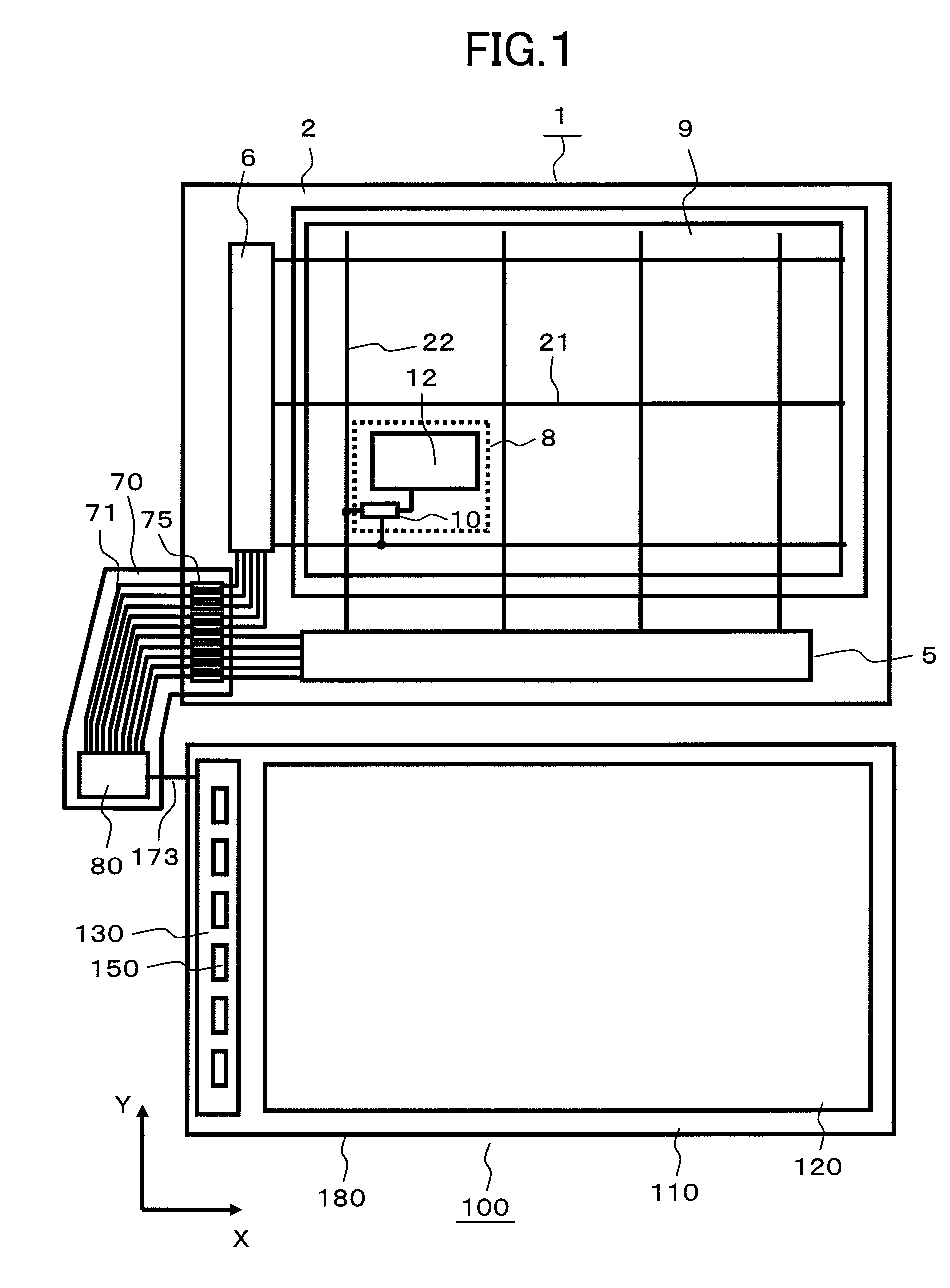

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Increase printing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous ink, set of reaction liquid and aqueous ink, and image forming method

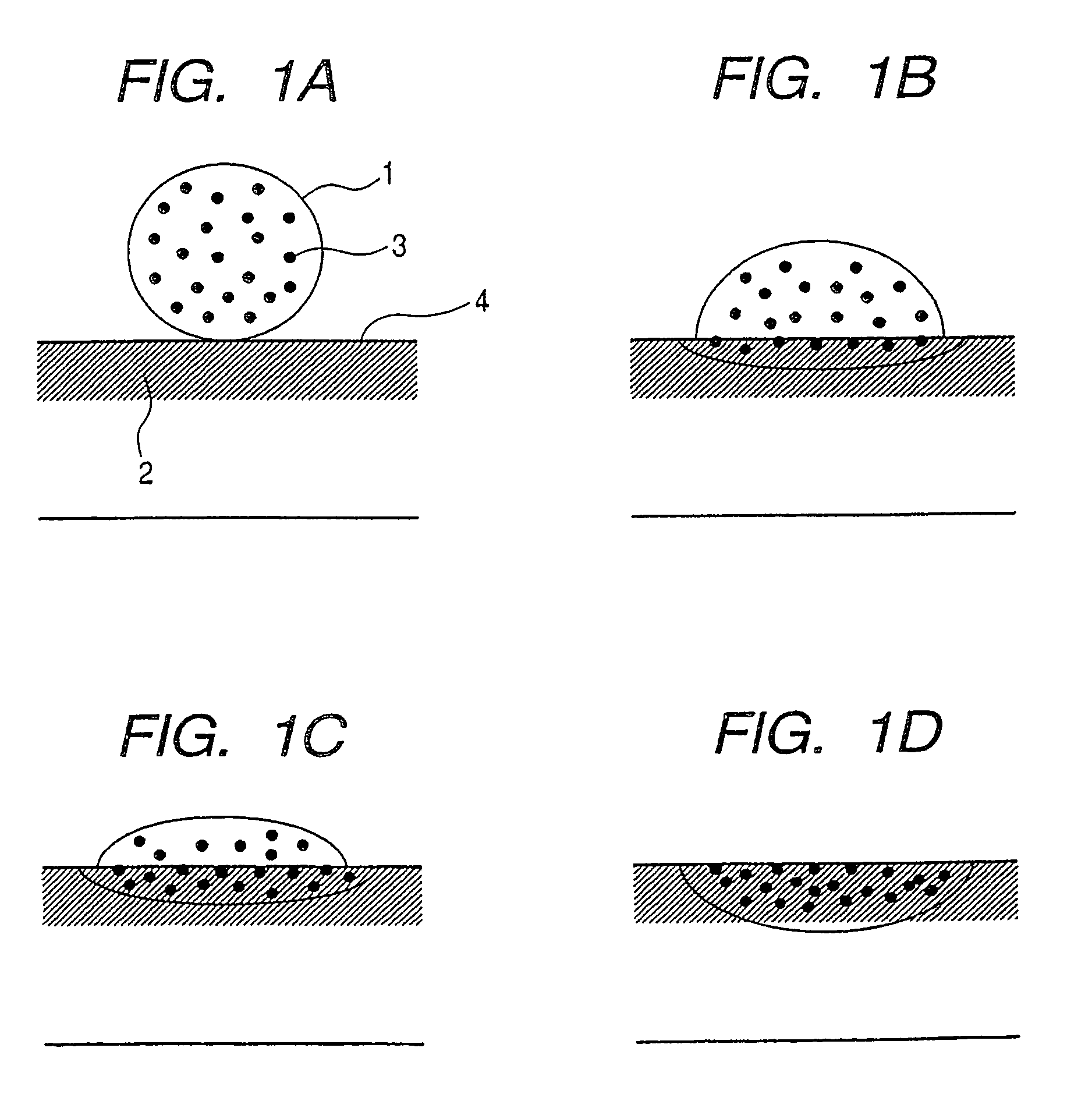

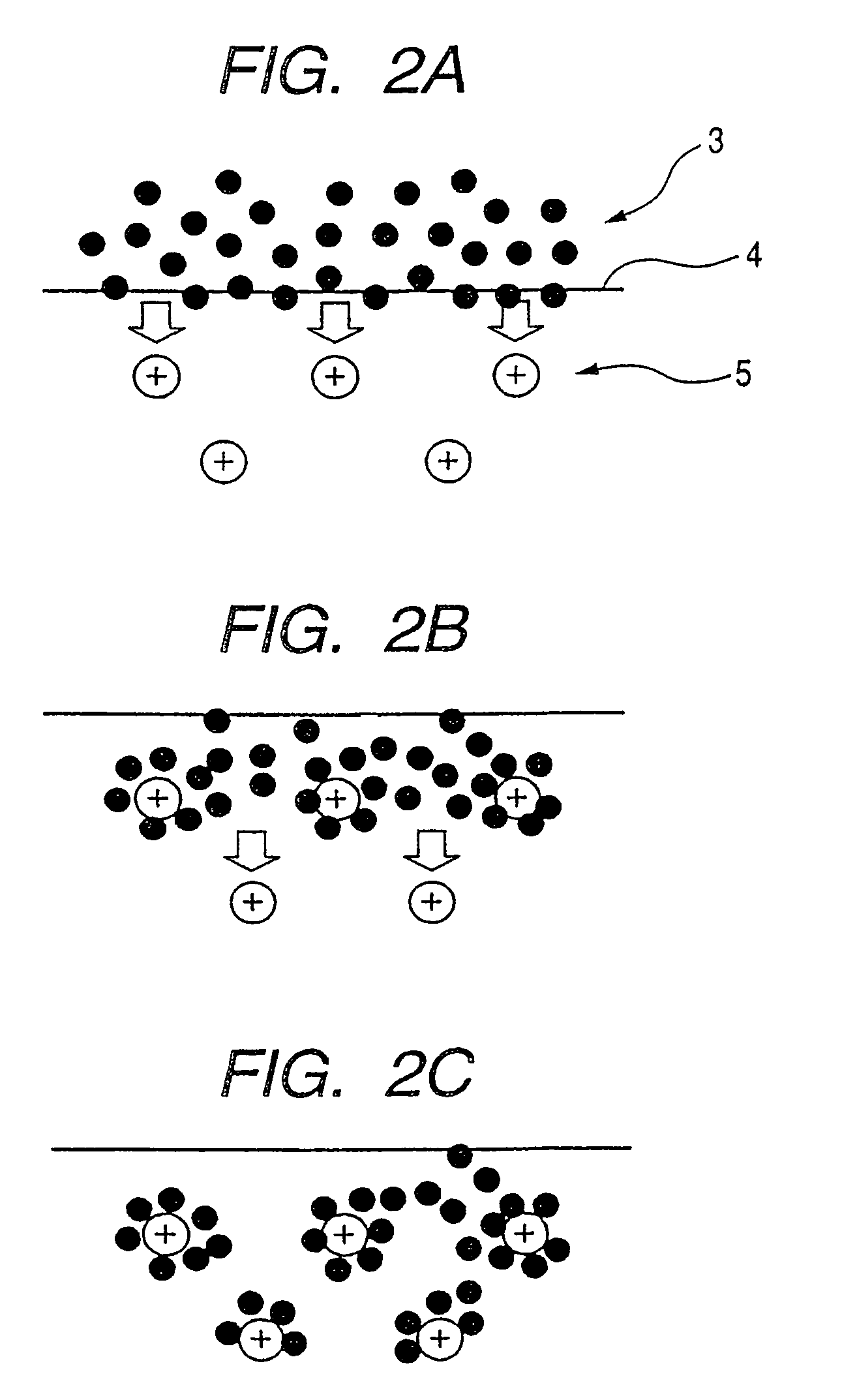

ActiveUS20060007288A1Uniform wear resistanceLess unclearnessMeasurement apparatus componentsInksPigment dispersionAnionic polymers

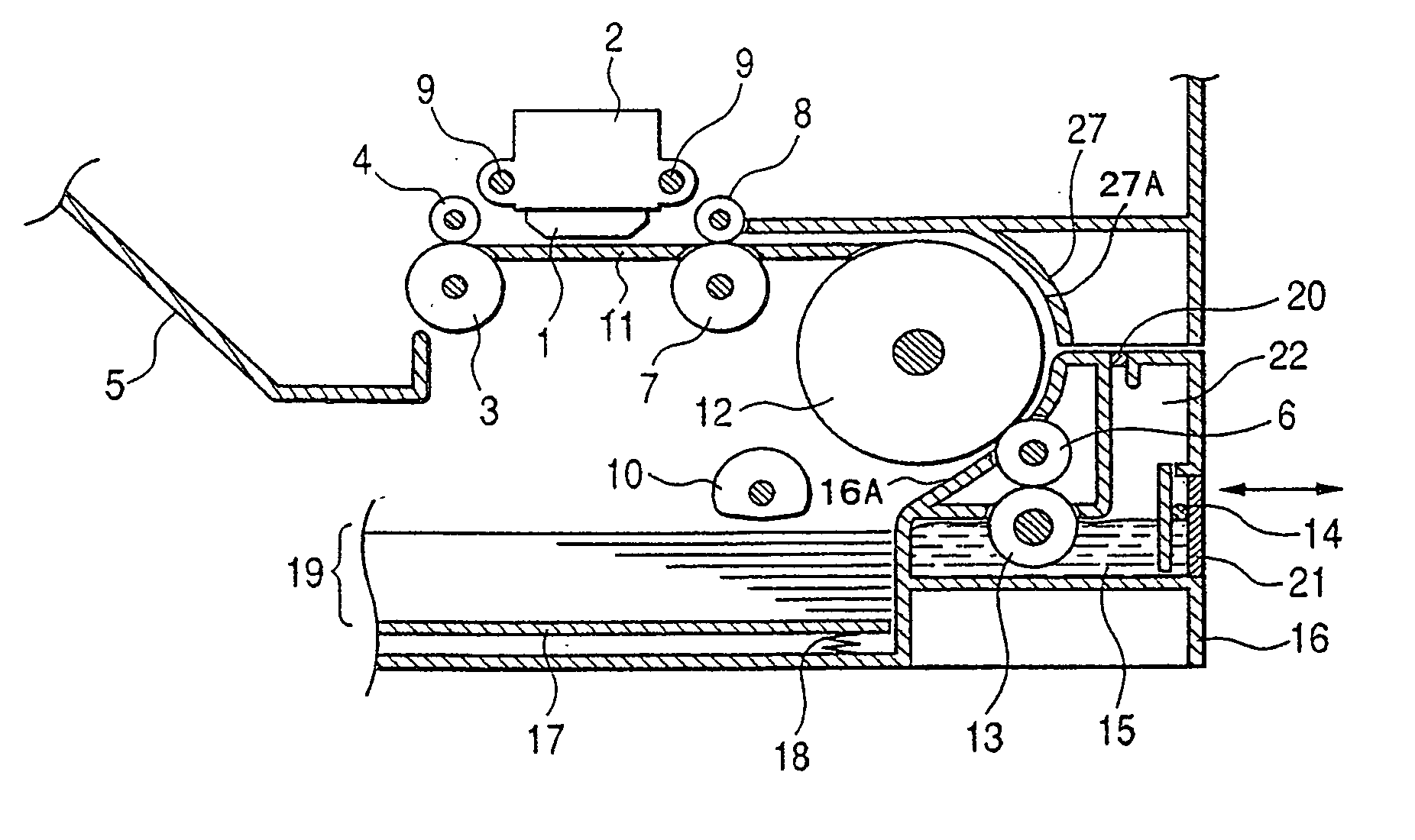

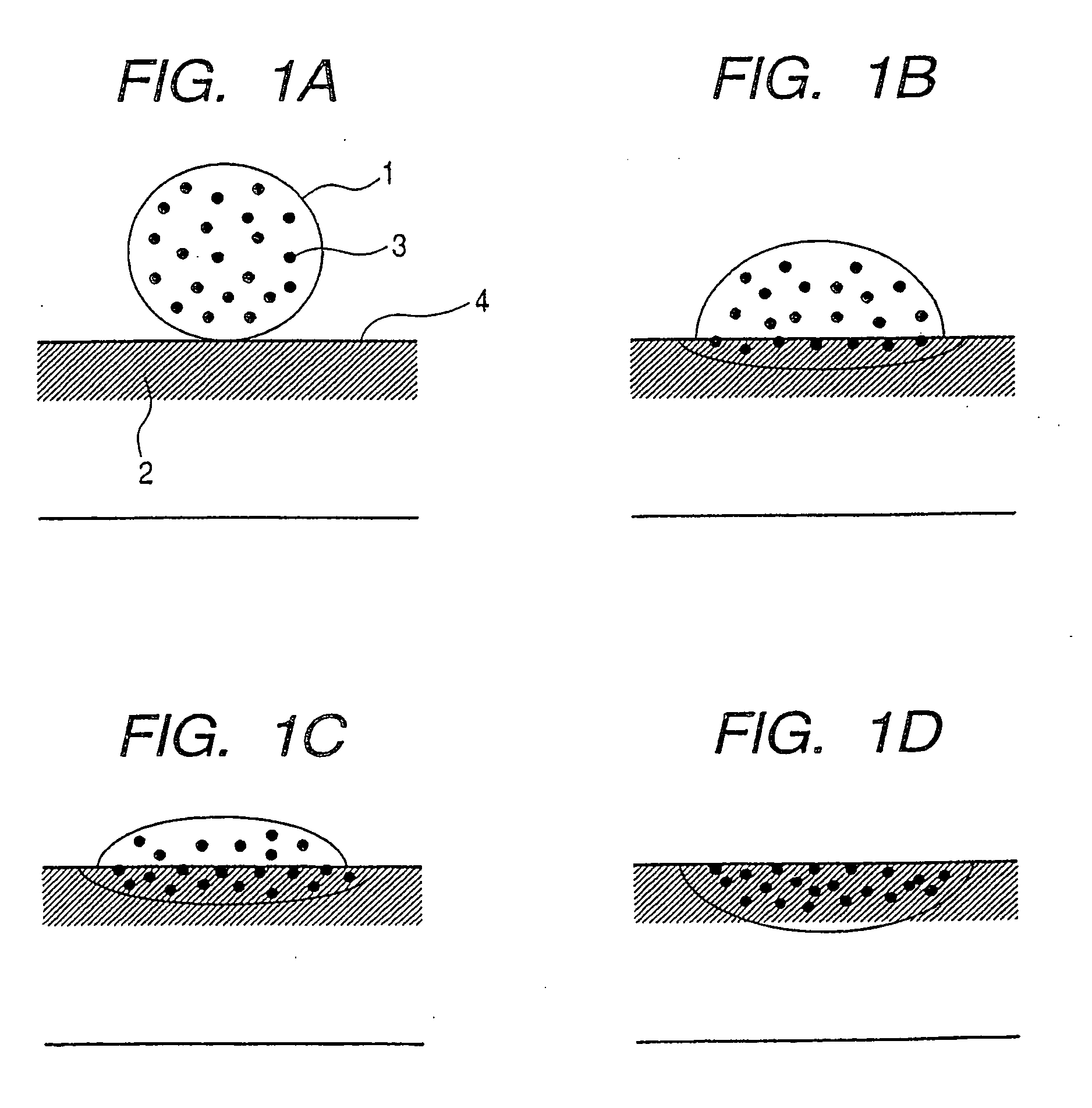

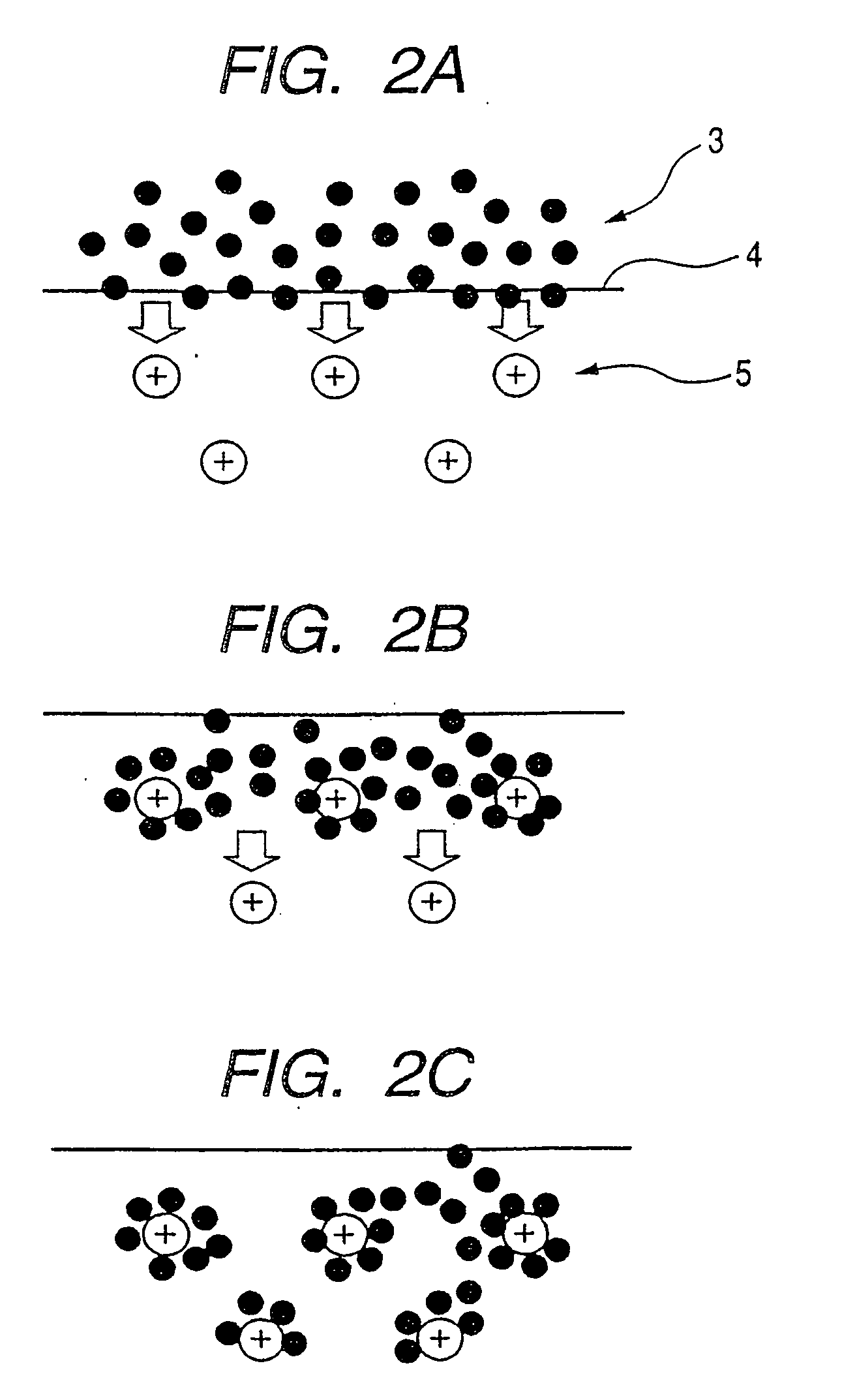

An aqueous ink, by which stable ink-jet recording can be conducted irrespective of printing environment, a substantially even image having abrasion resistance can be formed, no image soiling is caused even upon double-side printing, and a high-quality image improved in unclearness at a contour portion of the image and free from occurrence of color bleed can be provided, is provided. The aqueous ink is an aqueous ink used in a system that a reaction liquid containing at least a polyvalent metal and an aqueous ink containing at least a pigment dispersion, in which a pigment is dispersed with an anionic polymer dispersant, are used to form an image, wherein the aqueous ink satisfies specific condition.

Owner:CANON KK

Aqueous ink, set of reaction liquid and aqueous ink, and image forming method

ActiveUS7377631B2Less unclearnessIncrease printing areaMeasurement apparatus componentsInksPigment dispersionAnionic polymers

An aqueous ink, by which stable ink-jet recording can be conducted irrespective of printing environment, a substantially even image having abrasion resistance can be formed, no image soiling is caused even upon double-side printing, and a high-quality image improved in unclearness at a contour portion of the image and free from occurrence of color bleed can be provided, is provided. The aqueous ink is an aqueous ink used in a system that a reaction liquid containing at least a polyvalent metal and an aqueous ink containing at least a pigment dispersion, in which a pigment is dispersed with an anionic polymer dispersant, are used to form an image, wherein the aqueous ink satisfies specific condition.

