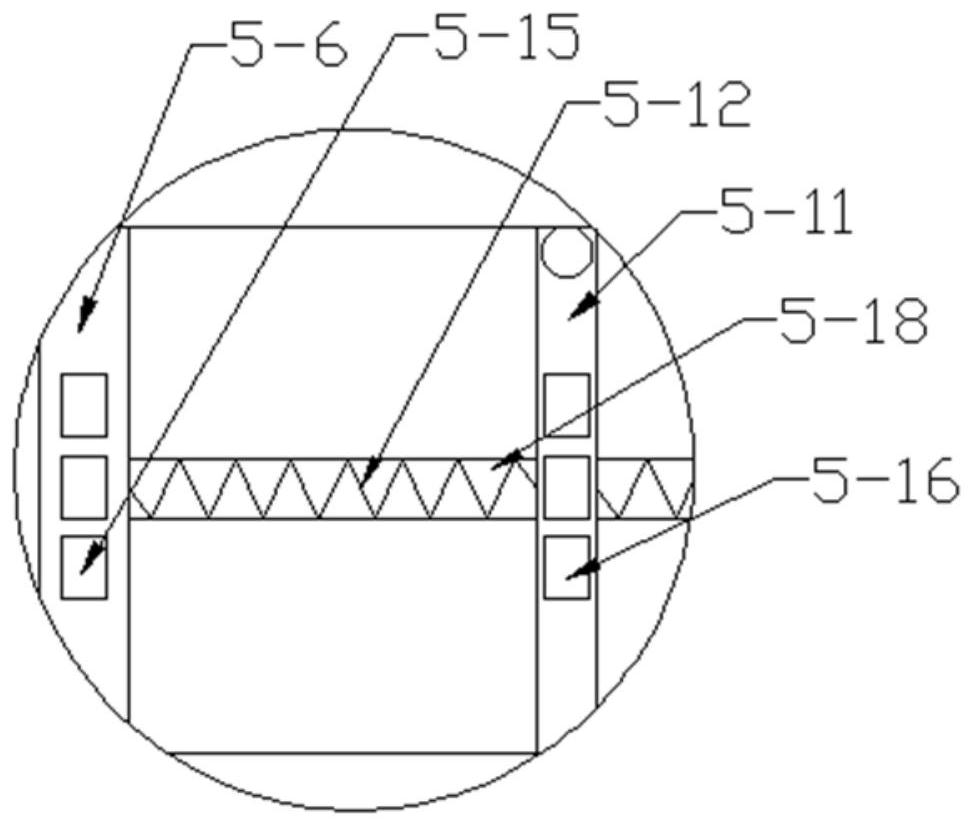

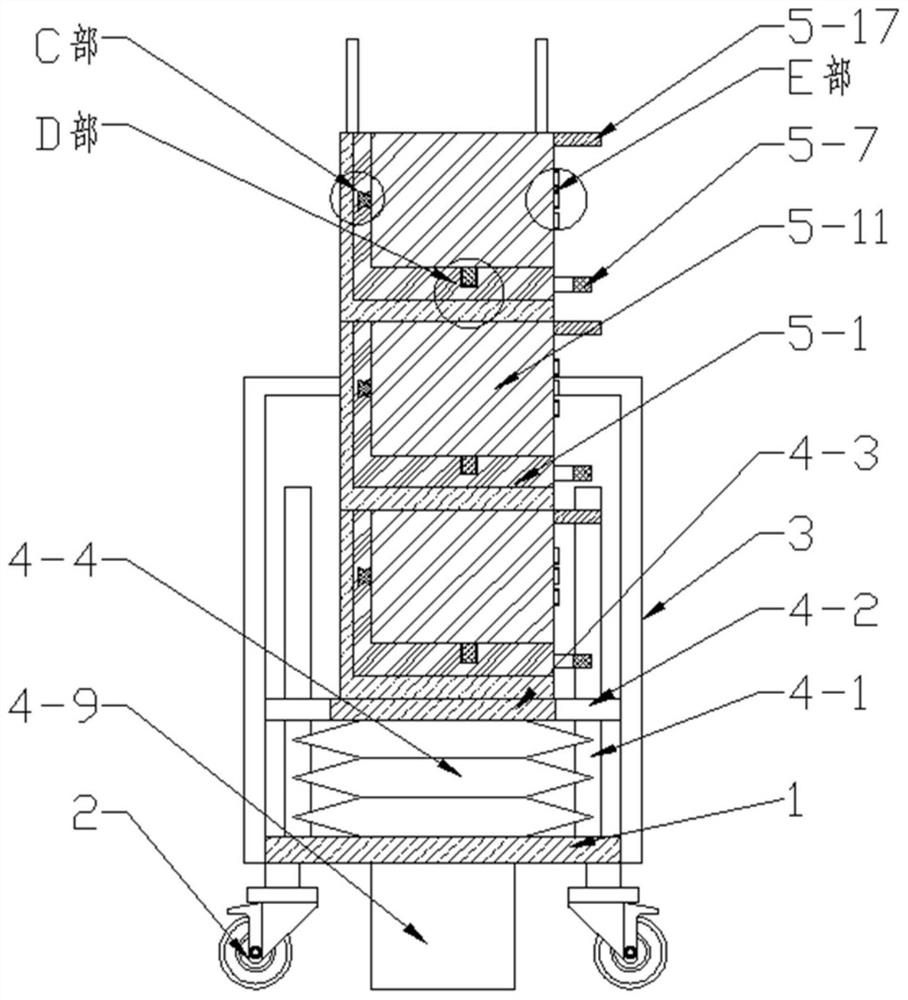

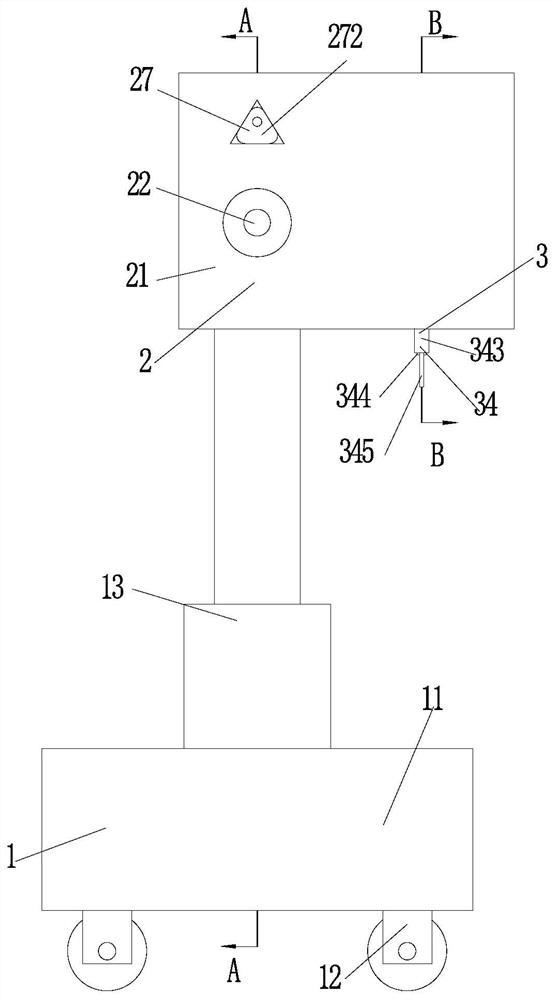

Book classification collator for library

InactiveCN112622997AAvoid repeated bending and squattingImprove practicalityServing tablesHand carts with multiple axesStructural engineeringMechanical engineering

The invention discloses a book classification collator for a library, and relates to the technical field of book management auxiliary devices. Limiting rods are fixed to the four corners of the upper surface of a first supporting plate correspondingly, and the limiting rods are movably sleeved with limiting rings; a second supporting plate is arranged among the four limiting rings, and the left side wall and the right side wall of the second supporting plate are fixed to the limiting rings on the left side and the right side correspondingly; an inflation supporting column is fixed to the upper surface of the first supporting plate, and the upper end of the inflation supporting column is fixed to the second supporting plate; a first one-way valve is arranged on the lower portion of the left side of the inflation supporting column, and airflow flows from inside to outside; a second one-way valve is arranged on the lower portion of the right side of the inflation supporting column, and the airflow flows from outside to inside. The height can be adjusted according to the positions of arranged books, so that a worker is prevented from repeatedly stooping and squatting down to arrange the books, and the practicability is improved; and the books can be fixed, loosening and deformation of the books are avoided, and the effect of protecting the books is achieved.

