Portable manual curved-surface screen printing machine

A screen printing machine, portable technology, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problem of difficulty in calibrating the printing starting position of the to-be-printed object, and inability to achieve large-area printing on a small machine. Simple structure, low manufacturing cost, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

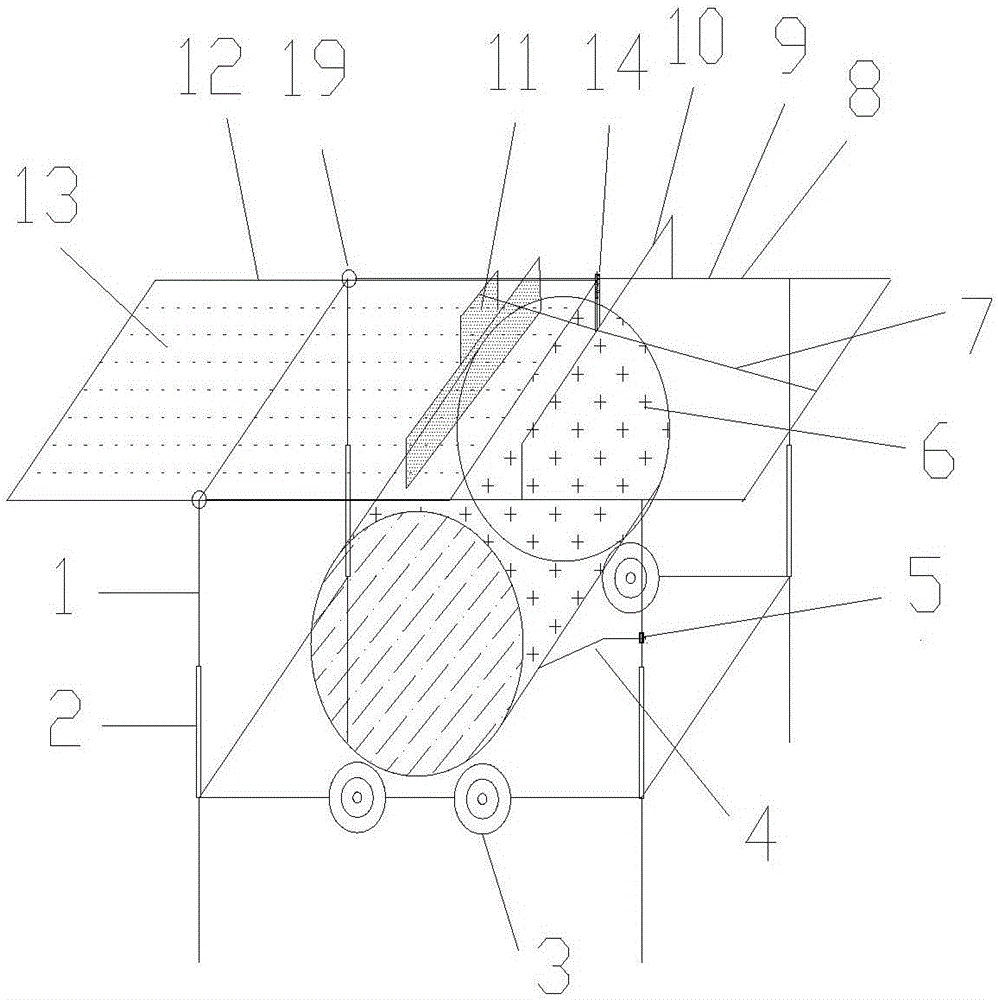

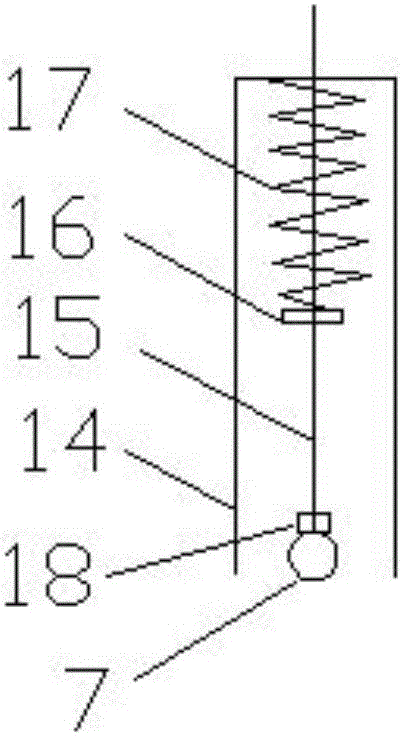

[0023] Portable manual curved surface screen printing machine mainly includes a frame, a top frame, a rectangular frame, a screen and a scraper. The top frame is located on the top of the frame and is U-shaped. The two ends of the U-shaped mouth are connected to the frame. The rotating shaft at the top makes the U-shaped top frame rotate around the rotating shaft, which is convenient for the pick-and-place of the material to be printed; the two sides of the U-shaped top frame are symmetrically installed with sliding guide rails, and a rectangular frame is installed in the sliding guide rail. Free sliding in the U-shaped top frame; the screen plate is fixed in the rectangular frame with fasteners; two rolling bearings are symmetrically installed on both sides of the lower beam of the frame to place the material to be printed, so that the material to be printed rubs against the screen plate It can rotate freely under the action of force; a positioning pin is installed on a suppor...

Embodiment 2

[0028] Portable manual curved surface screen printing machine mainly includes a frame, a top frame, a rectangular frame, a screen and a scraper. The top frame is located on the top of the frame and is U-shaped. The two ends of the U-shaped mouth are connected to the frame. The rotating shaft at the top makes the U-shaped top frame rotate around the rotating shaft, which is convenient for the pick-and-place of the material to be printed; the two sides of the U-shaped top frame are symmetrically installed with sliding guide rails, and a rectangular frame is installed in the sliding guide rail. Free sliding in the U-shaped top frame; the screen plate is fixed in the rectangular frame with fasteners; two rolling bearings are symmetrically installed on both sides of the lower beam of the frame to place the material to be printed, so that the material to be printed rubs against the screen plate It can rotate freely under the action of force; a positioning pin is installed on a suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com