Owner:CANON KK

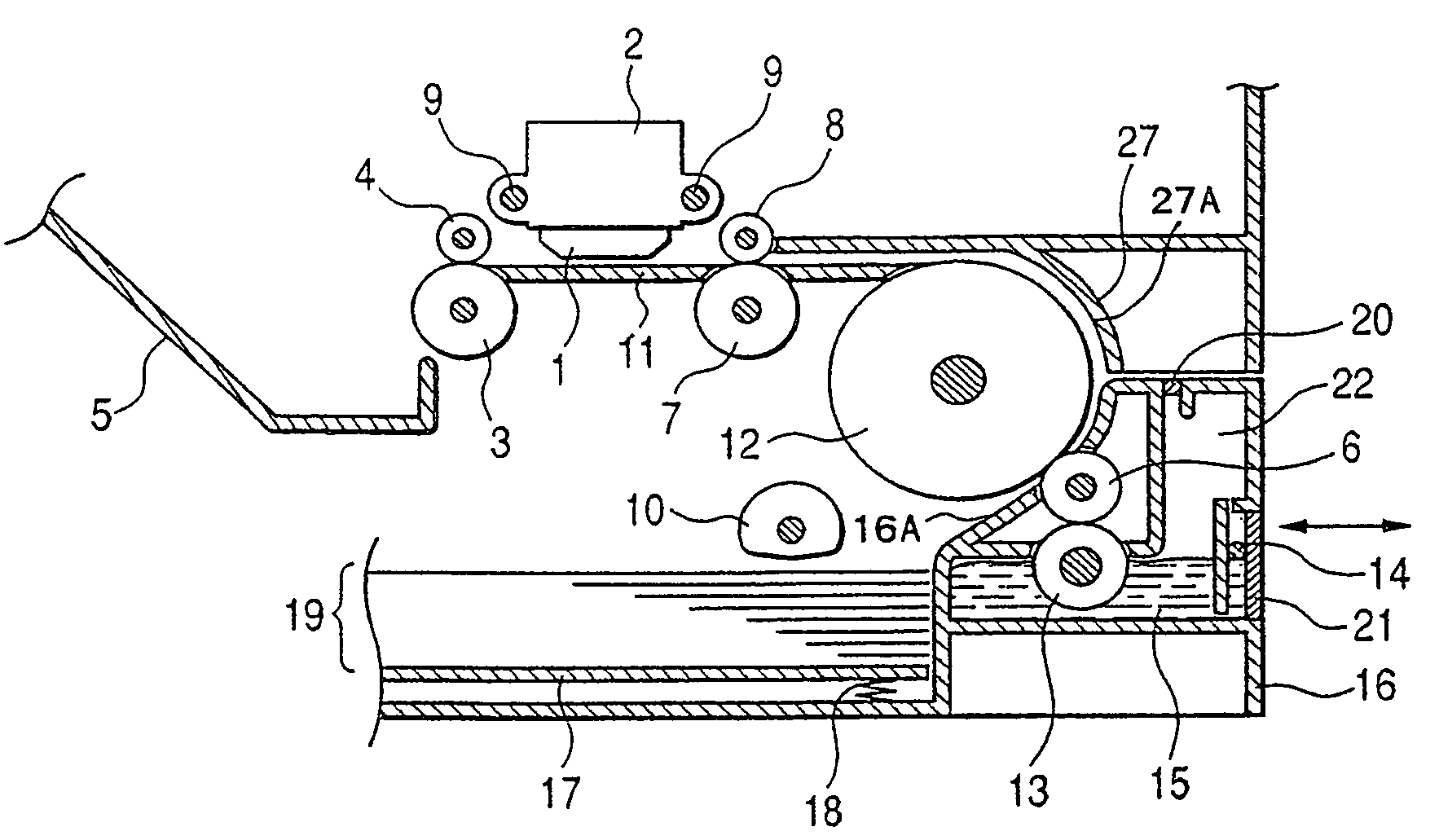

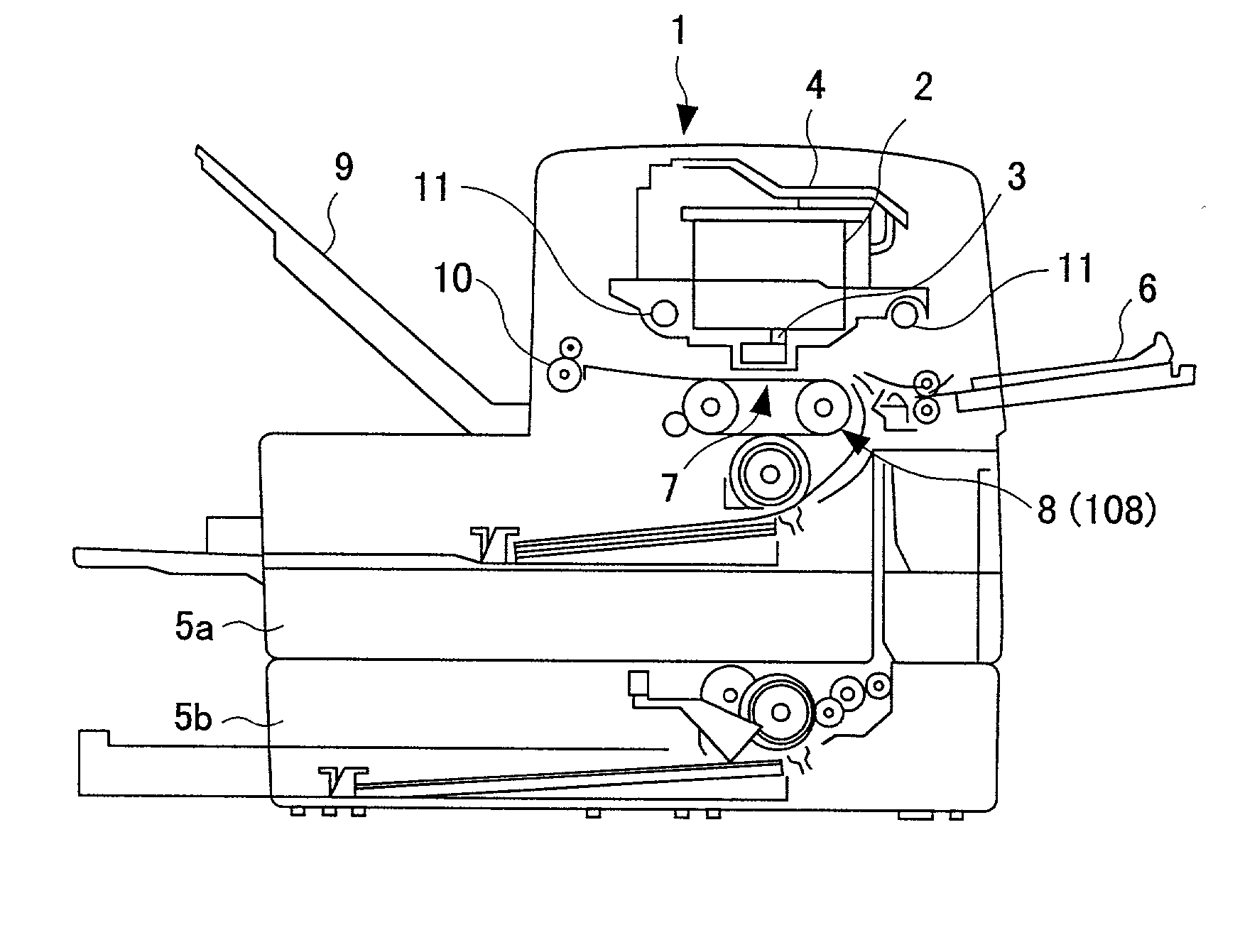

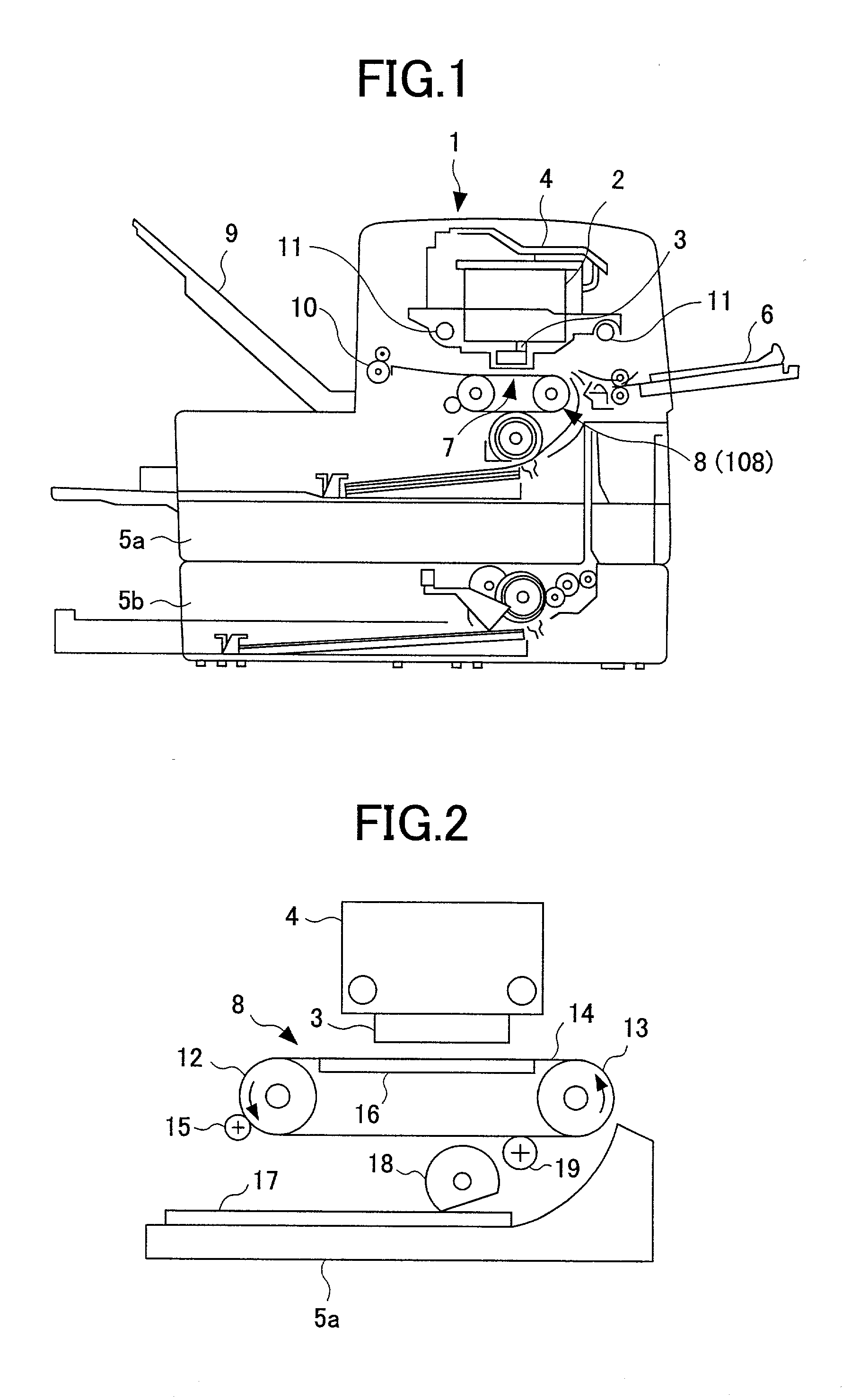

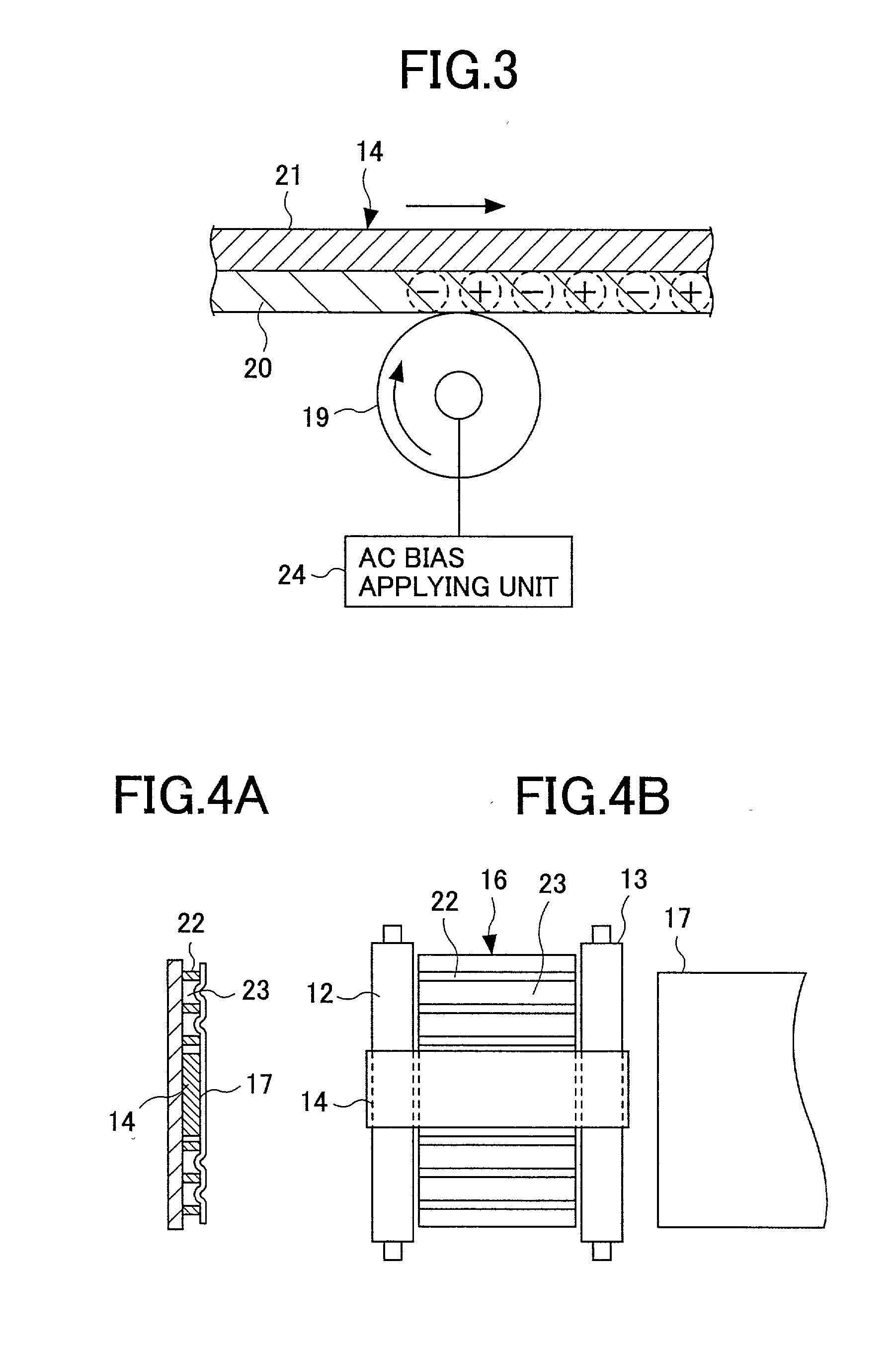

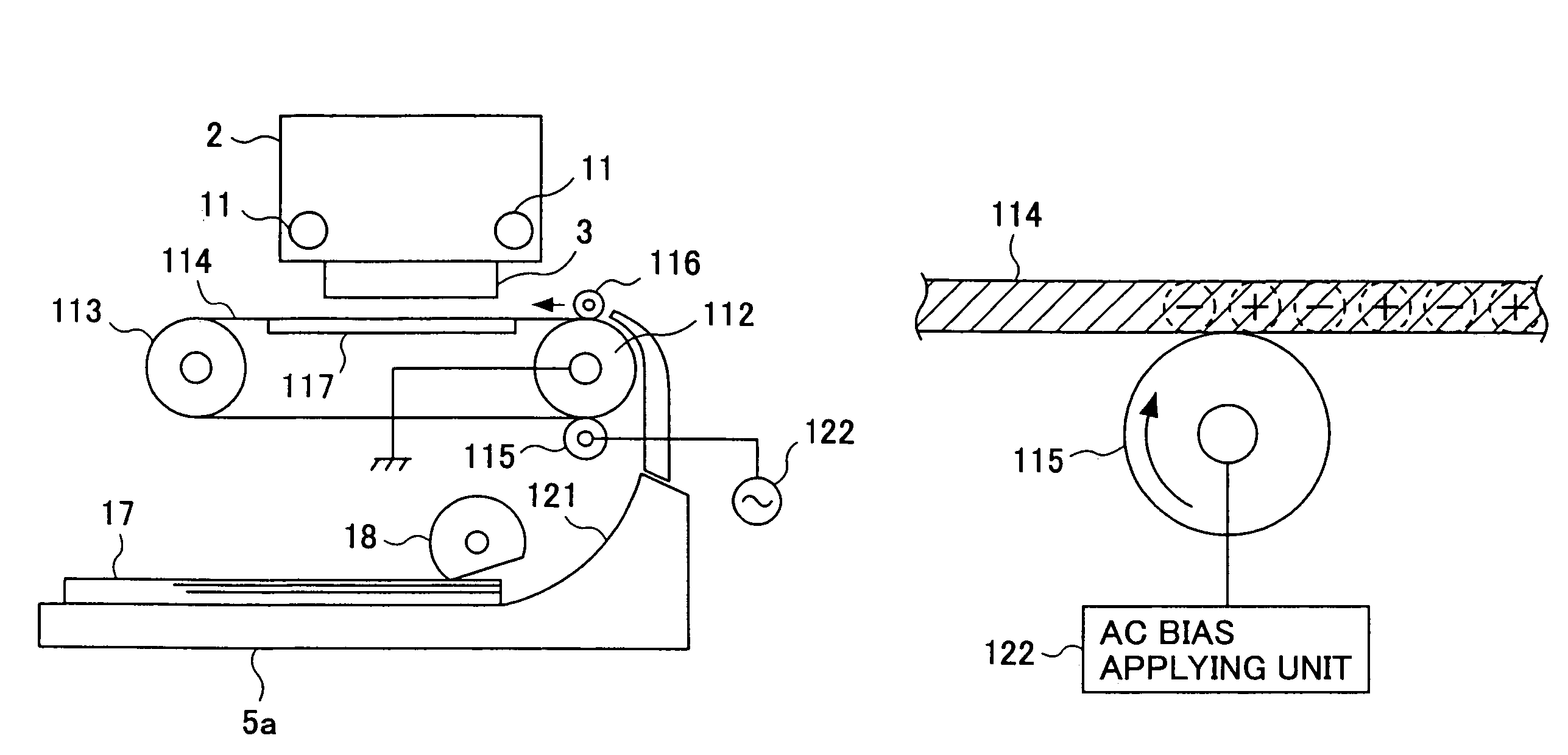

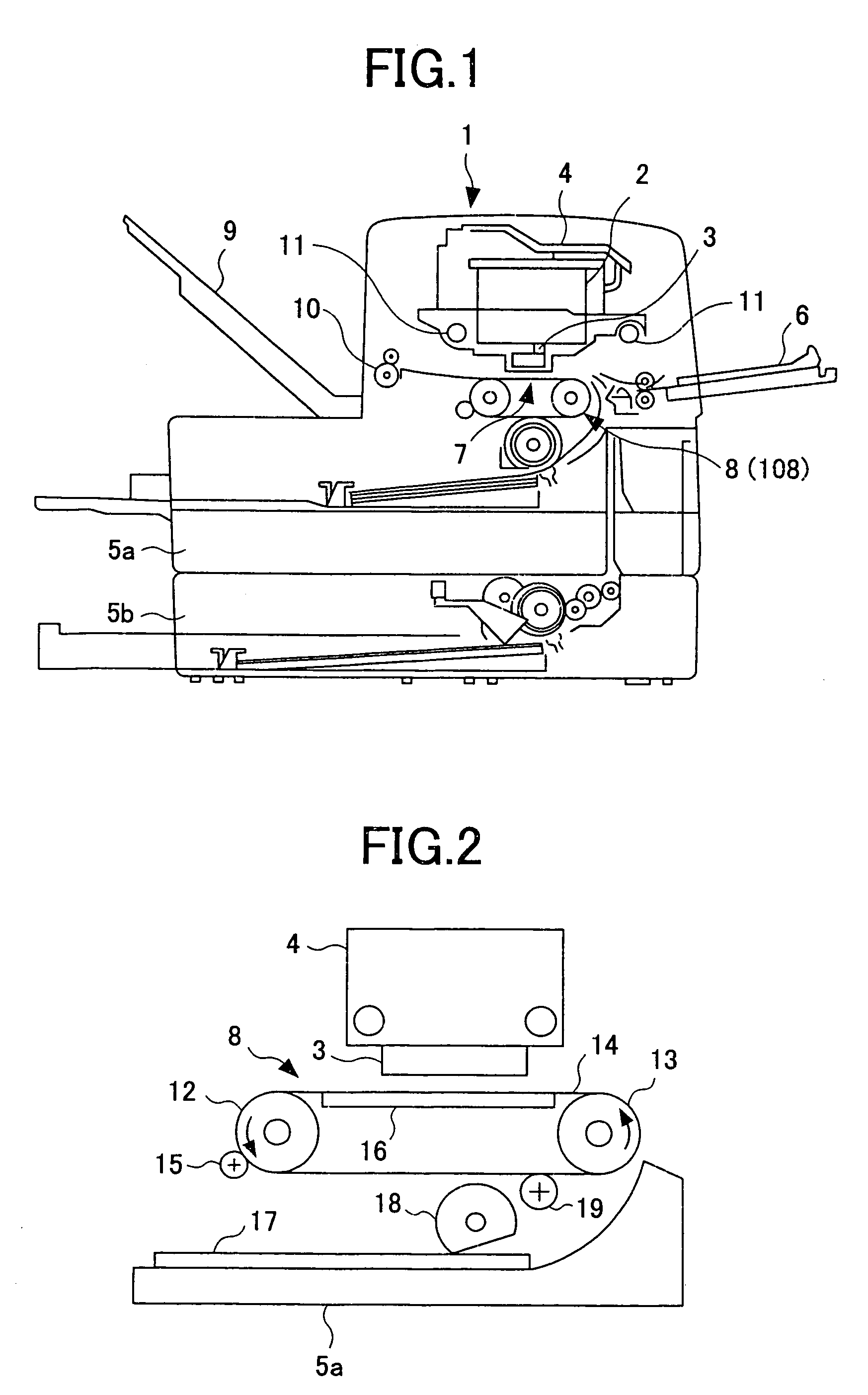

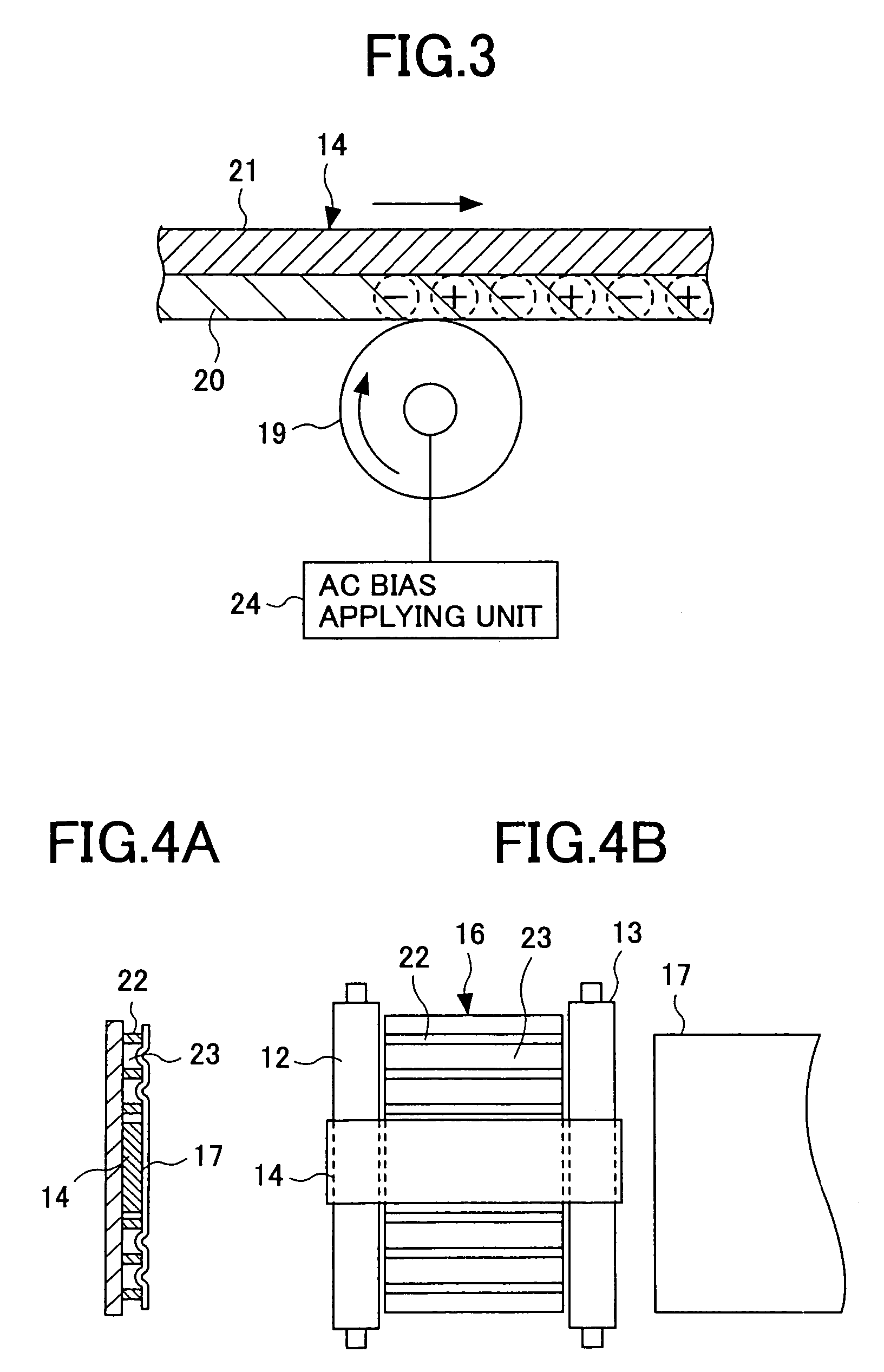

Recording-medium conveying device conveying a recording medium on a conveying belt charged with a positive charge and a negative charge alternately

InactiveUS20020126193A1Eliminate the problemHigh precisionOther printing apparatusArticle feedersImage recordingEngineering

This recording-medium conveying device comprises a conveying belt, the conveying belt, a belt charging unit, and a pressing roller. The conveying belt is wound around a driving roller and a driven roller so as to convey a recording medium to an image recording part. The conveying belt includes an insulating layer formed at one side contacting the recording medium. The belt charging unit is provided in contact with the insulating layer so as to charge the insulating layer with a positive charge and a negative charge alternately in a moving direction of the conveying belt by applying an AC bias to the conveying belt. The pressing roller presses the conveying belt against the driving roller so as to prevent the conveying belt from slipping on the driving roller.

Owner:RICOH KK

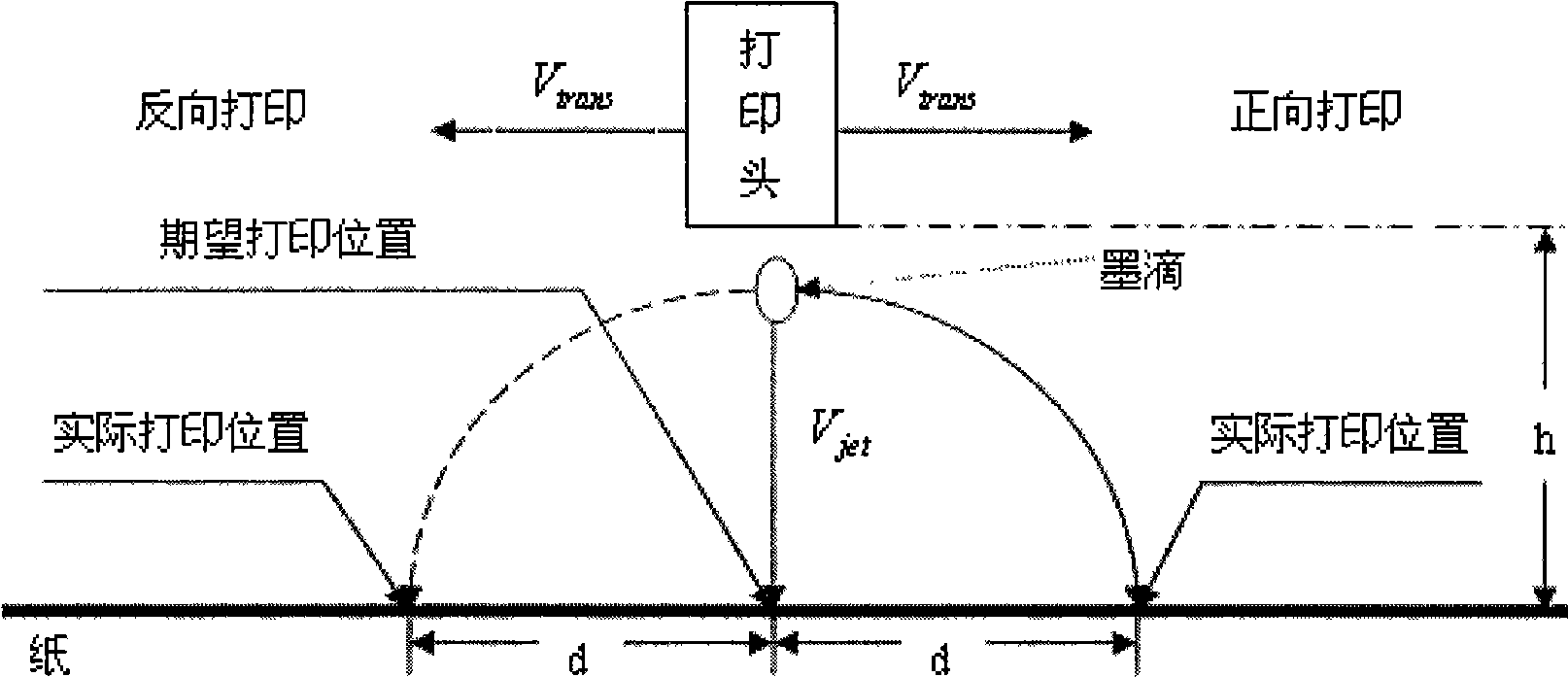

Ink droplet falling-point control method in ink jet printing

The invention relates to a method for controlling and compensating an ink dropping point in an inkjet printer. The method at least comprises: a step 101, in which according to the moving speed of a word car, the jetting speed of a nozzle in the self-motion of ink drops and the distance between the nozzle and a printing medium, a graph 2 is referred and Newton's laws of kinematics is used as basis to list an equation set of horizontal projectile motion; the time ts needed for early injection is calculated; a step 102, in which according to ts, sampling time T of Kalman filtering wave is determined; according to the moving speed of a uniform speed section of the word car and the ts in the step 101, a speed curve of the word car is divided so that the sampling time of the Kalman filtering wave is more than the time of early injection; a step 103, in which according to the determined initial value of the Kalman filtering wave and the observed displacement value of the word car, one-step prediction is carried out to obtain the state variable of next time; and a step 104, in which the predicted speed value in the step 103 is utilized to carry out calculation of relevant controlled quantity; and the step returned to the step 103 for iterative prediction. The method can compensate for errors of the ink dropping point, has good precision of prediction, broadens the printing area and improves printing efficiency.

