Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Minimum of equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

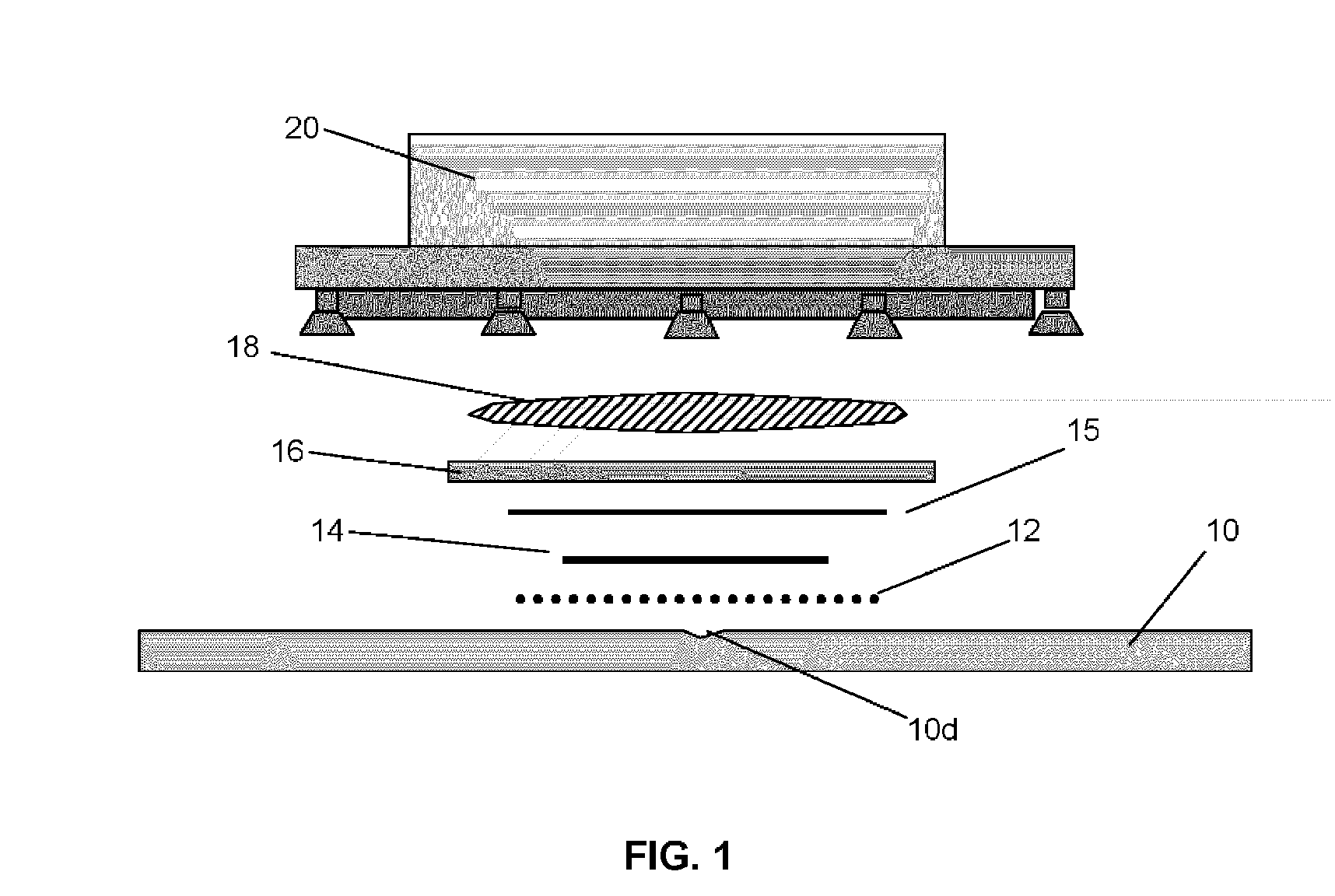

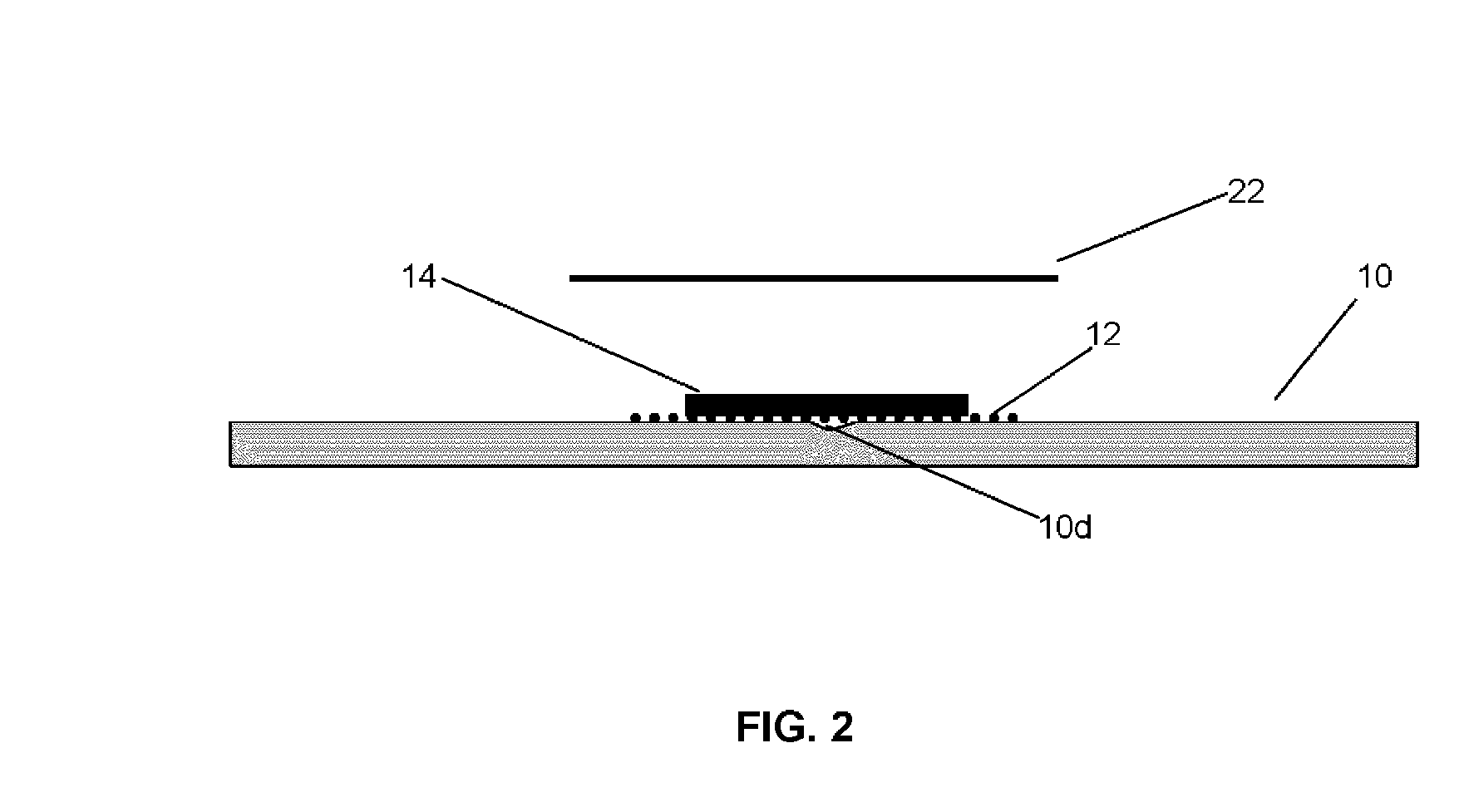

Fast line maintenance repair method and system for composite structures

InactiveUS20070095457A1Minimum skillQuick fixLighting and heating apparatusLayered productsAdhesiveRepair material

A fast line maintenance repair process for damaged composite structures includes the application of a pre-cured patch that uses a quick curing paste adhesive to bond the patch to the structure. The adhesive is cured at relatively low elevated temperatures provided by a chemical heat pack. The low temperature cure eliminates the need to dry out the part and permits the application of the repair in a hazardous environment. In a typical commercial airline application, airline maintenance personnel can install the repair at the flight gate. The repair is intended to restore the structure to a desired load capability in approximately one hour. The repair can be removed if need be with less overall damage than would occur upon removal of typical mechanically fastened repairs. All or some of the repair materials and tools can be provided in a portable kit.

Owner:THE BOEING CO

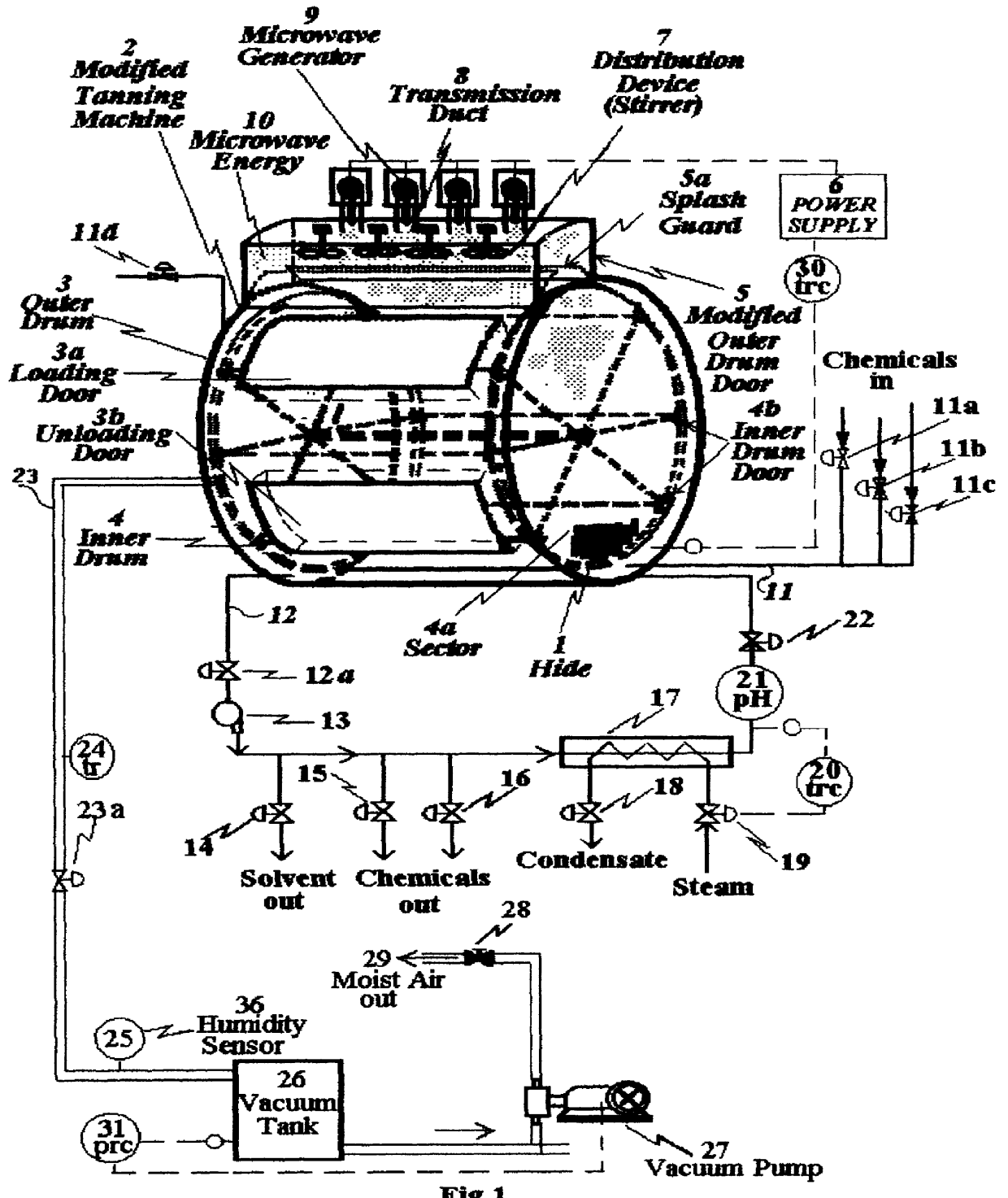

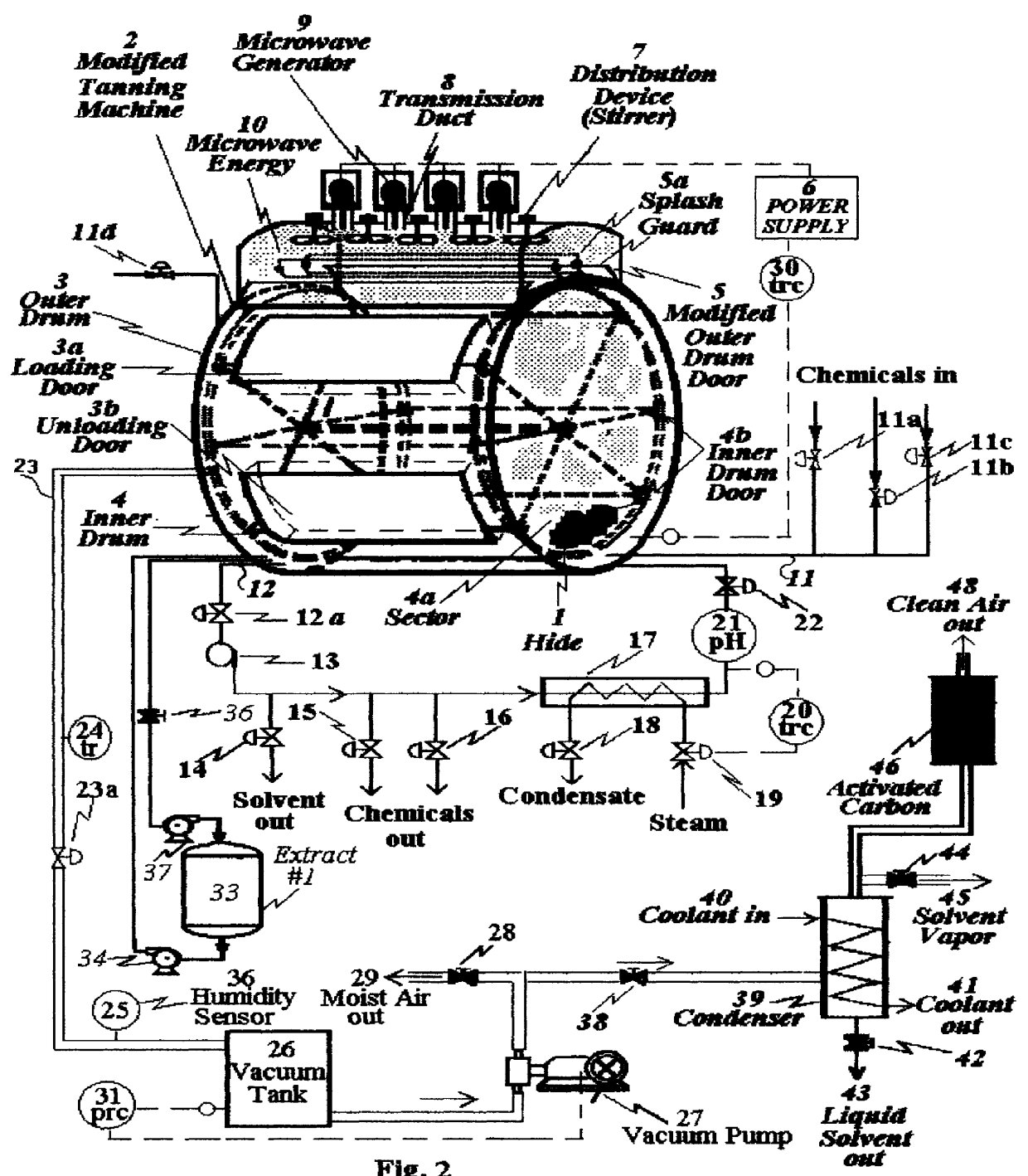

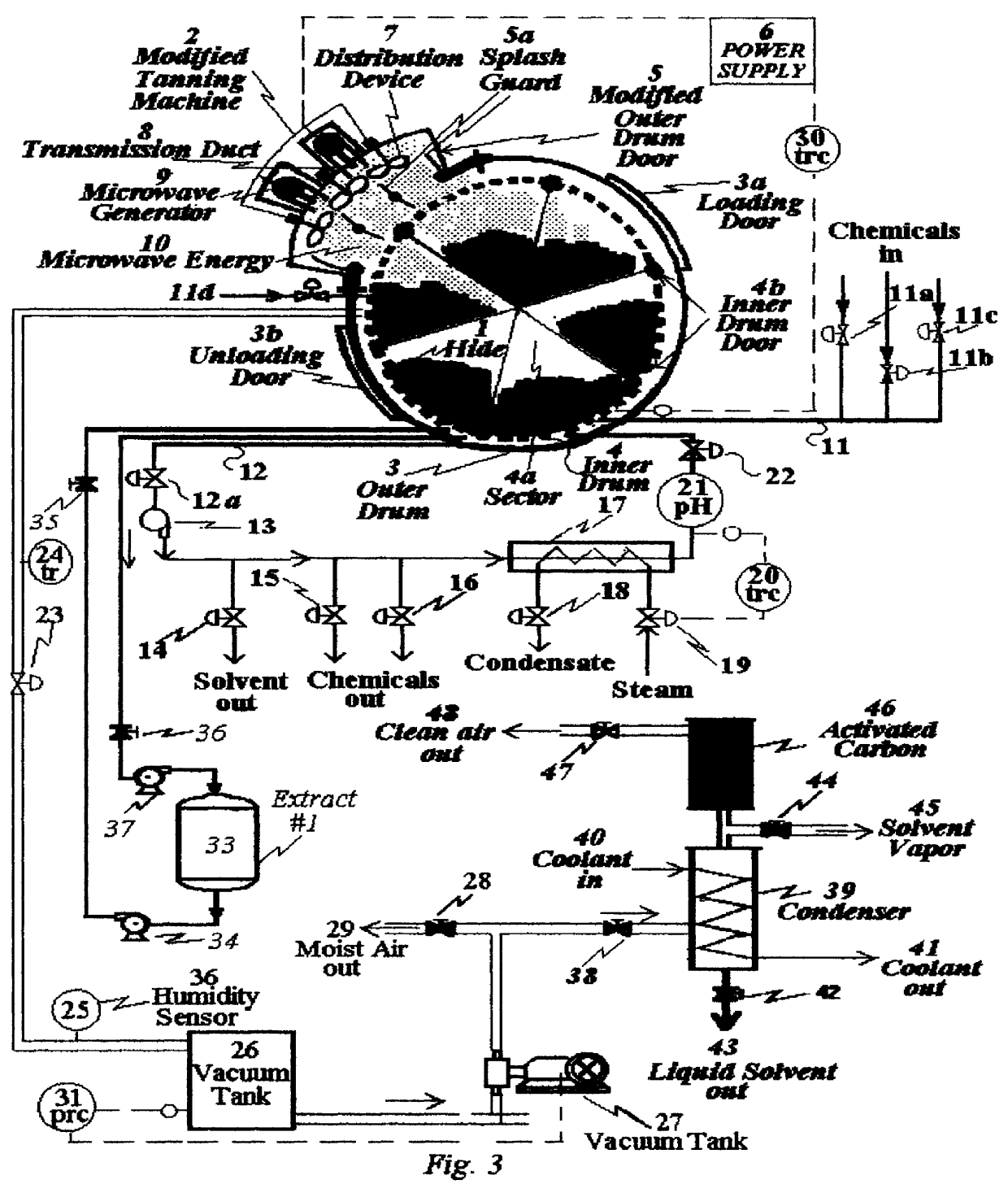

Microwave drying of hides under vacuum in tanning equipment

InactiveUS6092301AHigh market valueQuality improvementDrying solid materials with heatDrying solid materials without heatWater contentSolvent

By providing a hide processor or tanning drum with appropriate equipment for applying vacuum and microwave energy concurrently, these tanning machines become a versatile means of drying to yield dry hides that contain no salt yet store better than salted hides. In this novel process, fresh hides are loaded into the tanning machine where they are washed, demanured and then dried in situ under vacuum with concomitant application of microwave energy. Because the dried hides thus obtained are soft and pliable, they can be mechanically fleshed or shaved to remove the subcutaneous tissues rich in collagen and fat. Alternatively, the hides may be first dried in the tanning machine to below 35% moisture content and degreased using a solvent such as hexane. The solvent remaining in the hides after decantation of the unabsorbed liquid is vaporized at low temperature using vacuum and microwave energy. The hides are then dried in situ to the desired final moisture content. By shaving off the subcutaneous tissues of these hides a dry, fat-free, valuable undenatured collagen product is obtained. If the hides are unhaired before drying, they may be shaved and then accurately split. The process is also suitable for removing hair and fat from hide trimmings to obtain a valuable undenatured collagen product and fat. Furthermore, it can be used to remove fat from connective tissues and other animal offal containing no hair yielding a dry undenatured collagen product.

Owner:KOMANOWSKY MICHAEL

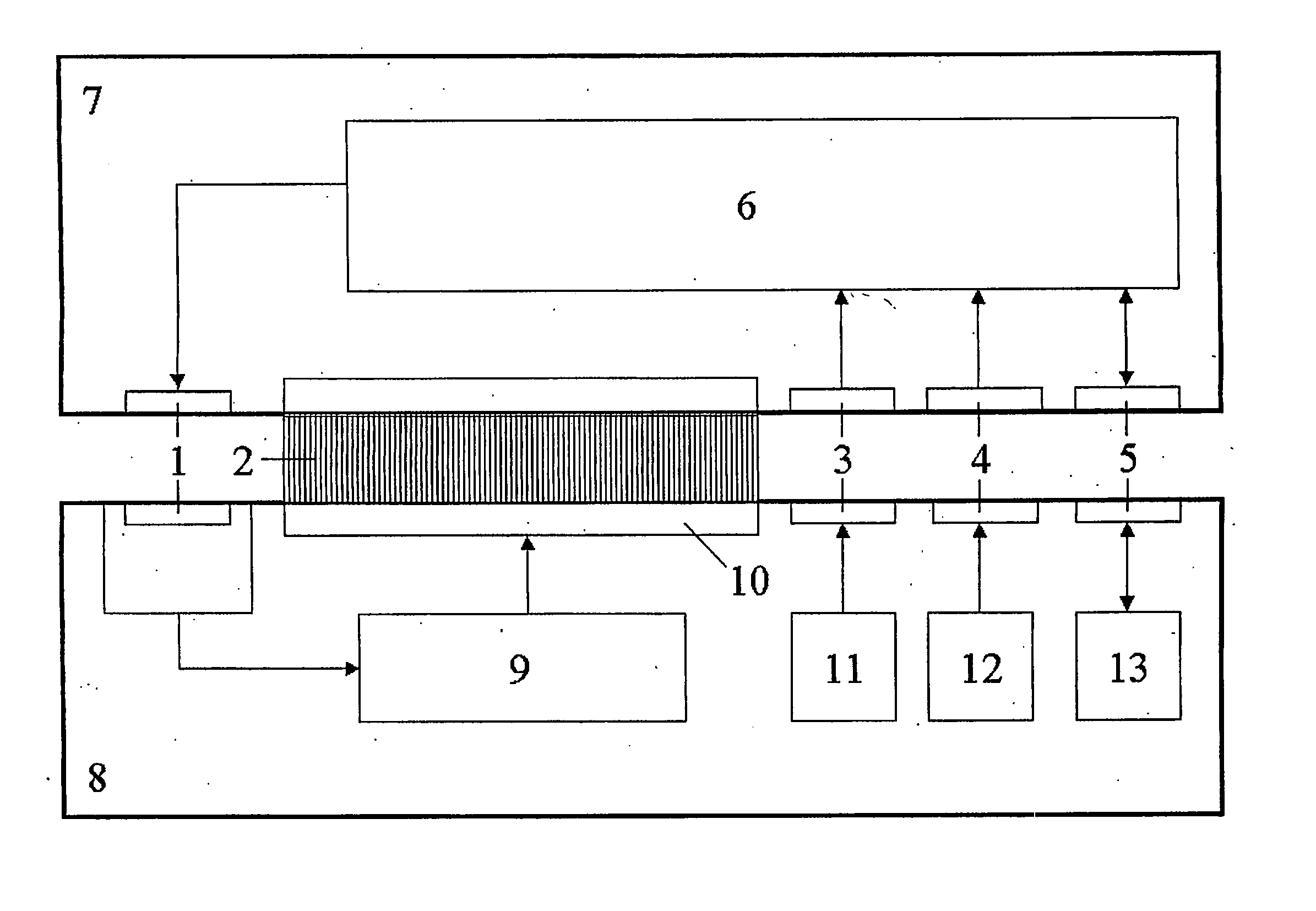

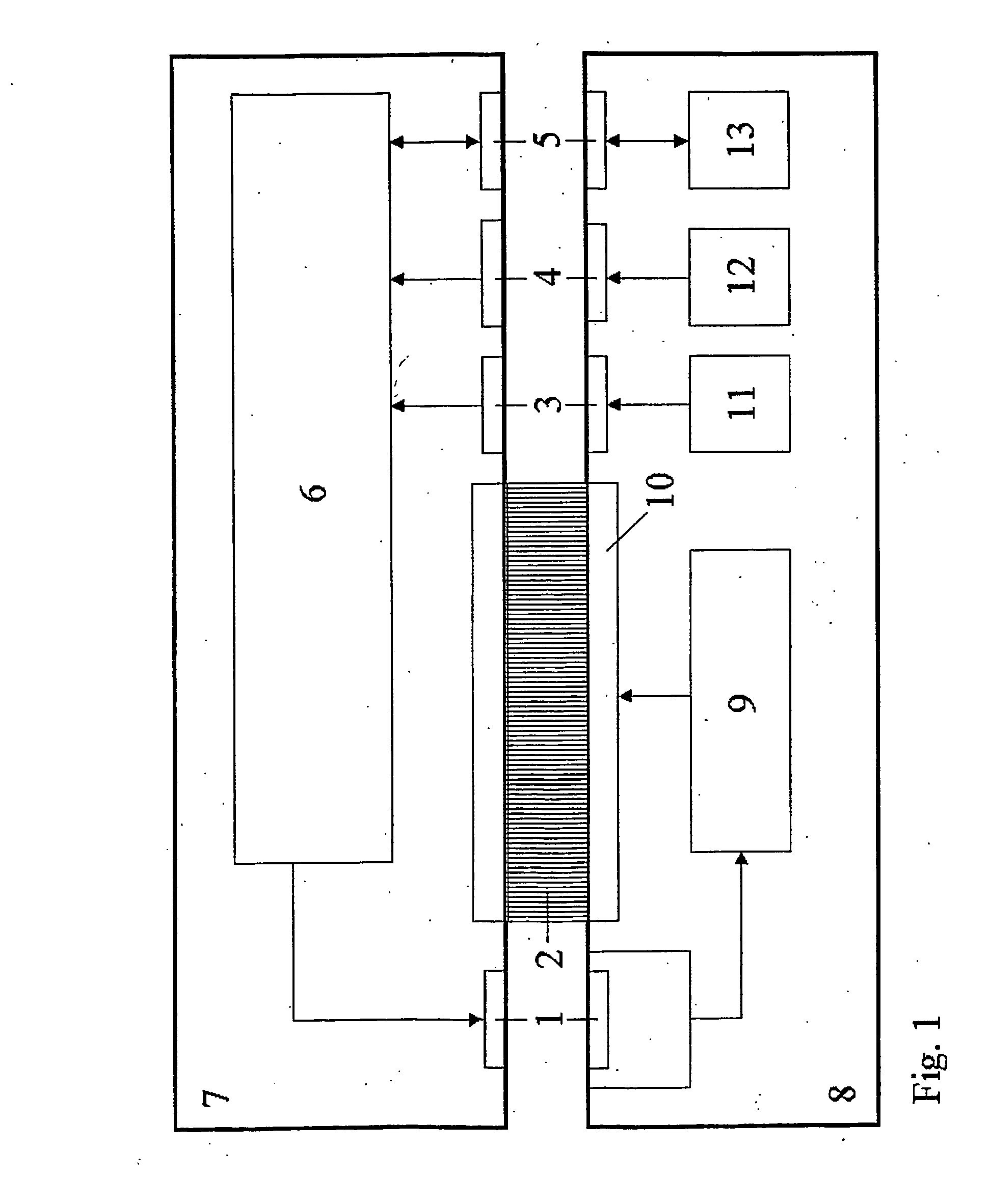

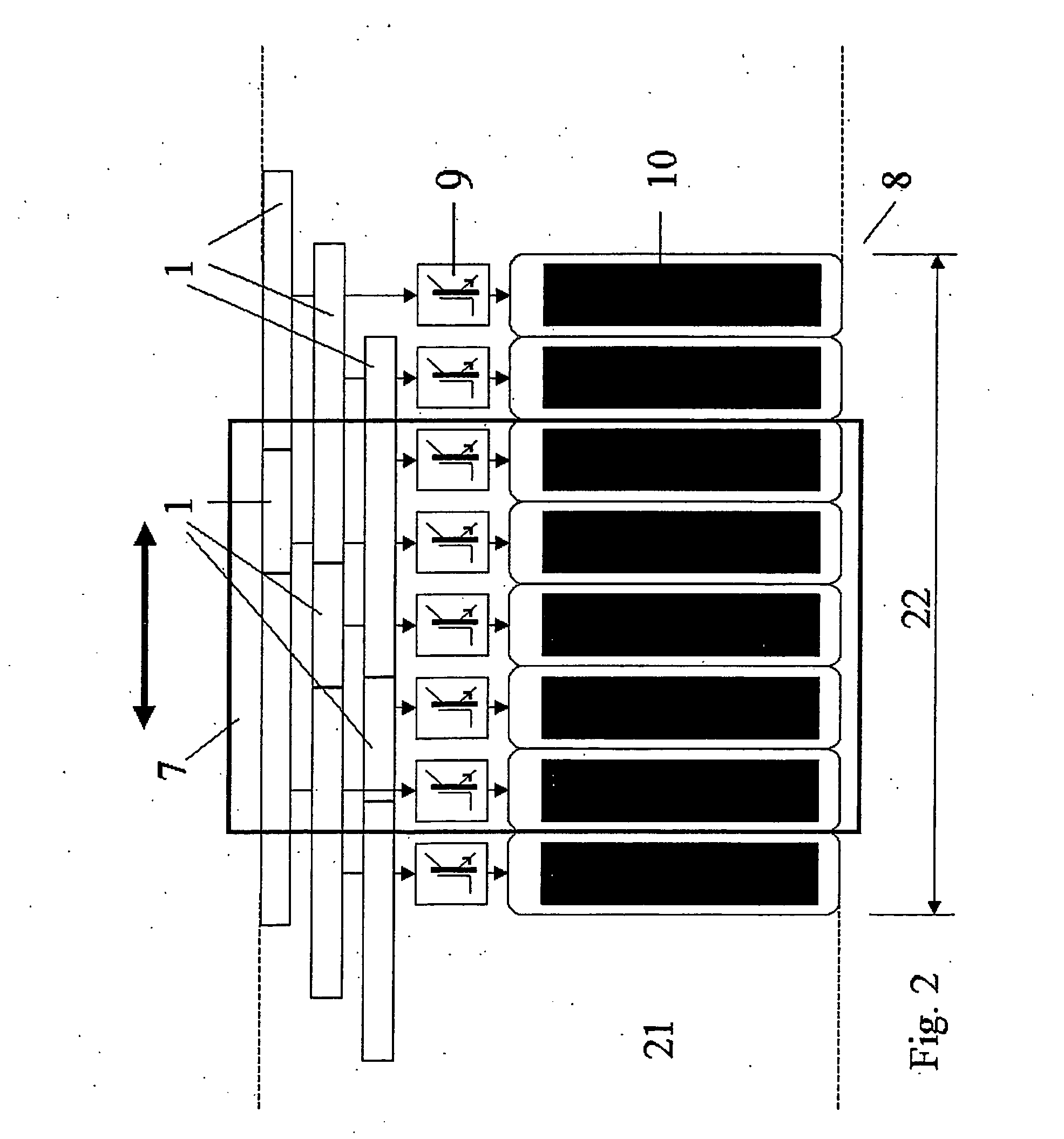

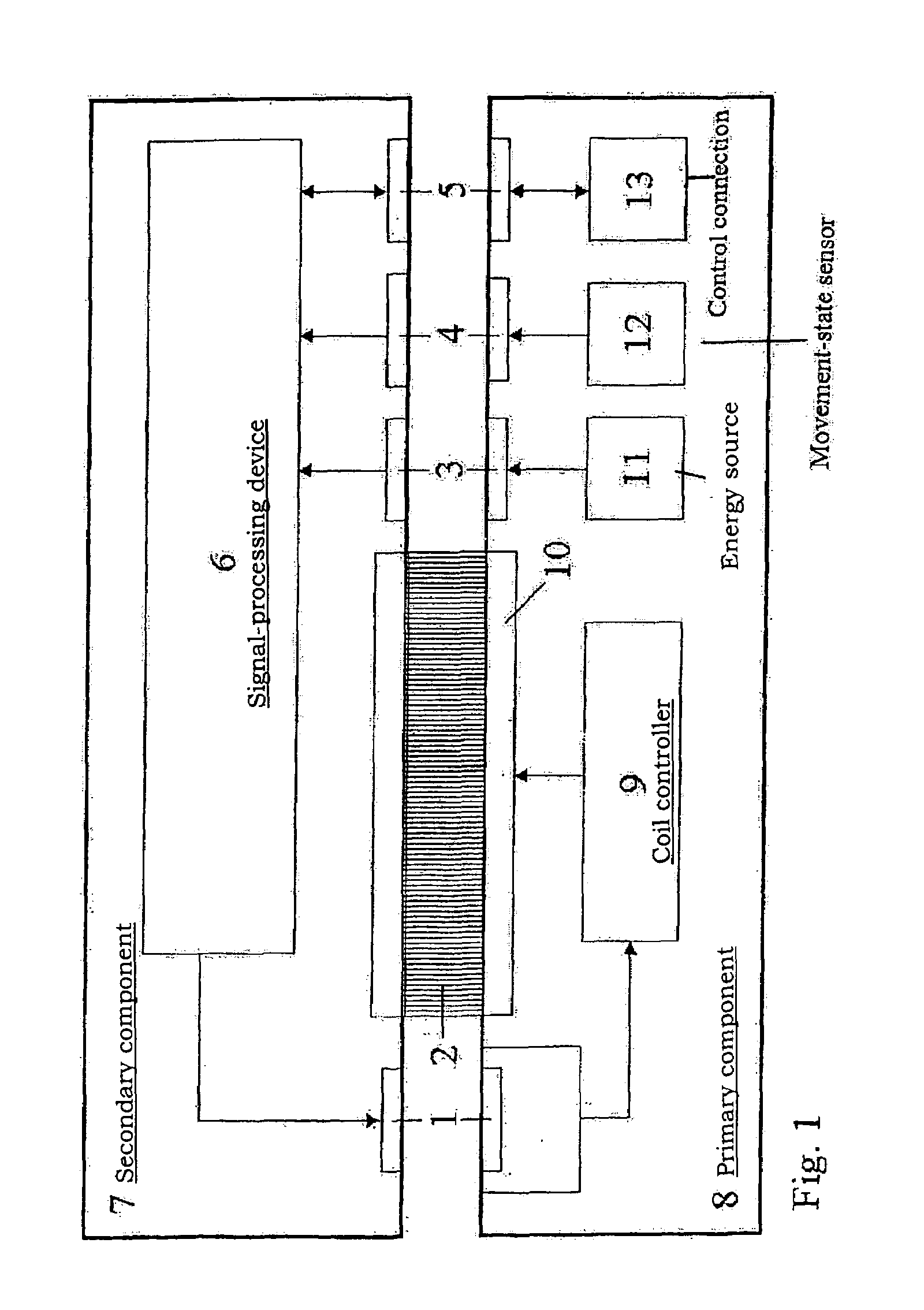

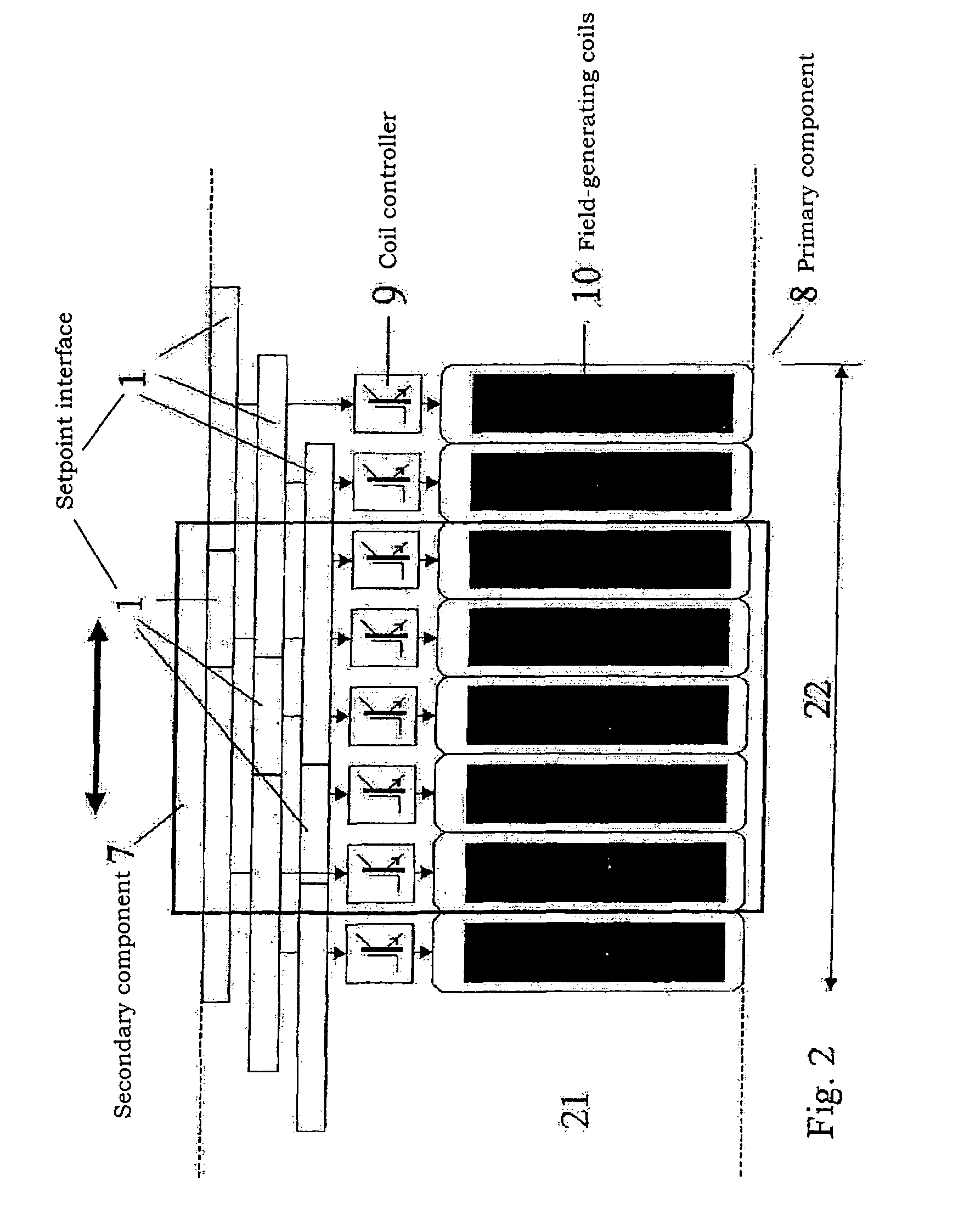

Linear motor with progressive motion control

InactiveUS20070013328A1Improve rigidityHigh positioning accuracyMotor/generator/converter stoppersDC motor speed/torque controlModularityMotion controller

In a linear motor and its progressive motion or motion control, e.g., for modular transport devices with straight and curved route sections forming a route course, extensive modularity or flexibility of the linear motor may be guaranteed with little expenditure in terms of equipment and software, e.g., with regard to various applications or machine configurations, e.g., when a plurality of secondary parts are used. A secondary part may have at least one permanent magnet and a signal processing device with a progressive motion or motion controller, which generates at least one set value relevant to the coil control. A set value is fed as a magnitude for commutation using a set value interface of a coil control that is stationary relative to the primary part. Device(s) are also provided for rigidly positioning the secondary part, the device(s) guiding the secondary part along a predetermined stretch.

