Heat sealing device for liquid laundry detergent production

A heat-sealing device and liquid technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inconvenient loading and unloading, complicated packaging bag clamping process, and influence of packaging bag packaging efficiency, etc., to speed up the heating process. The effect of sealing efficiency, simplification of clamping and fixing steps, and convenient loading and unloading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

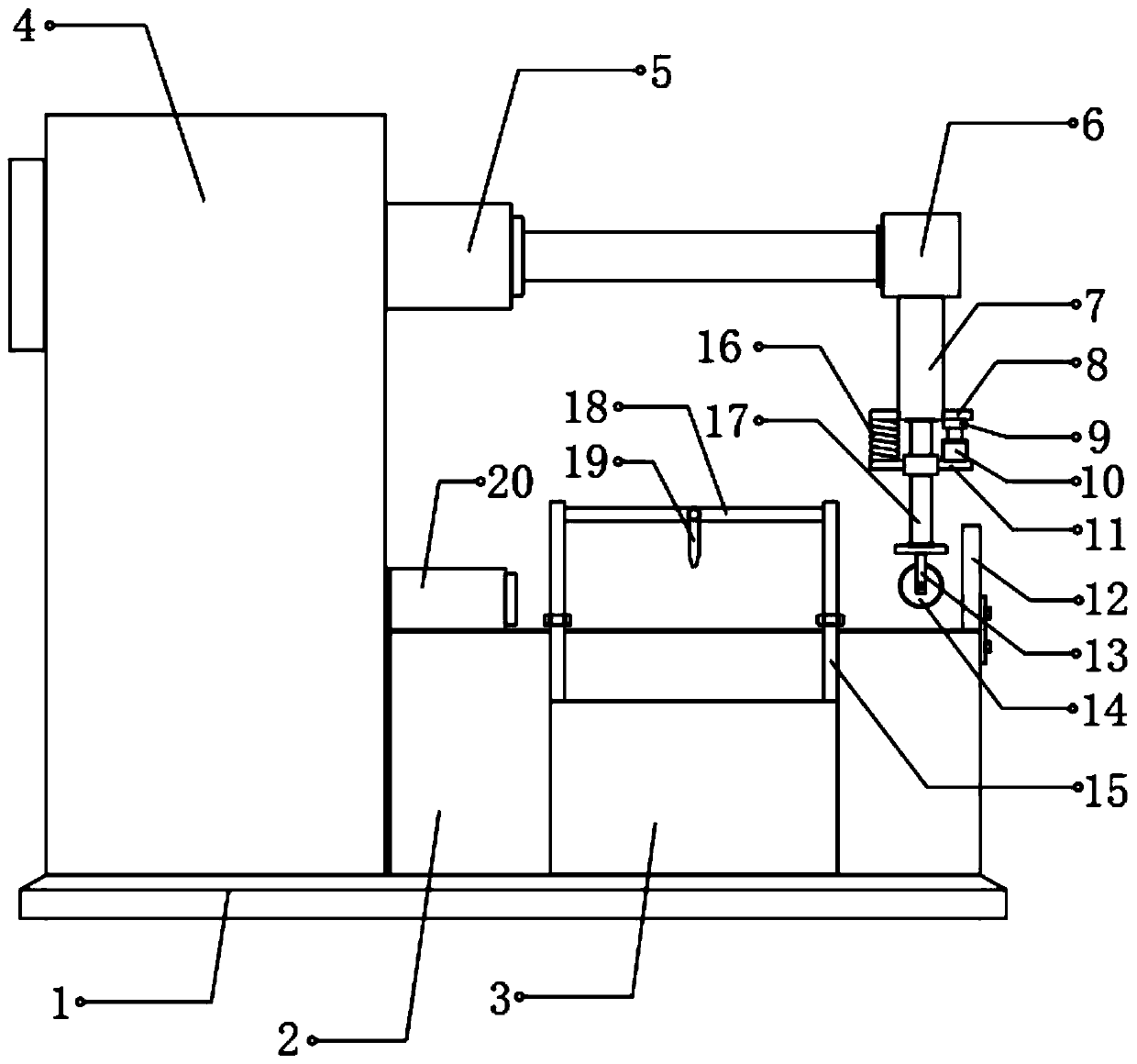

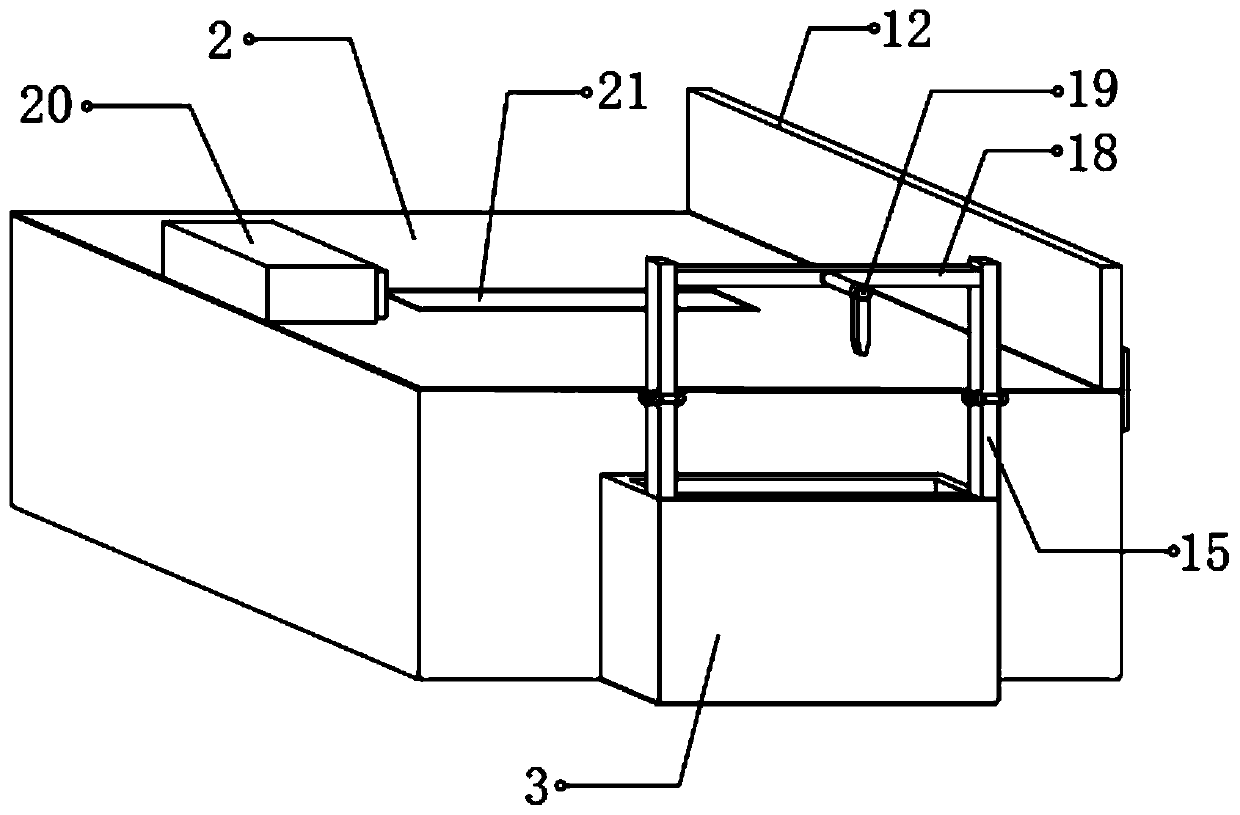

[0029] refer to Figure 1-3 , a heat sealing device for liquid laundry detergent production, comprising a base 1, one side of the top of the base 1 is fixedly connected with a workbench 2, and a resistance heater 21 is arranged at the middle position of the top of the workbench 2, and the other on the top of the base 1 The side is fixedly connected with a control box 4, and the top of the control box 4 near the workbench 2 is provided with a push rod motor 5, the push rod motor 5 is located directly above the resistance heater 21, and one end of the push rod motor 5 is fixedly connected with a connection block 6, and the bottom of the connection block 6 is fixedly connected with the insertion socket 7, the bottom of the insertion socket 7 is inserted with the insertion rod 17, and the bottom of the insertion rod 17 is fixedly connected with the roller frame 13, and the inner wall of the roller frame 13 is connected through the rotation of the bearing There are rollers 14, the ...