Owner:黄进 +4

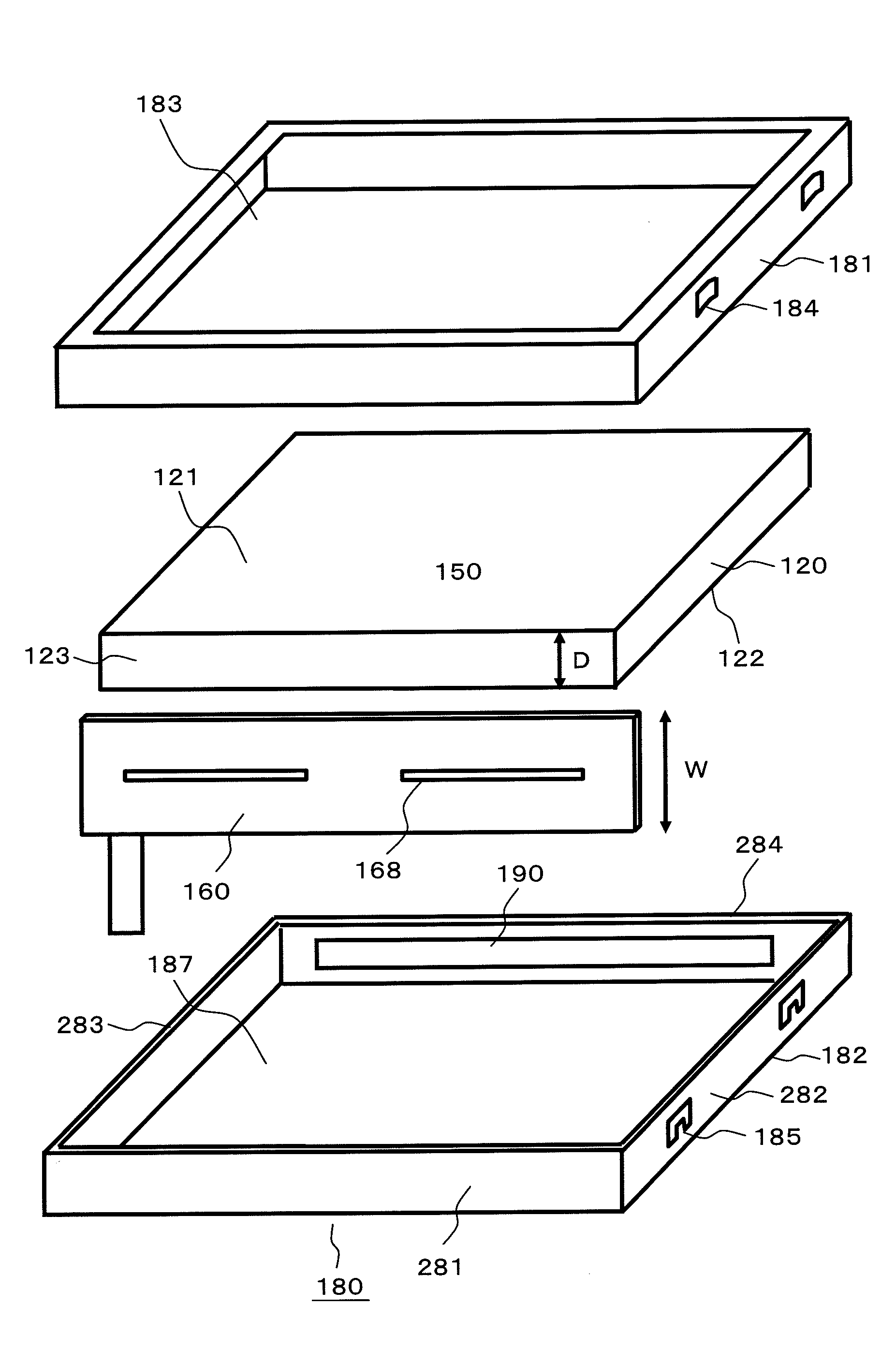

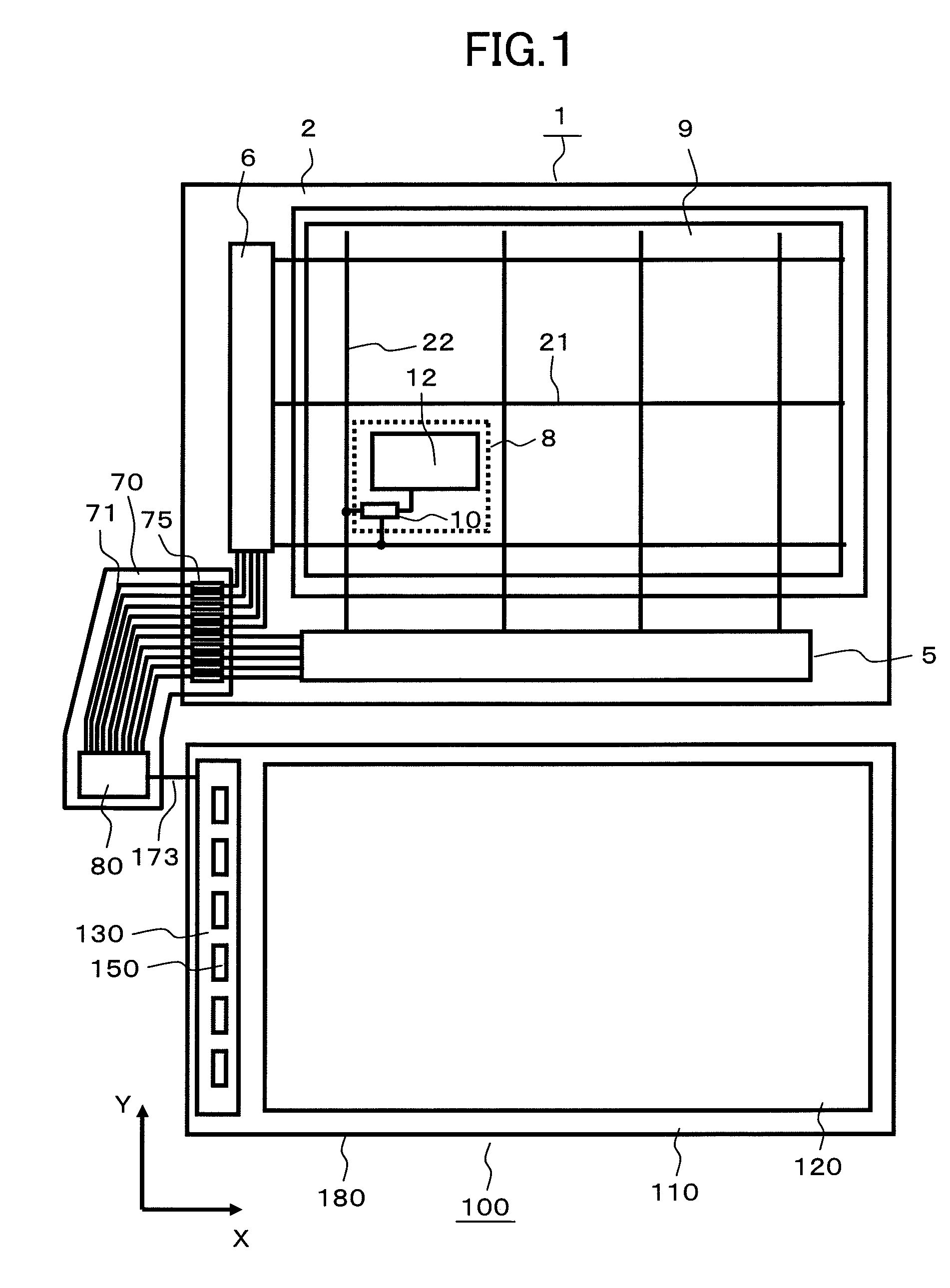

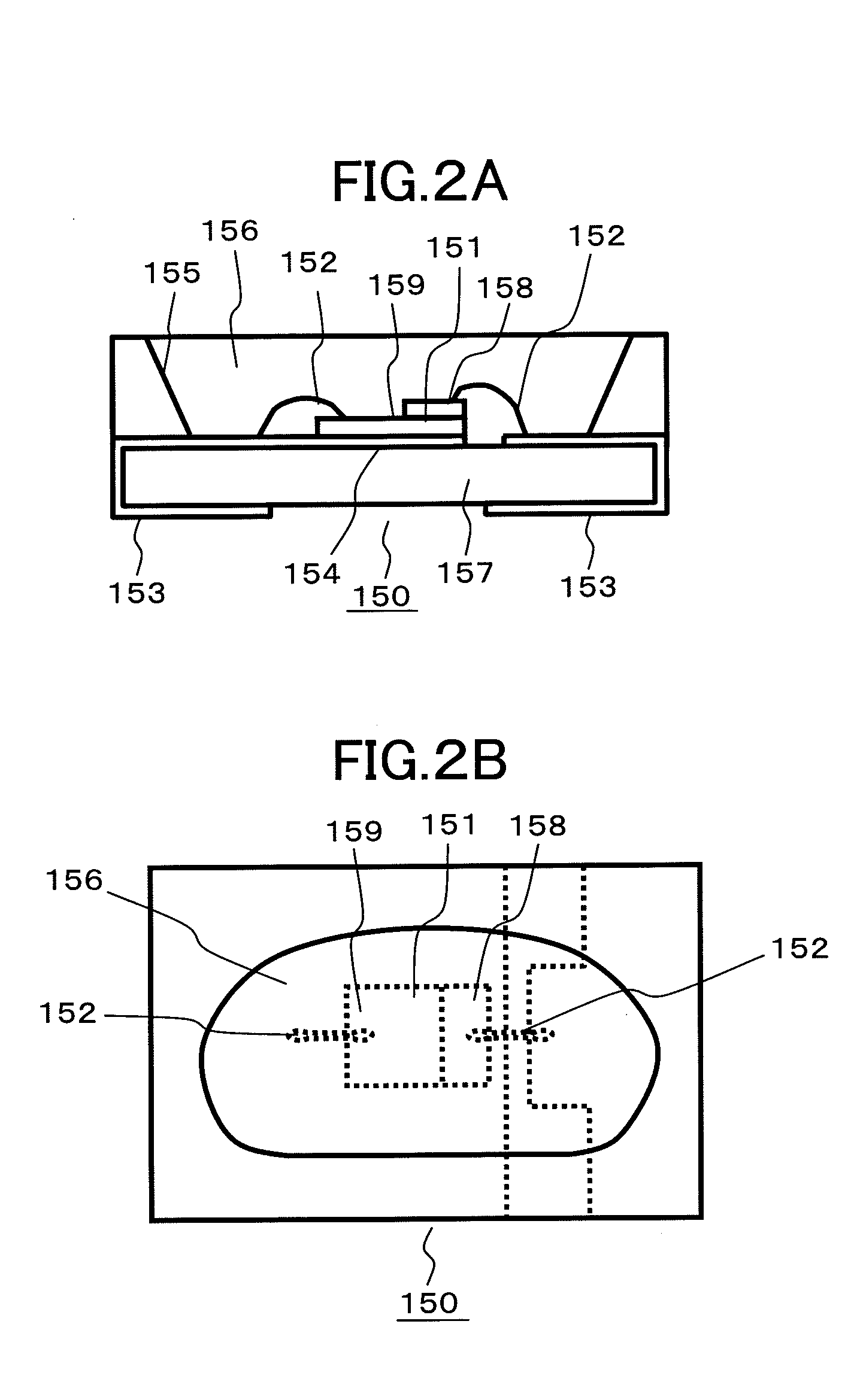

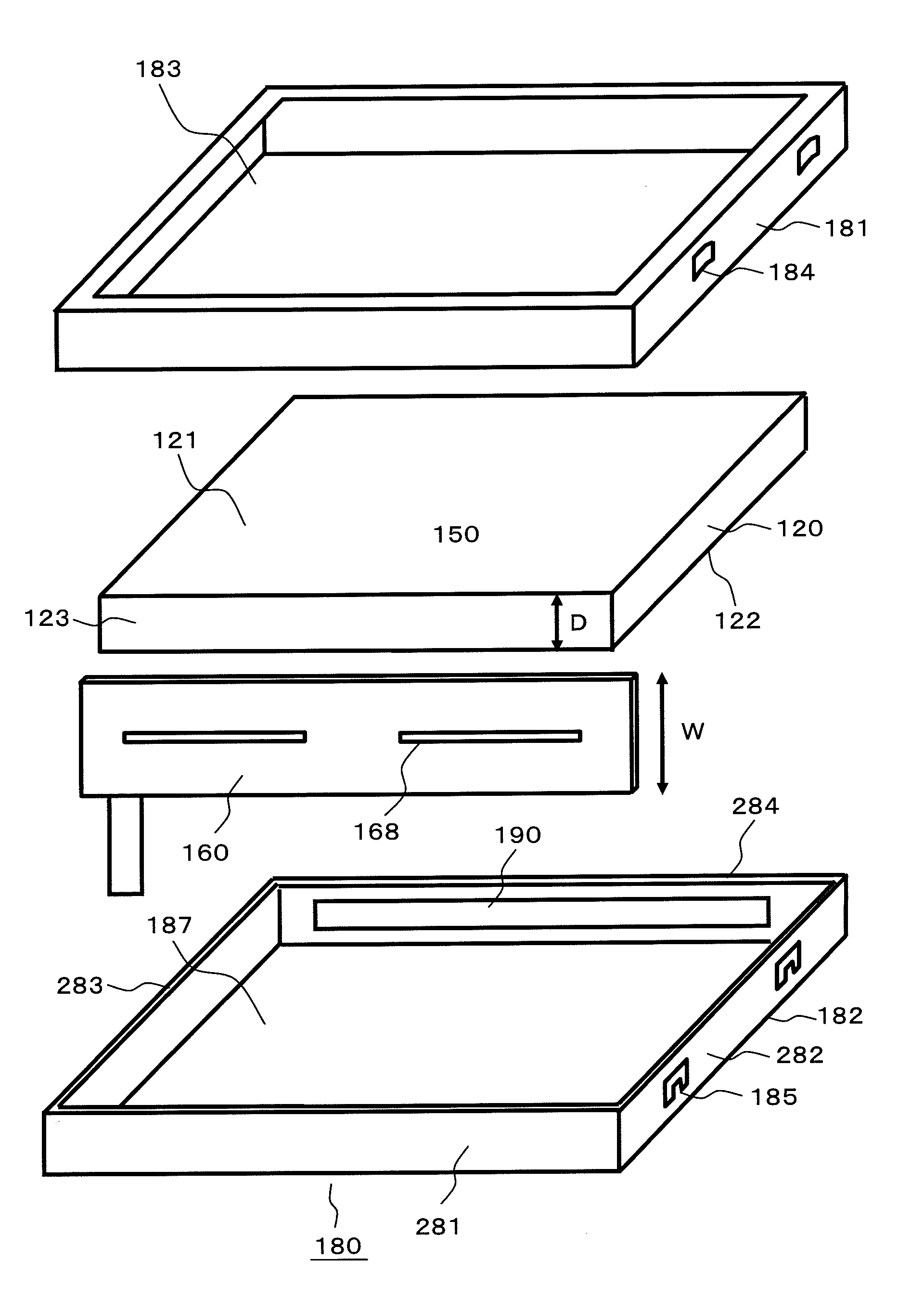

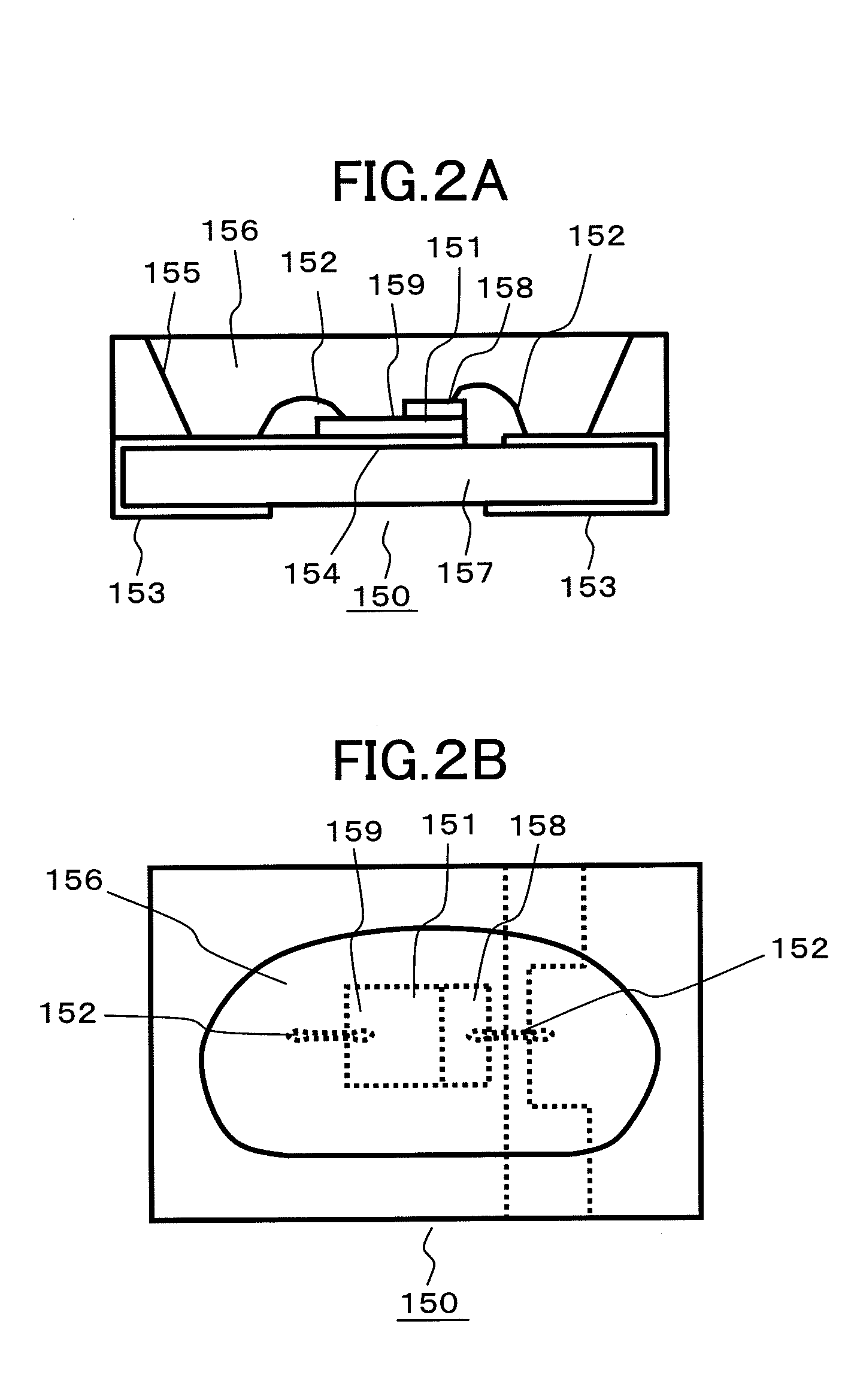

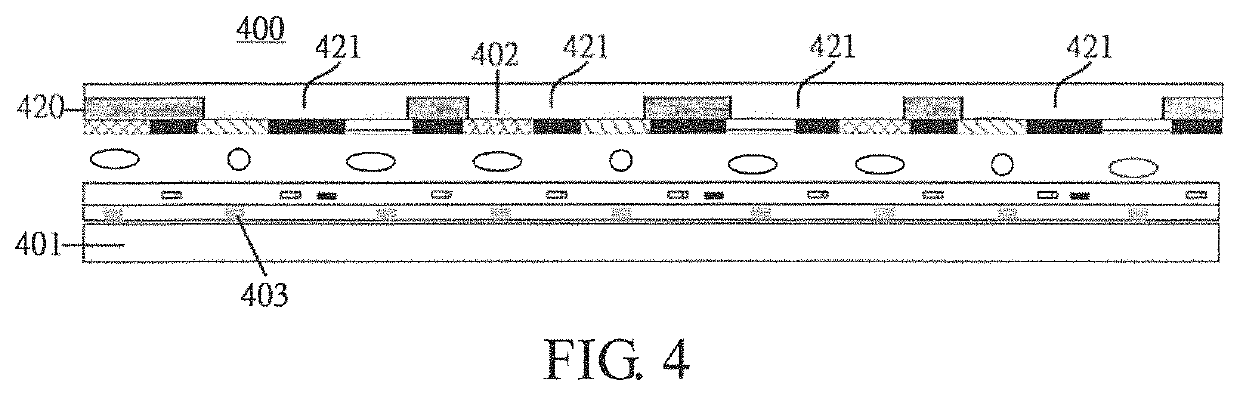

Liquid Crystal Display Device

ActiveUS20090109368A1Increase the areaEfficiently housedFinal product manufacturePrinted circuit aspectsLiquid-crystal displayLight guide

In a liquid crystal display device which uses light emitting diodes as a light source, the present invention provides a light source which can be effectively housed in a housing casing of a backlight even when an area of a printed circuit board is increased by taking radiation of heat from the light emitting diodes into consideration. A printed circuit board is formed by arranging light emitting diodes on a flexible substrate. The printed circuit board is formed with an area larger than an area of a light incident surface of a light guide plate, and is arranged to face the light incident surface of the light guide plate in an opposed manner. The light guide plate and the printed circuit board are housed in the inside of a housing casing, the printed circuit board is made foldable by forming slits in the printed circuit board thus enabling housing of the printed circuit board in the housing casing in a folded shape. Due to housing of the printed circuit board in a folded shape, a contact area of the printed circuit board with the housing casing is increased thus enhancing a heat radiation effect.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

Thick-type paperback perfect binding method

ActiveCN103434296AQuality improvementReduce labor intensityBookbinding adhesiveProduction lineCollation

The invention discloses a thick-type paperback perfect binding method. The method comprises the following steps: step one, overlaying book sections one by one together by a collating machine so as to form a whole book section; then knocking the book sections neatly, positioning, clamping, milling the back, pulling a trough, applying spot glue, thereby preparing the book sections collated for the first time; step two, repeatedly operating the step one until all the book sections are collated; step three, overlaying all the matched book sections together, splicing a book block, gluing through a gluing machine, gluing for the book back of the book block, and applying a seal cover, thereby obtaining the thick-type paperback. According to the method, a spot gluing mode is adopted, not only is the effect of fixing the collated book back each time achieved, but also the effect of saving glue materials is achieved; when in the subsequent book block collation, the glue body is firm after the book back is glued, and the glue disconnection phenomenon can be avoided, and the rejection rate is reduced greatly; the whole production line can be in place by one step, and the production efficiency is improved greatly; the obtained thick-type paperback is firm in binding, and long in service life.

Owner:ZHEJIANG XINHUA DIGITAL PRINTING

Recording-medium conveying device conveying a recording medium on a conveying belt charged with a positive charge and a negative charge alternately

InactiveUS7264347B2High precisionIncrease printing areaOther printing apparatusArticle feedersImage recordingEngineering

Owner:RICOH KK

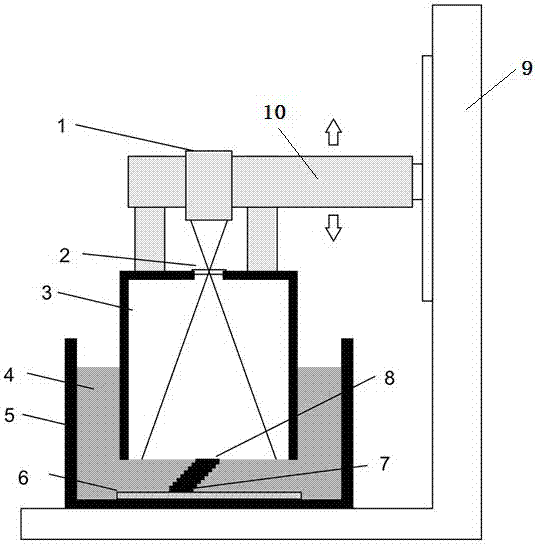

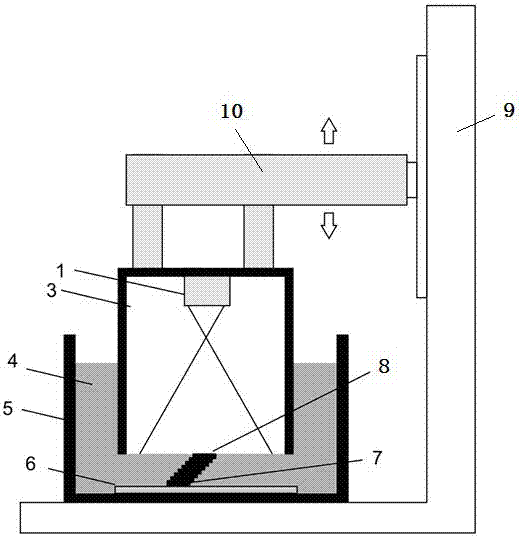

Liquid interface forming device

InactiveCN106985383AReduce stressFast molding speedManufacturing driving meansManufacturing environment conditioningElectrical and Electronics engineeringLiquid interface

The invention discloses a liquid interface forming device. The liquid interface forming device comprises a frame, a resin groove, a pattern generation device and a forming table surface; an inflation cavity is provided; one end, corresponding to the forming table surface, of the cavity is opened; the cavity is sunk in the resin groove with liquid photosensitive resins; the cavity and the pattern generation device are connected with the frame through first movable arms driven by a motor and capable of moving up and down; and the forming table surface is positioned on the inner surface of the resin groove. The liquid interface forming device is fast in forming speed, low in stress of formed objects, relatively larger in printing area and high in forming precision.

Owner:郭东

Liquid crystal display device

ActiveUS8269911B2Increase brightnessIncrease the number ofFinal product manufacturePrinted circuit aspectsLiquid-crystal displayLight guide