Owner:REXROTH INDRAMAT

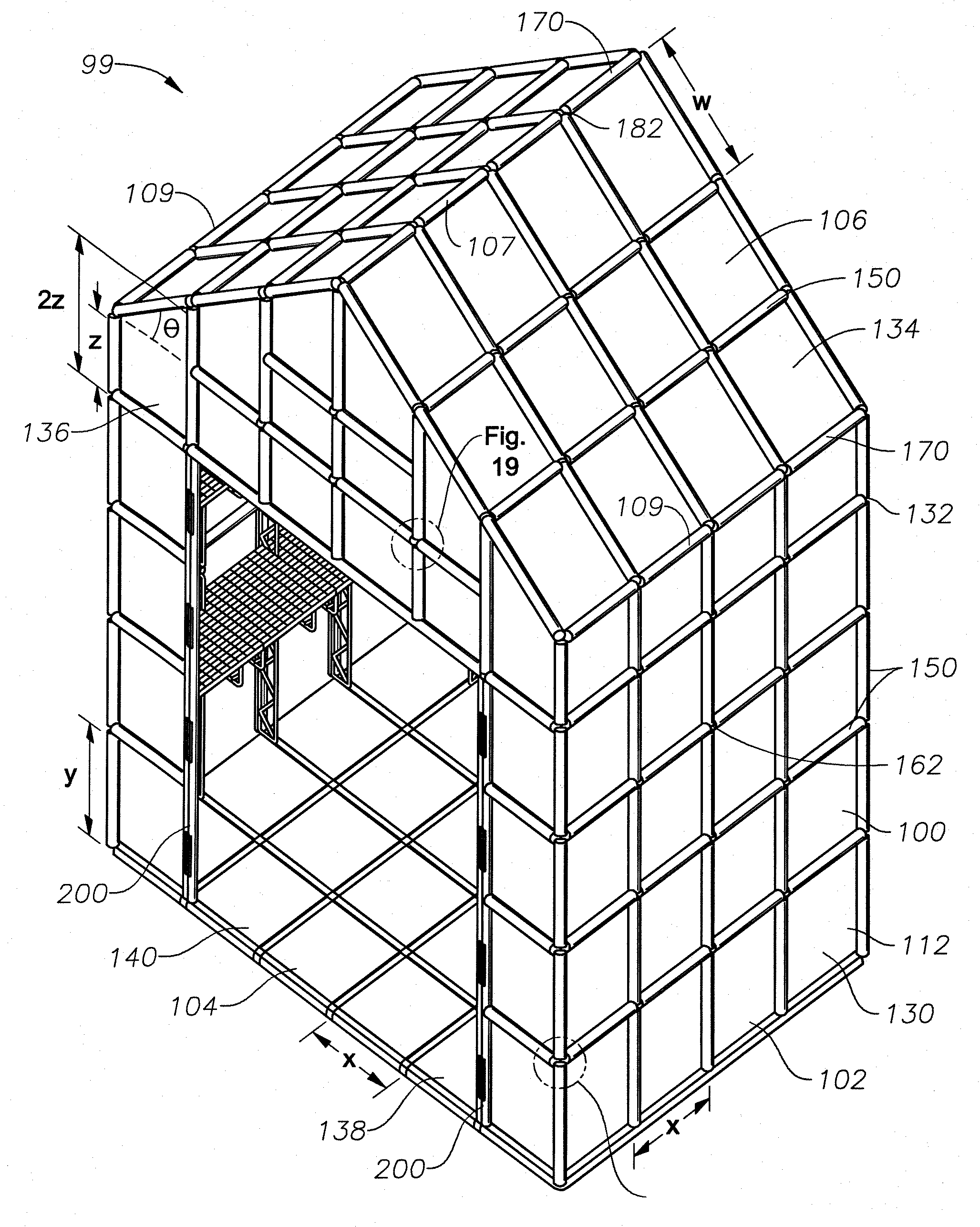

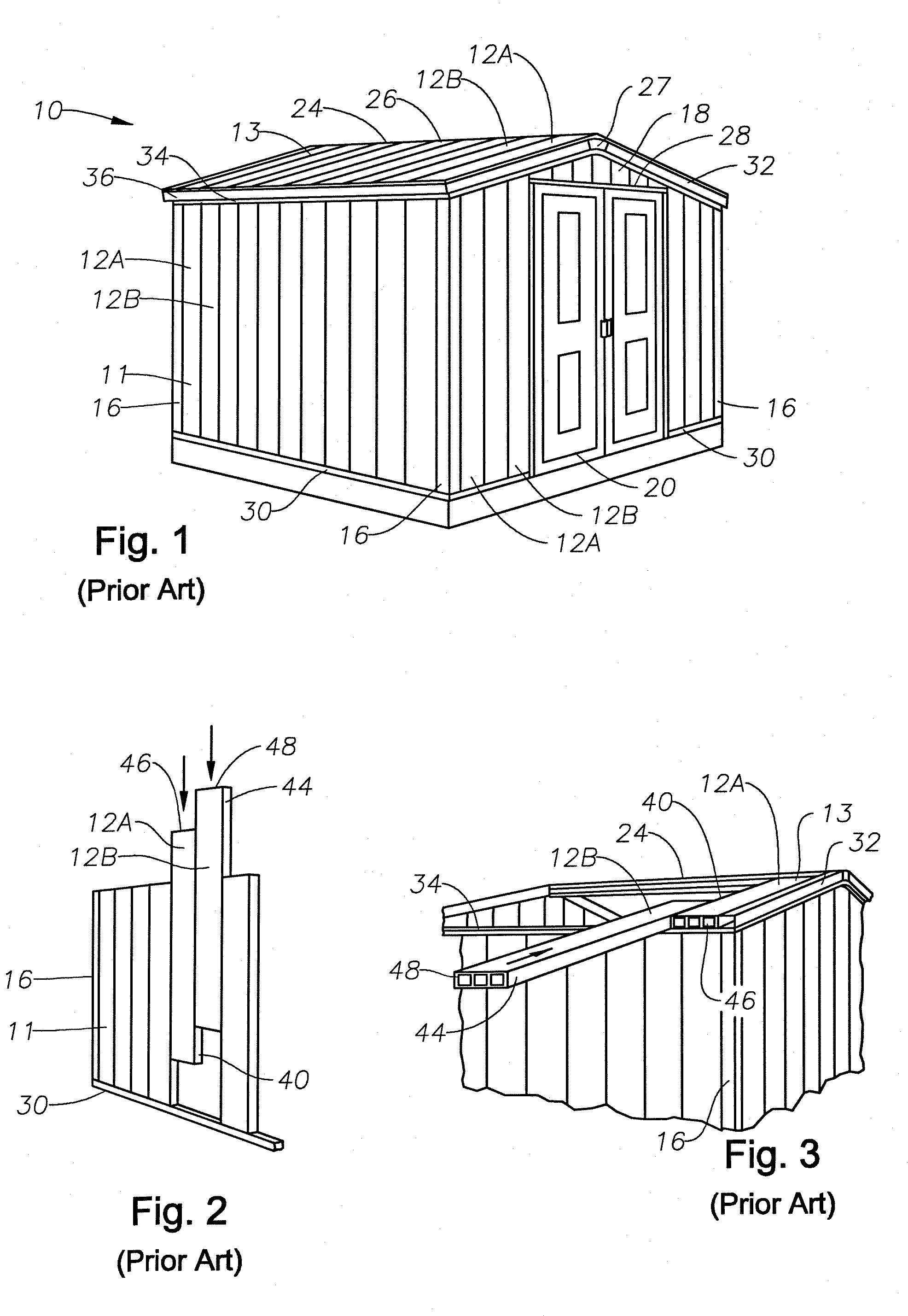

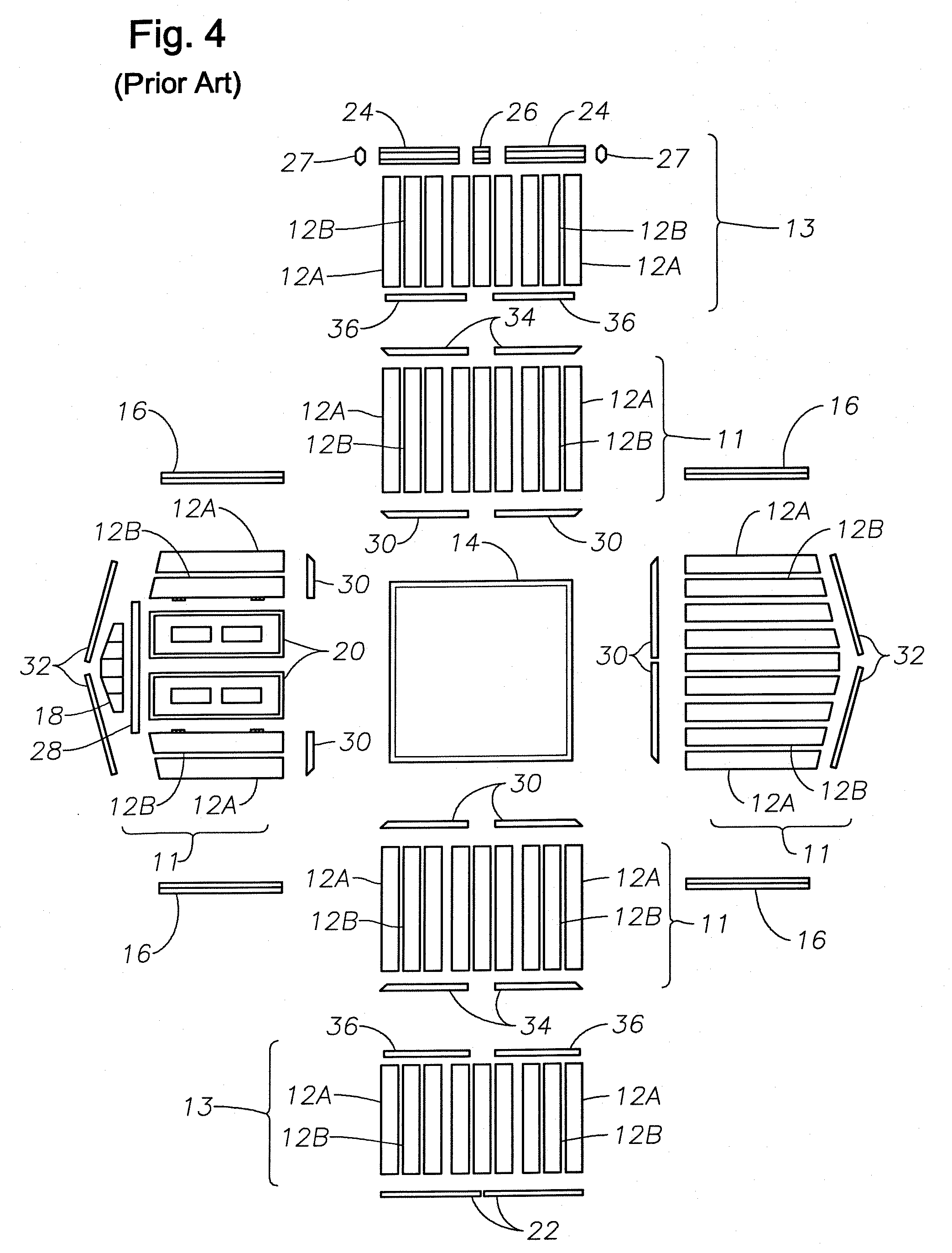

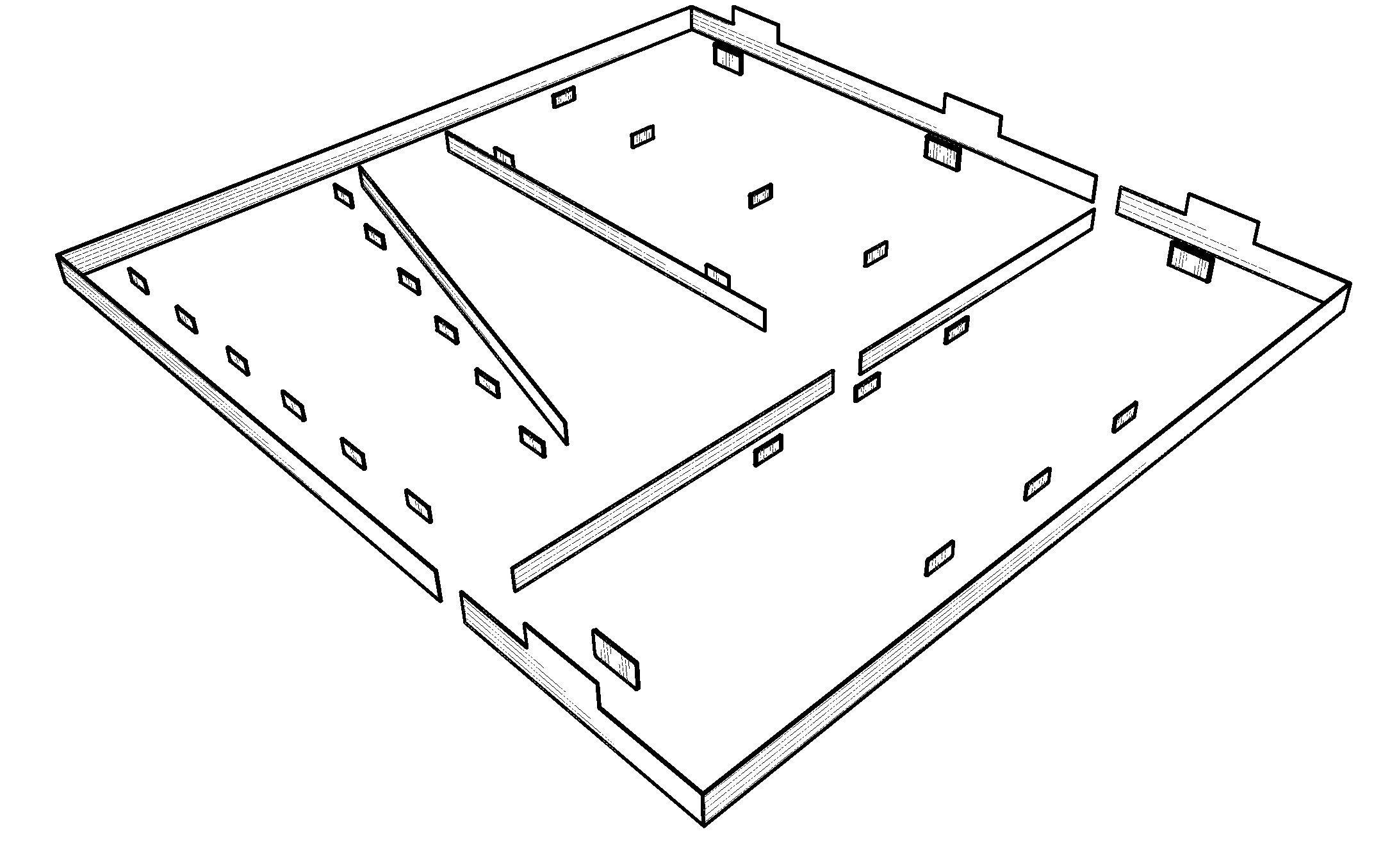

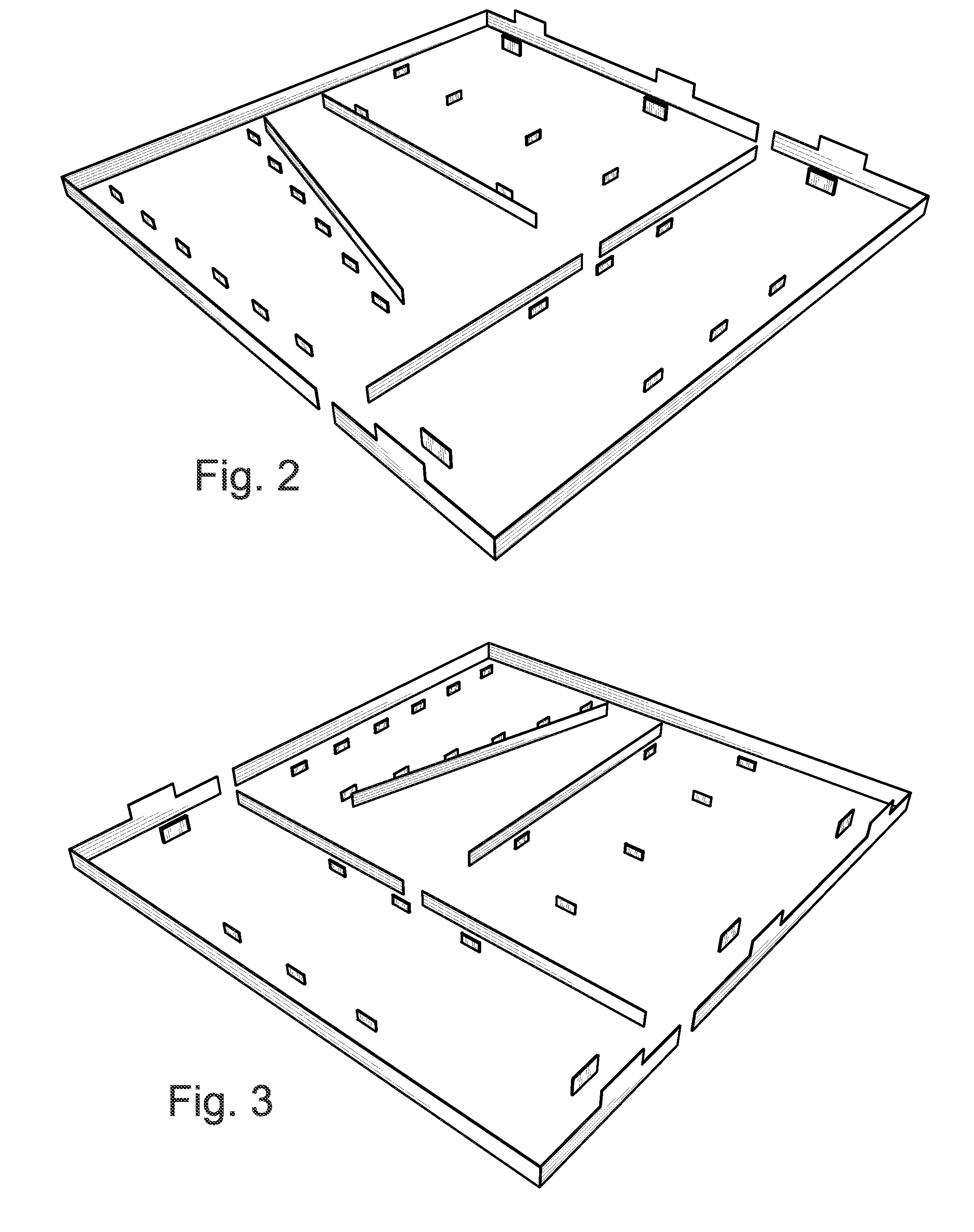

Method and system for a modular building structure

InactiveUS20090165401A1Low-cost factory manufactureRapid and efficient mannerArched girdersBuilding roofsGreenhousePlanar array

A method and system for construction of building structures from a variety of standard size panels having integral dovetail tenons on all four edges and a variety of connectors with corresponding mortises for interlocking the panels. The panels may be horizontally disposed to form floors, ceilings or roofs or may be vertically disposed to form walls. The panels are produced from blow-molded plastic. Panels are interlocked in columns and rows of a planar array to form walls, floors, roofs, etc. Panels can also be interlocked edge to edge in a non-planar orthogonal manner, allowing the panels to be interconnected in virtually unlimited ways. Plastic frame members with trussing interconnect to the panels to provide rigidity and strength to the assembled building structure. The panels may be formed of opaque material for ordinary sheds or of transparent or translucent material for greenhouses.

Owner:SMALLEY III ARTHUR L

Linear motor having progressive movement control

InactiveUS7385363B2Reduce loadMinimum of equipmentMotor/generator/converter stoppersDC motor speed/torque controlKinematic controllerMachine

In a linear motor and its progressive motion or motion control, e.g., for modular transport devices with straight and curved route sections forming a route course, extensive modularity or flexibility of the linear motor may be guaranteed with little expenditure in terms of equipment and software, e.g., with regard to various applications or machine configurations, e.g., when a plurality of secondary parts are used. A secondary part may have at least one permanent magnet and a signal processing device with a progressive motion or motion controller, which generates at least one set value relevant to the coil control. A set value is fed as a magnitude for commutation using a set value interface of a coil control that is stationary relative to the primary part. Device(s) are also provided for rigidly positioning the secondary part, the device(s) guiding the secondary part along a predetermined stretch.

Owner:REXROTH INDRAMAT

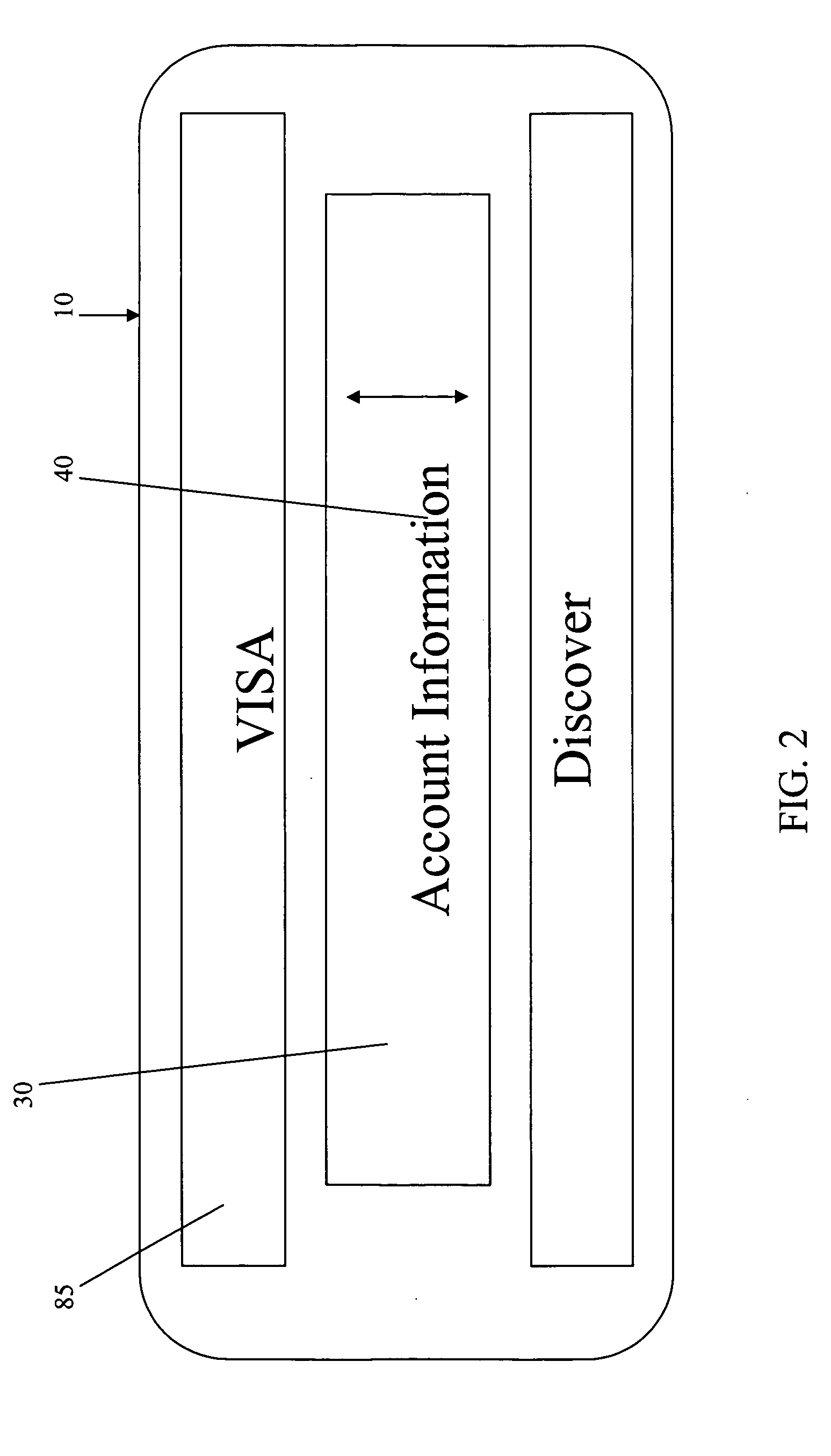

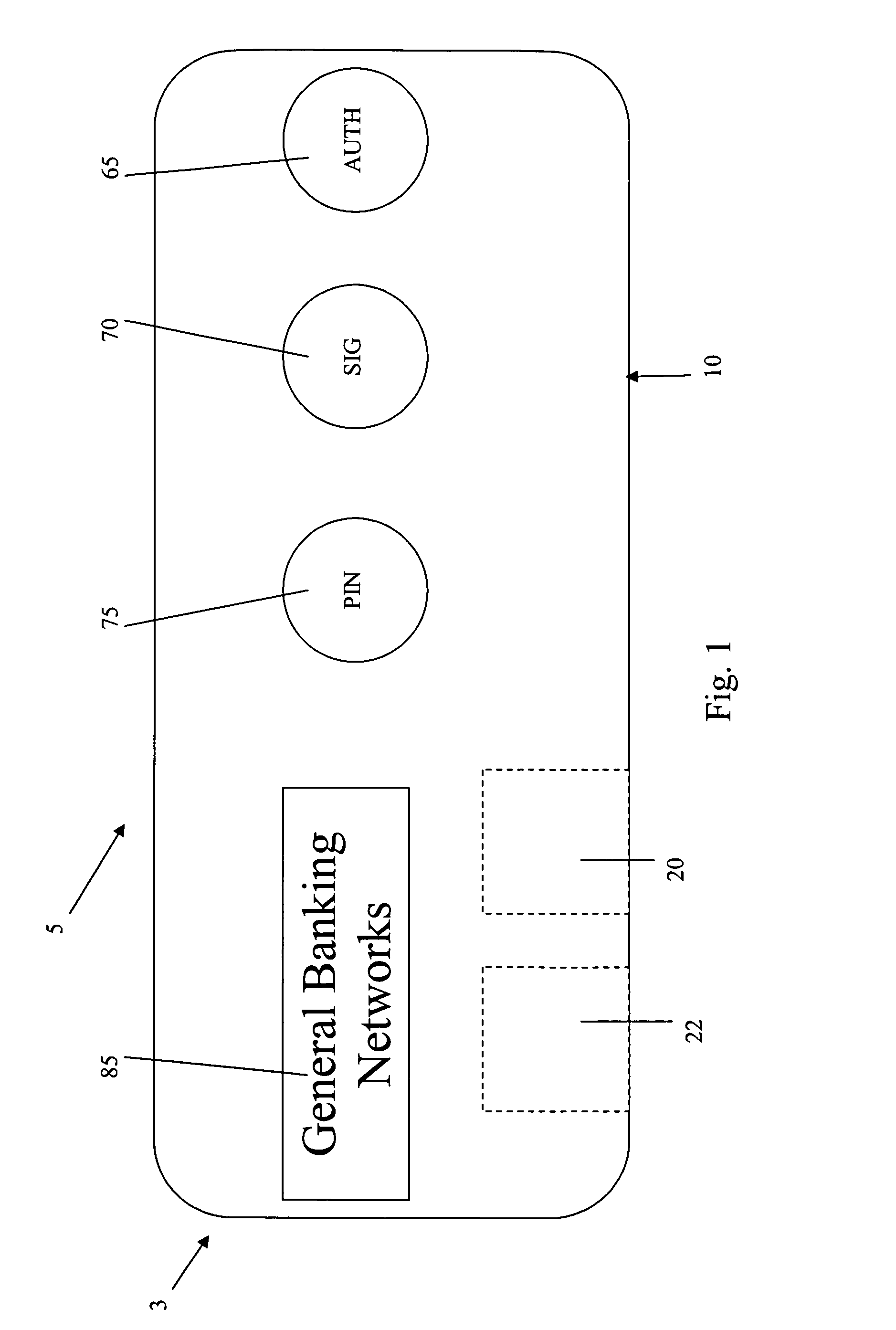

Authorization system and method

ActiveUS20080046747A1Reduce down timeReduce operating costsComplete banking machinesAcutation objectsDocking stationProcessor register

A system including a device having a screen and a memory to hold card data necessary to complete POS / ATM transactions. The device has an authorization, signature, PIN button and scroll wheel. Branding areas allow distributors to leverage space on the device. When the merchandise has been processed and ready to be paid for, the device holder either places their device in a docking station or holds it in front of a contact less reader. When the merchant is ready for authorization, the holder presses transmits the data to a register so the merchant can send the data through the card network for authorization. Once the transaction is authorized, the merchant requests the signature, fingerprint, and / or photo of the holder, which can be displayed, on the register to authenticate the holder. Upon completion, the transaction information is transmitted back to the device for storage and retrieval at a later date.

