Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve heat sealing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

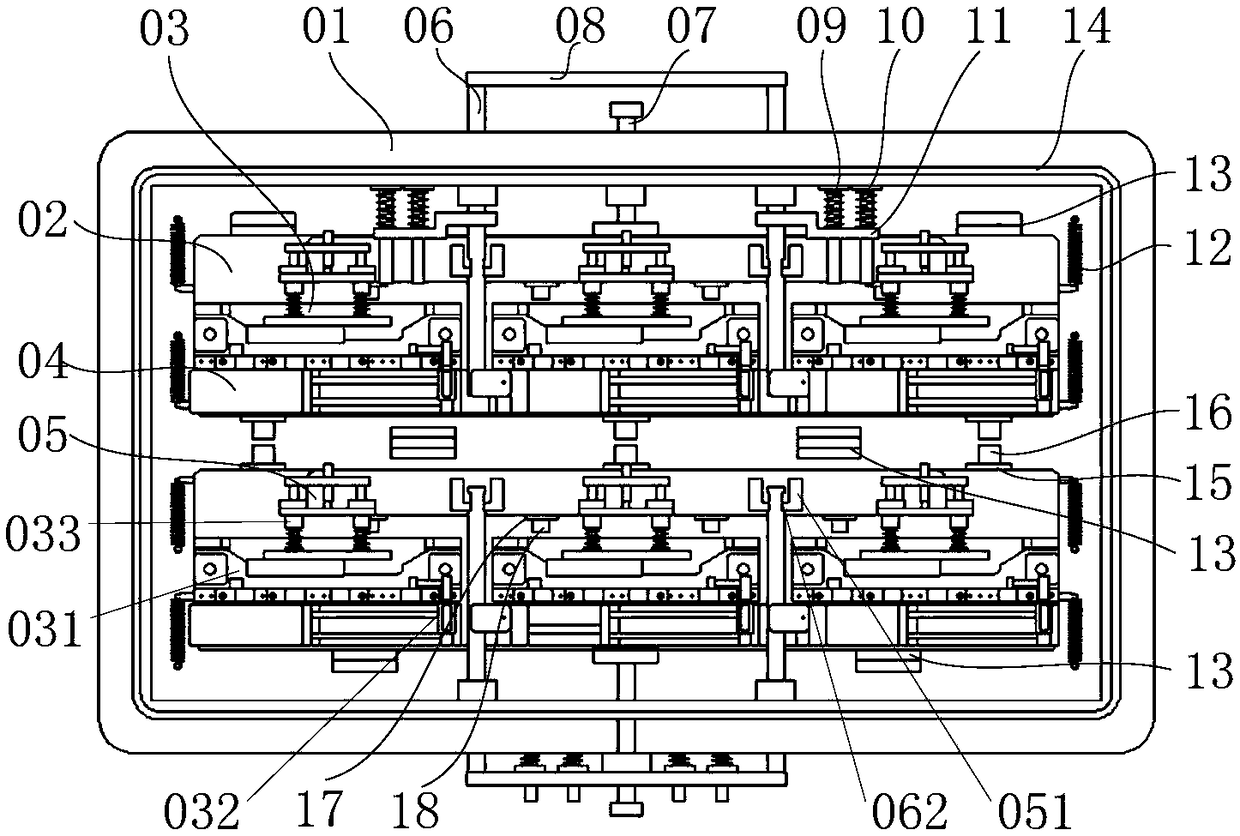

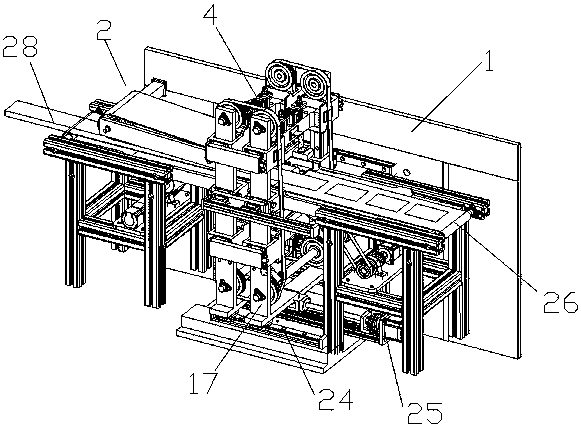

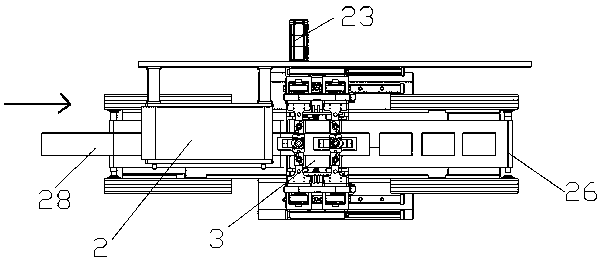

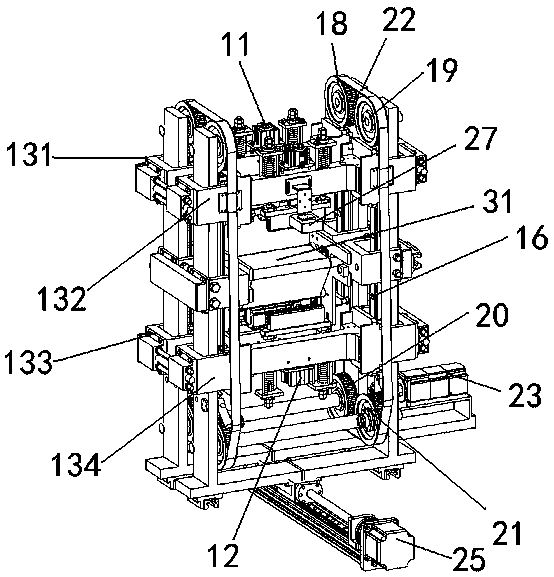

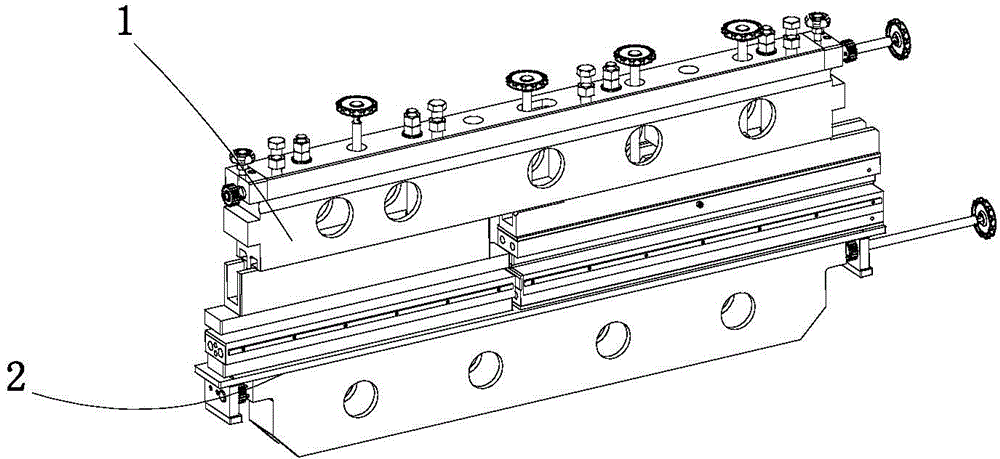

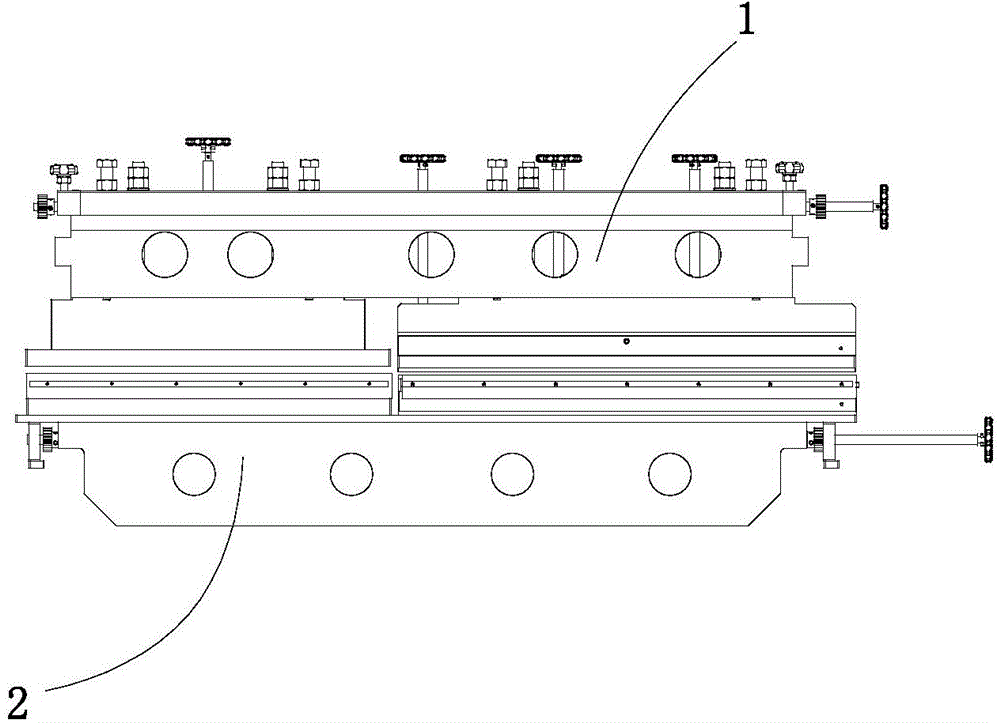

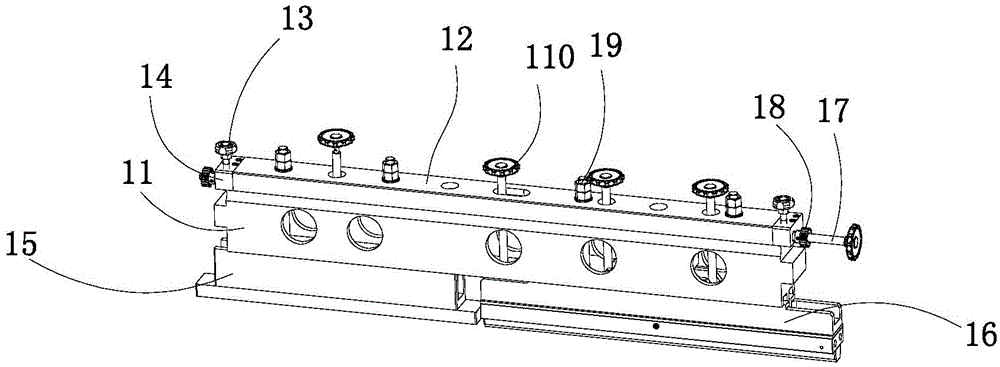

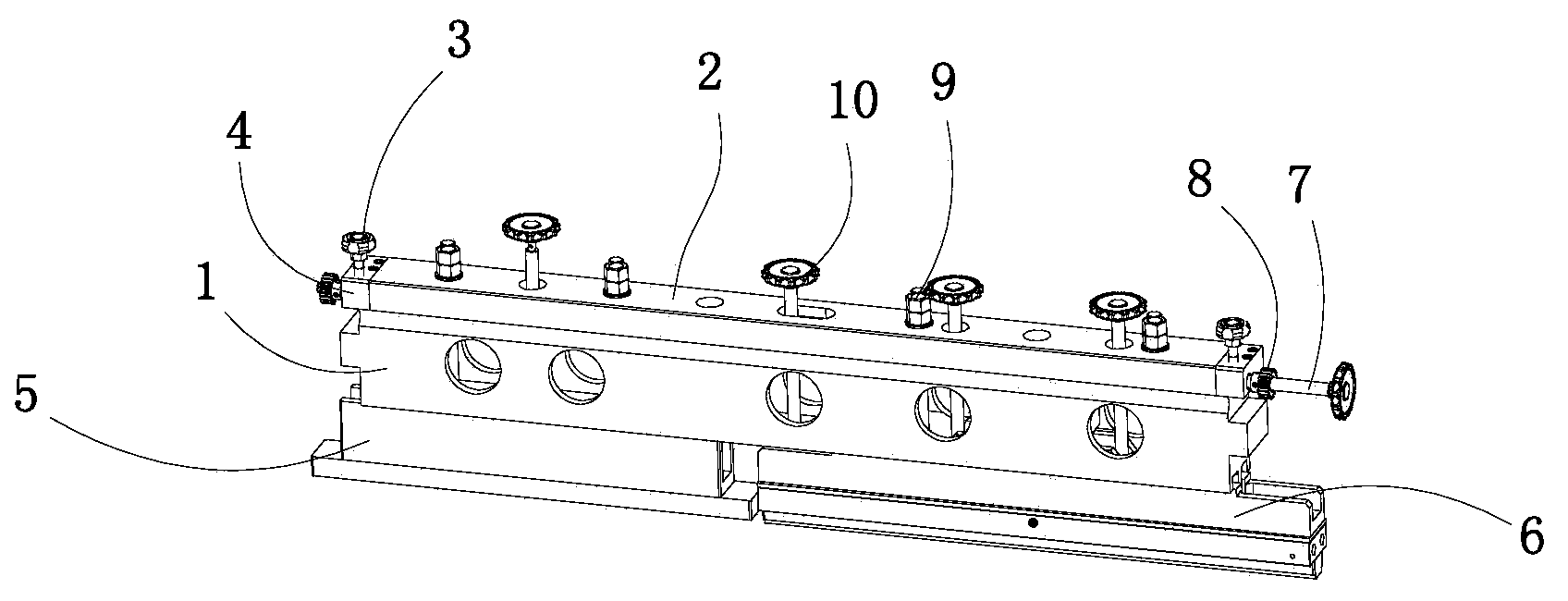

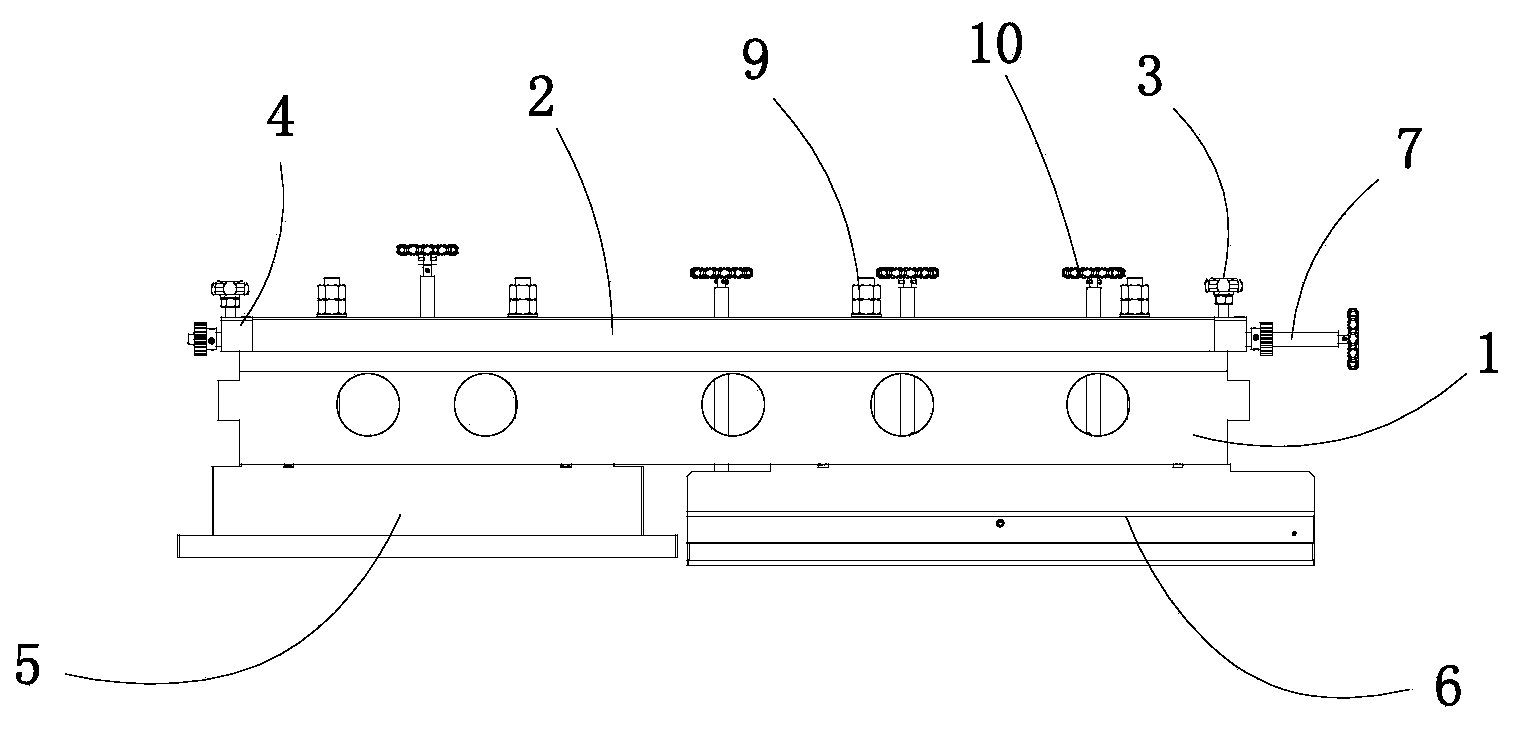

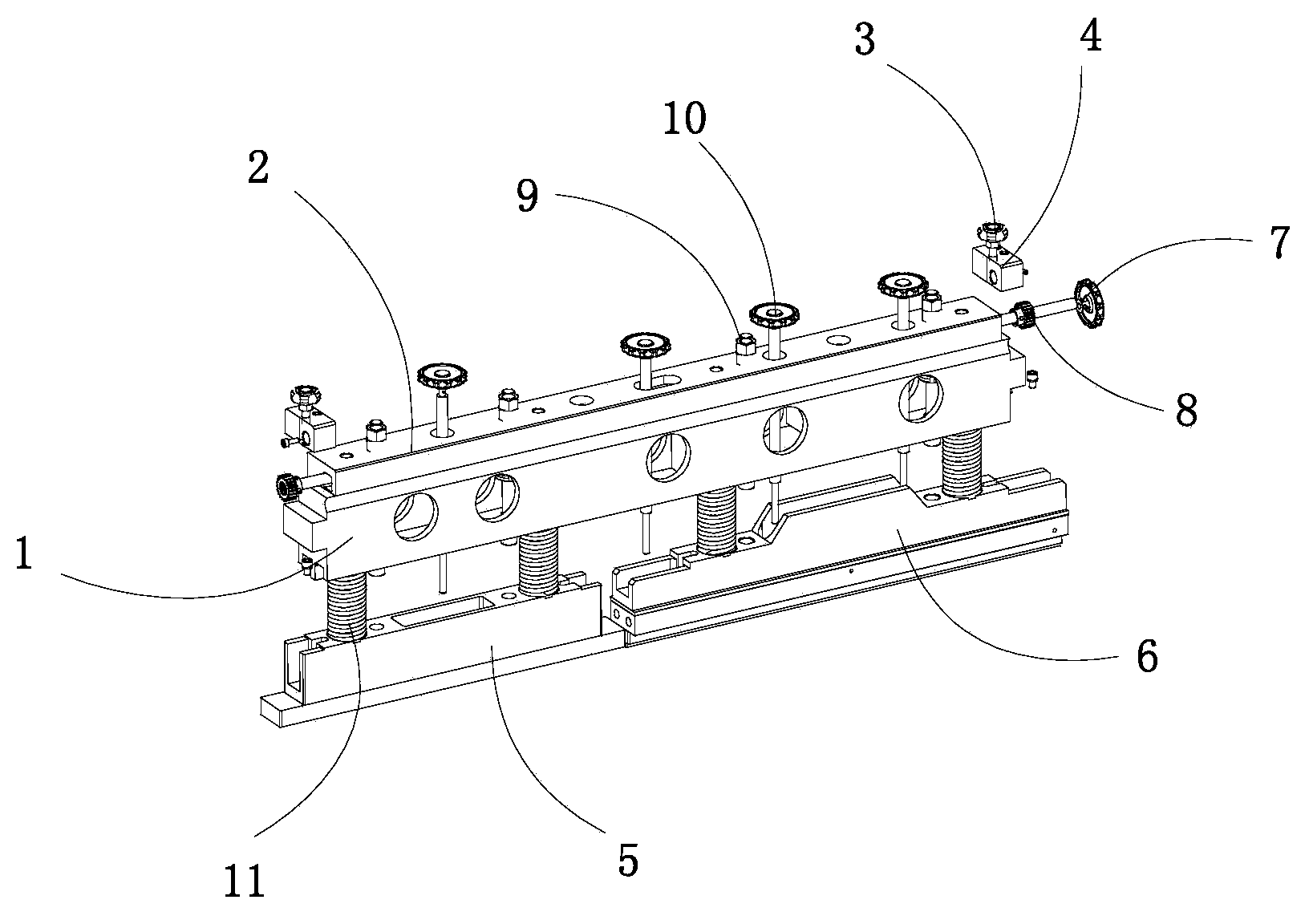

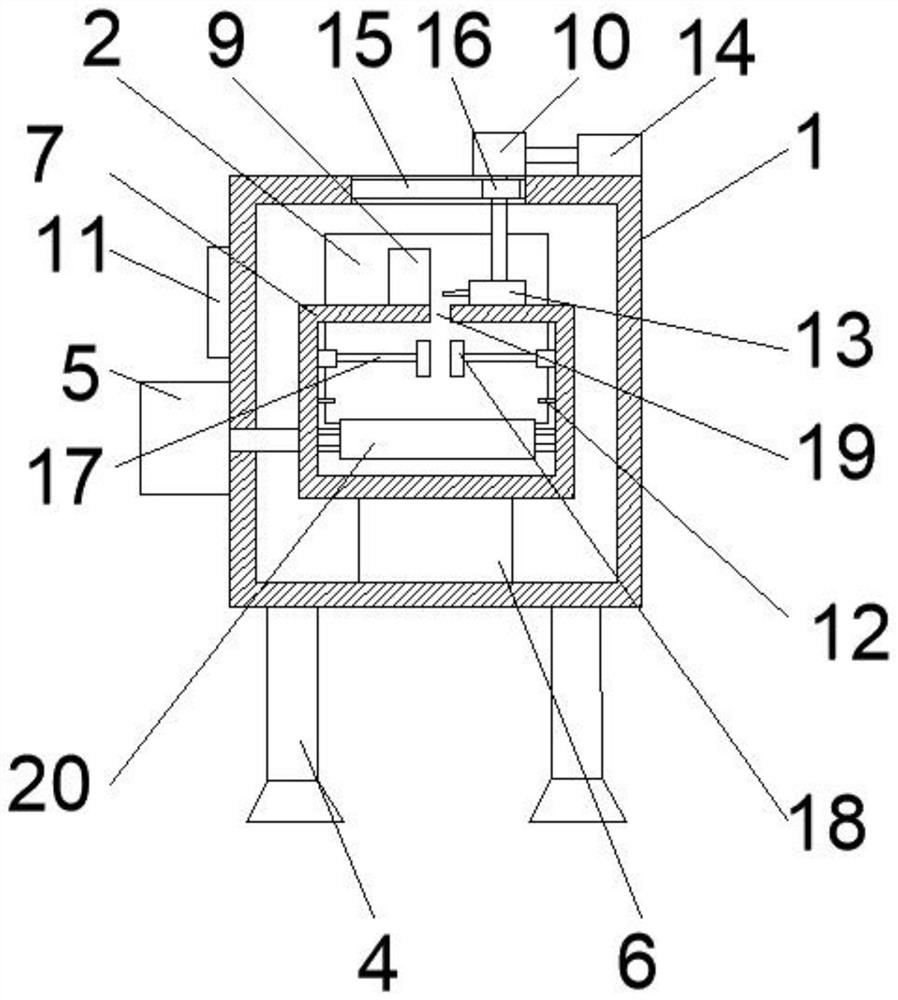

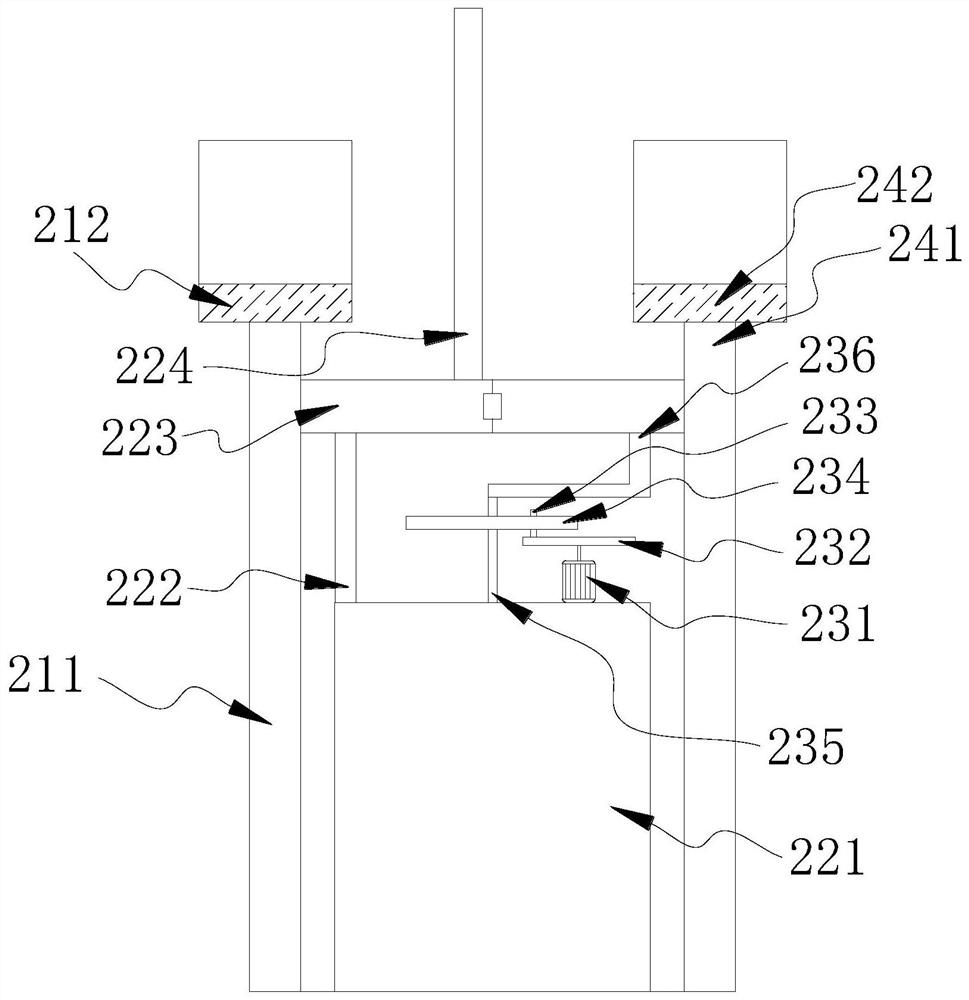

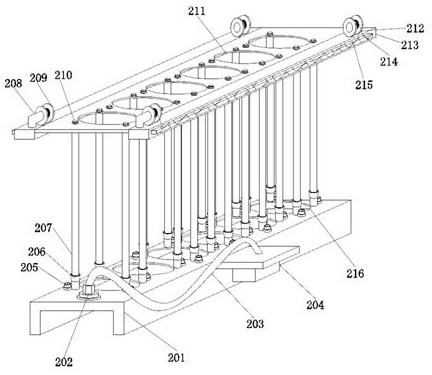

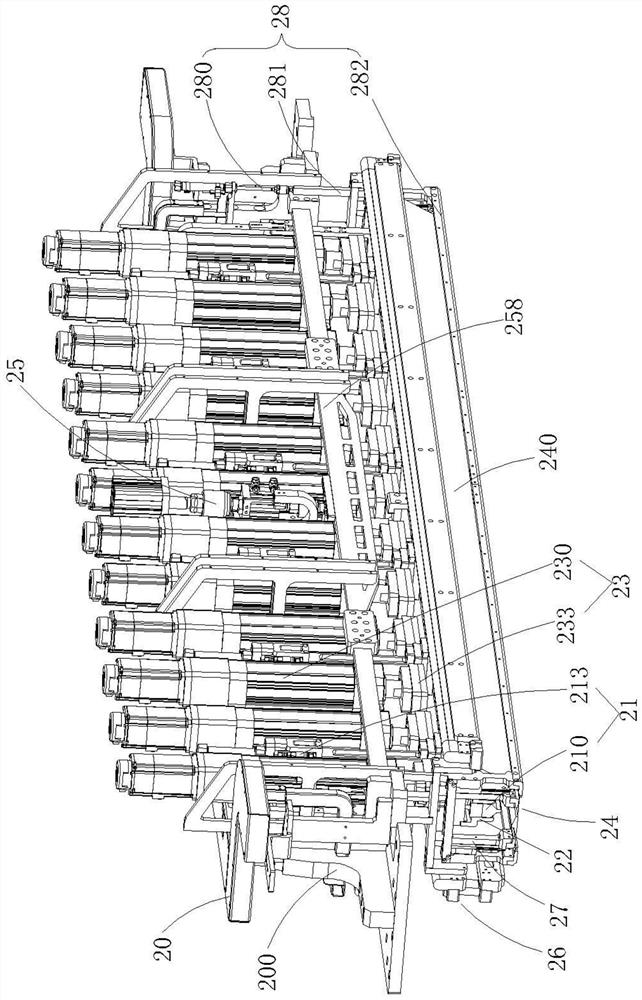

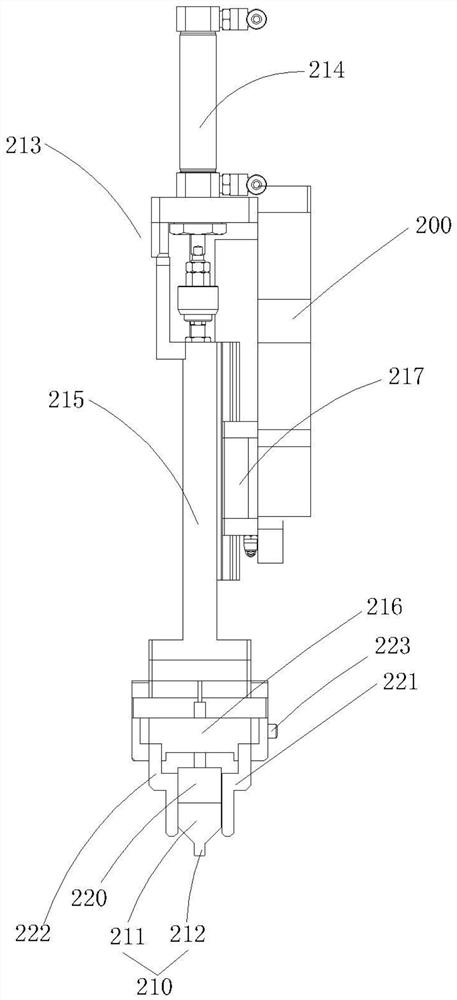

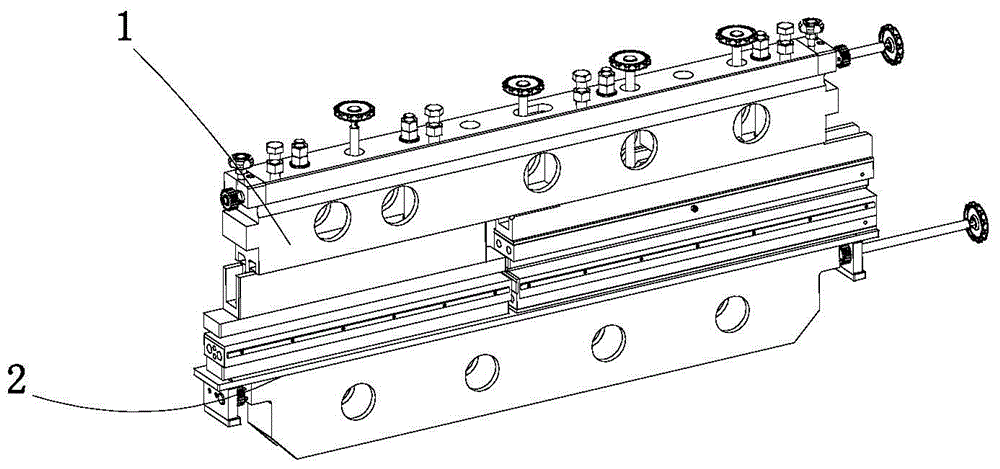

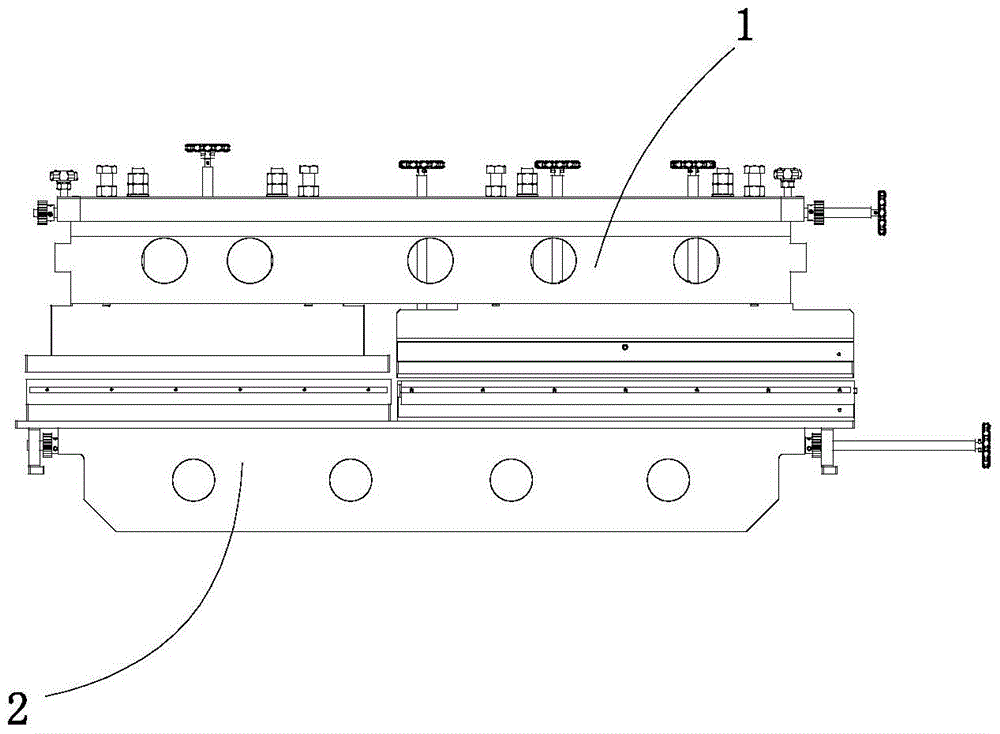

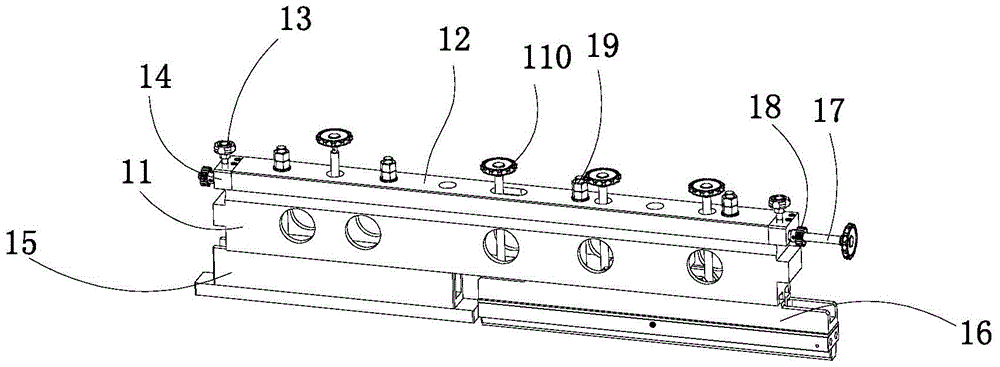