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA +1

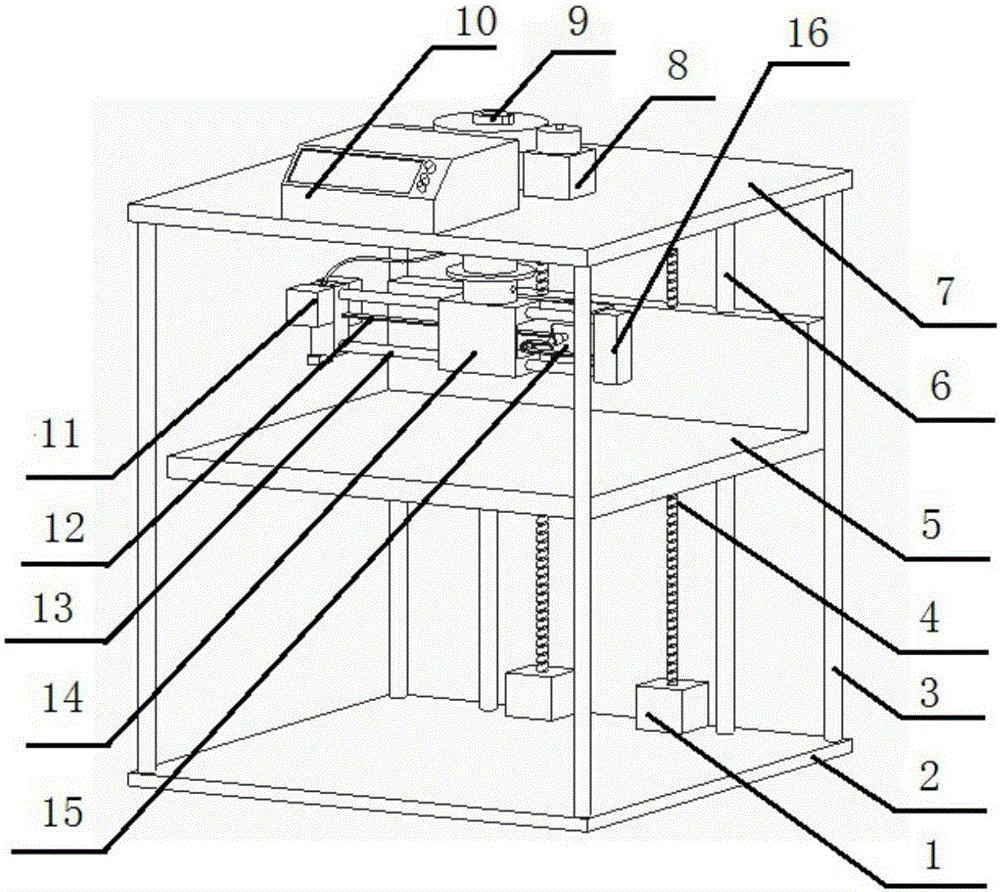

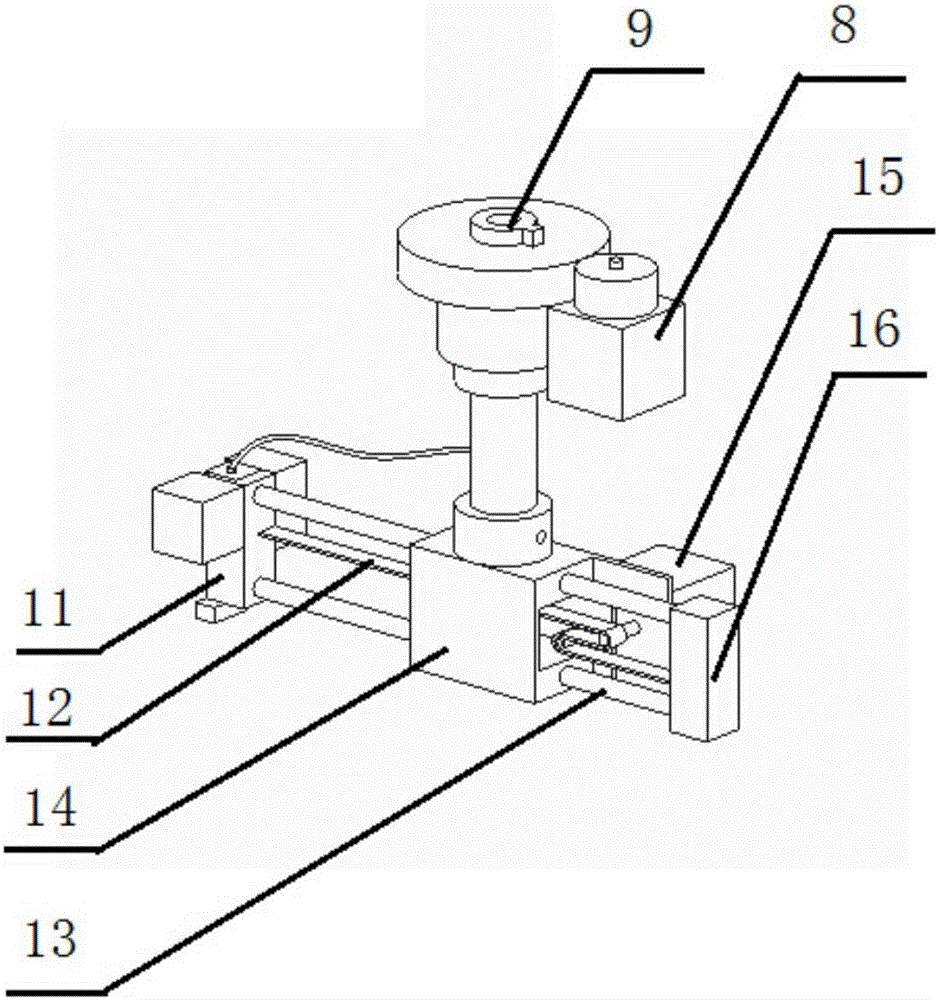

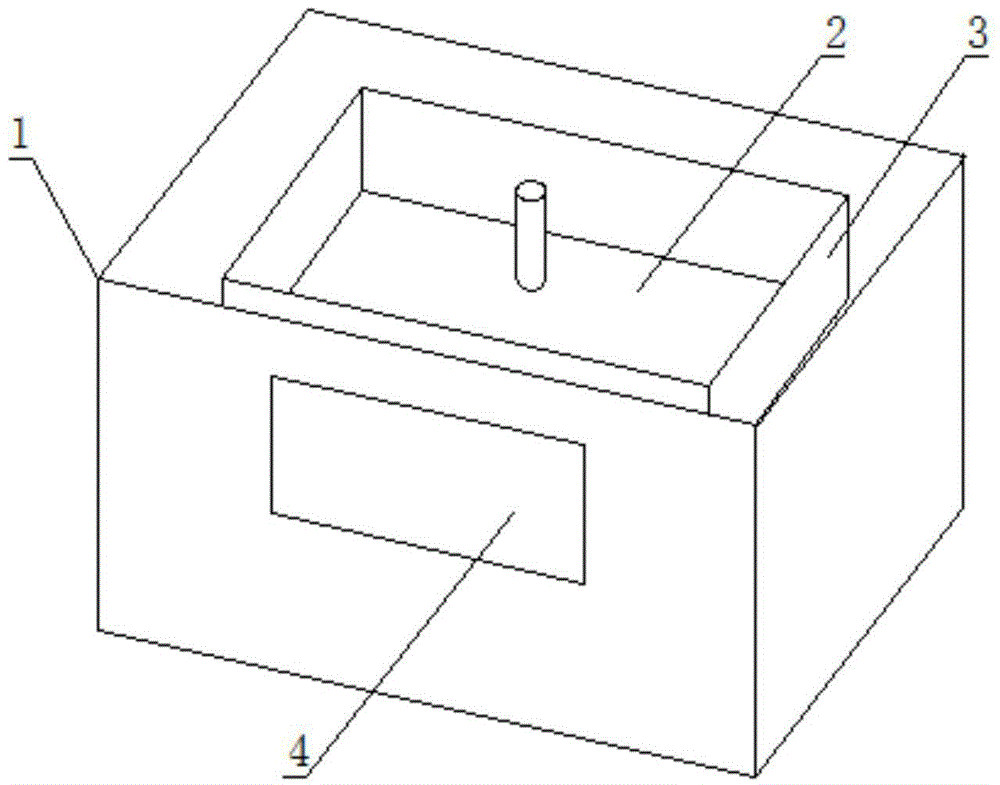

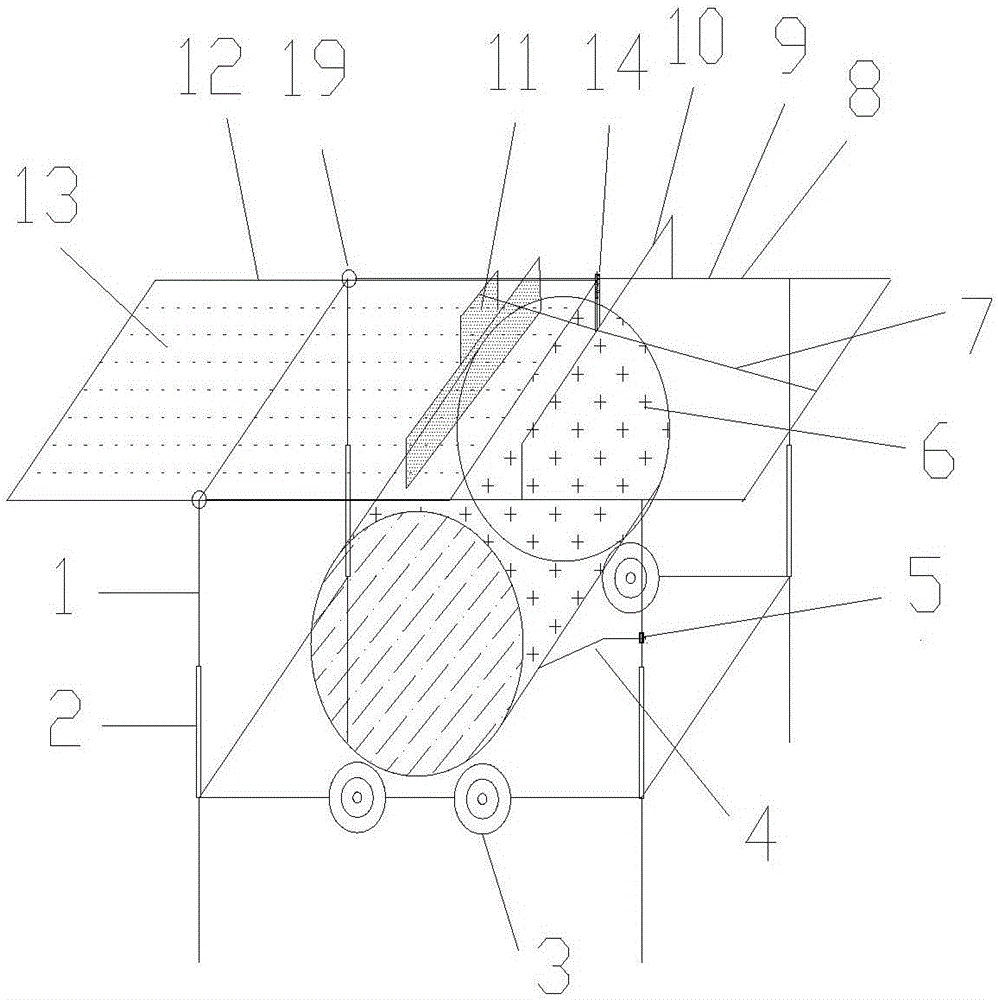

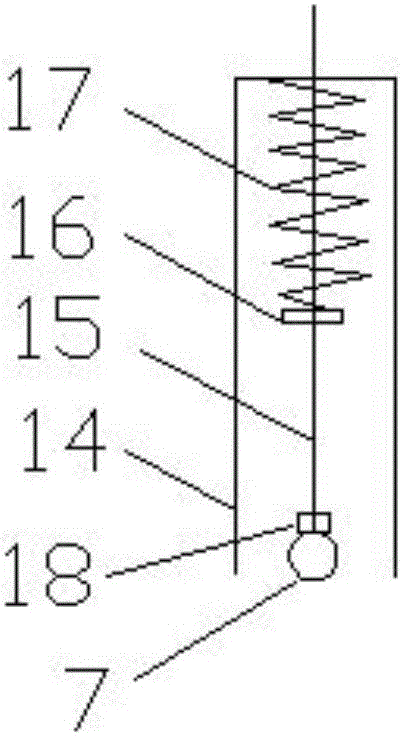

Cantilever type polar coordinate rapid molding system for board with complex curved surface

InactiveCN106003719ASimple designIncreased printing spaceAdditive manufacturing apparatusControl systemCantilever

The invention provides a cantilever type polar coordinate rapid molding system for a board with a complex curved surface. The cantilever type polar coordinate rapid molding system is characterized in that the rapid molding system comprises a main body framework which consists of a horizontally arranged bottom plate, a horizontally arranged top plate and a vertically arranged stand column, a spray head arranged at the lower end of the top plate and capable of rotating by 360 degrees according to a mode of a polar coordinate system, a control box arranged on the upper end surface of the top plate, and a working platform arranged between the top plate and the bottom plate and capable of moving up and down. According to the mode of the polar coordinate system, printing track for a curved-surface structure is a true circular arc, and operation parameters of a control motor only comprise radial length and a rotary angle of a obtained section area, so that design of a control system is relatively simple; and printing space is greatly improved in case of the same structure. The cantilever type polar coordinate rapid molding system has a simple structure, easy-to-accept appearance, very good stability and reproducibility.

Owner:DALIAN JIAOTONG UNIVERSITY

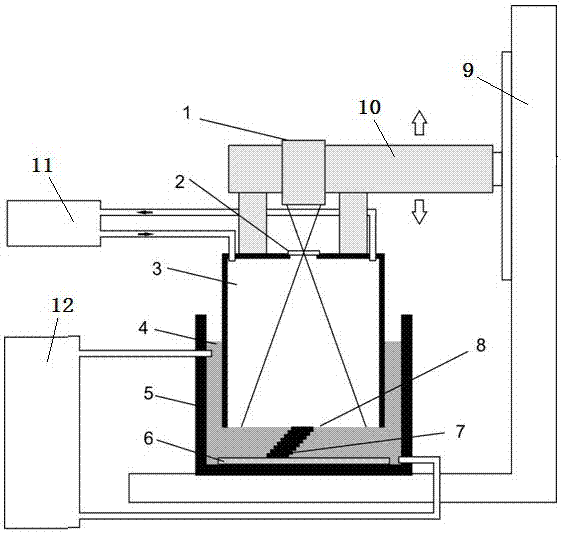

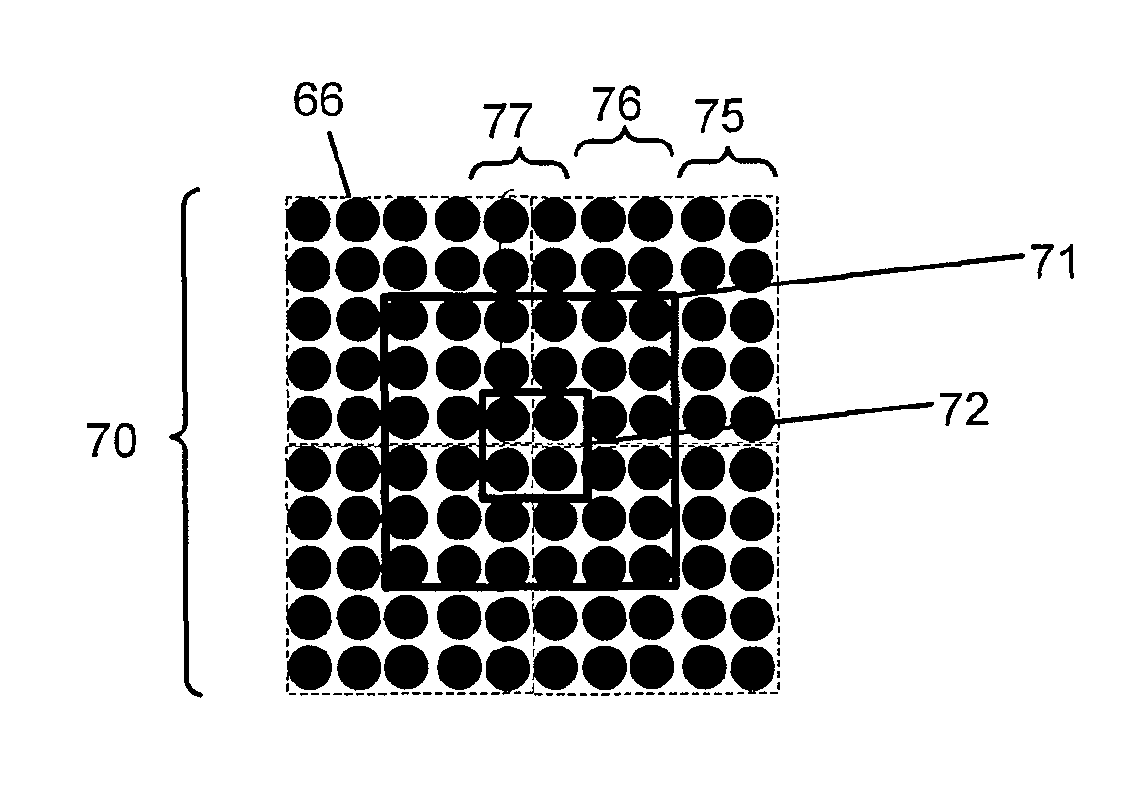

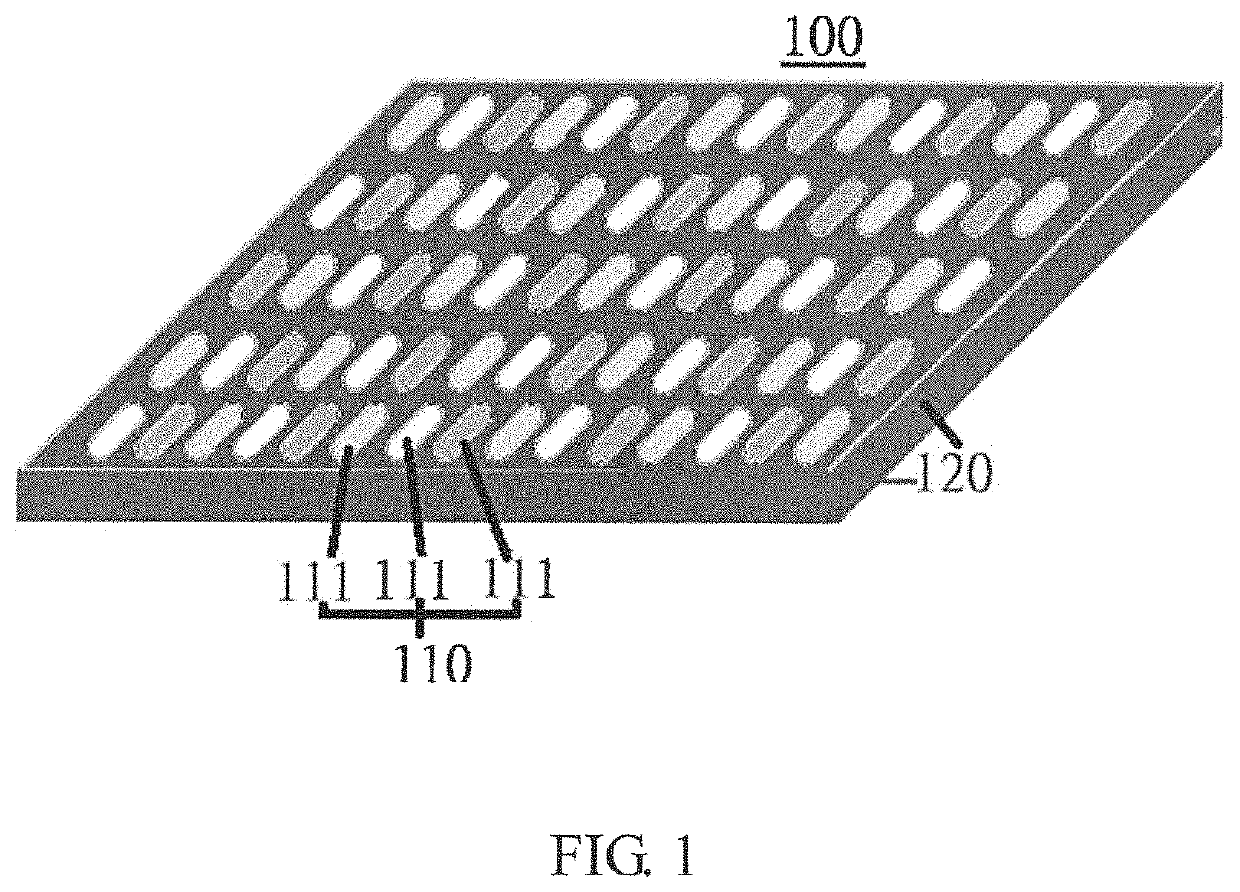

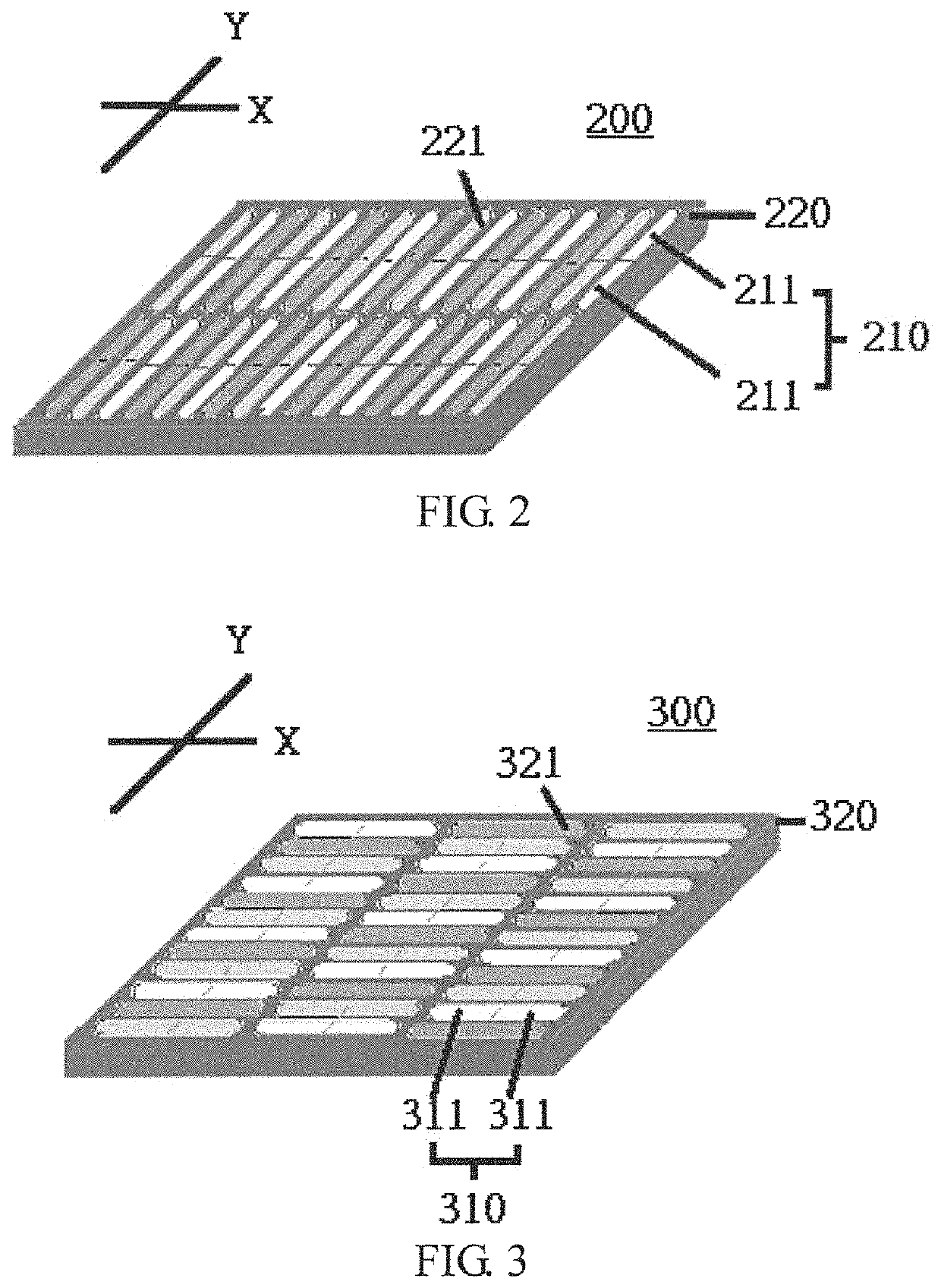

Photocuring 3D printer and working method thereof

InactiveCN105313333AReduce volumeIncrease printing speedAdditive manufacturing apparatusLight sourceEngineering

A photocuring 3D printer is technically characterized by comprising a printer body; a printing material tank and a printing platform are arranged in the printer body; a control screen used for conducting digital control on a digital path of ultraviolet by means of controlling a digital program is further arranged in the printer body; a control panel is arranged under the printing material tank; a light source plate is arranged under the control panel; ultraviolet light sources are arranged on the light source plate in an arrayed mode; an oxygen permeation membrane is arranged at the bottom of the inner surface of the printing material tank. A working method of the photocuring 3D printer comprises the steps that when the ultraviolet light sources illuminate, digital control over the digital path of the ultraviolet is achieved through the digital program in the control screen, so that a required image is controlled to be projected according to the digital program; and the encoded image is projected to the bottom of the printing material tank, so that photosensitive resin in the printing material tank is cured, and finally the photosensitive resin is cured onto the printing platform. By the adoption of the technical scheme, the size of the photocuring 3D printer is small, the printing speed and the printing area are increased, the manufacturing cost is low, and large-scale popularization is facilitated.

Owner:BONA YUNZHI TIANJIN TECH

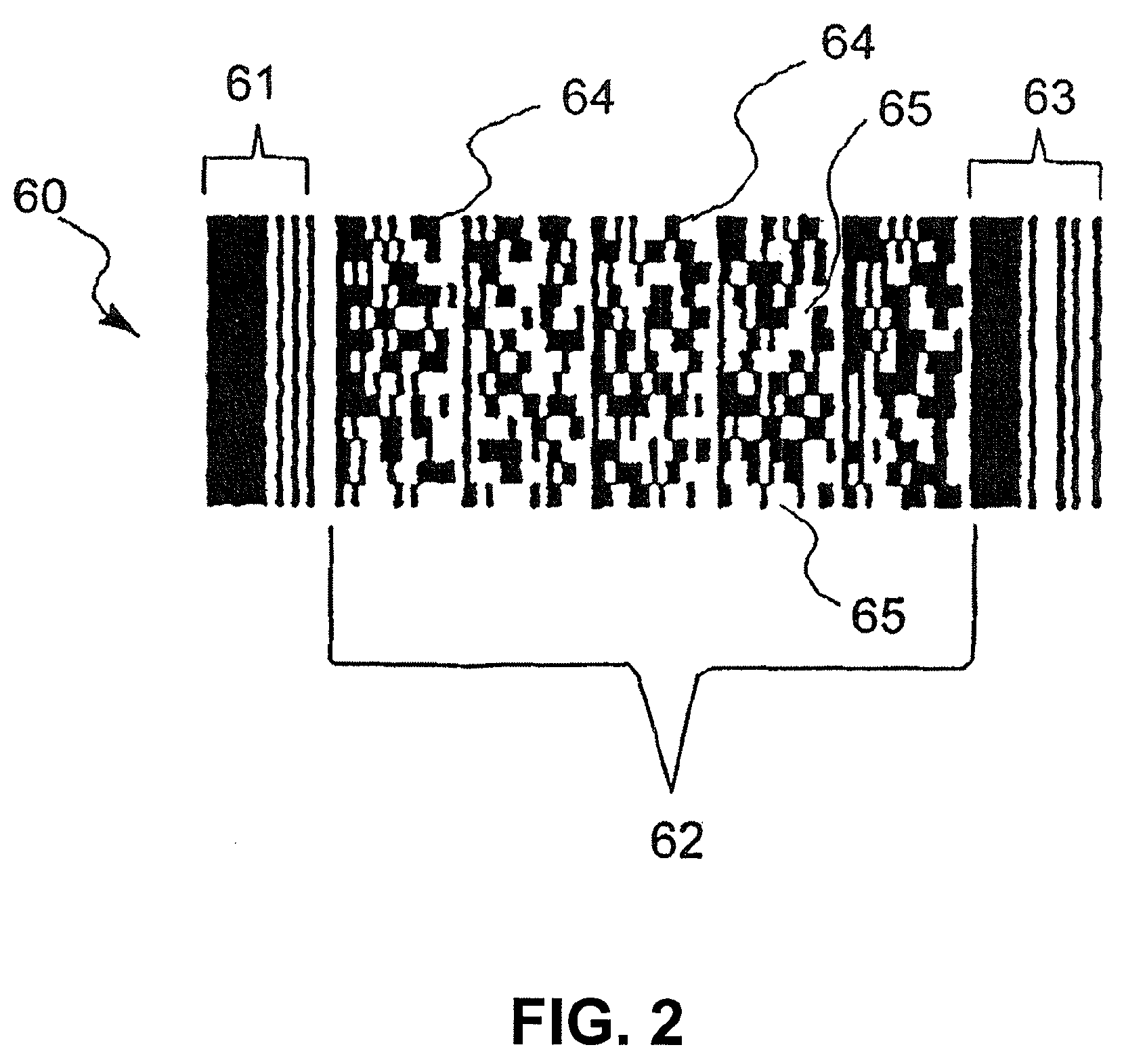

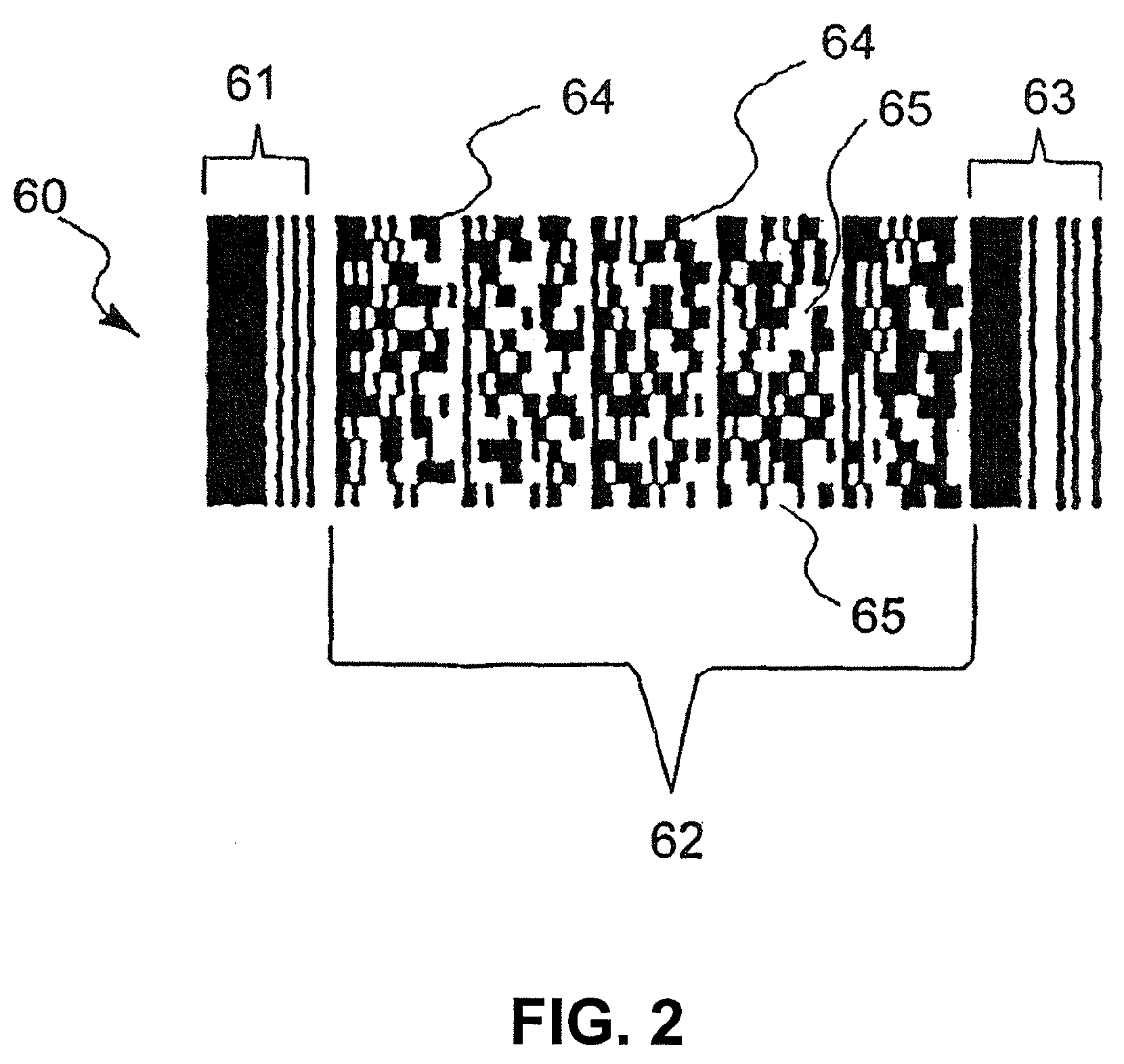

Print enhancement of pixels to improve readability

InactiveUS8235516B2Quality improvementIncrease printing areaMeasurement apparatus componentsTypewritersBarcodeComputer science