Owner:DEZHOU UNIV

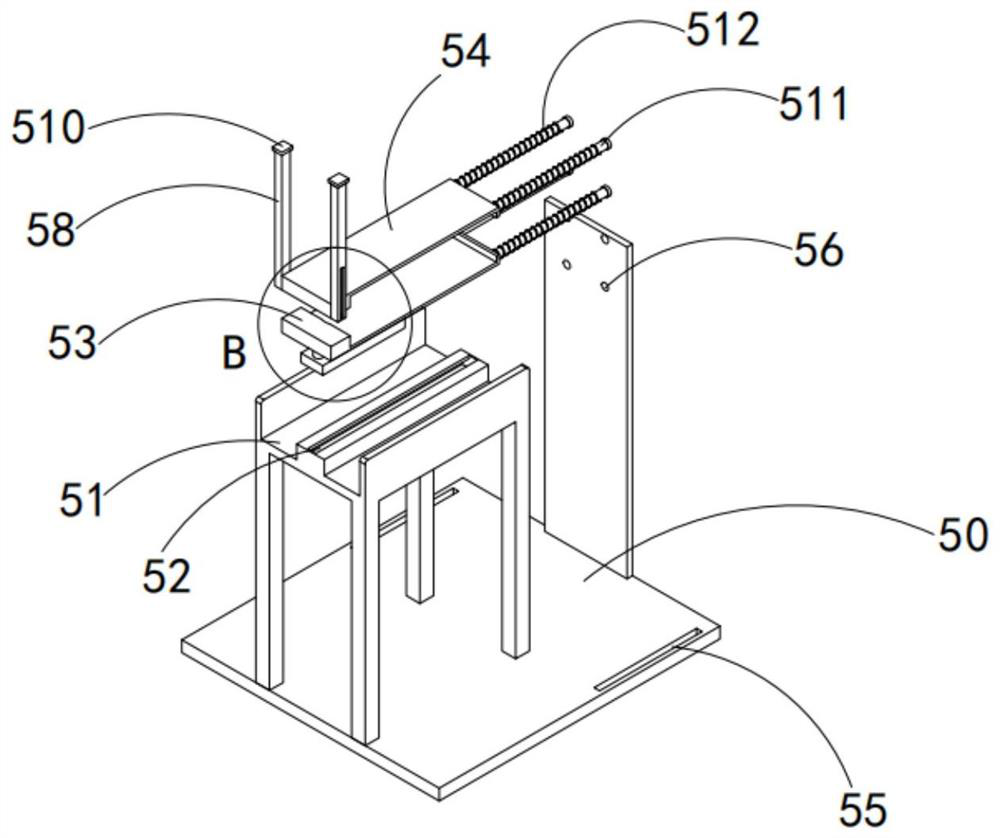

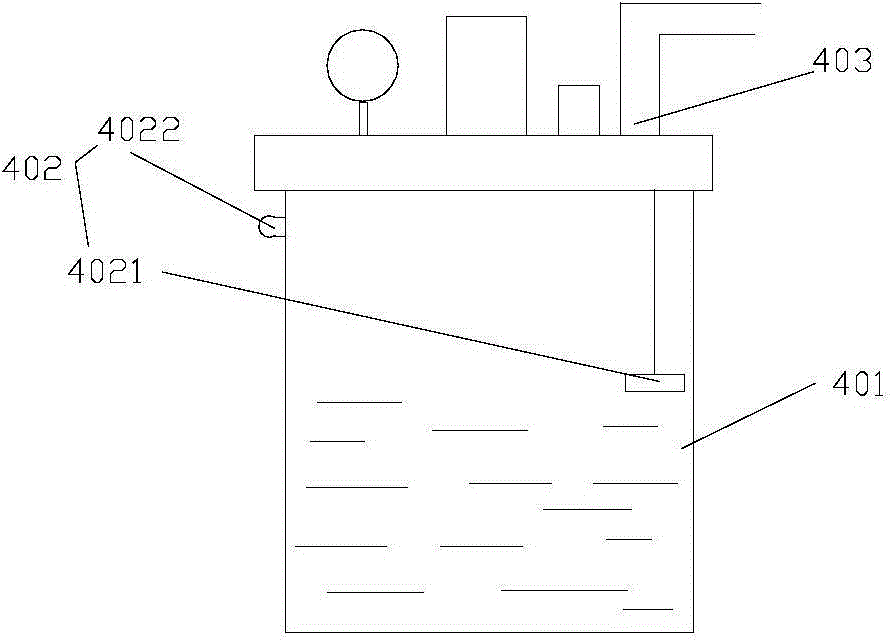

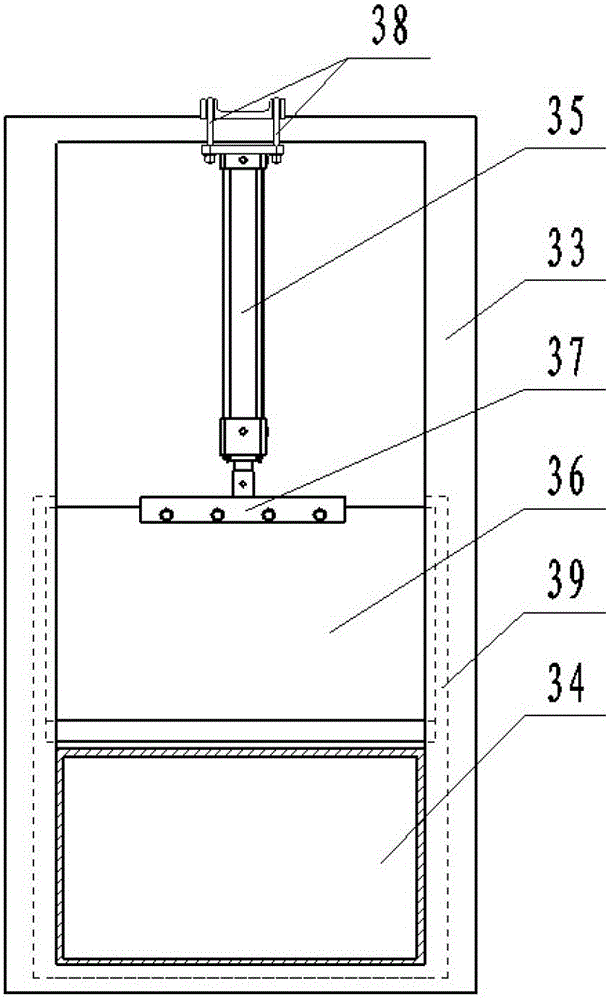

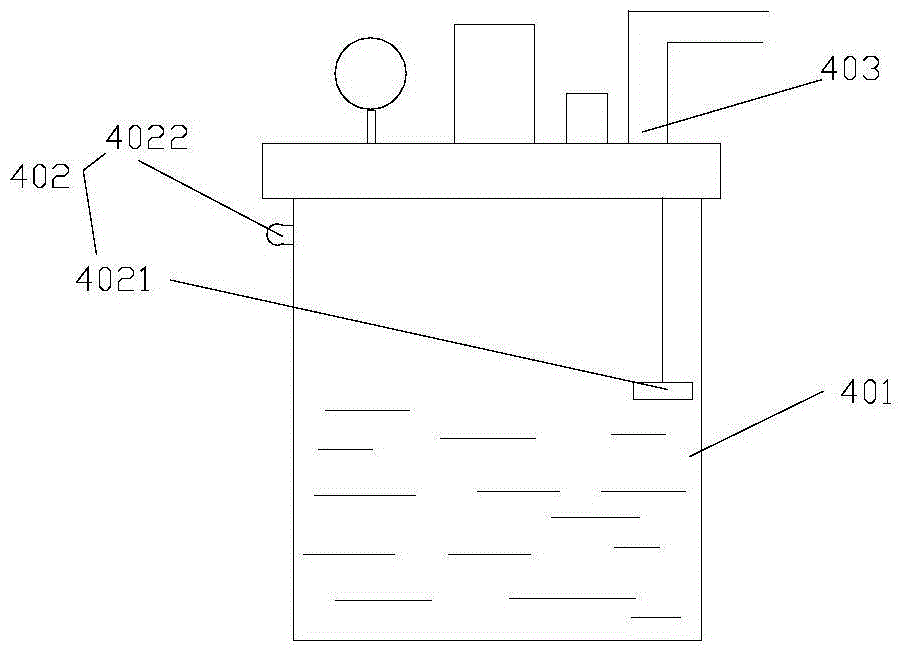

Polyamide production system

The invention discloses a polyamide production system. According to the technological processes, the polyamide production system comprises a polymerization device, an acidification kettle, a sheet frame pressure filter, a transition kettle, a centrifugal separation device, a film evaporator, a molecular distillation device, a pipeline changing and filtering device, a polycondensation device, a filter device and a prilling system in sequence from former to latter. According to the technological processes, the prilling system comprises a prilling mechanism, a particle conveying mechanism and a prilling, classifying and discharging mechanism in sequence from former to latter. The polyamide production system has the advantages of being high in processing efficiency, good in processing safety and low in product impurity rate.

Owner:ANQING HONGTAI NEW MATERIAL

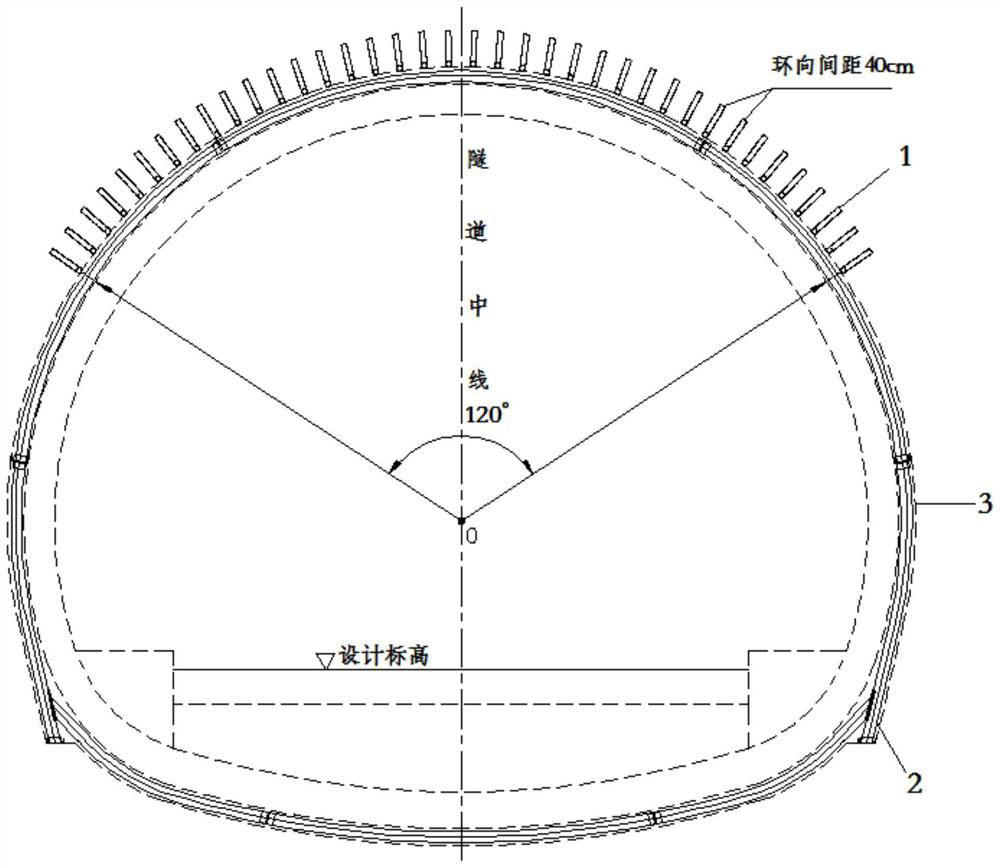

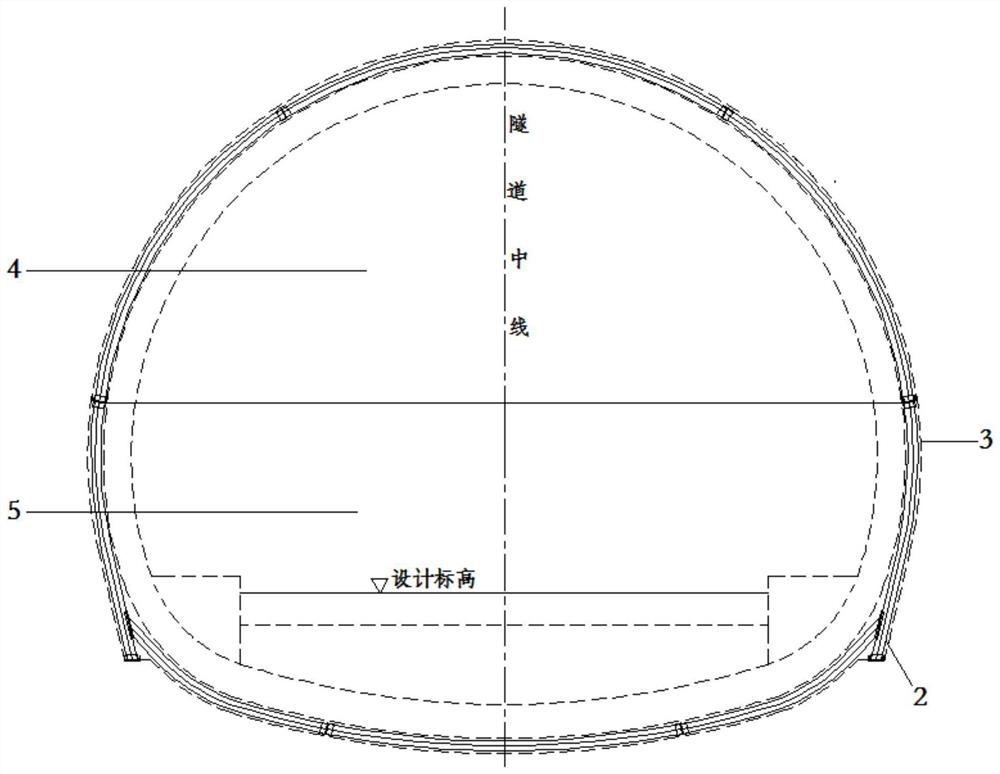

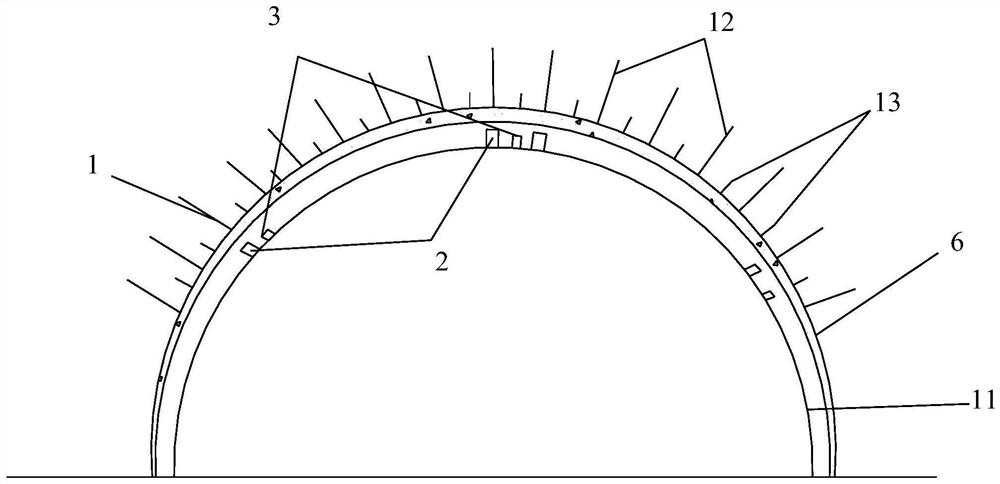

Construction method of high-crustal-stress soft rock extrusion large-deformation tunnel

ActiveCN113137235APrevent slippagePrevent loose deformationUnderground chambersHydro energy generationPre stressWorking environment

The invention discloses a construction method of a high-ground-stress soft rock extrusion large-deformation tunnel. The main control measures of the construction method comprises advanced pre-grouting, large-section excavation, large-diameter foot locking, resin pre-stressed anchor cable construction, double-control ring forming step pitch construction, cover arch installation and mechanical matching rapid construction. The construction method can improve the strength and stability of surrounding strata, reduce the disturbance frequency of excavation on broken surrounding rocks, actively support the surrounding rocks, quickly anchor and early load, control the expansion of a loose circle, strengthen the rigidity of resisting deformation of a primary support structure, compress an unfavorable stress state of the structure to be the shortest, improve the working efficiency, remarkably improve the working environment, reduce the labor intensity and save the labor, the construction problems that the tunnel face of the high ground stress soft rock extrusion large deformation tunnel is prone to collapse, deformation is uncontrollable, the progress is not ideal and the like are effectively solved, and the method has the advantages of overall utilization of resources, ordered management, guarantee of engineering safety and quality and the like.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP +1