Owner:FIDELITY INFORMATION SERVICES LLC

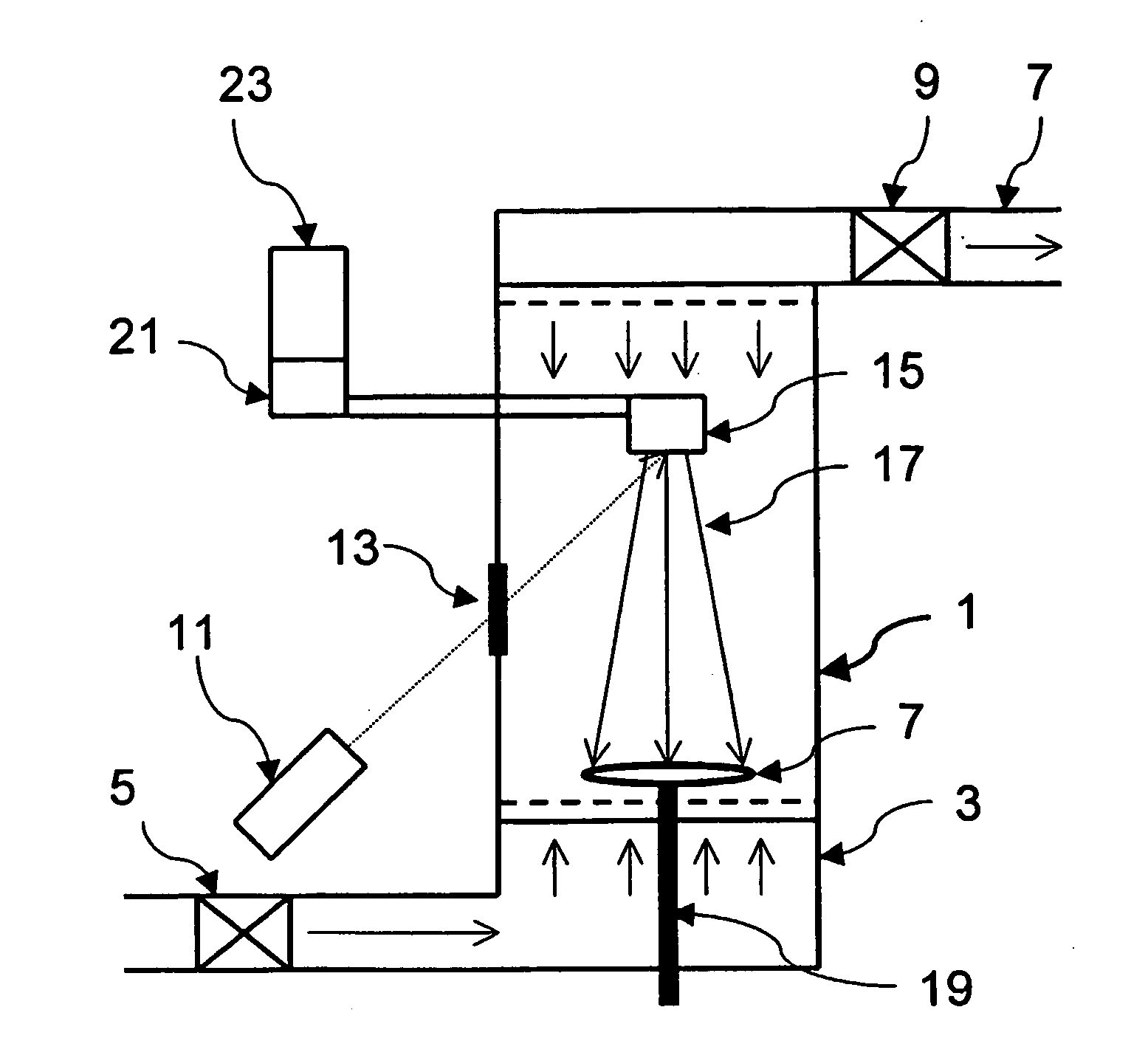

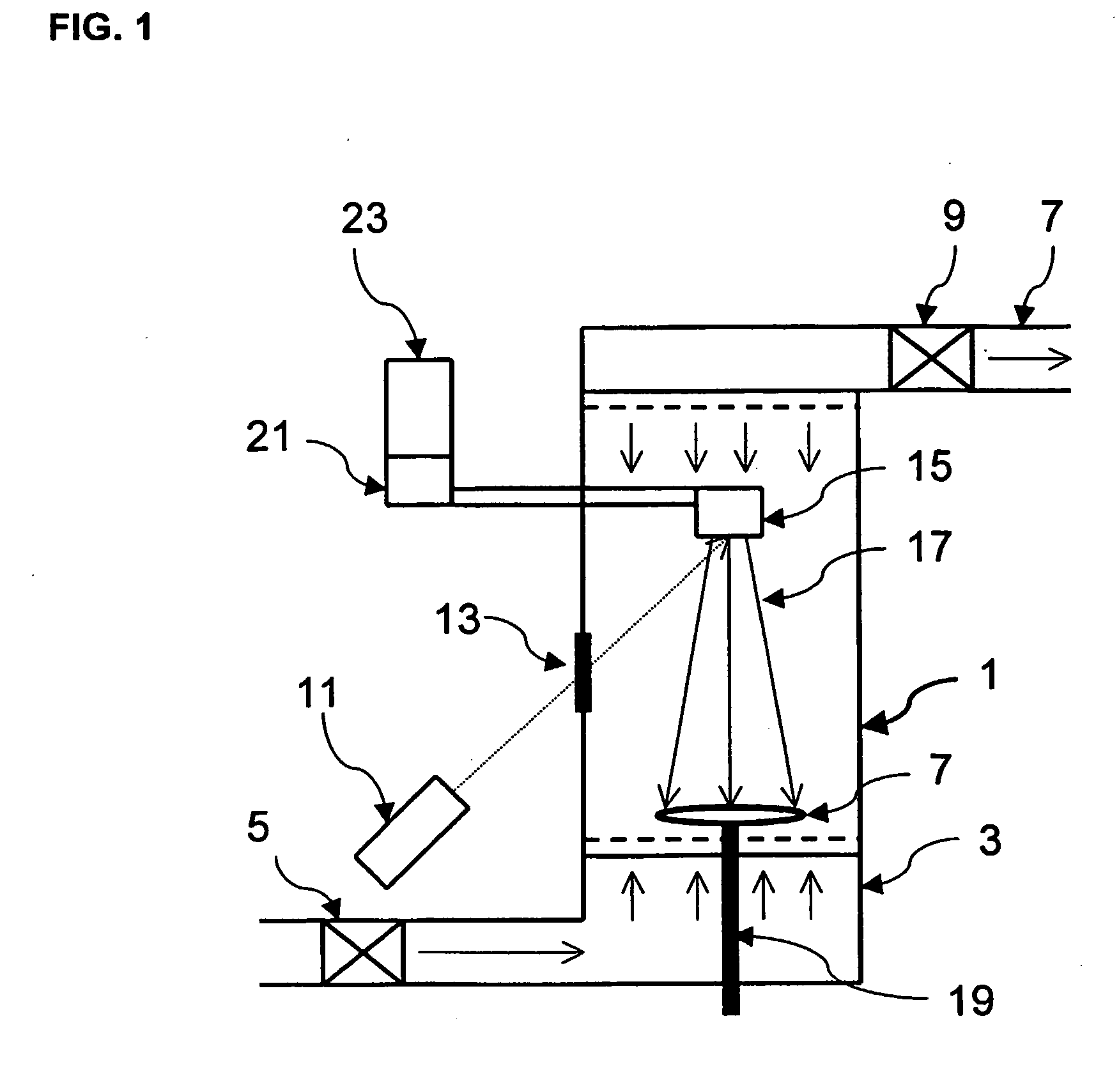

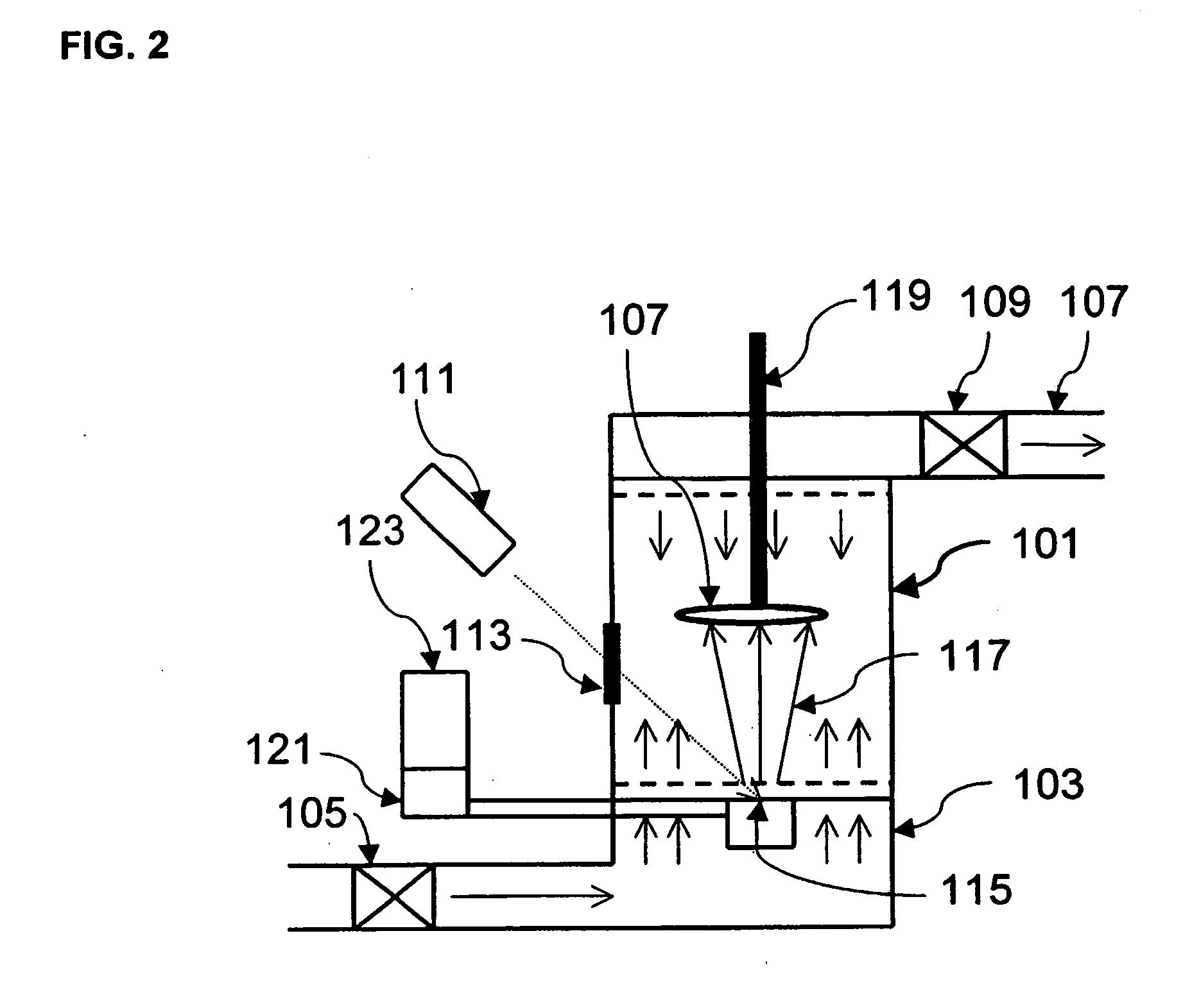

Method of pulsed laser assisted surface modification

InactiveUS20060051522A1Uniform coatingMinimum of equipmentElectric discharge heatingVacuum evaporation coatingLaser assistedSubstrate surface

A method comprising providing a target material (115), providing a substrate (107), ablating the target material (115) to form ablated target particulate material (117), directing the ablated particulate material (117) toward the substrate (107) with a gas flow, and coating the substrate surface (107).

Owner:NANOTHERAPEUTICS INC

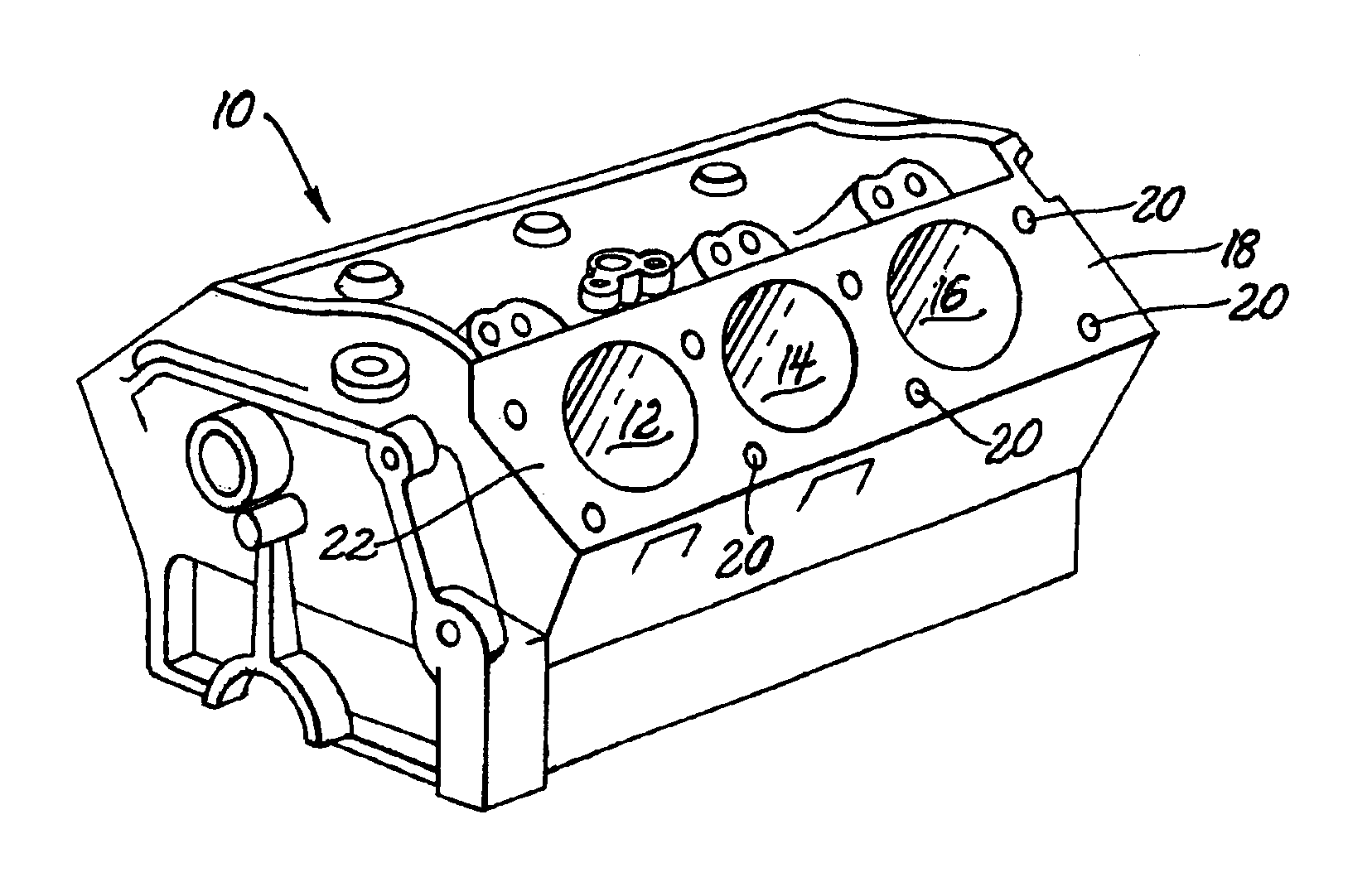

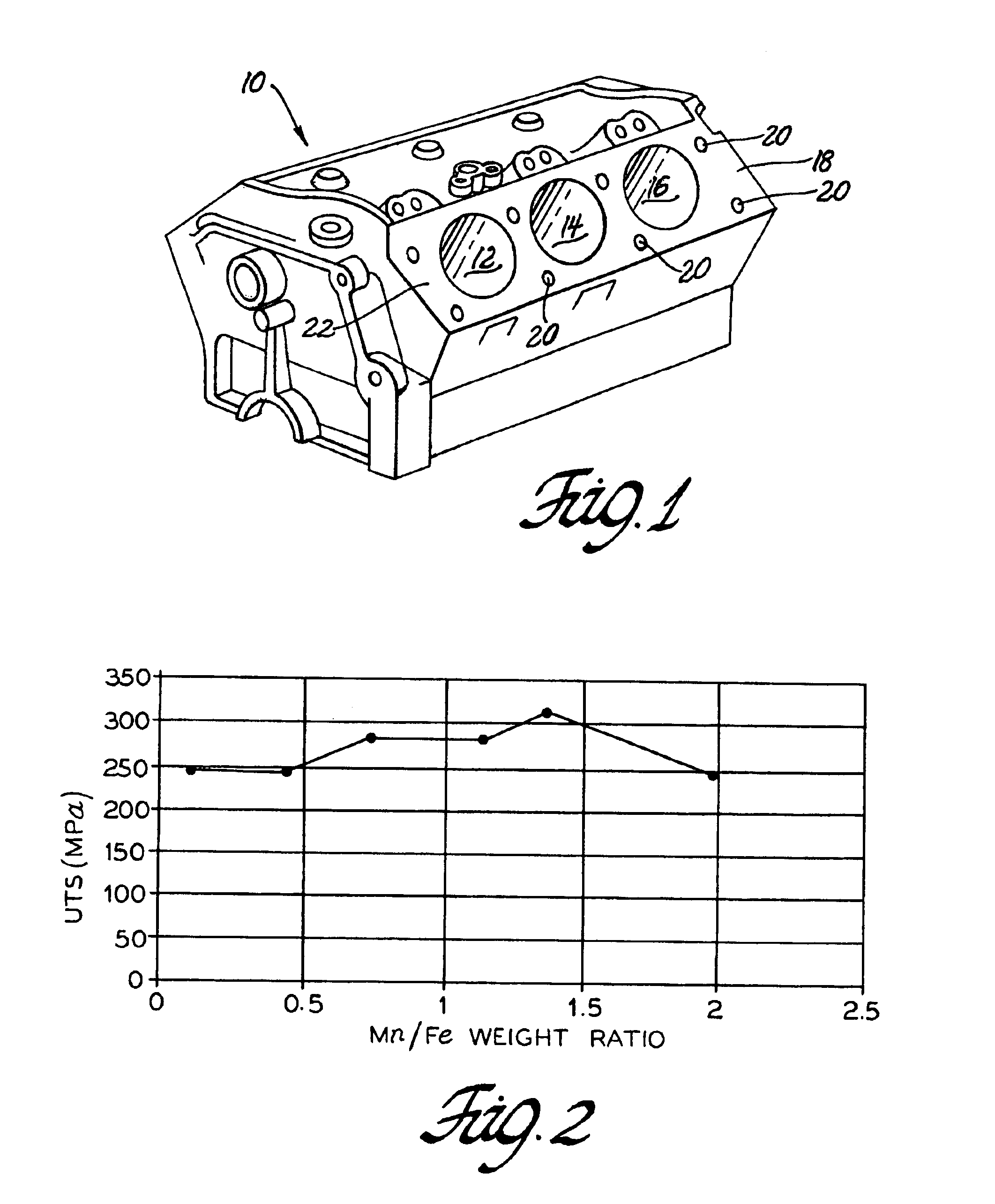

Aluminum alloy for engine blocks

An aluminum alloy is disclosed that is suitable for casting and machining cylinder blocks for engines, especially gasoline fuel engines for automotive vehicles. The casting has the strength and wear resistance to piston / seal scuffing for such engines. The alloy comprises, by weight, 9.5 to 12.5% silicon, 0.1 to 1.5% iron, 1.5 to 4.5% copper, 0.2 to 3% manganese, 0.1 to 0.6% magnesium, 2.0% max zinc, 0 to 1.5% nickel, 0.25% maximum titanium, up to 0.05% strontium and the balance aluminum, where the weight ratio of manganese to iron is 1.2 to 1.75 or higher when the iron content is equal to or greater than 0.4% and the weight ratio of manganese to iron is at least 0.6 to 1.2 when the iron content is less than 0.4% of the alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC

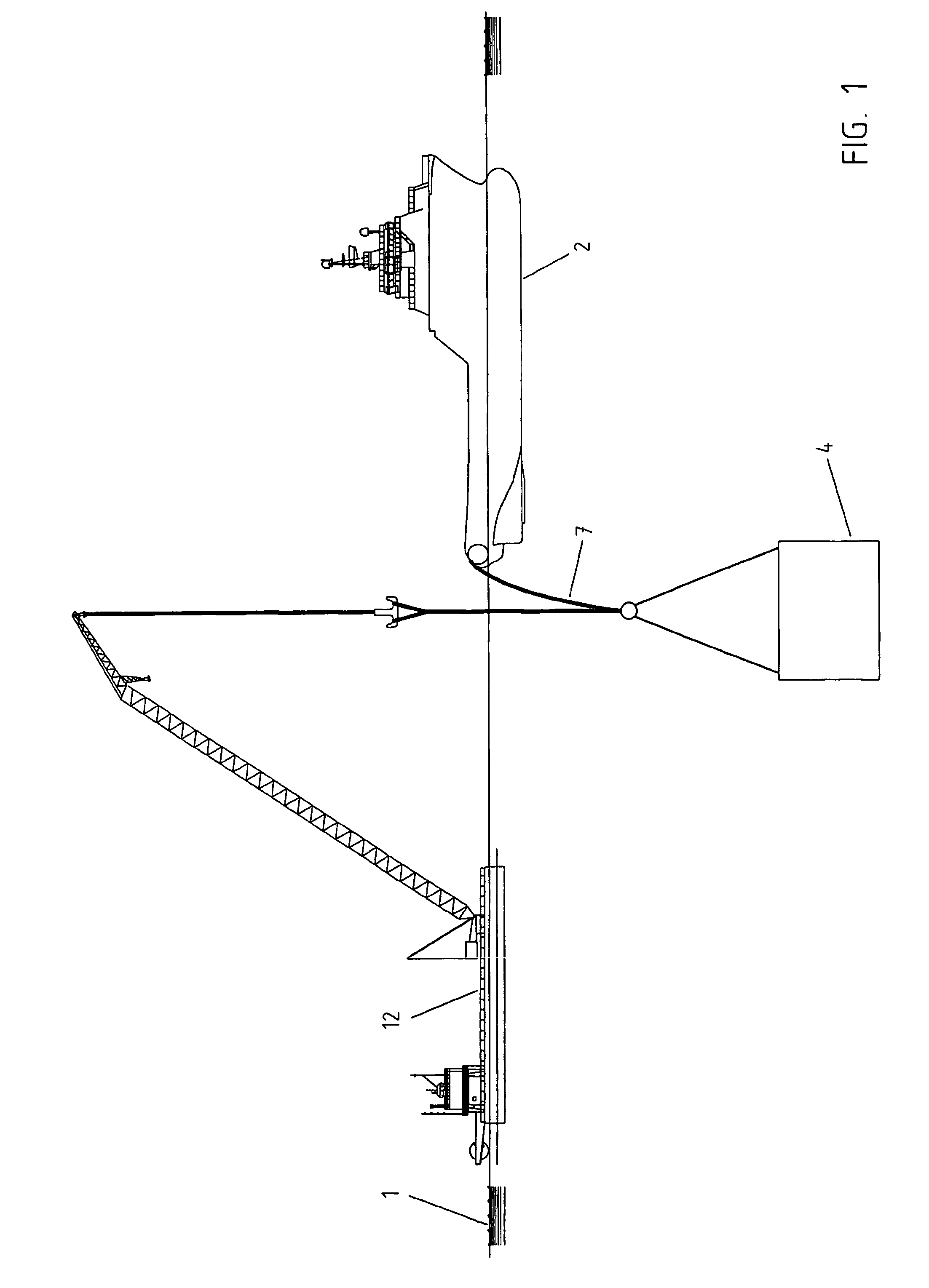

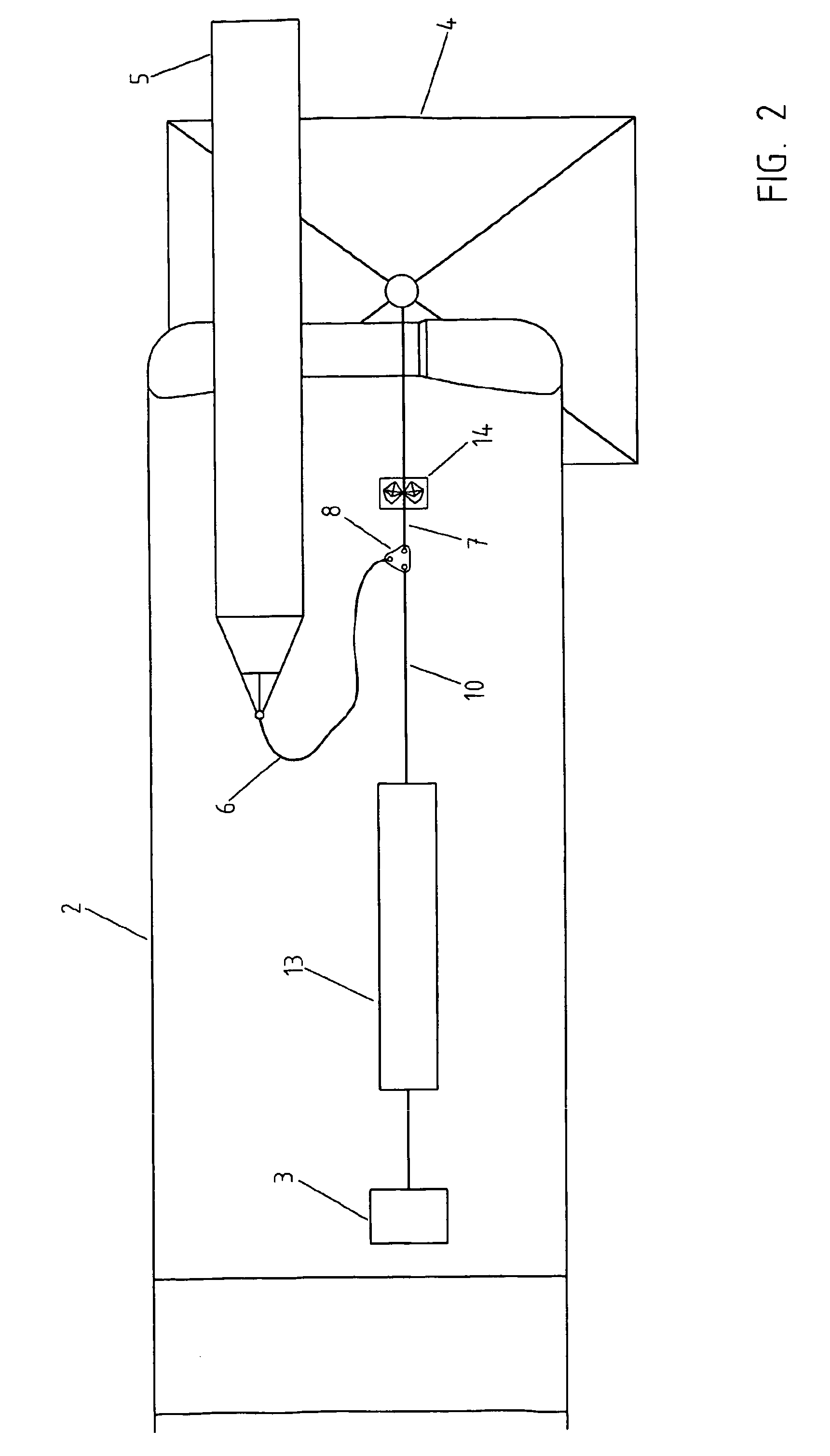

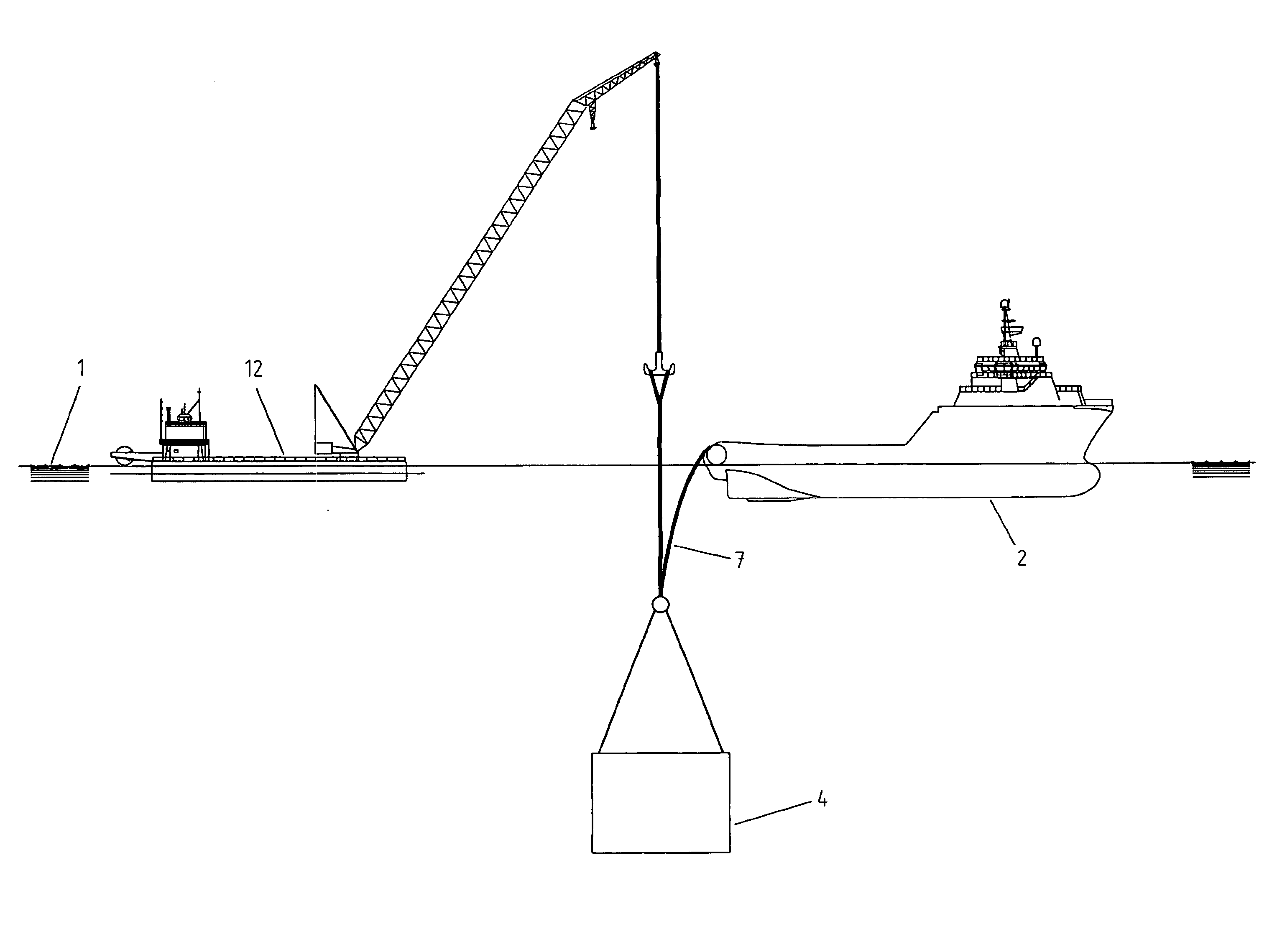

Method for underwater transportation and installation or removal of objects at sea

Method for transport and installation of objects at sea, particularly relating to transport and installation of obs jects that are part of the infrastructure in oil and gas fields offshore, the object (4) is put in the sea at a suitable location near the shore or in sheltered waters, then towed to the installation site while being suspended in a slender buoyancy unit (5) acting much like a heave compensating unit. Upon arrival at the installation site, the suspension of the object (4) is transferred from the buoyancy unit (5) to a heave compensated winch (3) on a surface vessel (2), preferably the same vessel as used for the preceding towing operation. The winch is used to lower is the object (4) to its destination on the sea bottom or a predetermined location above the sea bottom.