Owner:PITNEY BOWES INC

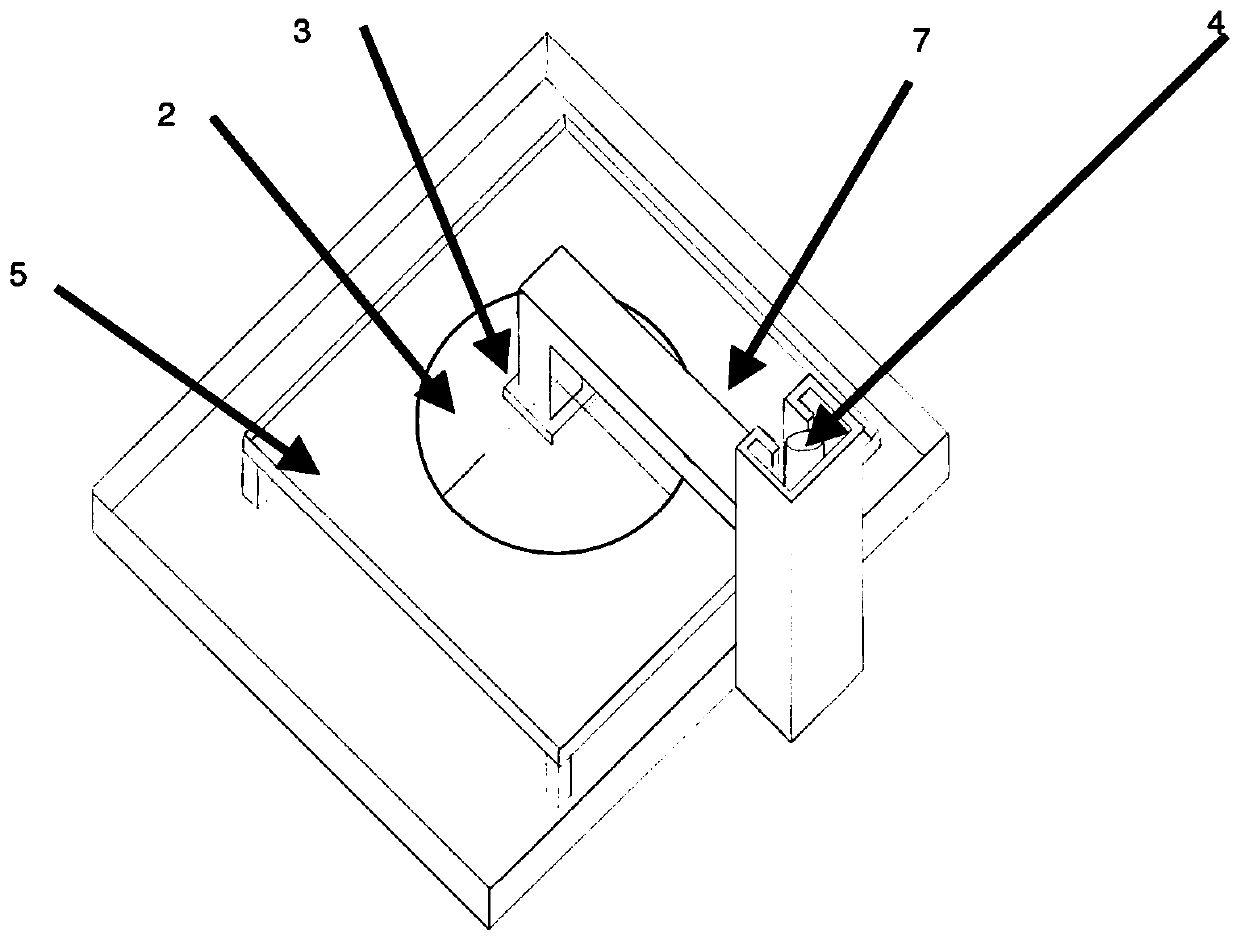

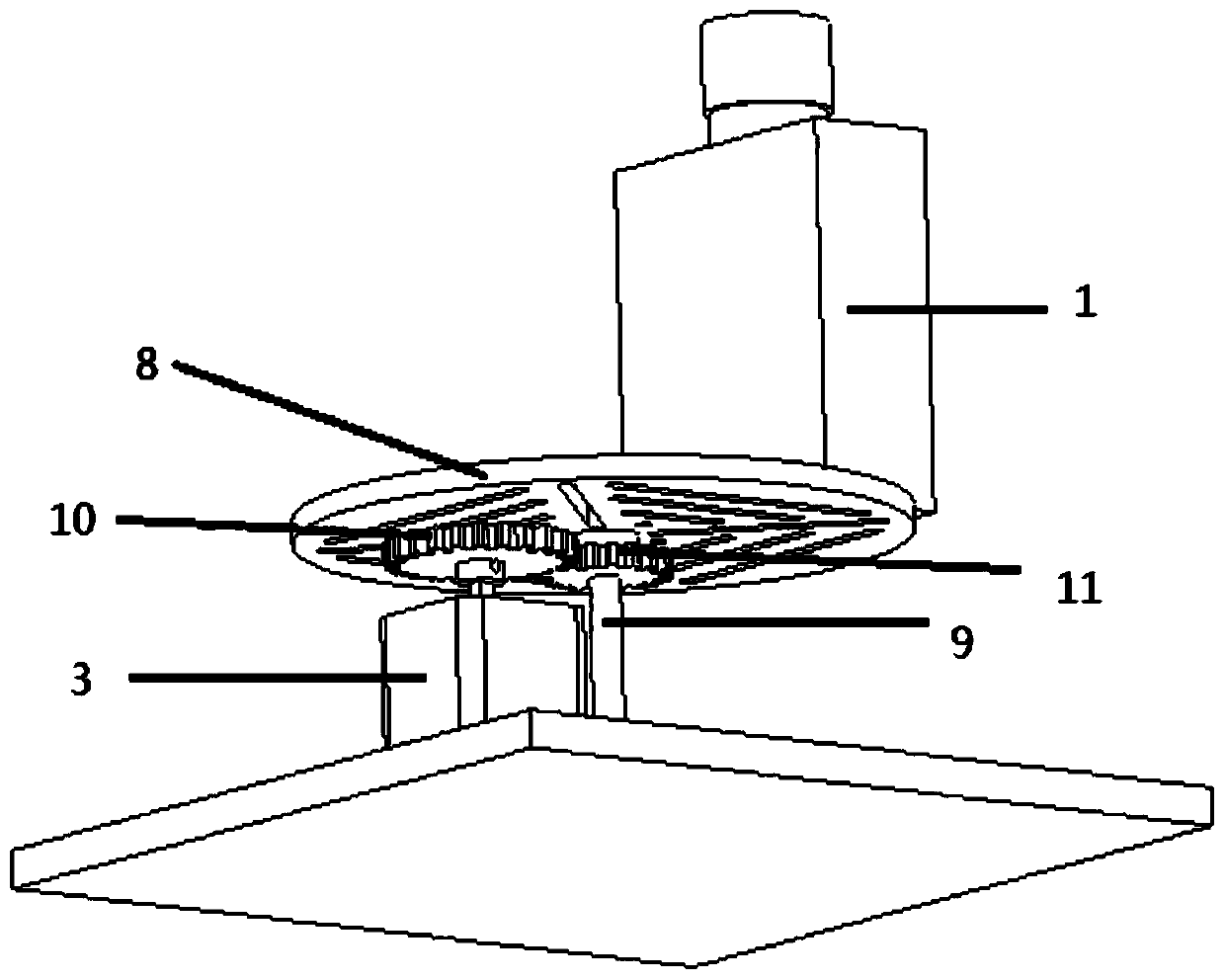

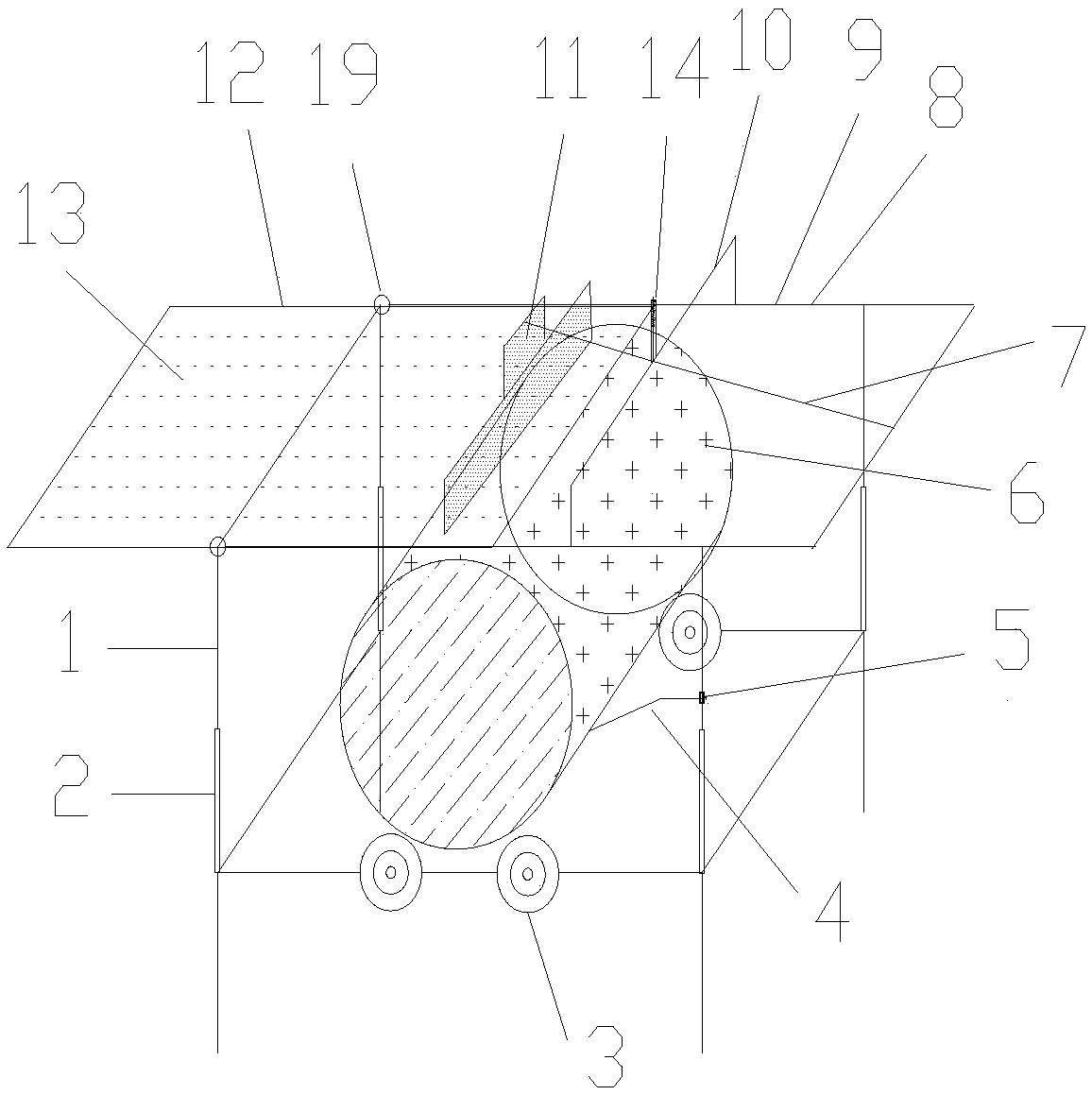

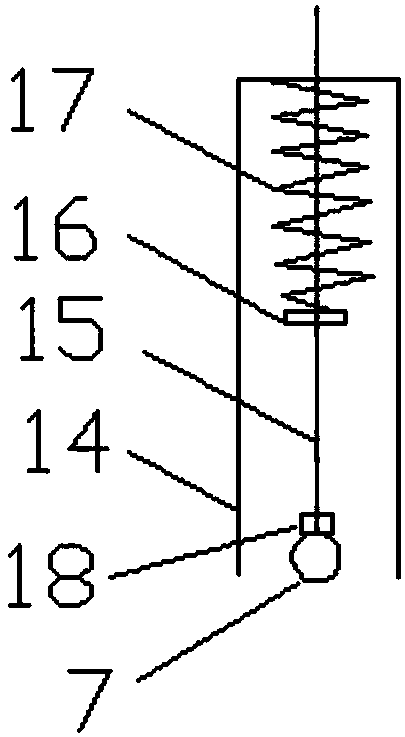

Portable manual curved-surface screen printing machine

The invention relates to a portable manual curved-surface screen printing machine, and belongs to the technical field of printing. The portable manual curved-surface screen printing machine mainly comprises a machine frame, a top frame, a rectangular frame, a screen printing plate and a scraping plate, wherein the top frame is located at the top of the machine frame and is in a U shape, and the two end points of a U-shaped opening are connected to a rotary shaft at the top end of the machine frame so that the U-shaped top frame can rotate around the rotary shaft; sliding guide rails are symmetrically mounted on the two sides of the U-shaped top frame, the rectangular frame is mounted in the sliding guide rails, and the rectangular frame can slide in the U-shaped top frame freely; the screen printing plate is fixed in the rectangular frame through fasteners; the two sides of a cross beam on the lower portion of the machine frame are each symmetrically provided with two bearings used for storing an article to be printed, and the article to be printed can rotate freely under the effect of friction force of the screen printing plate; and a positioning pointer is mounted on one supporting rod of the machine frame and points to the feature point of the article to be printed, and thus the initial printing position of the article to be printed is marked. The portable manual curved-surface screen printing machine is simple in structure, operation is flexible and convenient, the printing quality is good, the article to be printed can be printed and repaired on the using field, and batched printing can also be performed.

Owner:张昕宸

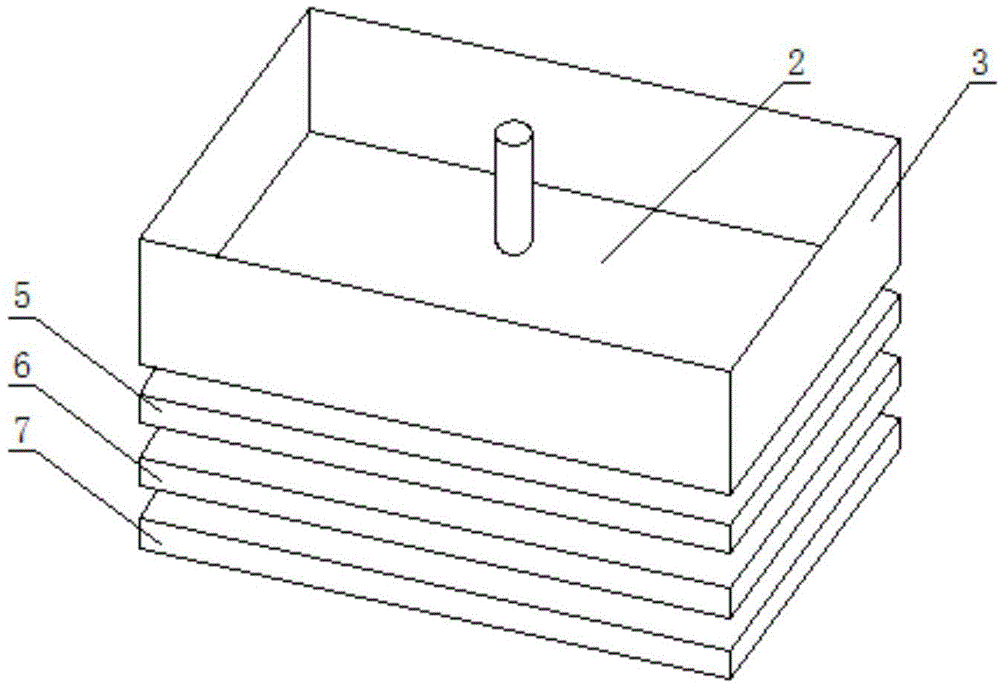

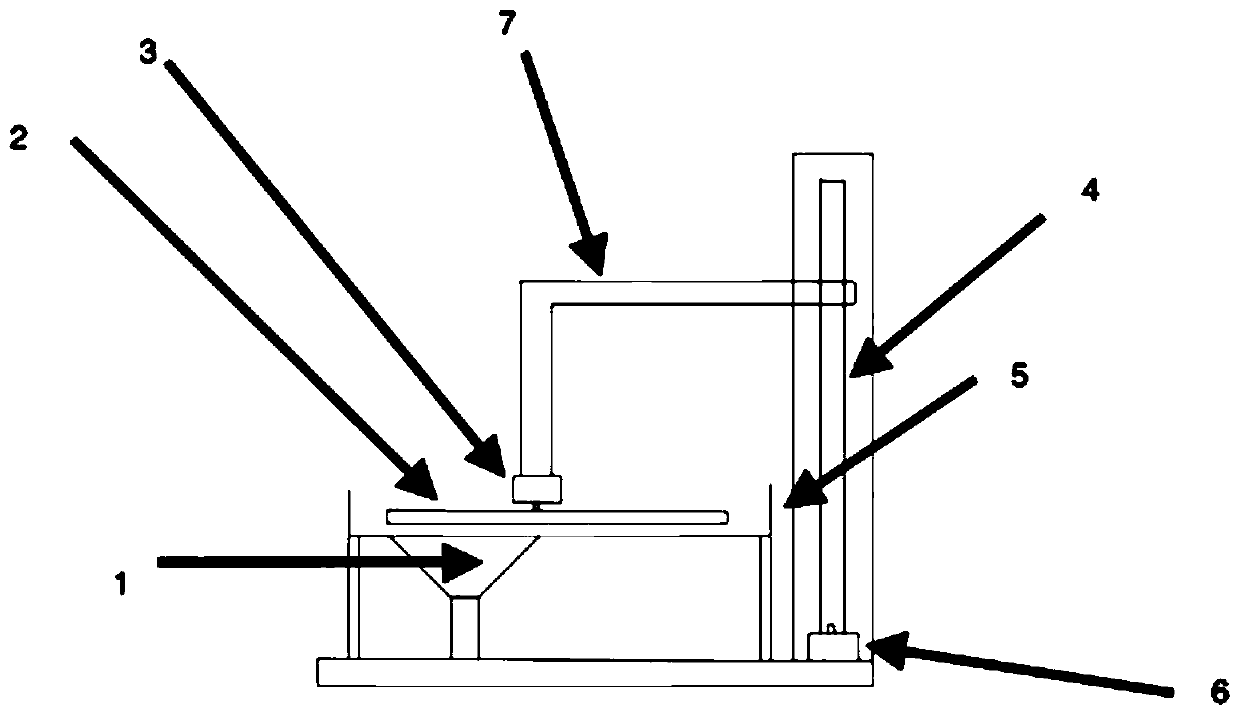

3D printing mechanism

PendingCN109834936ASimple structureReduce energy consumptionAdditive manufacturing apparatus3D object support structuresOptical processingImage resolution

The invention discloses a 3D printing mechanism. The 3D printing mechanism comprises a printing part and a lifting part; the printing part comprises a carrying table, a first motor, a digital opticalprocessing projector and a resin tank; the carrying table and a carrying table motor are connected, and when the carrying table motor is in operation, the carrying table is driven to rotate; a projection plane projected by the digital optical processing projector penetrates through the resin groove and is printed on at least part of the carrying table; and the lifting part is partly connected to the carrying table of the printing part. The 3D printing mechanism expands the effective area of printing to several times of the original effective areas of printing on the basis of maintaining the resolution ratio, and realizes microlithographic 3D printing with a larger size.

Owner:SOUTH CHINA UNIV OF TECH +1

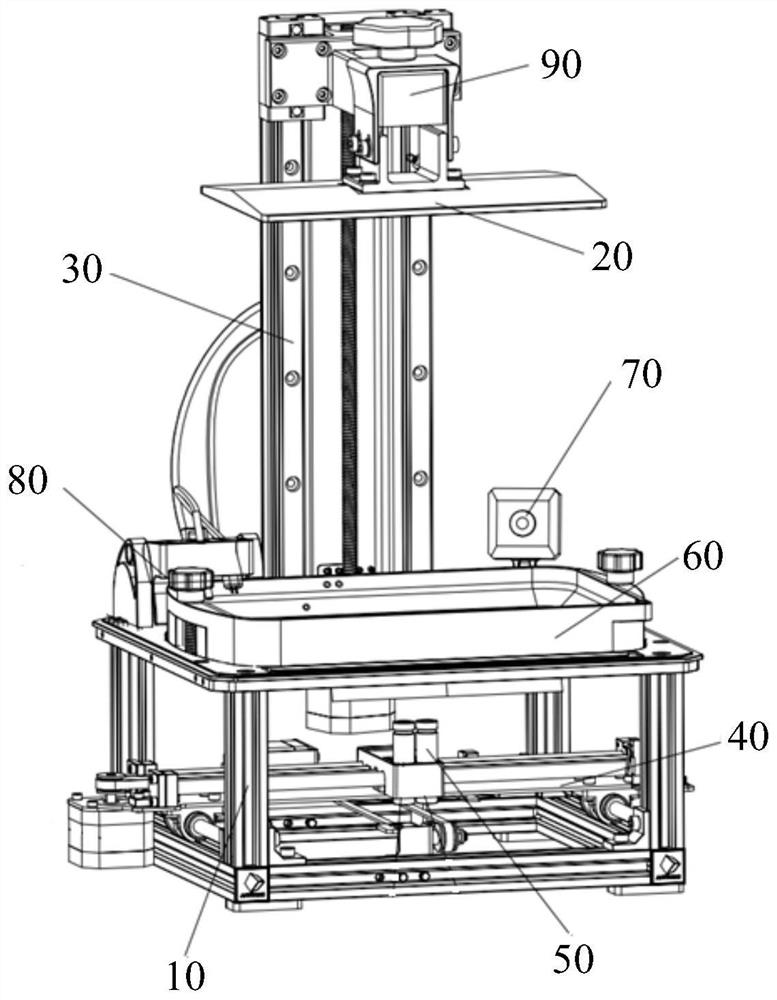

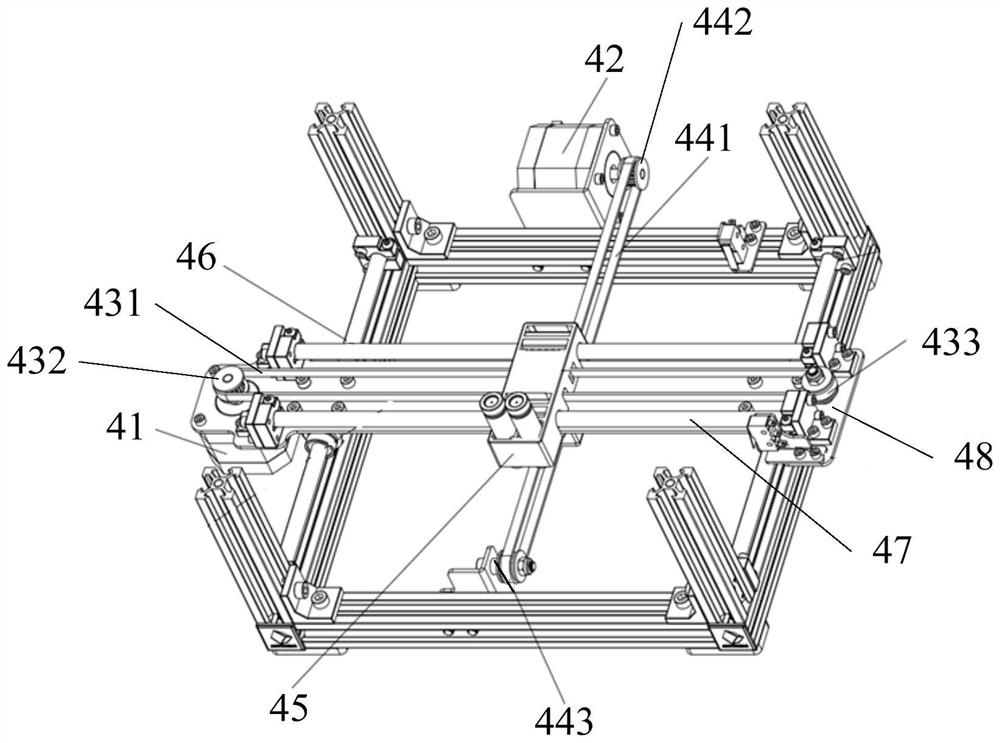

Printer

PendingCN113352605AExtended range of movementIncrease printing areaManufacturing platforms/substratesManufacturing driving meansComputer printingMechanical engineering

The invention discloses a printer. The printer comprises a base, a printing platform, a lifting assembly, a moving assembly, a laser module and a material groove, wherein the printing platform is arranged on the base through the lifting assembly; the laser module is arranged on the base through the moving assembly; the material groove is formed in the base; the moving assembly is used for driving the laser module to move in a first direction and / or a second direction so that the laser module can move to a to-be-sintered position, a printing material in the material groove can be sintered, and a printing model attached to the printing platform is formed; wherein the first direction and the second direction are both parallel to a bearing surface of the printing platform. Therefore, the comprehensive performance of the printer can be improved.