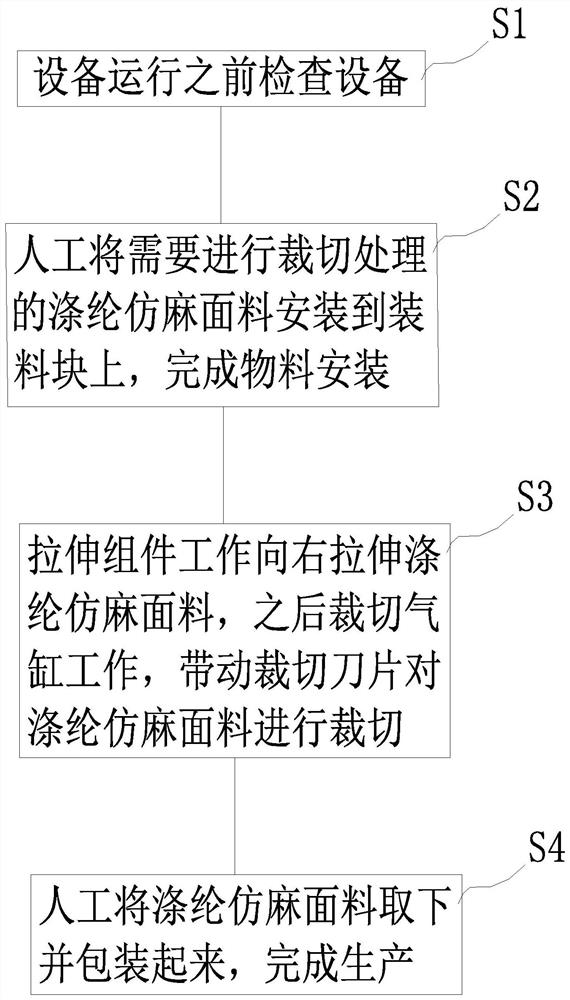

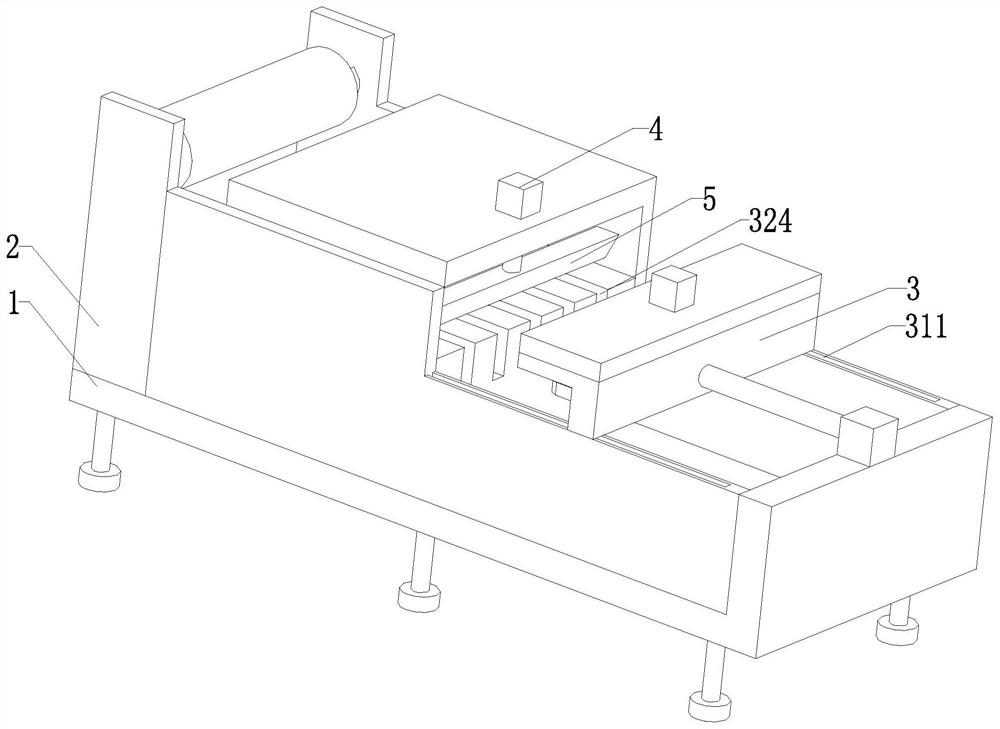

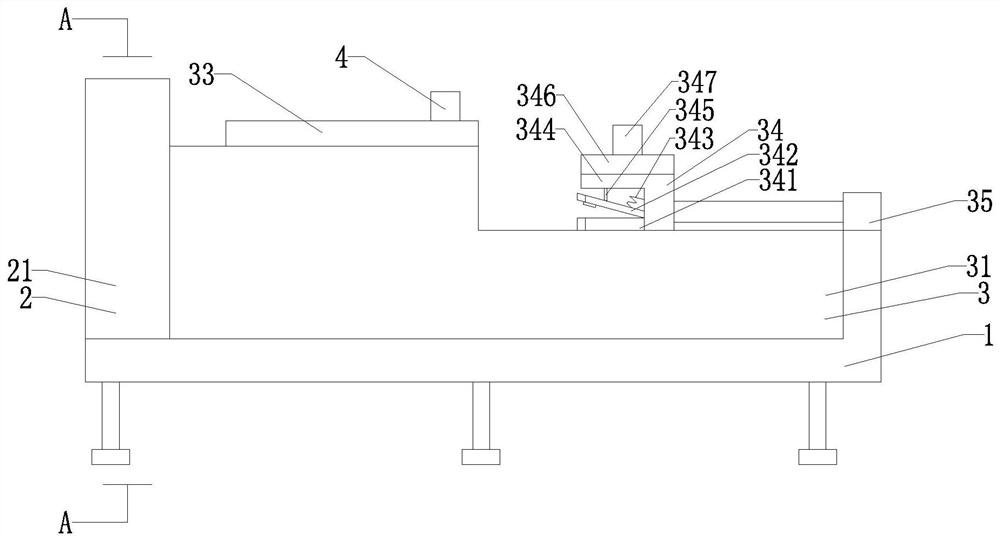

Polyester linen-like fabric production process

InactiveCN113445299AAvoid stretching and deformationQuality improvementSevering textilesPolyesterPolymer science

The invention relates to a polyester linen-like fabric production process. The polyester linen-like fabric production process mainly comprises the following steps of equipment inspection, fabric installation, stretching and cutting, and collection and packaging; polyester linen-like fabric cutting equipment comprises an installation base, a loading block, a stretching assembly, a cutting cylinder and a cutting blade; a material transferring assembly and a stretching assembly are installed on the upper end face of the installation base from left to right; the cutting air cylinder is installed on the stretching assembly; and the cutting blade is installed on an output shaft of the cutting air cylinder. The production process can solve the following problems in the cutting process of the polyester linen-like fabric: a, when the polyester linen-like fabric is cut, and when a mechanical arm clamps the polyester linen-like fabric, the situation that the polyester linen-like fabric is pulled and deformed occurs, and the quality of the polyester linen-like fabric is affected; and b, when the existing polyester linen-like fabric is cut, the cutting quality of the polyester linen-like fabric is affected due to the fact that the polyester linen-like fabric is loose in the conveying process and notches are uneven.

Owner:武汉思兰朵贸易有限公司

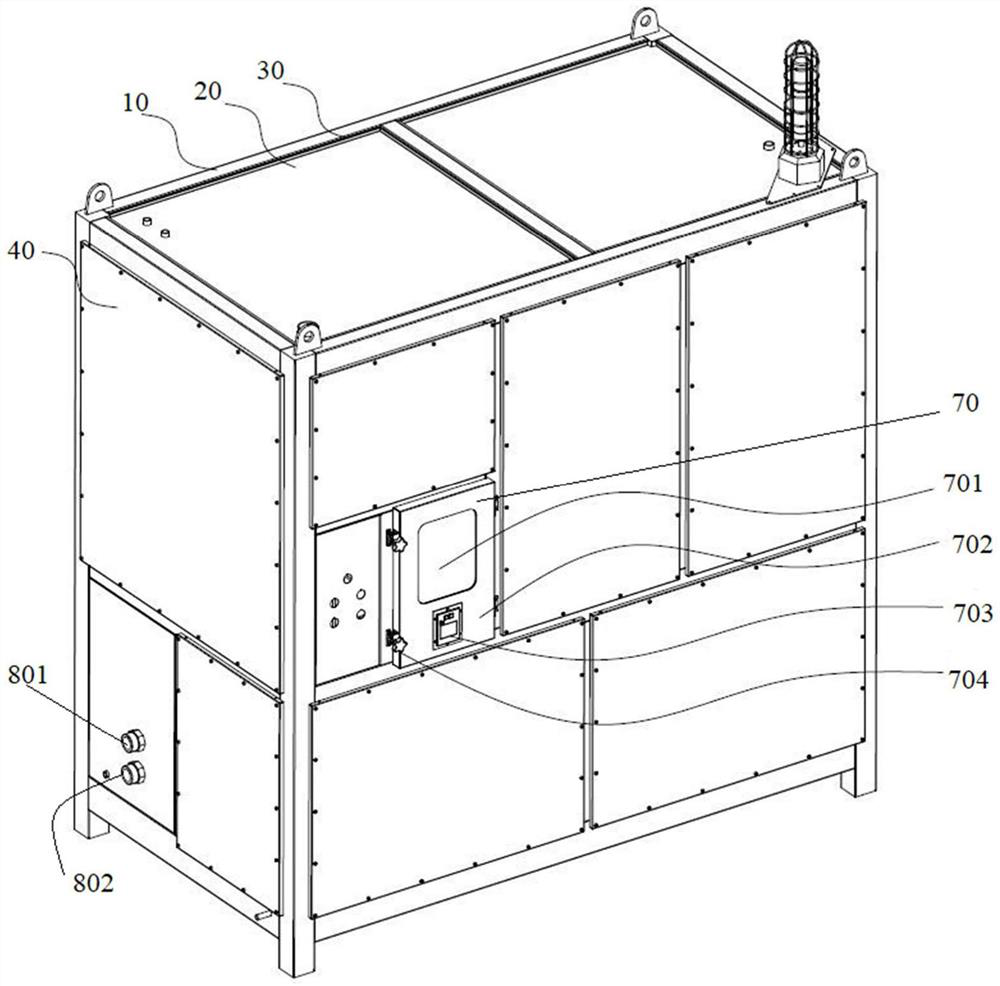

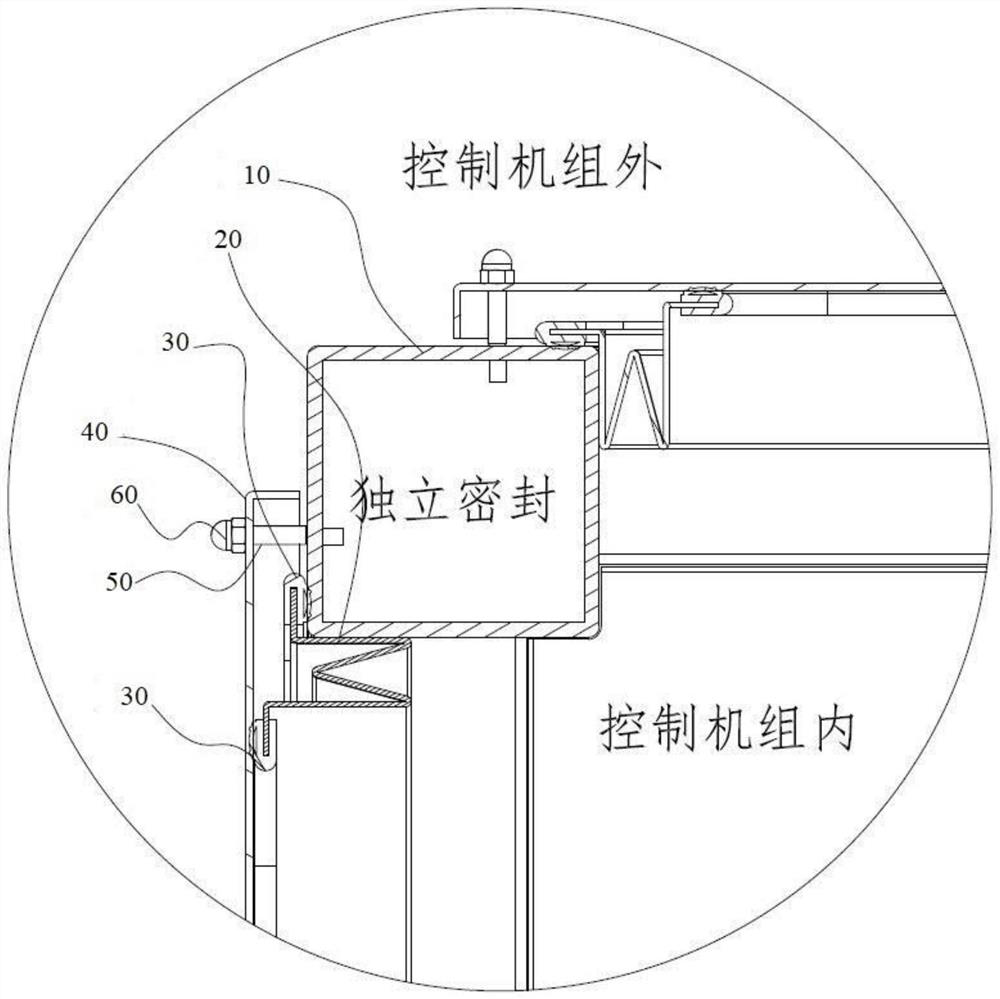

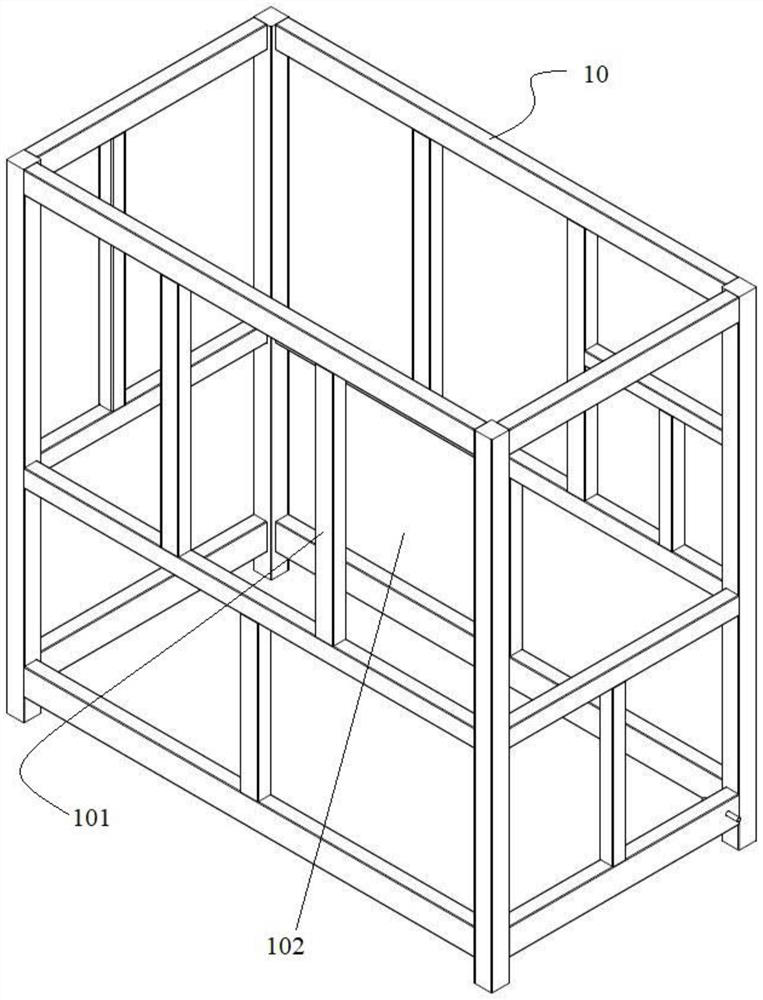

Positive pressure explosion-proof box body and positive pressure explosion-proof unit

ActiveCN114521074AEasy to replacePurpose of improving isolationCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringBody frame

The invention provides a positive pressure explosion-proof box body and a positive pressure explosion-proof unit, and the box body comprises a box body frame which is provided with a movable cover plate installation port; the rubber strip frame is elastic and is arranged at the movable cover plate mounting opening, and the rubber strip frame comprises a main body part forming the frame, and an outer edge and an inner edge which are arranged on the main body part; the sealing rubber strips are arranged on the outer edge and the inner edge; the number of the movable cover plates is at least one, the movable cover plates are detachably installed outside the movable cover plate installation openings, and after the movable cover plates are installed, the movable cover plates apply pressing force towards the inner side of the box body frame to the rubber strip frame by pressing the inner edges so that the outer edges can be tightly attached to the outer surfaces of the framework rectangular pipes. A first seal is formed between the outer edge and the framework rectangular tube, and a second seal is formed between the movable cover plate and the inner edge.