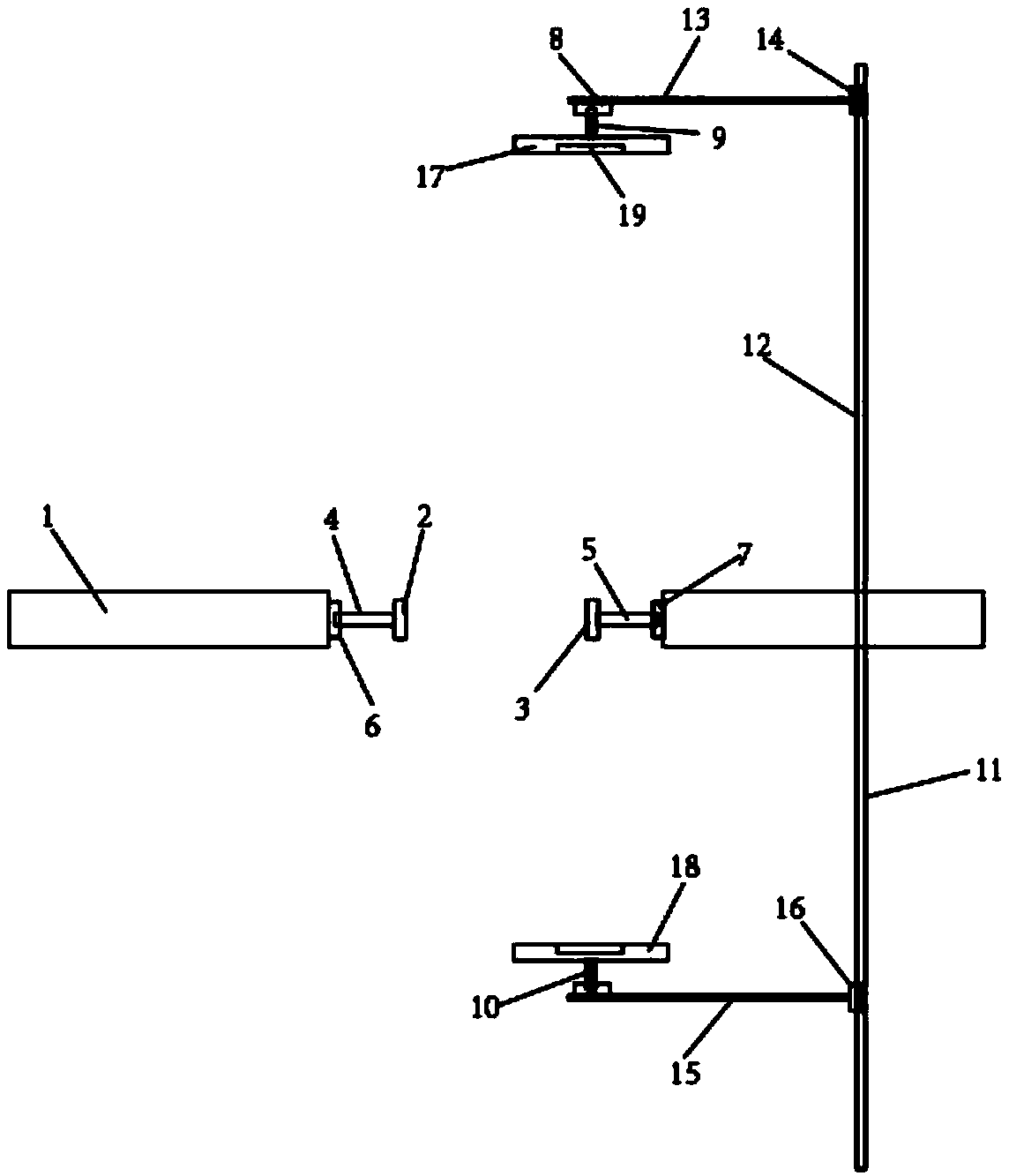

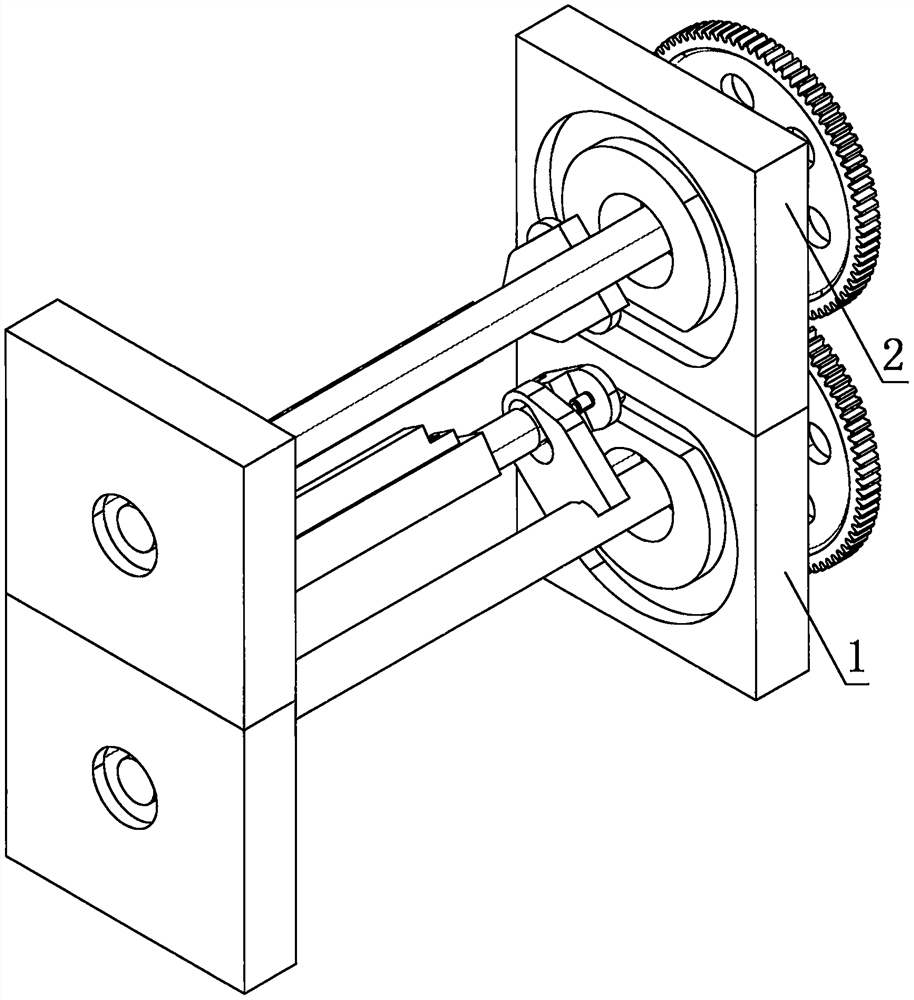

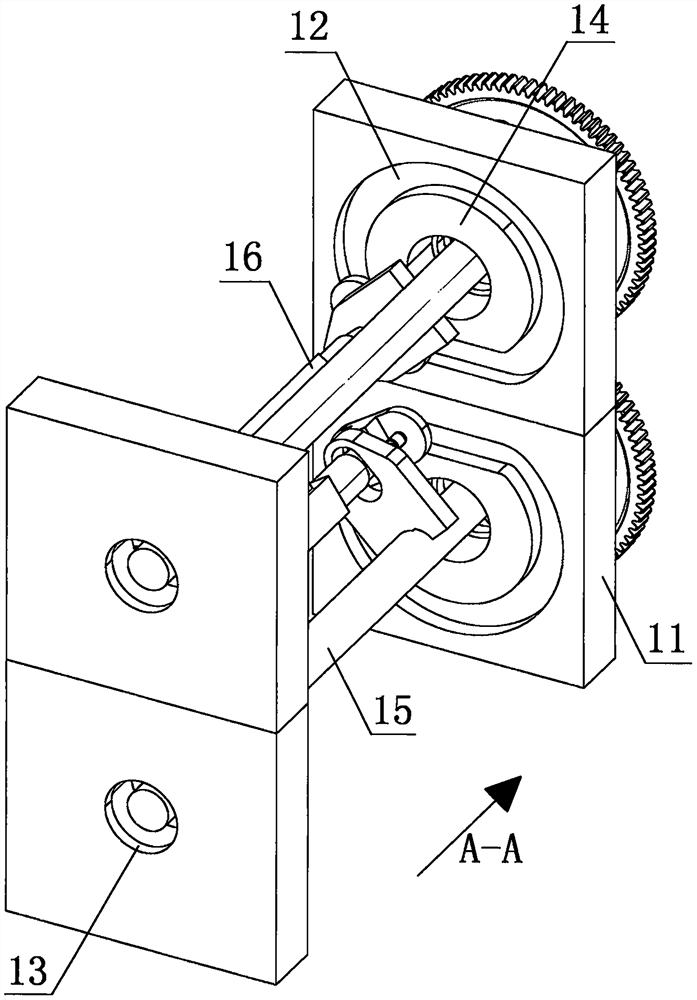

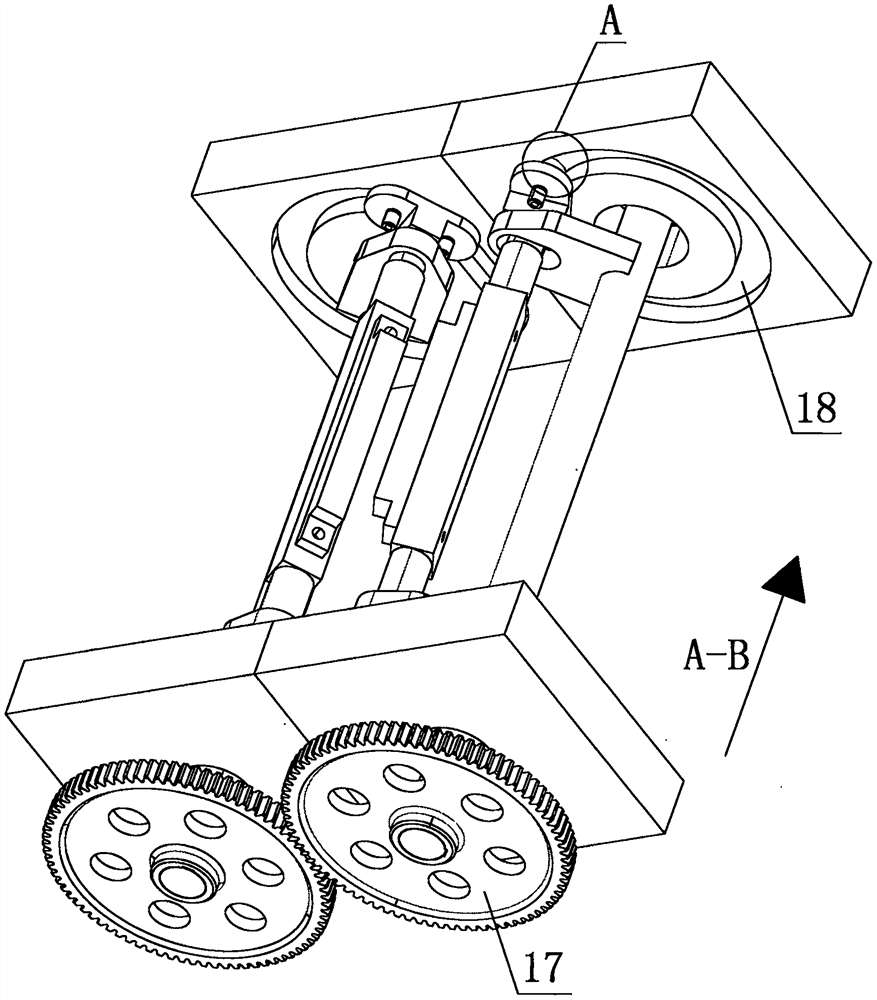

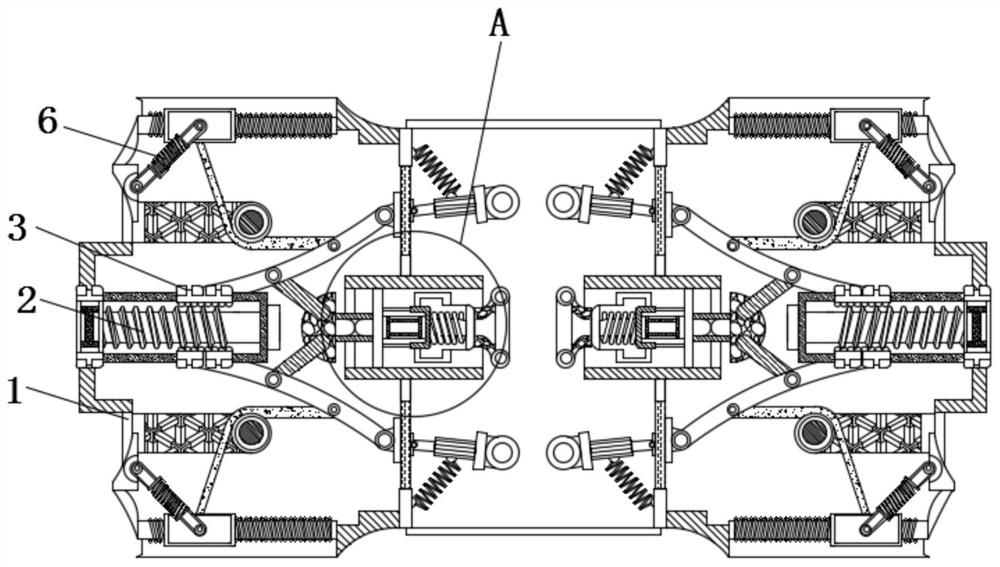

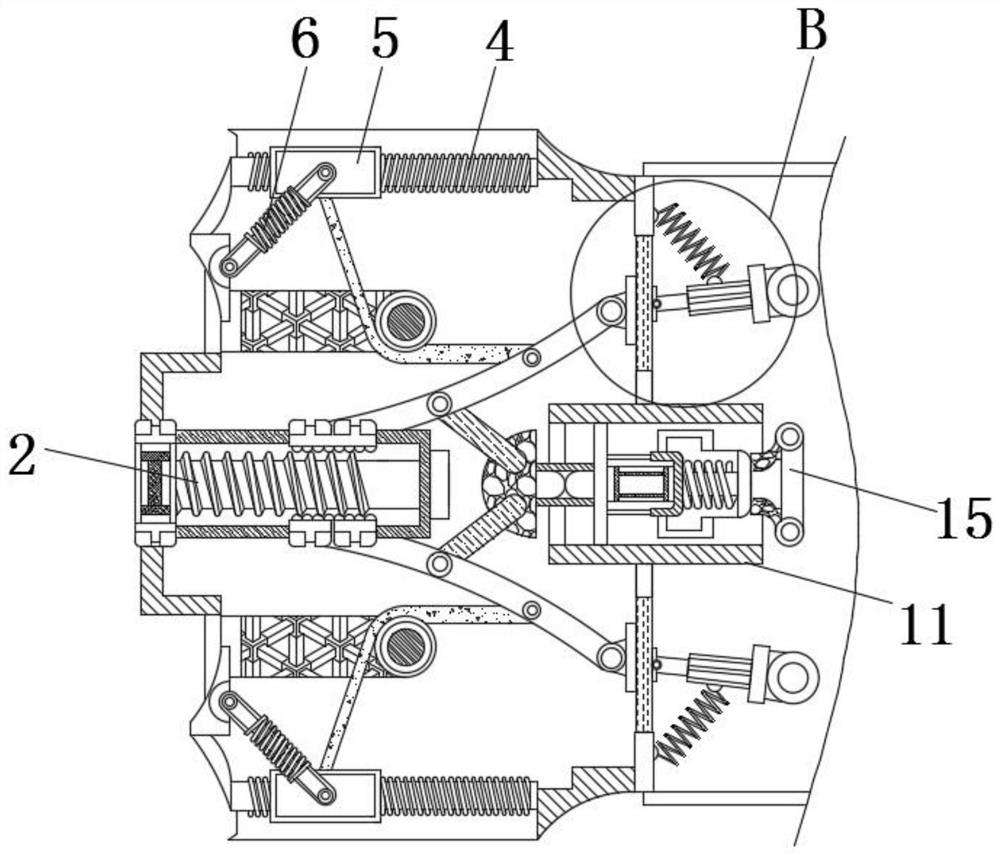

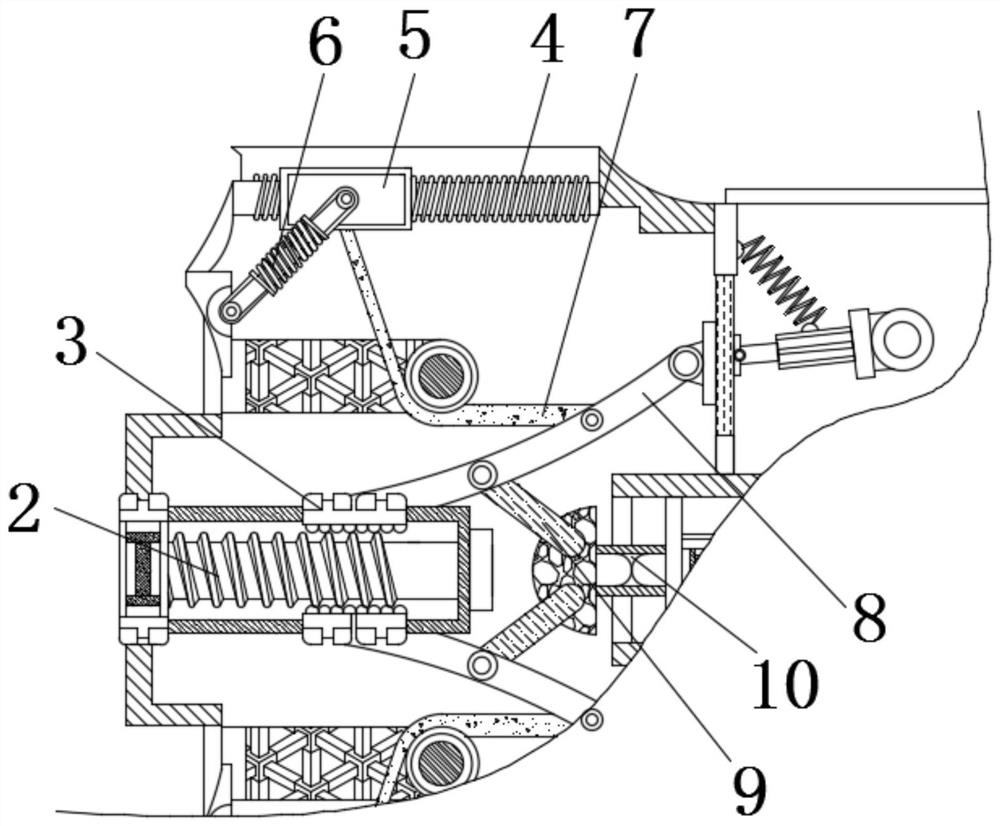

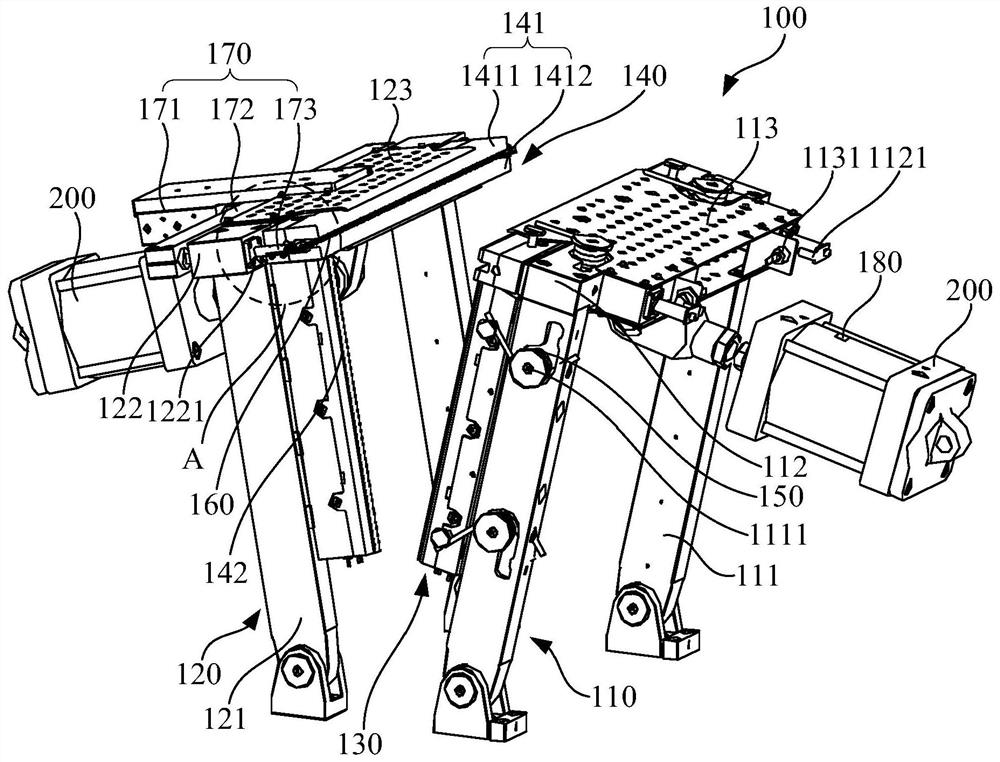

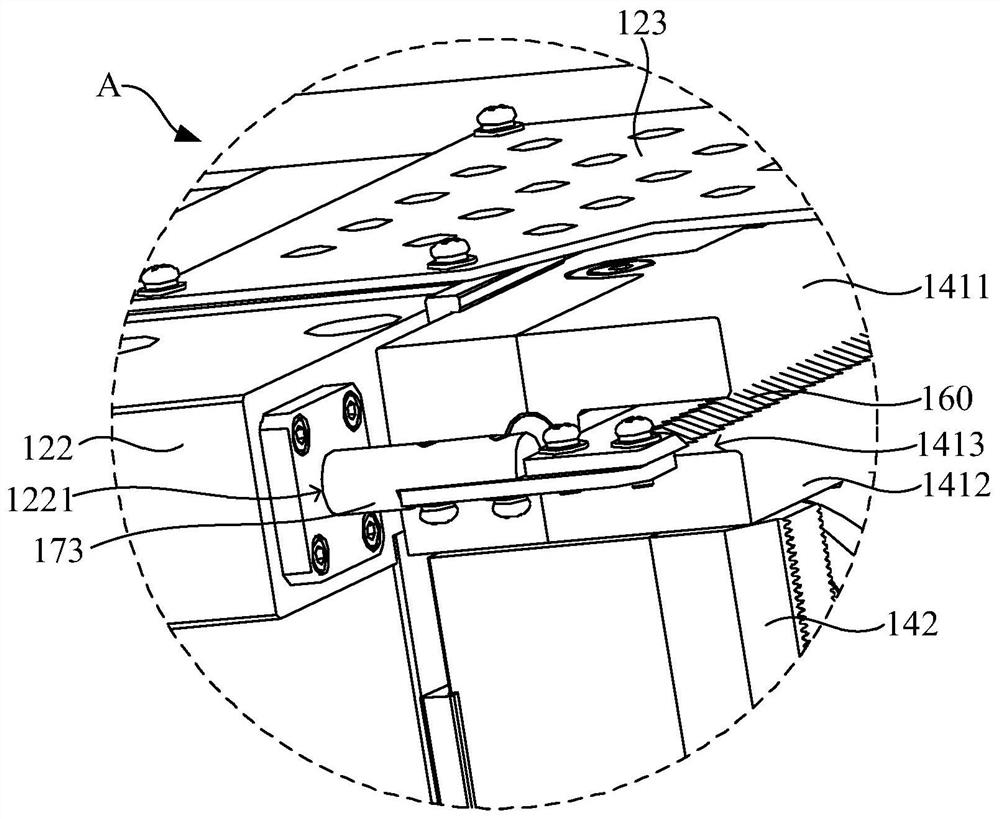

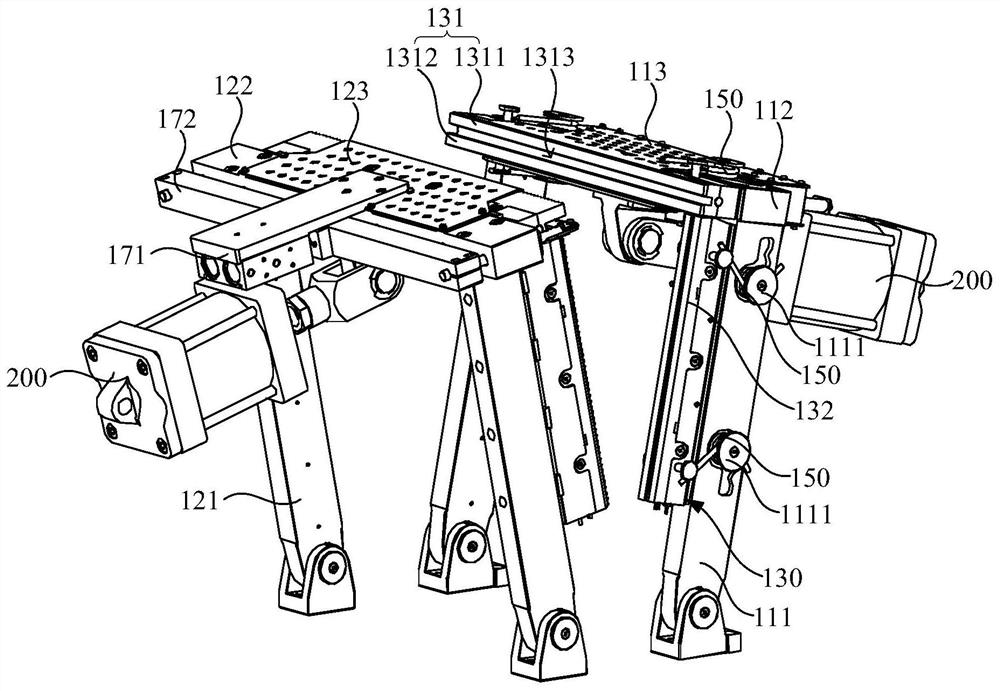

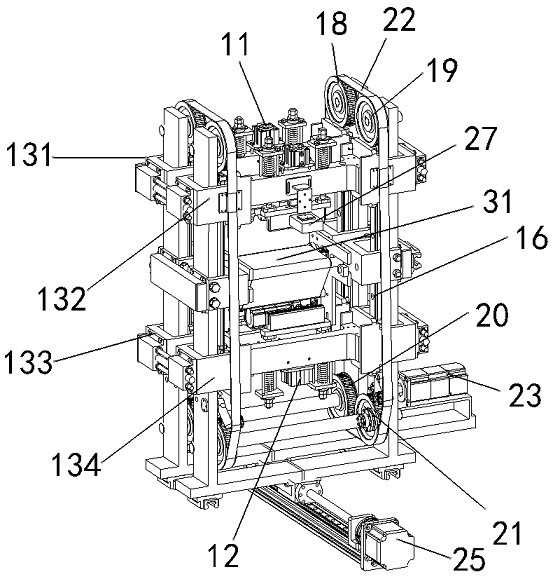

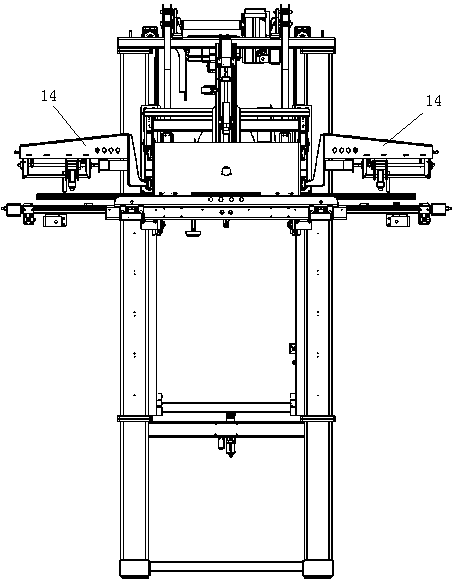

Battery core clamp

PendingCN108899574AHigh positioning accuracyRealize the heat sealing processAssembling battery machinesFinal product manufactureMobile bearingElectrical battery

The invention provides a battery core clamp and relates to the technical field of battery manufacturing equipment. The battery core clamp includes mobile bearing plates and clamp bodies disposed on the mobile bearing plates; each clamp body includes a battery core supporting mechanism, a battery core positioning mechanism and a battery core clamping mechanism, and the battery core supporting mechanisms are disposed on the mobile bearing plates and used for bearing battery cores; the battery core positioning mechanisms can move left and right relative to the mobile bearing plates and are used for clamping the battery cores for fixation or releasing the battery cores in the left and right direction; the battery core clamping mechanisms can move back and forth relative to the mobile bearing plates and are used for clamping the battery cores in the front and rear direction and then releasing the battery cores. The problems of low positioning accuracy, poor adaptability and the like of existing clamps are solved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