Owner:SHENZHEN ANYCUBIC TECH CO LTD

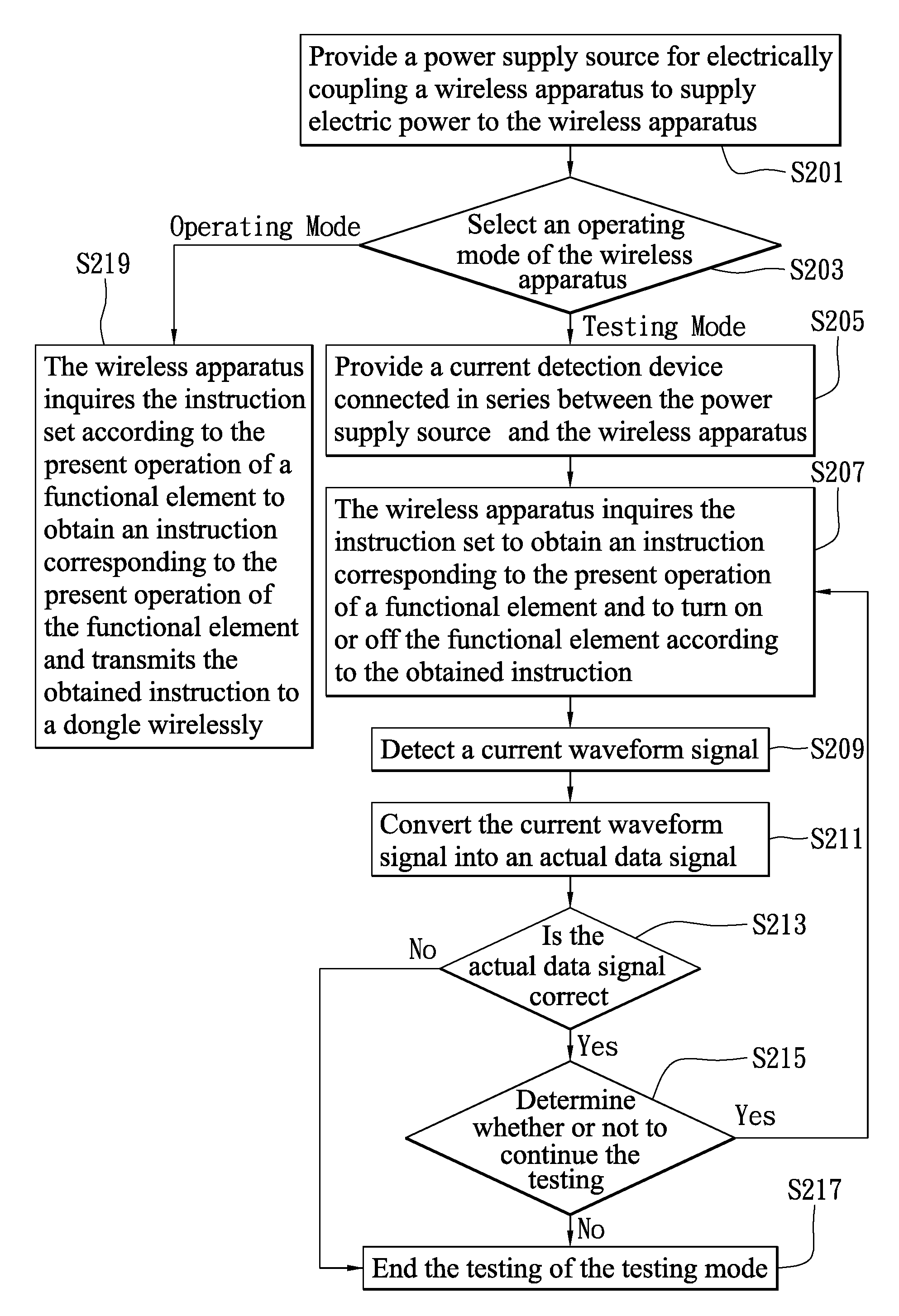

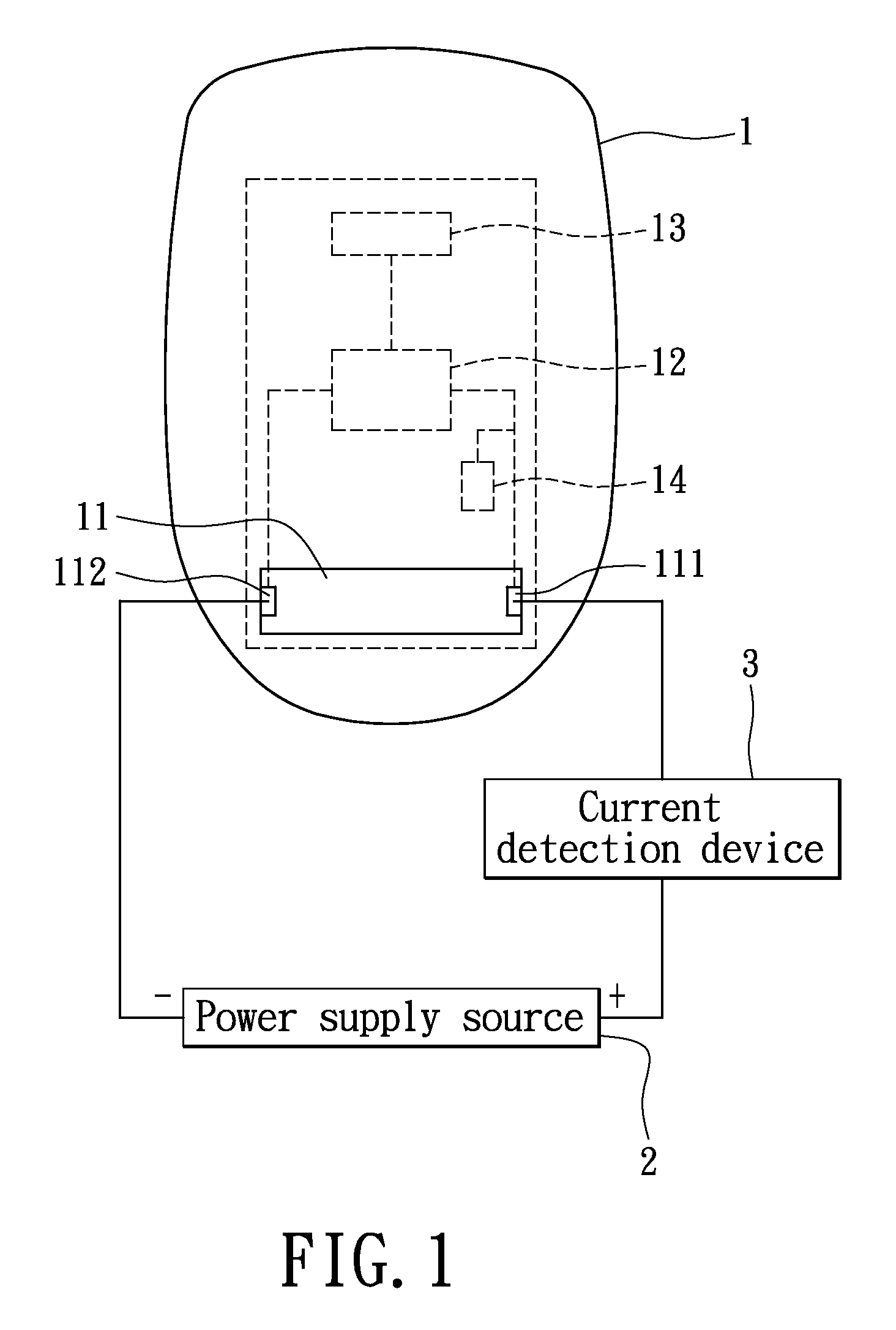

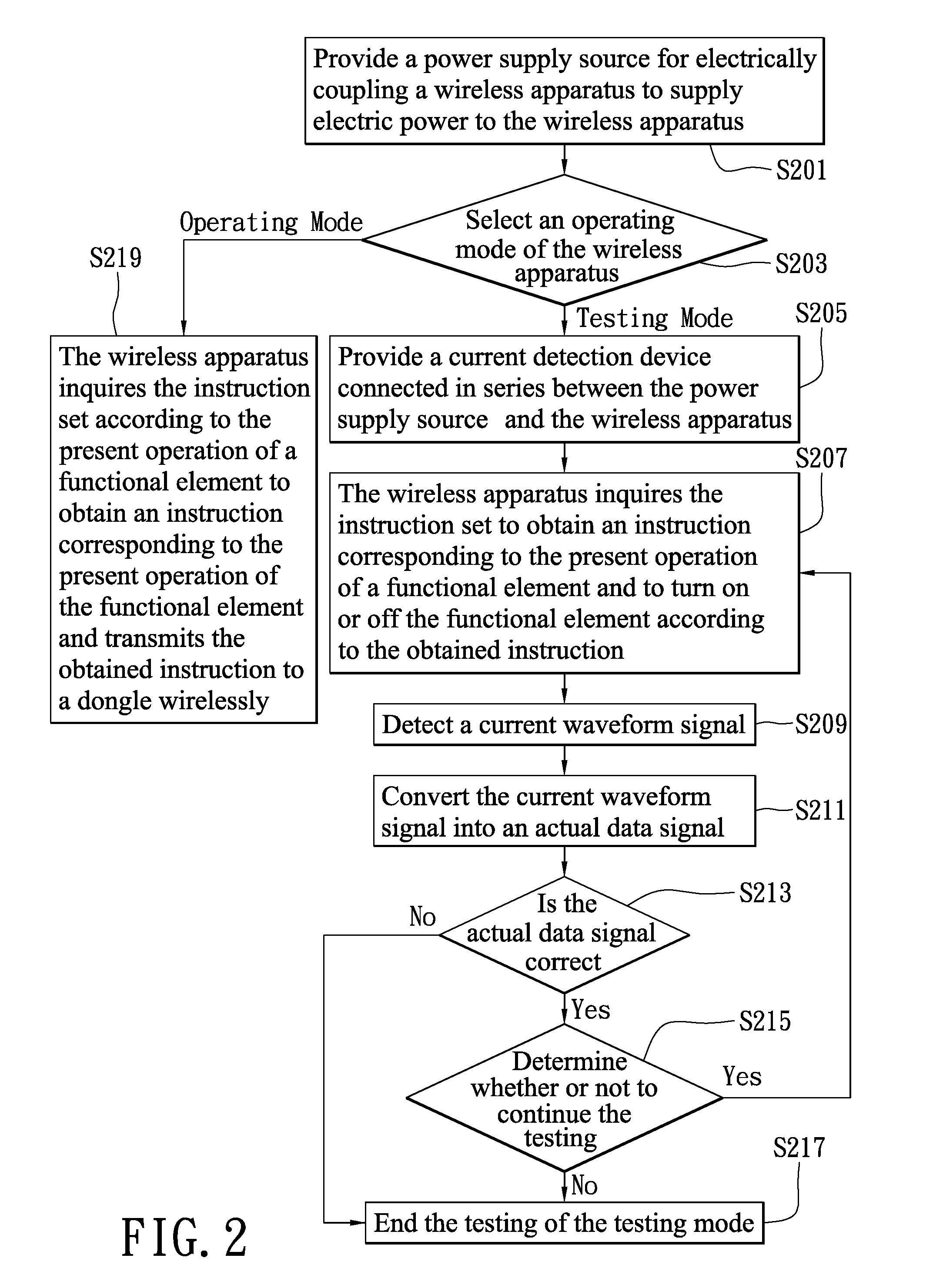

Testing method for electronic apparatus

ActiveUS20110012611A1Improve test efficiencyIncrease printing areaDigital data processing detailsHardware monitoringElectricityElectric equipment

An electronic apparatus includes a first power contact, a second power contact, and a control unit. The first power contact is electrically connected with an anode of a power supply source, and the second power contact is electrically connected with a cathode of the power supply source. The control unit electrically connects the first power contact and the second power contact for forming a signal transmission path and receiving the power generated by the power supply source. When the control unit is operated in a testing mode, the control unit operates in a working mode or a sleeping mode according to an instruction of a default instruction set for changing a current waveform signal transmitted over the signal transmission path, so as to achieve the purpose of providing a convenient and high-efficiency testing.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

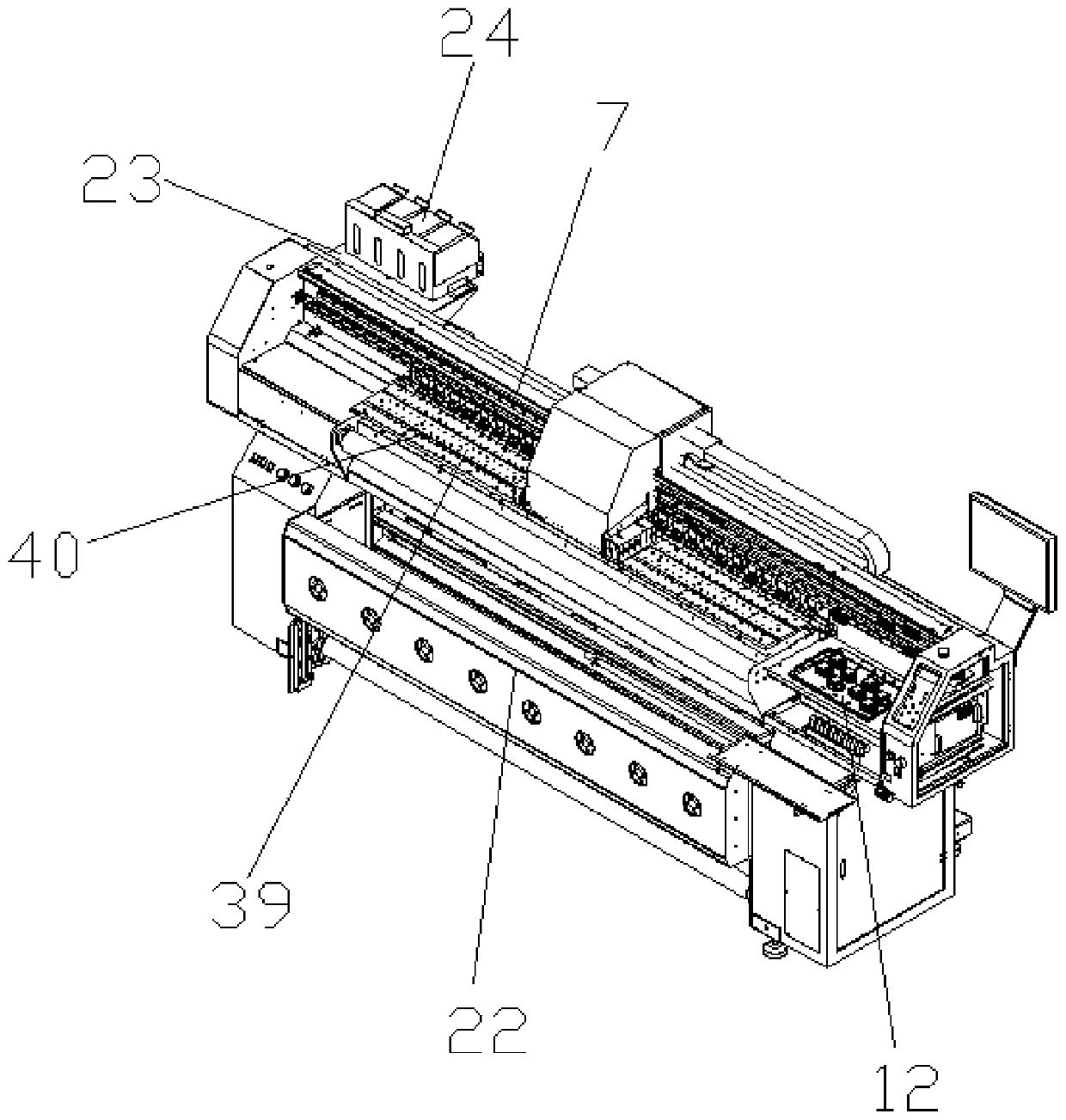

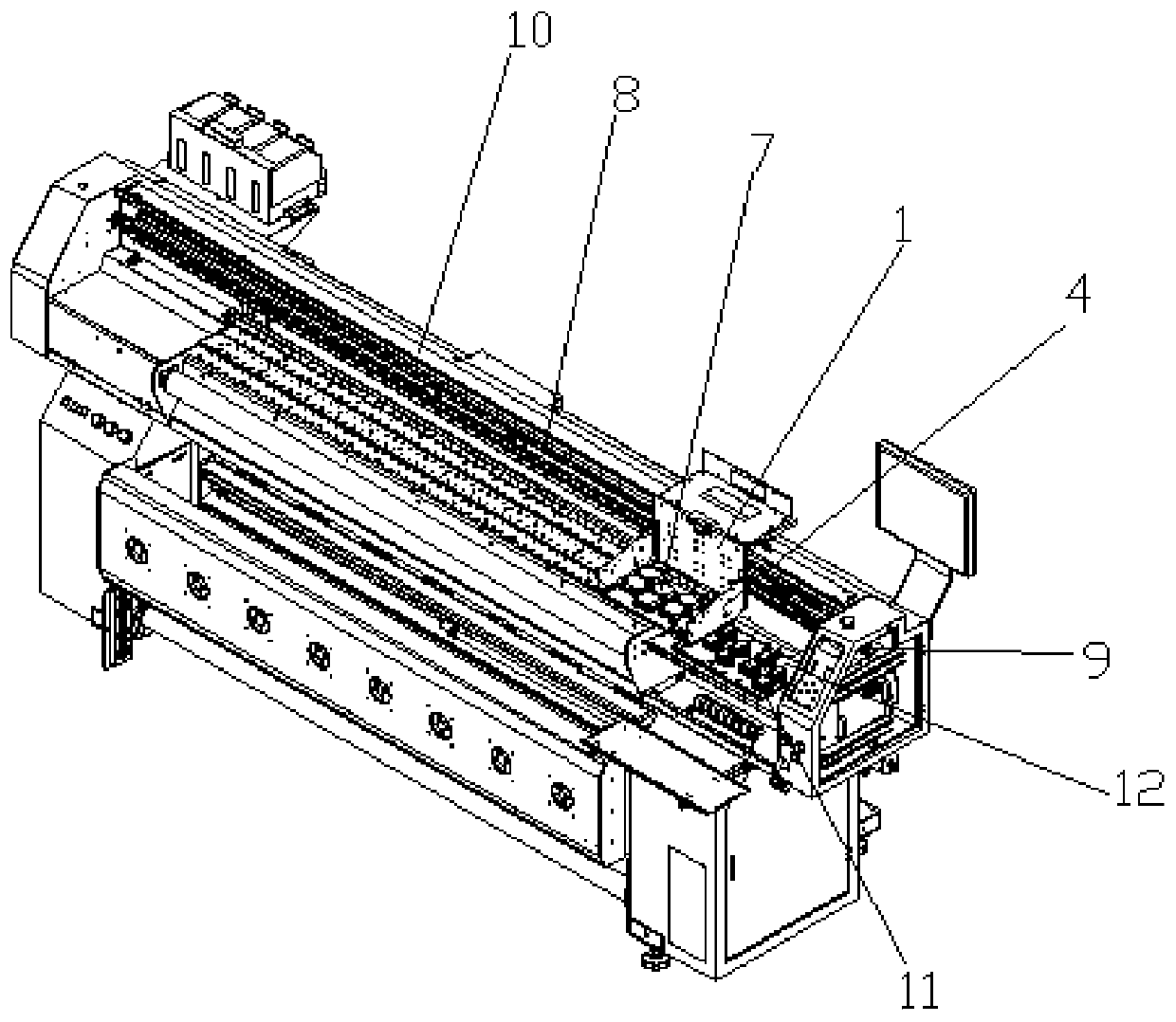

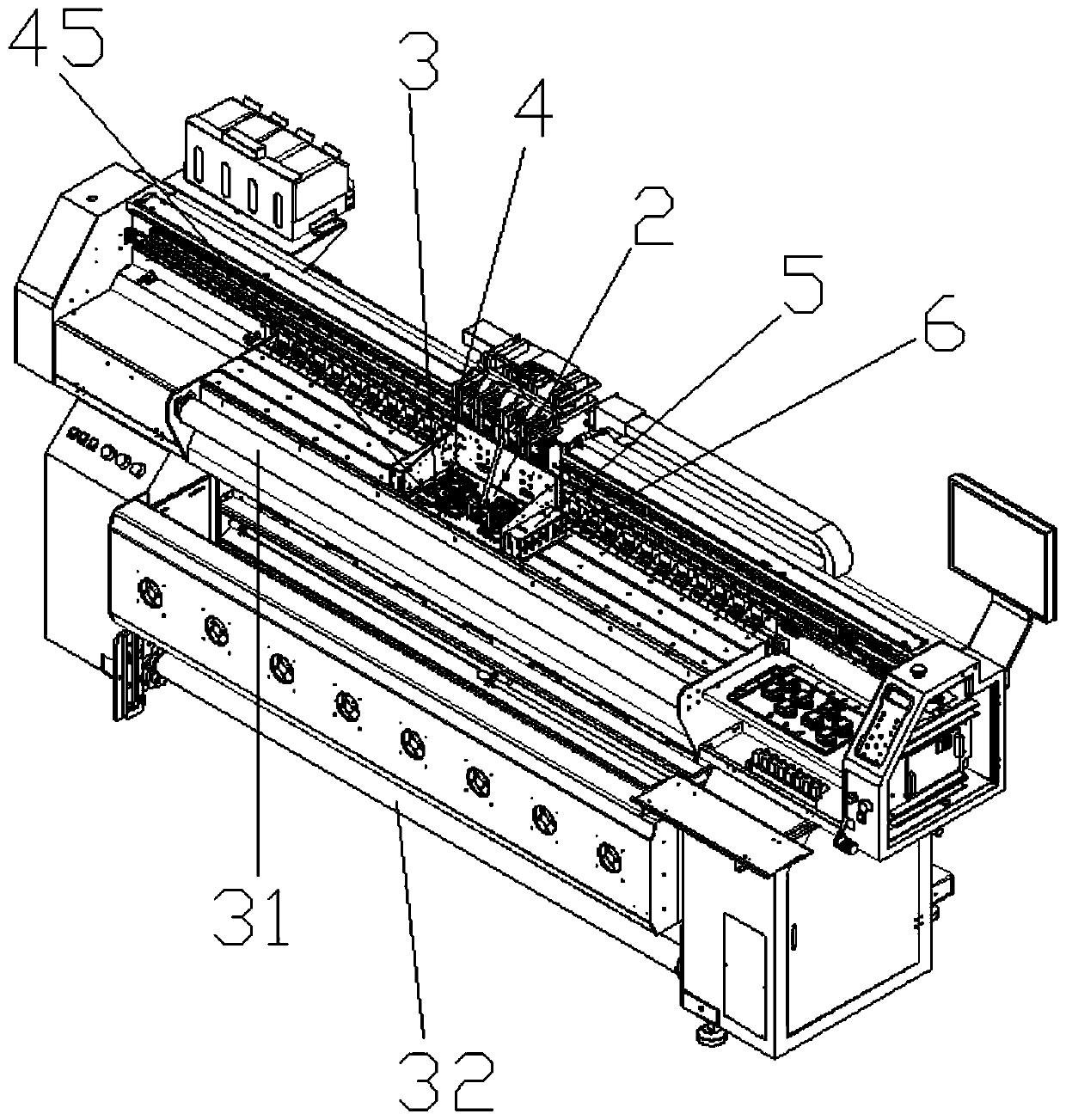

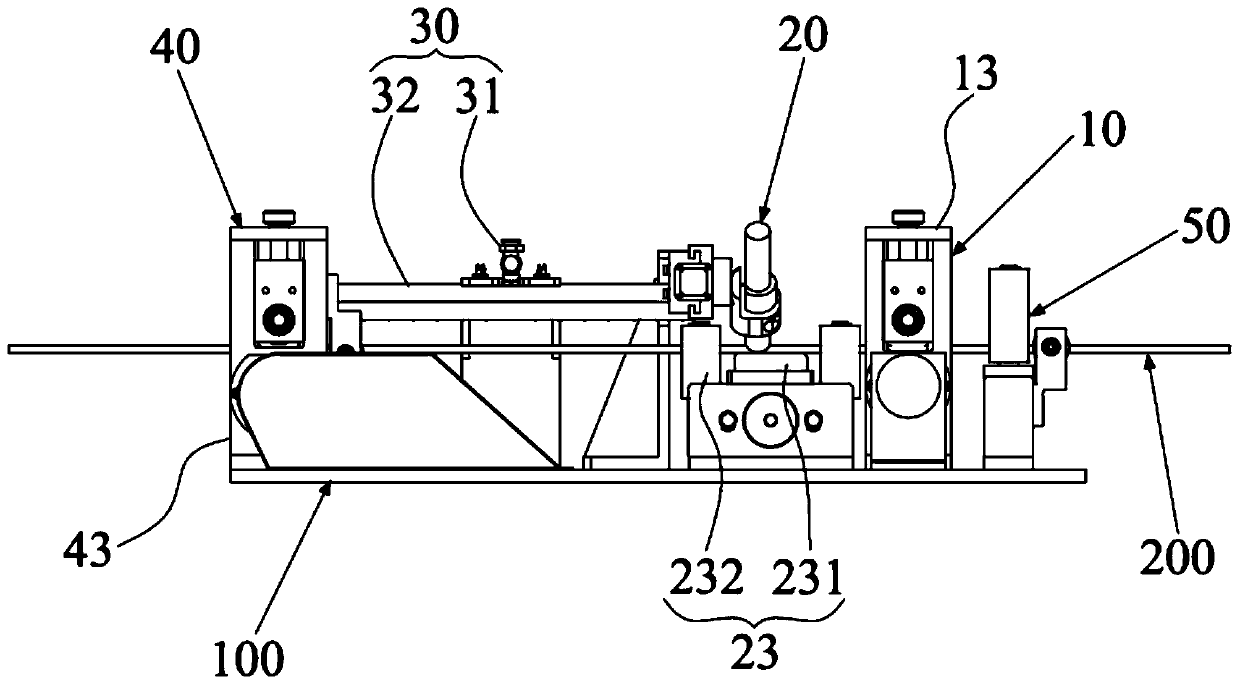

Novel efficient eight-head digital ink-jet printer

PendingCN110103589AIncrease printing areaImprove printing efficiencyTypewritersOther printing apparatusDigital inkInkjet printing

The invention discloses a novel efficient eight-head digital ink-jet printer which comprises a printer main body. A printing device, a spray head cleaning device, an airing device, an emptying device,a feeding device, a printing platform and a display screen. Eight printing spray heads are arranged on the printing device, and every two printing spray heads are arranged in a staggered manner, so that the printing range of the printer is wide and the printing efficiency is high. The novel efficient eight-head digital ink-jet printer can print to and fro repeatedly, and can clean the spray headsautomatically after printing.

Owner:杭州彩悦图邦科技有限公司

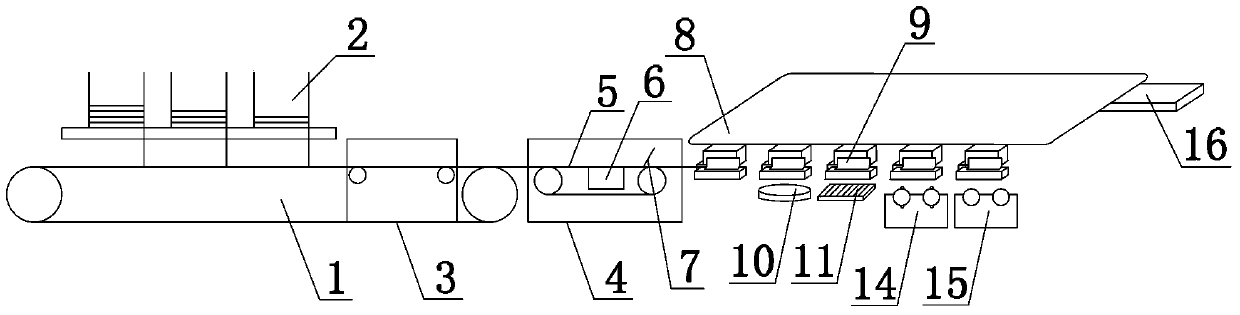

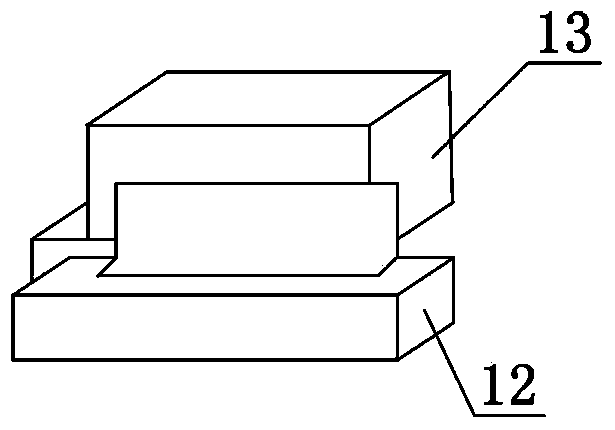

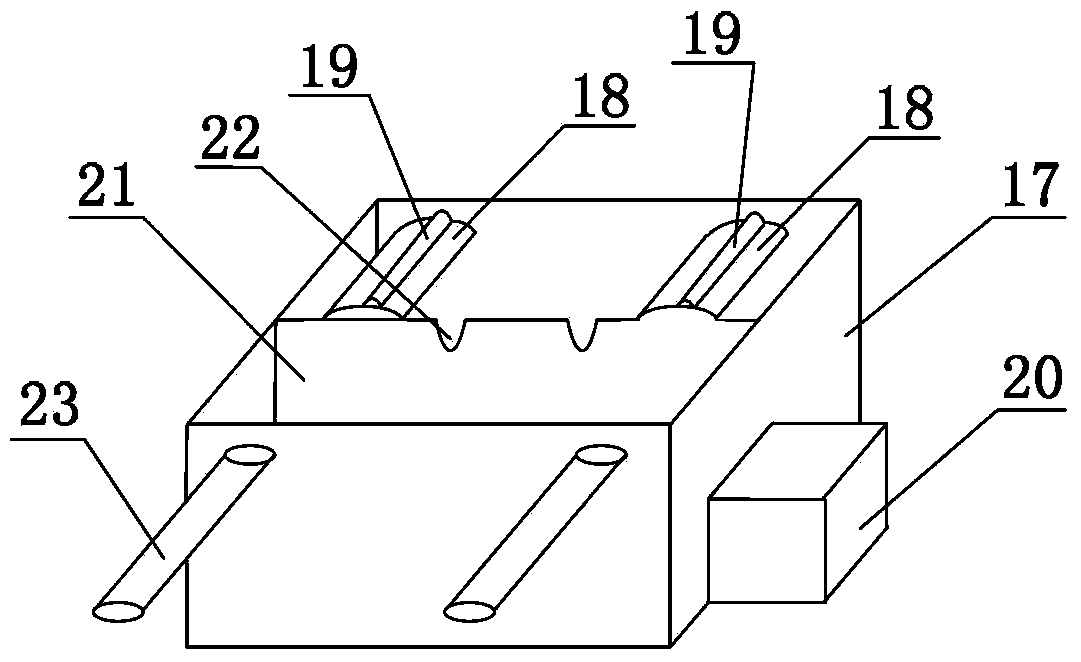

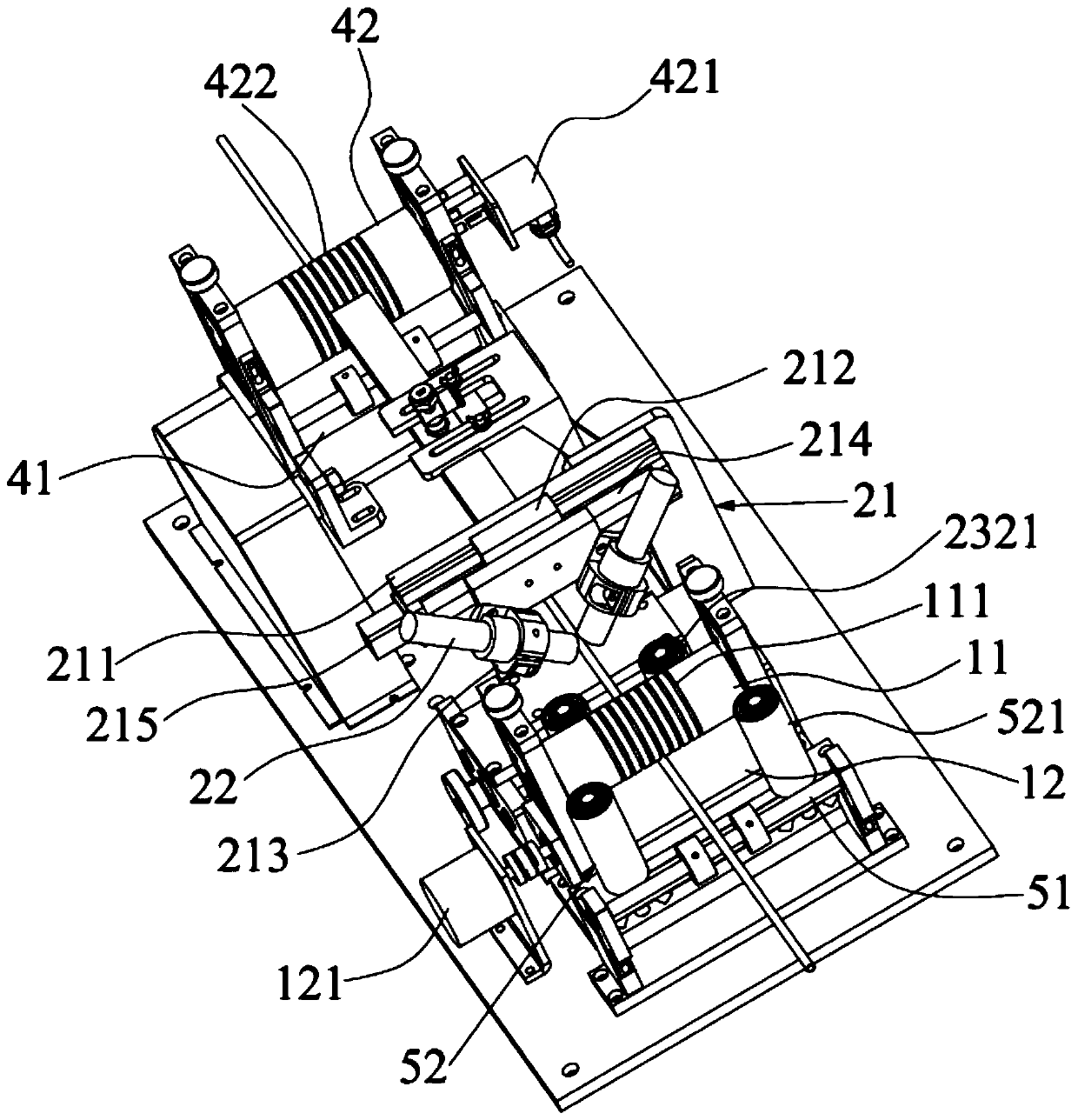

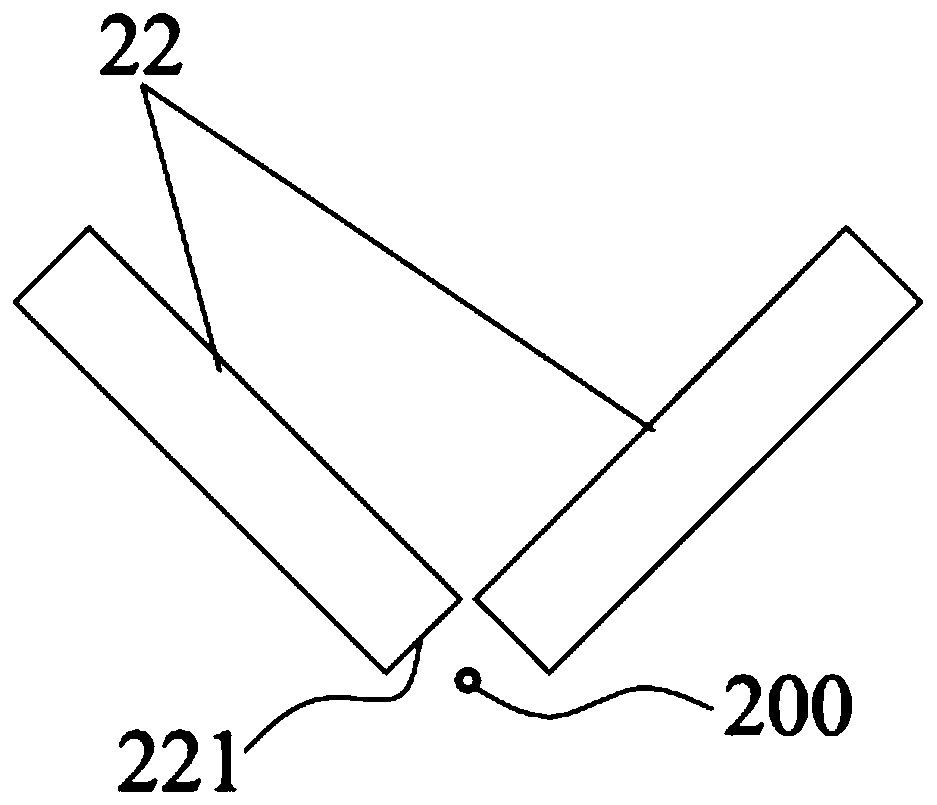

Code inkjet printing device for pipe or wire

PendingCN111572211APrecise positioningImprove environmental performanceTypewritersOther printing apparatusEngineeringInkjet printing