Owner:重庆阿泰可实验仪器有限公司

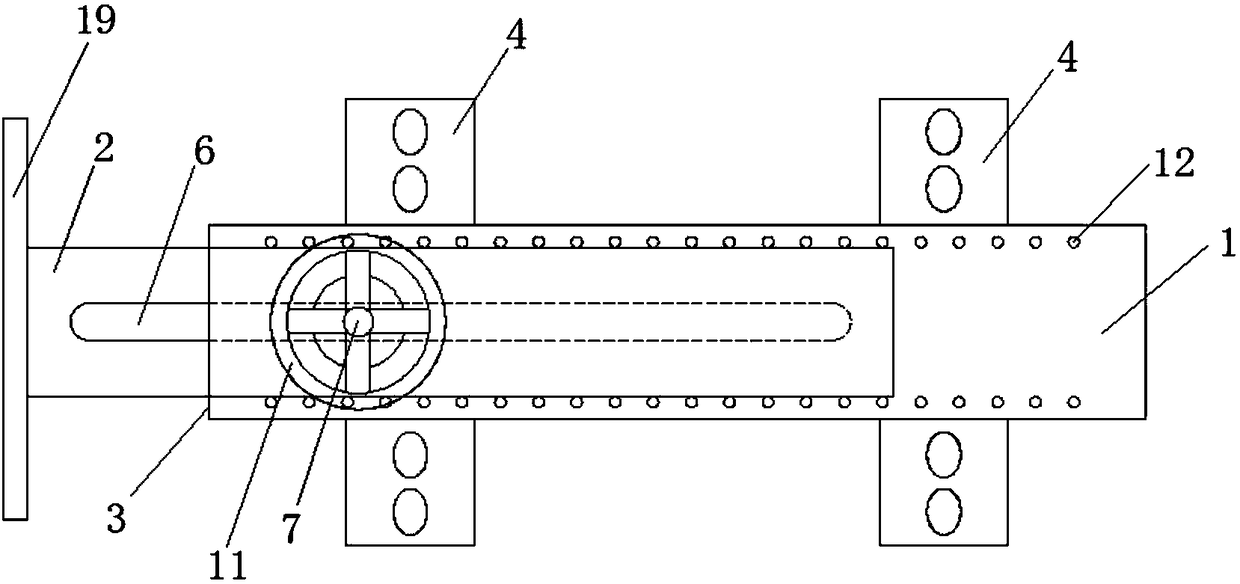

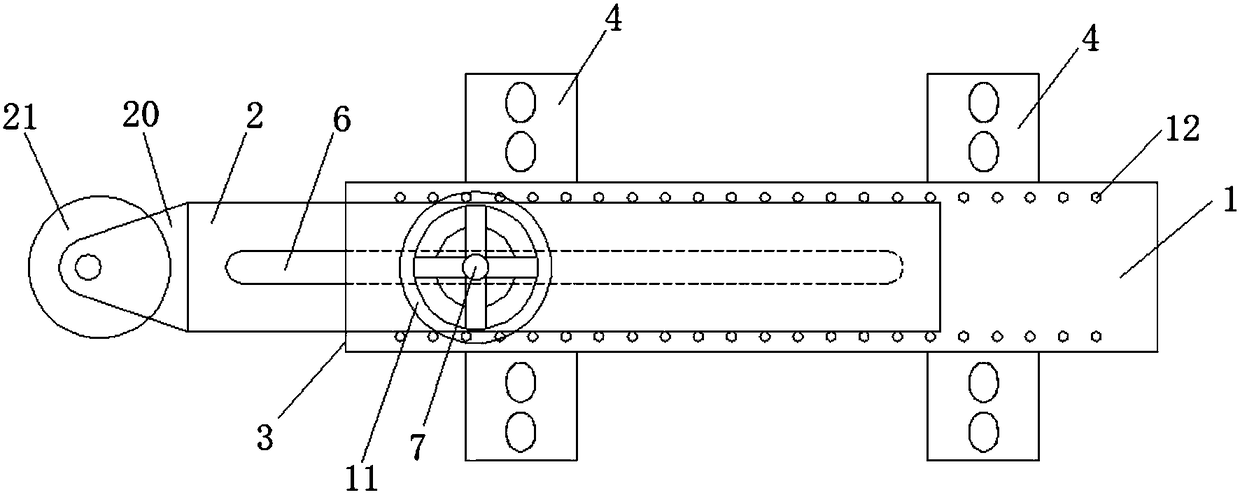

Belt tensioning device

InactiveCN108455188AImprove work efficiencyPrevent loose deformationConveyorsGearingAgricultural engineeringUltimate tensile strength

Owner:扬州益洋科技发展有限公司

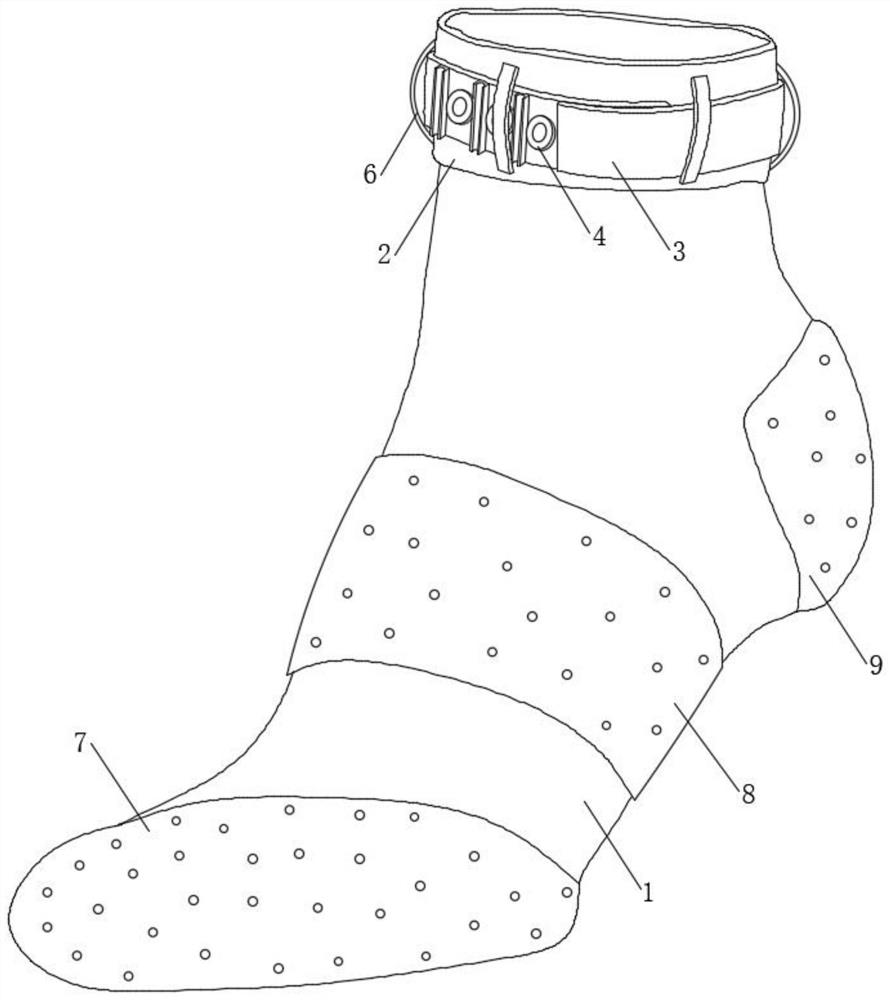

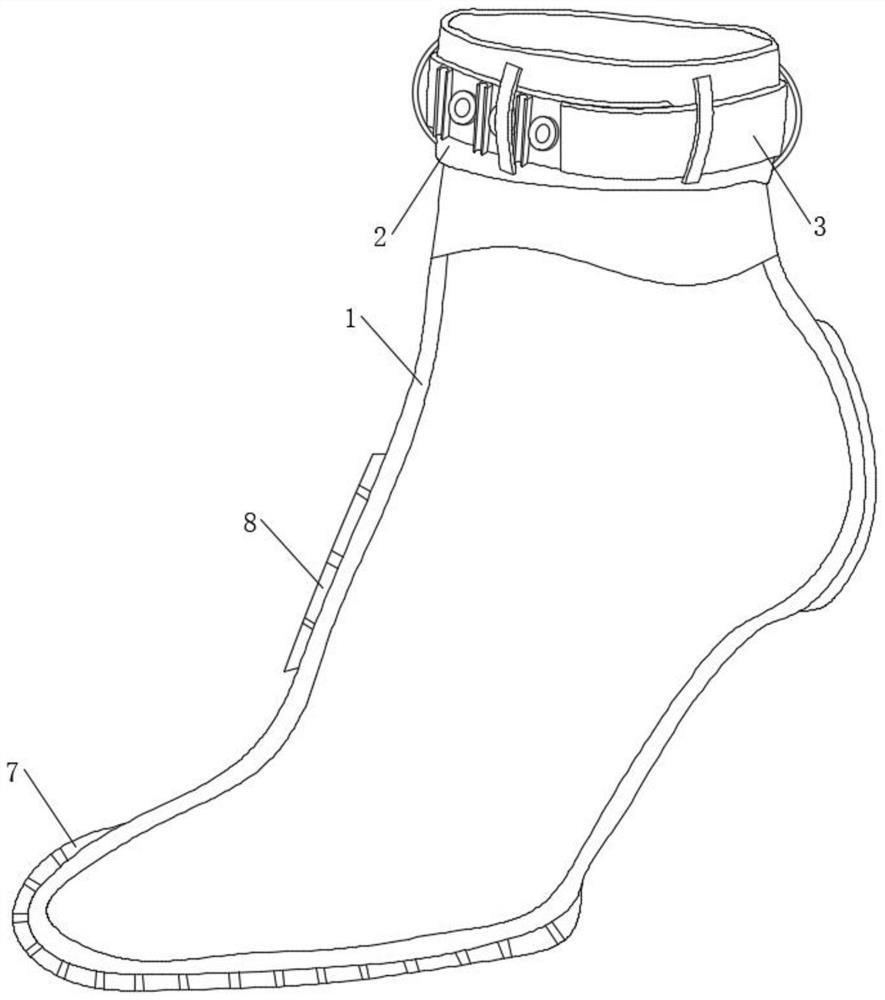

Sweat-absorbent sock and processing method thereof

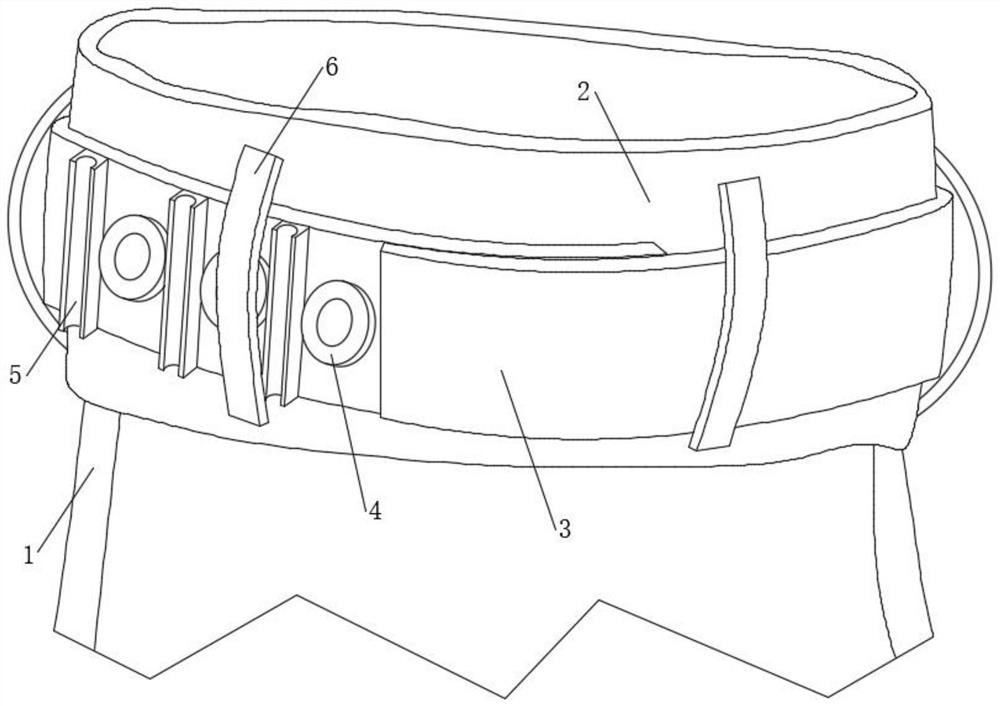

PendingCN113317565APrevent loose deformationTied firmlyPanty-hoseHosieryEngineeringStructural engineering

The invention discloses a sweat-absorbent sock and a processing method thereof. The sweat-absorbent sock comprises a sock main body, a connecting sock tube, a binding mechanism, a fixing mechanism and a clamping mechanism, the connecting sock tube is fixedly connected to the top end of the sock main body, the binding mechanism movably sleeves the connecting sock tube, the fixing mechanism is arranged on the binding mechanism, the clamping mechanism is arranged on the binding mechanism. the binding mechanism comprises a first binding belt, a second binding belt and an elastic band, the fixing mechanism comprises a female buckle and a male buckle, and the female buckle and the male buckle are buckled in a female-male mode. By means of the arrangement mode that the binding mechanism and the fixing mechanism are matched, the elastic band can be tensioned through the stretching and deforming of the elastic band, then the female buckle is selected, the male buckle and the female buckle are buckled with each other, the first binding belt, the second binding belt and the elastic band form a complete ring, loosening and deformation of the connecting sock tube are prevented, and the connecting sock tube can be stably bound to the root of a shank of the human body.