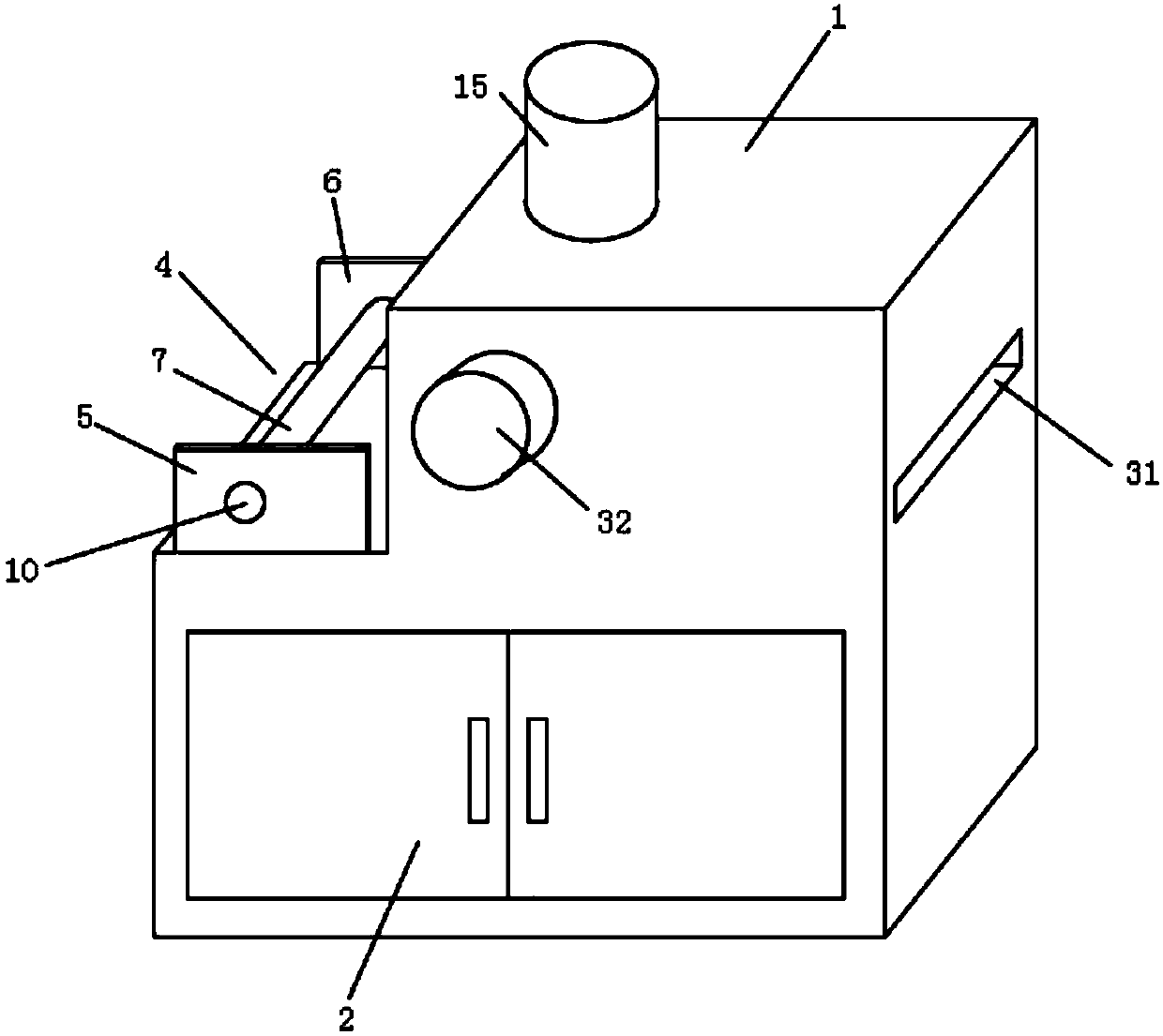

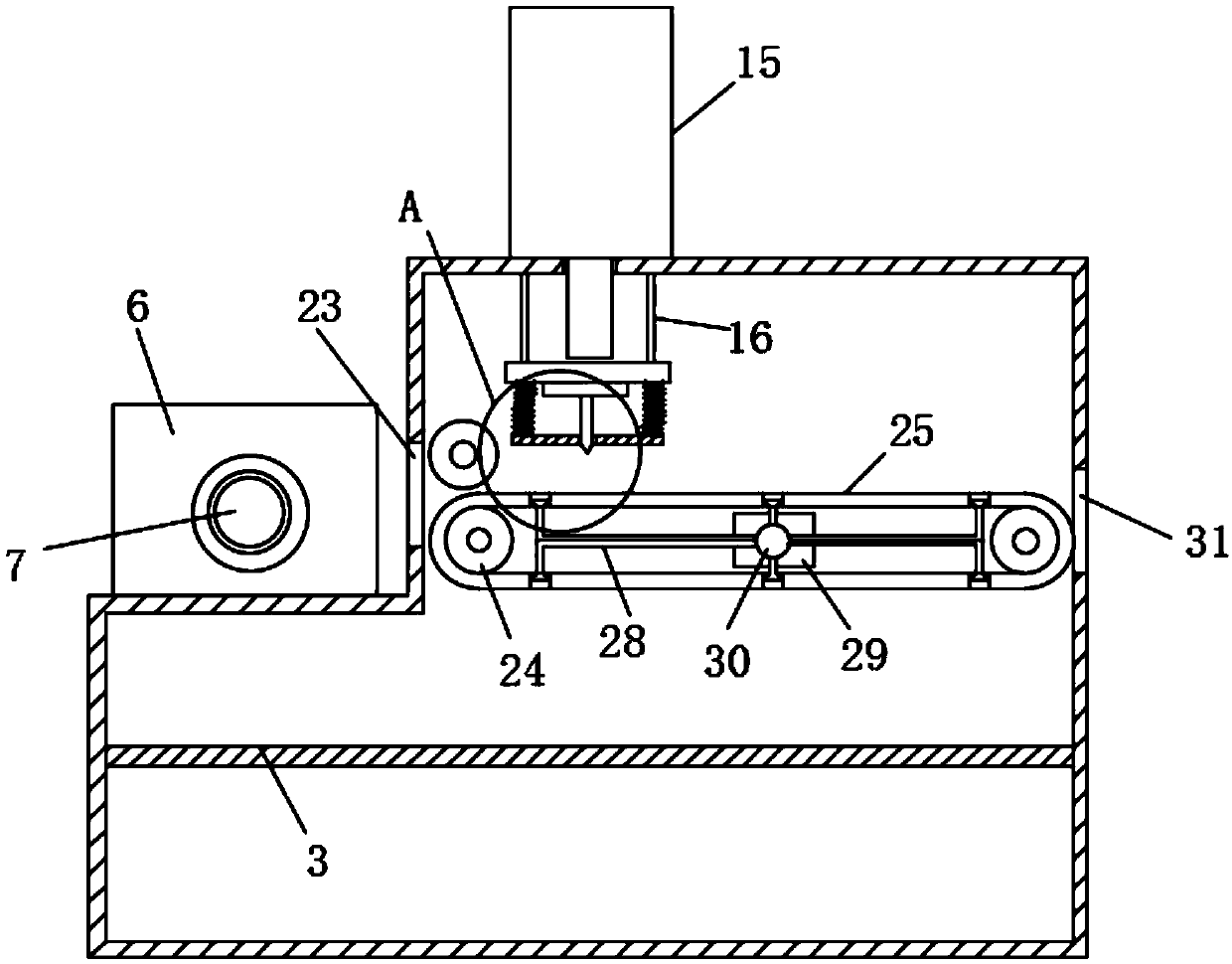

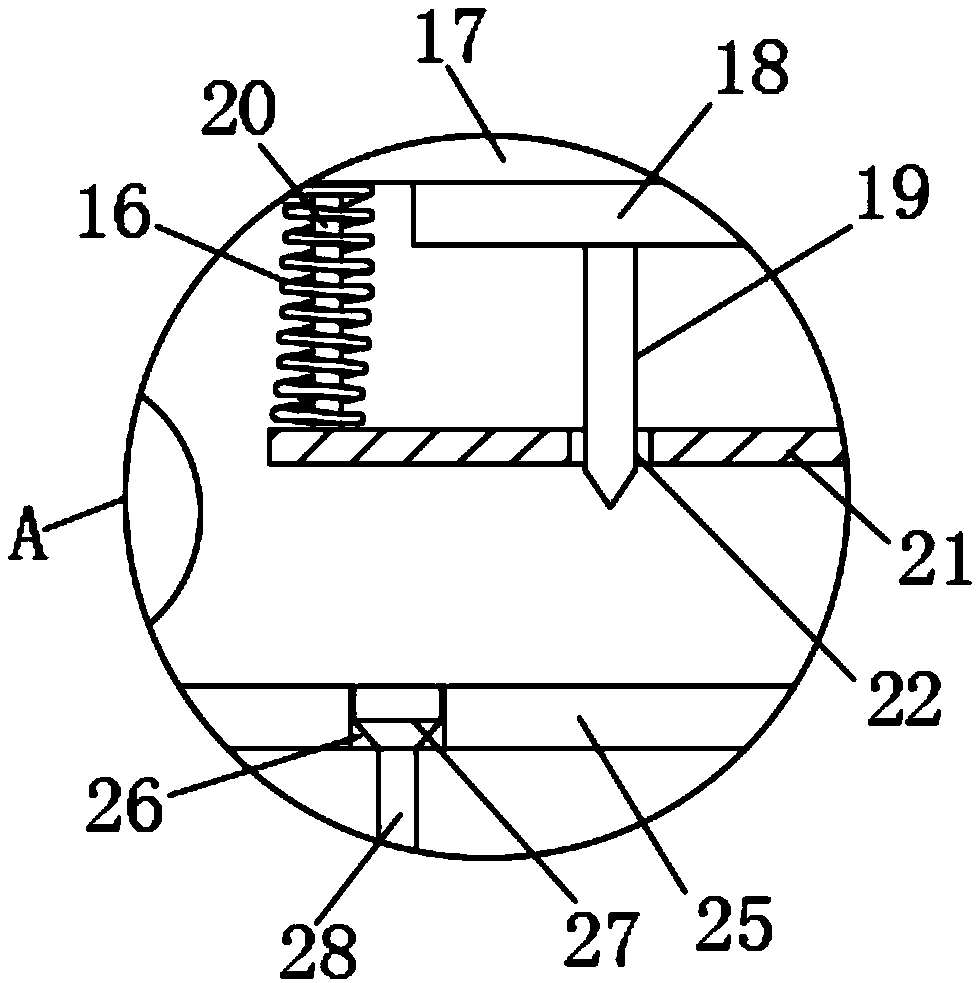

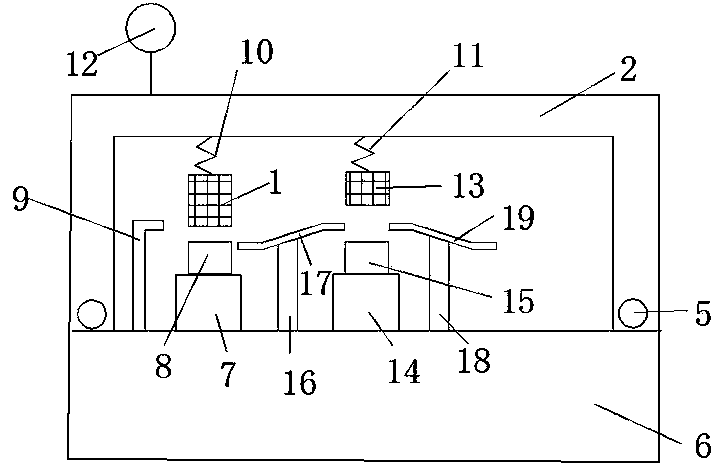

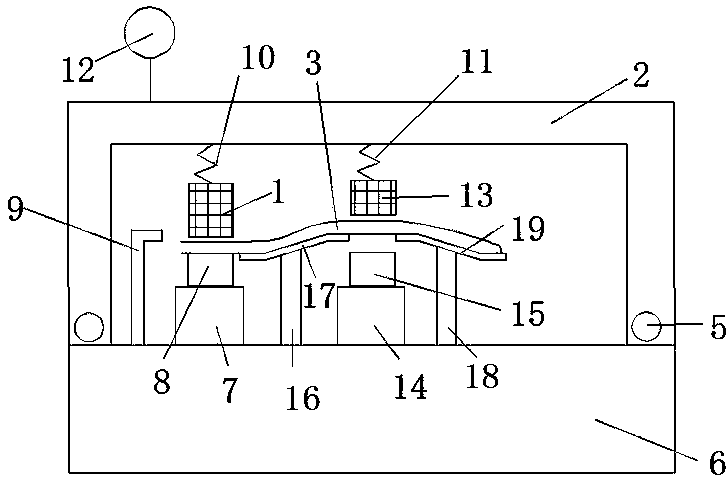

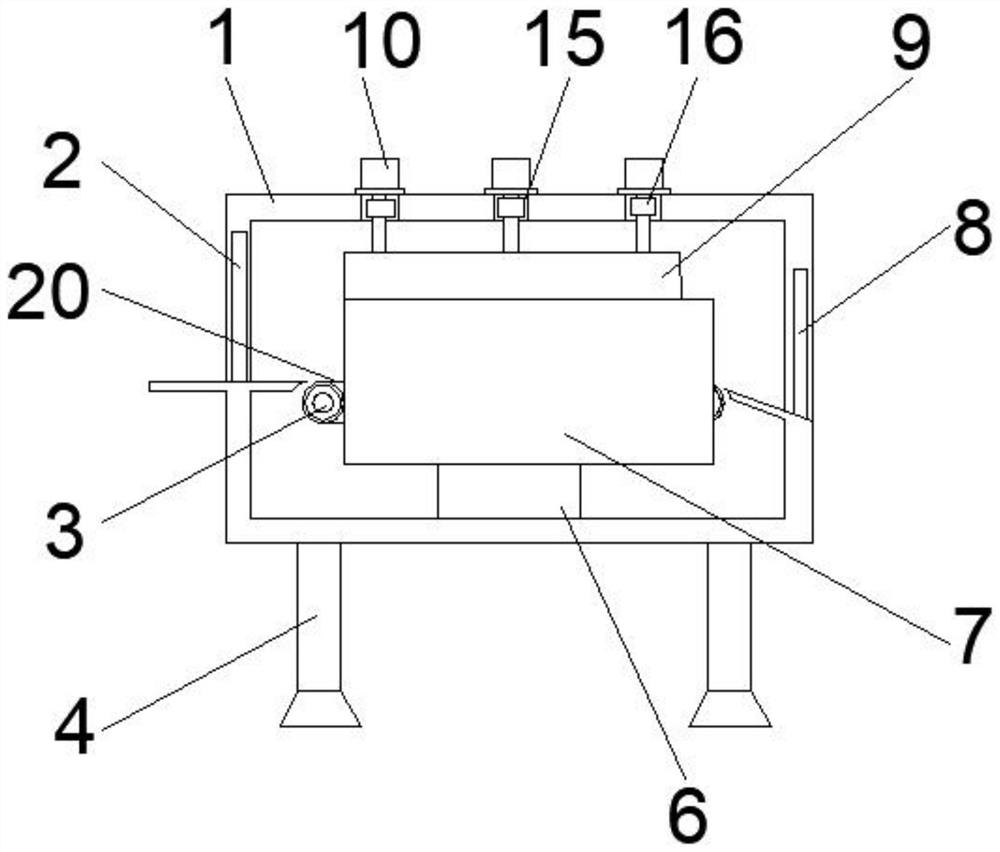

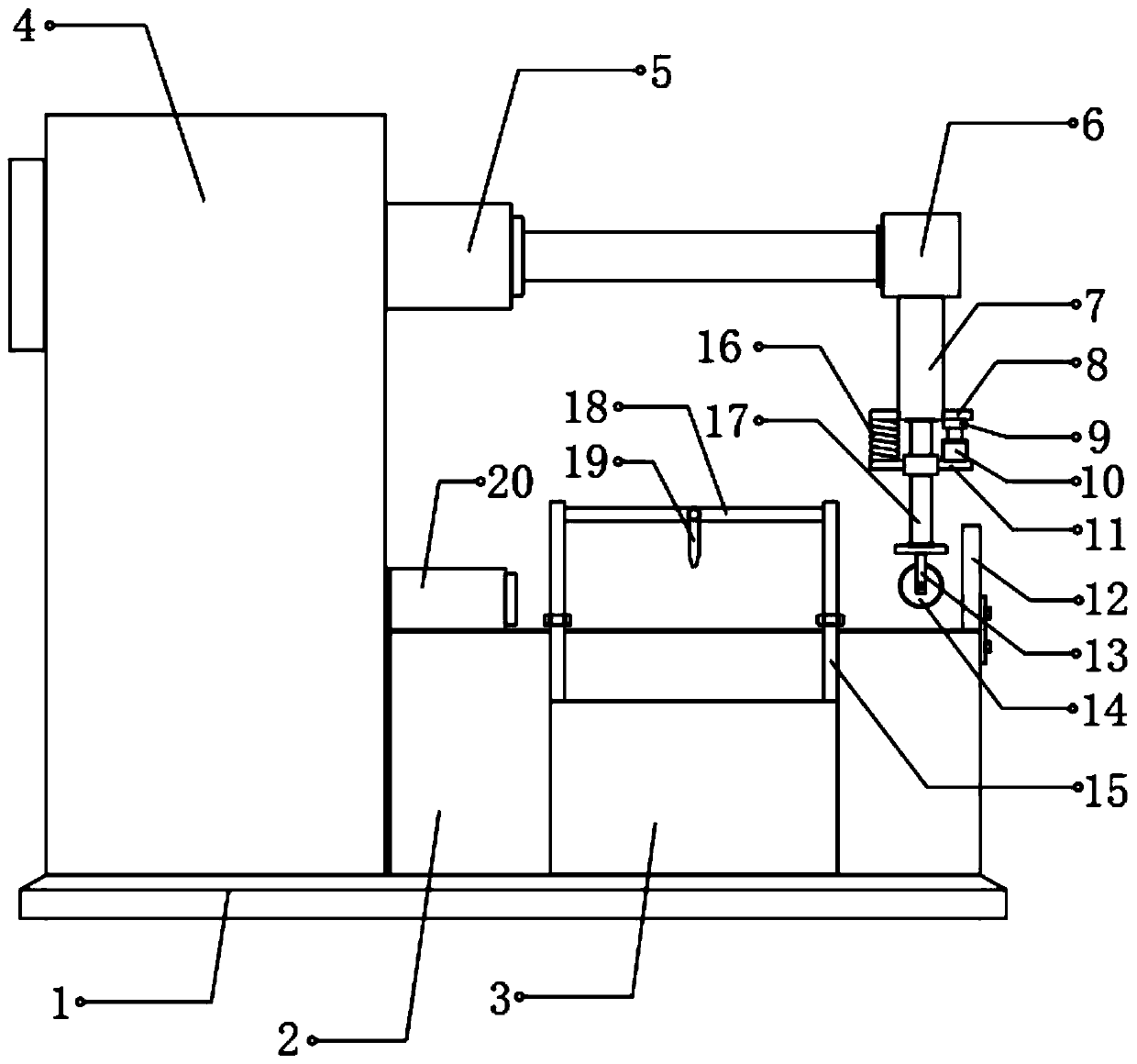

Plastic film heat-sealing device

InactiveCN109625451AEasy to placeSet firmlyWrapper twisting/gatheringTransmission beltSurface mounting

The invention discloses a plastic film heat-sealing device, which comprises a heat-sealing box. A film storing notch is formed in one side of the heat-sealing box, a film placing mechanism is arrangedon the surface of the film storing notch, a hydraulic pump is mounted on the upper surface of the heat-sealing box, a film cutting mechanism is arranged at the position, at the hydraulic pump, insidethe heat-sealing box, a film conveying mechanism is arranged at the position, below the film cutting mechanism, inside the heat-sealing box, the film conveying mechanism comprises a metal transmission belt and two sets of transmission wheels, a plurality of sets of mounting openings are evenly formed in the upper surface and the lower surface of the metal transmission belt, suction cups are mounted in the mounting openings, one ends of the suction cups are connected with hoses in a communicating mode, an air pump is fixedly mounted inside the metal transmission belt, and the hoses are connected with the air outlet end of the air pump in a communicating mode. In the using process of the plastic film heat-sealing device, a plastic film coil is placed conveniently, and a film subjected to heat sealing can be moved to a film outlet to be discharged through transmission of the metal transmission belt; and artificial manual operation is not needed in the heat sealing process, and the heat sealing efficiency of the plastic film is improved.

Owner:合肥云龙塑业有限公司

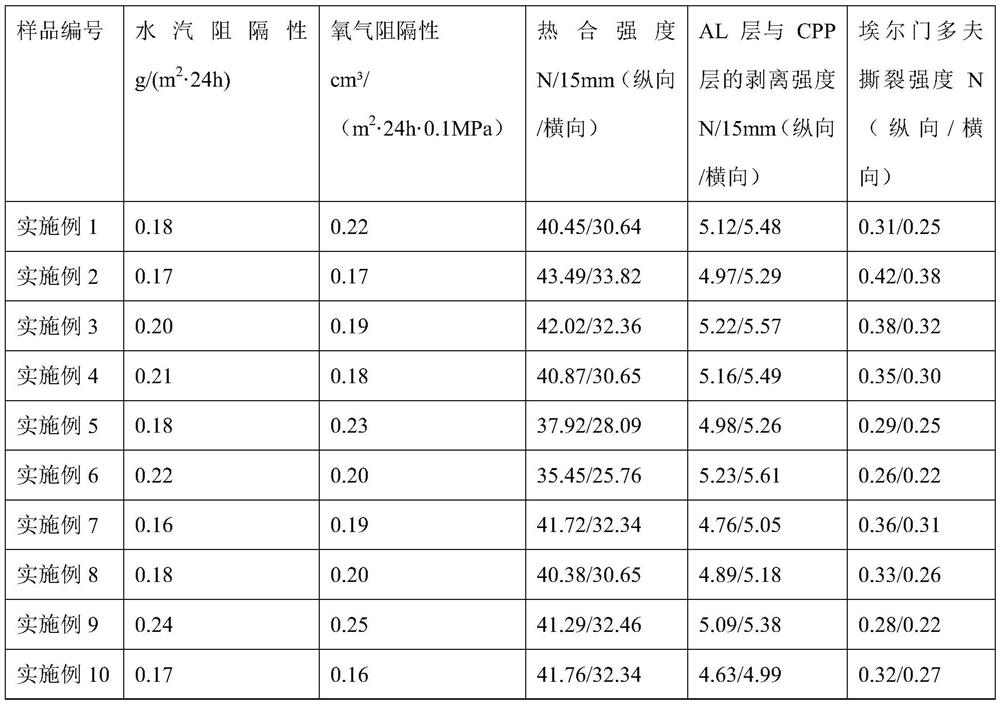

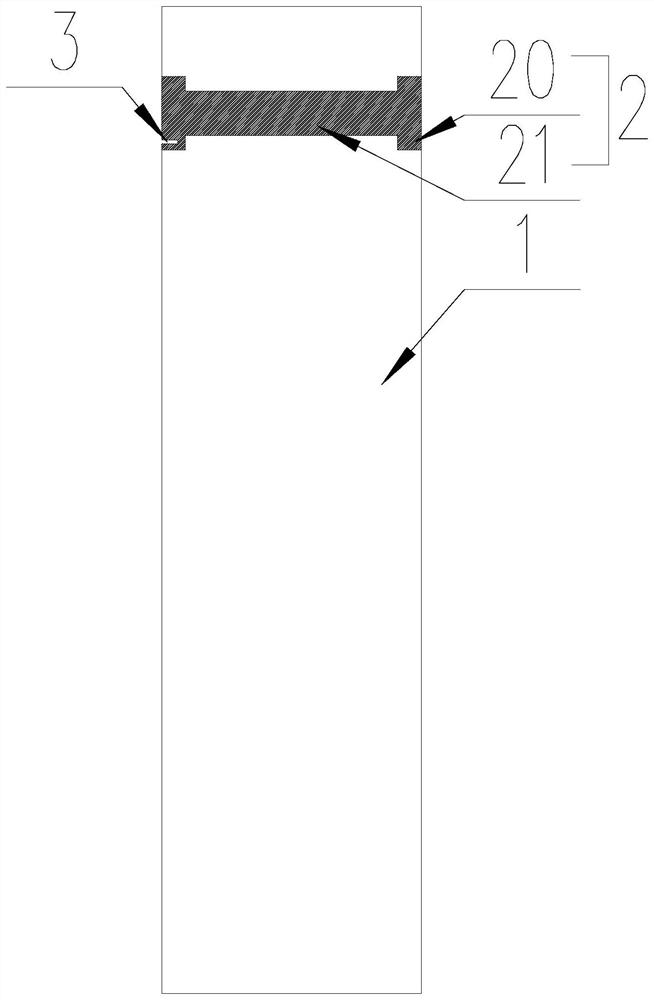

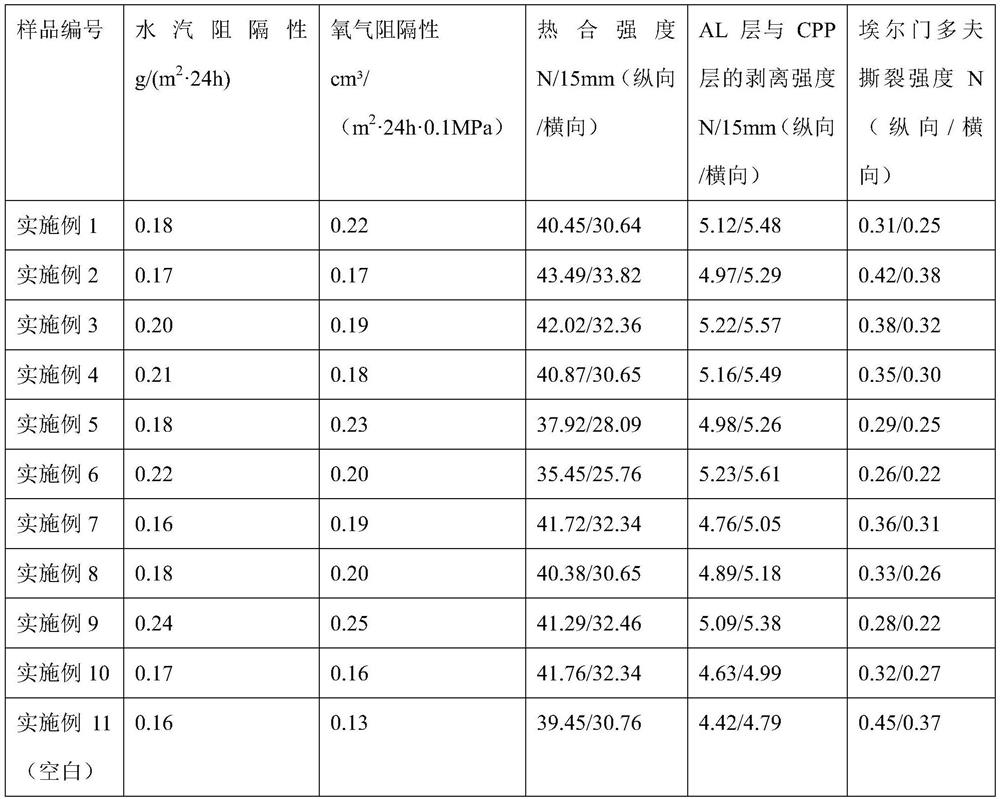

Preparation method of modified casting polypropylene film and easy-to-tear PET-AL-CPP medicine-packaging composite film

InactiveCN111716858AFast deliveryReduce adverse effectsSynthetic resin layered productsPharmaceutical containersPolymer scienceComposite film

The invention discloses a preparation method of a modified casting polypropylene film and an easy-to-tear PET-AL-CPP composite film. The invention aims to solve the problems that CPP in an existing PET-AL-CPP composite film is good in toughness and a flexible packaging bag prepared from the existing PET-AL-CPP composite film and used for packaging a liquid medicine is not easy to tear, poor in linear tearing performance and prone to causing splashing or side leakage of the liquid medicine. The preparation method of the invention comprises the following steps: adding 1-5 parts of a silicon dioxide coated aluminum oxide nanomaterial into 95-97 parts of polypropylene resin, and carrying out blending, melting and granulating to obtain a polypropylene inner-layer mixture; and 2, extruding polypropylene outer-layer resin and the polypropylene inner-layer mixture of obtained in the step 1 to obtain the polypropylene film. The film prepared in the invention has the advantages of good comprehensive performance, easiness in tearing, good linear tearing performance and the like.

Owner:SICHUAN HUILI IND

Rotary type two-end heat-sealing die

InactiveCN109878820AControllable job speedImprove heat sealing efficiencyWrapper twisting/gatheringEngineeringPressure sensor

Owner:TIANJIN HAIJING PLASTIC PROD

Powder packaging machine

ActiveCN111605818AImprove packaging qualityReduced chance of wrinklingWrapper twisting/gatheringPackaging automatic controlStructural engineeringElectrical and Electronics engineering

The invention relates to a powder packaging machine and relates to the technical field of packaging machines. The powder packaging machine comprises a rack. A sorting mechanism is arranged on the rack. The sorting mechanism comprises a tension detection part, a thrust device, a collecting device and a meter counting wheel. The tension detection part is arranged on the rack and is used for detecting the pressure on a packaging bag. The thrust device is arranged on the rack. The thrust device comprises a thrust air cylinder, a thrust seat and a thrust roller. The collecting device is arranged onthe rack and comprises a sliding way, a collecting box, a drive air cylinder and a collecting box. The meter counting wheel is arranged on the rack. By means of the powder packaging machine, when thepackaging bag is stuck, the tension detection part controls the sliding way to move, meanwhile, the thrust roller moves to make the packaging bag tend to be flat, and therefore the packaging bag moves into the collecting box to be collected; and meanwhile, the tension detection par triggers a signal to control the sliding way to get away from a cut-off mechanism, the packaging bag which is cut off falls into the collecting box, and the packaging quality of the packaging machine is improved.

Owner:浙江美生日化用品有限公司

Plastic bag heat sealing device

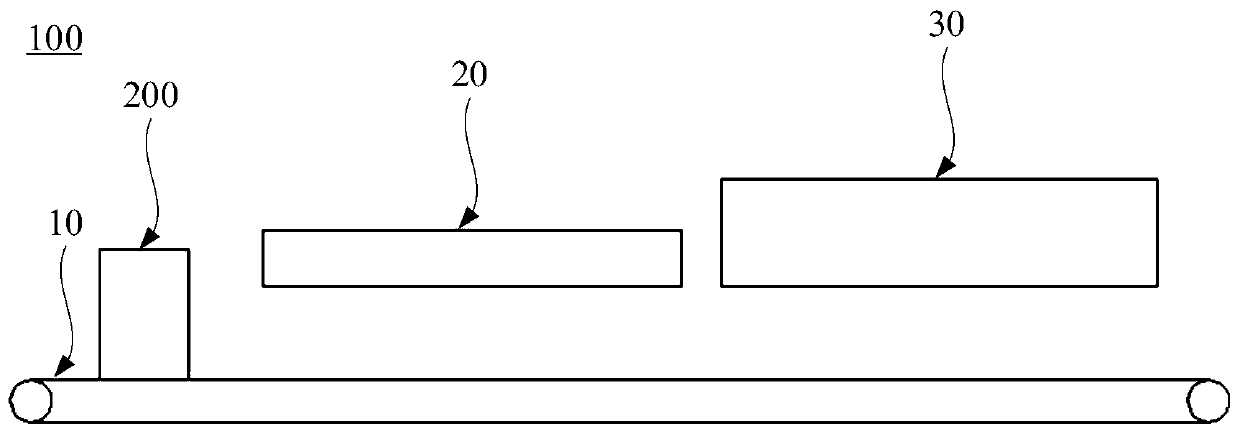

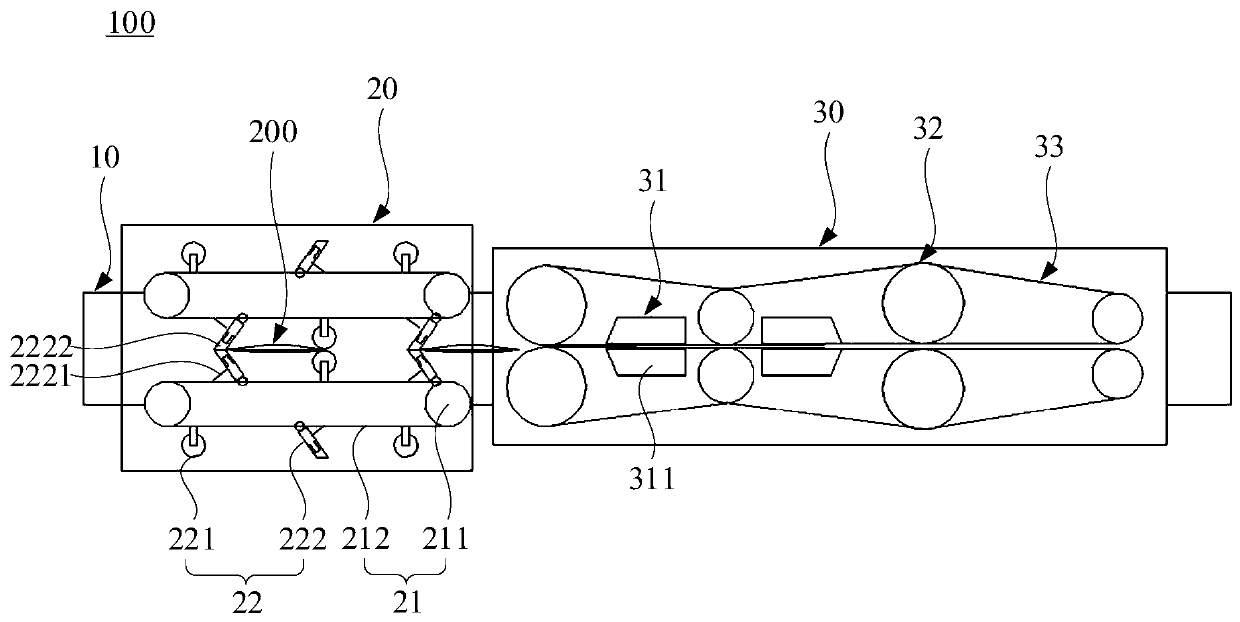

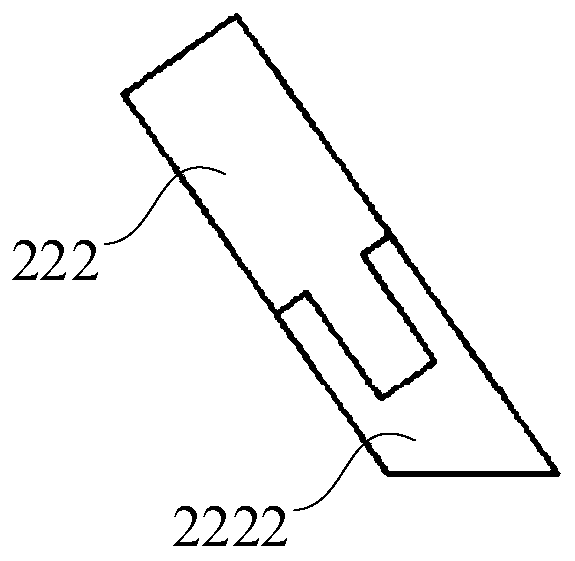

PendingCN111169096AImprove heat sealing efficiencyReduce labor costsBag making operationsPaper-makingHeat sealerEngineering

The invention discloses a plastic bag heat sealing device, and relates to the technical field of plastic bag heat sealing. The plastic bag heat sealing device comprises a conveying belt, a clamping mechanism and a heat sealing mechanism, wherein the clamping mechanism and the heat sealing mechanism are sequentially arranged above the conveying belt in the conveying direction of the conveying belt;the clamping mechanism clamps an opening of a to-be-sealed plastic bag and is matched with the conveying belt to convey the to-be-sealed plastic bag in the conveying direction; and the heat sealing mechanism is located at the conveying tail end of the clamping mechanism, a feeding port of the heat sealing mechanism is engaged with the opening of the to-be-sealed plastic bag for heat sealing treatment, and the heat sealing mechanism is matched with the conveying belt to send out the heat-sealed plastic bag from a discharging port of the heat sealing mechanism. The plastic bag heat sealing device can improve the heat sealing efficiency of the plastic bag and can reduce the labor cost at the same time.

