Polyester linen-like fabric production process

A production process and fabric technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of polyester linen-like fabric pulling deformation, polyester linen-like fabric loose deformation, uneven cutting incision, etc., to avoid loose deformation , improve quality, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

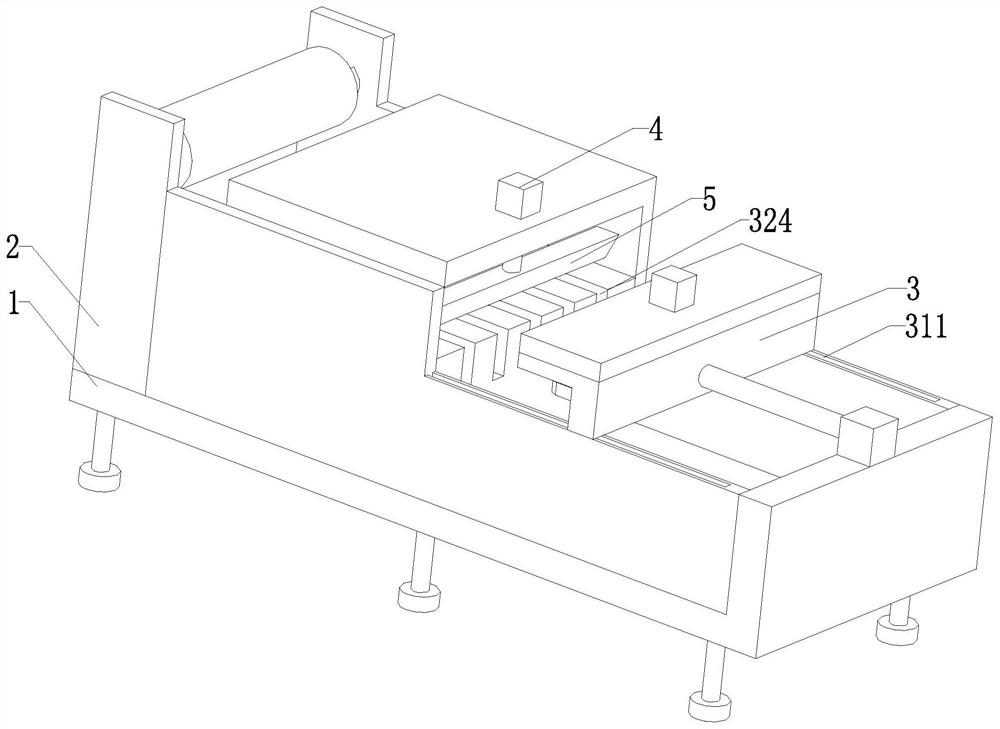

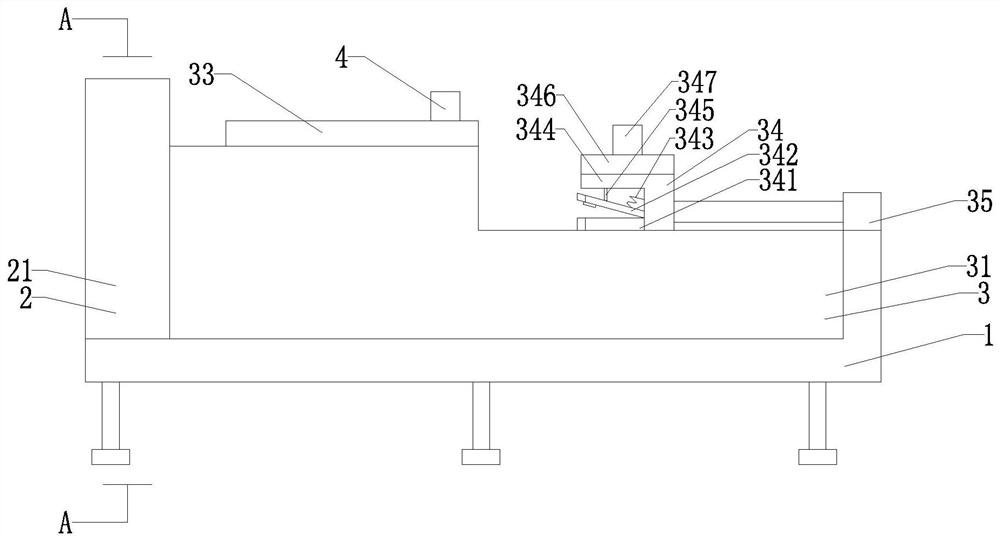

[0035]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

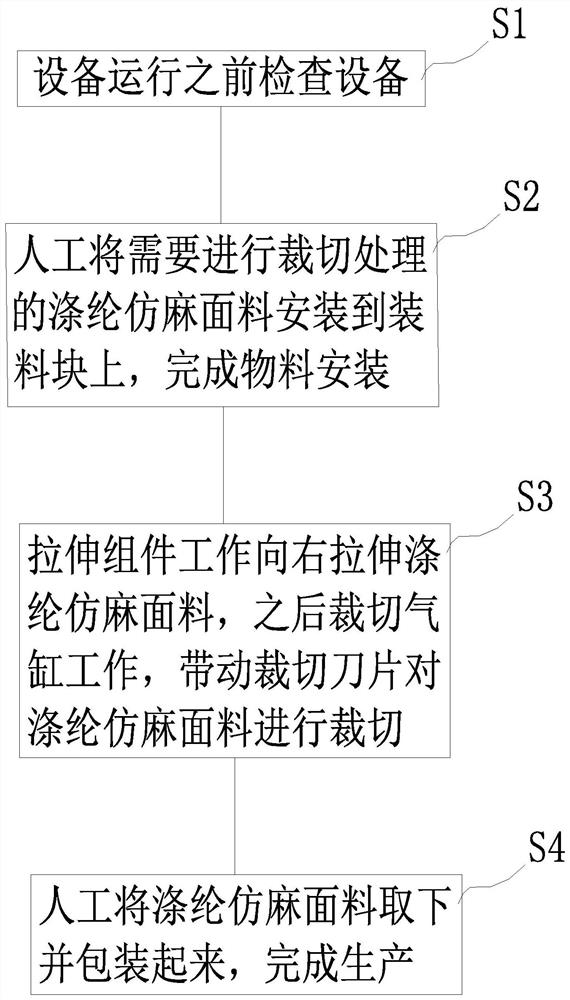

[0036] See figure 1 , A polyester, ruts production process, mainly including the following steps:

[0037] Step 1: Equipment check: The operation of the polyester imitation ruthenium cutting equipment is checked before the polyester imitation ribbon cutting equipment;

[0038] Step 2: Fabric installation: Artificial will need to cut the polyester ruts to the loading block 2, thereby completing the fabric installation operation;

[0039] Step 3: Topping: After completing the fabric installation operation, the fabric is stretched on the right side, and then drive the cutting blade 5 on the stealing cylinder 4. The fabric is cut;

[0040] Step 4: Collect packaging: After completing the stretching homework, manually take the polyester emulata fabric that cut the cut into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com