Owner:江苏舒跑科技有限公司

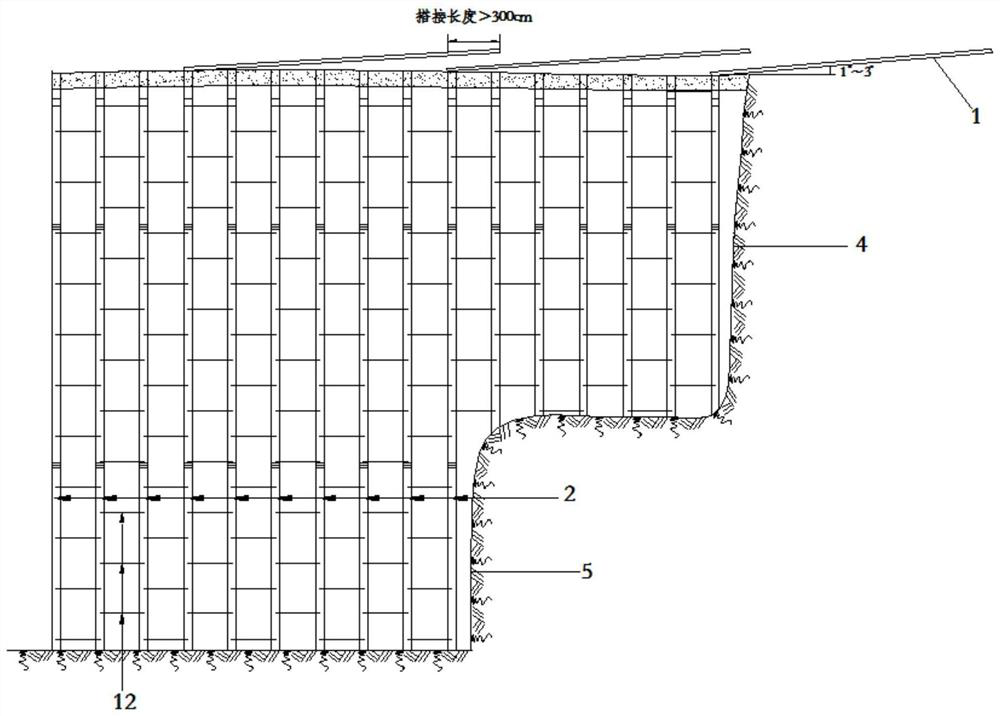

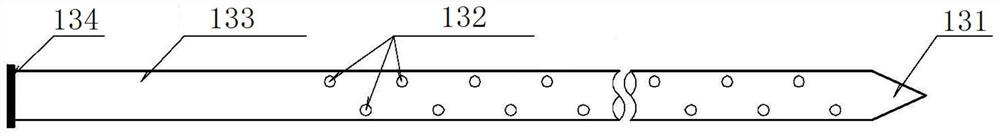

Shallow underground excavation tunnel excavation supporting system and construction method

PendingCN112502746AGood plugging effectPrecise control of inclinationUnderground chambersDrainageSupporting systemPipe

The invention provides a shallow underground excavation tunnel excavation supporting system and a construction method, and relates to the technical field of tunnel engineering. A long pipe shed and asmall guide pipe are adopted for pre-grouting to reinforce an advance support, the long pipe shed and the small guide pipe are arranged for grouting support, so that the reinforcing effect is good, and the grouting quality is easy to control; by arranging a pipe shed orifice guide device with the adjustable inclination and a guide pipe inclination adjusting device which are fixedly installed on asteel arch frame, the inclination and the installation position of the pipe shed and the guide pipe can be accurately controlled, the construction is fat, and the effect is remarkable; and by adoptingwater injection bag grout leaking for temporary plugging and installing a tunnel vault large-size water spraying cavity supporting system, relaxation deformation of surrounding rock can be effectively prevented, the integrity of the vault surrounding rock is improved, and a good blocking and discharging effect on pore water is achieved.

Owner:ANHUI ROAD & BRIDGE GRP

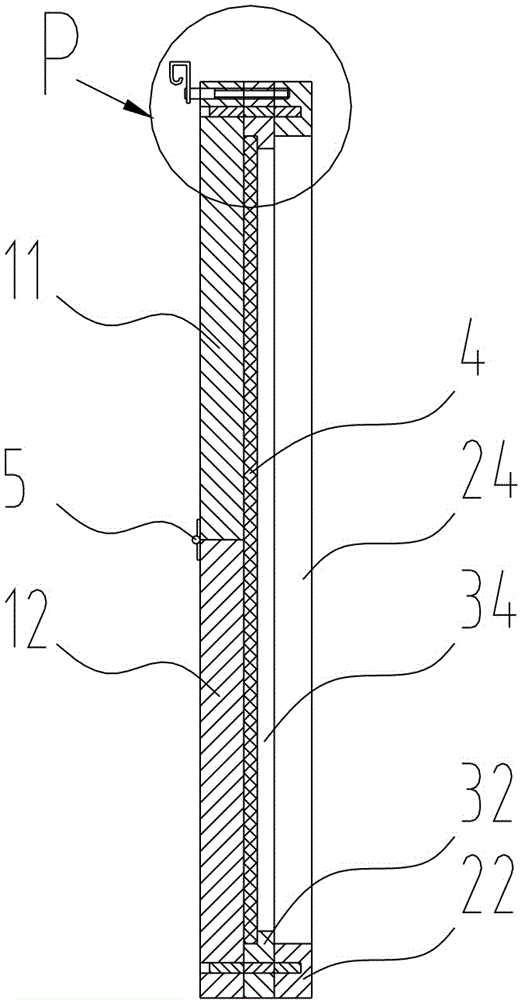

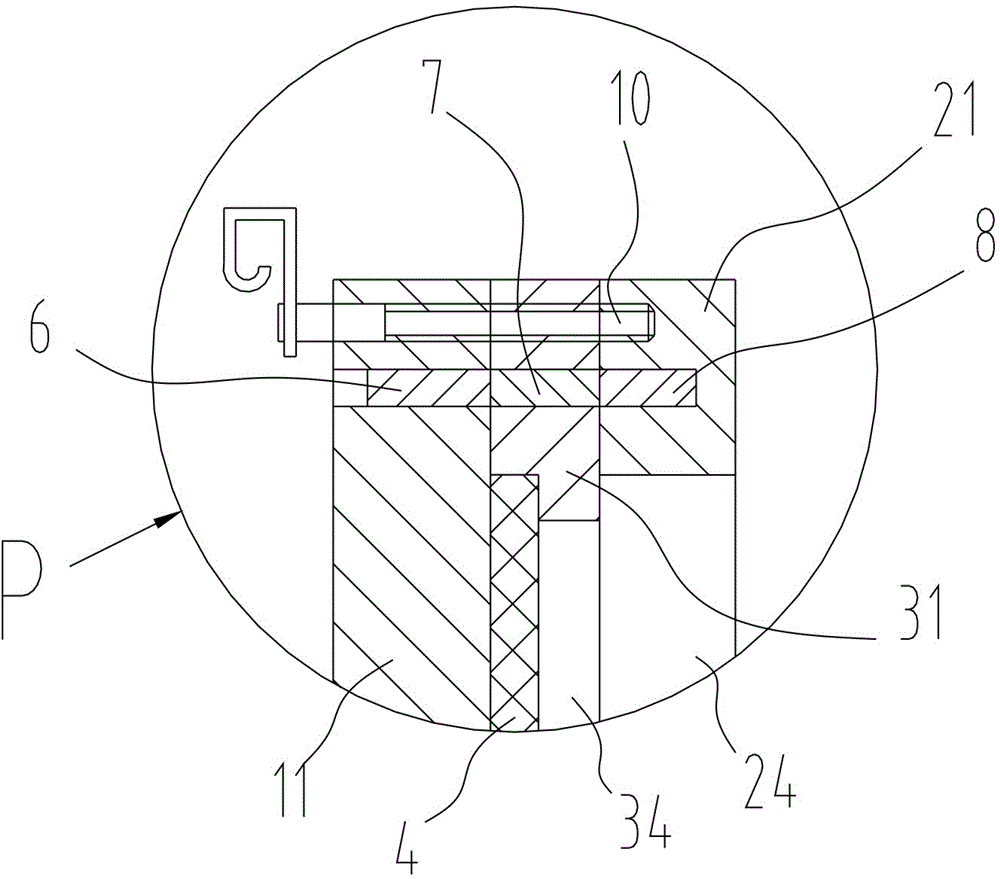

Telescopic clothesline easy to suspend and suspending method of clothesline

InactiveCN105350269ASimple structureEasy to hangTextiles and paperClothes-linesEngineeringClothes line

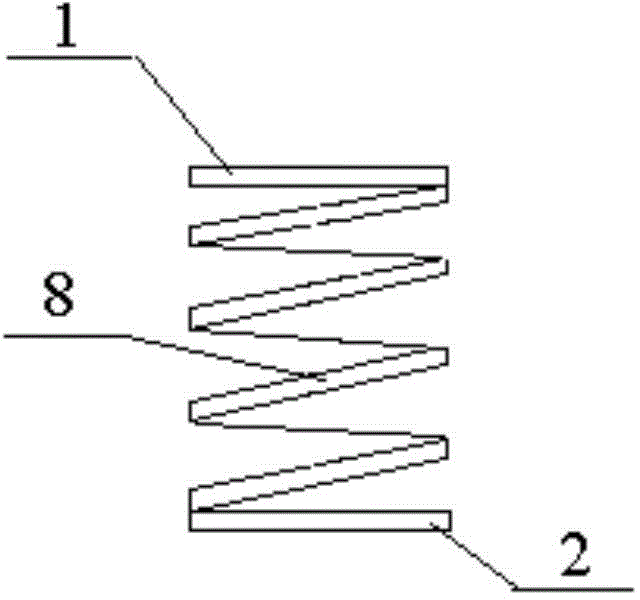

The invention relates to a telescopic clothesline easy to suspend and a suspending method of the clothesline. A spring is arranged on a clothesline body, the clothesline body is glidingly sleeved with multiple rigid sleeves arranged in the same direction, the spring can adjust the overall length of the clothesline, loosening and deformation of the clothesline body are avoided, and the weight bearing capacity of the clothesline body is improved; an insertion section is arranged at one end of each rigid sleeve, a plugging section is arranged at the other end, and the inner diameter of the plugging section is equal to or larger than the outer diameter of the insertion section; during suspension, multiple rigid sleeves can be combined to form a long rigid pipe through plugging matching of the insertion sections and the plugging sections. A user can lift a ring at the end part of the clothesline up to the suspending position for suspension like lifting a rod, and the rigid sleeves can separate a clothes rack. The telescopic clothesline has the advantages of simple structure, convenience and safety in suspension, wide application range, high bearing capability, low probability of loosening and deformation, long service life, low production cost, capability of automatically separating the clothes rack and improving the airing effect of the clothes and the like, and has a very wide market application prospect.

Owner:叶明俤

Device and method for processing large square hay bundle into high-density small square hay bundle

InactiveCN102714990BIncrease initial cut-in pressurePrevent loose deformationBalingCuttersHigh densityMechanical engineering

The invention relates to a hay bundle processing machine and a hay bundle processing method, in particular to a device and a method which can be used for cutting a large square hay bundle into hay slices, conducting secondary compression forming after the hay slices are cut into sections and conducting bundling, section cutting and collection operation to the formed hay bundles. A device for processing a large square hay bundle into high-density small square hay bundles comprises a feeding mechanism, a large square hay bundle slicing mechanism, a hay slice separation and conveying mechanism, a hay slice section-cutting mechanism, a secondary compression mechanism, a bundling mechanism, a formed hay bundle section-cutting mechanism and a formed hay bundle collection mechanism. The device and the method have the advantages that the large square hay bundle can be processed into the high-density small square hay bundles, the final products can be tidily collected and the subsequent operation efficiency is improved.

Owner:CHINA AGRI UNIV

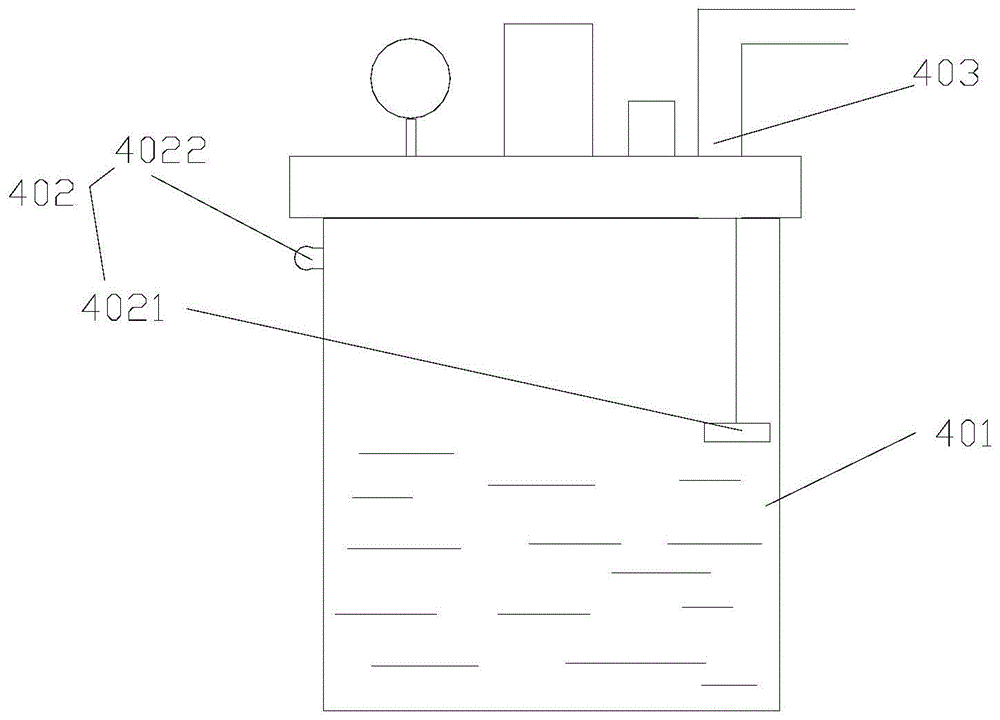

Polyamide granulation system

The invention discloses a polyamide granulation system. According to the technological process, a granulation mechanism, a granulation conveying mechanism and a granulation grading discharging mechanism are sequentially included from front to back; the granulation mechanism comprises a distributing device and a transmission device; the granulation conveying mechanism comprises a conveying device, and conveys granules flowing out of the granulation cylinder; a plurality of automatic spraying devices are arranged on one side of the conveying device, and a waste gas collection device is arranged above the conveying device; the waste gas collection device comprises an air draft device and a ventilation channel; and the granulation grading discharging mechanism comprises a scraper, a sieve, a discharging hopper, an air blower, a separating device, a discharging pipe, a floccule collecting device and a second multi-way pipe. Mounting flexibility of a motor can be improved, the impurity rate of a product obtained after granulation is reduced, and the system has the advantages of having the grading function, being capable of carrying out proper cooling, exhausting organic waste gas in time, and ensuring normal operation of a leveling plate.