Owner:深圳市道元实业有限公司

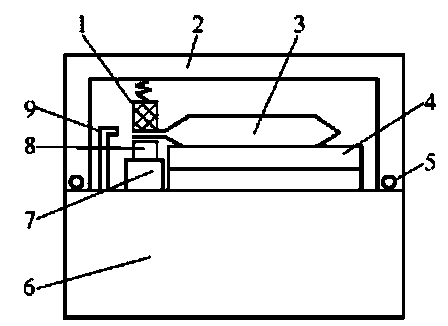

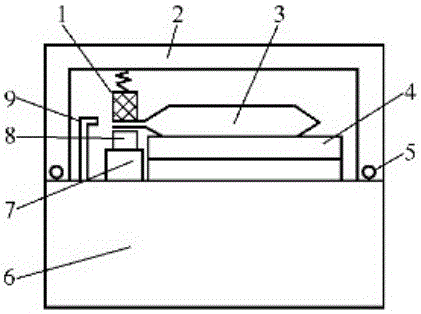

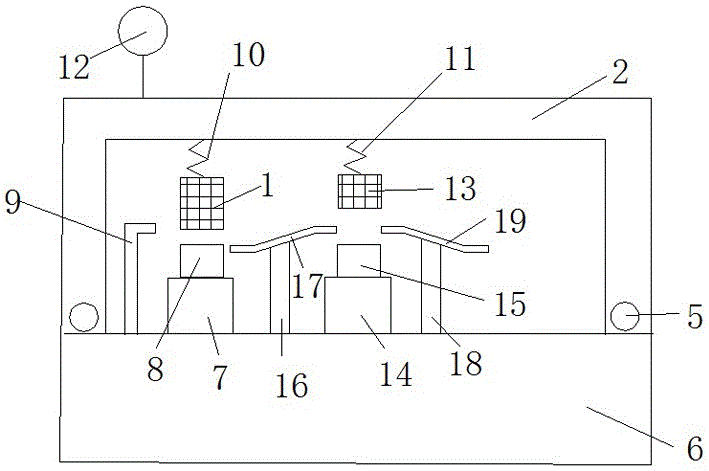

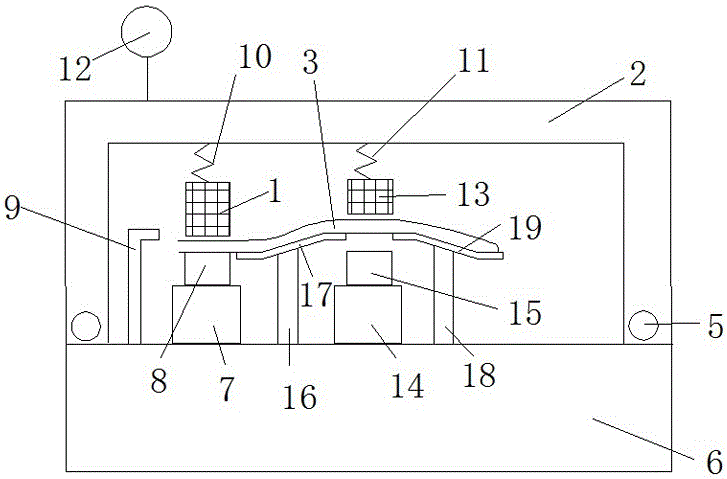

Vacuum chamber structure of novel packaging machine

InactiveCN104163262AImprove efficiencyImprove heat sealing efficiencyWrapper twisting/gatheringPackaging under vacuum/special atmosphereAgricultural engineeringVacuum chamber

The invention discloses a vacuum chamber structure of a novel packaging machine. The vacuum chamber structure comprises a box body at the bottom and a vacuum chamber cover at the top. The inner portion of the vacuum chamber cover is connected with a rubber cushion plate through a first spring. The box body is provided with a pressurizing device corresponding to the rubber cushion plate. A heat-seal rod is arranged on the pressurizing device. An air inflation pipe opening is formed in the box body. The vacuum chamber structure is characterized in that the inner portion of the vacuum chamber cover is connected with a center rubber cushion plate through a second spring, a center pressurizing device corresponding to the center rubber cushion plate is arranged on the box body, a center heat-seal rod is arranged on the center pressurizing device, a first supporting column is arranged between the pressurizing device and the center pressurizing device, a first supporting plate is arranged on the first supporting column, a second supporting column is arranged on the other side of the center pressurizing device, and a second supporting plate is arranged on the second supporting column. Heat-seal efficiency is improved.

Owner:王君 +5

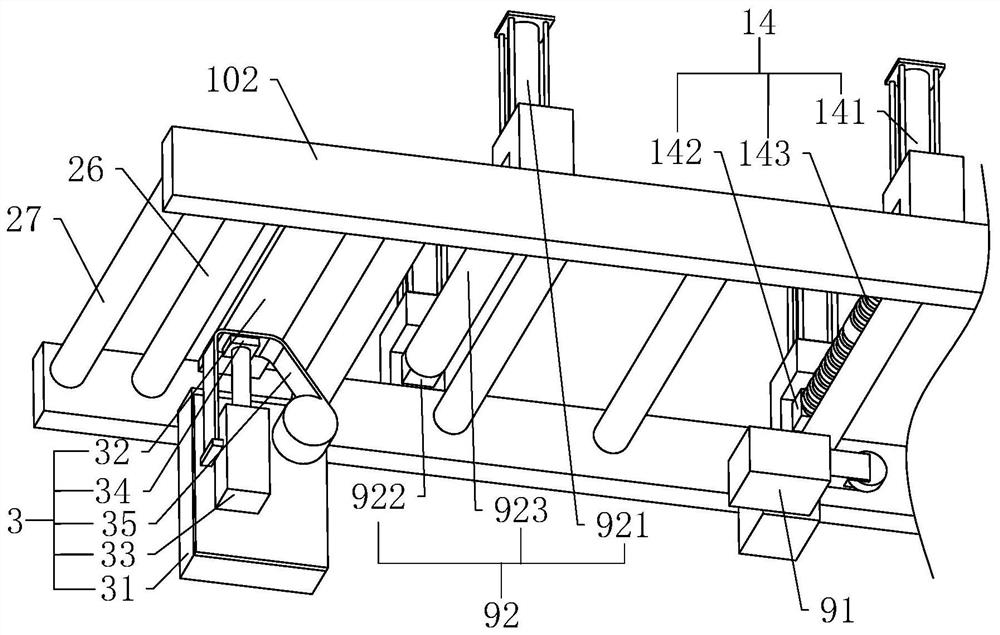

Wet tissue outer packing double-station synchronous heat seal shearing mechanism and working method thereof

ActiveCN109606847AImprove heat sealing efficiencySimple structureWrapper twisting/gatheringEngineeringWorking set

The invention provides a wet tissue outer packing double-station synchronous heat seal shearing mechanism and a working method thereof. The wet tissue outer packing double-station synchronous heat seal shearing mechanism comprises a machine frame, wherein the machine frame is transversely provided with a group of flattening and conveying devices which are used for conveying strip-shaped wet tissueraw materials and clamping the strip-shaped wet tissue raw materials up and down, a transition conveying device is further arranged at the discharge ports of the flattening and conveying devices, andthe two ends of the transition conveying device are provided with two groups of double-heat seal head shearing devices which are synchronously meshed with the wet strip-shaped tissue raw materials and are matched with the strip-shaped wet tissue raw materials. The wet tissue outer packing double-station synchronous heat seal shearing mechanism is simple in structure, convenient to adjust and operate, and high in flexibility, and improves the heat sealing quality and has practicability.

Owner:FUZHOU UNIV

Hot sealing device of bag making machine

ActiveCN104149392AImprove heat sealing efficiencySimple and efficient operationBox making operationsPaper-makingEngineeringMechanical engineering

The invention relates to a hot sealing device of a bag making machine. The hot sealing device comprises an upper pressing plate structure and a hot sealing plate structure which are arranged vertically, the upper pressing plate structure comprises a pressing plate supporting body, the lower surface of the pressing plate supporting body is fixedly connected with a pressing plate set, and the upper surface of the pressing plate supporting body is fixedly connected with a mounting block. The hot sealing plate structure comprises a hot sealing plate supporting body, the upper surface of the hot sealing plate supporting body is fixedly connected with a hot sealing plate through a mounting plate, second end blocks are arranged at the two ends of the hot sealing plate supporting body in a packaging body, and a second adjusting rod is connected in the second end blocks at the two ends of the hot sealing plate supporting body and the hot sealing plate supporting body in a penetrating mode. The pressing plate structure and the hot sealing plate structure are adopted to improve the hot sealing efficiency. Vertical adjusting screw rods and horizontal adjusting rods are arranged to adjust the hot sealing strength and the hot sealing position conveniently, and the device is easy and convenient to adjust. The pressing plate and the pressing plate supporting body are connected through a spring, elastic hot sealing is achieved, the spring is hidden in the pressing plate supporting body, and the device is compact in structure. The adjusting rods are arranged in the hot sealing plate structure to adjust the hot sealing position conveniently, and the device is easy and convenient to adjust.

Owner:浙江恩特包装新材料股份有限公司

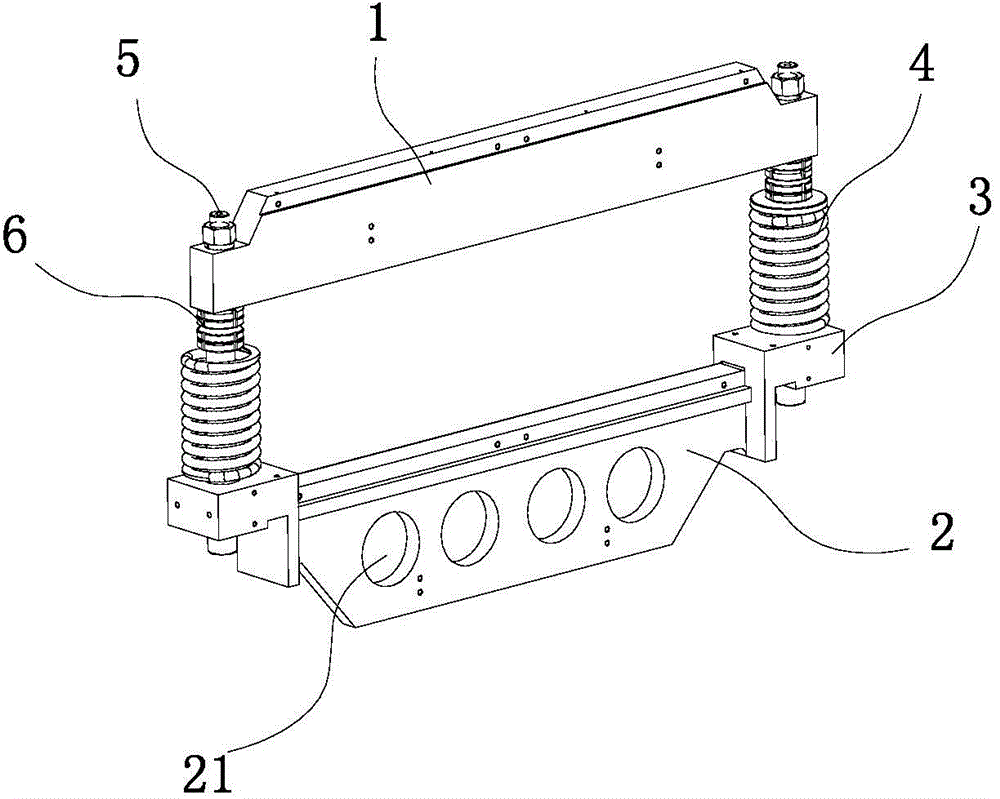

Upper pressure plate structure for heat sealing device of bag making machine

The invention relates to an upper pressure plate structure for a heat sealing device of a bag making machine. The upper pressure plate structure comprises a pressure plate support body, wherein the lower surface of the pressure plate support body is fixedly connected to a pressure plate group, and the upper surface of the pressure plate support body is fixedly connected to an installation block; the pressure plate support body is provided with a downward groove, first support blocks and second support blocks, which are arranged in pairs, are formed in the groove, and the paired second support blocks are arranged between the paired first support blocks; end blocks are respectively packaged on the two ends of the pressure plate support body, and each end block is provided with a locking regulating wheel; a regulating rod penetrates the end blocks and the pressure plate support body, gears are respectively arranged on two ends of the regulating rod, and each gear is arranged on the outer side of the corresponding end block. According to the upper pressure plate, by adopting the two groups of pressure plate structures, the heat sealing efficiency is improved; through setting an adjusting screw and the regulating rod, the heat sealing intensity and the heat sealing position are conveniently adjusted, and the operation is simple; the pressure plate and the pressure plate support body are connected through a spring, so that the elastic heat sealing is achieved, the spring is hidden in the pressure plate support body, and the structure is compact; the pressure plate has the advantages of simple structure and convenience for assembly.

Owner:佛山市丰彩世家包装实业有限公司

Heat sealing device for food packaging machine

InactiveCN111891493ASimple structureEasy to operateWrapper twisting/gatheringThermodynamicsEngineering

The invention discloses a heat sealing device for a food packaging machine in the technical field of food packaging. The heat sealing device comprises a heat sealing box main body, one side of the outer surface of the heat sealing box main body is provided with a feed port, the other side of the outer surface of the heat sealing box main body is provided with a discharge port, and the bottom of the inner cavity of the heat sealing box main body is fixedly connected with a base; a fixing box is fixedly connected to the top of the base, a heat sealing groove is formed in the top of the outer surface of the fixing box, a heat sealing plate is fixedly connected to the side, close to the heat sealing groove, of the top of the outer surface of the fixing box, and a heat sealing cutter is movablyconnected to the other side, close to the heat sealing groove, of the top of the outer surface of the fixing box. One side of an inner cavity of the fixing box is fixedly connected with a third electric telescopic rod and an infrared sensor, the infrared sensor is located on the lower side of the third electric telescopic rod, the heat sealing device for the food packaging machine is simple in structure and convenient to operate, and the heat sealing efficiency of food bags is improved.

Owner:广西天品科技有限公司

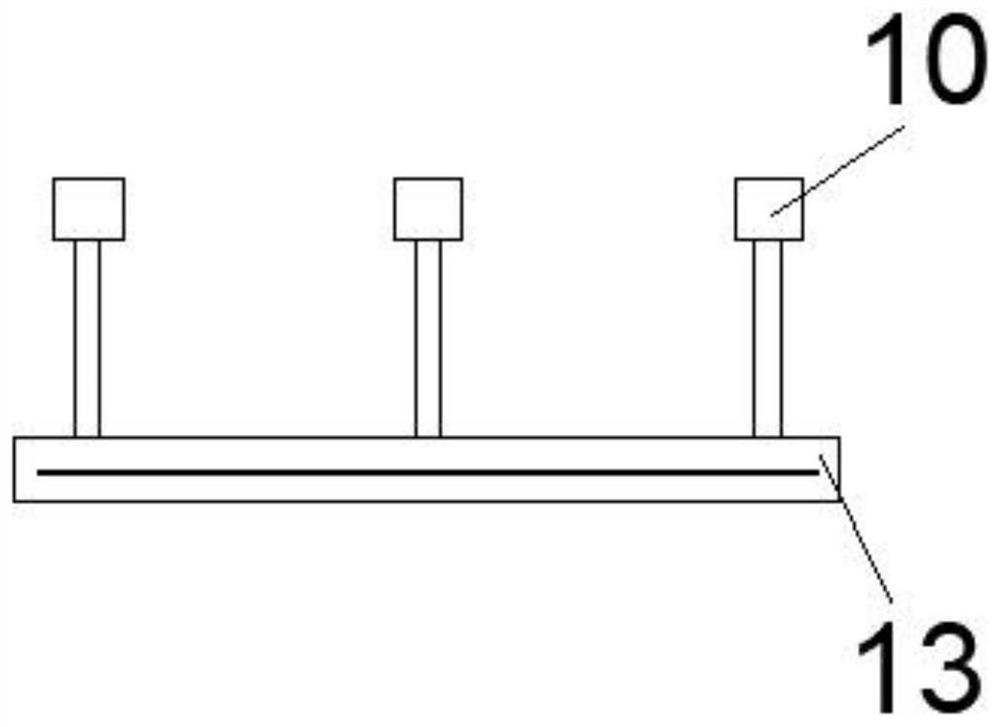

Modified casting polypropylene film, easy-to-tear PET-AL-CPP medicine packaging composite film and packaging bag

InactiveCN111730946AImprove brittlenessEasy to tear offSynthetic resin layered productsPharmaceutical containersPolymer scienceComposite film

The invention discloses a modified casting polypropylene film and an easy-to-tear PET-AL-CPP composite film. The problem that the existing PET-AL-CPP composite film has good CPP toughness and is not easy to tear open after being made into a soft packaging bag for packaging liquid drugs, and the tearing linearity is poor, which is easy to cause splashing or side leakage of liquid drugs is solved. The modified casting polypropylene is used in a medicine packaging composite film and comprises a polypropylene inner layer and a polypropylene outer layer, wherein the polypropylene outer layer is a layer bonded with an adhesive, the polypropylene inner layer is a heat sealing layer, phenolic resin is added into the polypropylene outer layer, and a silicon dioxide coated aluminum oxide nano material is added into the polypropylene inner layer. The packaging film has the advantages of being good in comprehensive performance, easy to tear, good in linear easy-to-tear performance and the like.