Embodiment 2

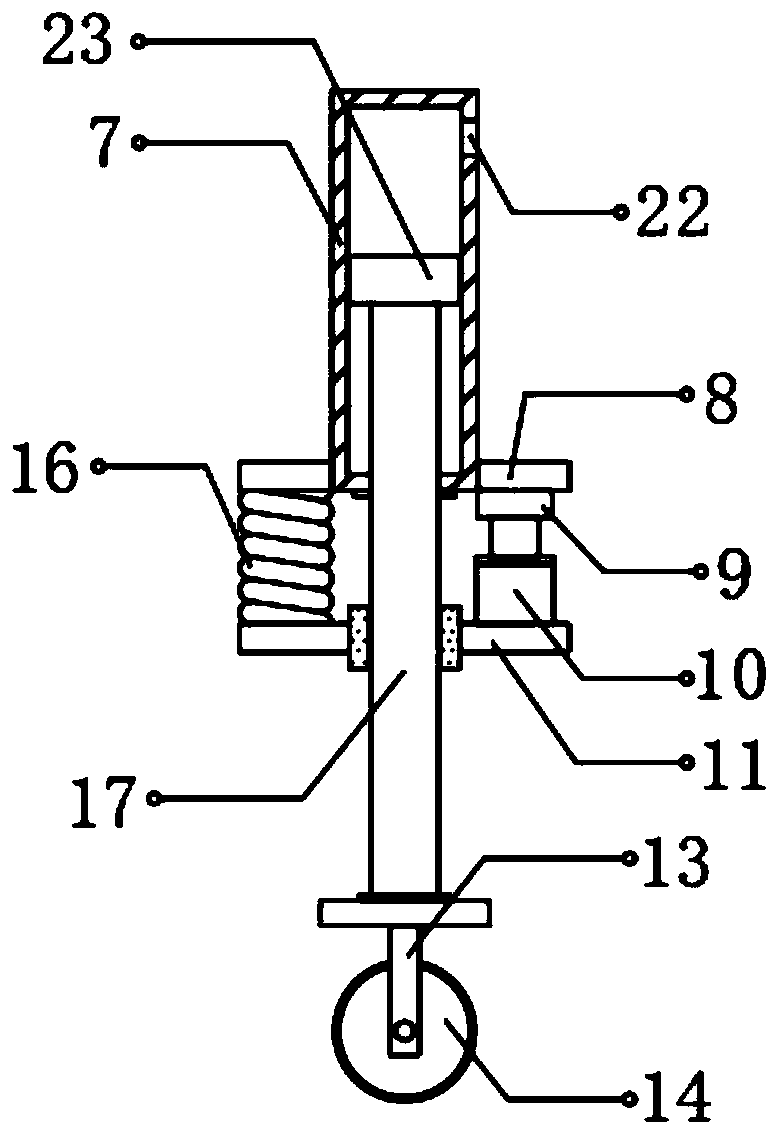

[0038] refer to Figure 4, a heat-sealing device for the production of liquid laundry detergent. Compared with Embodiment 1, the number of the fixed plate 8 and the movable plate 11 in this embodiment is set to one, and the positioning block 9 is fixed below the fixed plate 8, and the electromagnet 10 is fixed on the top of the moving plate 11, the spring 16 is arranged inside the insertion sleeve 7, and the bottom of the spring 16 is welded to the top of the piston 23.

[0039] Working principle: The position of the spring 16 is replaced, and the spring 16 is protected by the insertion sleeve 7, so that the spring 16 is not easy to be rusted and disturbed, and the space occupied by the device is saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com