Owner:AKER MARINE CONTRACTORS

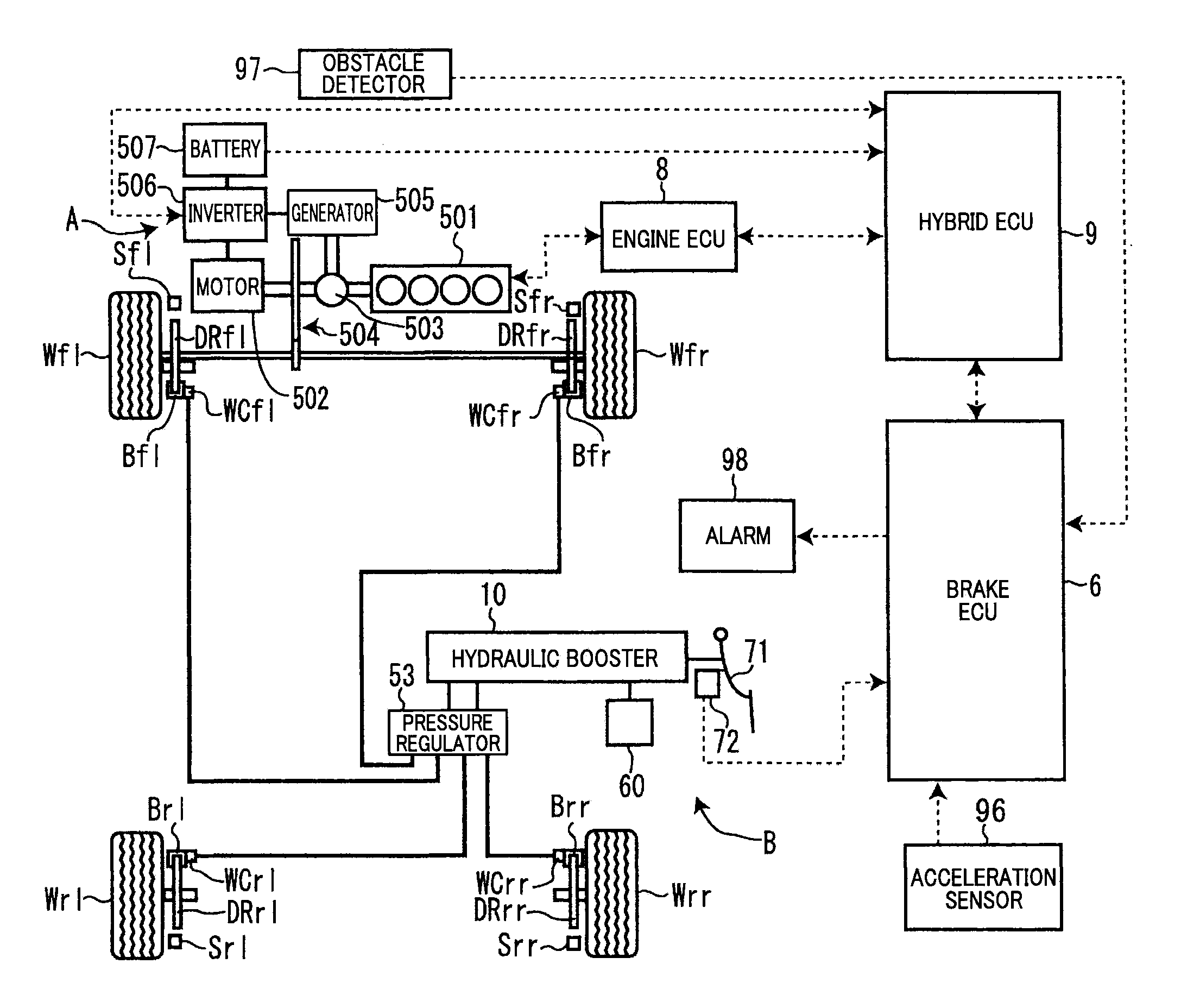

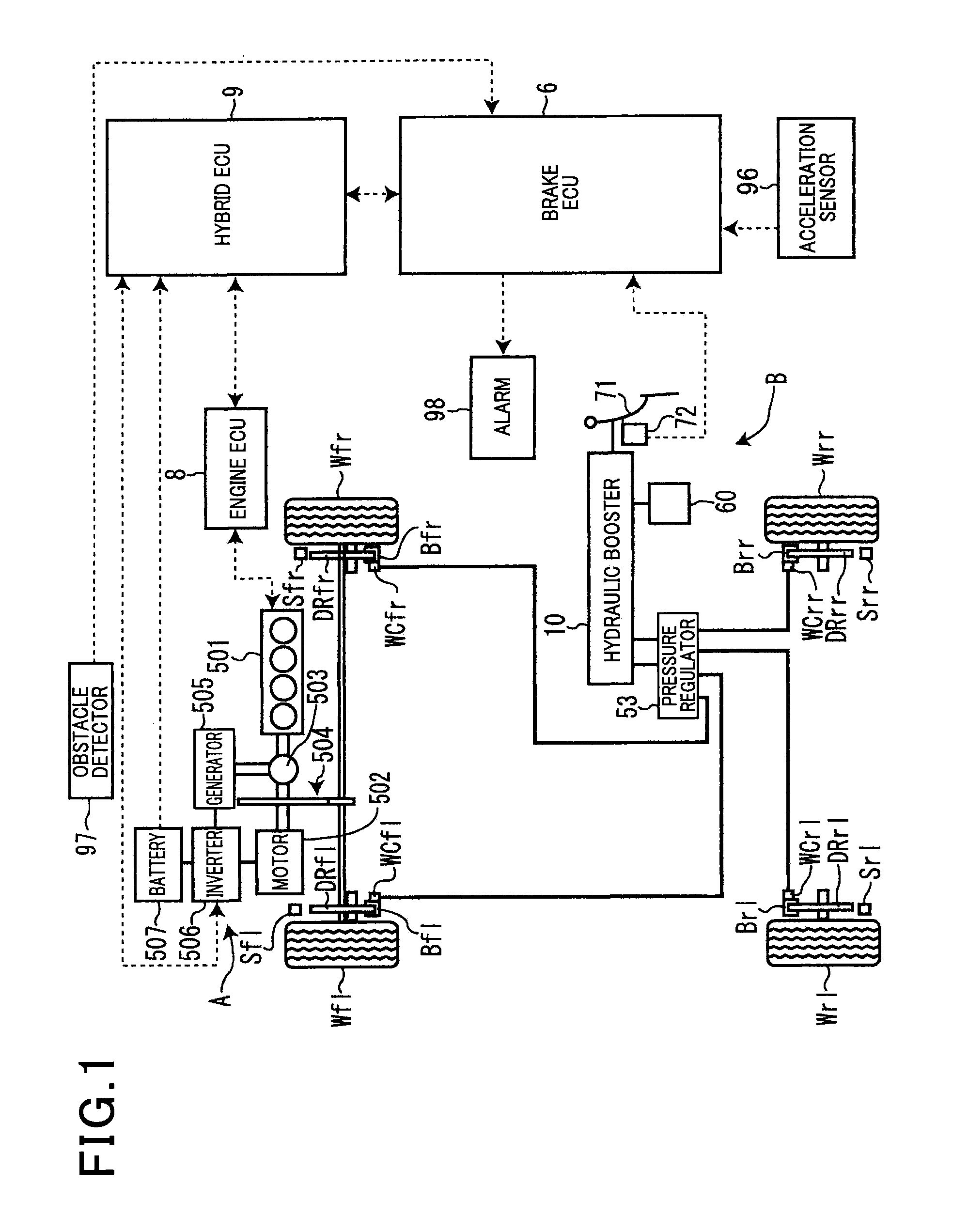

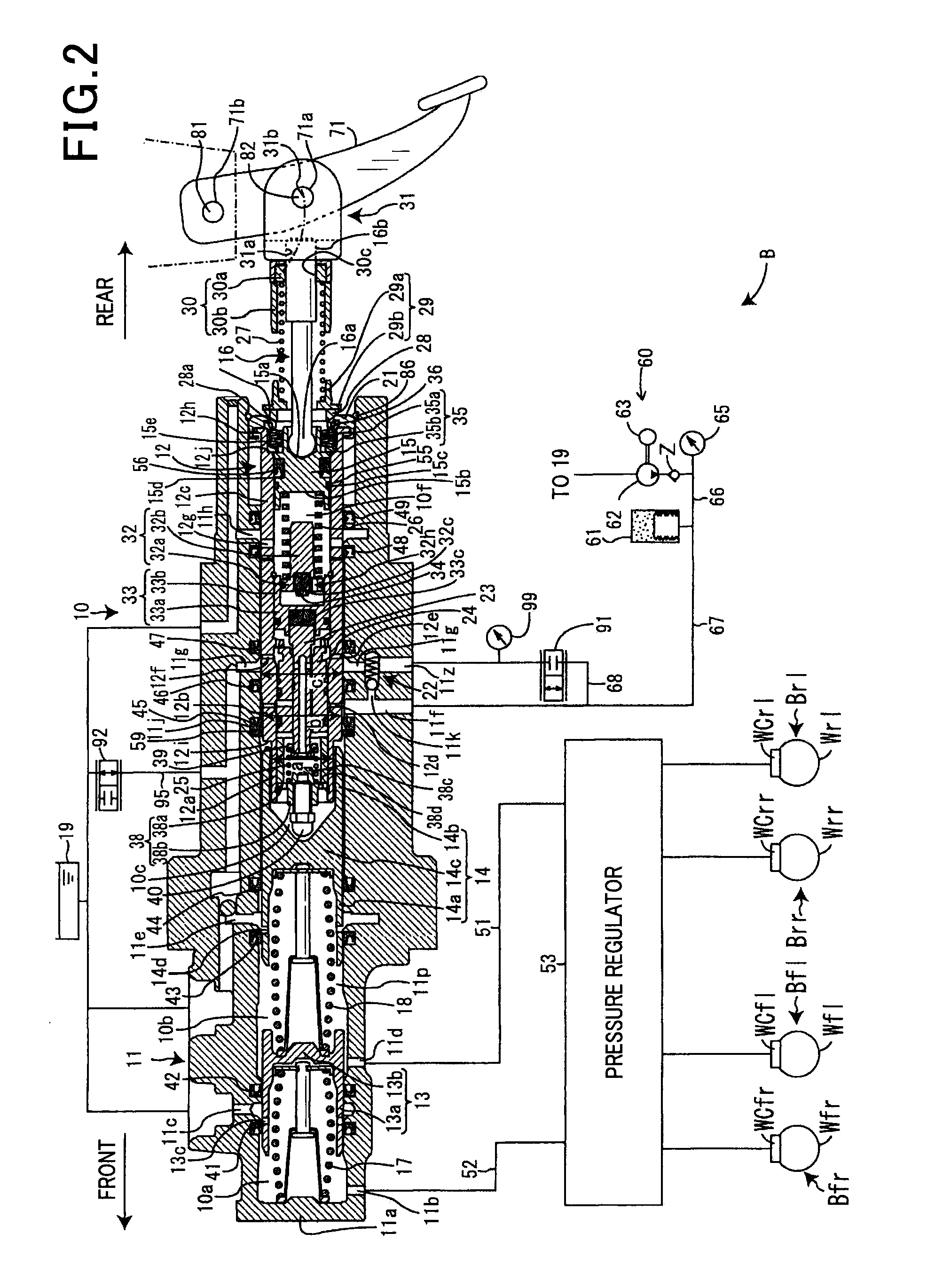

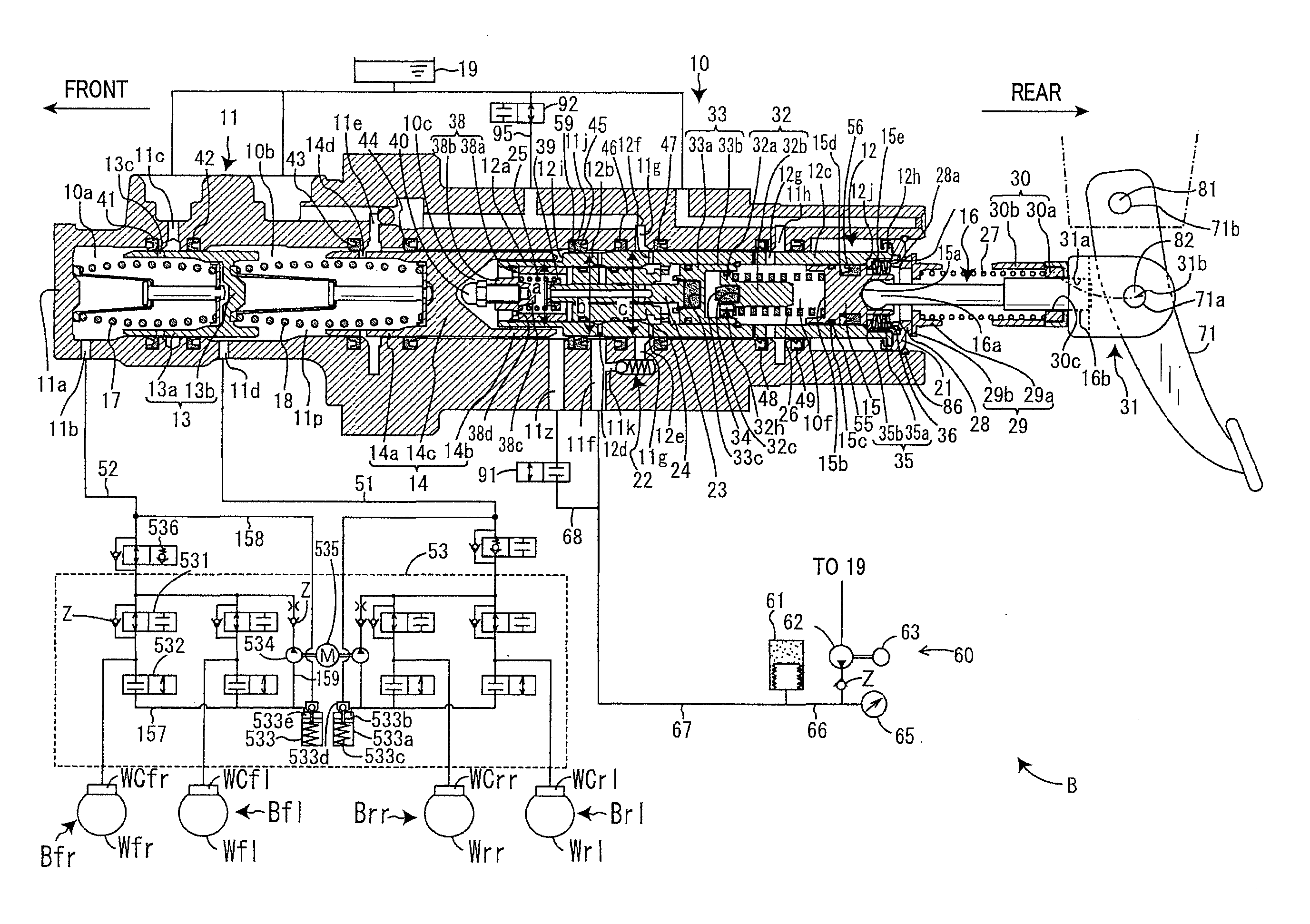

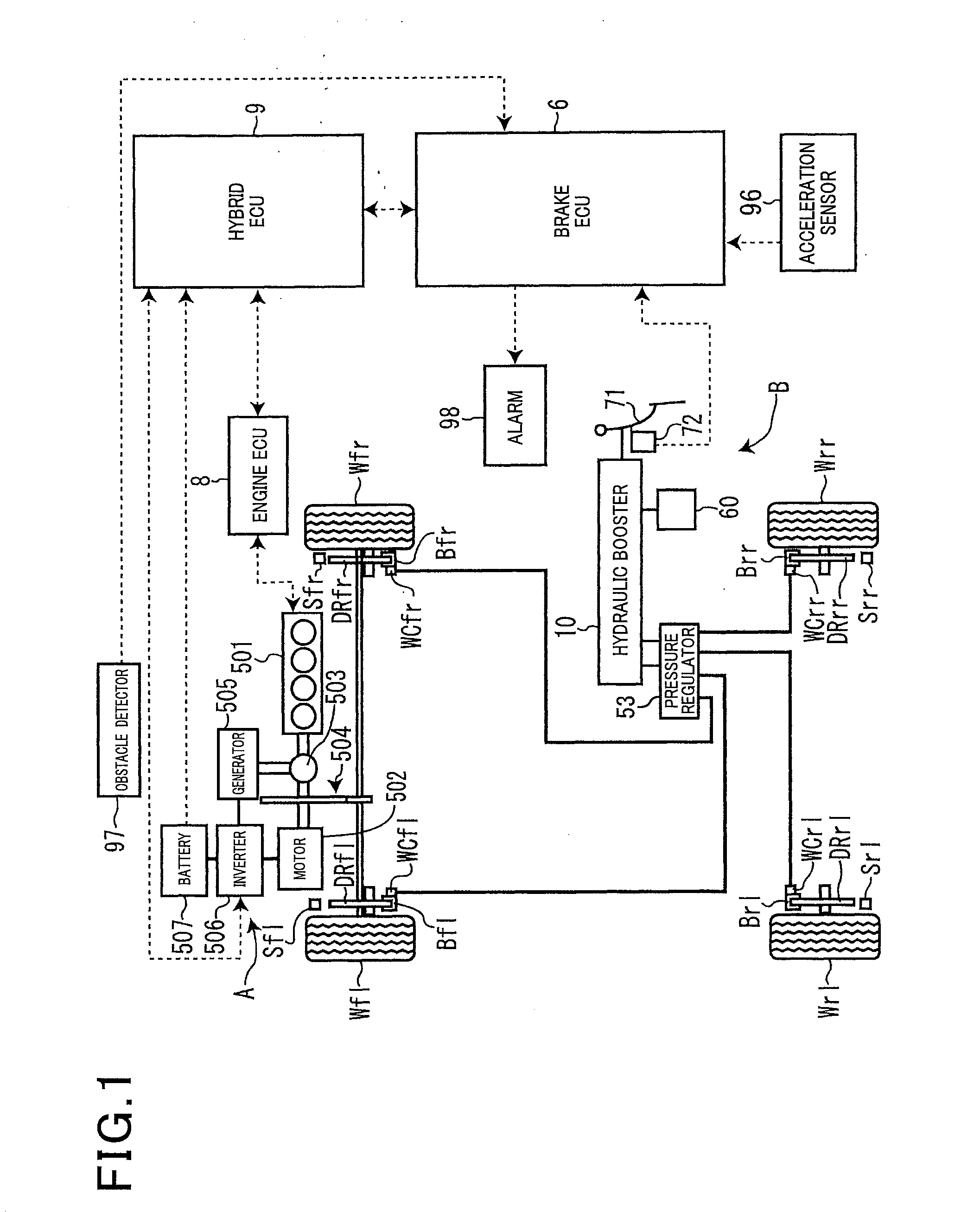

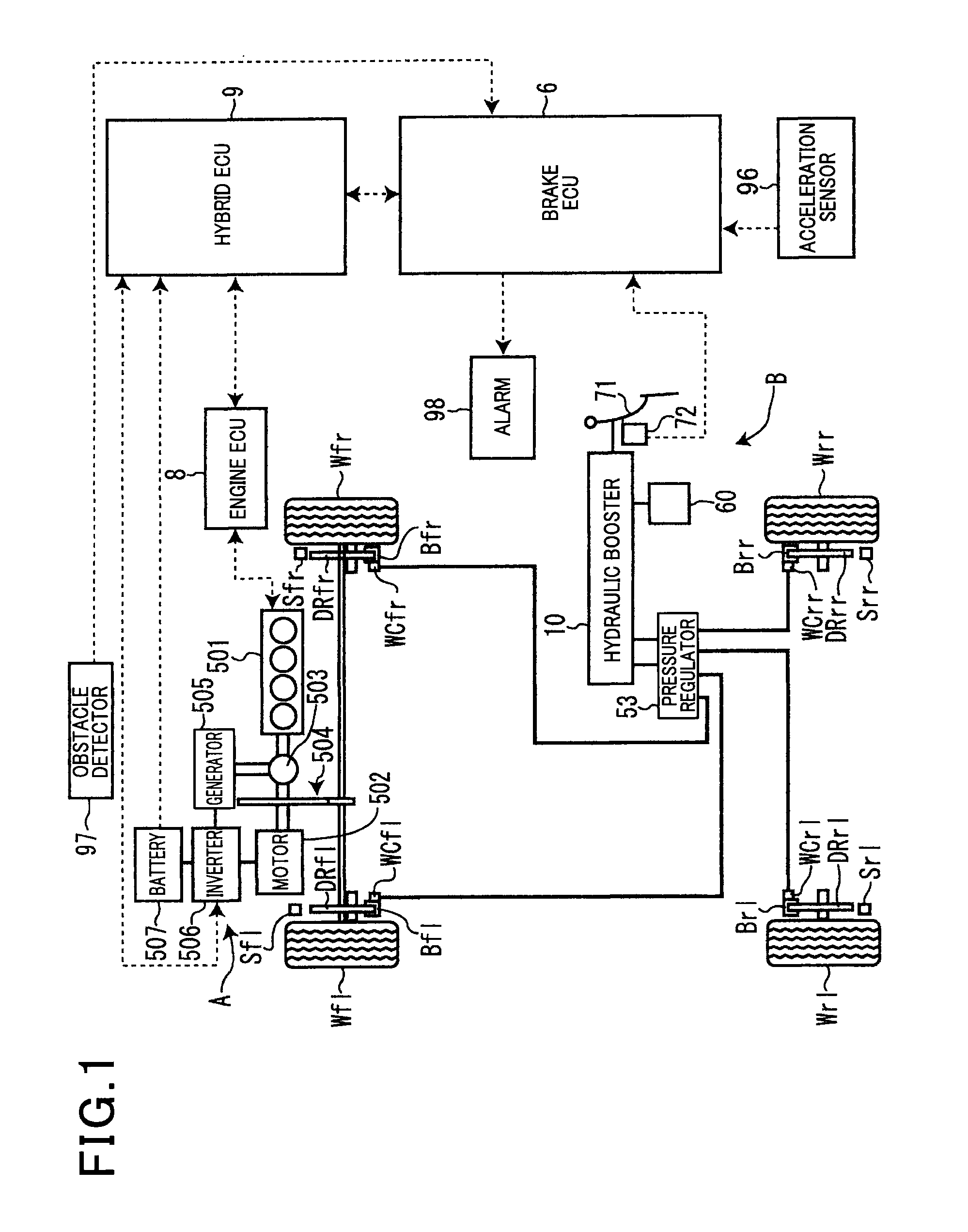

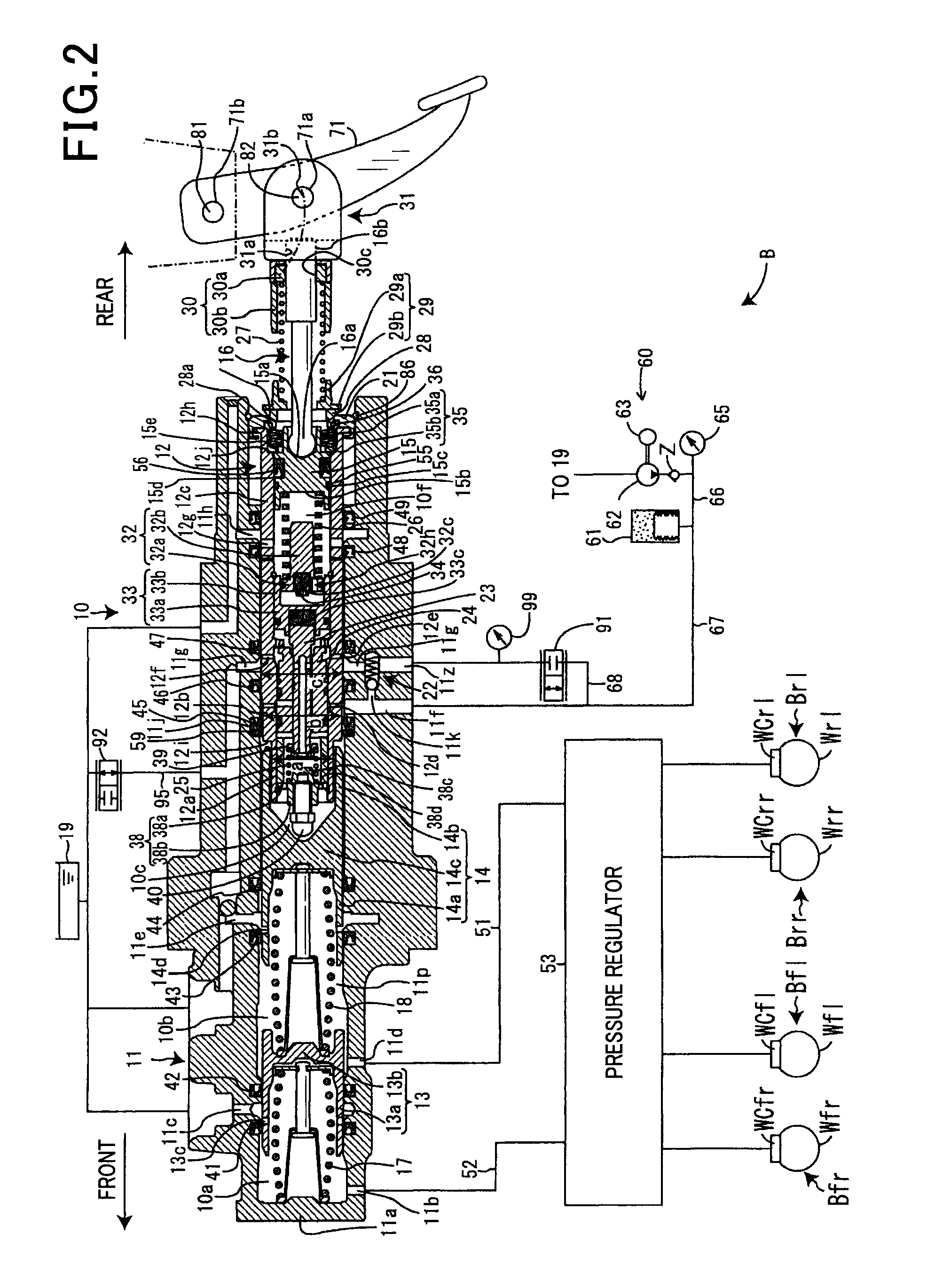

Braking apparatus for vehicle with collision avoidance mechanism

ActiveUS20150210256A1Easy to installImprove installabilityAutomatic initiationsFluid braking transmissionSpool valveSolenoid valve

A braking apparatus for a vehicle is provided which includes a hydraulic booster to make wheels of the vehicle produce frictional braking force, a solenoid valve, and a collision avoidance controller. The solenoid valve selectively exerts the hydraulic pressure of brake fluid stored in an accumulator on a spool valve in the booster. When determining that there is a risk of a collision with an obstacle, the collision avoidance controller opens the solenoid valve to achieve emergency braking to minimize the risk of the collision. Basically, emergency braking is achieved by installing the solenoid valve to selectively exert the hydraulic pressure on the spool valve, thus allowing an emergency avoidance braking system to be constructed with a minimum of equipment and facilitating the mountability of the braking apparatus in the vehicles.

Owner:ADVICS CO LTD

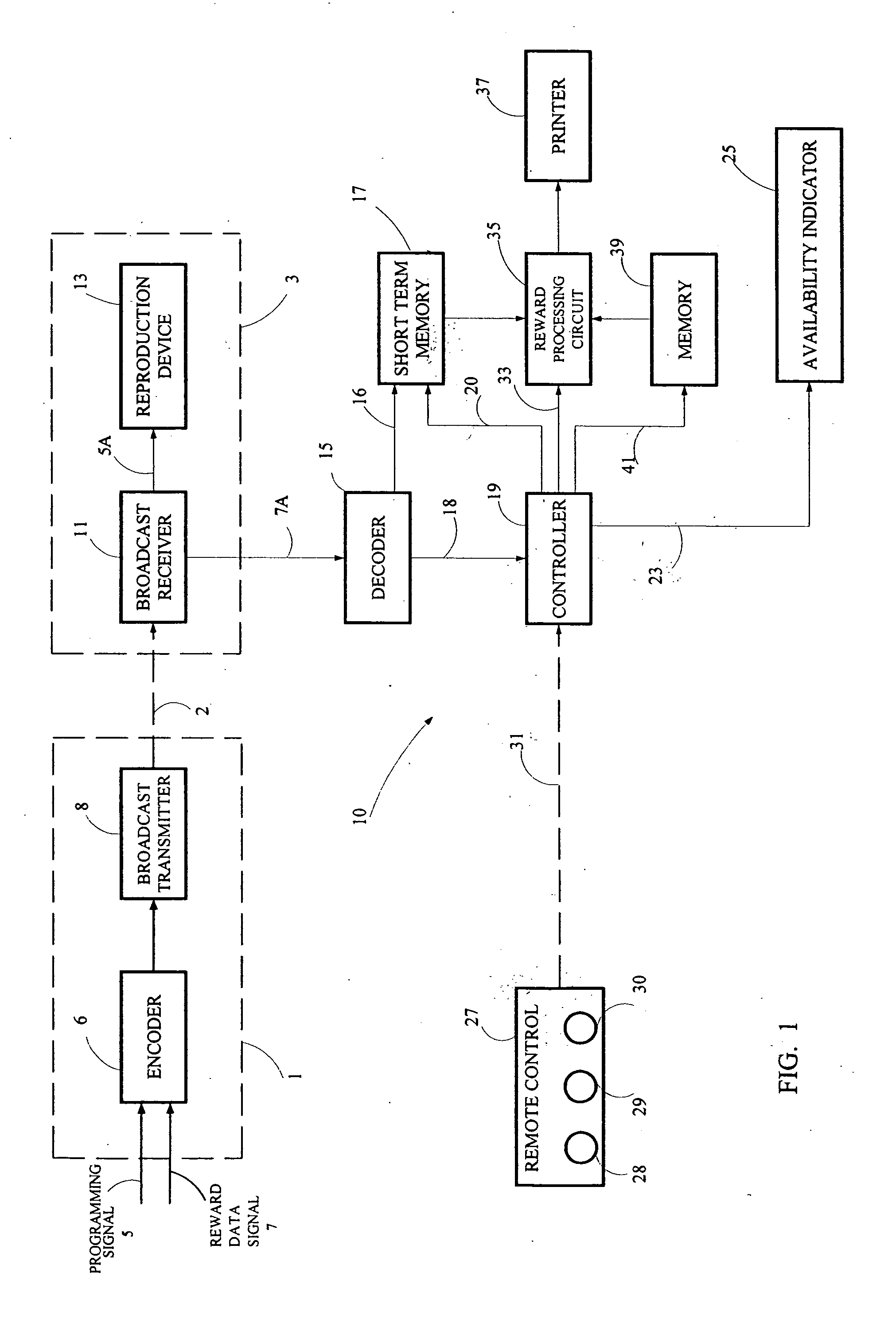

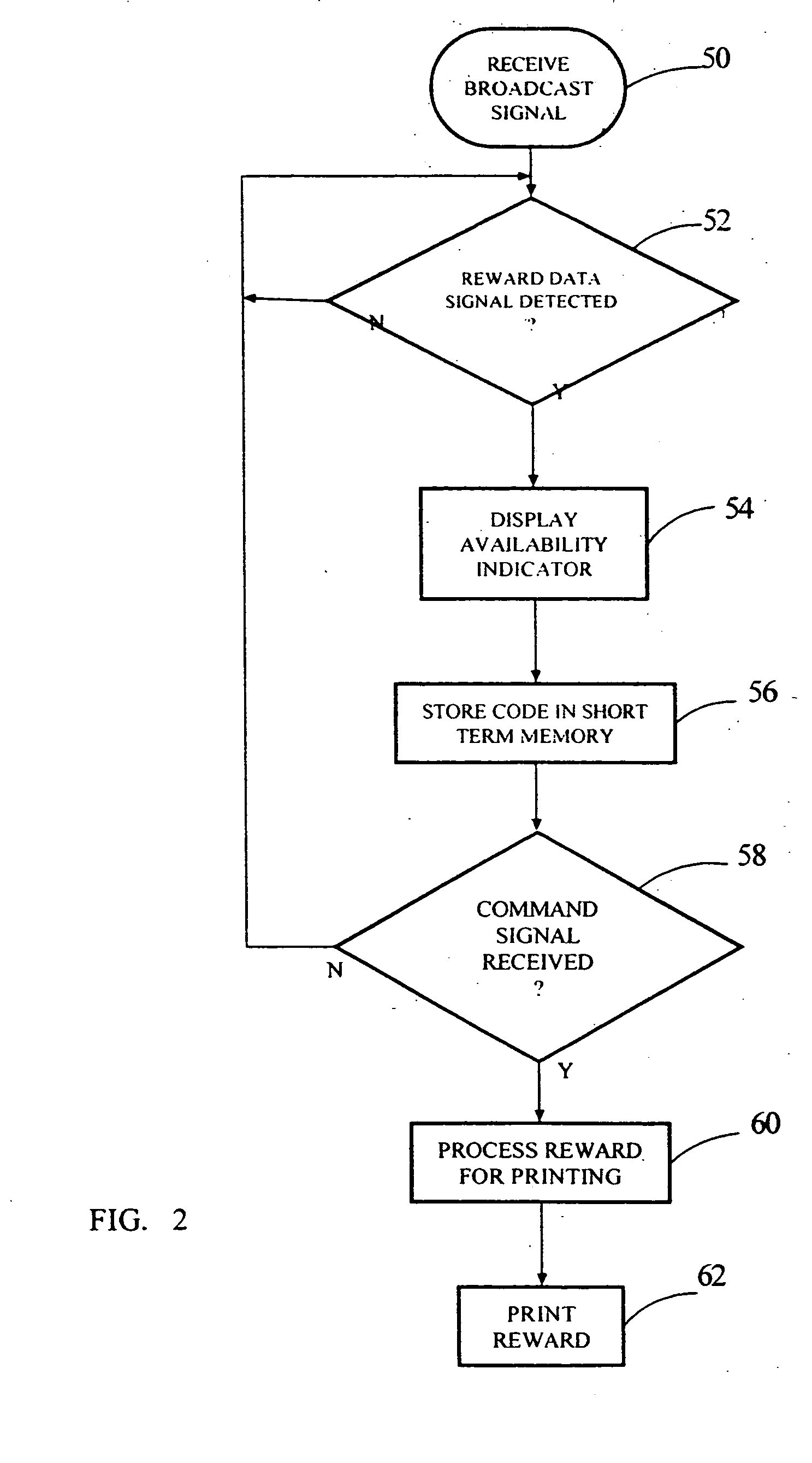

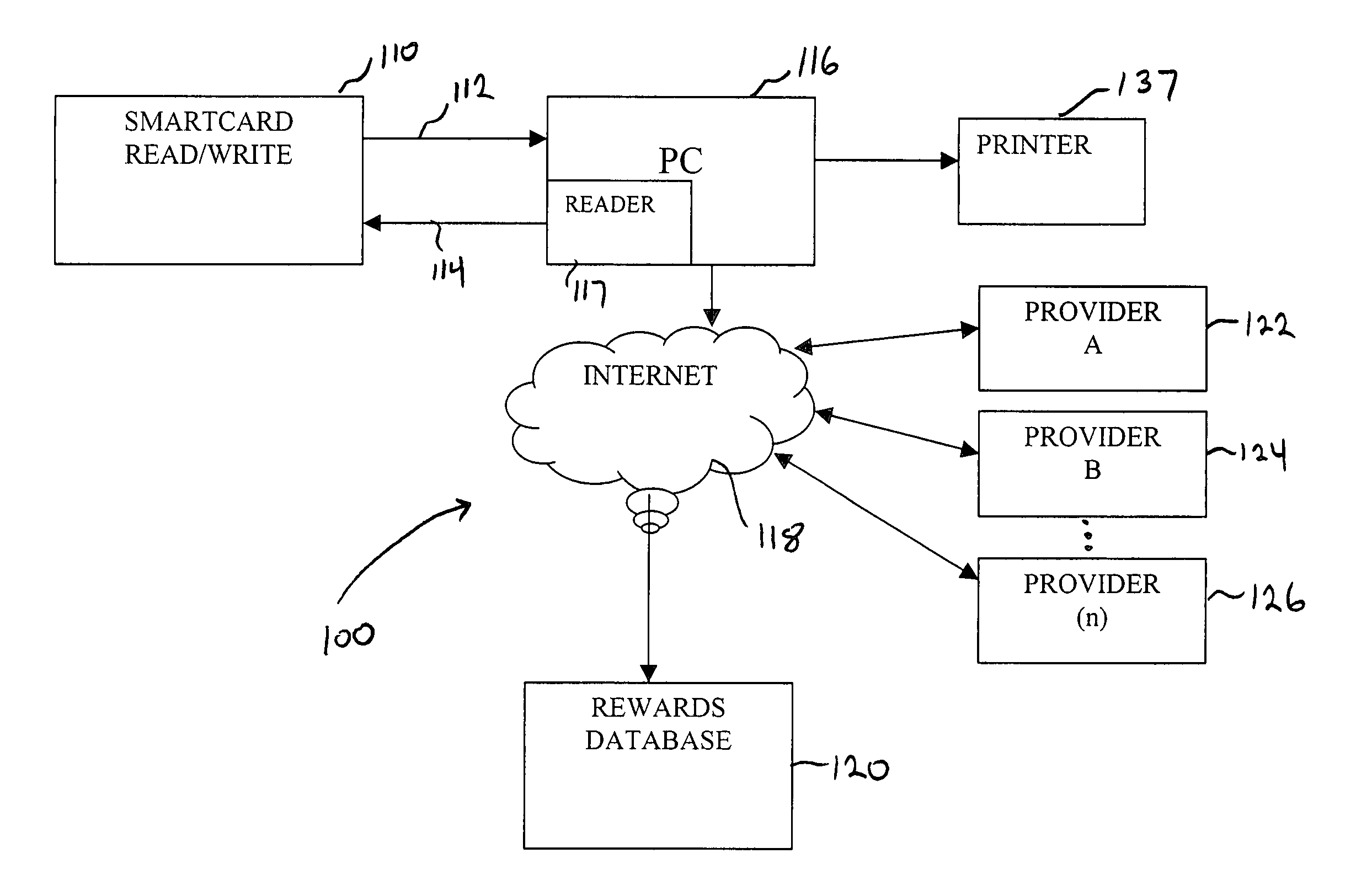

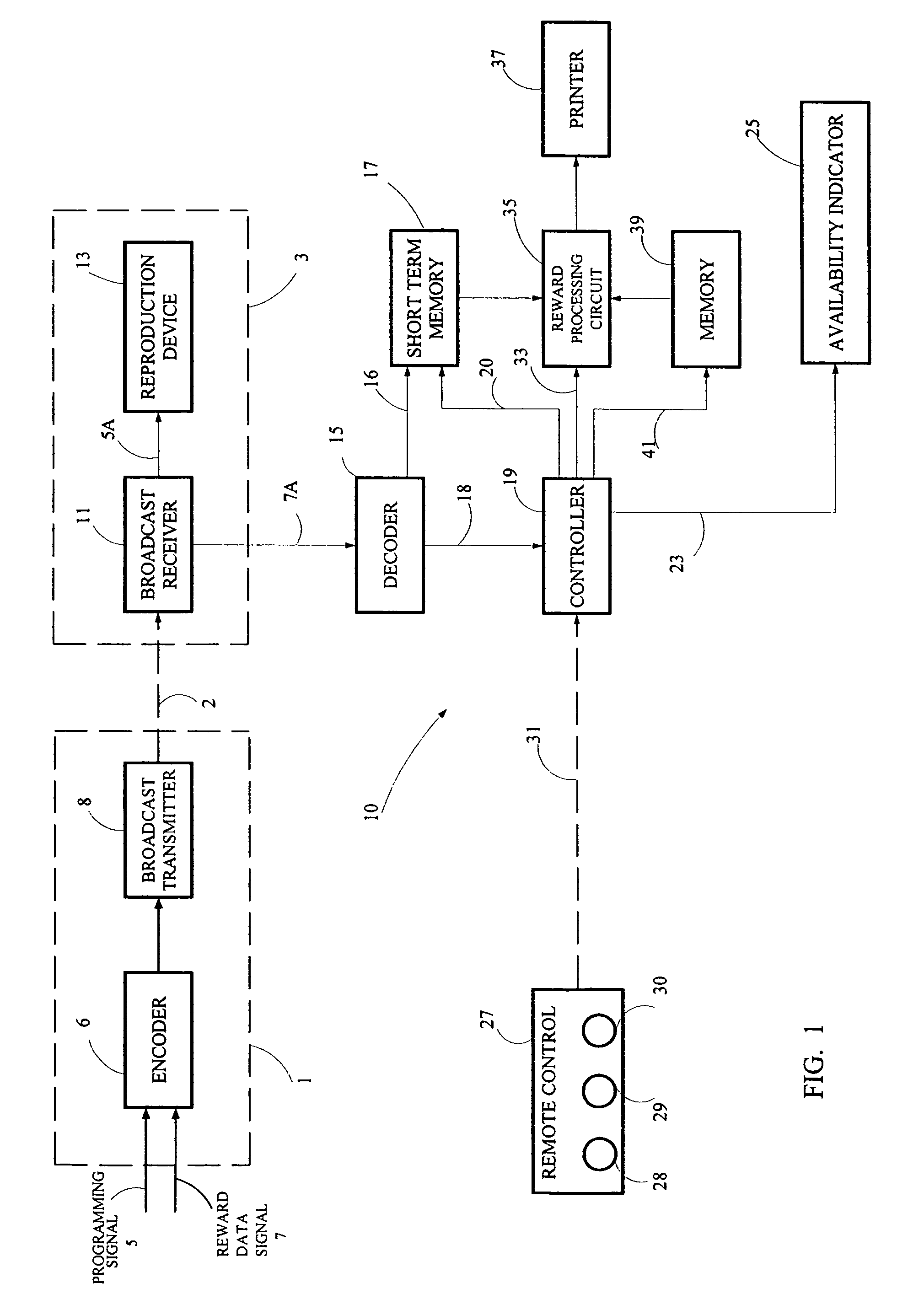

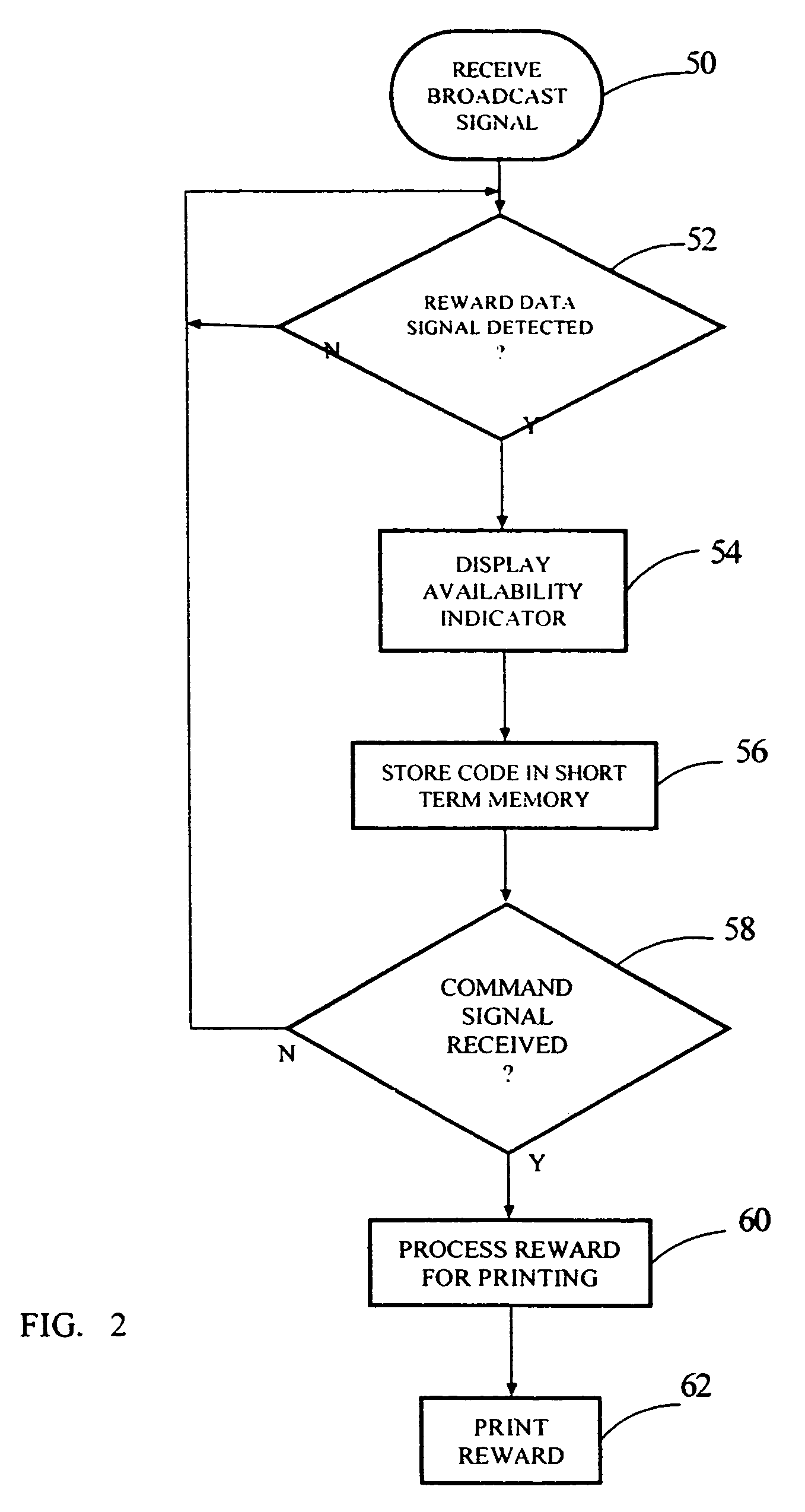

Interactive reward associated with a broadcast

ActiveUS20040230993A1Minimum of equipmentEasy to useTelevision system detailsAdvertisementsData signalCAPTCHA

An interactive technique for generating a supplementary, program-related output. A programming signal and a supplementary, program-related data signal containing rewards data for product or service purchases are combined into a broadcast signal which is then broadcast from a program signal source. The broadcast signal is received, and the programming signal of the received broadcast signal is performed with reproduction equipment for an audience. The rewards data is stored on a portable storage media for use in accessing rewards corresponding to the rewards data. The rewards data can be used for printing coupons used in redeeming the rewards or for use in accessing rewards validation codes for storage on the portable storage media. The portable storage media and / or the printed coupons can then be used to purchase the corresponding goods or services.