Owner:ANQING HONGTAI NEW MATERIAL

A polyamide production system

Owner:ANQING HONGTAI NEW MATERIAL

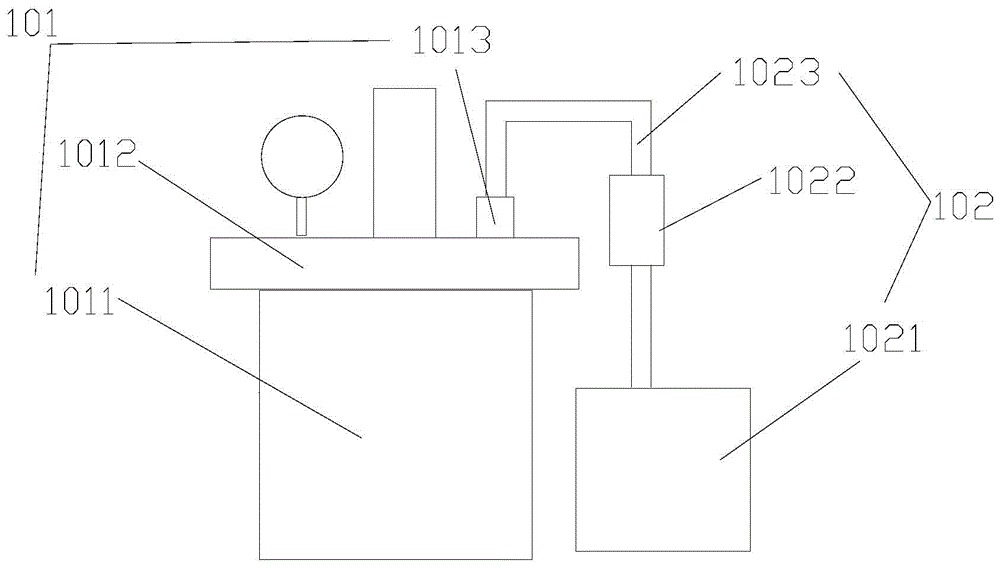

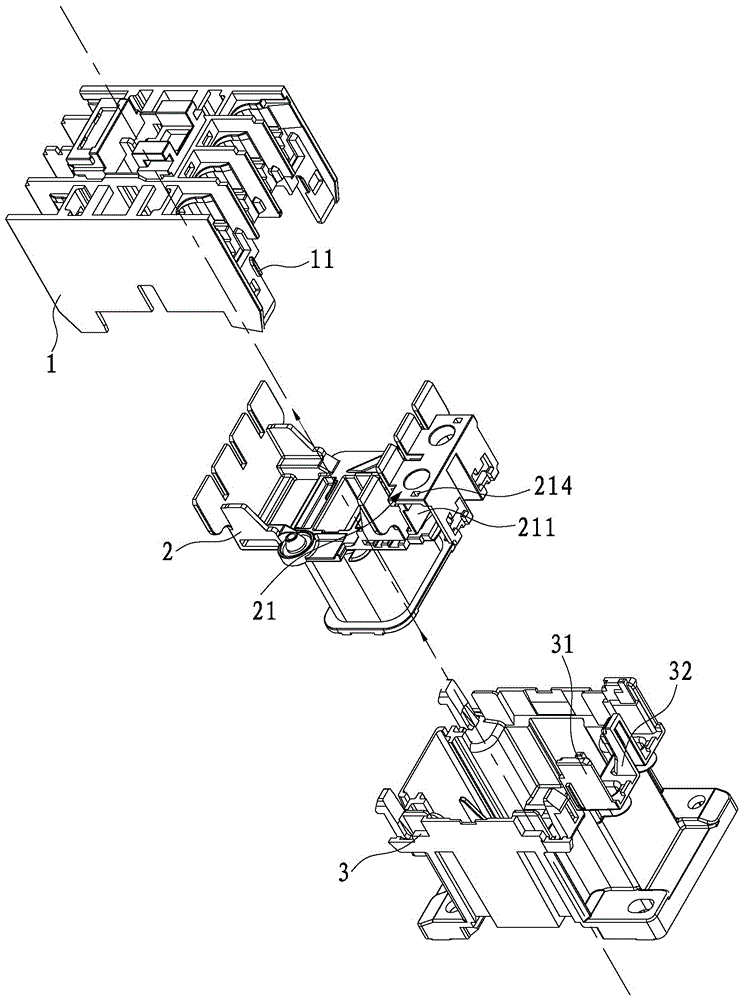

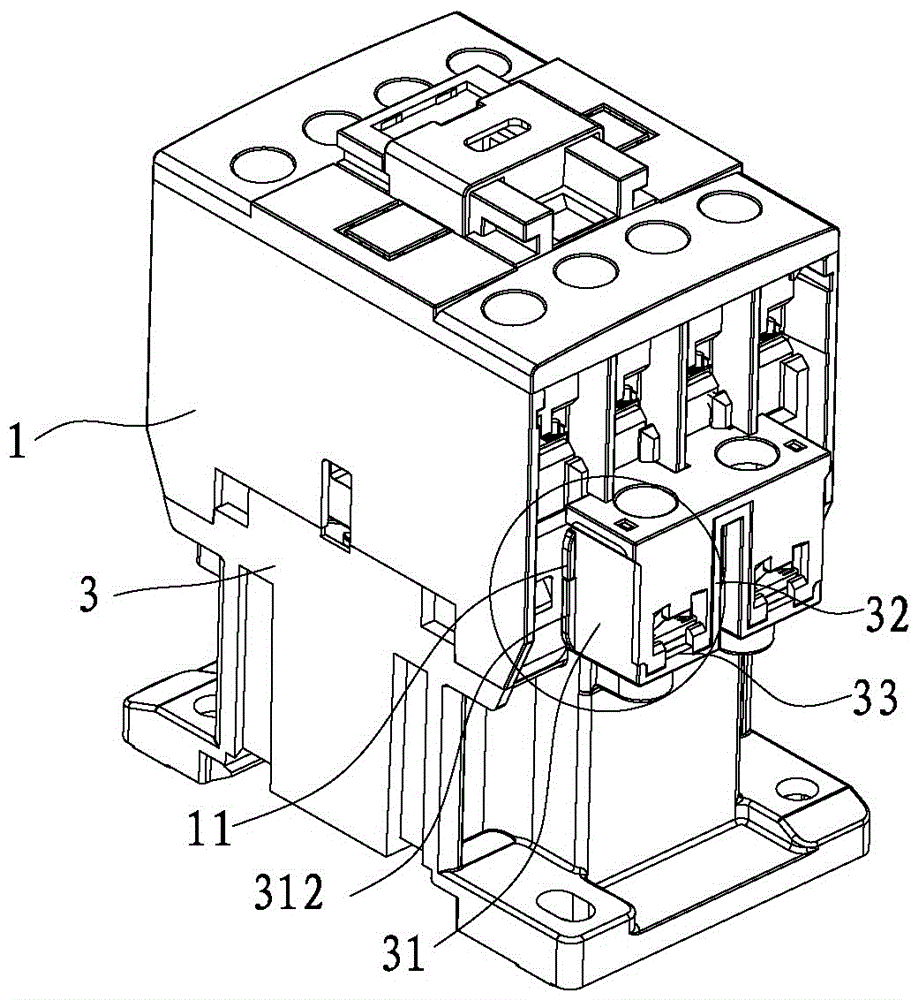

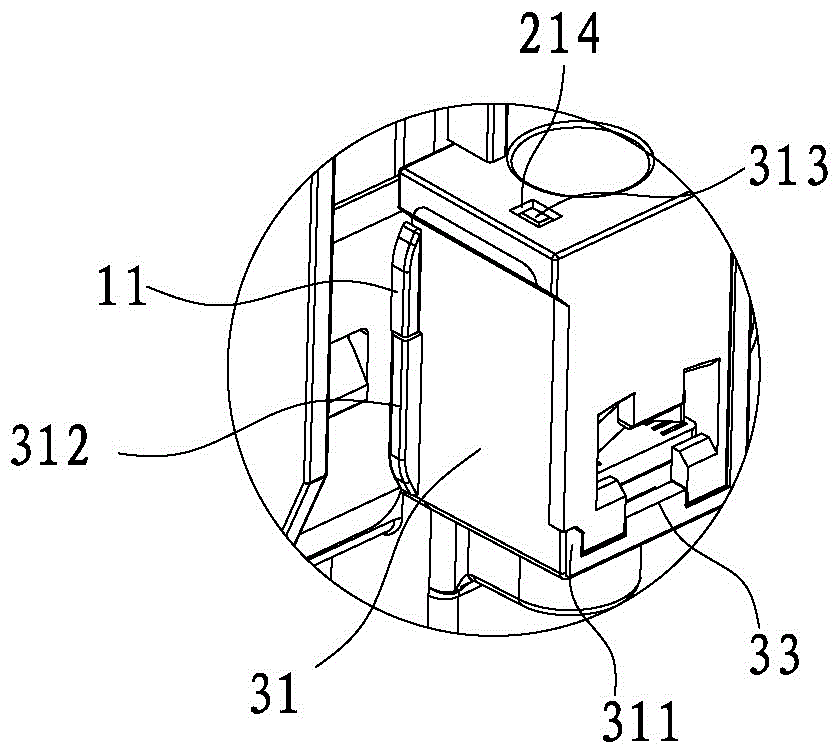

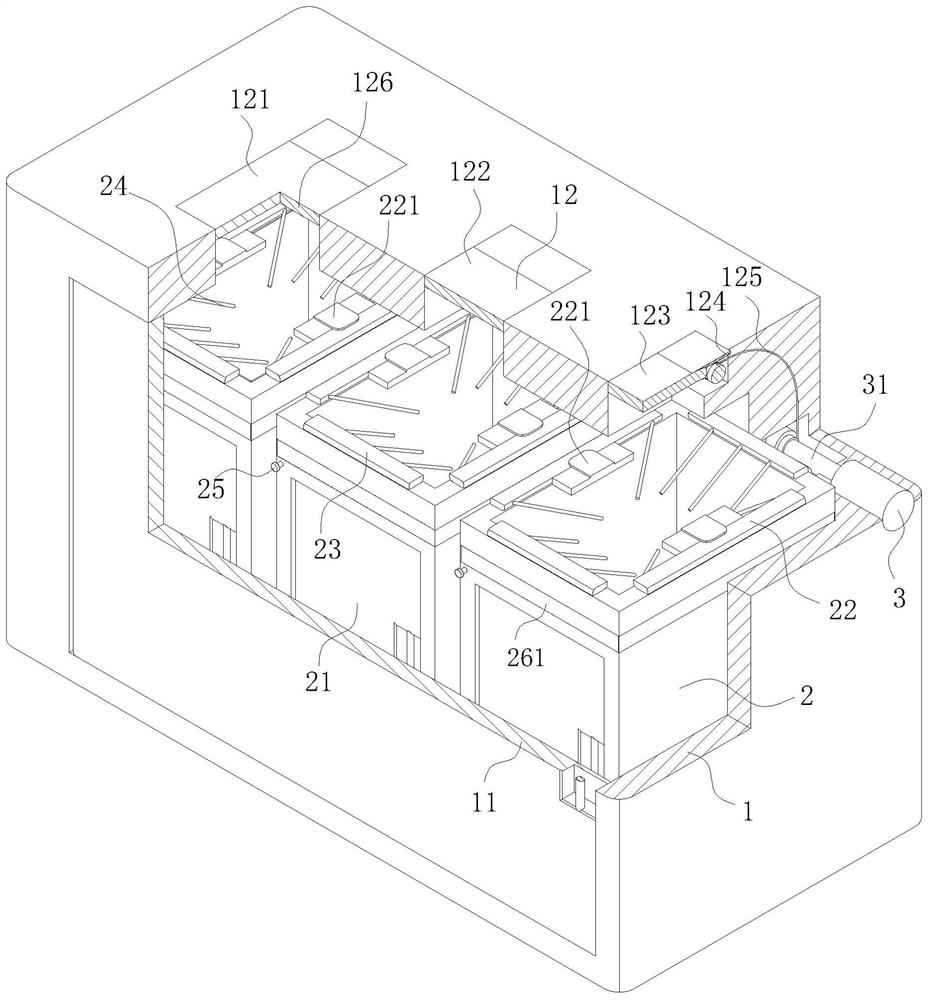

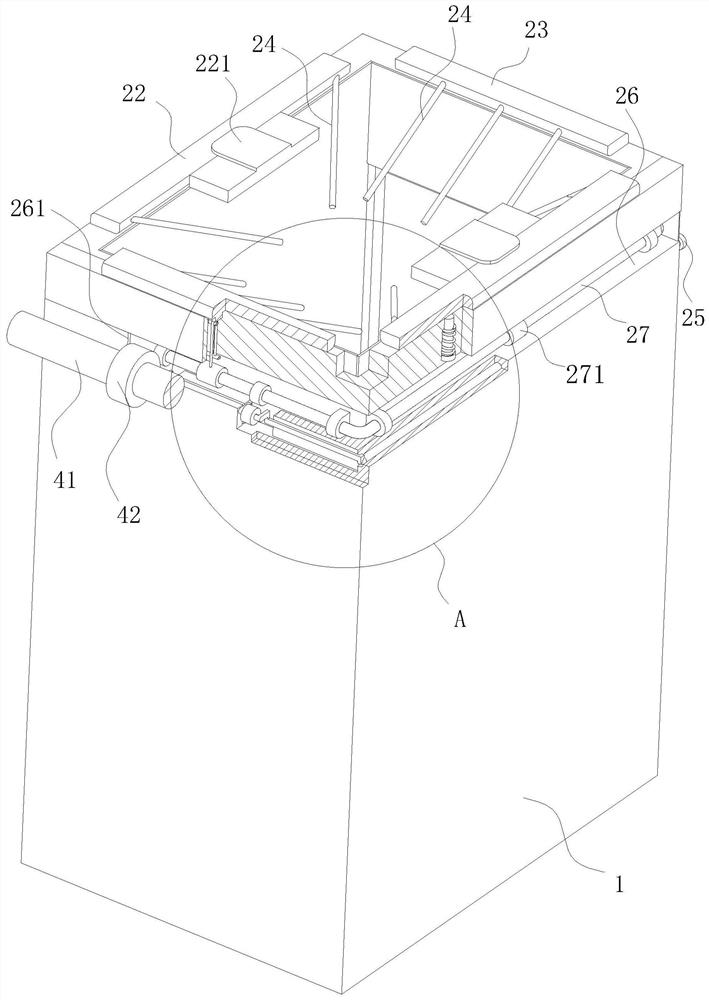

A kind of anti-loosening structure

ActiveCN104078282BPrevent looseningPrevent loose deformationElectromagnetic relay detailsProtective switch terminals/connectionsEngineeringMechanical engineering

The invention discloses an anti-disengaging structure which comprises a body, a coil frame and a base. The coil frame is installed in the body, and a containing cavity with an opening in one side is formed in the coil frame. A first clamping plate and a second clamping plate are formed on the base, the body is installed on the base, the containing cavity is clamped between the first clamping plate and the second clamping plate, the first clamping plate is clamped in the opening, and the first clamping plate and the second clamping plate clamp the containing cavity. A clamping groove is formed in the side wall of the opening, a clamping block is formed on the first clamping plate, and the clamping block is clamped in the clamping groove. By means of the anti-disengaging structure, the containing cavity can be prevented from disengagement and deformation, and a wiring terminal conductive metal plate is effectively prevented from disengagement.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

Indoor intelligent classification garbage can

InactiveCN112499013AAvoid time-consuming cleaningPrevent leakageWaste collection and transferRefuse receptaclesResource recoveryStructural engineering

Owner:安徽妮可威家居用品有限公司

Horn vibrating piece sewn into wires and manufacturing method thereof

ActiveCN109391879BImprove bindingPrevent loose deformationNon-planar diaphragms/conesDiaphragm extensionsWire cuttingEngineering

The present invention provides a horn vibrating reed sewn into a wire and a method for sewing a wire into a horn vibrating reed. The method comprises a preparation step a sewing step, a wire cutting step, a hot compacting step and a cutting step. The method produces a plurality of horn vibrating reed sewn into wires through the steps, each horn vibrating reed comprises: one body, wherein the center position of the body is provided with a punching hole, and the body is provided with a wave portion; at least one metal wire continuously sewn at the wave portion of the elastic wave body; and at least one sewing thread continuously sewn at the wave portion of the elastic wave body and connected in an interweaving mode with the metal wire to form a plurality of fixed structures. Therefore, the horn vibrating reed sewn into the wire and the method for sewing the wire into the horn vibrating reed can effectively avoid the conditions of deformation, loosening or cracking of the metal wire afterlong-term vibration and can avoid the condition of unbalance vibration due to malposition when the metal wire and the horn vibrating reed are combined.