Owner:SICHUAN HUILI IND

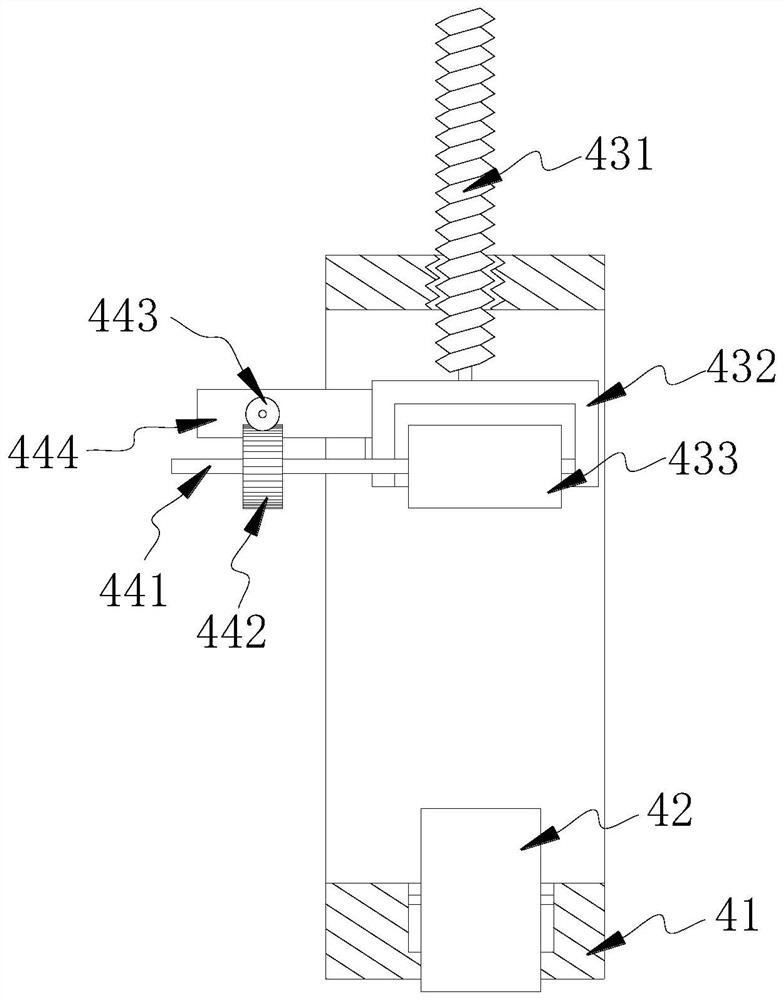

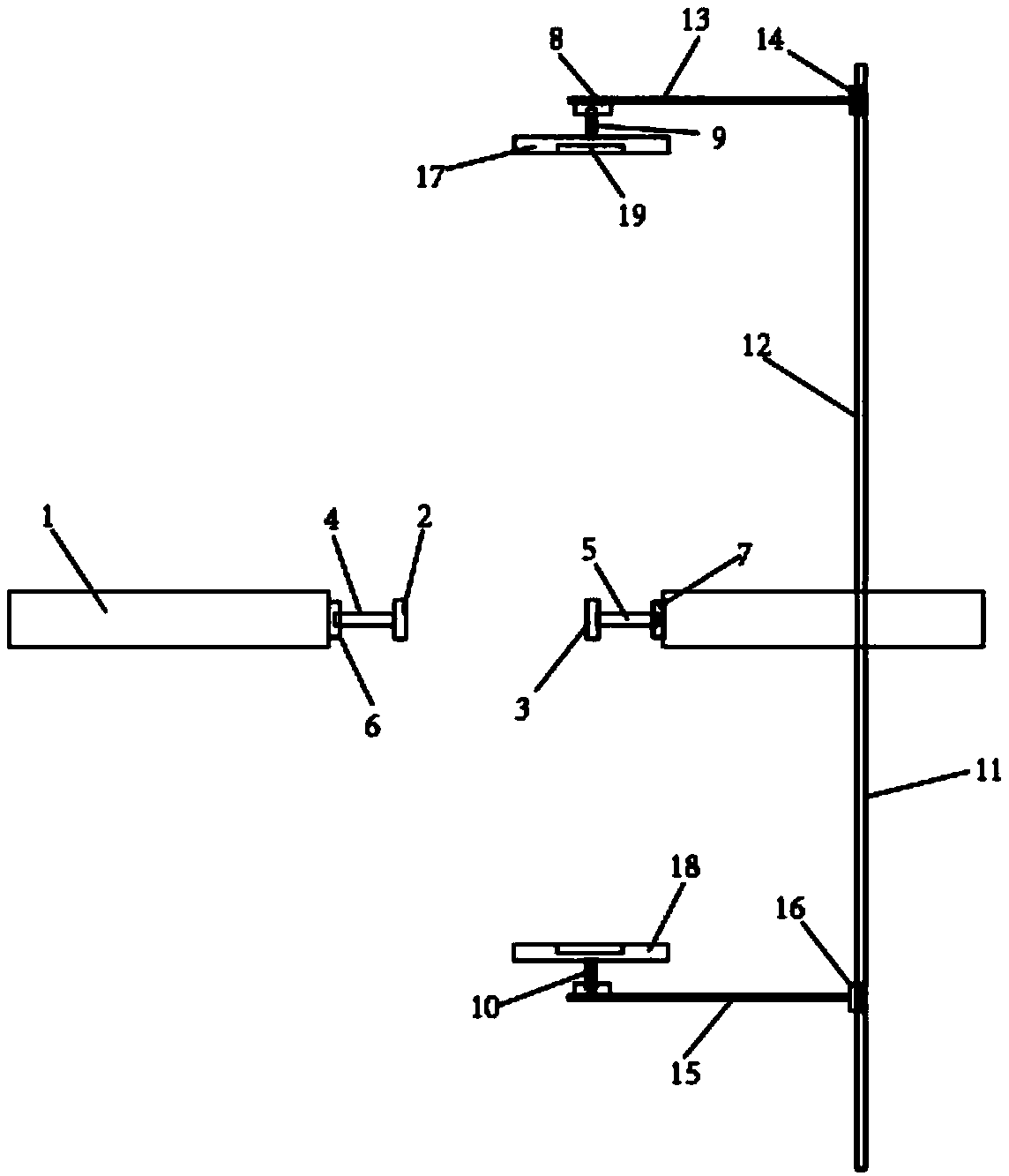

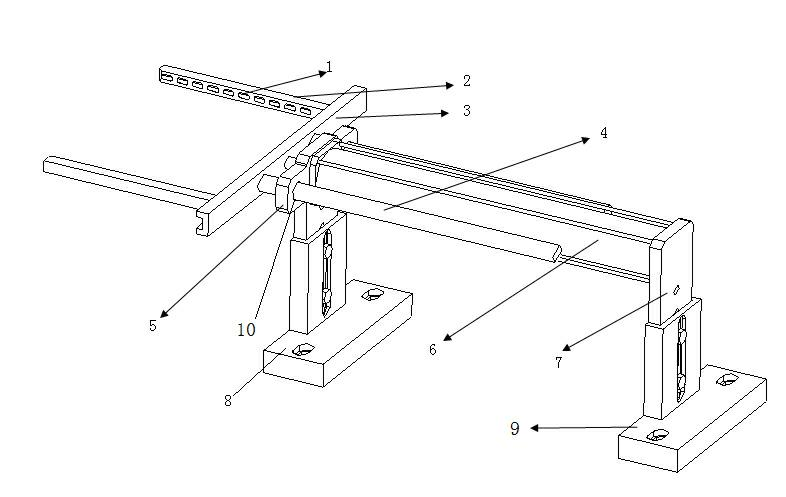

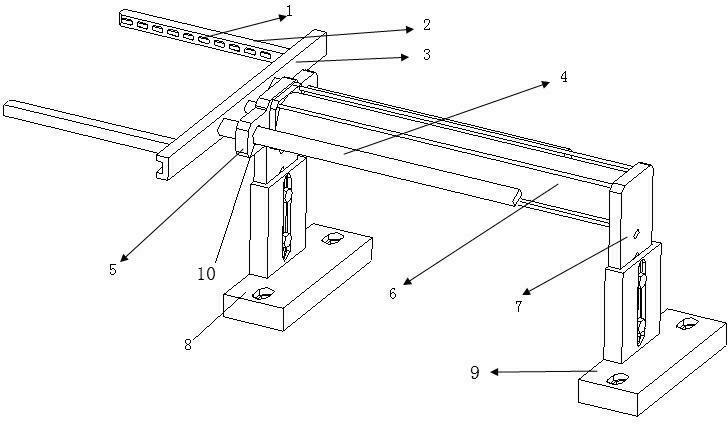

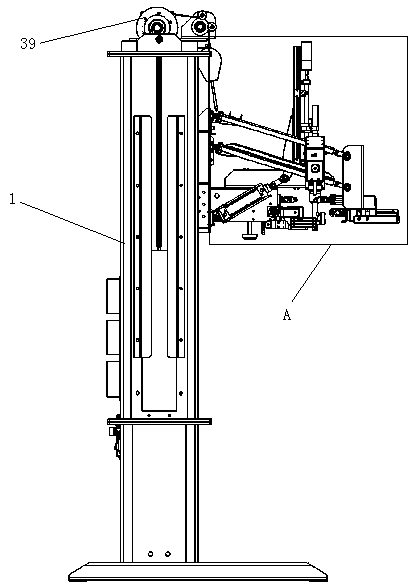

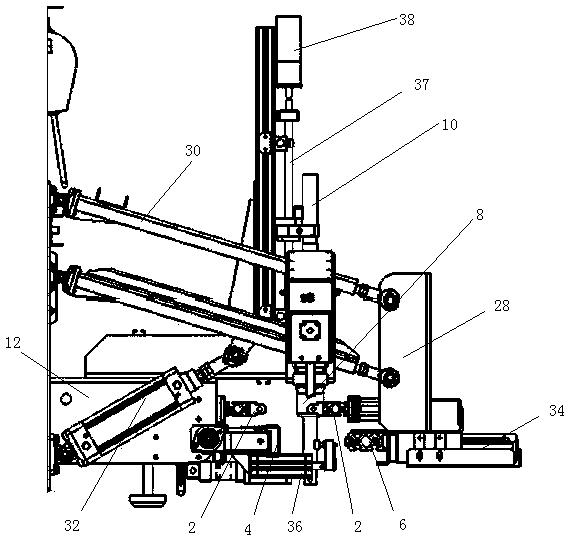

Wiring auxiliary device for wire and cable

ActiveCN112186658BReduce labor costsEasy to fold lineApparatus for joining/termination cablesHeat sealerSeat belt

The invention belongs to the technical field of wire and cable wiring assistance, in particular to a wiring auxiliary device for wires and cables, including a bottom plate, an assembly mechanism is fixedly connected to the top of the bottom plate, a cable is arranged inside the assembly mechanism, and one side of the assembly mechanism is fixed It is connected with a rotating mechanism, and the top of the bottom plate is fixedly connected with a heat-sealing mechanism. The driving wheel drives the sheave to do intermittent movement through the lever, and the sheave drives the transmission rod to rotate through the rotating rod, thereby driving the transmission rod to rotate at a fixed angle, so that the first The rotating plate on the second support plate rotates, thereby through the limit of the limit rod, the second placement seat drives the cable to bend, the fixed rod fixes the rotating plate on the first supporting plate, and the two rotating plates rotate mutually , so as to facilitate the folding line operation of the device, the operation is simple, the rotation is fixed at an angle, the efficiency of the folding line operation of the device is improved, and the labor cost of the folding line operation is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

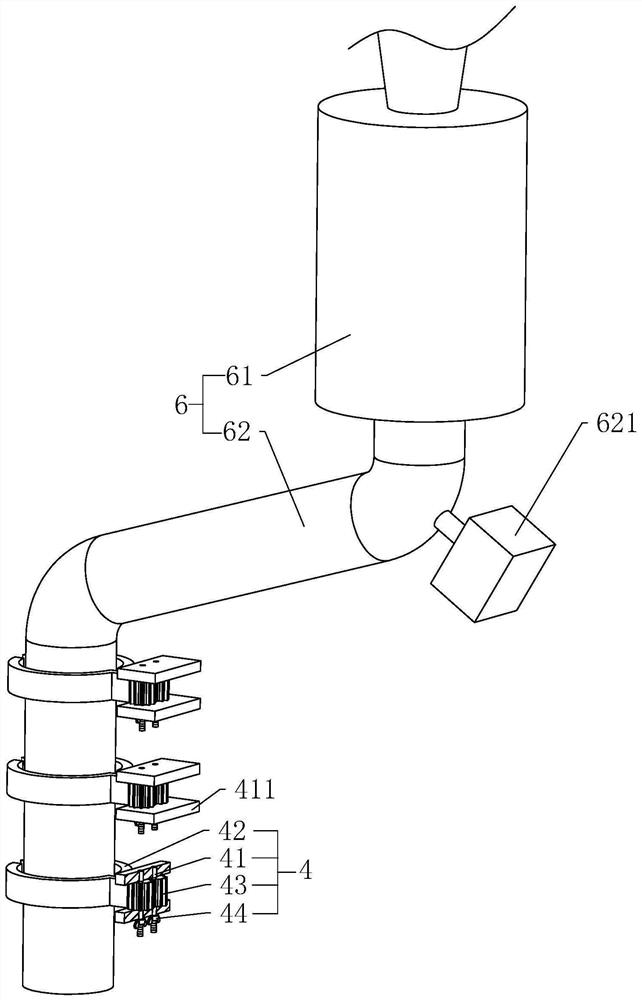

Full-automatic tea and coffee filtering and sealing integrated packaging equipment

ActiveCN114275250APrecise deliveryImprove heat sealing efficiencyWrapper twisting/gatheringPackaging automatic controlEngineeringPaper cup

The invention relates to the technical field of tea packaging, and discloses full-automatic tea and coffee filtering and sealing integrated packaging equipment which comprises an equipment main body, a collecting device, a heat sealing assembly and a cup placing device, the collecting device is installed at the top of the equipment main body, and the collecting device comprises an installation carrier; limiting columns are evenly distributed on the top of the installation carrier, limiting pieces are arranged at the bottoms of the limiting columns, a fixing plate is installed on the tops of the limiting columns, strip-shaped fixing blocks are symmetrically arranged on the two sides of the fixing plate, material taking plates in the strip-shaped fixing blocks are pulled out, arc-shaped grooves are aligned with the limiting pieces, and the limiting pieces are forcibly extruded to move upwards. A convex ring in a limiting piece is separated from an annular groove of a limiting column, at the moment, all cups in a second receiving hole can be upwards moved to the position of a first discharging hole at a time, and another operator quickly takes out the paper cups moving to the position of the first discharging hole; therefore, the situation that an operator needs to take out the paper cups one by one by holding the paper cups with hands from the limiting columns is avoided, and the cup taking efficiency is greatly improved.

Owner:东莞市立茗机械有限公司

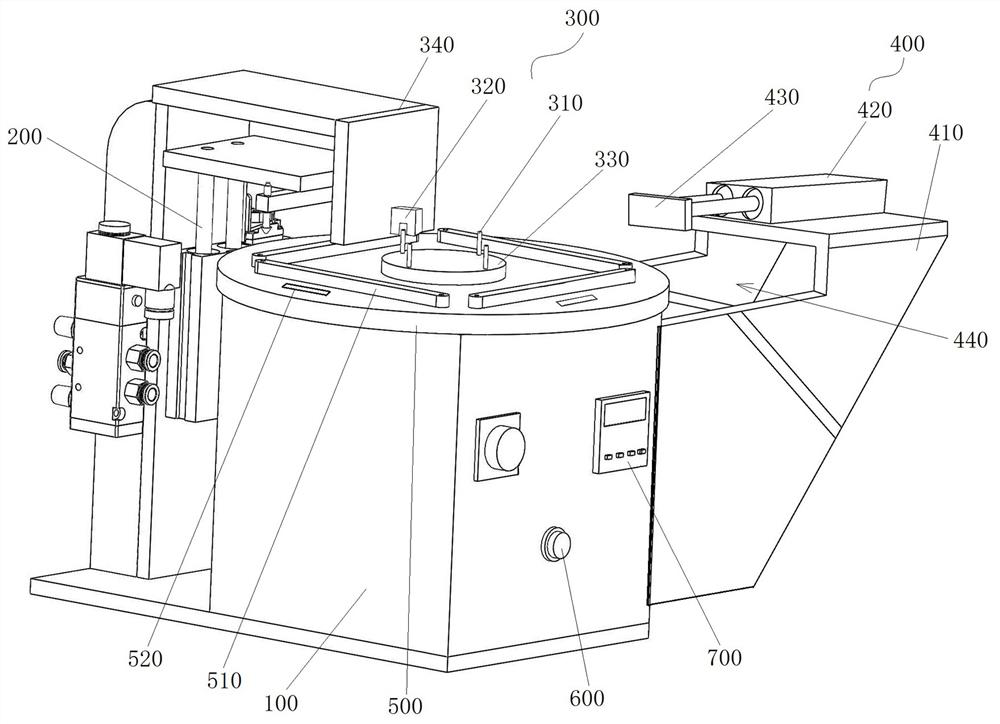

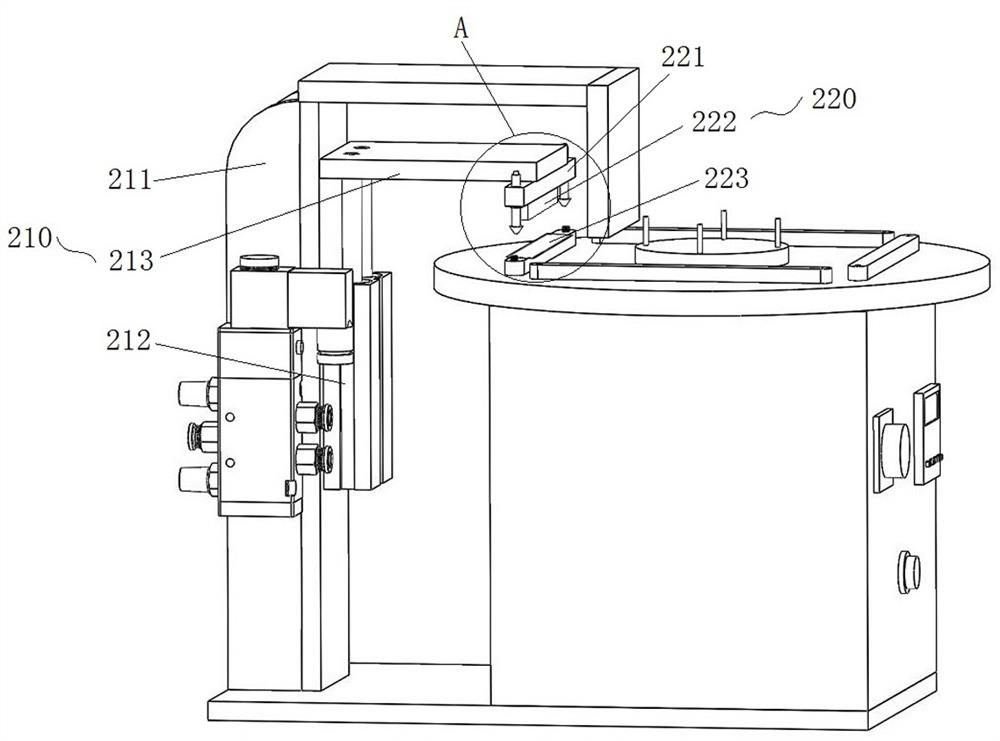

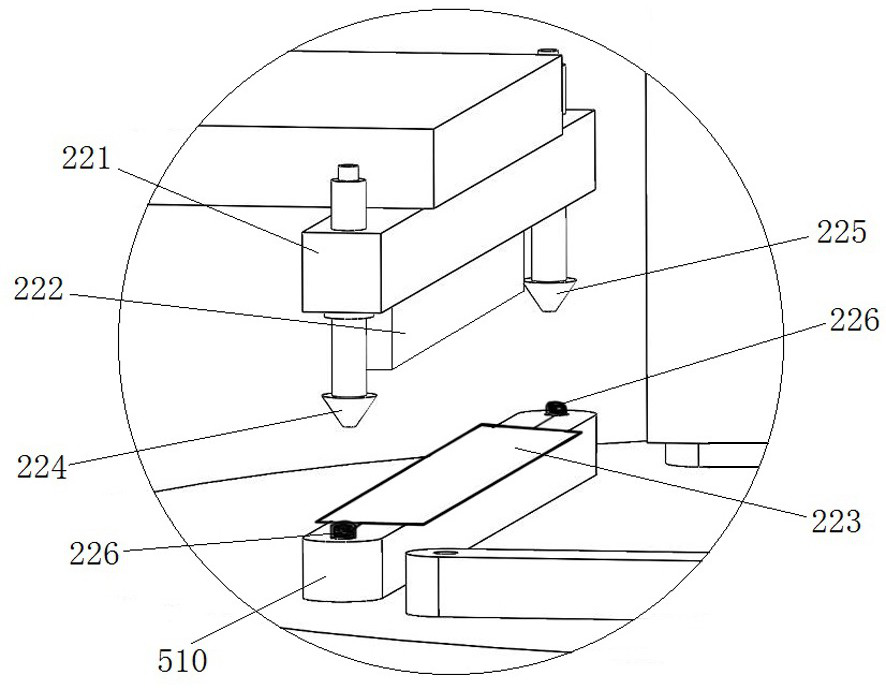

Automatic Heat Sealing Equipment

The invention discloses an automatic heat-sealing device, which comprises a safety module, the safety module includes a protective frame; a welding module, the welding module heat-presses and seals the parts to be sealed, the welding module is connected with the protective frame, and the welding module includes a sealing knife assembly, a heating The heat preservation component and the pressurization component, the sealing knife component is connected with the heating and heat preservation object and the pressure component is set on both sides of the sealing knife component; the rotating platform module, the parts to be sealed are placed on the rotating platform module, and the rotating platform module transports the parts to be sealed to the welding position The rotary platform module includes a rotary table and a rotary power device, and the rotary power device drives the rotary table to rotate; a positioning module, the position of the to-be-sealed item is determined according to the positioning module, and the positioning module includes a locator, and the locator is fixed on the protective frame. The invention can automatically heat-press seal the sealed parts, reduce labor intensity and improve heat-sealing efficiency, and the equipment adopts modular design, compact structure, easy installation and disassembly, and convenient maintenance.

Owner:SUZHOU XINDALU PLASTIC HARDWARE IND

Heat sealing device of bag making machine

ActiveCN104149392BEasy to adjustImprove heat sealing efficiencyPaper-makingBox making operationsMechanical engineeringEngineering

The invention relates to a hot sealing device of a bag making machine. The hot sealing device comprises an upper pressing plate structure and a hot sealing plate structure which are arranged vertically, the upper pressing plate structure comprises a pressing plate supporting body, the lower surface of the pressing plate supporting body is fixedly connected with a pressing plate set, and the upper surface of the pressing plate supporting body is fixedly connected with a mounting block. The hot sealing plate structure comprises a hot sealing plate supporting body, the upper surface of the hot sealing plate supporting body is fixedly connected with a hot sealing plate through a mounting plate, second end blocks are arranged at the two ends of the hot sealing plate supporting body in a packaging body, and a second adjusting rod is connected in the second end blocks at the two ends of the hot sealing plate supporting body and the hot sealing plate supporting body in a penetrating mode. The pressing plate structure and the hot sealing plate structure are adopted to improve the hot sealing efficiency. Vertical adjusting screw rods and horizontal adjusting rods are arranged to adjust the hot sealing strength and the hot sealing position conveniently, and the device is easy and convenient to adjust. The pressing plate and the pressing plate supporting body are connected through a spring, elastic hot sealing is achieved, the spring is hidden in the pressing plate supporting body, and the device is compact in structure. The adjusting rods are arranged in the hot sealing plate structure to adjust the hot sealing position conveniently, and the device is easy and convenient to adjust.

Owner:浙江恩特包装新材料股份有限公司

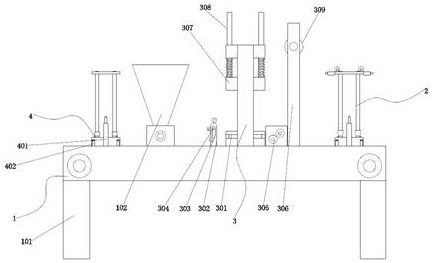

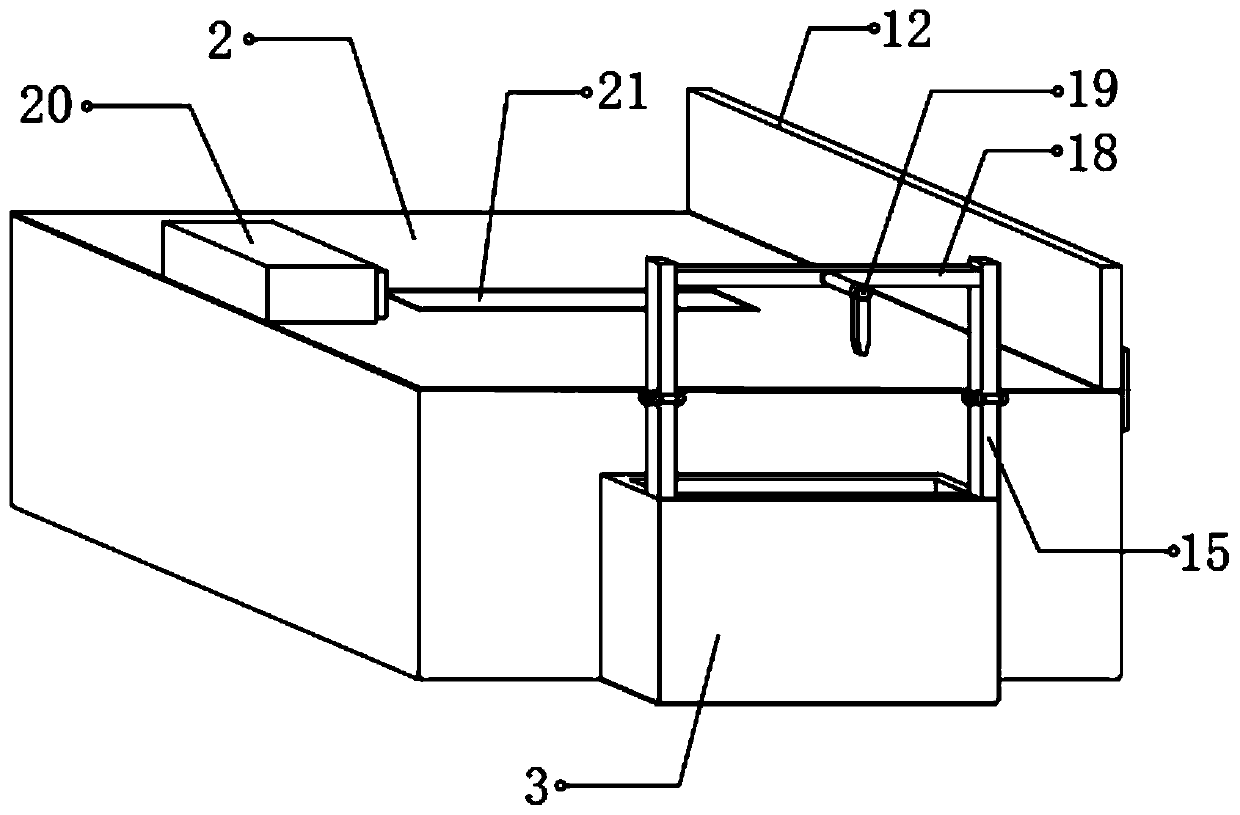

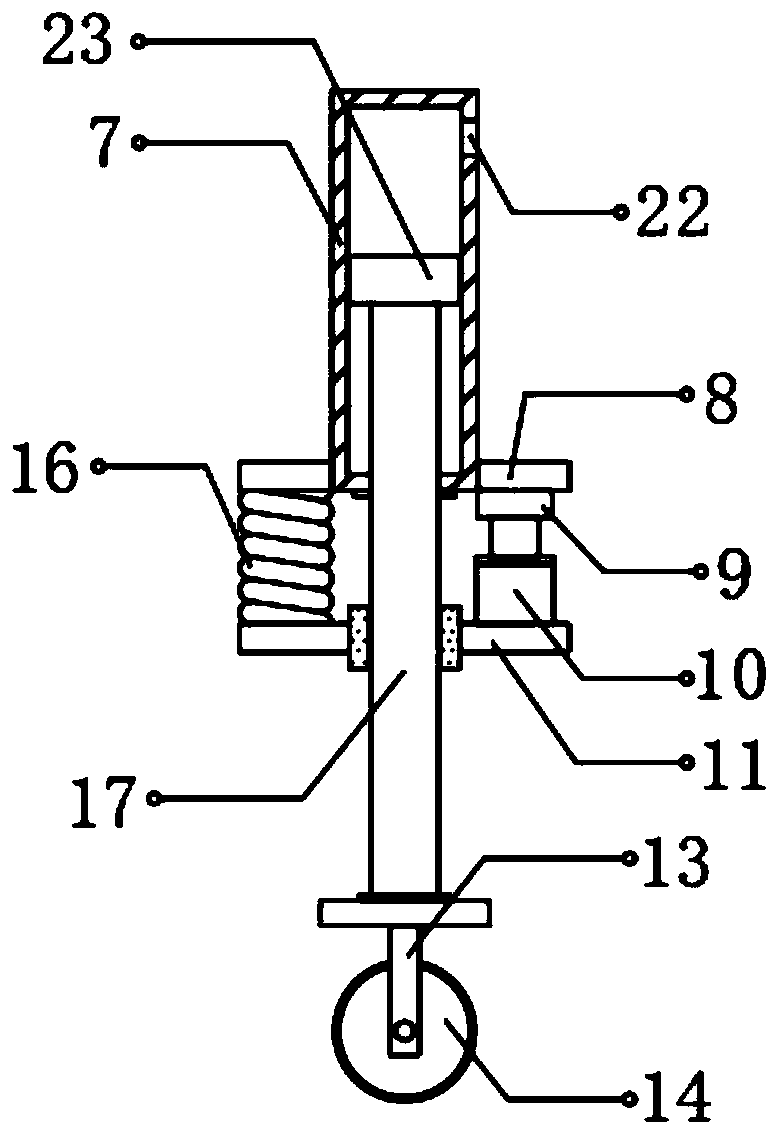

Finishing and packaging heat seal equipment

InactiveCN109878830AControllable job speedImprove heat sealing efficiencyWrapper twisting/gatheringEngineeringSpeed regulator

The invention provides finishing and packaging heat seal equipment. The equipment comprises a fixing device, a heat seal device, a rotary device and an adjusting device, wherein the adjusting device is arranged on the fixing device, the heat seal device is connected with the adjusting device, the rotary device comprises a rotary motor, a rotary shaft and a speed regulator, the rotary motor is arranged on the adjusting device, an output shaft of the rotary motor is connected with the rotary shaft, the other end of the rotary shaft is connected with the heat seal device, and the speed regulatoris arranged on the rotary shaft. The equipment has the advantages that a to-be-heat sealed object is fixed to the packaging device, cooperative telescopic clamping of a clamping air cylinder and a connecting member is adopted by the fixing device, so that the device can adapt to the to-be-heat sealed object with different transverse size, and therefore the application range of the device is improved.

