Belt tensioning device

A technology of tensioning device and belt, applied in transmission device, belt/chain/gear, transportation and packaging, etc., can solve the problems of difficult adjustment, abnormal noise adjustment, and large friction, so as to reduce labor intensity and improve work efficiency. Efficiency, the effect of preventing loosening and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further clarified below in conjunction with specific drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

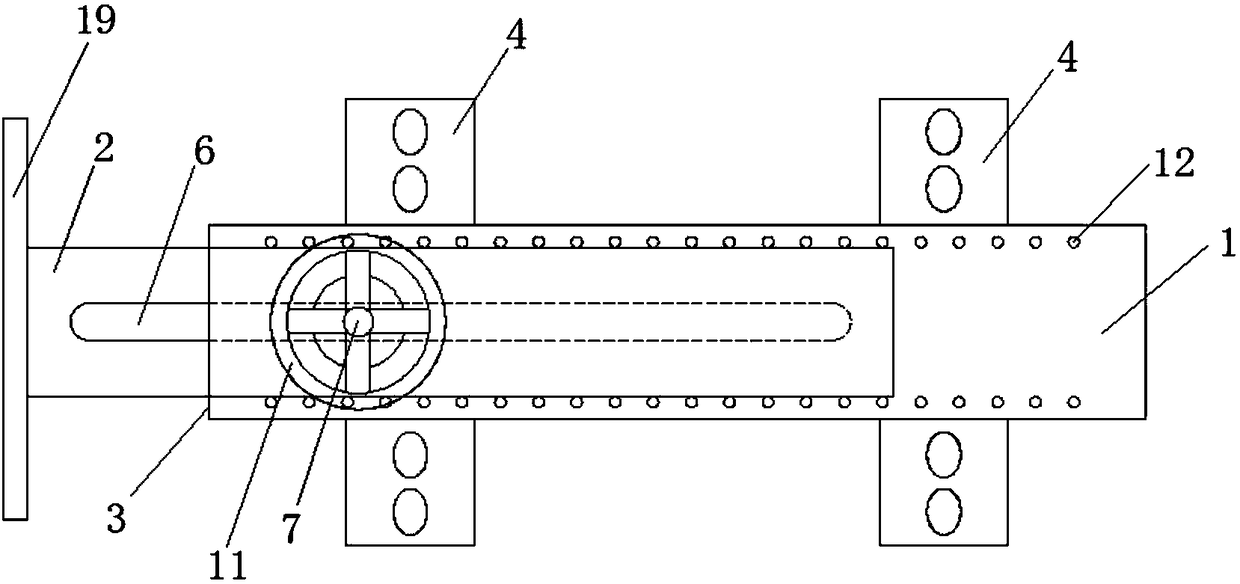

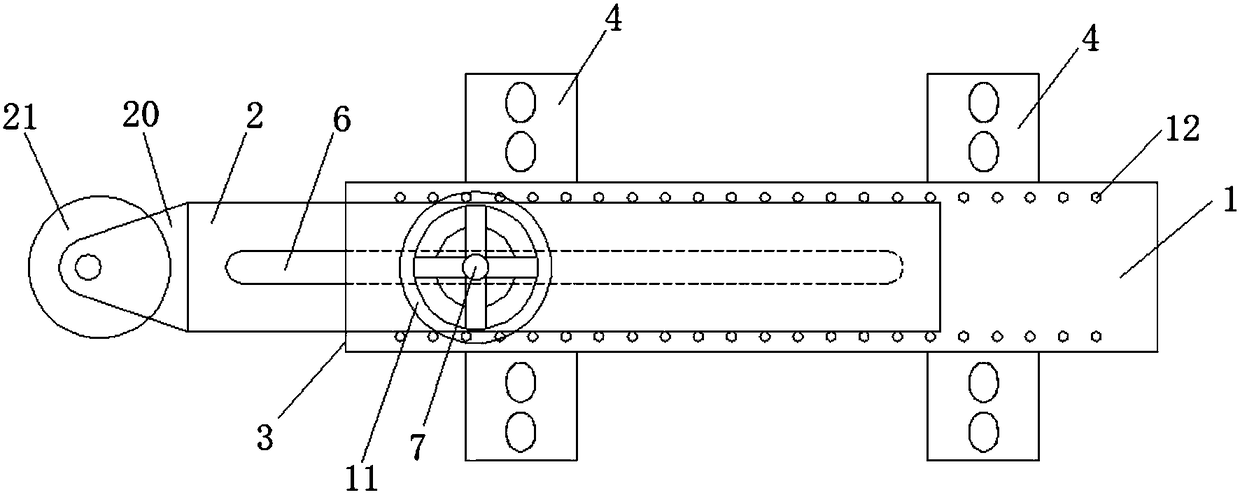

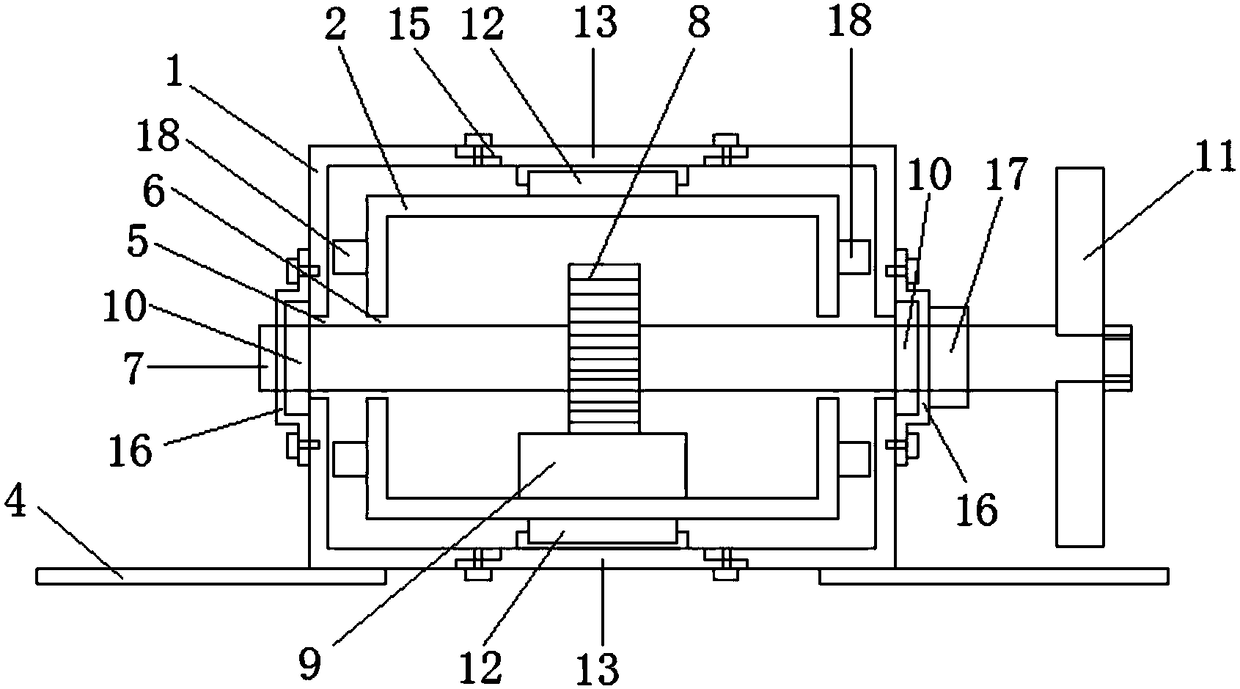

[0024] Such as Figures 1 to 4 As shown, the embodiment of the present invention provides a belt tensioning device, which includes a housing 1 and an inner sleeve 2, the left side of the housing 1 has an opening 3, and the interior is hollow, preferably in a square barrel structure, on the bottom side of the housing 1 A mounting base 4 is fixed, and the mounting base 4 is used to fix the device on the frame of the belt conveyor. The inner sleeve 2 is also a square barrel-shaped structure, the right end of the inner sleeve 2 passes through the opening 3 on the left side of the outer shell 1, and goes deep into the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com