Owner:WINMORE

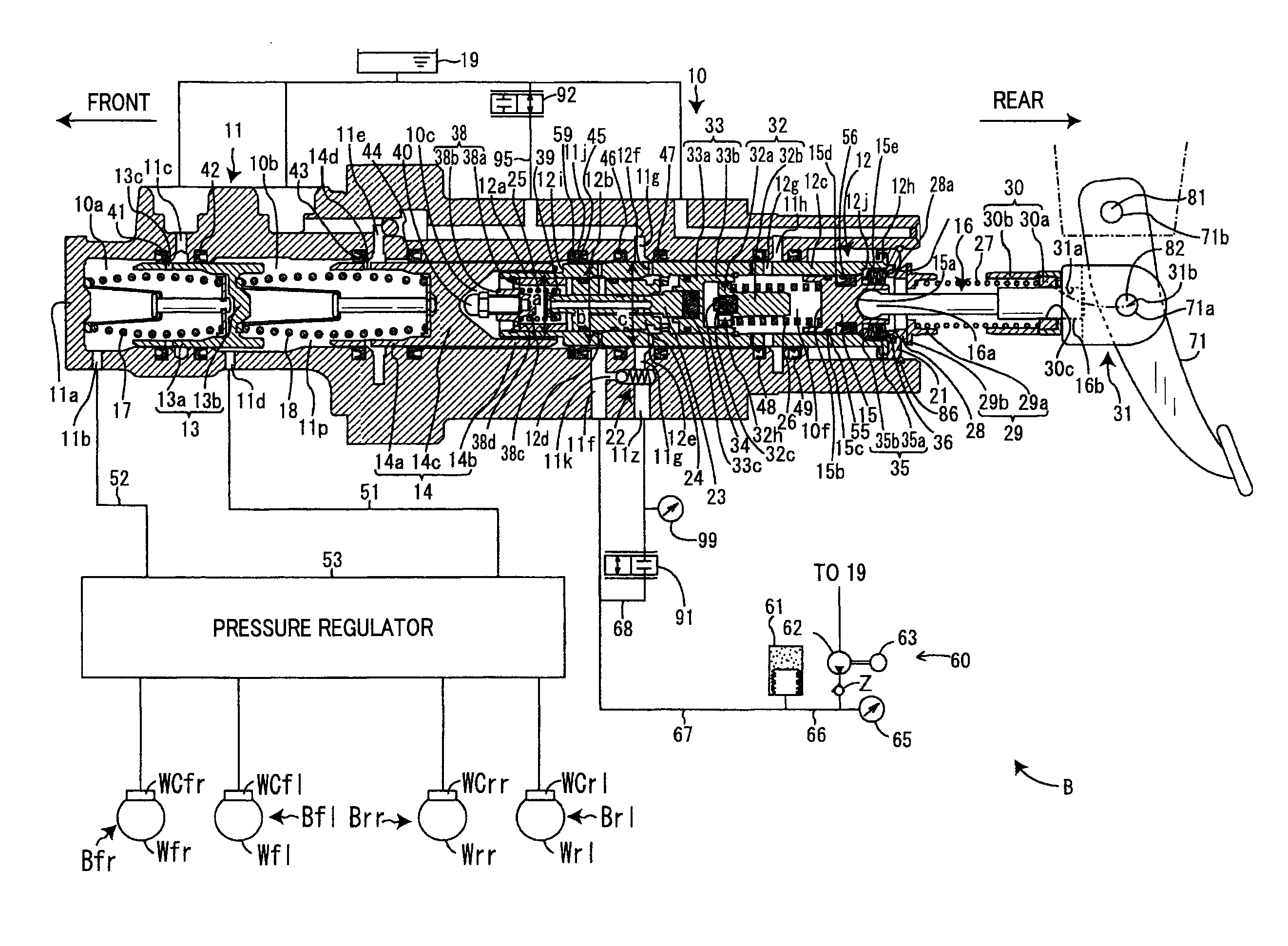

Brake system for vehicle with collision avoidance mechanism

InactiveUS20150001919A1Easy to installImprove installabilityBraking element arrangementsAutomatic initiationsIn vehicleSolenoid valve

A braking device for a vehicle is provided which includes a hydraulic booster to make wheels of the vehicle produce frictional braking force, a solenoid valve installed in a flow path connecting between a brake fluid accumulator and a servo chamber of the hydraulic booster, and a collision avoidance controller. When determining that there is a risk of a collision with an obstacle, the collision avoidance controller opens the first solenoid valve to achieve emergency braking to minimize the risk of the collision. Basically, the emergency braking is achieved only using the solenoid valve, thus allowing an emergency avoidance mechanism of the braking device to be constructed with a minimum of equipment and facilitating the mountability of the braking device in vehicles.

Owner:DENSO CORP

Method for underwater transportation and installation or removal of objects at sea

InactiveUS20050152748A1Low costReduce dynamic loadTowing/pushing equipmentArtificial islandsOil and natural gasWinch

Method for transport and installation of objects at sea, particularly relating to transport and installation of obs jects that are part of the infrastructure in oil and gas fields offshore, the object (4) is put in the sea at a suitable location near the shore or in sheltered waters, then towed to the installation site while being suspended in a slender buoyancy unit (5) acting much like a heave compensating unit. Upon arrival at the installation site, the suspension of the object (4) is transferred from the buoyancy unit (5) to a heave compensated winch (3) on a surface vessel (2), preferably the same vessel as used for the preceding towing operation. The winch is used to lower is the object (4) to its destination on the sea bottom or a predetermined location above the sea bottom.

Owner:AKER MARINE CONTRACTORS

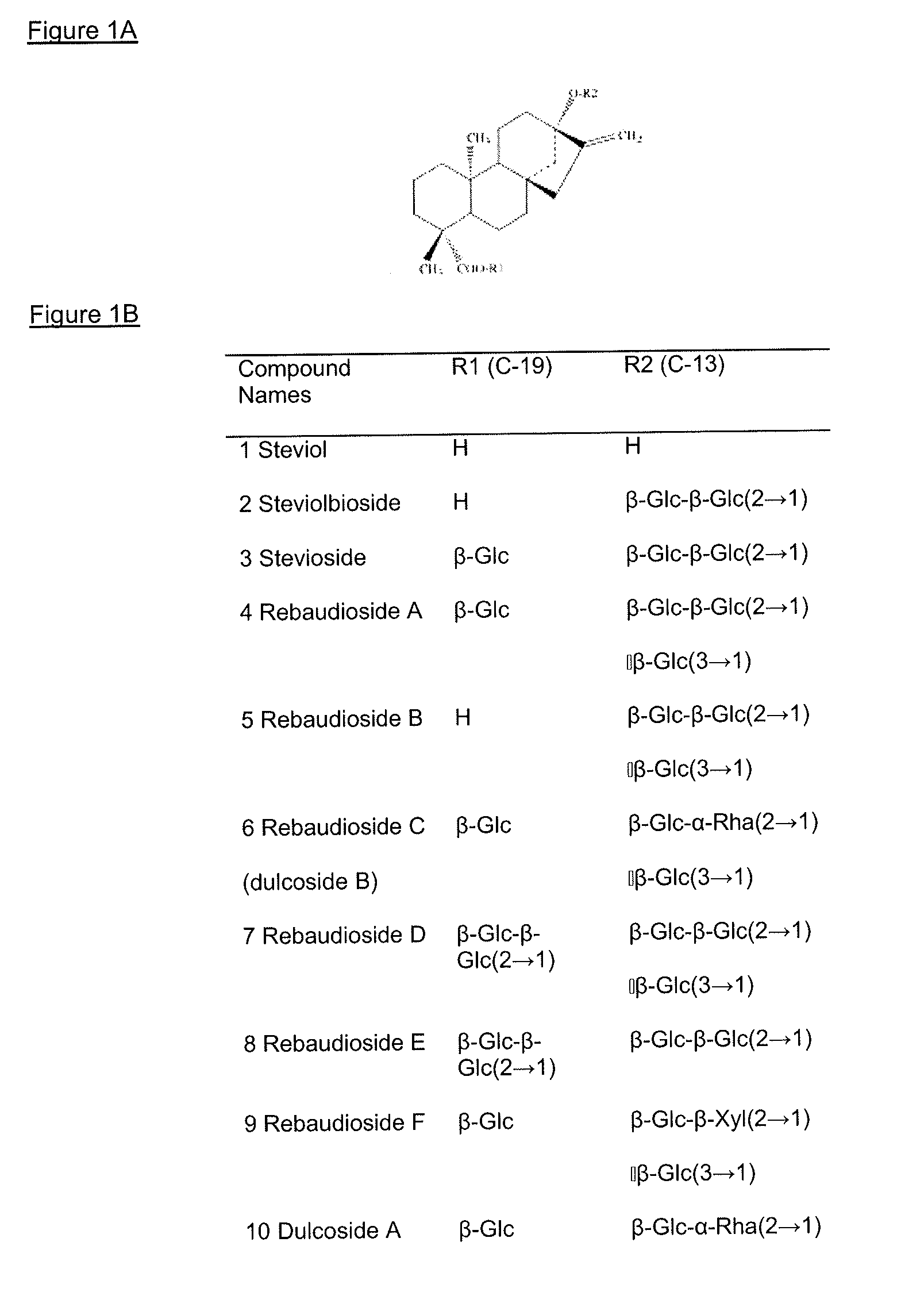

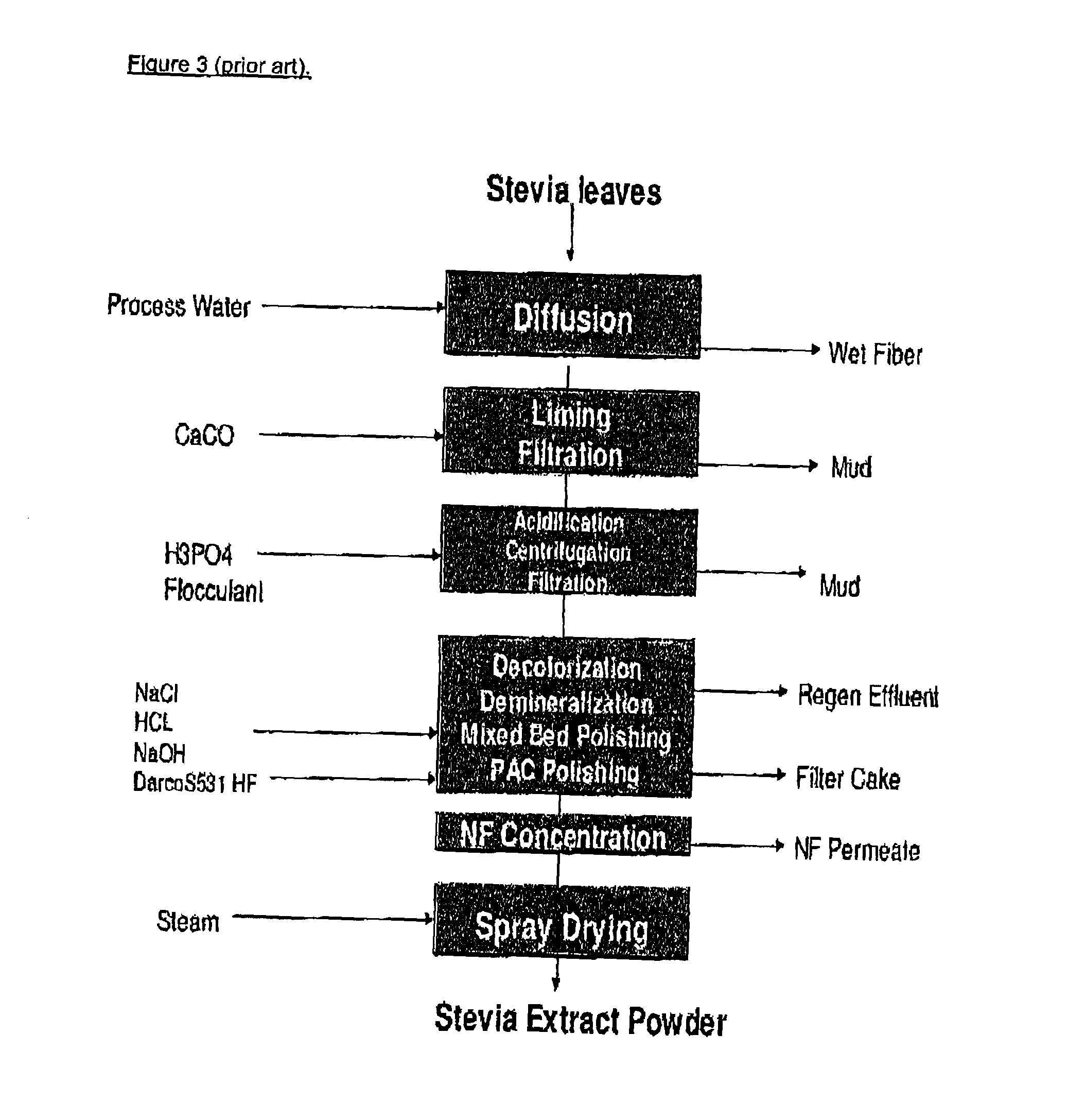

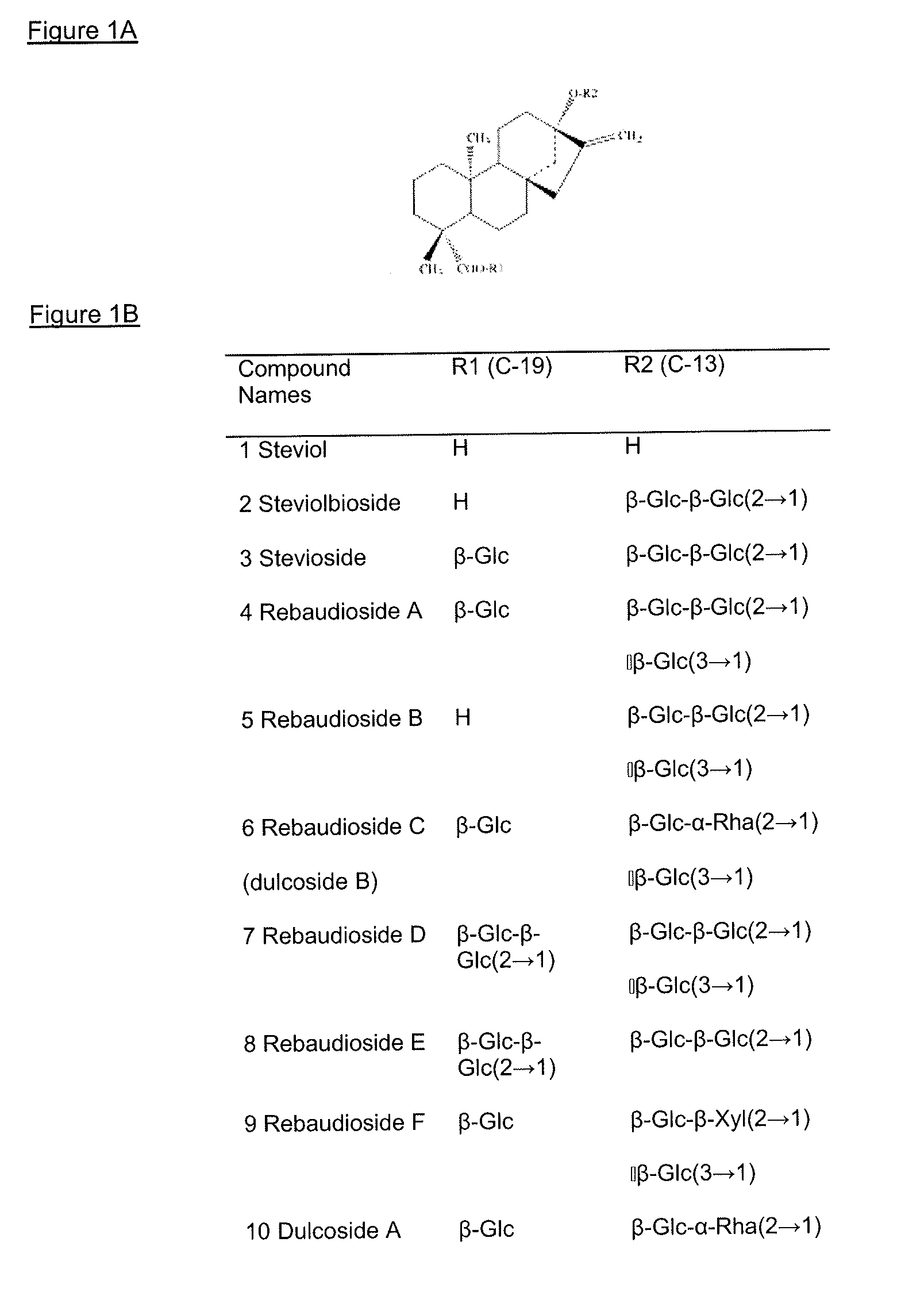

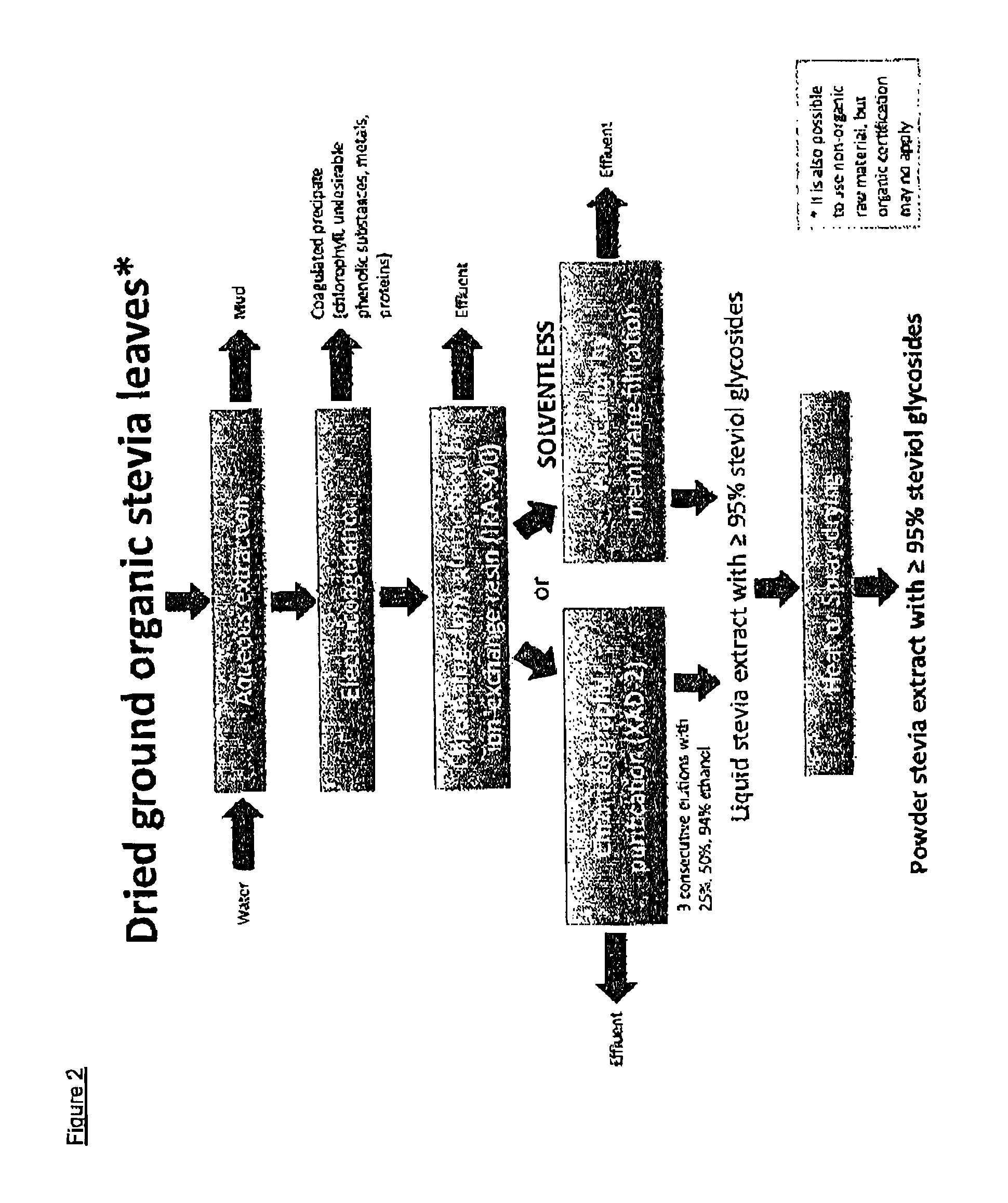

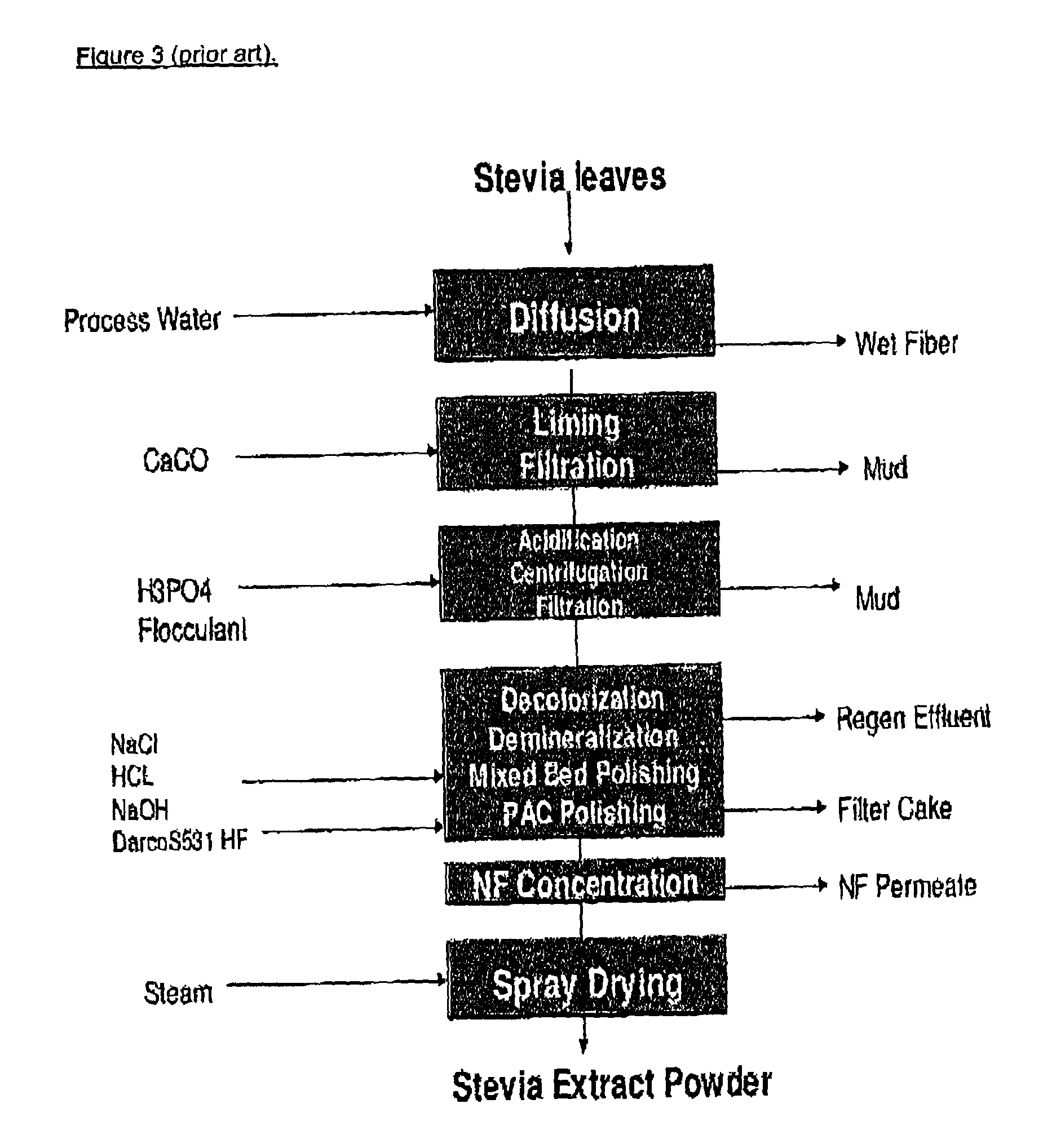

Extraction method for providing an organic certifiable stevia rebaudiana extract

ActiveUS20130108718A1Simple processHigh sweetnessBiocideSemi-permeable membranesOrganic certificationStevia <genus>

A simple extraction method for preparing an organic certifiable stevia extract with high sweetness and optionally with antioxidant properties is provided. The extraction method involves extraction of stevia leaves that have been dried and grinded with a hot solvent generally regarded as safe (GRAS), allowing the dissolution of the sweetening compounds naturally present therein. These sweetening compounds include steviosides and rebaudioside A, which are purified from the extracts by two or more successive chromatographic purifications steps. The sweetening compounds are then eluted with an appropriate elution solvent. The simplicity and organic certification of the method provide advantages over the methods currently employed in the stevia industry.