Owner:TIANJIN HAIJING PLASTIC PROD

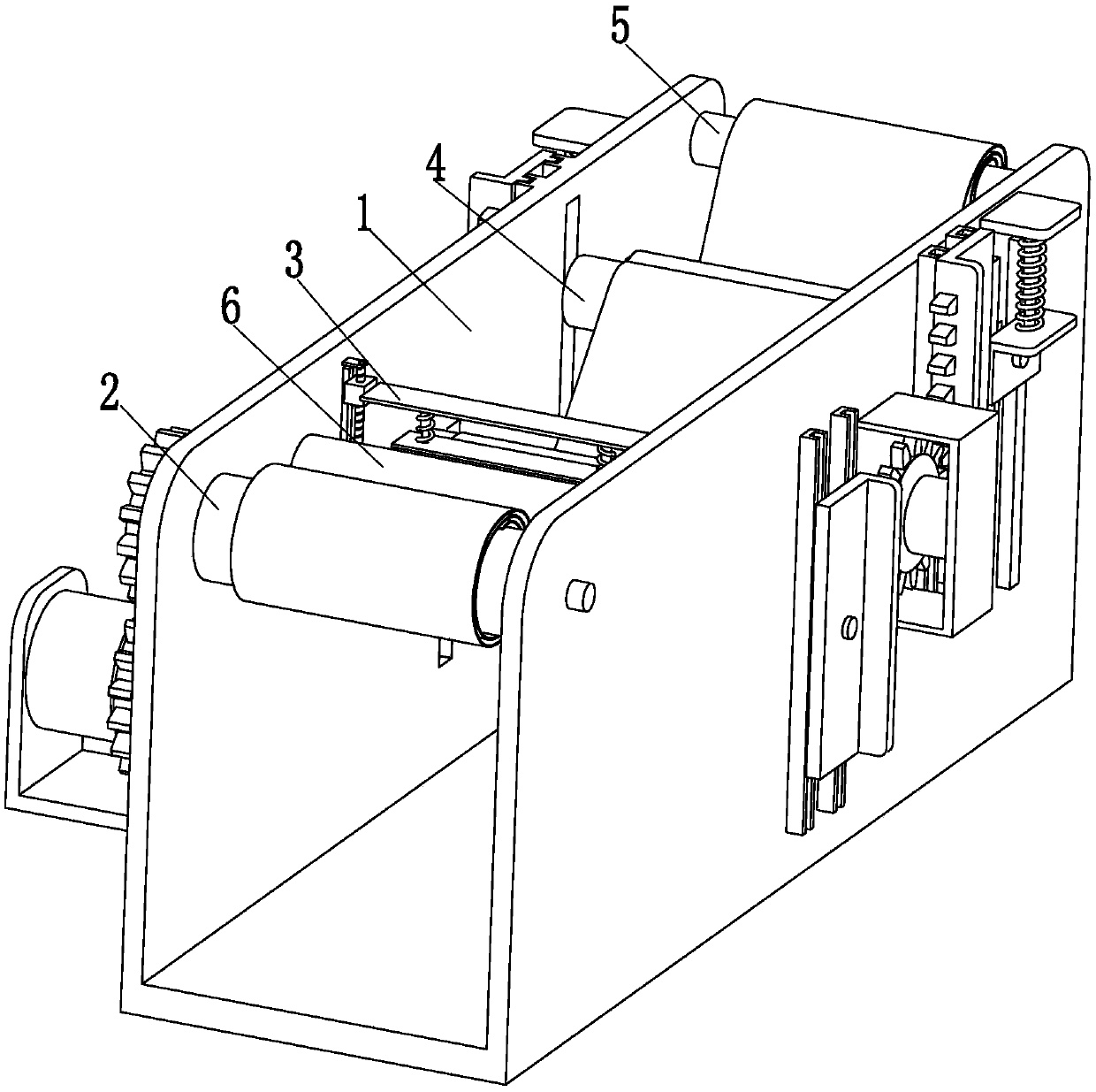

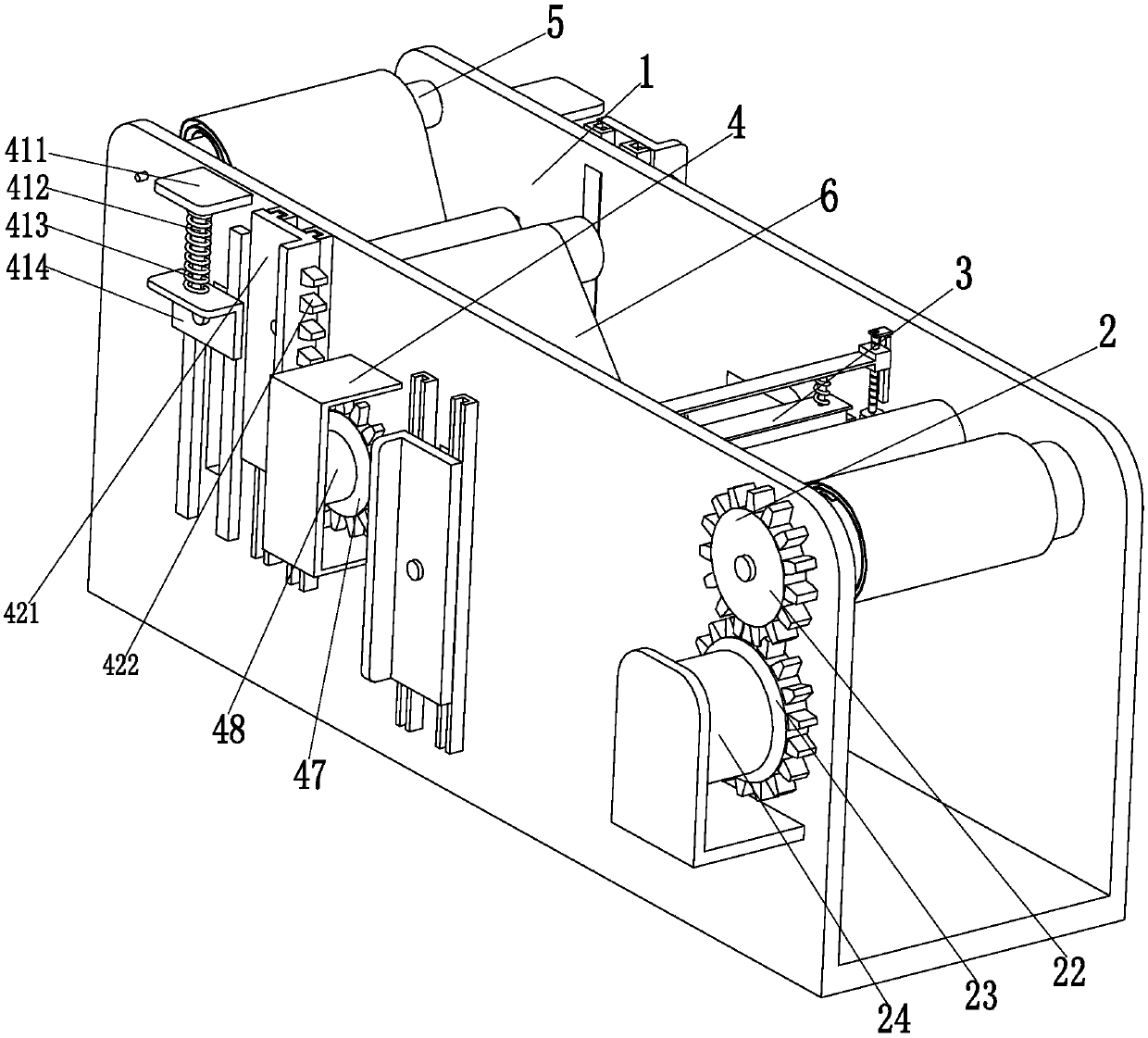

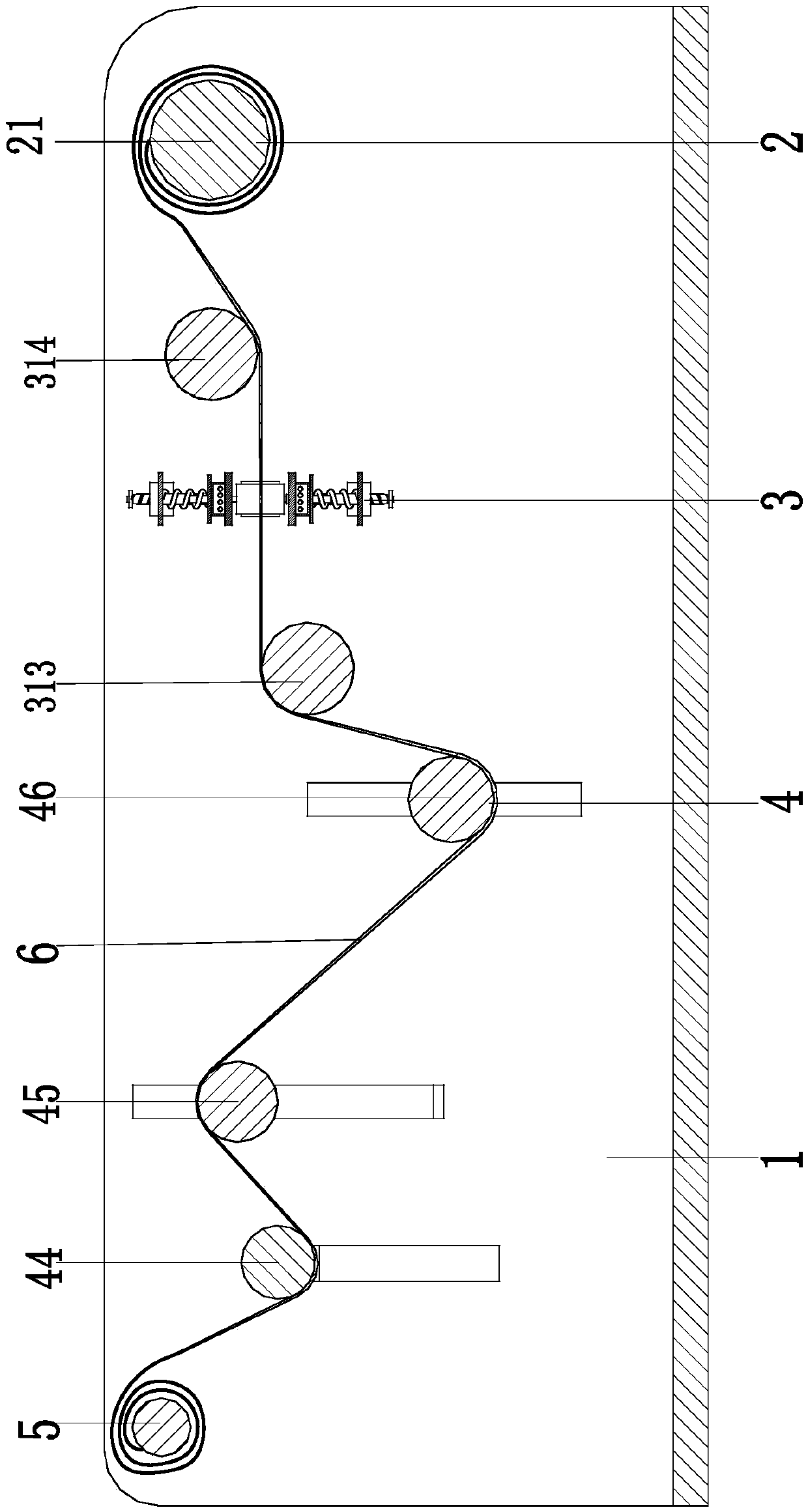

A heat-sealing device for high-density polyethylene medical dialysis paper

ActiveCN107187107BSolve uneven heat sealingImprove heat sealing efficiencyBag making operationsPaper-makingEngineeringMechanical engineering

The invention relates to a high-efficiency heat sealing device used for high-density polyethylene medical dialyzing paper. The high-efficiency heat sealing device used for the high-density polyethylene medical dialyzing paper comprises a working frame which is sequentially provided with a winding device, a heat sealing device, a tensioning device and a winding roller from front to back; the winding roller is wound with a dialyzing paper body; the dialyzing paper body sequentially penetrates through the winding roller, the tensioning device, the heat sealing device and the winding device from back to front; and the winding device, the heat sealing device and the tensioning device are matched to be used for finishing the heat sealing process of the medical dialyzing paper. The problems that in an existing medial dialyzing paper heat sealing process, an existing heat sealing device is uneven in heat sealing, not accurate in heat sealing position, long in heat sealing consuming time, low in heat sealing efficiency and the like due to uneven conveying of the medial dialyzing paper are solved, the high-efficiency heat sealing function of the medical dialyzing paper can be achieved, uneven heat sealing caused by uneven conveying of the medical dialyzing paper is avoided, and the device has the advantages of being short in heat sealing consuming time, accurate in heat sealing position, high in heat sealing efficiency and the like.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

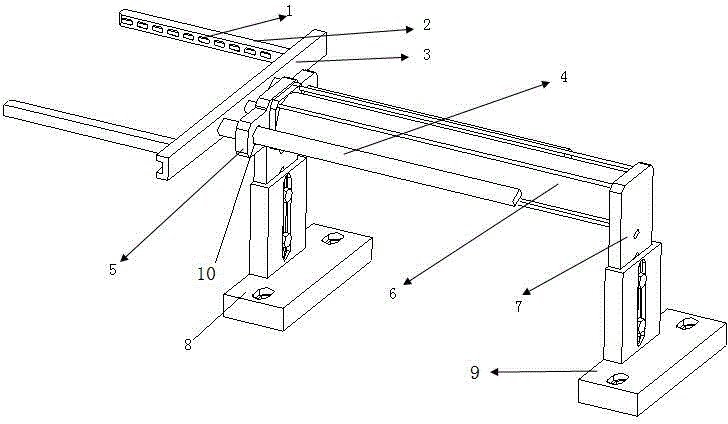

Novel pillow packaging machine transverse heat sealing mechanism and processing technology thereof

PendingCN111824519AImprove heat sealing efficiencyGood heat sealing performanceWrapper twisting/gatheringPackaging automatic controlHeat sealerElectric machinery

The invention discloses a novel pillow packaging machine transverse heat sealing mechanism and a processing technology thereof. Aiming at the problems that a heat sealing mechanism of existing pillowpackaging machines moves up and down to press and heat-seal a packaging bag, a bag opening of the packaging bag is liable to be damaged on one side, and the heat sealing effect is bad, by installing two sets of the same heat-sealing mechanism up and down side by side, a side plate base of the heat-sealing mechanism is provided with mounting grooves and mounting holes to cooperate with a bearing and a screw to be provided with a heat sealer, one end of the screw is provided with a meshing transmission gear and externally connected with a drive motor for rotation, heat sealing strips of the heatsealer simultaneously heat-seal both sides of a bag opening by synchronous and reverse rotation, the transmission gear rotates by a full turn, and the heat sealing strips can complete heat-sealing ofthe bag opening of the packaging bag. Through double-sided heat-sealing, the heat-sealing efficiency of the packaging bag is improved, the heat-sealing effect is also improved, the effect that the bag opening is heat-sealed firmly, does not separate easily and let packaged objects fall out, and the heat sealing mechanism is convenient and practical.

Owner:保定精诺自动化设备制造有限公司

Clamping die for heat sealing of lead acid storage battery case cover

InactiveCN102569909BEasy to processSimple structureFinal product manufactureCell component detailsElectrical batteryHot melt

Owner:JIANGSU LEOCH BATTERY

Delay type heat sealing auxiliary equipment for plastic packaging bag sealing

InactiveCN113044318AAvoid heat seal crackingExtension of timeWrapper twisting/gatheringPlastic packagingCrank

The invention relates to the technical field of plastic packaging bag sealing equipment, in particular to delay type heat sealing auxiliary equipment for plastic packaging bag sealing. The delay type heat sealing auxiliary equipment comprises a treatment table, a driving shaft is rotatably connected to the interior of the left side of the interior of the treatment table, and a movable sliding plate is connected to the exterior of the right end of the driving shaft in an engaged manner; and a crank connecting rod is hinged to the upper surface of the movable sliding plate, a pulling rope is fixedly connected to the rear surface of the crank connecting rod, and a positioning sliding plate is fixedly connected to the upper end of the pulling rope. The temperature of a heat sealing plate is controlled through a sliding rheostat, so that the temperature of the heat sealing plate cannot scald a packaging bag; and an extrusion transmission plate drives a transmission pressing plate at the right side to restore to the original position, at the moment, an extension spring is linearly restored, and then the heat sealing plate is restored, so that the heat sealing time is possibly well prolonged, the effect of improving the heat sealing efficiency of the equipment is achieved, the phenomenon of heat sealing cracking at the heat sealing position is avoided, and the heat sealing success rate of the equipment is improved.

Owner:褚红岗

Sealing and cutting structure, packaging mechanism and packaging device

ActiveCN111717480BImprove packaging effectImprove heat sealing efficiencyWrapper twisting/gatheringThermodynamicsHeat transfer efficiency

The invention discloses a sealing and cutting structure, a packaging mechanism and a packaging device, which drive the first bracket and the second bracket to move relative to each other, so that the first bracket and the second bracket are close to each other, ensuring that the first heat-sealing module and the second heat-sealing mold The groups are pressed together; then, the sealed packaging material is cut by a cutting piece to form an independent package. Since a buffer is provided between the first heat-sealing module and the first bracket, and / or between the second heat-sealing module and the second bracket, when the first heat-sealing module and the second heat-sealing module press When in place, the cushioning part acts as a buffer for the first heat-sealing module or the second heat-sealing module, ensuring that the heat-sealing edge of the package is straight and uniform, without defects such as warping, and improving the packaging effect of the packaging material. At the same time, this solution adopts buffer parts, cancels the silicone strips on the first heat-sealing module and the second heat-sealing module, improves the heat transfer efficiency on the heat-sealing module, improves the heat-sealing efficiency of the packaging material, and shortens the heat-sealing time .

Owner:GRG INTELLIGENT TECH SOLUTION CO LTD +1

A dual-station synchronous heat-sealing and shearing mechanism for wet tissue outer packaging and its working method

ActiveCN109606847BImprove heat sealing efficiencySimple structureWrapper twisting/gatheringPaper towelWet wipe

The invention provides a wet tissue outer packing double-station synchronous heat seal shearing mechanism and a working method thereof. The wet tissue outer packing double-station synchronous heat seal shearing mechanism comprises a machine frame, wherein the machine frame is transversely provided with a group of flattening and conveying devices which are used for conveying strip-shaped wet tissueraw materials and clamping the strip-shaped wet tissue raw materials up and down, a transition conveying device is further arranged at the discharge ports of the flattening and conveying devices, andthe two ends of the transition conveying device are provided with two groups of double-heat seal head shearing devices which are synchronously meshed with the wet strip-shaped tissue raw materials and are matched with the strip-shaped wet tissue raw materials. The wet tissue outer packing double-station synchronous heat seal shearing mechanism is simple in structure, convenient to adjust and operate, and high in flexibility, and improves the heat sealing quality and has practicability.

Owner:FUZHOU UNIV

Clamping die for heat sealing of lead acid storage battery case cover

InactiveCN102569909AEasy to processSimple structureFinal product manufactureCell component detailsEngineeringMechanical engineering

Owner:JIANGSU LEOCH BATTERY

A New Vacuum Chamber Structure of Packaging Machine

InactiveCN104163262BImprove efficiencyImprove heat sealing efficiencyWrapper twisting/gatheringPackaging under vacuum/special atmosphereAgricultural engineeringVacuum chamber

The invention discloses a vacuum chamber structure of a novel packaging machine. The vacuum chamber structure comprises a box body at the bottom and a vacuum chamber cover at the top. The inner portion of the vacuum chamber cover is connected with a rubber cushion plate through a first spring. The box body is provided with a pressurizing device corresponding to the rubber cushion plate. A heat-seal rod is arranged on the pressurizing device. An air inflation pipe opening is formed in the box body. The vacuum chamber structure is characterized in that the inner portion of the vacuum chamber cover is connected with a center rubber cushion plate through a second spring, a center pressurizing device corresponding to the center rubber cushion plate is arranged on the box body, a center heat-seal rod is arranged on the center pressurizing device, a first supporting column is arranged between the pressurizing device and the center pressurizing device, a first supporting plate is arranged on the first supporting column, a second supporting column is arranged on the other side of the center pressurizing device, and a second supporting plate is arranged on the second supporting column. Heat-seal efficiency is improved.