The invention discloses a code inkjet printing device for a pipe or a wire. The code inkjet printing device comprises a meter counting mechanism, a code inkjet printing mechanism, a drying mechanism and a traction mechanism which are sequentially arranged in the conveying direction of the pipe or the wire; the meter counting mechanism and the traction mechanism are used to synchronize the deliveryof the pipe or the wire, the meter counting mechanism comprises a meter pressing wheel and a meter counting wheel matched with the meter pressing wheel, and the traction mechanism comprises a supporting wheel and a synchronous pressing wheel matched with the supporting wheel; and the code inkjet printing mechanism comprises a code inkjet printing frame and at least two code inkjet printing headswhich are arranged on the code inkjet printing frame and connected with a code inkjet printing machine, the at least two code inkjet printing heads are distributed around the periphery of the pipe orthe wire, and the drying mechanism is used to dry the pipe or the wire after code inkjet printing. According to the code inkjet printing device, the code inkjet printing is carried out on the pipe orthe wire through the code inkjet printing heads arranged between the meter counting mechanism and the traction mechanism, so that the jet printing position is accurate, and compared with a type wheel,the environment-friendly performance is higher; and the at least two code inkjet printing heads are arranged around the periphery of the pipe or the wire for code inkjet printing, so that the jet printing area is increased, the code inkjet printing contents can be completely arranged on the surface of the pipe or the wire in a jet printing mode, and the jet printing quality is high.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

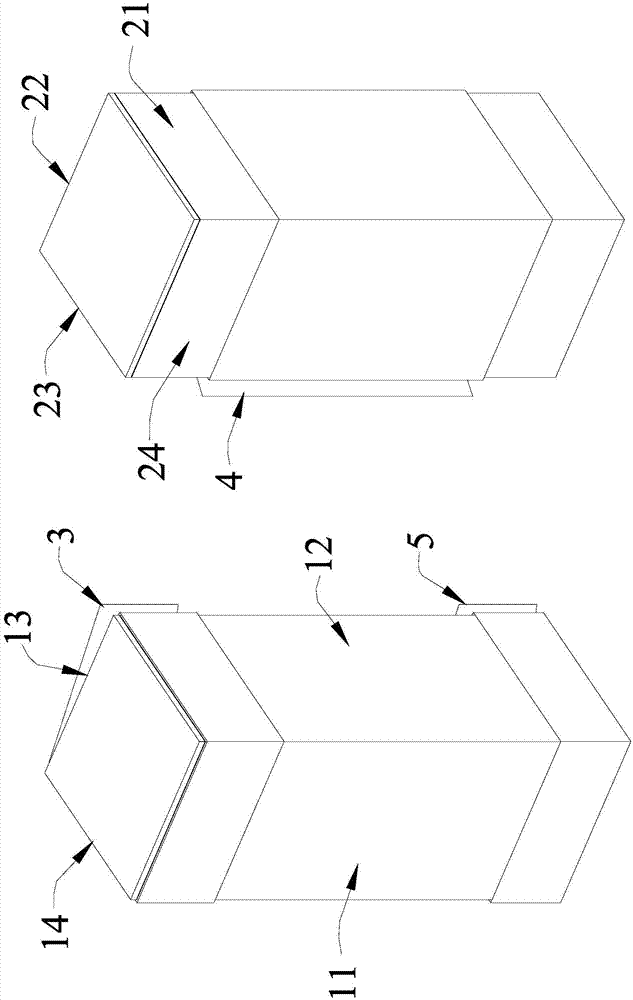

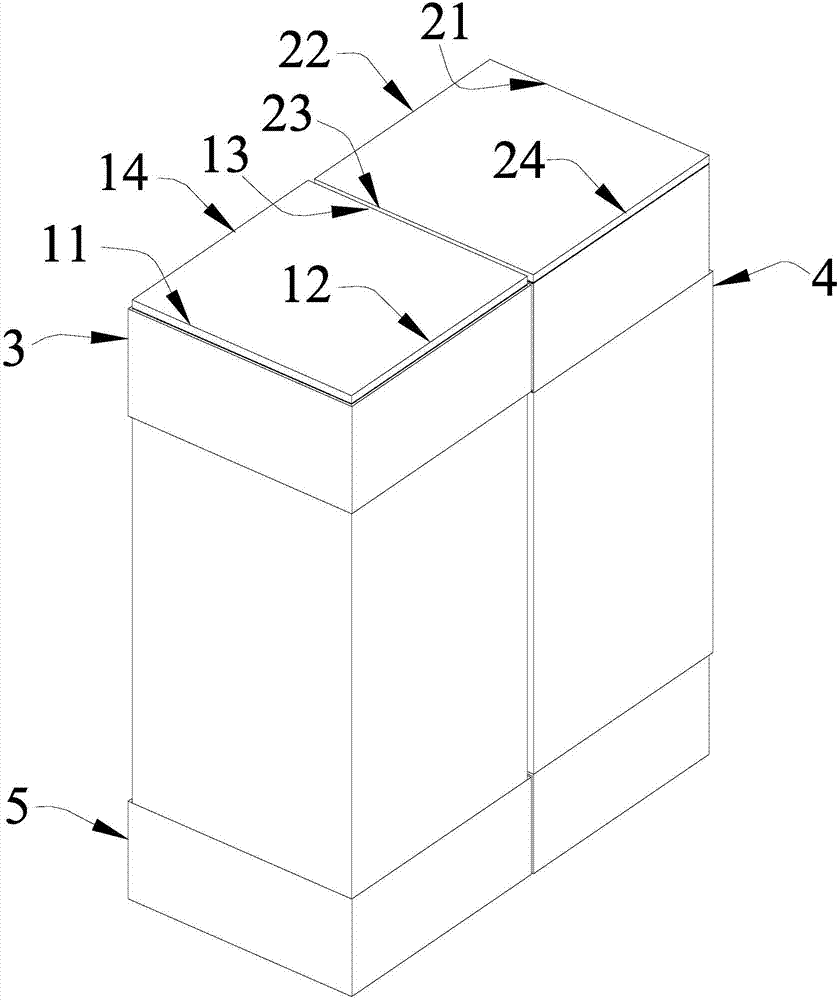

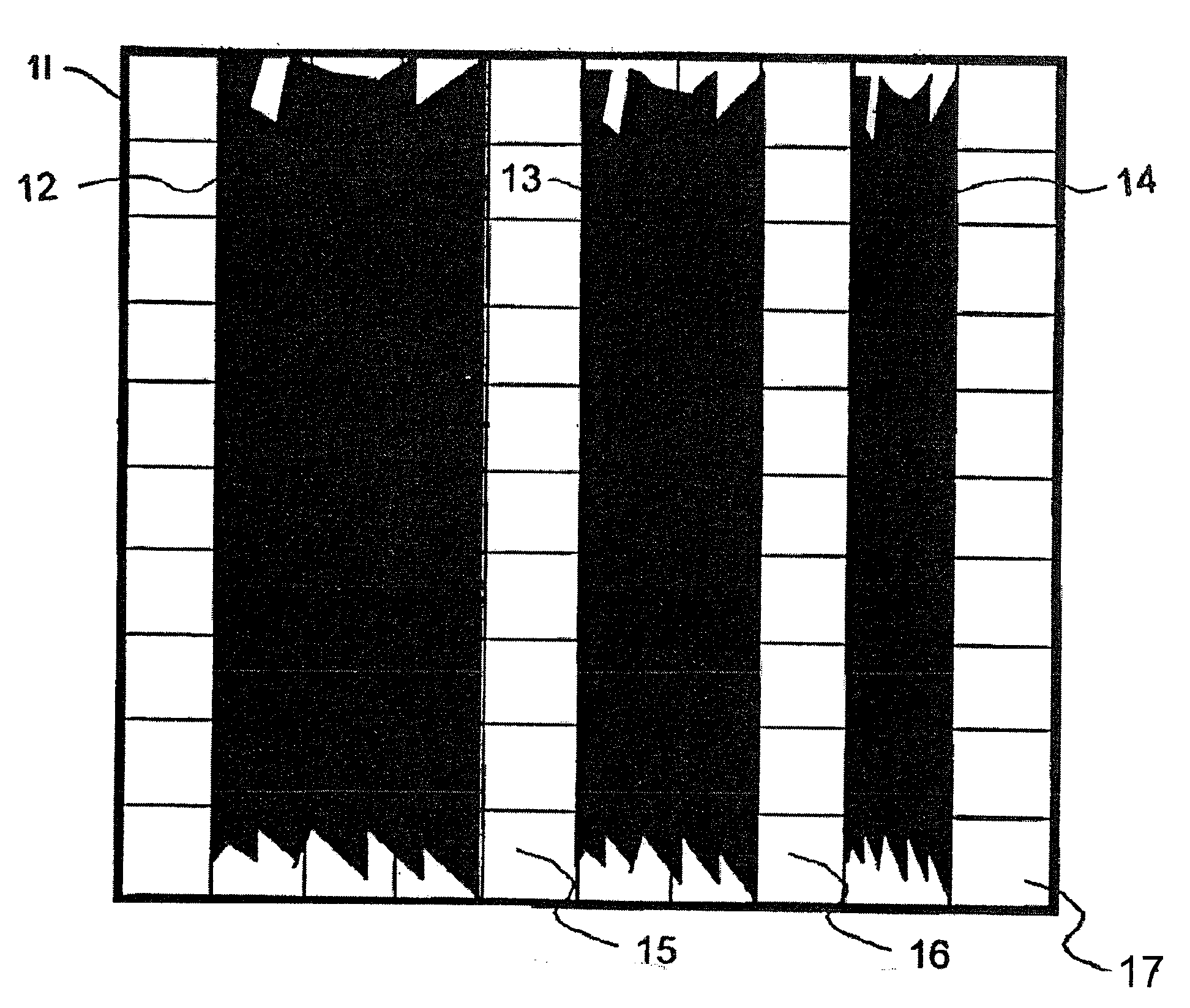

Mutual-switch double-body-type packaging box

Owner:广州市恒远彩印有限公司

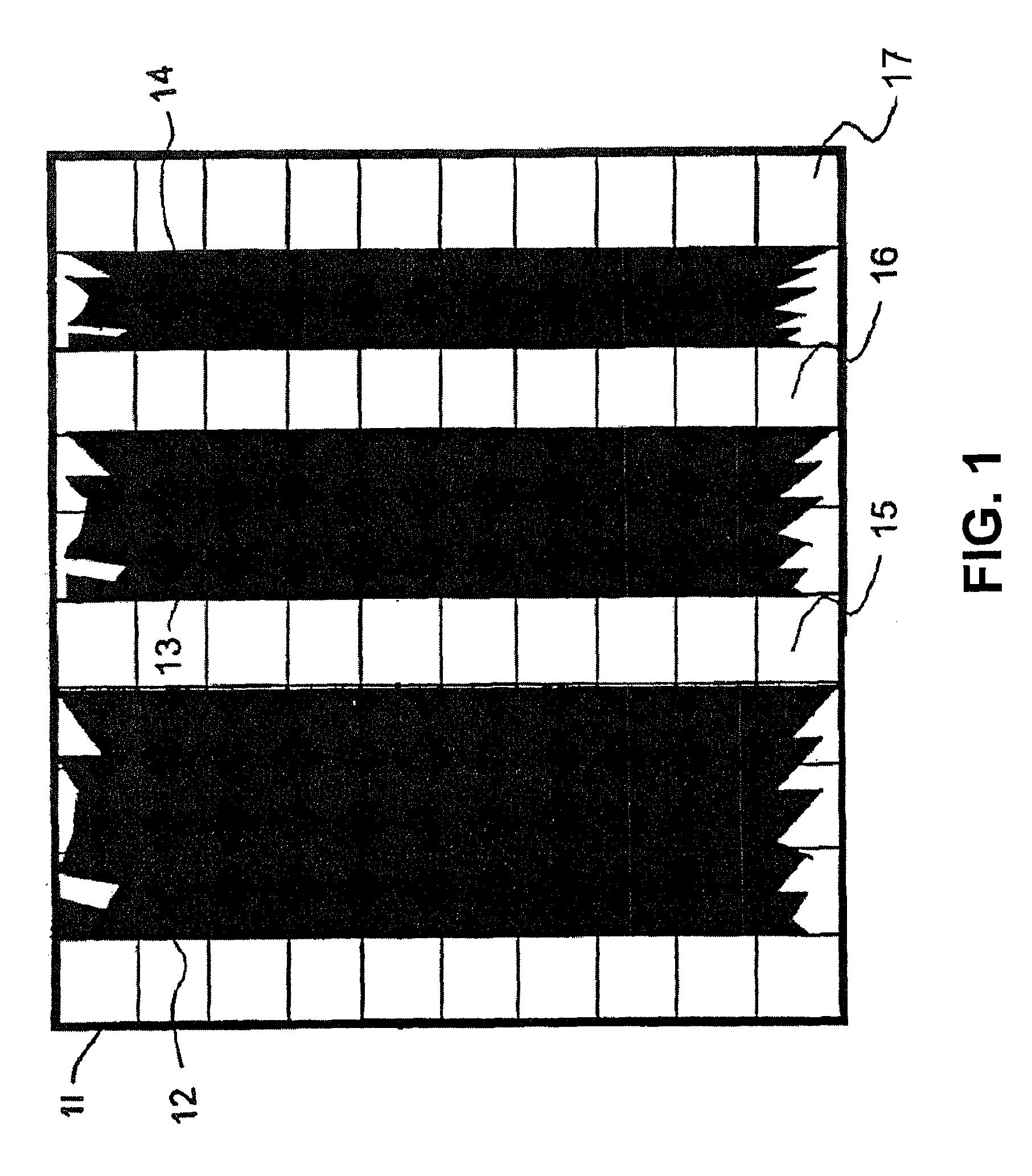

Print enhancement of pixels to improve readability

InactiveUS20100157007A1Improve quality of printed imageIncrease printing areaMeasurement apparatus componentsTypewritersBarcodeComputer science

A method to improve the image of a printed barcode by enhancing coverage of the print pixels within solid printed areas to improve the print uniformity and decrease the graininess of the typical ink jet printing by dissolving a small percentage of the colorant and distributing more uniformly. The parameter improved by the invention is the graininess or uniformity of coverage. The contrast ratio within barcode data elements can be also improved without causing unwanted image bleed into unintended areas. Hence, the printed barcode will contain more clearly defined printed and non printed areas to enable the barcode to be accurately read. The invention prevents also unwanted bleeding in areas where it could lower the quality of the printed material by avoiding application of enhanced coverage facilitators when desired white space is identified within a minimum distance.

Owner:PITNEY BOWES INC

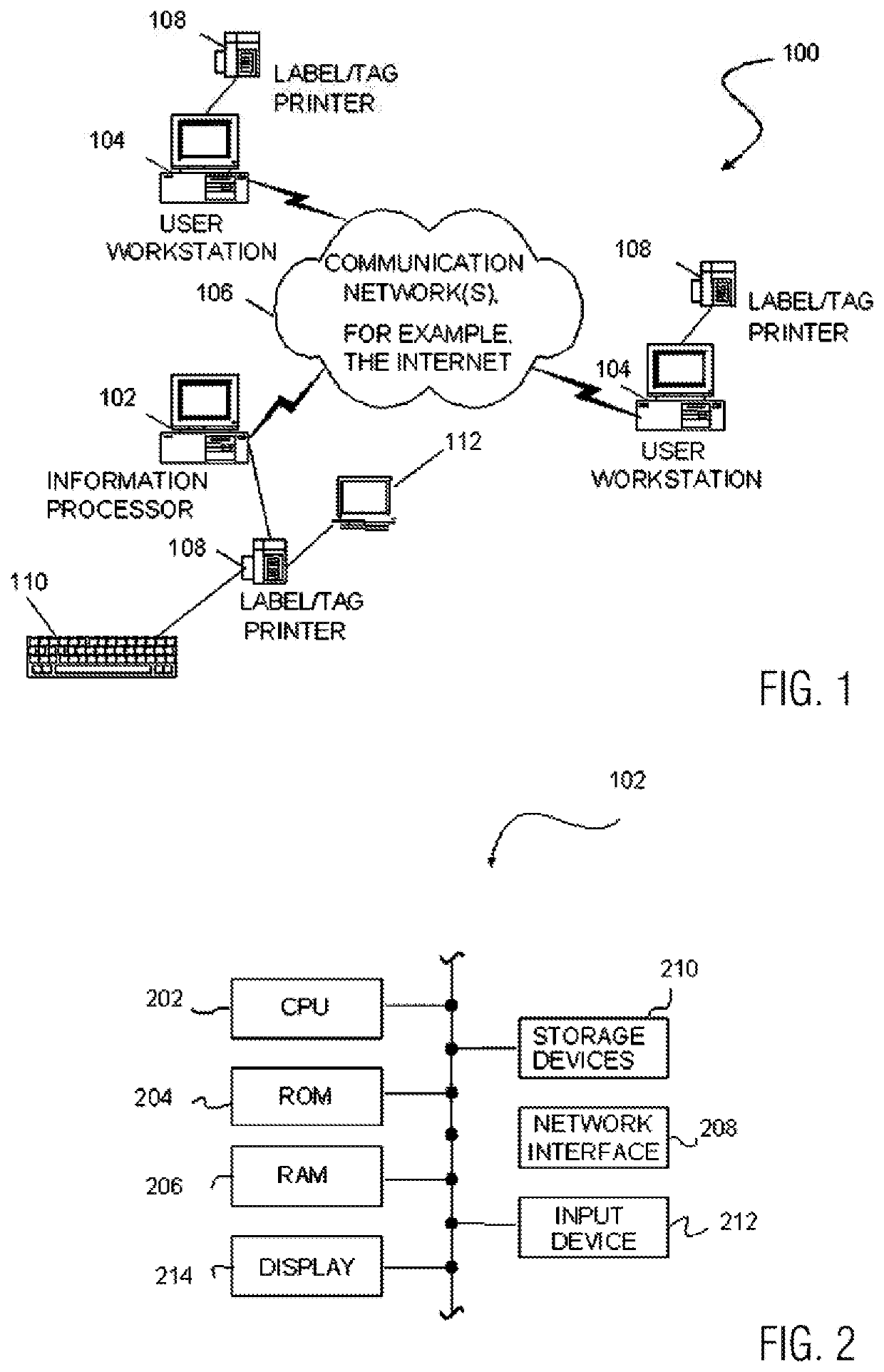

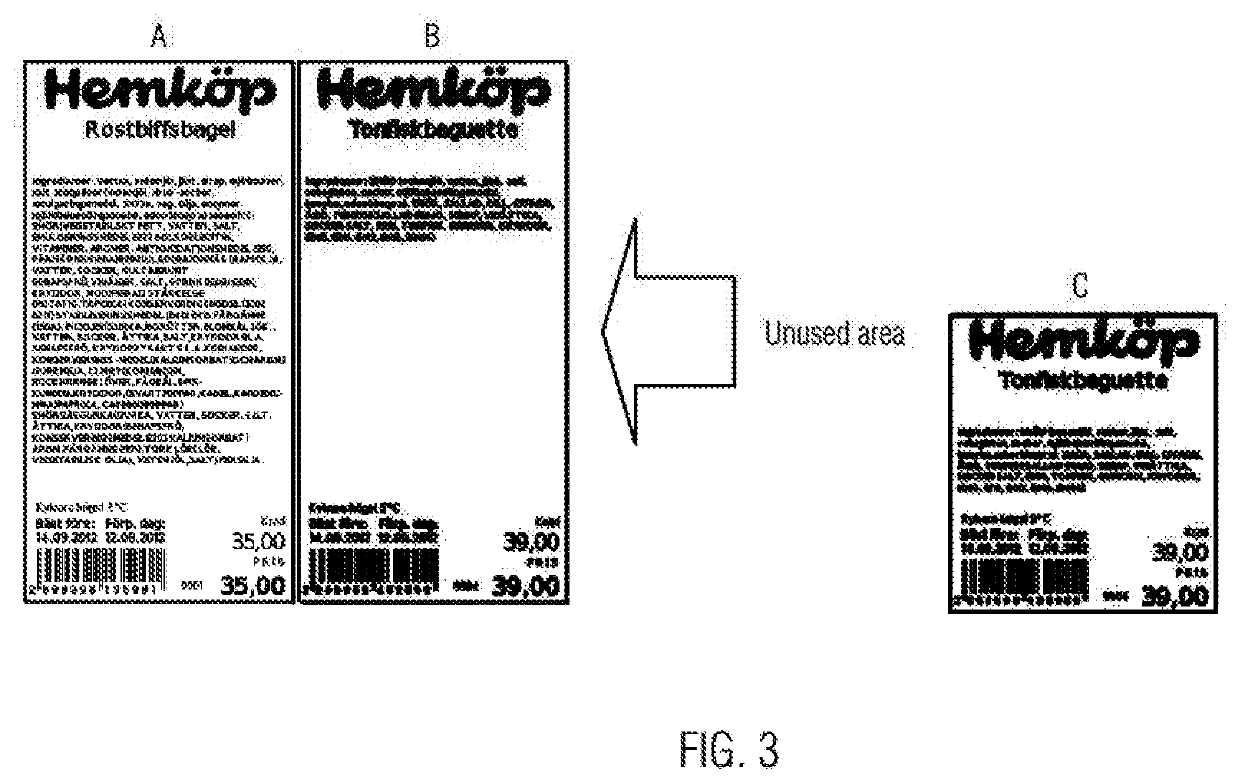

Label cost saving function

ActiveUS20200142648A1Reduce white spaceSmall sizeNatural language data processingPictoral communicationPaper sheetProcess engineering

The present invention provides a computer-implemented method and system for modifying given layout data on the basis of predetermined parameters for reducing unused white areas in accordance with a given printing layout. The invention is particularly applicable in the framework of label and tag printers employing continuous media. On the one hand, the reduction of unused white areas can lead to an overall reduction in the paper size, thus rendering the labels more environmentally friendly. On the other hand, the layout can also be improved, leading to a better usage of the available space for printing data thereon.

Owner:SATO HLDG CORP

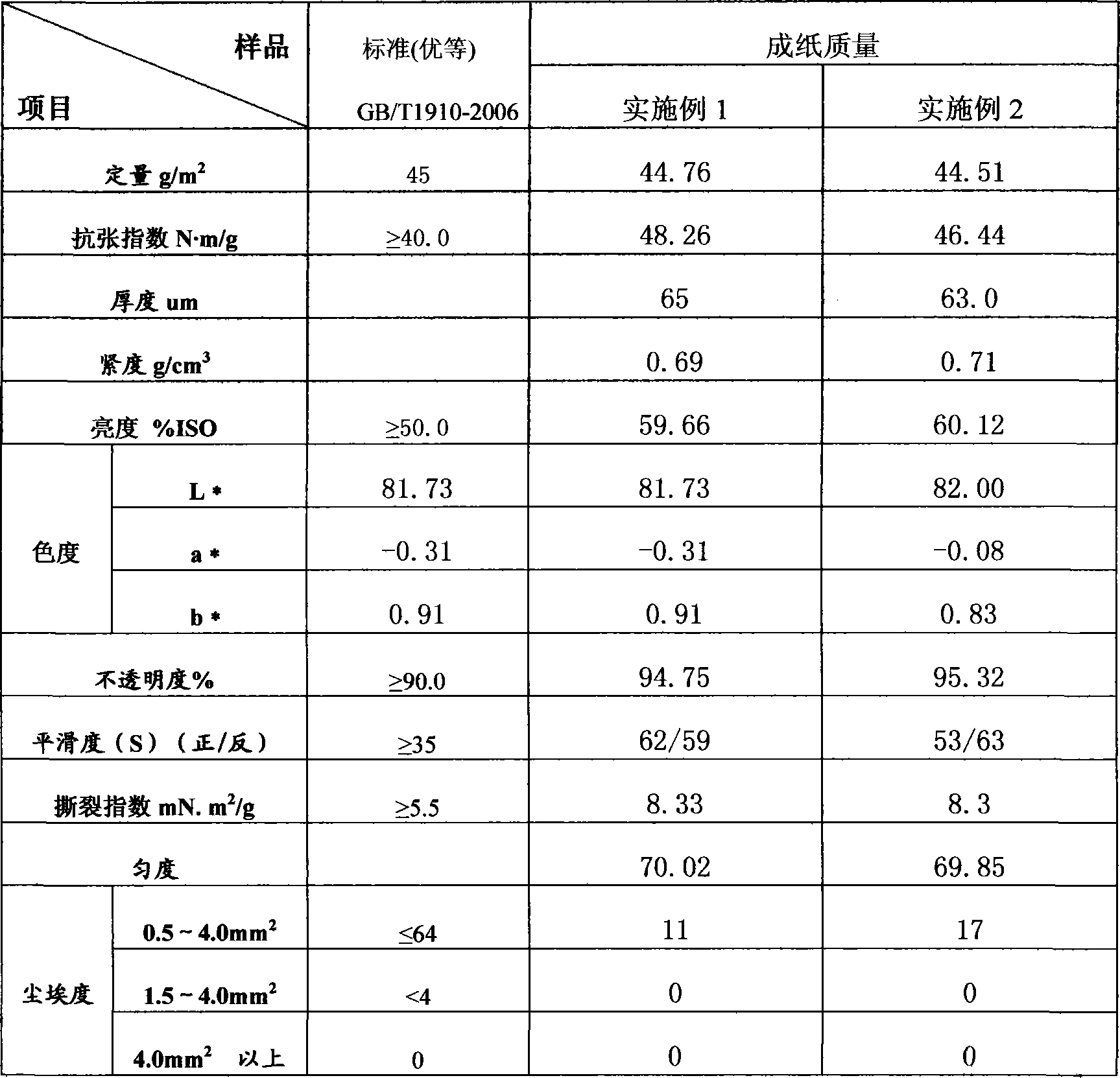

Method for producing low basis weight newsprint by 100 percent deinking waste pulp added with retention and drainage agent

InactiveCN101225615BEmission reductionReduce pollutionNon-fibrous pulp additionPaper recyclingFiberPolyacrylamide

Owner:GUANGDONG IND TECHN COLLEGE +1

A desktop 3D printing device

The invention relates to a desktop 3D-printing forming device comprising a base plate, a machine frame and connection blocks. The machine frame is a bottomless rectangular frame and is fixed on the base plate; vertex angles of the machine frame are provided with the connection blocks, adjacent connection blocks are connected with Y-direction guide rails, and transmission systems are arranged above the connection blocks and between adjacent connection blocks; the end of one transmission system at one side is connected to one end of a step motor output shaft, and the other end of the step motor output shaft is connected to the end of the other transmission system at the other side; the Y-direction guide rails which are on two opposite sides are provided with slide blocks, and the top end of the Y-direction guide rails which are on two opposite sides are connected with the transmission systems; X-direction guide rails are arranged between the slide blocks which are two opposite sides, and printing systems are arranged between the X-direction guide rails; the printing systems are connected with wire feeders; the base plate is vertically provided with a linear motor, and output shaft is a Z-direction guide rail; the Z-direction guide rail is connected with one end of an installing beam; and a heating work plate is arranged on the top of another end of the installing beam, and is under the printing systems. Moulding precision is high, processing speed is fast, technology is simple, cost is low, and the desktop 3D-printing forming device can be widely applied in household and the field of teaching.