Owner:JUSTBIO

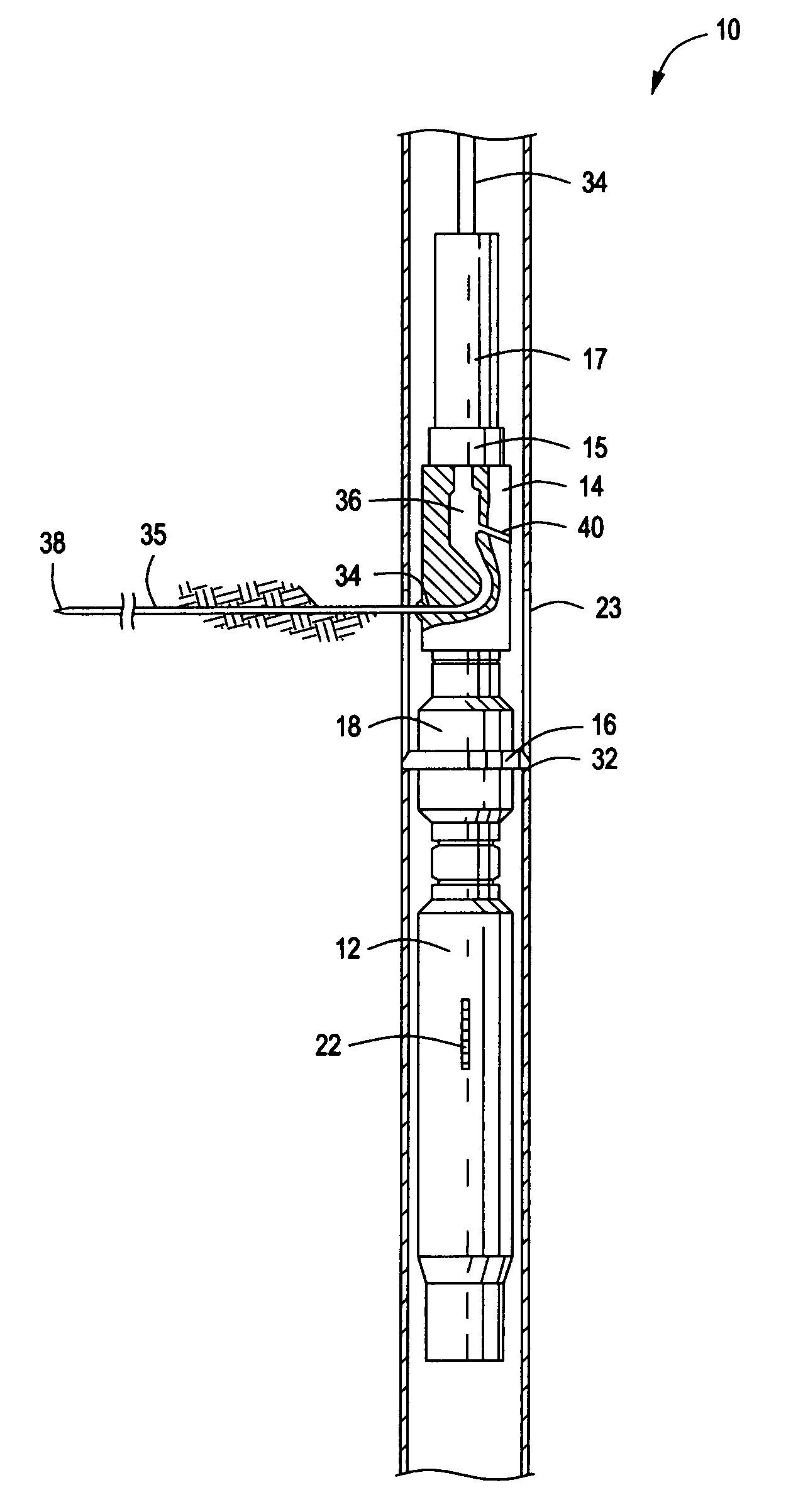

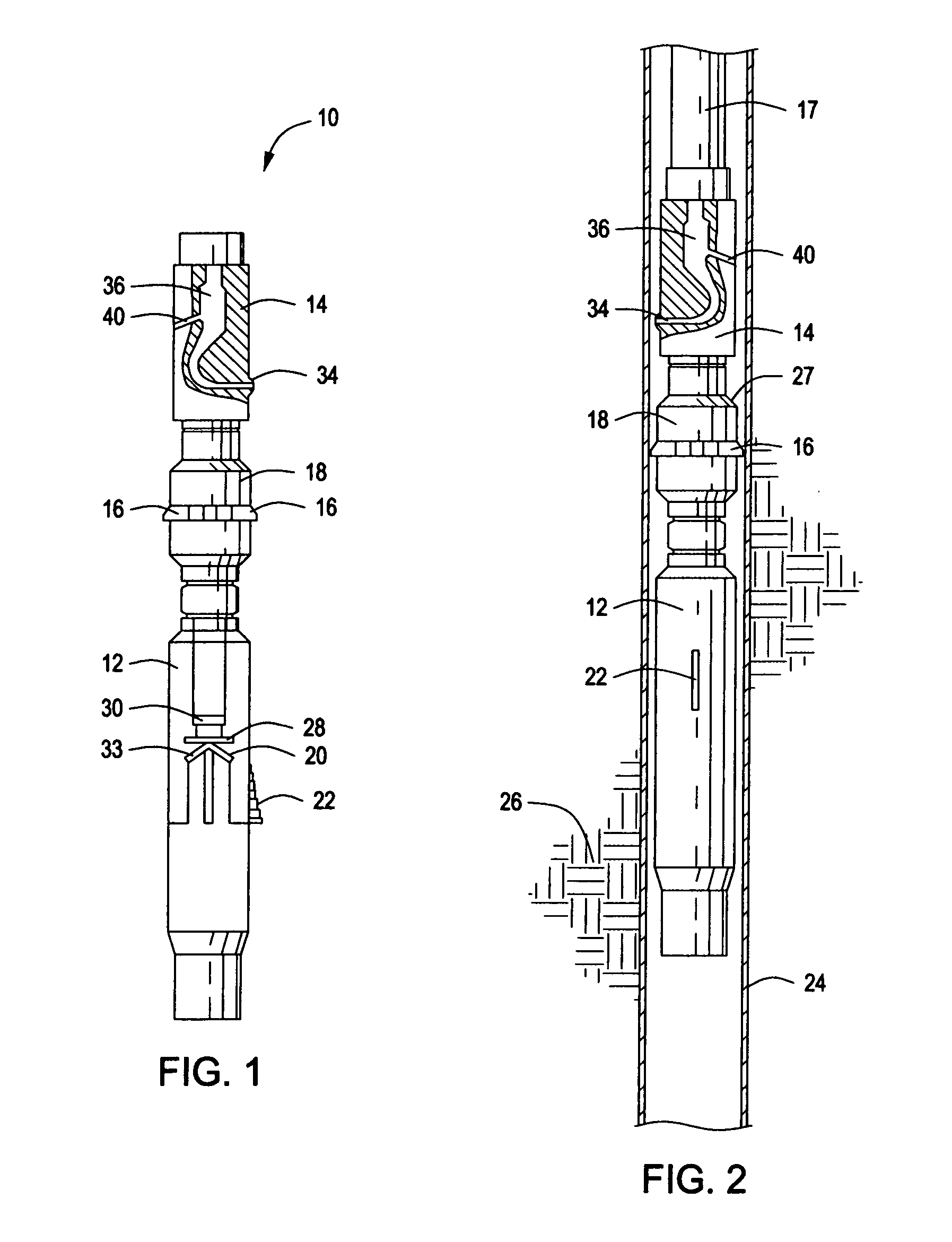

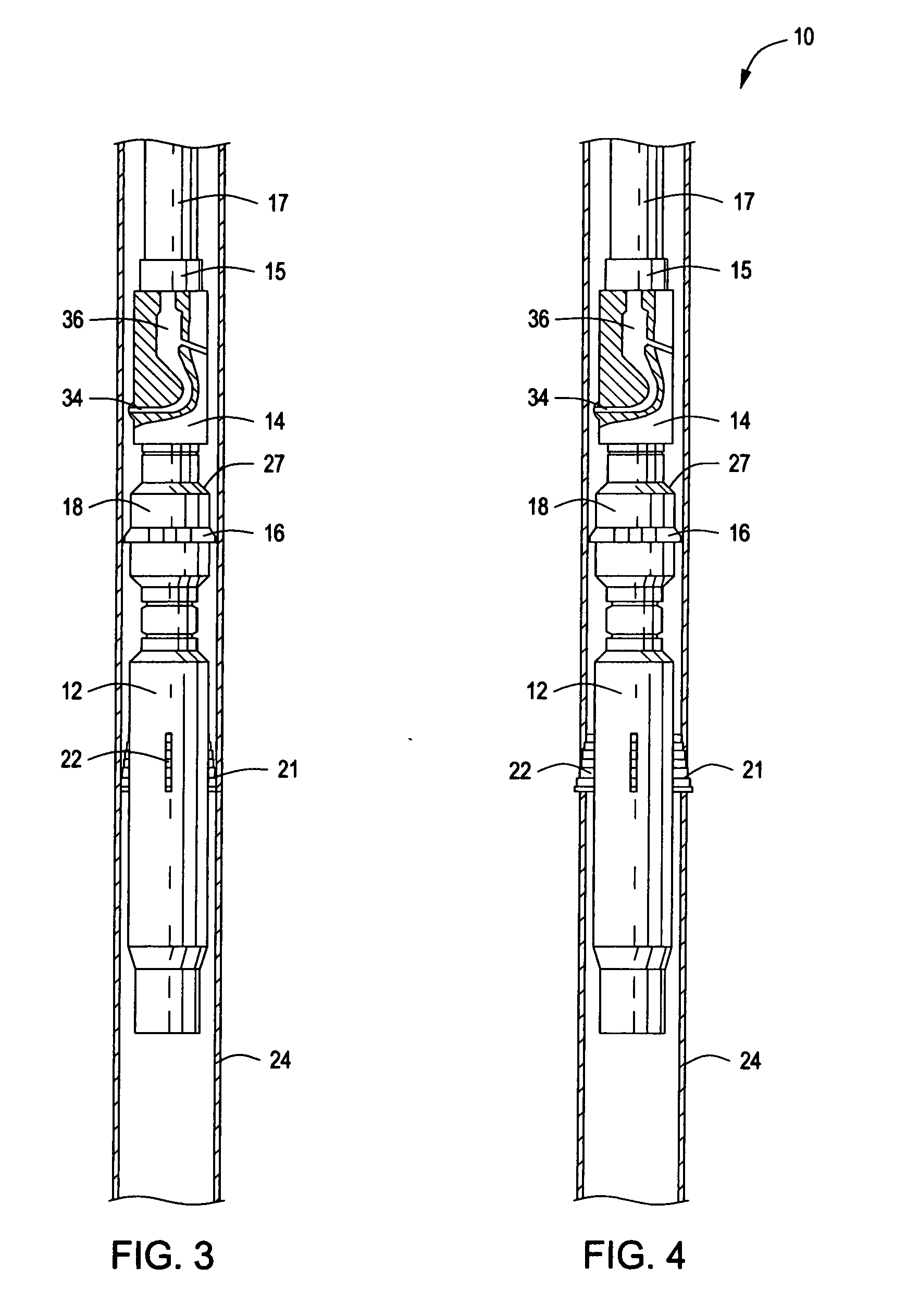

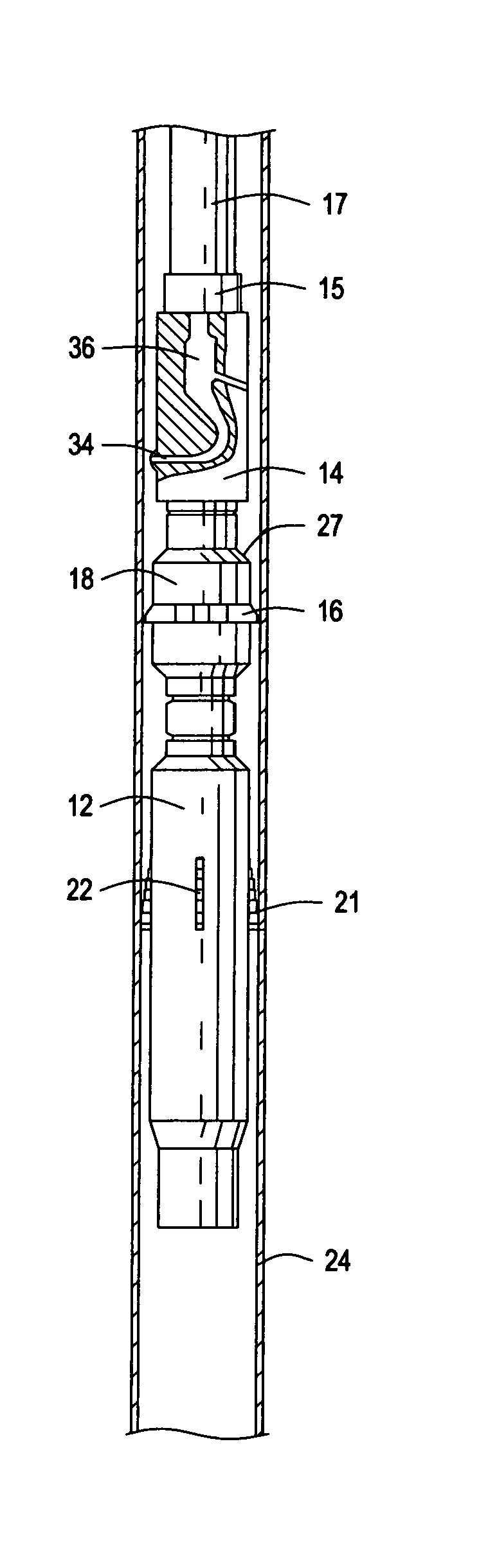

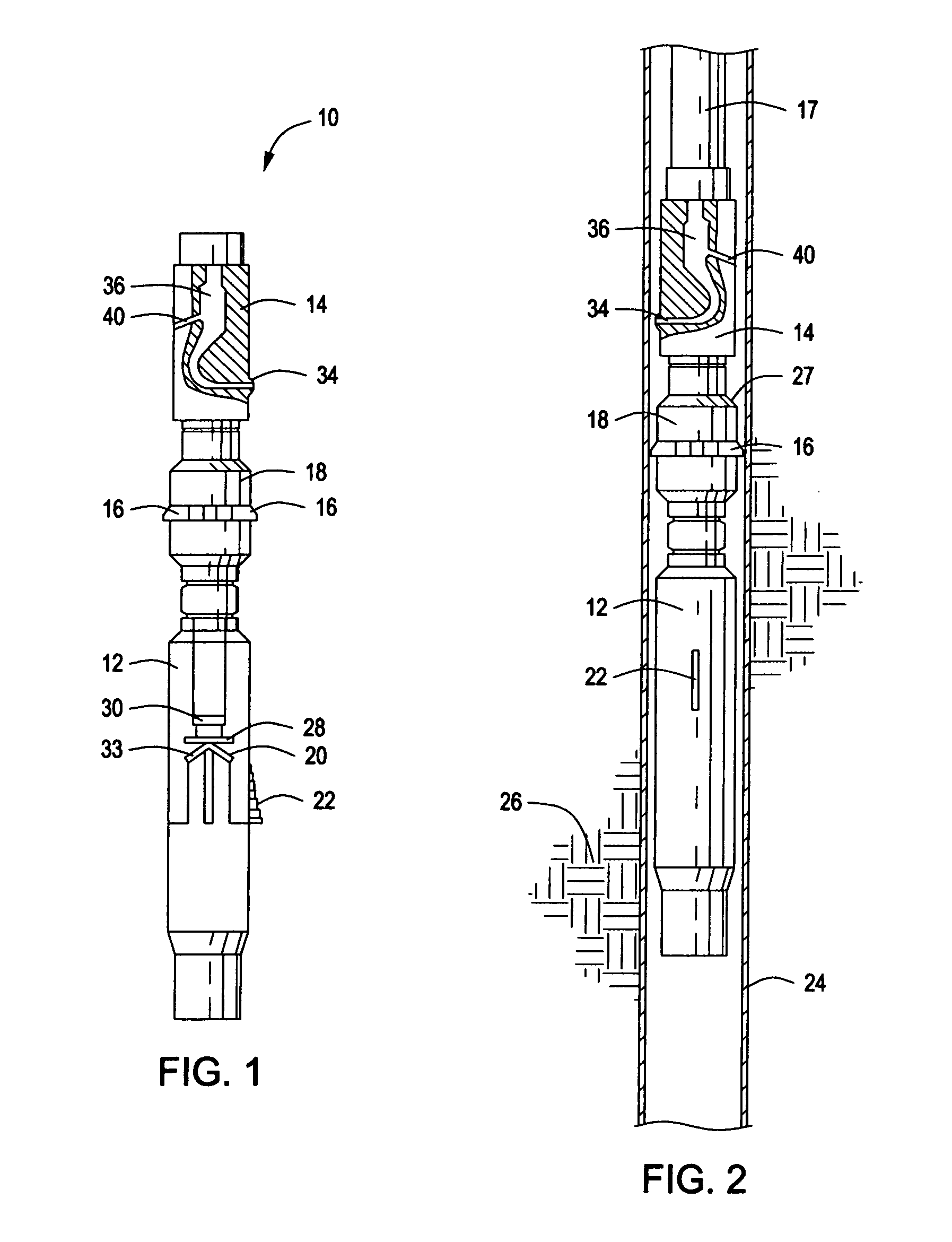

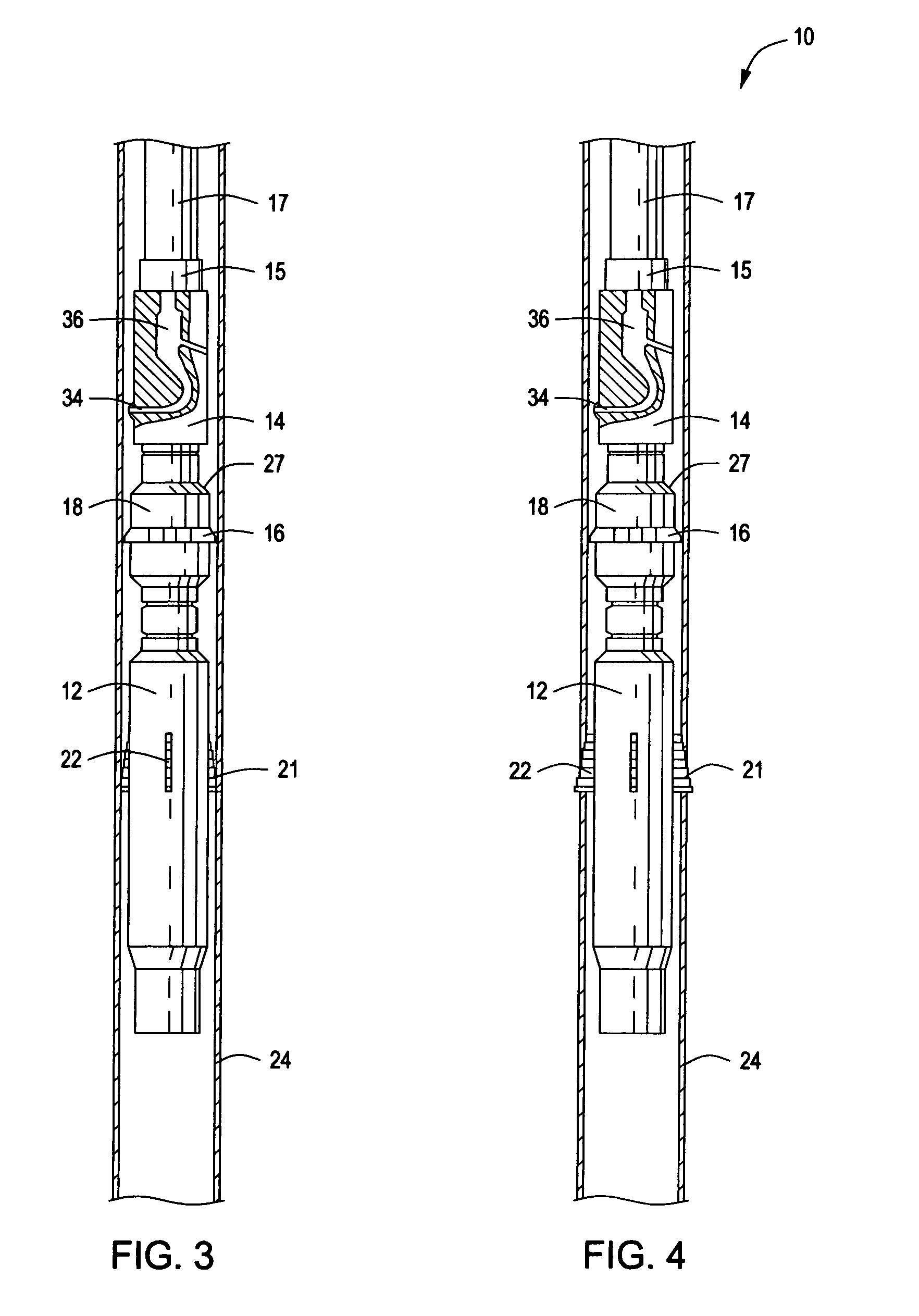

Method and apparatus for single run cutting of well casing and forming subsurface lateral passages from a well

An apparatus and system for a single run process for well installations to cut or mill away a section of the casing of a well and then position an attached deflecting device to form radial boreholes or passages in a production formation that is intersected by the wellbore. This invention allows the lateral boreholes to be selectively oriented angularly upwardly or downwardly in relation to the casing space that has been formed or oriented in selectively radially spaced relation if desired.

Owner:SCHLUMBERGER TECH CORP

Authorization system and method

ActiveUS8020756B2Low costShorten the timeComplete banking machinesAcutation objectsDocking stationProcessor register

A system including a device having a screen and a memory to hold card data necessary to complete POS / ATM transactions. The device has an authorization, signature, PIN button and scroll wheel. Branding areas allow distributors to leverage space on the device. When the merchandise has been processed and ready to be paid for, the device holder either places their device in a docking station or holds it in front of a contact less reader. When the merchant is ready for authorization, the holder presses transmits the data to a register so the merchant can send the data through the card network for authorization. Once the transaction is authorized, the merchant requests the signature, fingerprint, and / or photo of the holder, which can be displayed, on the register to authenticate the holder. Upon completion, the transaction information is transmitted back to the device for storage and retrieval at a later date.

Owner:FIDELITY INFORMATION SERVICES LLC

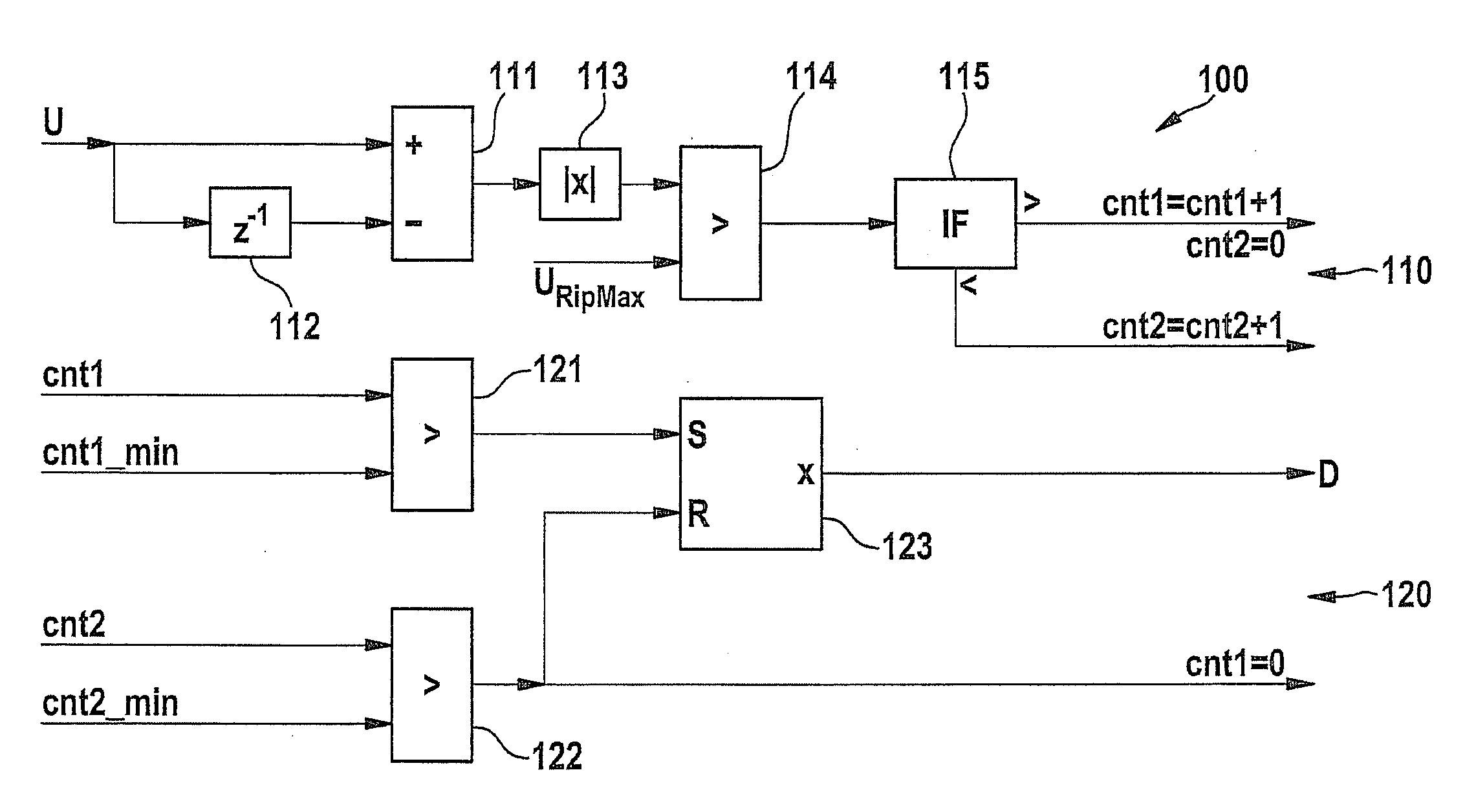

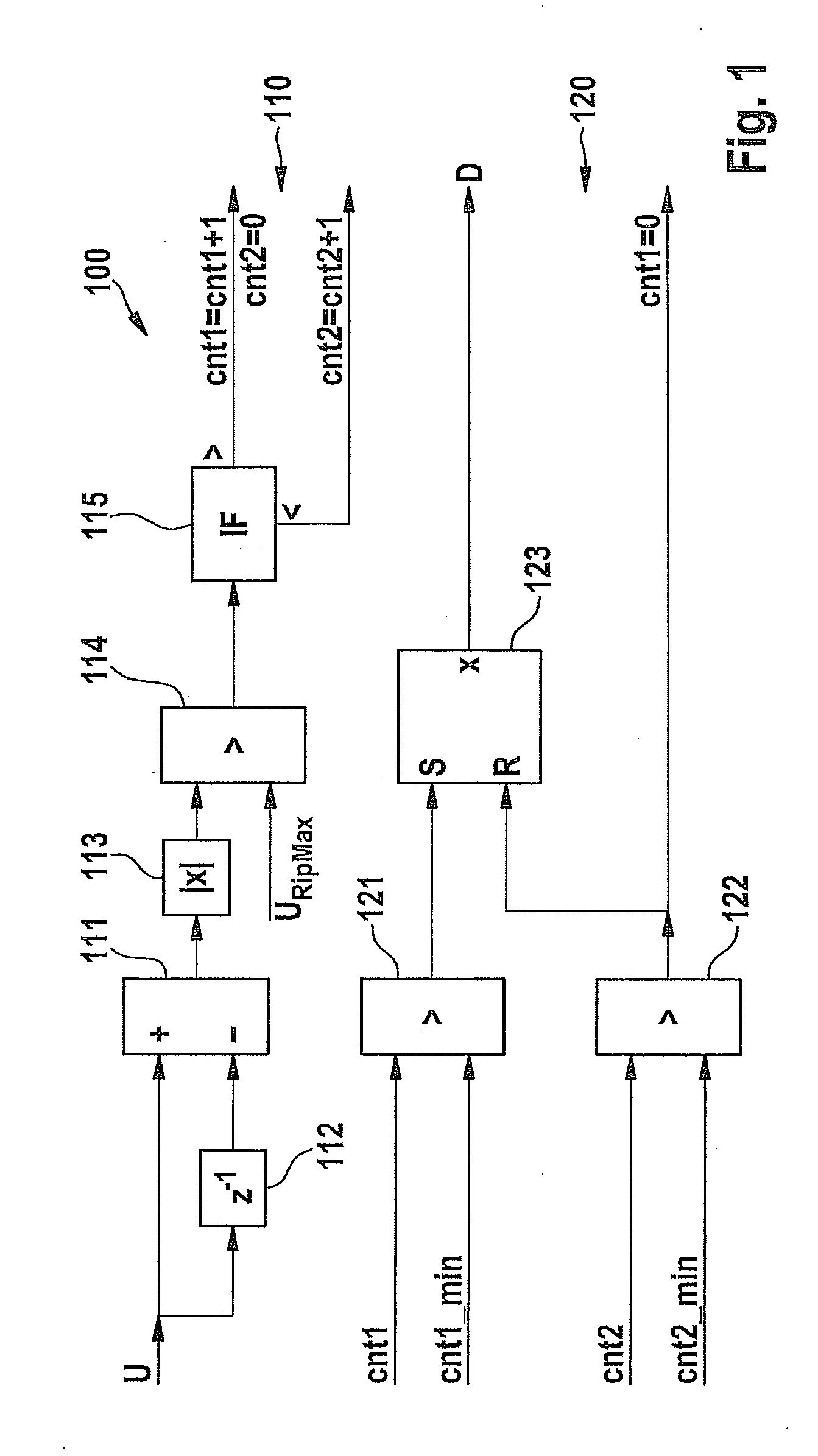

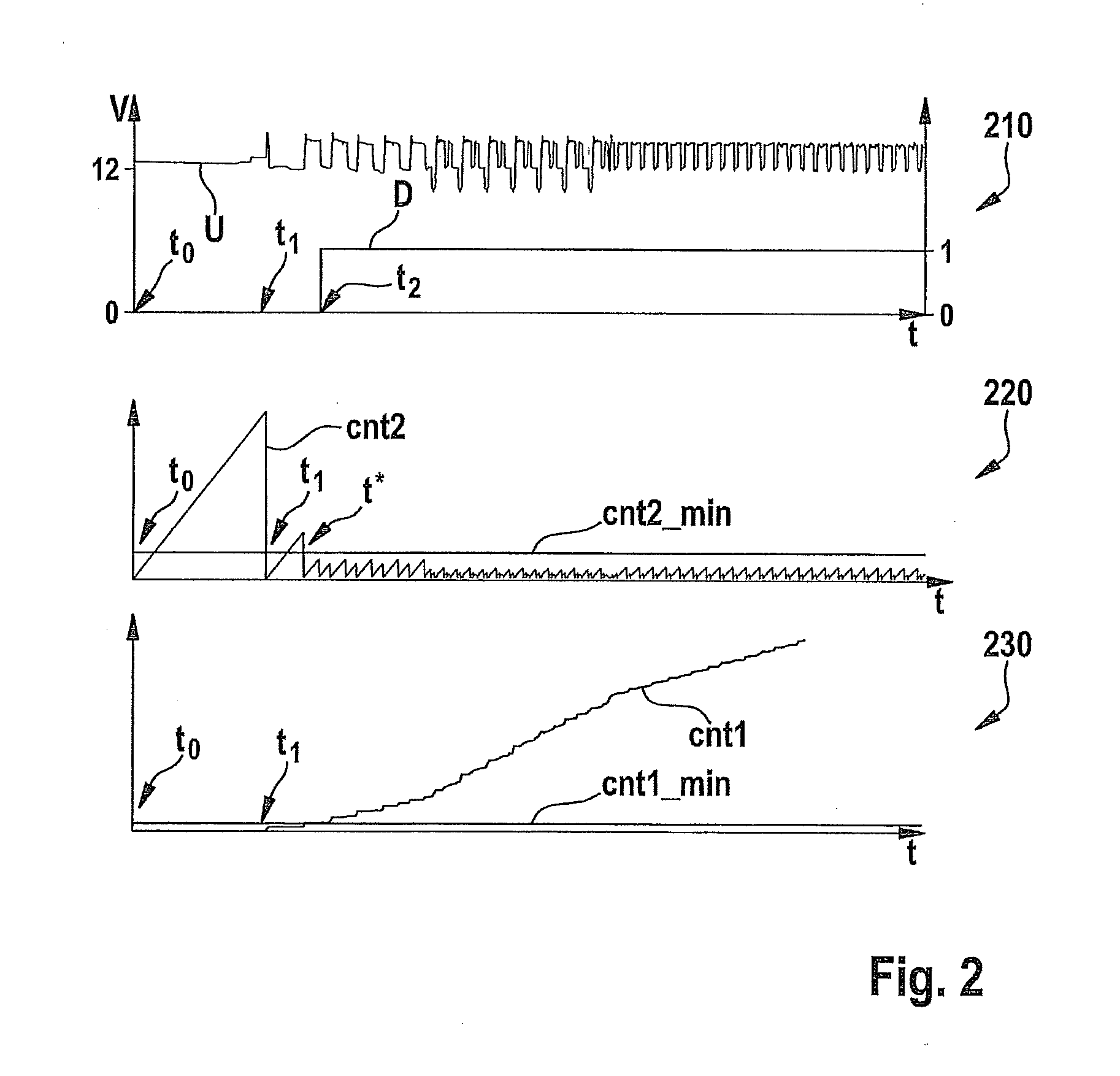

Method for assessing the ripple of a signal

ActiveUS20130085697A1Increase robustnessEasy to implementNoise figure or signal-to-noise ratio measurementAmplifier modifications to reduce noise influenceEngineeringComputational physics

A method for assessing a ripple of a signal, includes: a) determining a first signal value at a determination point in time, b) determining a signal value difference between the first signal value and a signal value determined at a previous determination point in time, c) incrementing an undershoot counter if the signal value difference falls below a first difference threshold value, and incrementing an overshoot counter and resetting the undershoot counter if the signal value difference exceeds a second difference threshold value, and d) determining that no ripple overshoot is present and resetting the overshoot counter if the undershoot counter overshoots an undershoot threshold value, and determining that a ripple overshoot is present if the overshoot counter exceeds an overshoot threshold value and the undershoot counter does not exceed an undershoot threshold value.

Owner:ROBERT BOSCH GMBH

Method and apparatus for single run cutting of well casing and forming subsurface lateral passages from a well

An apparatus and system for a single run process for well installations to cut or mill away a section of the casing of a well and then position an attached deflecting device to form radial boreholes or passages in a production formation that is intersected by the wellbore. This invention allows the lateral boreholes to be selectively oriented angularly upwardly or downwardly in relation to the casing space that has been formed or oriented in selectively radially spaced relation if desired.

Owner:SCHLUMBERGER TECH CORP

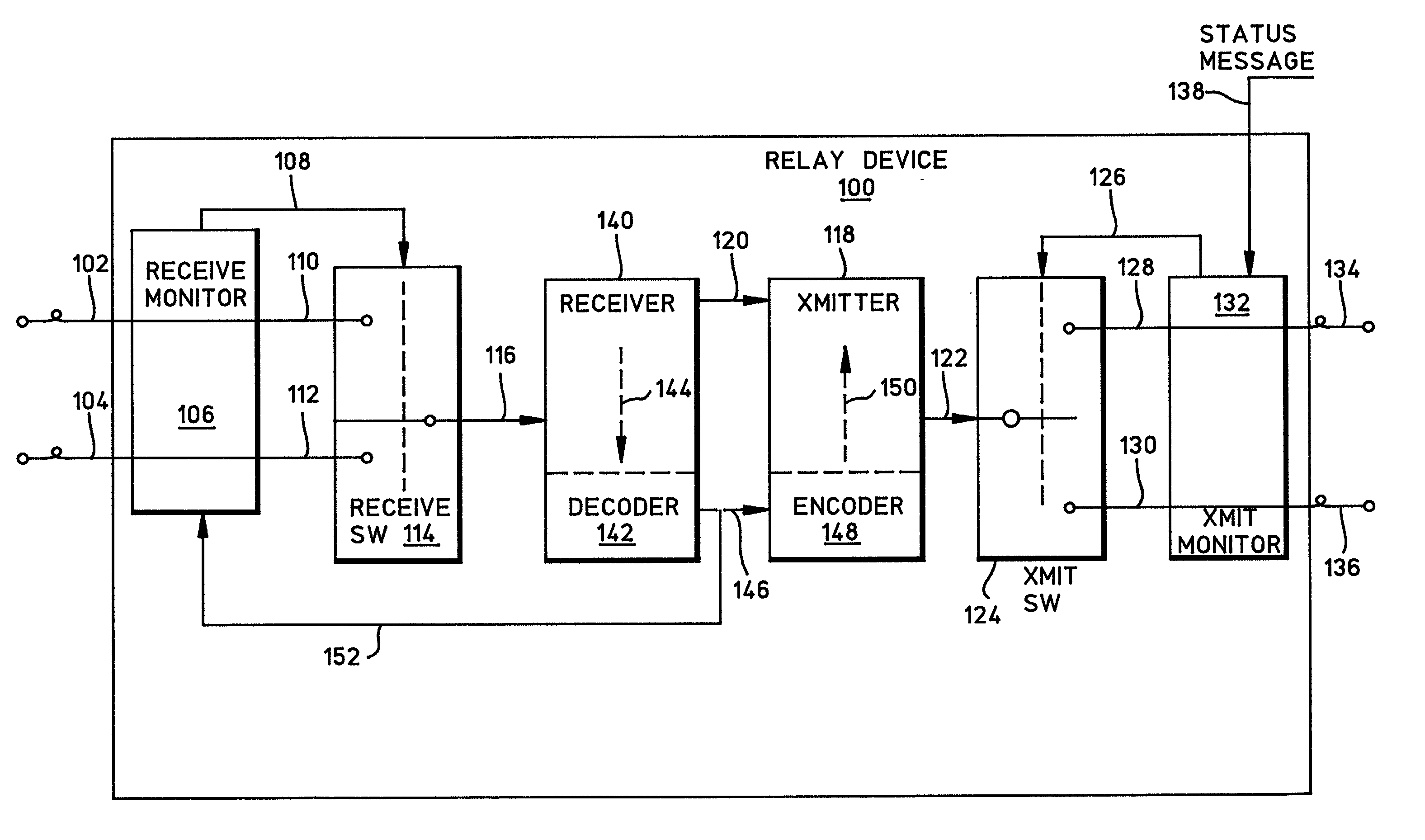

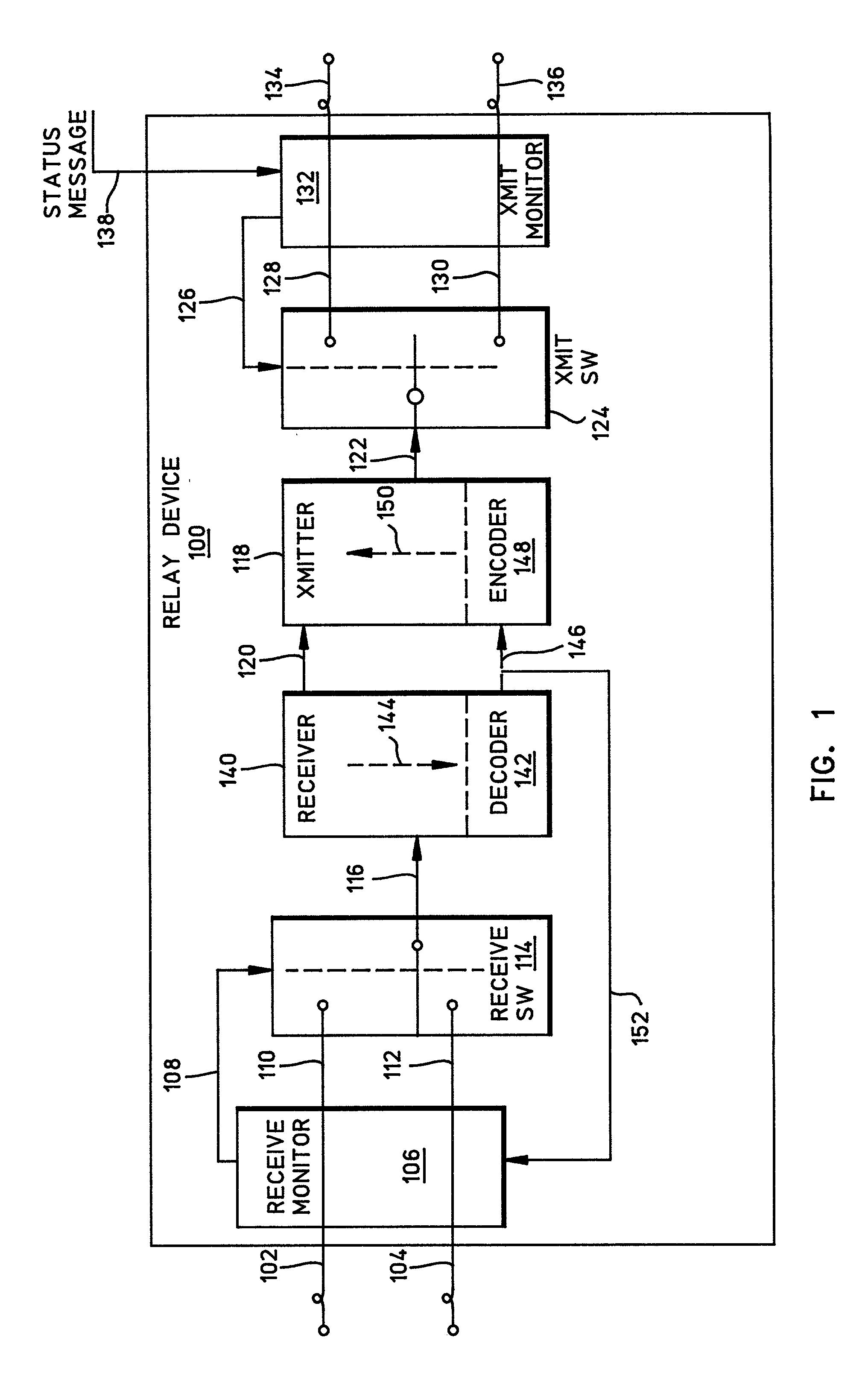

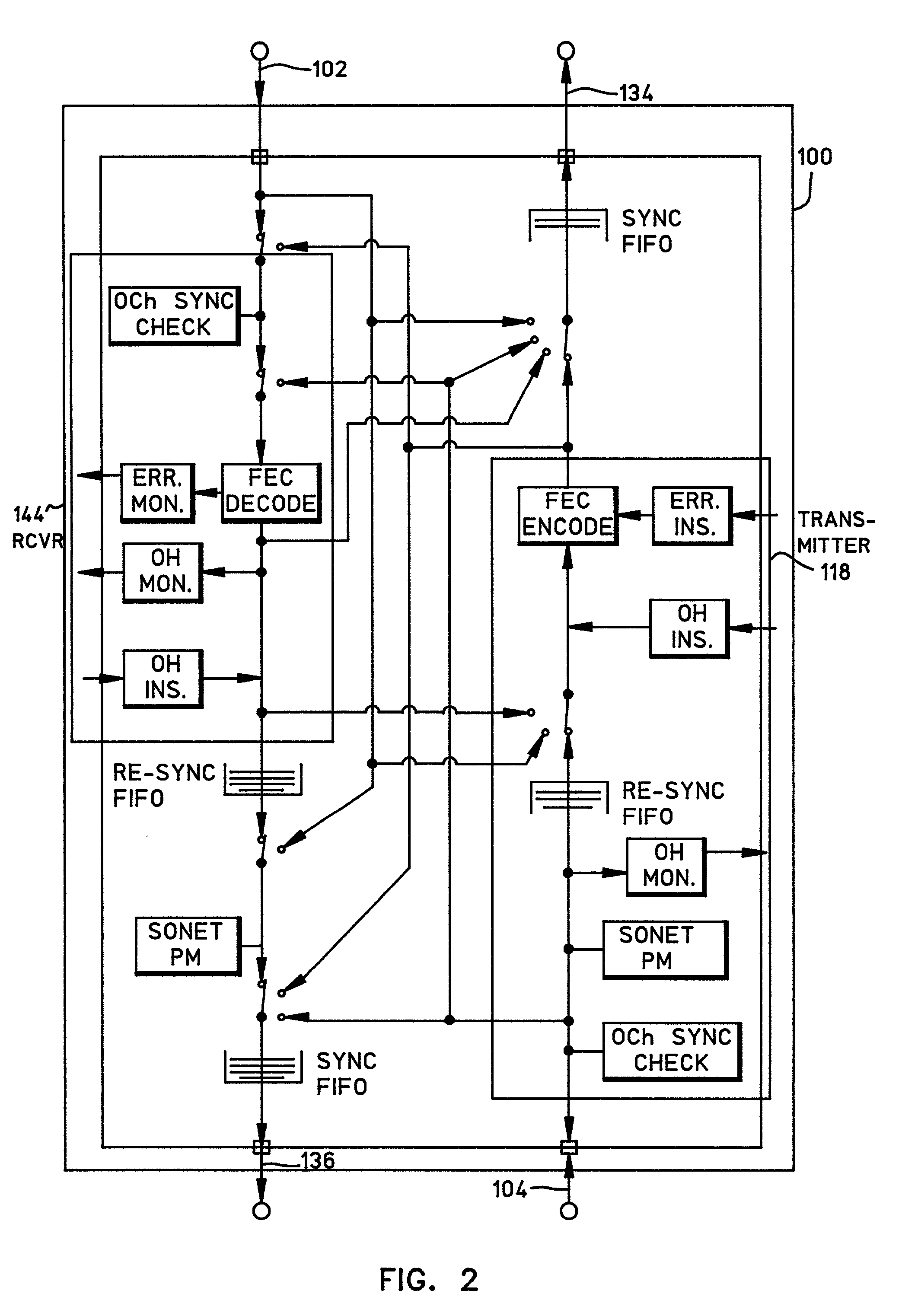

System and method for redundant path connections in digital communications network

ActiveUS6961366B1Easy diagnosisCreate in networkPulse transformerFrequency-division multiplex detailsDevice MonitorForward error correction

A system and method for providing redundancy in an integrated circuit (IC) relay device has been disclosed. The relay device accepts communications on a first and second receive path. The relay device monitors communications on both the receive paths, and selects a path having a high degree of integrity. Likewise, the relay selectively supplies communications on a first and second transmit path. The relay device selects the transmit path having the proper measure of communication integrity. Communications integrity can be based upon internally monitored criteria such as bit error rate, synchronization, clock signals, and forward error correction. Alternately, the integrity is determined external to the relay, and the relay responds to external switch commands.

