Ink droplet falling-point control method in ink jet printing

An inkjet printing and control method technology, applied in printing and other directions, can solve the problems such as the inability to continue to improve the printing resolution, the lack of speed accuracy of the LMS algorithm, and the limitation of the speed of the carriage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below with reference to the accompanying drawings.

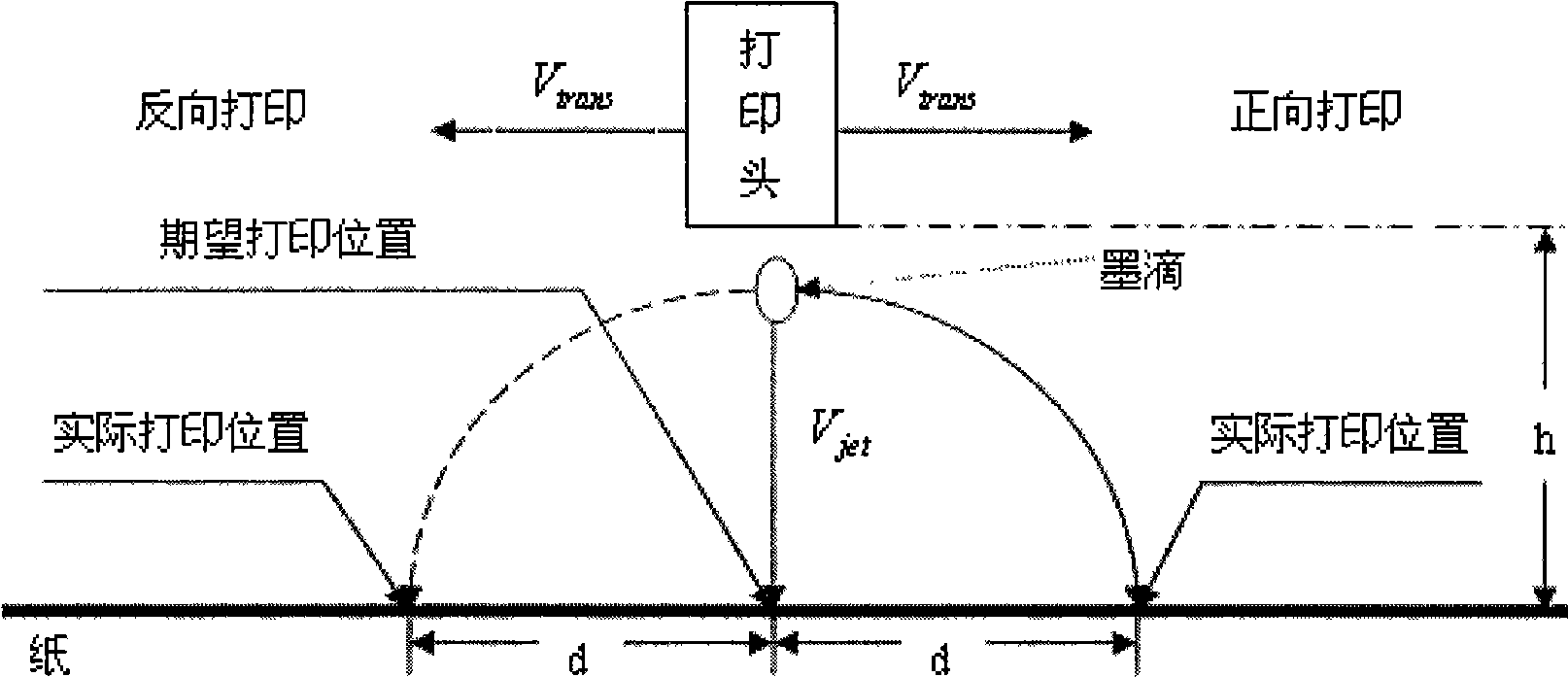

[0066] like figure 2 As shown, for an inkjet printer, after the ink drop is ejected from the moving nozzle, its trajectory is affected by the reciprocating motion of the character carriage. The reciprocating motion of the carriage will cause a 2d deviation in the drop point of the ink drop compared to the expected position.

[0067] image 3 It is the running curve of the character car. The curve consists of acceleration zone, uniform zone and deceleration zone. There are some undesirable jitter phenomena in the acceleration zone, uniform zone and deceleration zone, which means that only fixed compensation d is not good To solve this problem, it is powerless to print in the acceleration and deceleration areas.

[0068] Will image 3 The running curve of the Chinese character car is divided into many small sections. In the same sampling segment on the runni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com