Owner:大原博

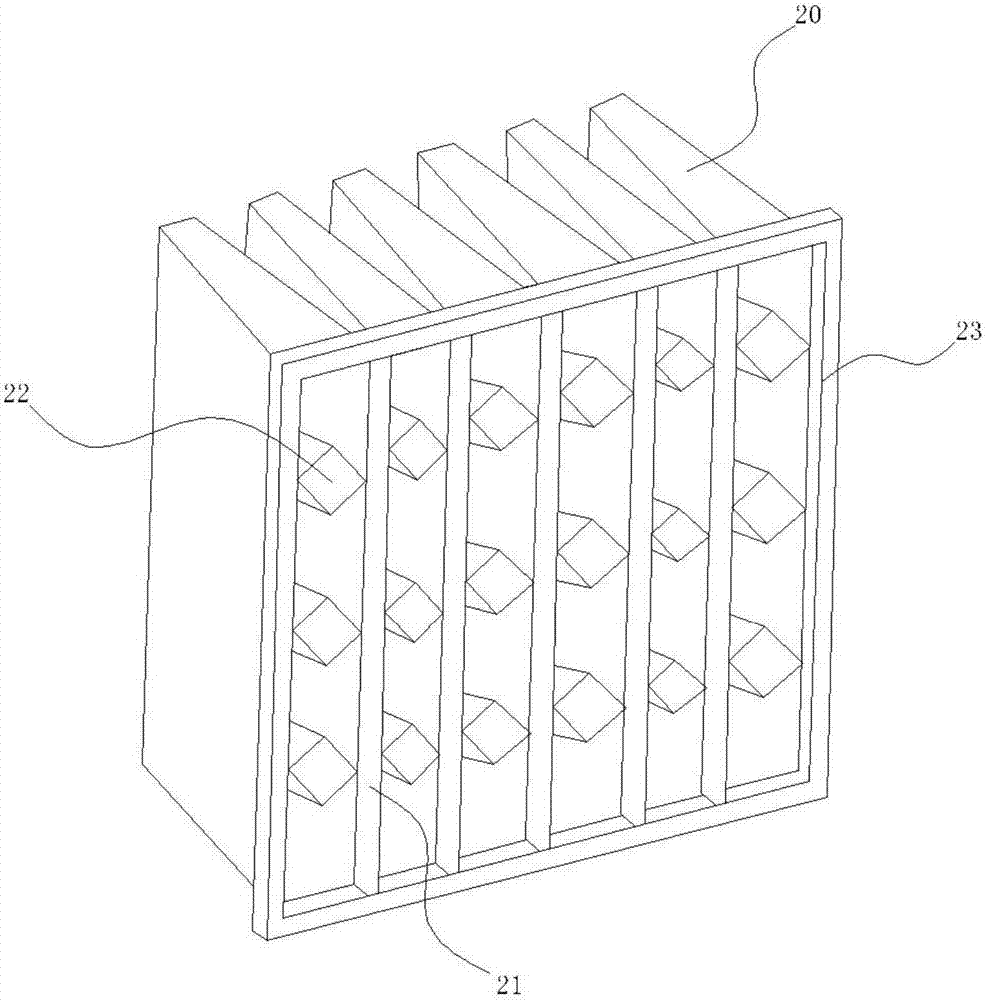

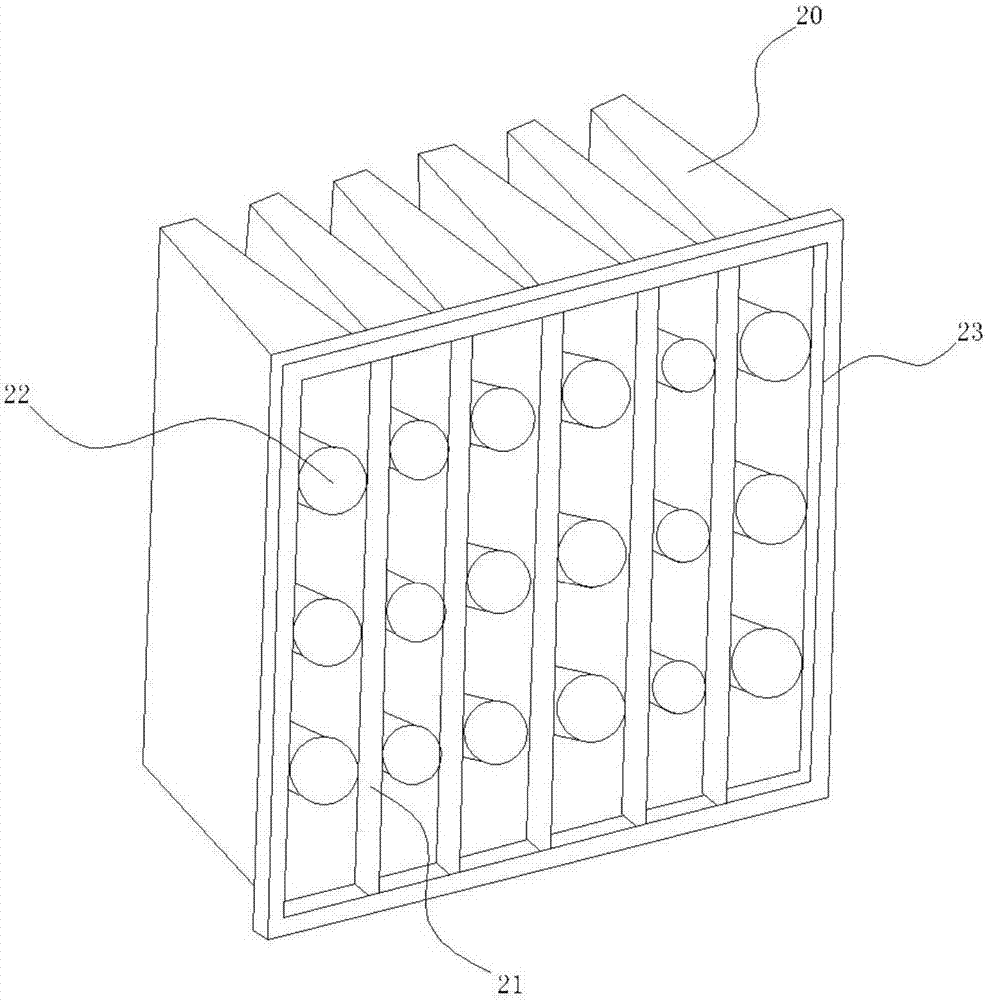

Filter and air conditioner comprising same

ActiveCN107569936APrevent loose deformationTake advantage ofDispersed particle filtrationLighting and heating apparatusFiberEngineering

The invention provides a filter and an air conditioner comprising the same. The filter comprises a frame and a filter bag arranged on the frame. The frame is provided with a fixed bar. The filter bagis arranged on the fixed bar. A supportive pocket is arranged in the filter bag. The filter bag is made of mixed fibers. The provided filter and air conditioner have the advantages that the supportivepocket in the filter bag can support the filter bag, the filtering area can be fully utilized, the filter bag will not become loosen and deformed when the wind direction changes, the dust in the filter bag will not be blown out, and the dedusting is not needed for the equipment arranged in the air outlet therefore.