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

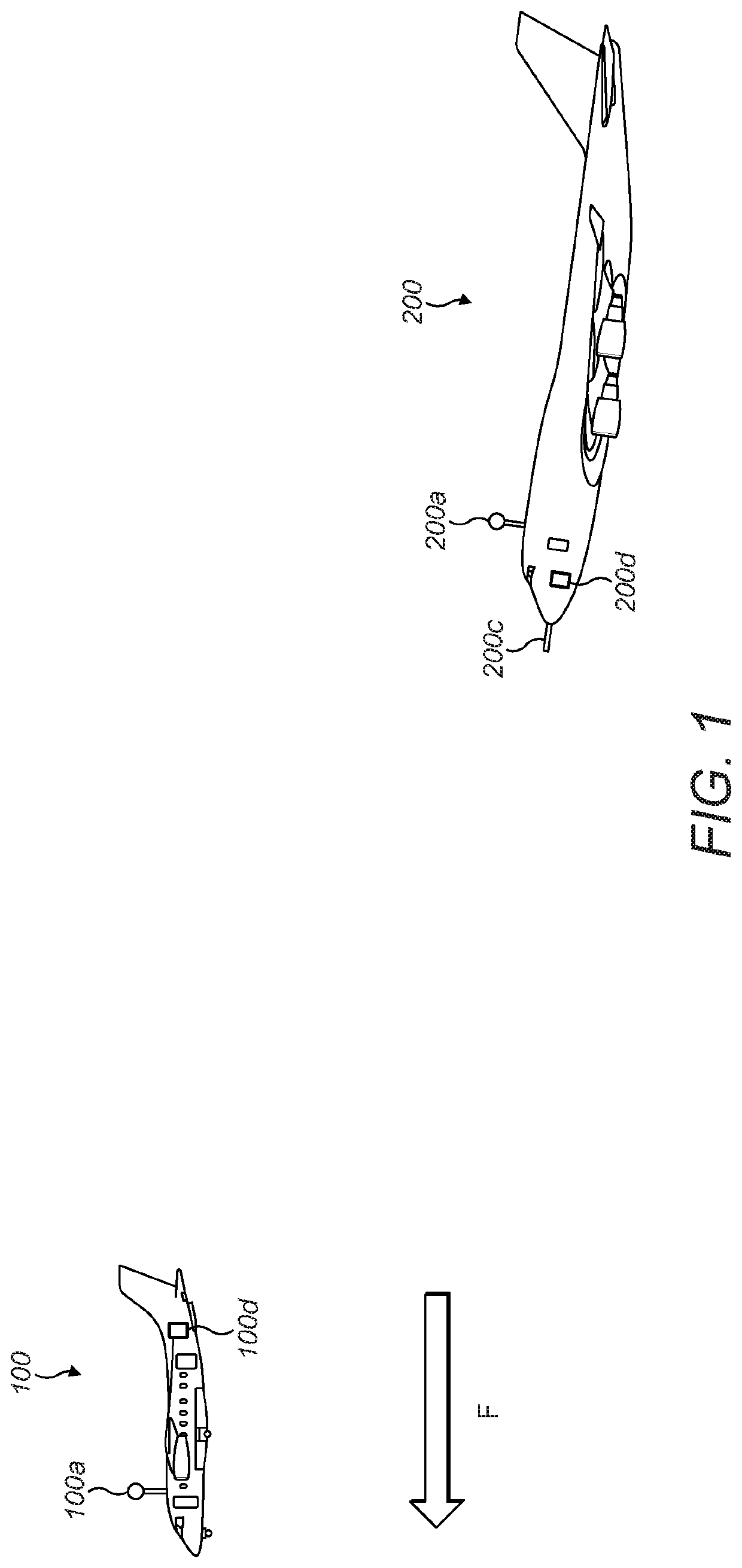

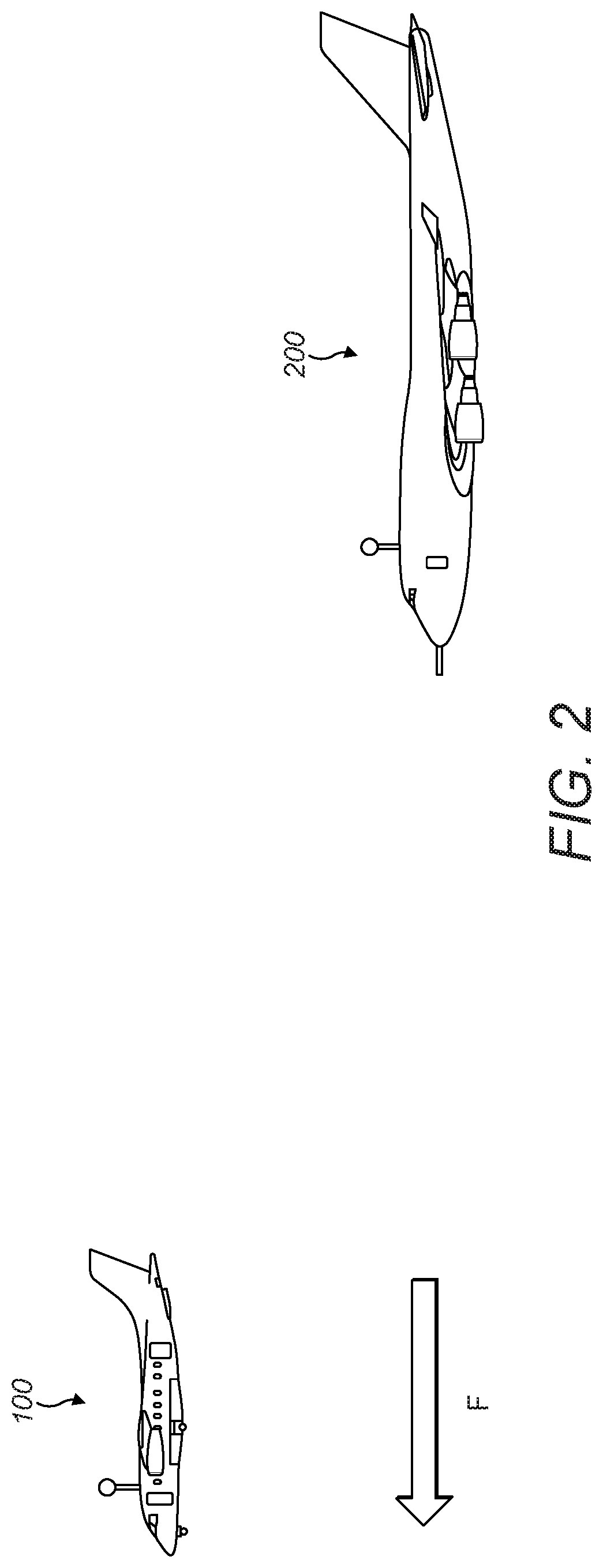

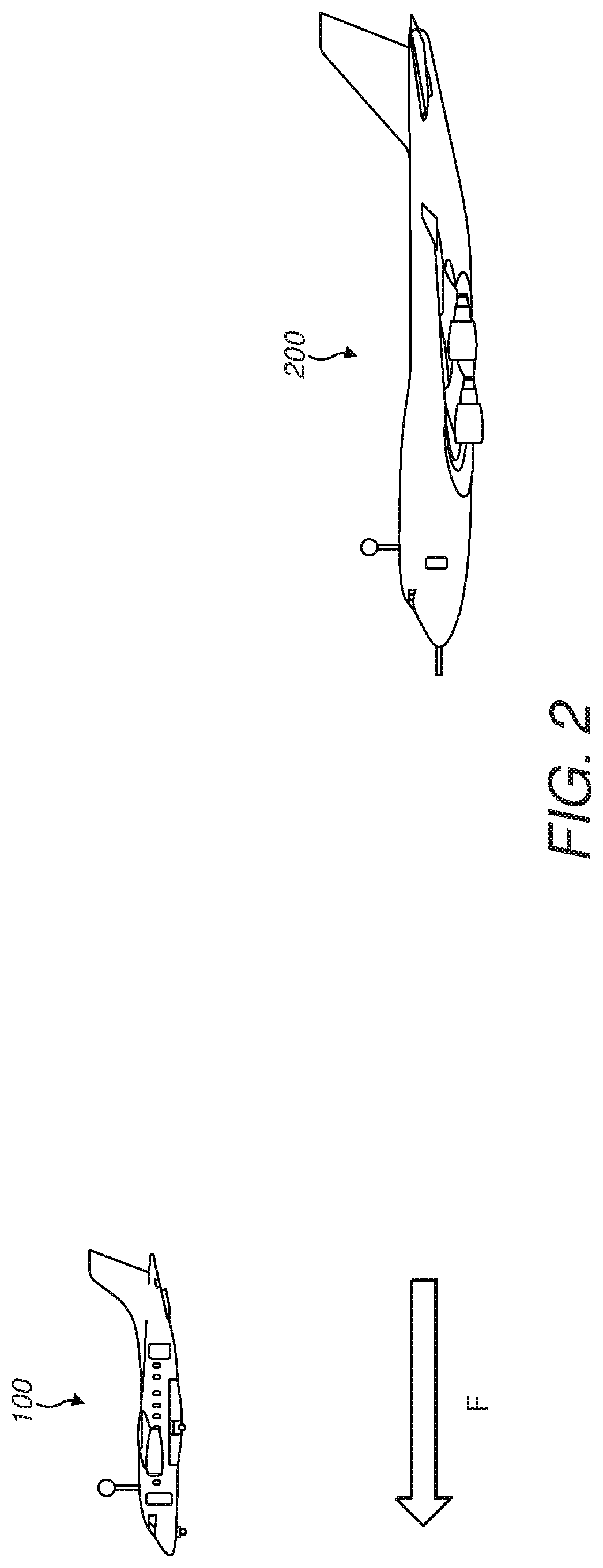

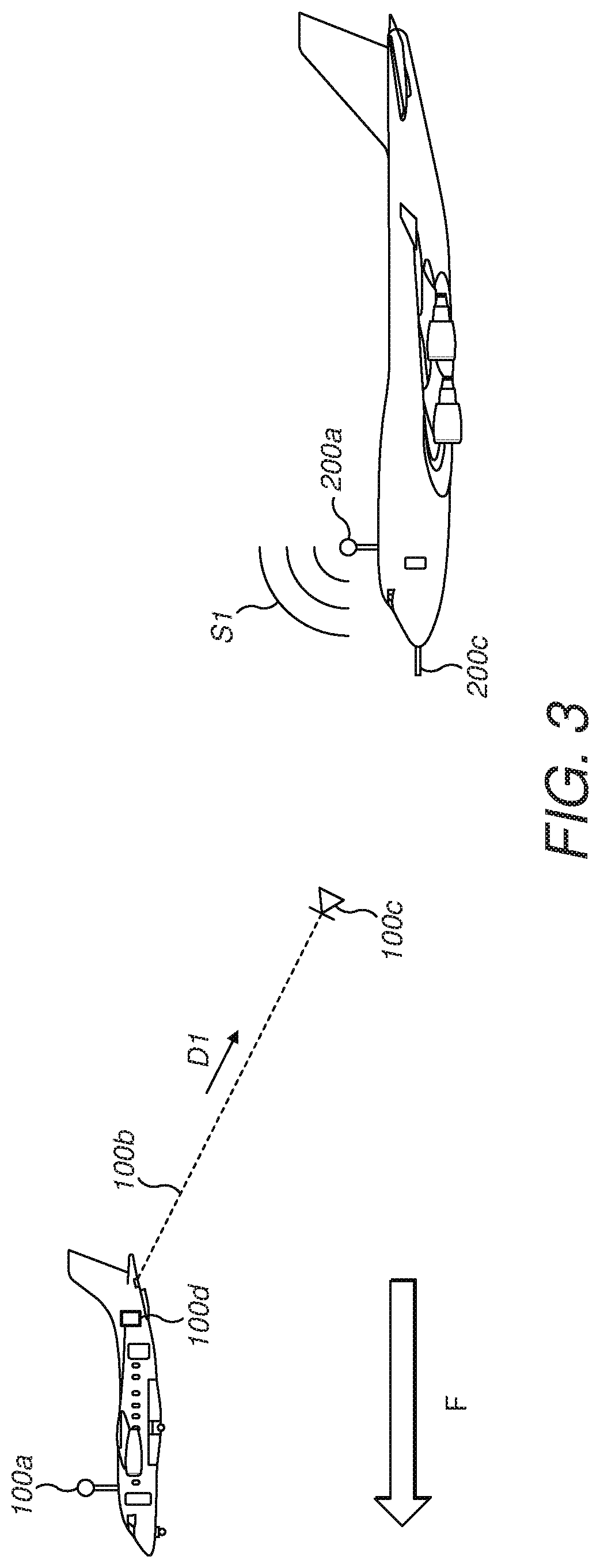

Methods and systems for in-flight fuelling of aircraft

ActiveUS20210197981A1Minimise costReduce riskAircraft componentsBatteries data exchangeAutomotive engineeringAirplane

A method of operating a fuel tanker aircraft for in-flight fuelling comprises: transmitting a deploy command signal from a communication unit of the tanker aircraft to a communication unit of a fuel receiver aircraft, to cause a line and drogue to deploy from the receiver aircraft; controlling at least one of the tanker aircraft and the drogue to engage the drogue with a first end of a fuel hose of the tanker aircraft, a second end of the fuel hose being connected to the tanker aircraft; and transmitting a return command signal from the communication unit of the tanker aircraft to the communication unit of the receiver aircraft, to cause the line and drogue to return to the receiver aircraft with the first end of the fuel hose, wherein the tanker aircraft is located behind the receiver aircraft and the deploy command signal is for causing the line and drogue to deploy rearwardly of the receiver aircraft.

Owner:PITMAN JAMES

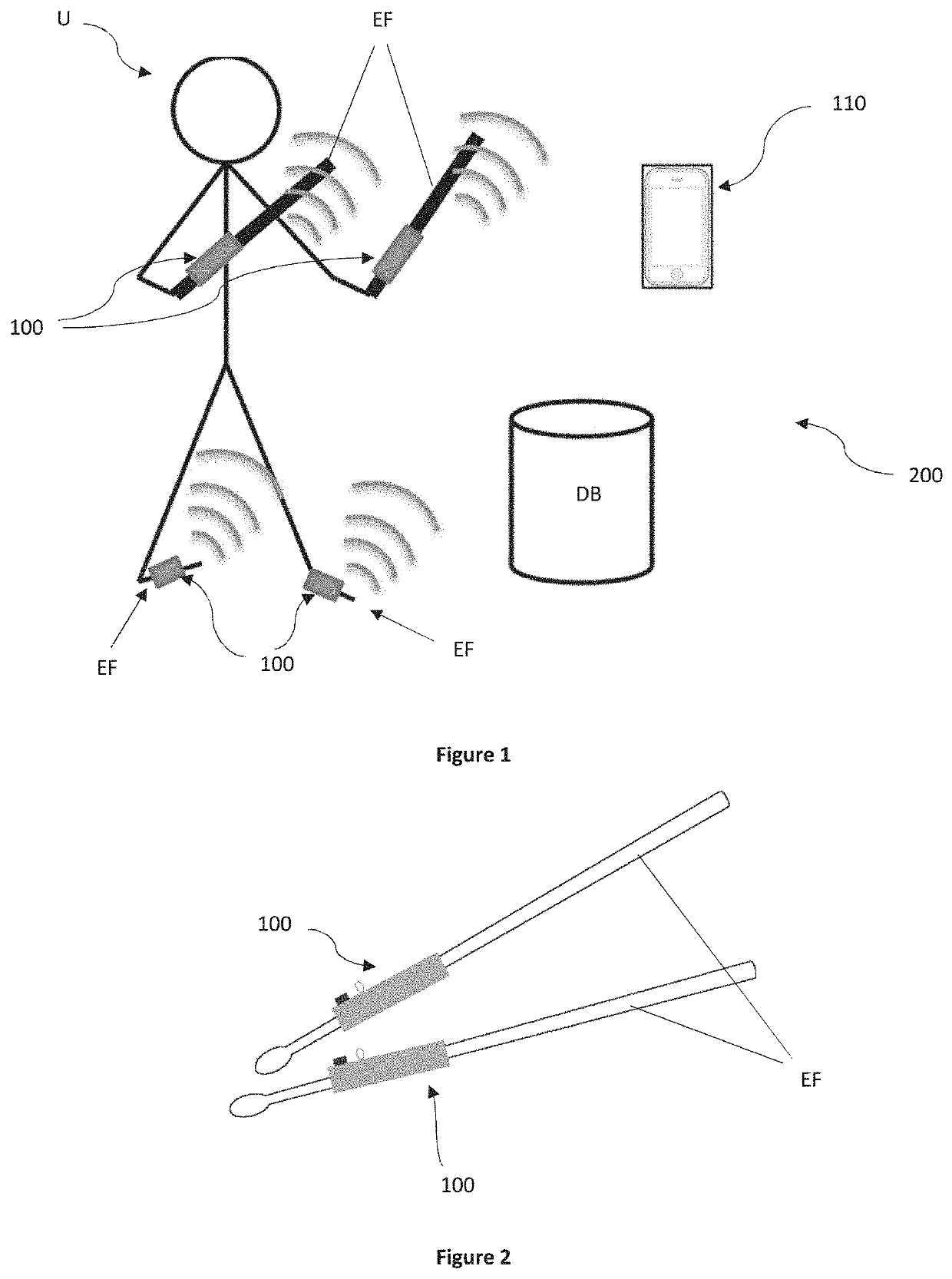

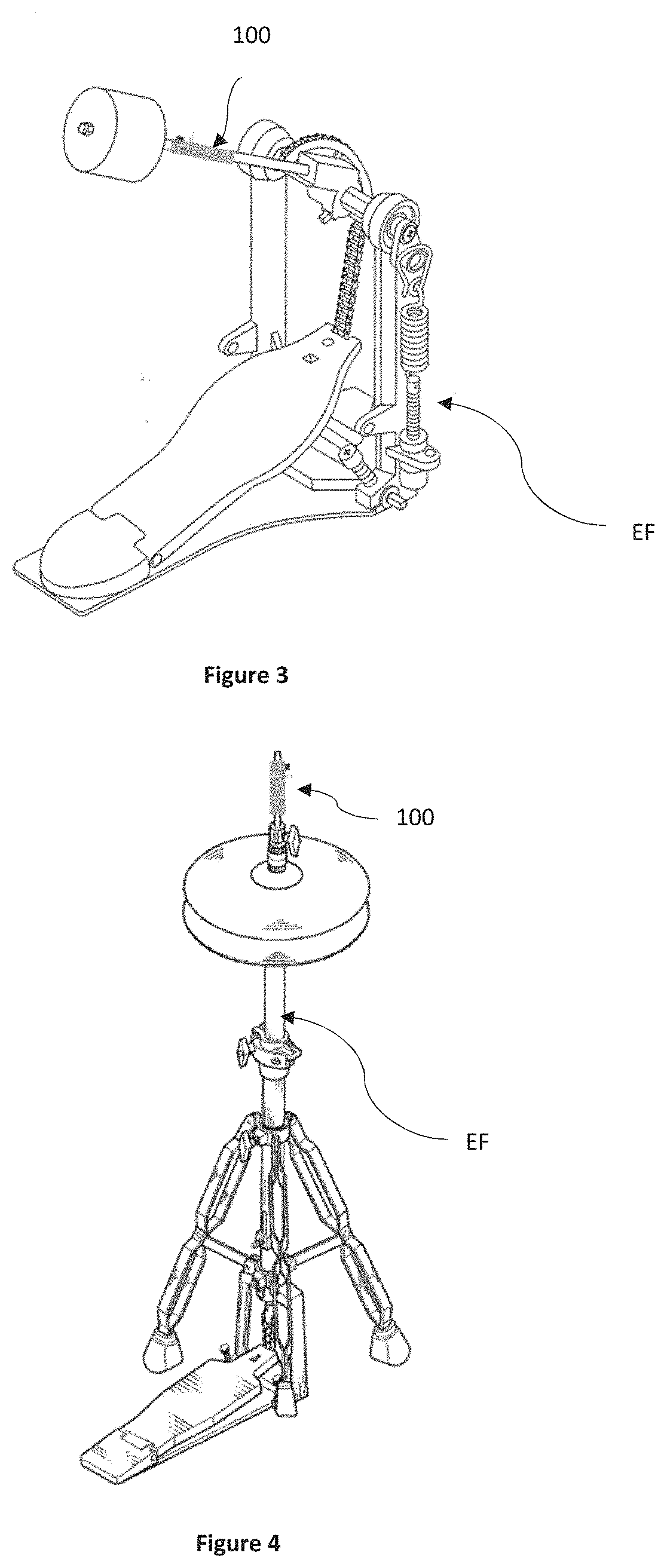

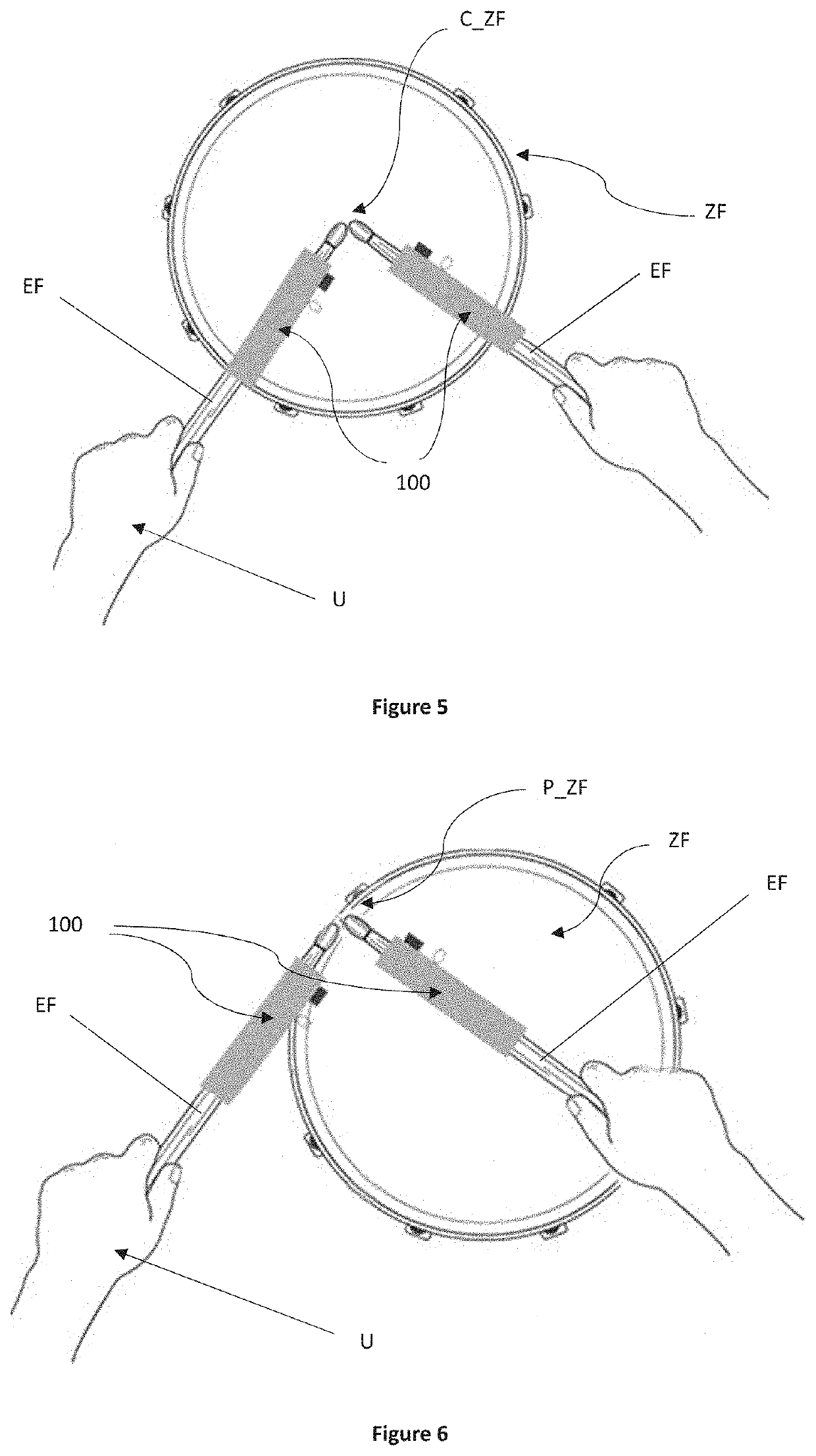

Emulation of at least one sound of a drum-type percussion instrument

ActiveUS20200111461A1Not hinder strokePreserving their playing comfort and pleasureElectrophonic musical instrumentsPercussion musical instrumentsMobile electronicsEngineering

The present invention relates to a removable electronic device for emulating at least one sound of a drum-type percussion instrument, said device being intended to instrumentalise a striking element. A defining means defines a striking area on a tangible support. An allocating means allocates a drum element associated with a predetermined sound to the striking area, in a database. At least one sensor generates a stroke signal having at least one piece of stroke information on a stroke of a user with the striking element in the striking area. A computer processing means implements a processing algorithm configured to process the stroke signal to spatially locate said stroke in order to detect the area struck and to determine the drum element corresponding to this area struck. A generating means is configured to generate a sound signal comprising information on the sound virtually generated by said stroke of the striking element in said area struck.

Owner:REDISON

Methods and Systems for In-Flight Charging of Aircraft

PendingUS20210362872A1Reduce riskLow costAircraft componentsBatteries data exchangeCommunication unitFlight vehicle

A method of operating a supply aircraft for in-flight recharging comprises: transmitting a deploy command signal from a communication unit of the supply aircraft to a communication unit of a receiver aircraft, to cause a line and drogue to deploy from the receiver aircraft; controlling at least one of the supply aircraft and the drogue to engage the drogue with a first end of an electrical cable of the supply aircraft, a second end of the electrical cable being connected to the supply aircraft; and transmitting a return command signal from the communication unit of the supply aircraft to the communication unit of the receiver aircraft, to cause the line and drogue to return to the receiver aircraft with the first end of the electrical cable. The supply aircraft is located behind the receiver aircraft and the deploy command signal is for causing the line and drogue to deploy rearwardly of the receiver aircraft.

Owner:BRULIC LTD

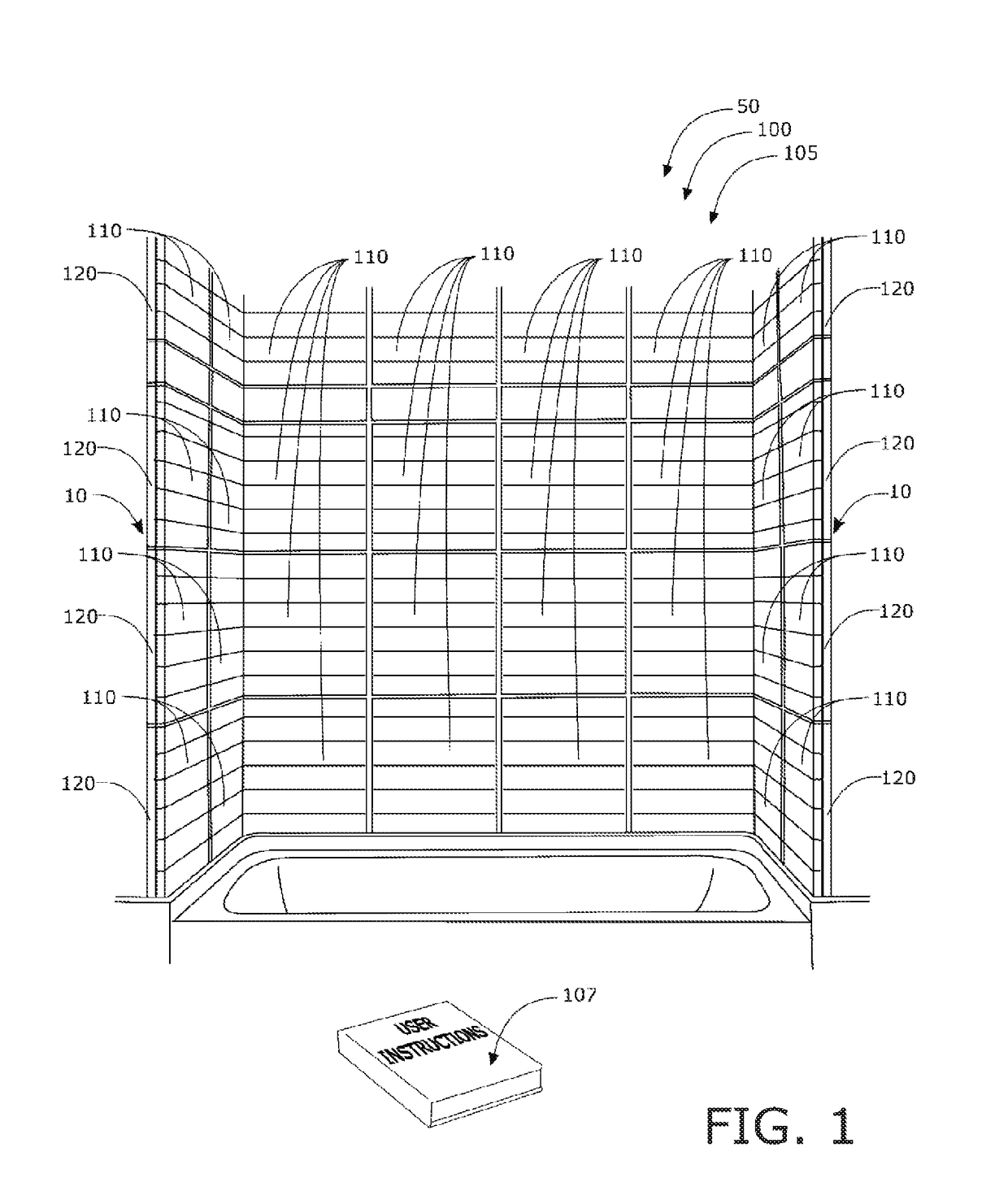

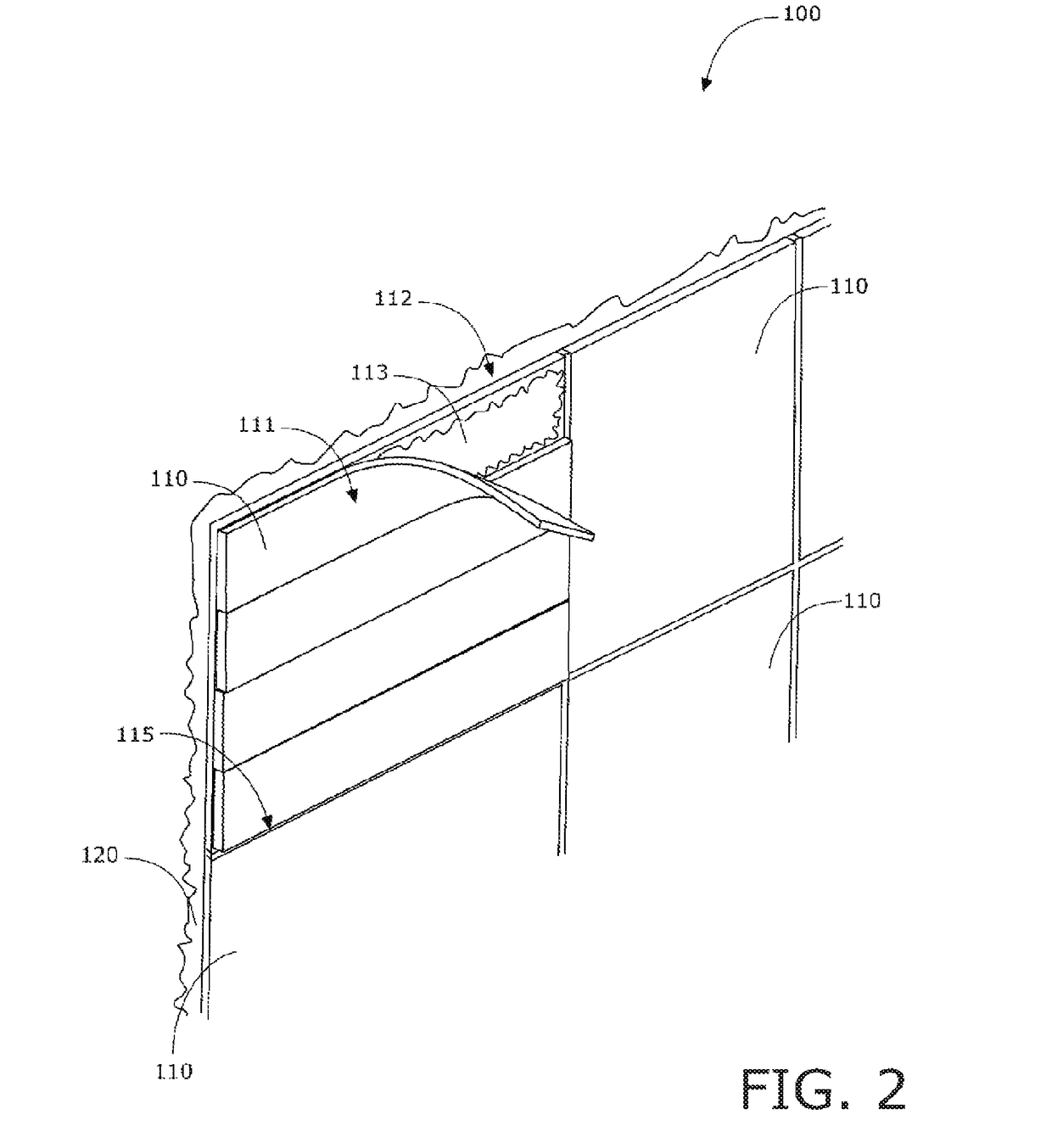

Prefabricated tiling system and method

A prefabricated tiling system includes a tiled panel assembly and a mounting adhesive configured to affix the tiled panel assembly on a planar surface. The tiled panel assembly further includes a tiling material configured to couple with a mounting substrate through the use of a tiling adhesive. The prefabricated tiling system is useful for providing a lightweight and waterproof system for applying a plurality of tiles to a planar surface with minimal equipment and technical knowledge required.

