A dual-station synchronous heat-sealing and shearing mechanism for wet tissue outer packaging and its working method

A technology of shearing mechanism and wet tissue, which is applied in the field of double-station synchronous heat-sealing and shearing mechanism for the outer packaging of wet tissue. Efficiency, simple structure, and fast shearing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

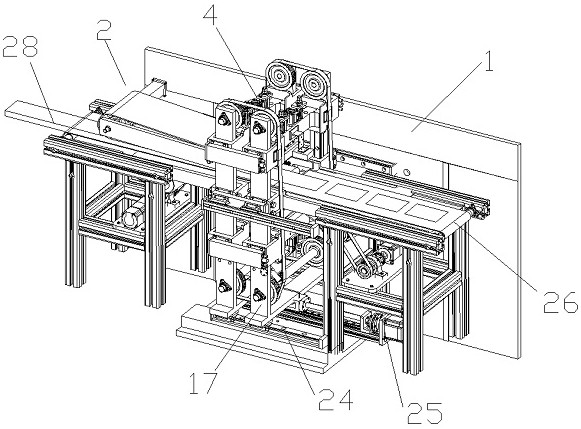

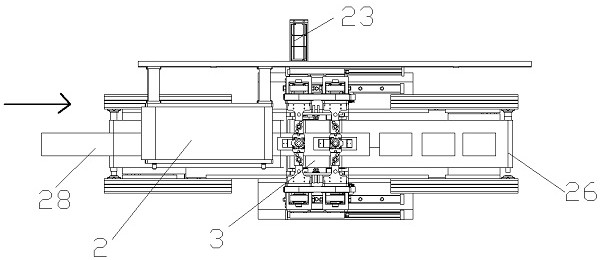

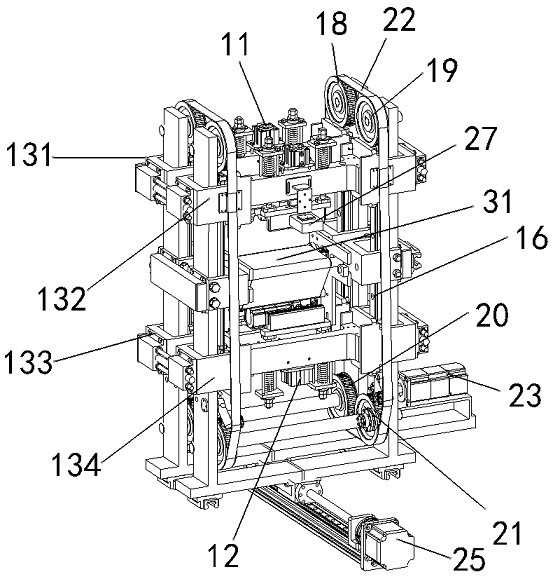

[0022] Example: such as Figure 1~5 As shown, in this embodiment, a double-station synchronous heat-sealing and shearing mechanism for wet tissue outer packaging is provided, including a frame 1, and a group of strip-shaped wet tissue is provided laterally on the frame 1. Raw materials and the flattening conveying device 2 that flattens the strip-shaped wet tissue raw material 28 by clamping up and down. The outlet of the flattening conveying device 2 is also provided with a transition conveying device 3. A group of double heat-seal head shearing devices 4 that simultaneously engage and cooperate with strip-shaped wet tissue raw materials are provided respectively.

[0023] In this embodiment, the transition conveying device 3 is a first belt transmission mechanism 31, and a pair of heat-sealed fixing plates 5 are respectively symmetrically arranged on the upper and lower ends of the inlet and outlet of the first belt transmission mechanism 31, each A heat-sealed fixed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com