Owner:王君 +5

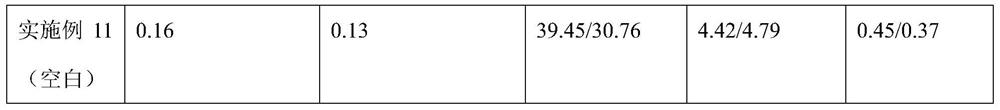

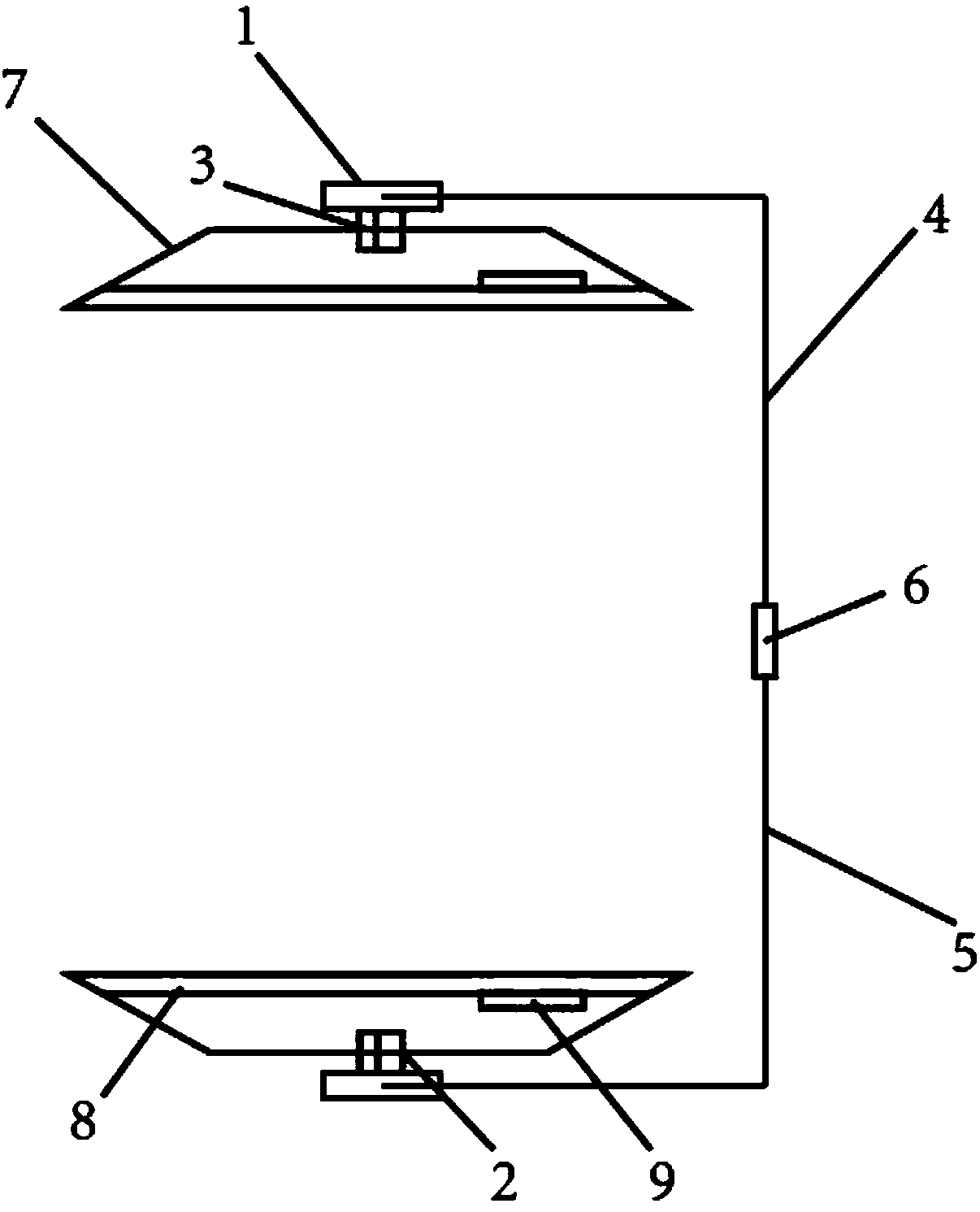

A vacuum heat sealing device for plastic bags

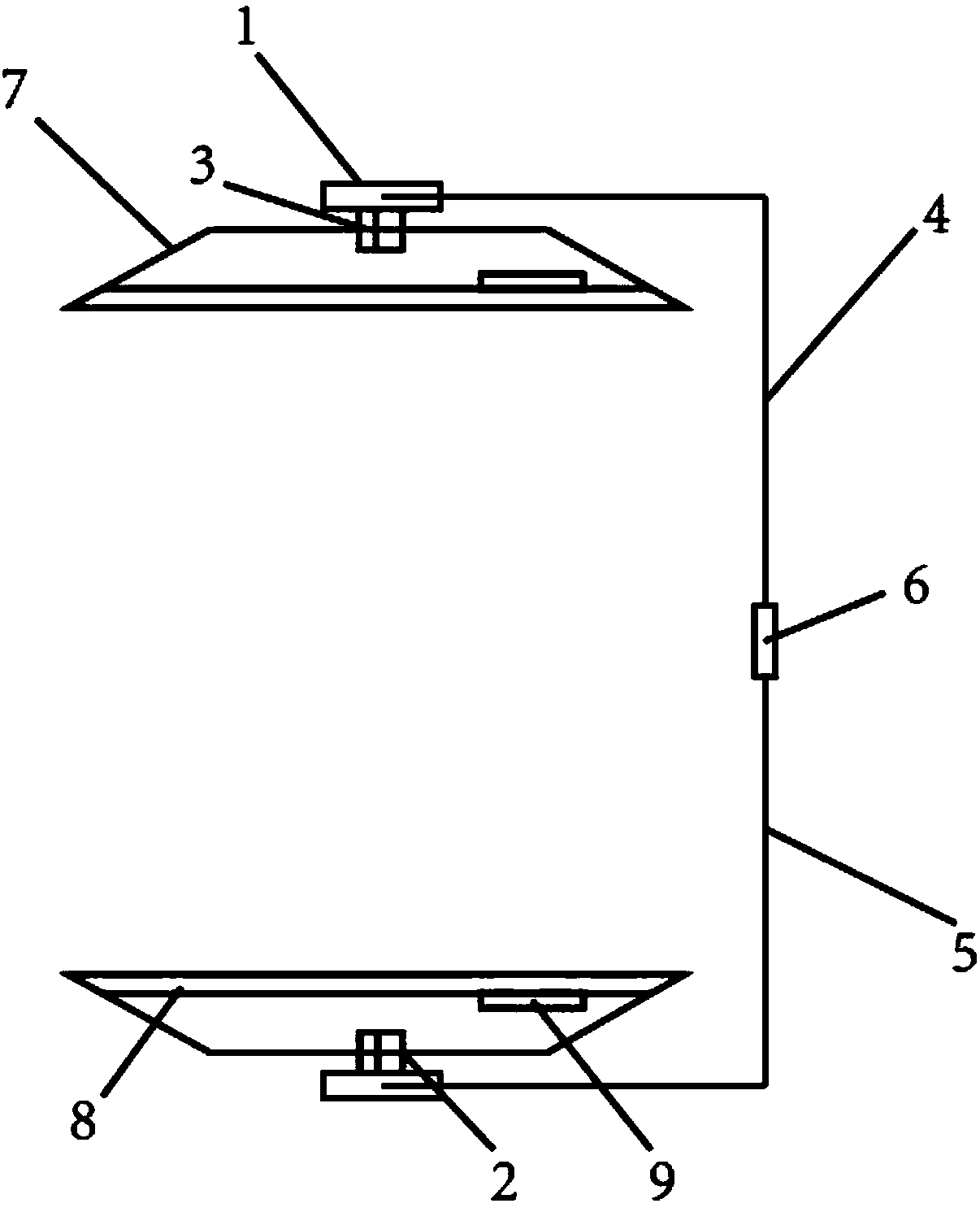

ActiveCN105711886BEasy to heat sealImprove heat sealing efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringVacuum tube

A vacuum sealing device capable of vacuuming and heat sealing a plastic bag comprises: a machine frame (1); at least one plastic bag fixation component arranged on the machine frame (1); a heat sealing bar (4) and a heat sealing press block (6) configured to heat seal a plastic bag, capable of moving horizontally in relation to each other, and arranged below the plastic bag fixation component; and a vacuum tube (10) arranged above the plastic bag fixation component and capable of extending into the plastic bag. By integrating the vacuum and heat sealing mechanisms, the device can create a vacuum in a plastic bag and then heat seal the same, increasing heat sealing efficiency, and is simple in structure and easy to operate.

Owner:JAINENG IND INTELLIGENT EQUIP KUNSHAN CO LTD

Heat sealing device for liquid laundry detergent production

InactiveCN110902047AClamping and fixing steps simplifiedImprove heat sealing efficiencyWrapper twisting/gatheringLiquid laundry detergentProcess engineering

The invention relates to a heat sealing device for liquid laundry detergent production; the heat sealing device comprises a base; a workbench is fixedly connected to one side of the top of the base, aresistance heater is arranged in the middle of the top of the workbench, a control box is fixedly connected to the other side of the top of the base, and a push rod motor is arranged at the top of the side, close to the workbench, of the control box. When the device is used, a packaging bag filled with materials is placed in a box body; the opening end faces upwards, one side of the packaging bagis attached to a rotating frame; the rotating frame is pressed to the workbench through a handle; the resistance heater is attached to the opening of the packaging bag; rollers are controlled to be in contact with the workbench; the push rod motor drives the rollers to roll on the workbench to press the portions, making contact with the resistance heater, of the packaging bags in a rolling mode,so heat sealing of the packaging bags is completed; at the moment, the heat-sealed packaging bags can be taken out by turning the rotating frame upwards through the handle; by using the heat sealing device, the clamping and fixing steps of the packaging bags are simplified, and the heat sealing efficiency of the packaging bags is improved.

Owner:株洲蓝海包装有限公司

Heat-seal plate mounting rack

InactiveCN105479811AConvenient centralized installationSimple structureBox making operationsPaper-makingMechanical engineeringEngineering

Owner:WUXI HENGSHENG MOTOR CO LTD

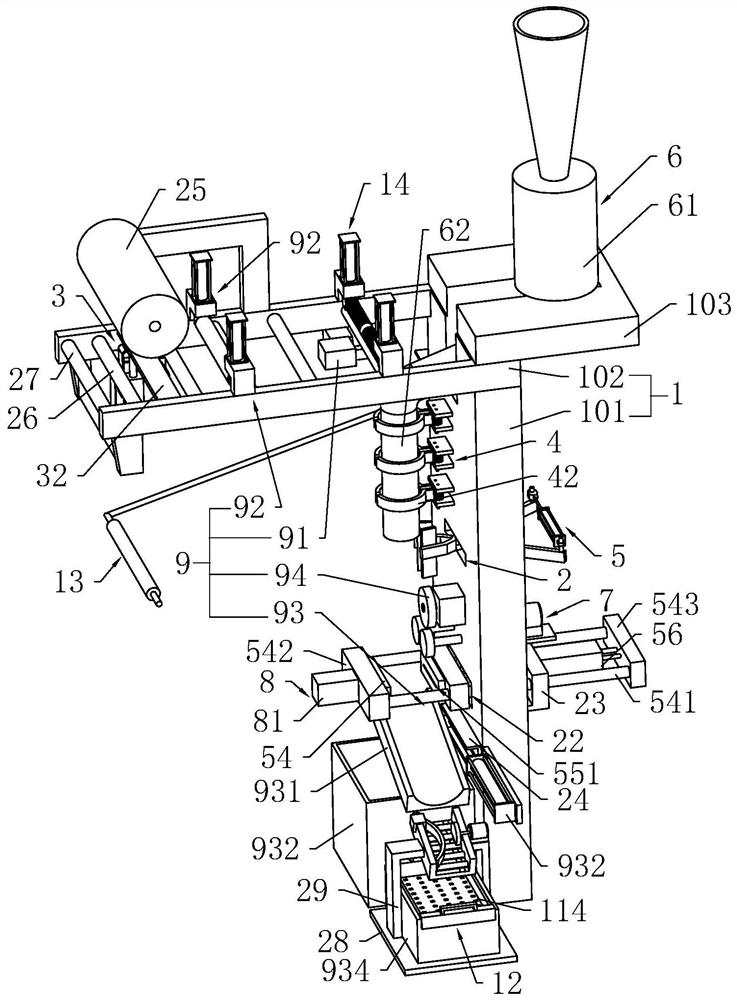

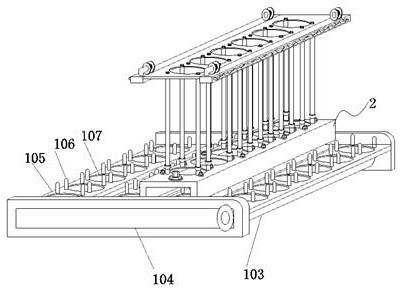

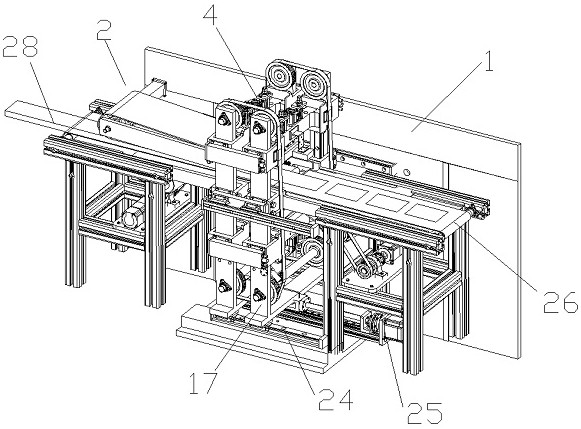

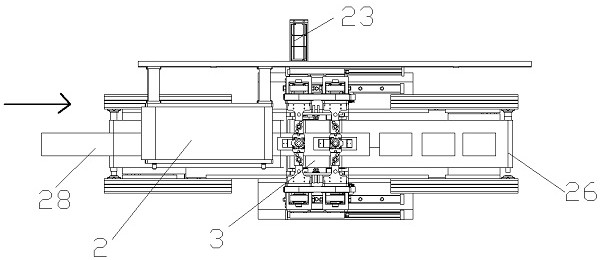

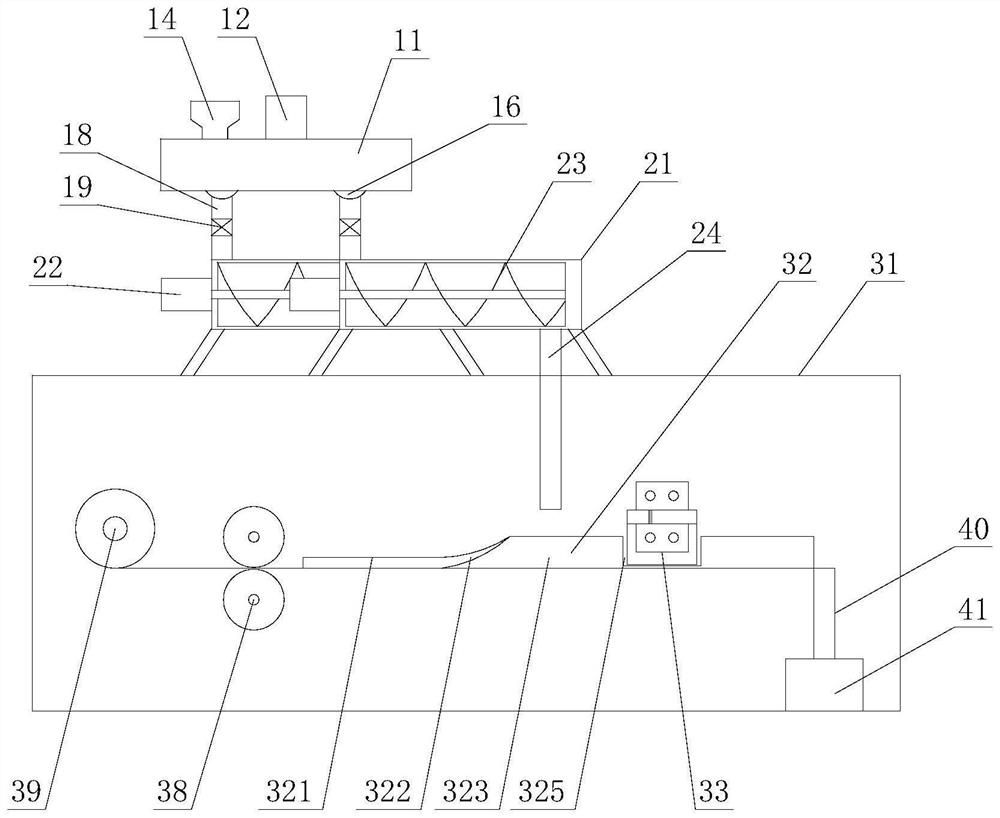

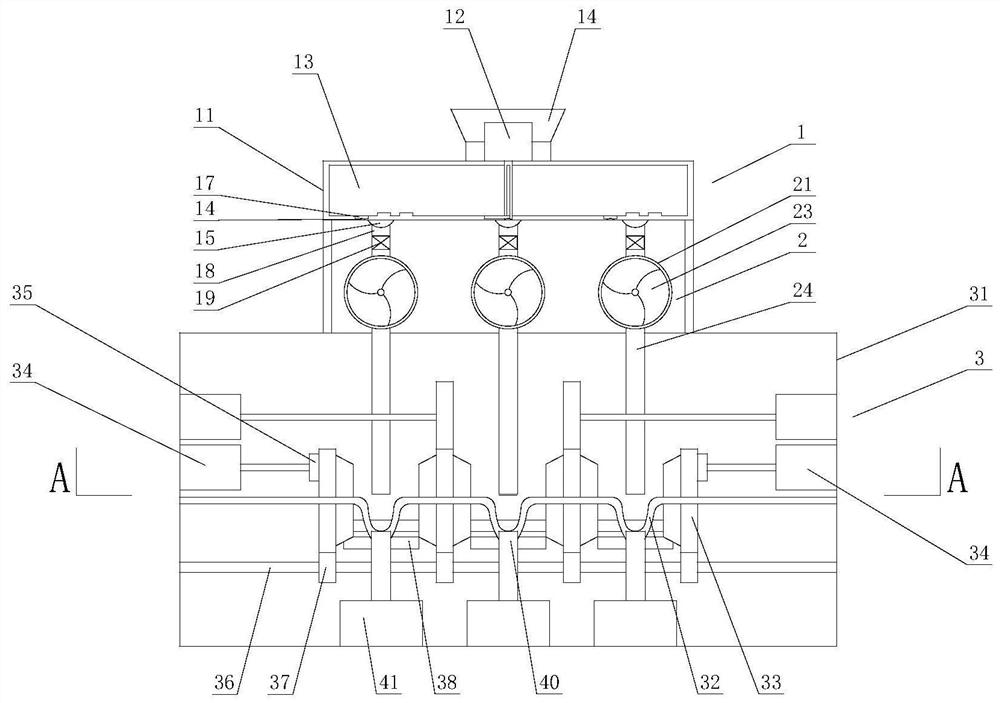

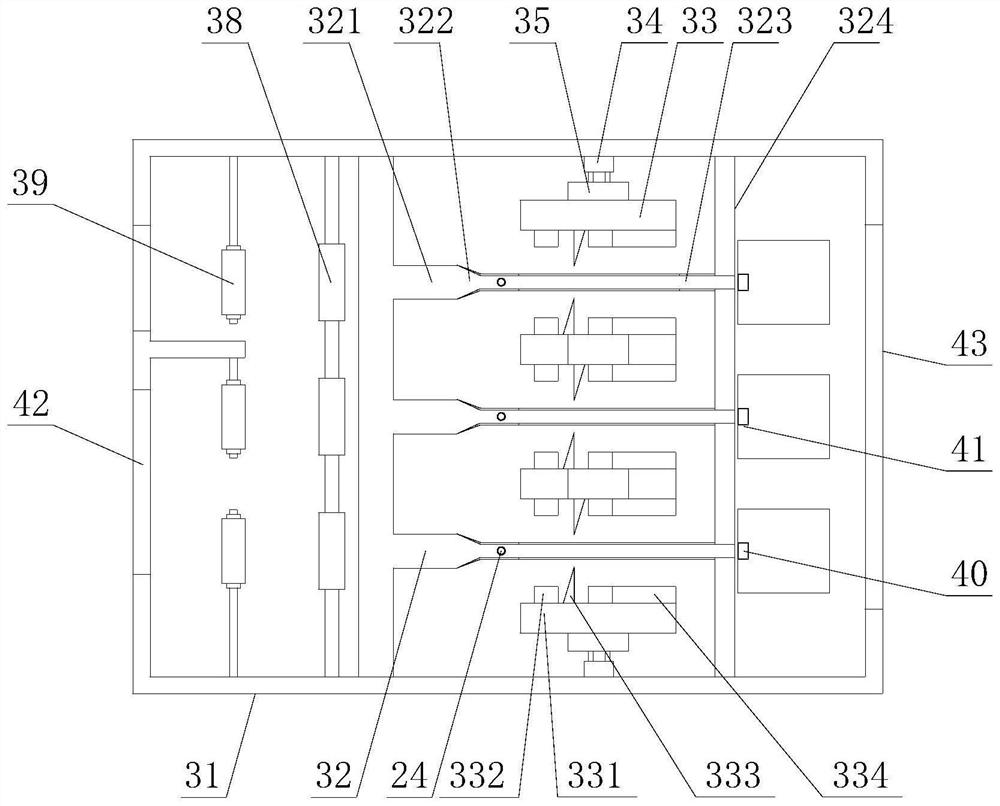

Deoxidizer heat-sealing packaging machine and packaging method

ActiveCN109264099BImprove heat sealing efficiencyReduce in quantityWrapper twisting/gatheringEngineeringPacking method

The invention relates to a desoxidant hot-sealing packing machine and a packing method thereof. The desoxidant hot-sealing packing machine comprises a feeding device, a conveying device and a hot-sealing device, wherein the feeding device comprises a feeding box, the feeding box is internally provided with a stirring paddle, the bottom of a stirring box is provided with a plurality of feeding channels, the lower portion of each feeding channel is connected with a conveying device, a conveying channel of each conveying device extends to the inner portion of the hot-sealing device; the inner portion of the hot-sealing device is provided with plastic package paper channels, hot-sealing shear plates and hot-sealing shear driving devices, the plastic package paper channels correspond to the conveying channels one to one, the hot-sealing shear plates and the plastic package paper channels are arranged at intervals, each hot-sealing shear plate is matched with the corresponding hot-sealing shear driving device, each plastic package paper channel enters the corresponding plastic package paper channel through a traction roller, and the rear ends of the plastic package paper channels are provided with discharging channels respectively. The desoxidant hot-sealing packing machine and the packing method thereof have the advantages that hot-sealing packing can be carried out on desoxidants on the plastic package paper channels simultaneously, the number of the hot-sealing shear plates can be reduced, the purpose of increasing hot-sealing speed is achieved, and the energy consumption required by the hot-sealing shear plates is reduced.

Owner:湖州精耕农机有限公司

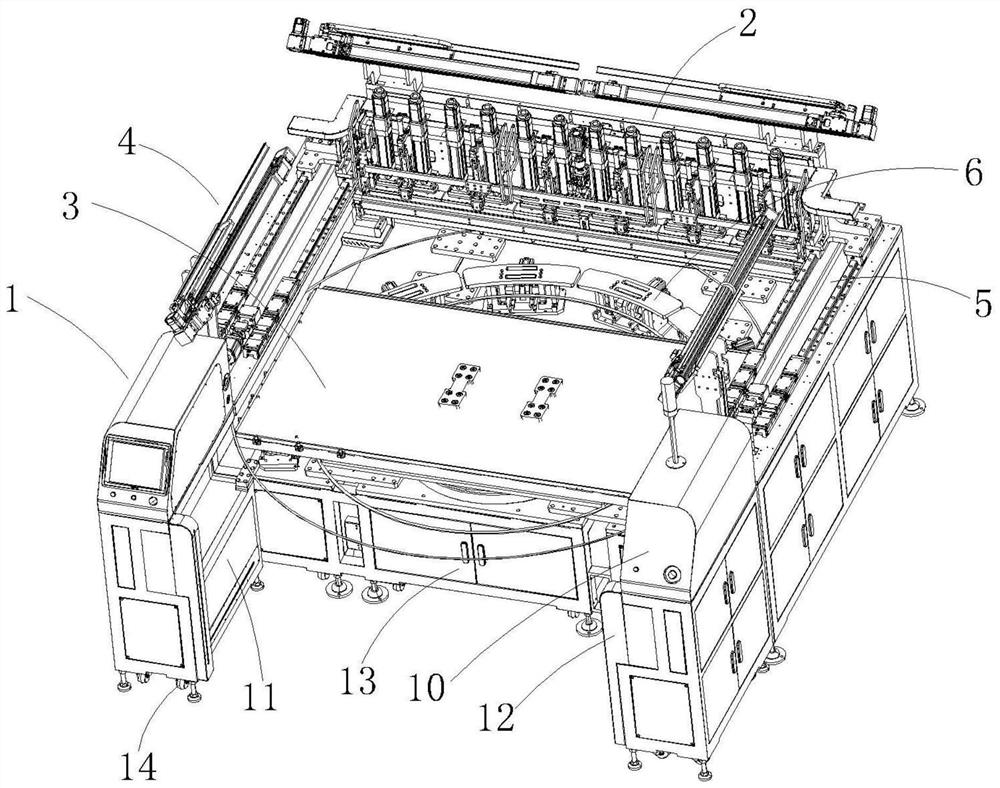

Rotary battery automatic packaging heat sealing machine and packaging method

PendingCN112319949ARealize automatic heat sealingImprove heat sealing qualityWrapper twisting/gatheringRotary conveyorsHeat sealerControl system

The invention discloses a rotary battery automatic packaging heat sealing machine. The machine comprises a machine frame, a hot pressing device, a positioning device and a discharging device. A rotarydisc is arranged on the machine frame, a plurality of cushion blocks are arranged on the rotary disc in an annular array mode, the positioning device is arranged on the rotary disc, and the hot pressing device and the discharging device are sequentially arranged in the rotating direction of the rotary disc. A control system is further arranged in the machine frame and is in control connection with the rotary disc, the hot pressing device, the discharging device and the positioning device. When a battery is to be packaged, a packaging bag with the battery in is placed on the rotary disc, a sealing opening is placed on the cushion block, then the rotary disc rotates, the sealing opening is rotated to the hot pressing device through the positioning device, the sealing opening is subjected toheat sealing through the hot pressing device, and after heat sealing is completed, the packaging bag is removed through the discharging device. In this way, full-automatic heat sealing of the batterypackaging bag is achieved; and because a traditional pedal type semi-automatic heat sealing machine is replaced with the rotary type automatic heat sealing machine, the heat sealing quality can be improved, and meanwhile the heat sealing efficiency is improved.

Owner:GUANGDONG SENEASY INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com