Owner:NINGBO HECHUANG RAPID TECH

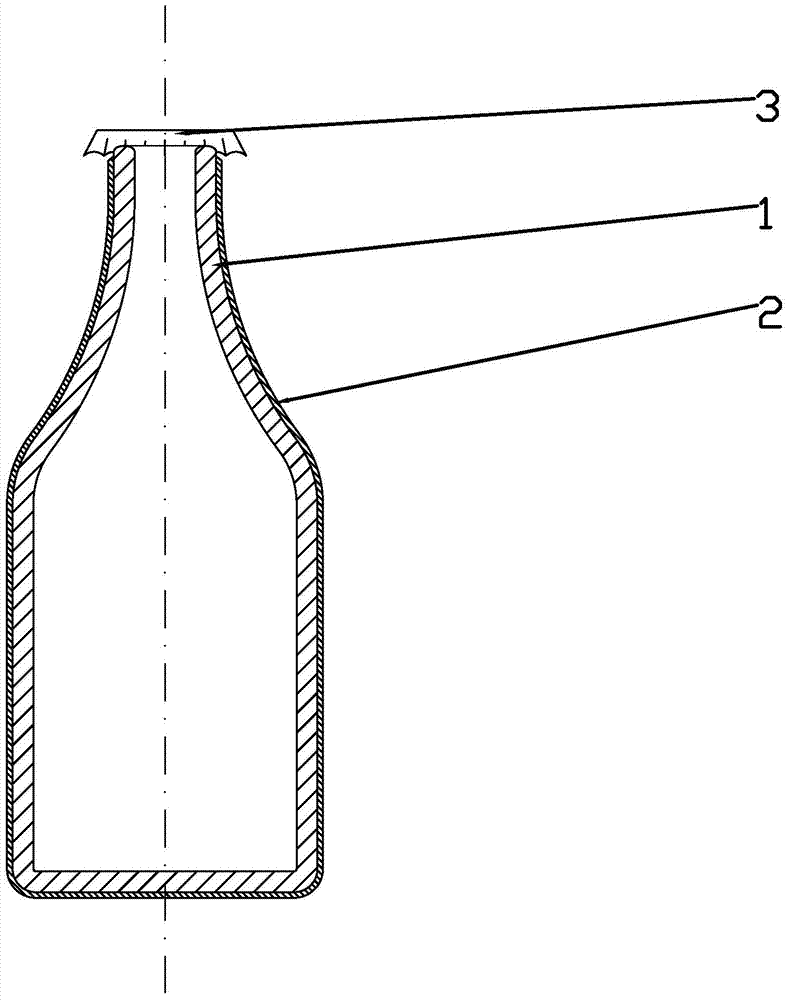

Wrap-type anti-explosion beer bottle label

InactiveCN104512602AIncrease printing areaPrevent collapseStampsCoverings/external coatingsEngineeringPlastic film

The invention relates to a wrap-type anti-explosion beer bottle label. The wrap-type anti-explosion beer bottle label mainly solves a problem that a beer bottle is busted to damage people. The wrap-type anti-explosion beer bottle label comprises the beer bottle and a bottle label; and the bottle label covers the outer surface of the beer bottle except for a bottle opening, is made of a heat-shrinkable plastic film, is a seamless cup-shaped soft capsule of which the boundary dimension is larger than the diameter of the beer bottle, and is attached to the surface of the beer bottle by a heat shrinkage process under the action of precompression. The bottle label is sleeved on the outer surface of the beer bottle by using the heat shrinkage process, so that a printed area of package information is increased, a shock absorption function is achieved when the beer bottle is under the action of external force, and debris of the beer bottle can be prevented from damage to people when the beer bottle is busted.

Owner:王震亚

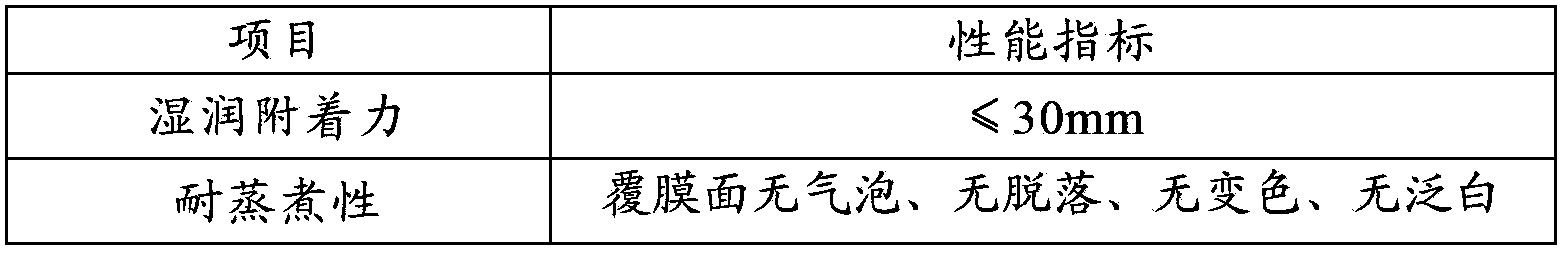

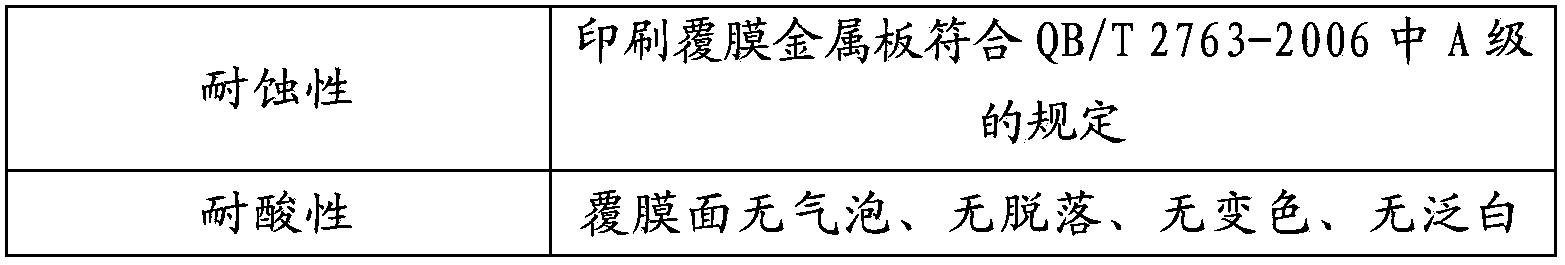

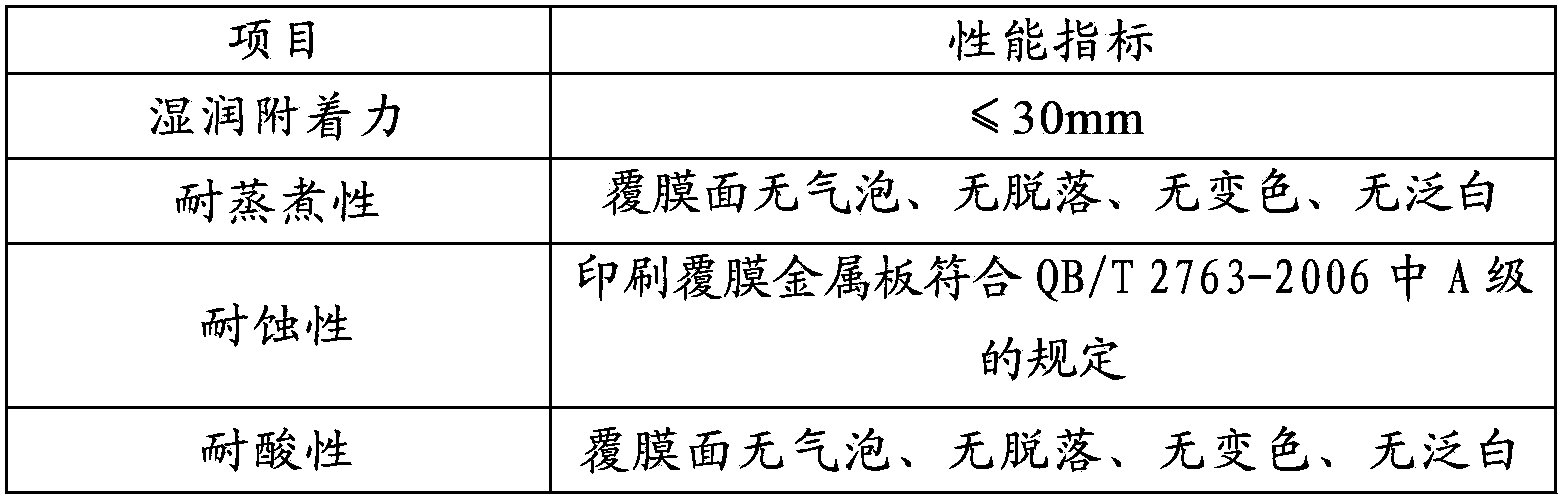

A printed film-coated metal plate and its production method

ActiveCN102825863BImprove safety qualitySimple processLaminationLamination apparatusPolyesterComposite film

Owner:ORG TECH CO LTD

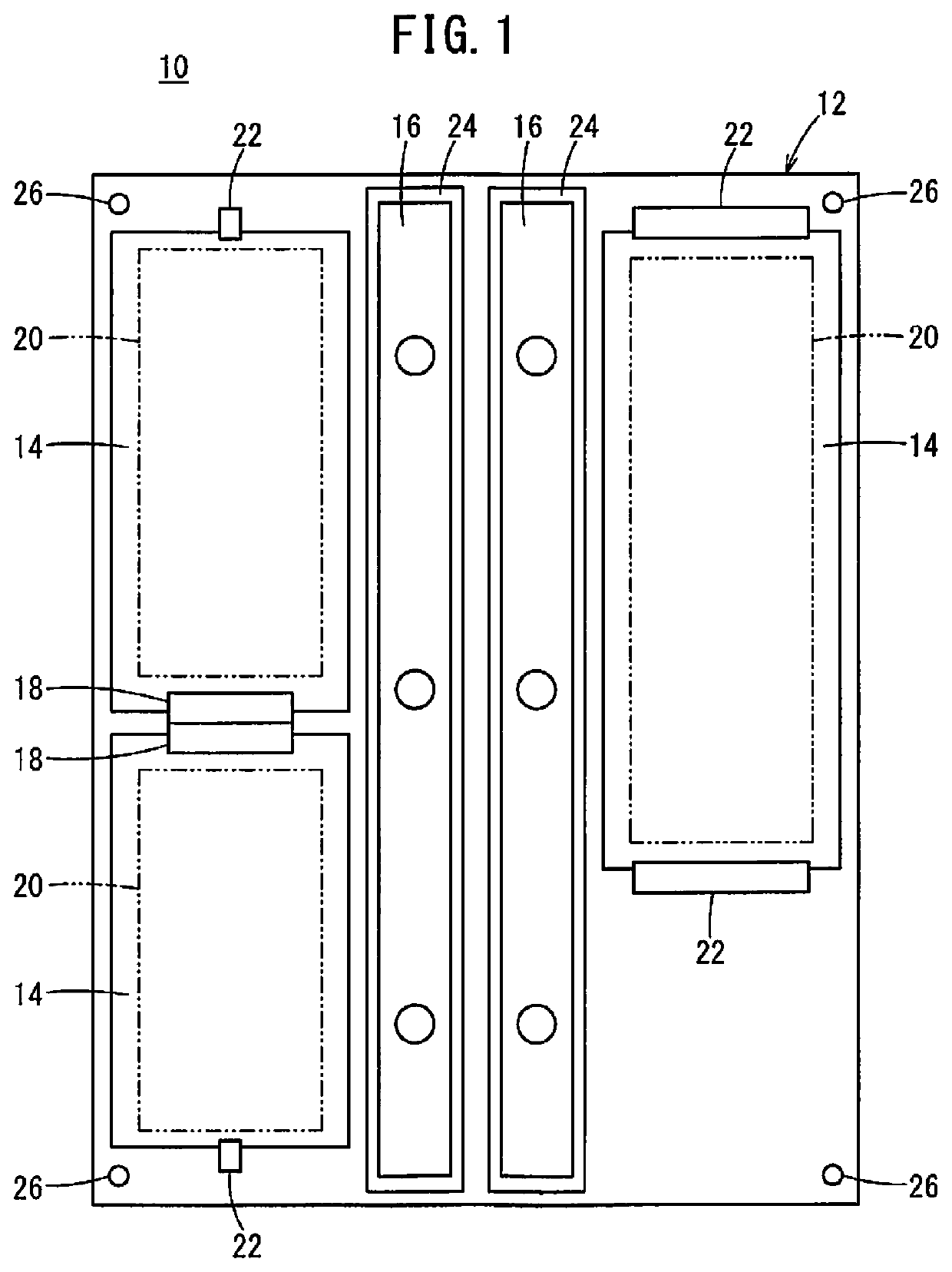

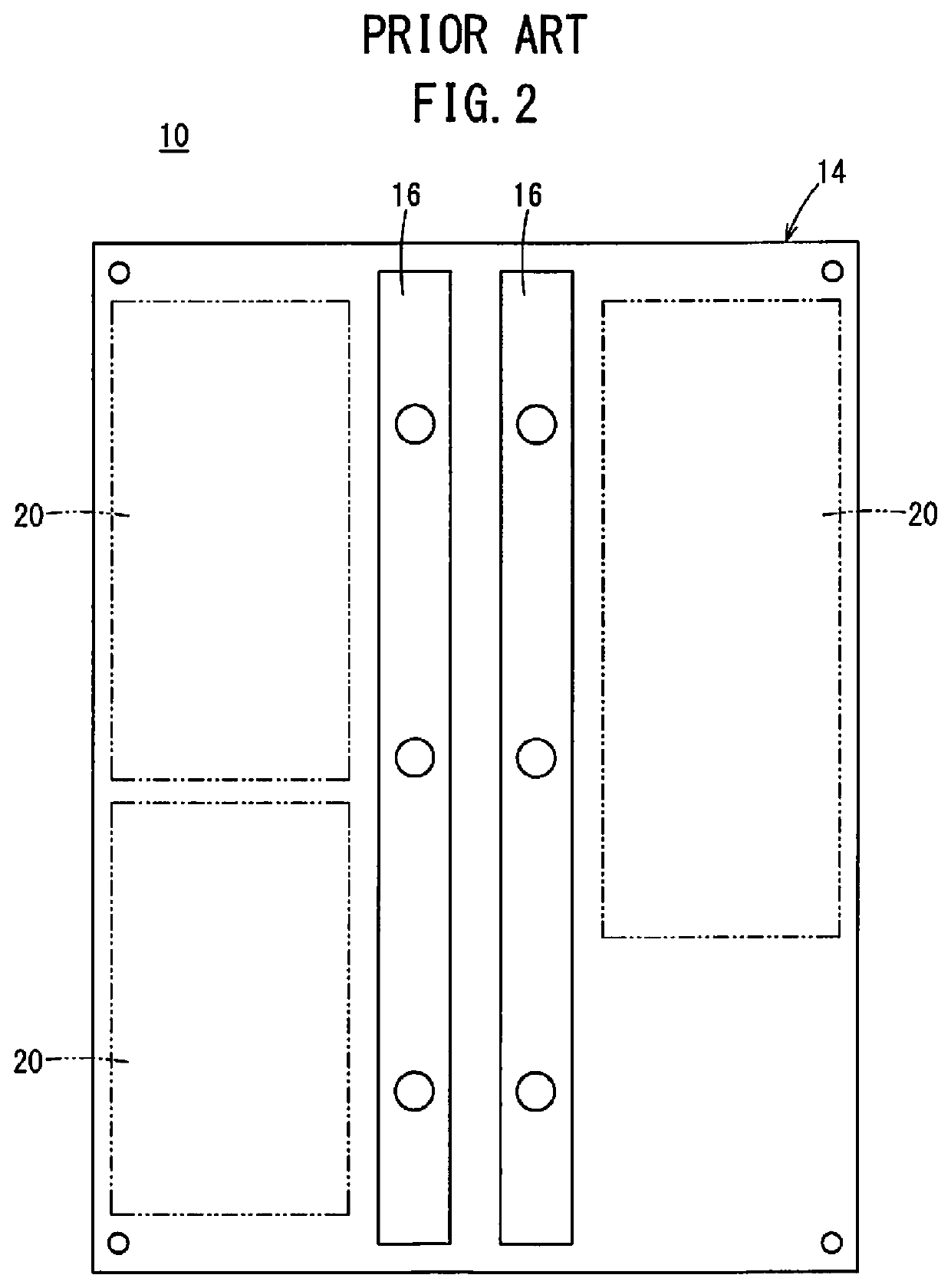

Electric device and motor driving device

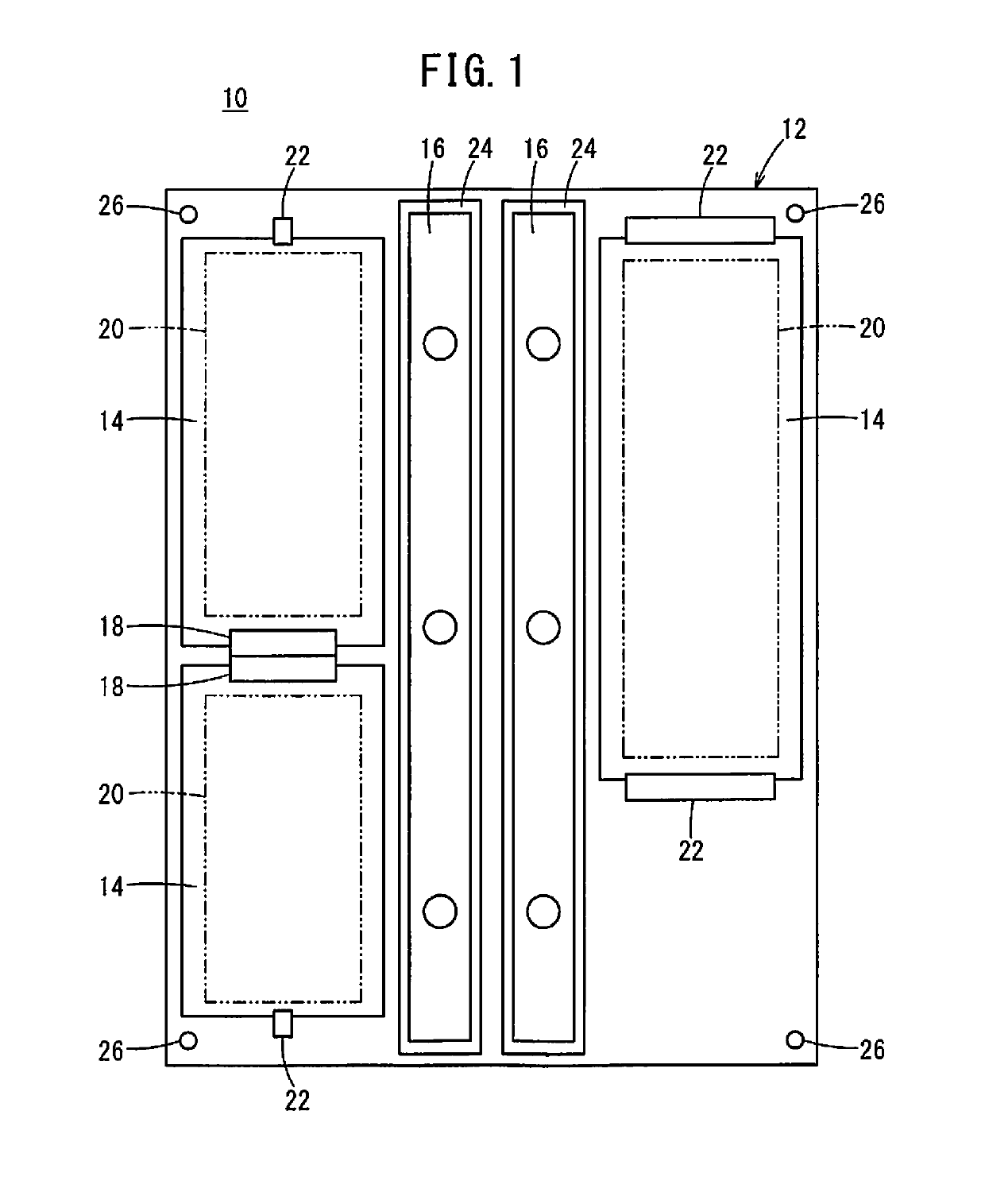

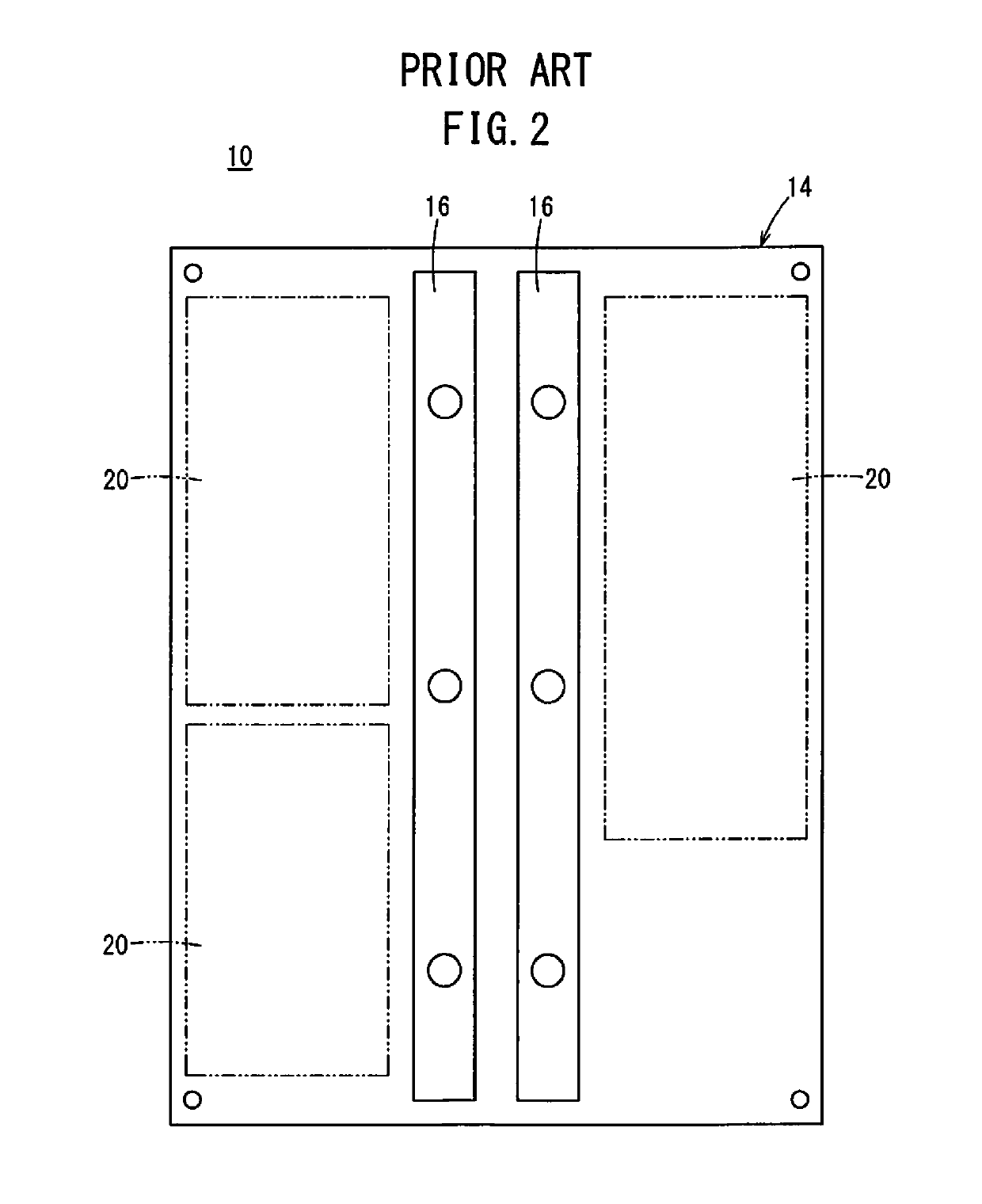

ActiveUS10827638B2Manufacturing cost is increasedIncrease printing areaPrinted circuit assemblingPrinted circuit aspectsMotor driveElectric machine

Owner:FANUC LTD

Electric device and motor driving device

ActiveUS20190230809A1Manufacturing cost be increaseManufacturing cost is increasedPrinted circuit assemblingPrinted circuit aspectsEngineeringElectric motor

Owner:FANUC LTD

Display

ActiveUS11164923B2Increase success rateIncrease printing areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A Portable Manual Curved Screen Printing Machine

ActiveCN106671582BIncrease travel distanceIncrease printing areaScreen printersPrinting pressFriction force

The invention relates to a portable manual curved-surface screen printing machine, and belongs to the technical field of printing. The portable manual curved-surface screen printing machine mainly comprises a machine frame, a top frame, a rectangular frame, a screen printing plate and a scraping plate, wherein the top frame is located at the top of the machine frame and is in a U shape, and the two end points of a U-shaped opening are connected to a rotary shaft at the top end of the machine frame so that the U-shaped top frame can rotate around the rotary shaft; sliding guide rails are symmetrically mounted on the two sides of the U-shaped top frame, the rectangular frame is mounted in the sliding guide rails, and the rectangular frame can slide in the U-shaped top frame freely; the screen printing plate is fixed in the rectangular frame through fasteners; the two sides of a cross beam on the lower portion of the machine frame are each symmetrically provided with two bearings used for storing an article to be printed, and the article to be printed can rotate freely under the effect of friction force of the screen printing plate; and a positioning pointer is mounted on one supporting rod of the machine frame and points to the feature point of the article to be printed, and thus the initial printing position of the article to be printed is marked. The portable manual curved-surface screen printing machine is simple in structure, operation is flexible and convenient, the printing quality is good, the article to be printed can be printed and repaired on the using field, and batched printing can also be performed.

Owner:张昕宸

Method for preparing printing electron by adopting catalytic type nano particles

InactiveCN101873768BIncrease printing areaReduce processing costsConductive pattern formationChemical platingNanoparticle

The invention discloses a method for preparing printing electron by adopting catalytic type nano particles. The method adopts the following steps of: printing resin on a substrate, printing the catalytic type nano particles onto the resin after the resin is solidified or half solidified to form a circuit with electric conductivity and catalytic property, then carrying out chemical plating treatment on the circuit and plating a metal layer with high electric conductivity so as to obtain an electronic circuit. The printing electron prepared by the method lowers the processing cost greatly, the obtained electronic circuit has the advantages of high electric conductivity, high stability and the like, and the application of electron for printing and manufacturing in a plurality of fields of a battery, a display, a sensor, an RFID tag, an interactive package, a solar panel, a loudspeaker and the like can be pushed.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com