Owner:广州洁诺净化设备有限公司 +1

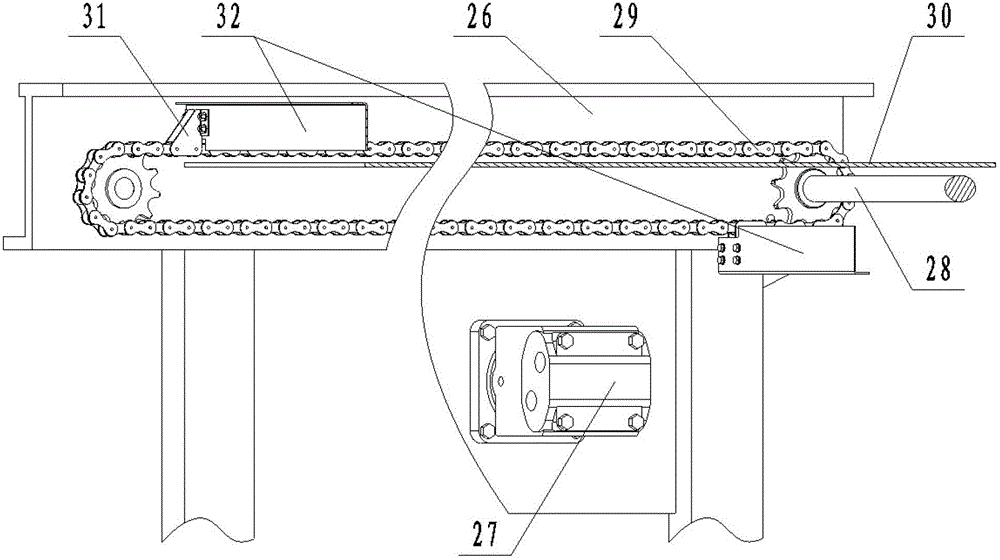

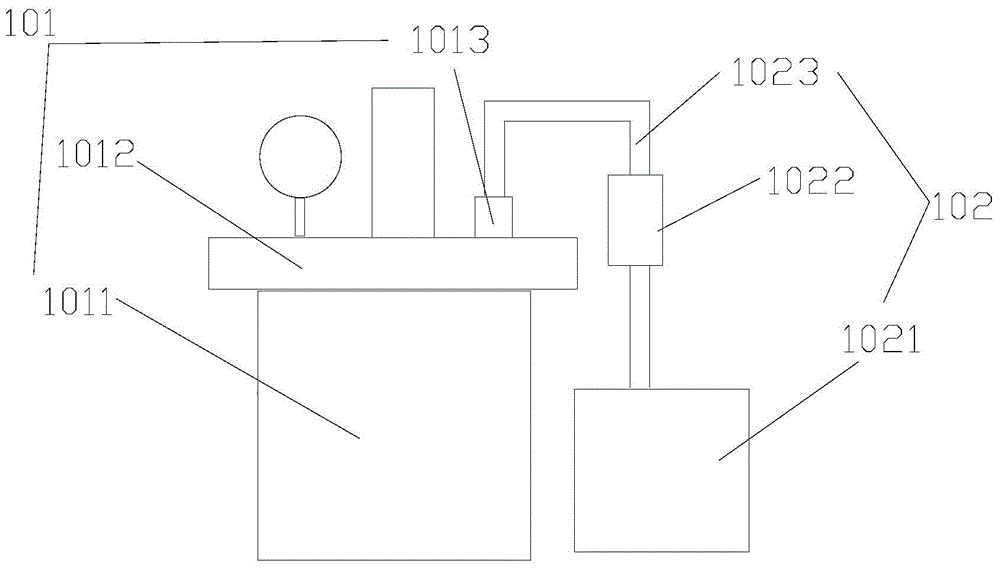

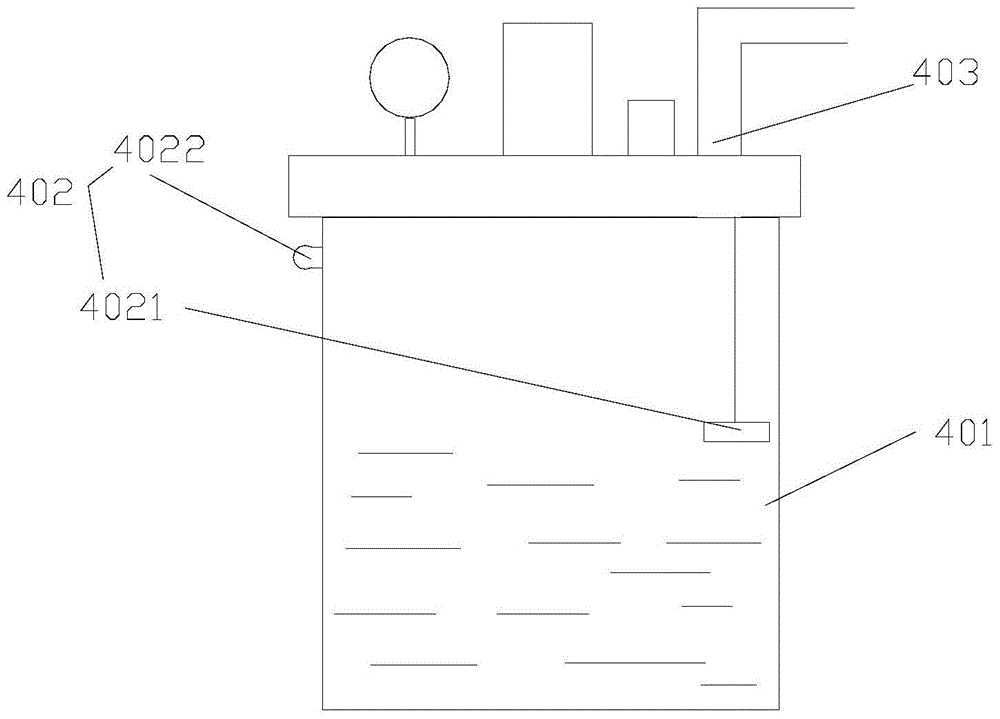

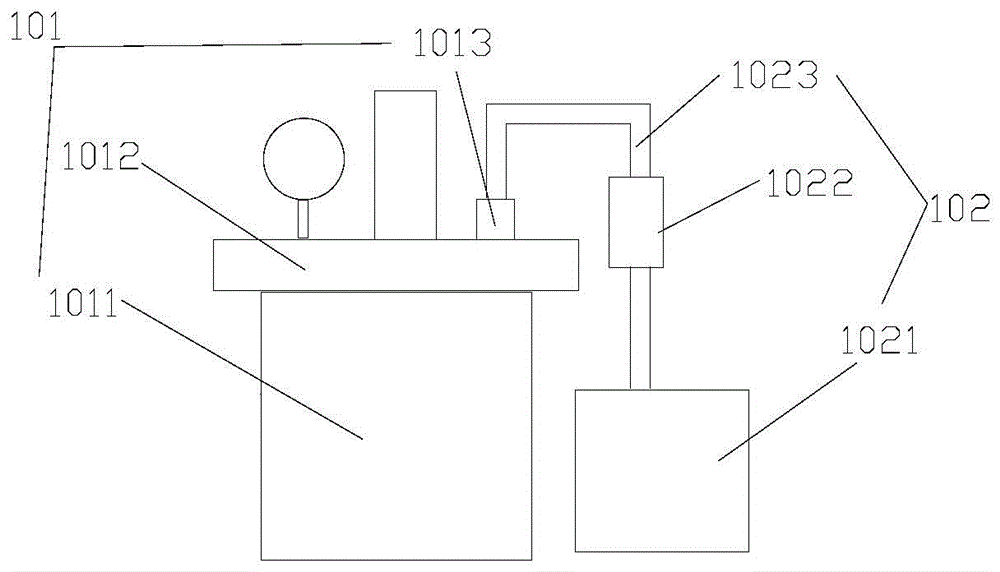

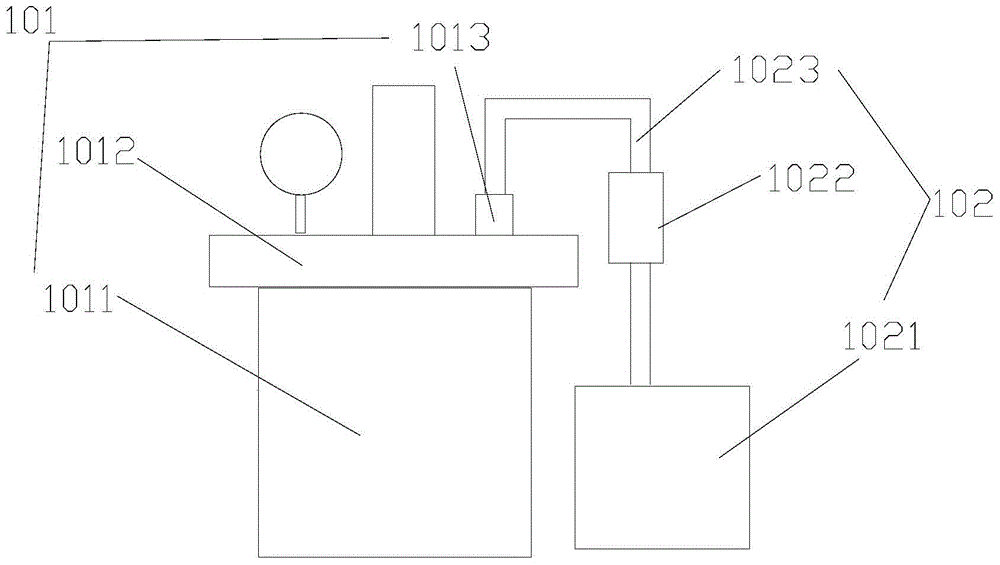

Granulation mechanism of polyamide production system

InactiveCN104960105AIncrease flexibilityPrevent loose deformationGearingDirt cleaningEngineeringMechanical engineering

The invention discloses a granulation mechanism of a polyamide production system. The granulation mechanism comprises a distributing device, a transmission device and an air drafting device arranged above the distributing device. The distributing device comprises a granulation tube and a grain cutting device. The grain cutting device comprises a grain cutter and a transmission shaft, the grain cutter is sleeved with the transmission shaft, a body part of the transmission shaft is contained inside a cavity of the granulation tube, and the two ends of the transmission shaft extend out of the cavity of the granulation tube. Multiple material holes arrayed regularly are formed in the bottom of the granulation tube, a feeding port is formed in the top of the granulation tube, and the material holes, the feeding port and the cavity are communicated with one another. The transmission device comprises a motor, a first gear, a second gear and a chain. The first gear and the second gear are sleeved with the chain, an output shaft of the motor is connected with the first gear, and the second gear is connected with the end of the transmission shaft. The granulation mechanism has the advantages that the installing flexibility of the motor can be improved, and organic waste gas can be purified in due time.

Owner:ANQING HONGTAI NEW MATERIAL

A hose storage device for a fire hydrant

ActiveCN111514500BPrevent loose deformationAvoid windingFire rescueElectric machineryWorking environment

Owner:广东爱得威建设(集团)股份有限公司

A polyamide production system and production method thereof

Owner:ANQING HONGTAI NEW MATERIAL

Frame for easy disassembly and transportation

The invention provides a picture frame convenient to disassemble, assemble and transport. The picture frame convenient to disassemble, assemble and transport comprises a rectangular bottom plate, a border assembly and a frame pressing assembly which is located between the bottom plate and the border assembly, and a first magnet set is arranged on the periphery of the surface of the bottom plate; the frame pressing assembly comprises four independent pressing plates, each pressing plate is provided with a second magnet set, and the four pressing plates are in magnetic connection with the bottom plate by attraction force between the second magnet sets and the first magnet set; the border assembly comprises four independent borders, and the four pressing plates are pressed by the four borders respectively. According to the picture frame convenient to disassemble, assemble and transport, calligraphy and painting mounting can be achieved rapidly, and by means of the magnetic attraction force of the first magnet set and the second magnet sets, position locating of each pressing plate on the bottom plate can be completed automatically; during disassembly, the pressing plates are manually removed only, no tool is needed, and disassembly is facilitated greatly. The border assembly comprises the four independent borders, and therefore during transportation, the four borders and the four pressing plates are convenient to transport.

Owner:周巧

A polyamide processing device

The invention discloses a polyamide processing device. The polyamide processing device comprises a polycondensation device, a filtering device and a pelleting system sequentially from front to back according to a technical process. The polycondensation device comprises a polycondensation reactor, a dropping device, a first pipe bundle condenser and a first gas guiding pipe. The filtering device comprises a filter, a second feeding pipe, a first discharging pipe and an oil pipe. The pelleting system comprises a pelleting mechanism, a pellet conveying mechanism and a pelleting graded discharging mechanism sequentially from front to back according to the technical process. The polyamide processing device has the advantages of high processing efficiency and processing safety and low product impurity rate.

Owner:ANQING HONGTAI NEW MATERIAL

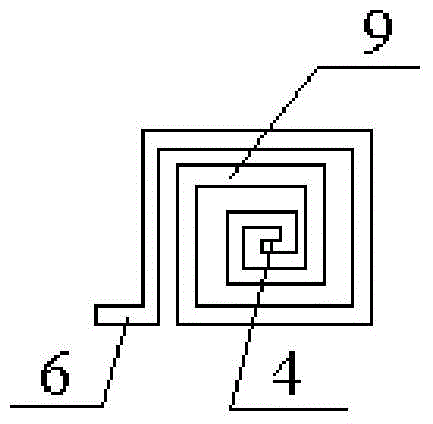

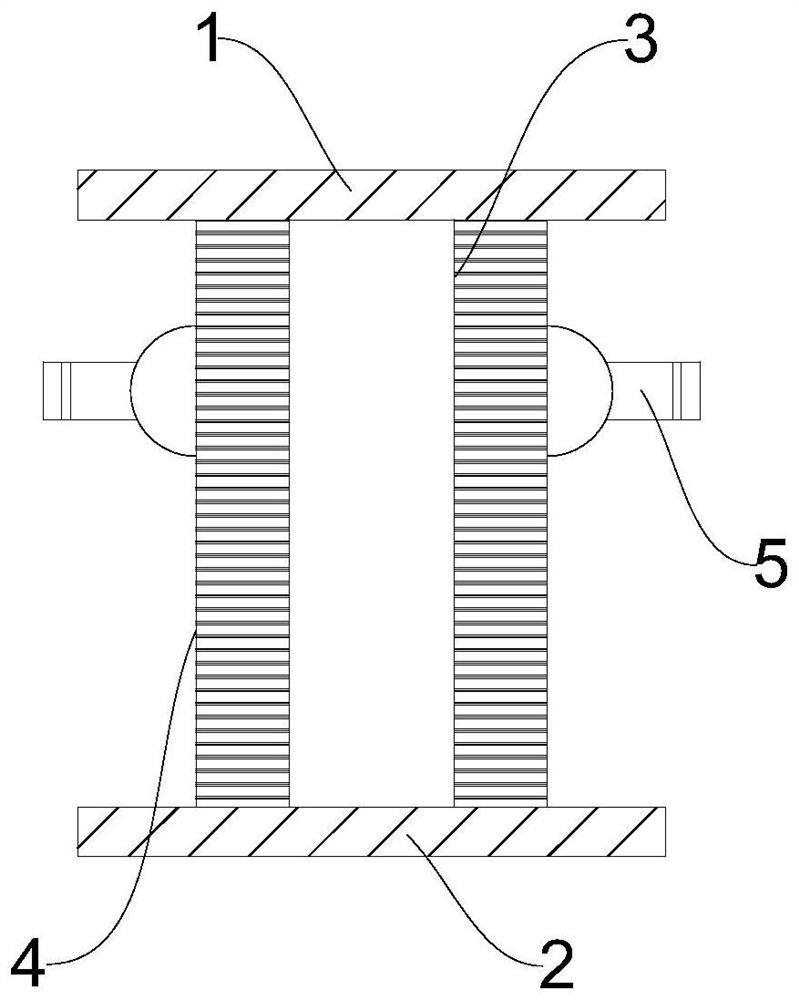

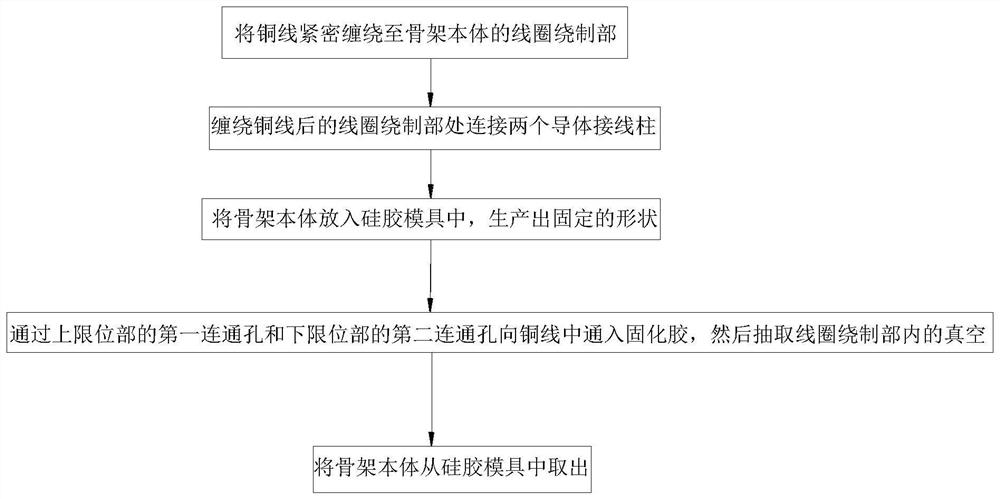

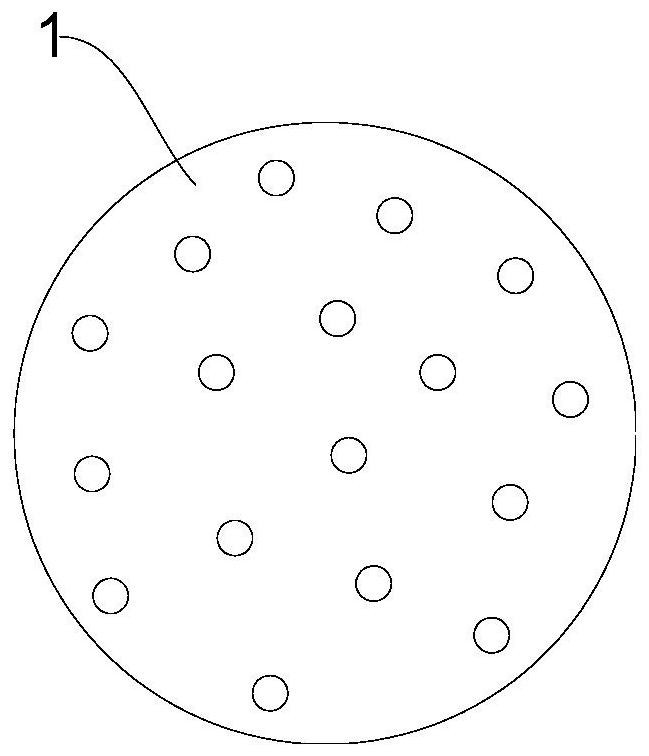

Centered electromagnetic coil and preparation method thereof

ActiveCN113257537ANo looseningPrevent water from getting wetTransformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorCopper wire

The invention provides a centered electromagnetic coil and a preparation method thereof. The invention relates to the technical field of electromagnetic coils. According to the scheme, on one hand, the centered electromagnetic coil comprises a framework body; an upper limiting part and a lower limiting part are arranged at the two ends of the framework body respectively; the framework body is provided with a coil winding part used for winding the electromagnetic coil; and the coil winding part is connected with copper binding posts; and on the other hand, the preparation method of the centered electromagnetic coil comprises the following steps that a copper wire is tightly wound to the coil winding part of the framework body; the coil winding part wound with the copper wire is connected with two conductor binding posts; and the framework body is placed in a silica gel mold to obtain a fixed shape. On one hand, binding and fixing of the copper wire can be omitted, and the labor cost and the time cost are reduced; and on the other hand, silica gel mold opening and glue injection curing are achieved, and the mold cost is low.

Owner:葛连志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com