Owner:ULICI IOAN

Extraction method for providing an organic certifiable Stevia rebaudiana extract

ActiveUS8728545B2High sweetnessImprove antioxidant capacityBiocideSemi-permeable membranesOrganic certificationElution

A simple extraction method for preparing an organic certifiable stevia extract with high sweetness and optionally with antioxidant properties is provided. The extraction method involves extraction of stevia leaves that have been dried and grinded with a hot solvent generally regarded as safe (GRAS), allowing the dissolution of the sweetening compounds naturally present therein. These sweetening compounds include steviosides and rebaudioside A, which are purified from the extracts by two or more successive chromatographic purifications steps. The sweetening compounds are then eluted with an appropriate elution solvent. The simplicity and organic certification of the method provide advantages over the methods currently employed in the stevia industry.

Owner:JUSTBIO

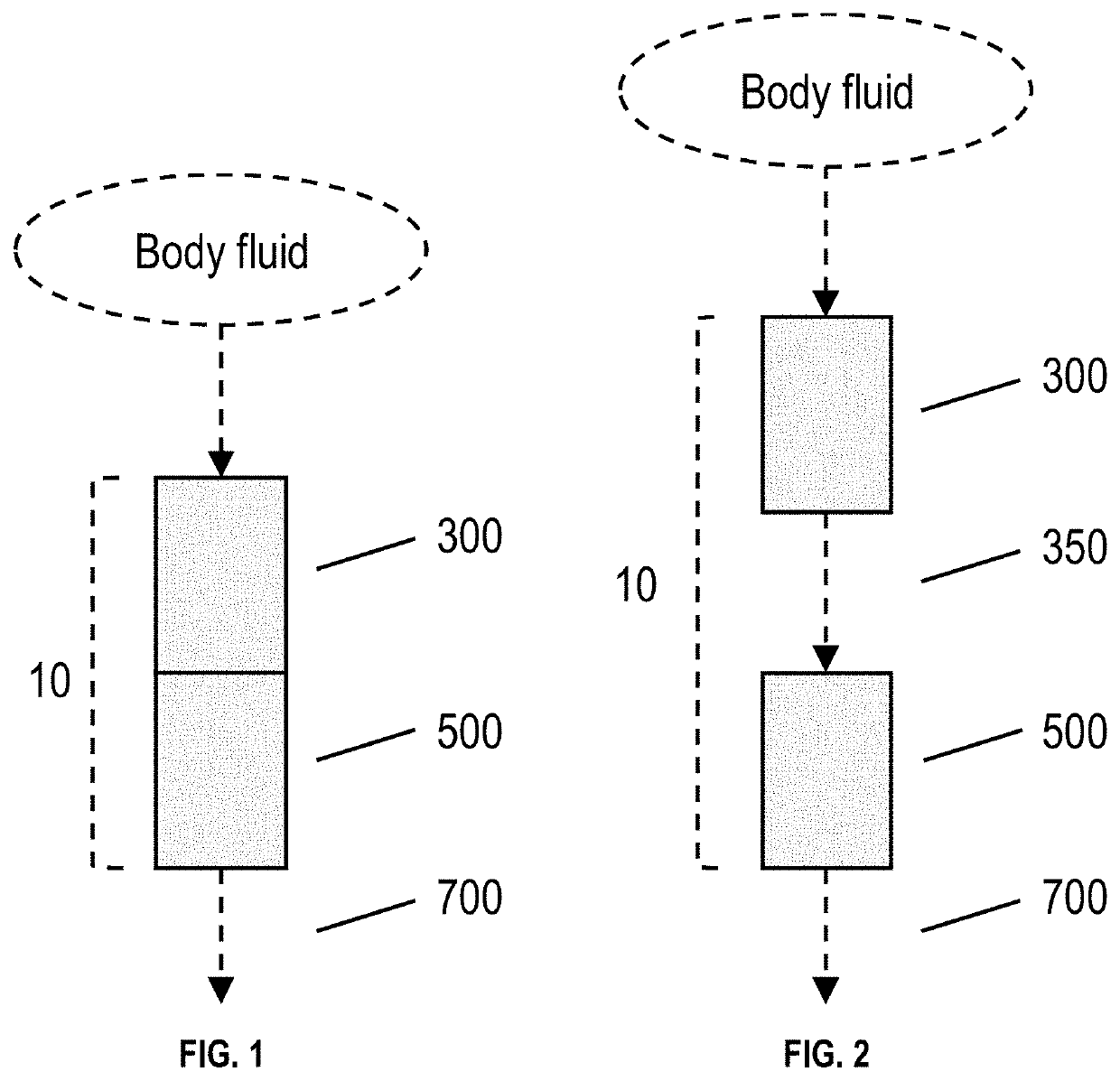

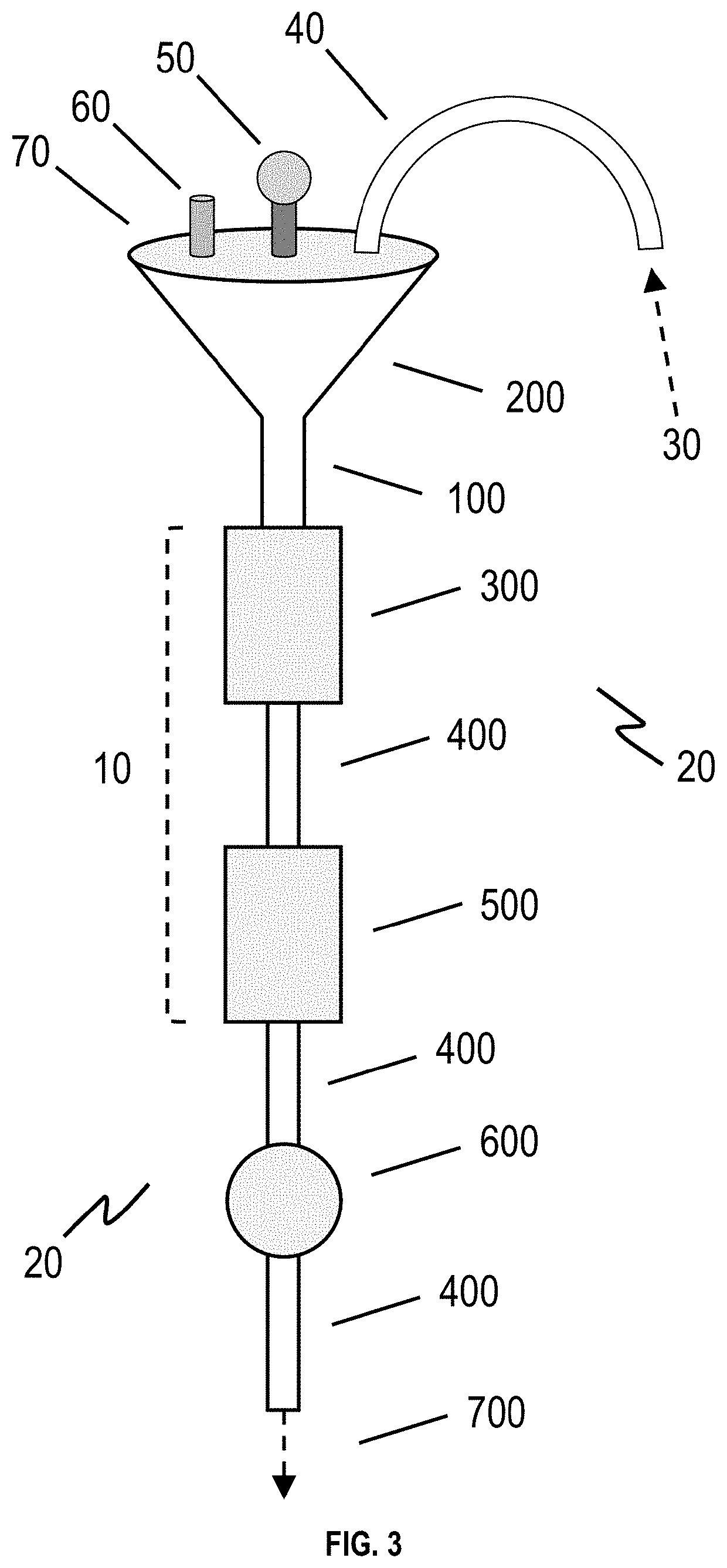

Pressurized filtration system and device for rapid extraction and recycling of medication from body fluid

ActiveUS11014025B1Avoid wastingMinimum of equipmentMembranesGas treatmentPharmaceutical drugBody fluid

The present disclosure relates to a system for the selective extraction and recycling of medication from body fluid, using a pressurized filtration system and device. The disclosure further relates to methods for extracting and / or recycling medication from body fluid in a pressurized system and methods of using the medication collected / extracted from that body fluid.

Owner:BUFORD KEVIN STEVEN CREAGH

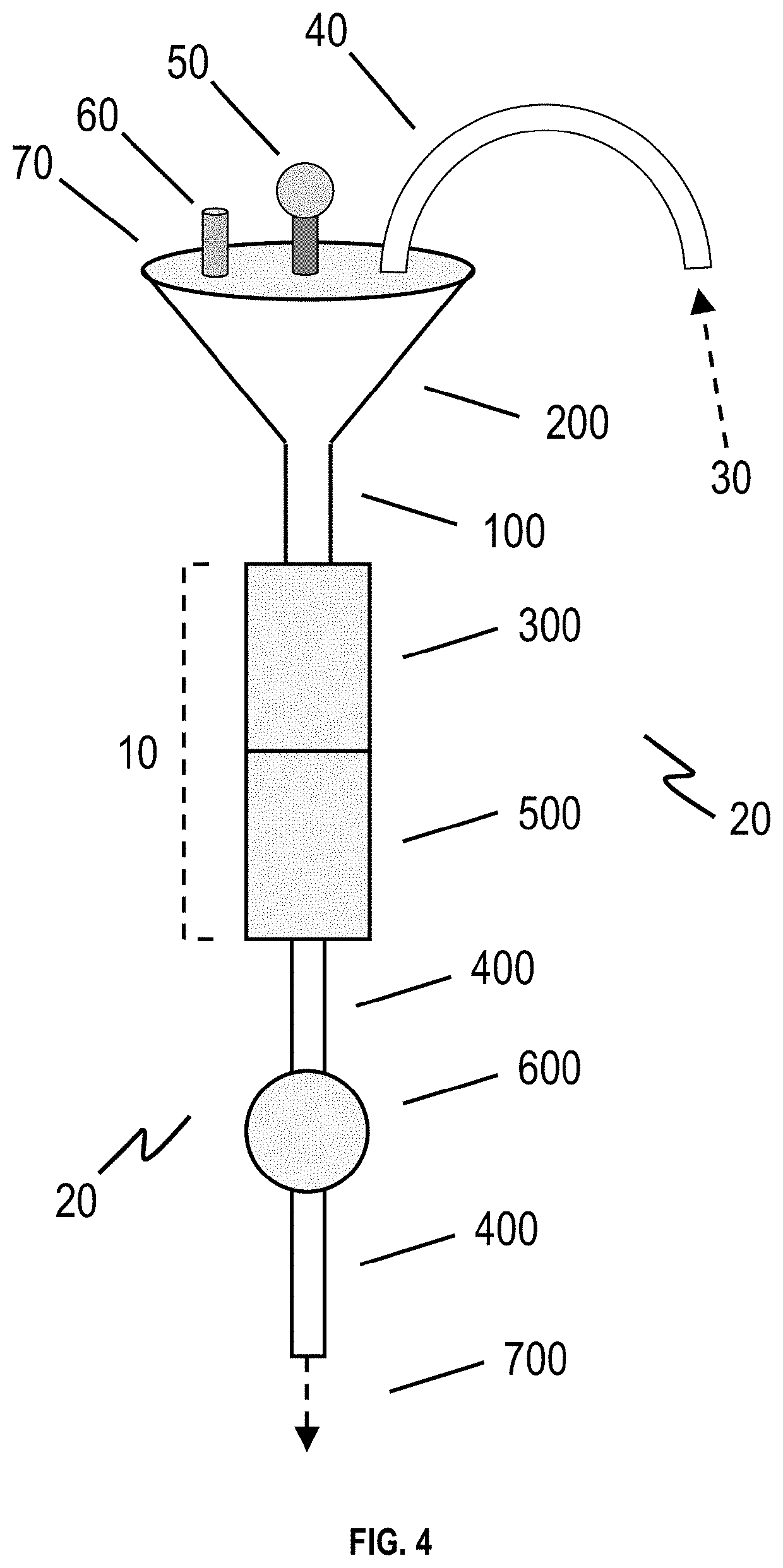

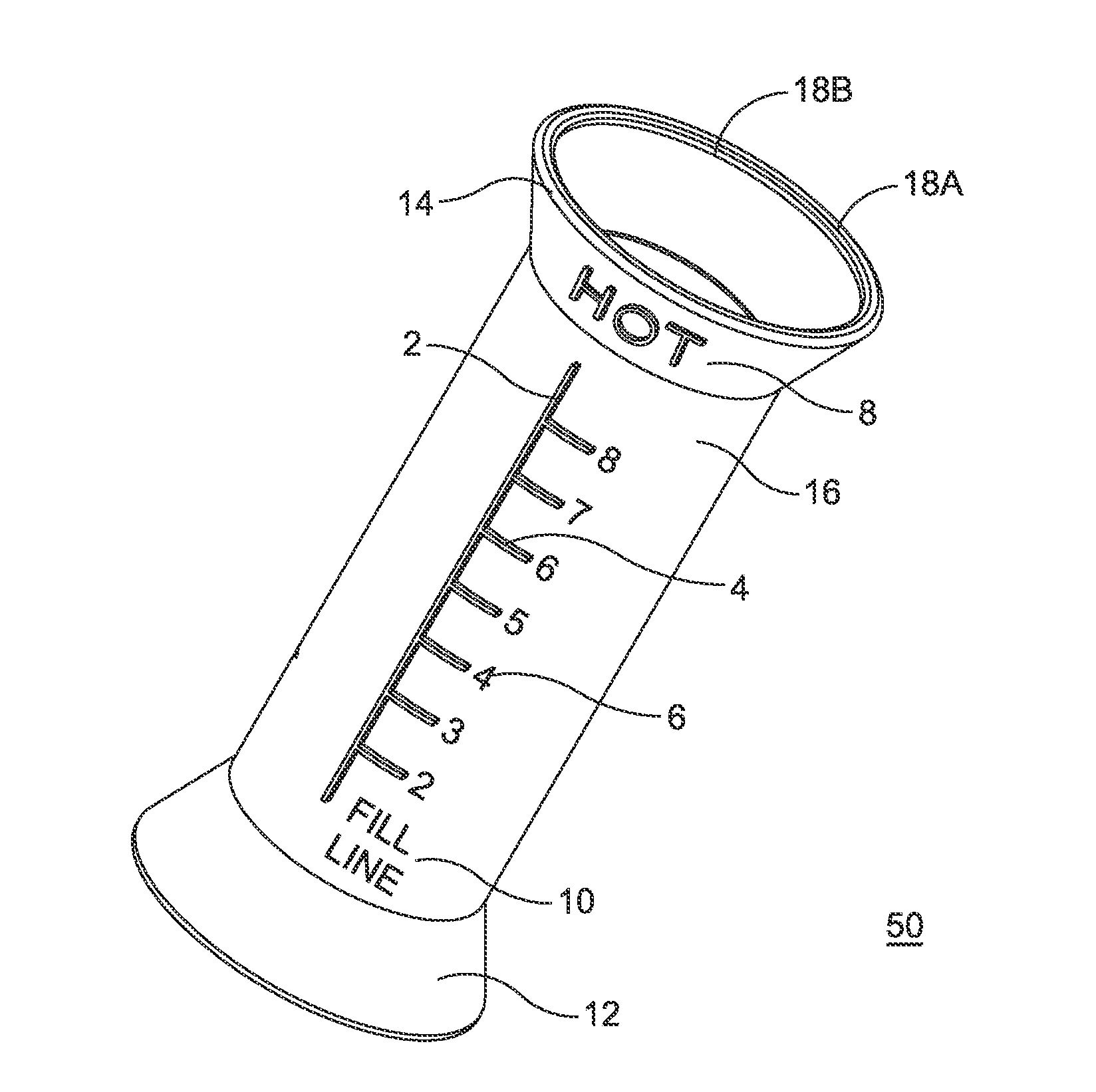

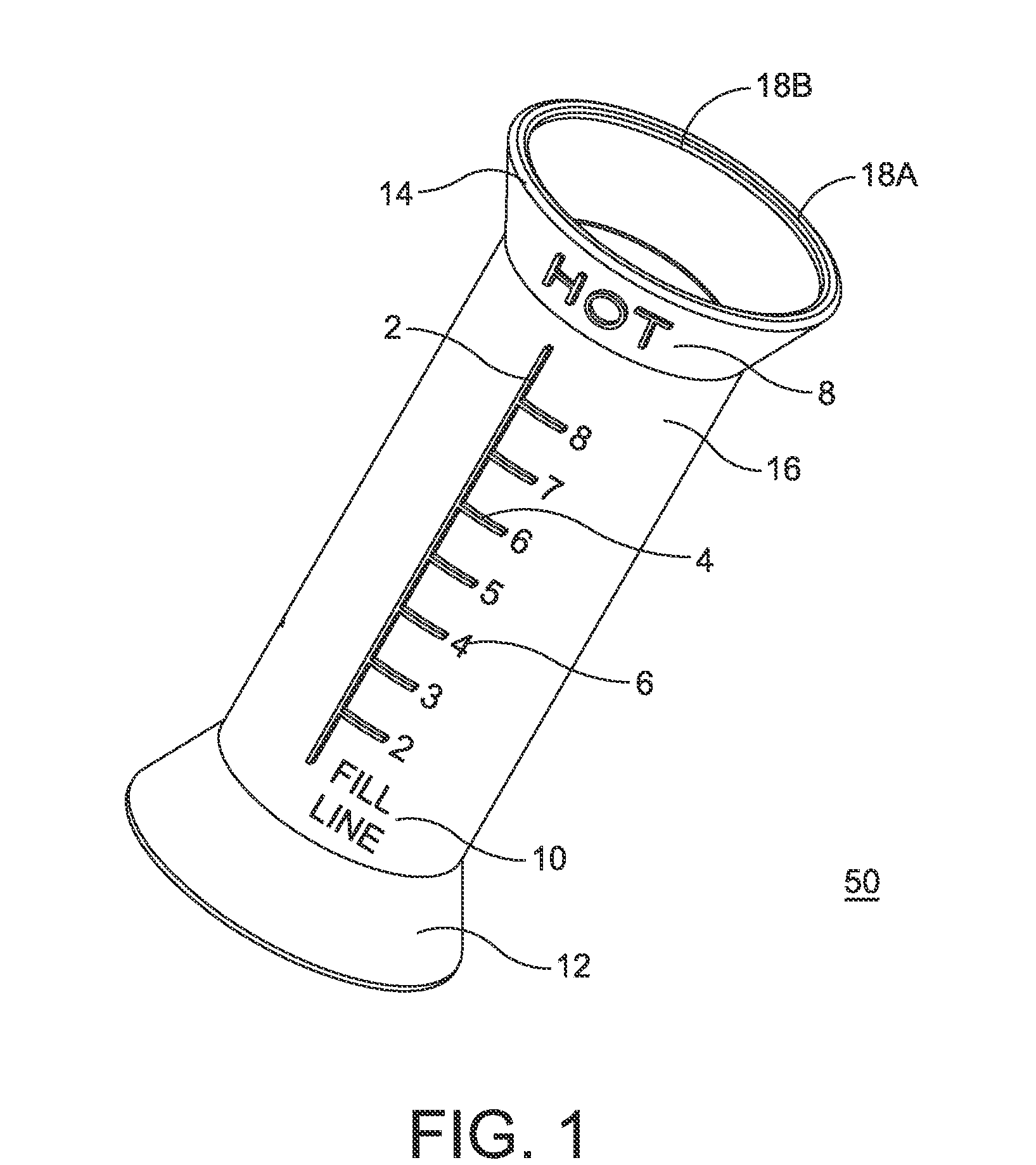

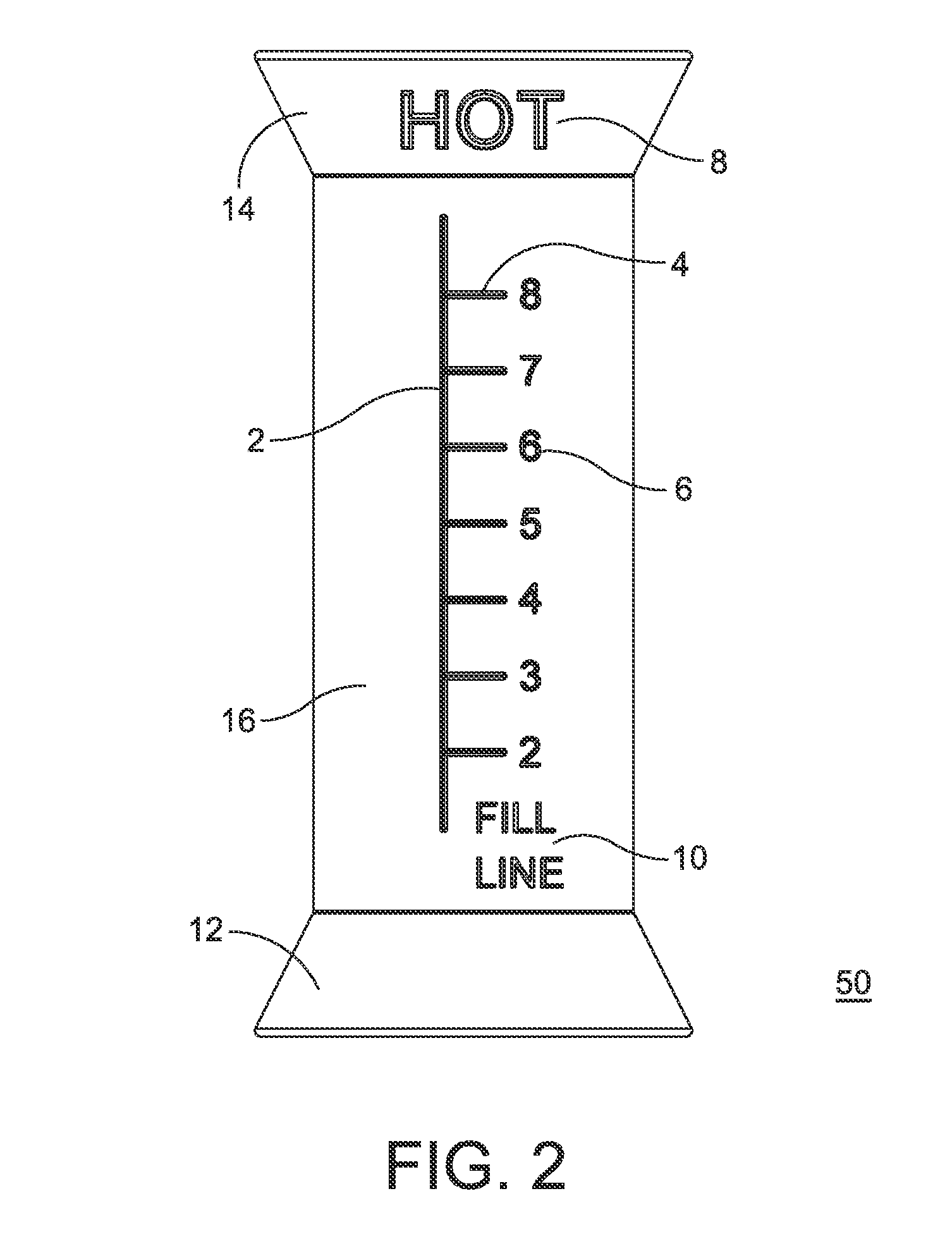

Apparatus for Preparing a Temperature Sensitive Beverage

InactiveUS20150030737A1Not significant financial burdenHeating step is fasterOther accessoriesBeverage vesselsMedicineTemperature sensitive

A flask has a body, base, mouth, and one or more indicia to enable preparation of beverages with a desired temperature. Specific embodiments include the preparation of baby formula and tea. The one or more indicia can show one or more levels, quantities, or both. A level or quantity contained within the flask has a proper percentage of liquid, as calculated and so embedded as a feature into the flask, while the corresponding indicium on the flask for the level or quantity shows the total amount of liquid needed, so that the preparation of temperature sensitive beverage with a desired temperature will be convenient and quick. In another aspect, a method for preparing a temperature sensitive beverage fills a flask up to a volume shown by one or more indicia, heats the liquid in the flask, and combines the heated liquid with unheated liquid to attain a beverage with a desired final volume and a desired final temperature.

Owner:J MORRONE CONSULTING

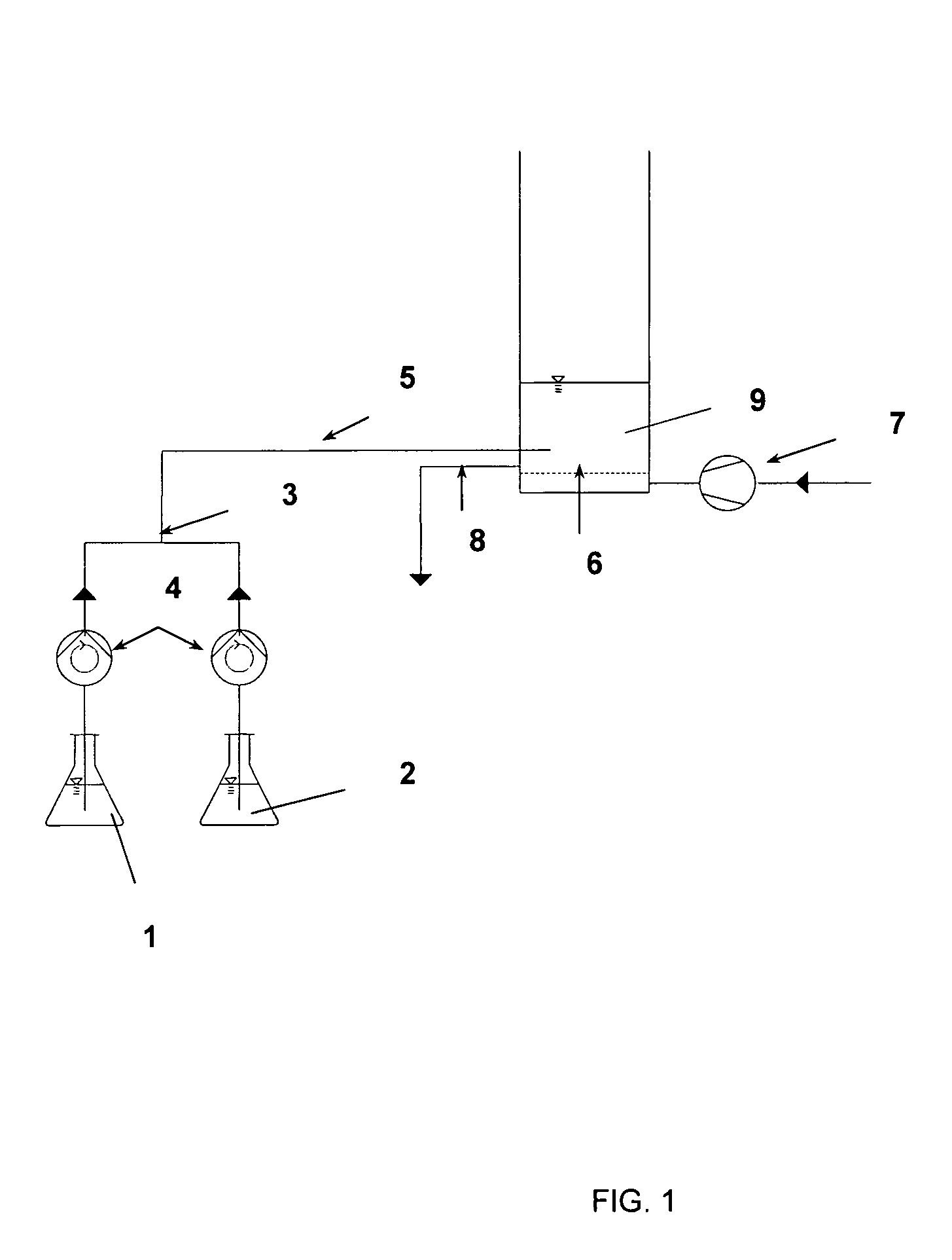

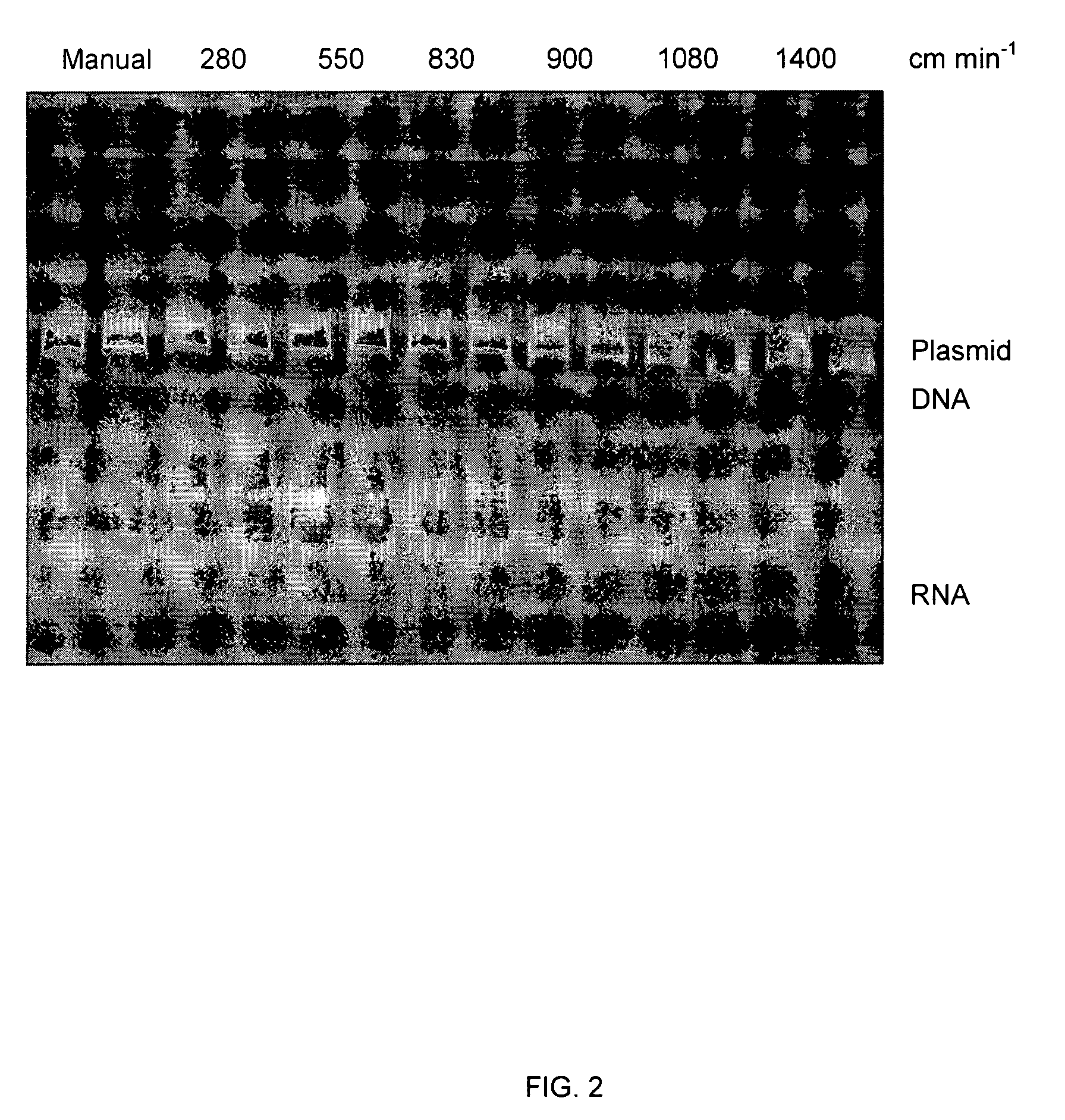

Method for producing extra-chromosomal nucleic acid molecules

ActiveUS7842481B2Maximal reduction of shear forceSeparationBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

Owner:PLASMIDFACTORY

Method for playing, scoring and judging individual players in a soccer related game

InactiveUS20150005110A1Improve individual soccer ball skillMinimum of equipmentBall sportsSize parameterPersonalization

The invention herein relates to a method for playing, scoring and judging skill level of a player of a soccer related game involving modules of rebound type walls, each module comprising two or more opposing rebound type walls of preferred distance and size parameters. The purpose of this invention is to provide a basic method of interacting within rebound type wall modules to improve individual soccer ball skills This method helps to facilitate, optimize and guide individual soccer training within said modules with the goal of attaining fundamental as well as personalized soccer ball skills The method is further intended to lead to improvement of said skills over a period of time in relation to the amount of interaction the player would have with the ball and said wall modules.

Owner:PROCONTROL INC

Braking apparatus for vehicle with collision avoidance mechanism

ActiveUS9561783B2Easy to installImprove installabilityFoot actuated initiationsAutomatic initiationsSpool valveSolenoid valve

A braking apparatus for a vehicle is provided which includes a hydraulic booster to make wheels of the vehicle produce frictional braking force, a solenoid valve, and a collision avoidance controller. The solenoid valve selectively exerts the hydraulic pressure of brake fluid stored in an accumulator on a spool valve in the booster. When determining that there is a risk of a collision with an obstacle, the collision avoidance controller opens the solenoid valve to achieve emergency braking to minimize the risk of the collision. Basically, emergency braking is achieved by installing the solenoid valve to selectively exert the hydraulic pressure on the spool valve, thus allowing an emergency avoidance braking system to be constructed with a minimum of equipment and facilitating the mountability of the braking apparatus in the vehicles.

Owner:ADVICS CO LTD

Interactive reward associated with a broadcast

ActiveUS9124916B2Minimum of equipmentEasy to useTelevision system detailsAdvertisementsData signalCAPTCHA

An interactive technique for generating a supplementary, program-related output. A programming signal and a supplementary, program-related data signal containing rewards data for product or service purchases are combined into a broadcast signal which is then broadcast from a program signal source. The broadcast signal is received, and the programming signal of the received broadcast signal is performed with reproduction equipment for an audience. The rewards data is stored on a portable storage media for use in accessing rewards corresponding to the rewards data. The rewards data can be used for printing coupons used in redeeming the rewards or for use in accessing rewards validation codes for storage on the portable storage media. The portable storage media and / or the printed coupons can then be used to purchase the corresponding goods or services.

Owner:WINMORE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com