A vacuum heat sealing device for plastic bags

A heat-sealing device and plastic bag technology, applied in the field of plastic bag heat-sealing, can solve problems such as troublesome, inability to ensure consistent heat-sealing quality, etc., and achieve the effects of improving heat-sealing quality, improving heat-sealing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

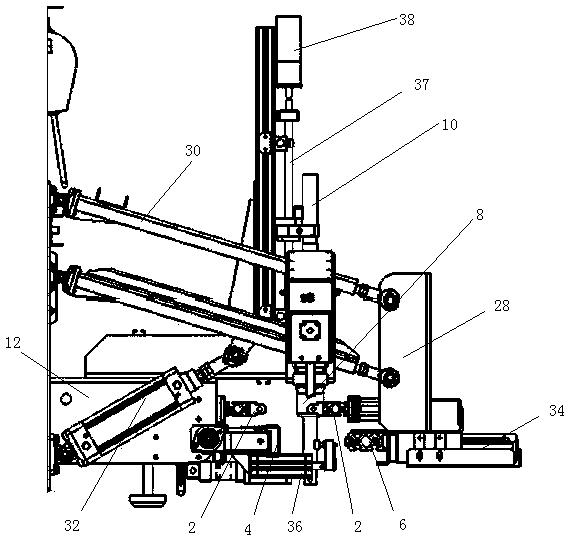

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

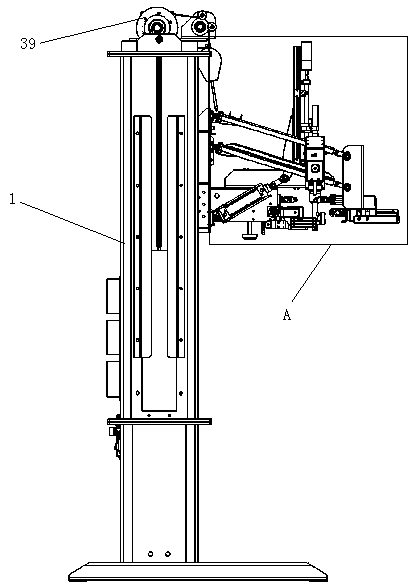

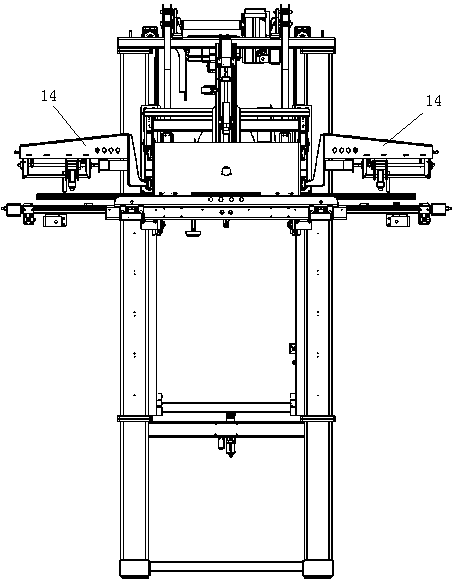

[0026] Such as Figure 1-Figure 4 As shown, a plastic bag vacuum heat sealing device includes a frame 1, on which at least one set of plastic bag fixing components is arranged, and a relatively horizontally movable, A heat-sealing strip 4 and a heat-sealing pressing block 6 are used for heat-sealing the plastic bag, and a vacuum tube 10 that can extend into the plastic bag is arranged above the plastic bag fixing assembly.

[0027] In this embodiment, both sides of the frame 1 are provided with a pocket fixing device 14, and the pocket fixing device 14 includes a guide rod 18, and two clips for clamping a plastic bag are arranged on the guide rod 18. The holder 22 is connected to the guide rod 18 through the slider 20, and the slider 20 is driven by the first servo motor 26 and can move horizontally relative to the guide rod 18, and the slider 20 is relatively The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com