Deoxidizer heat-sealing packaging machine and packaging method

A deoxidizer and packaging machine technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high energy consumption and low heat sealing efficiency, reduce power consumption, improve heat sealing efficiency, and reduce the number of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

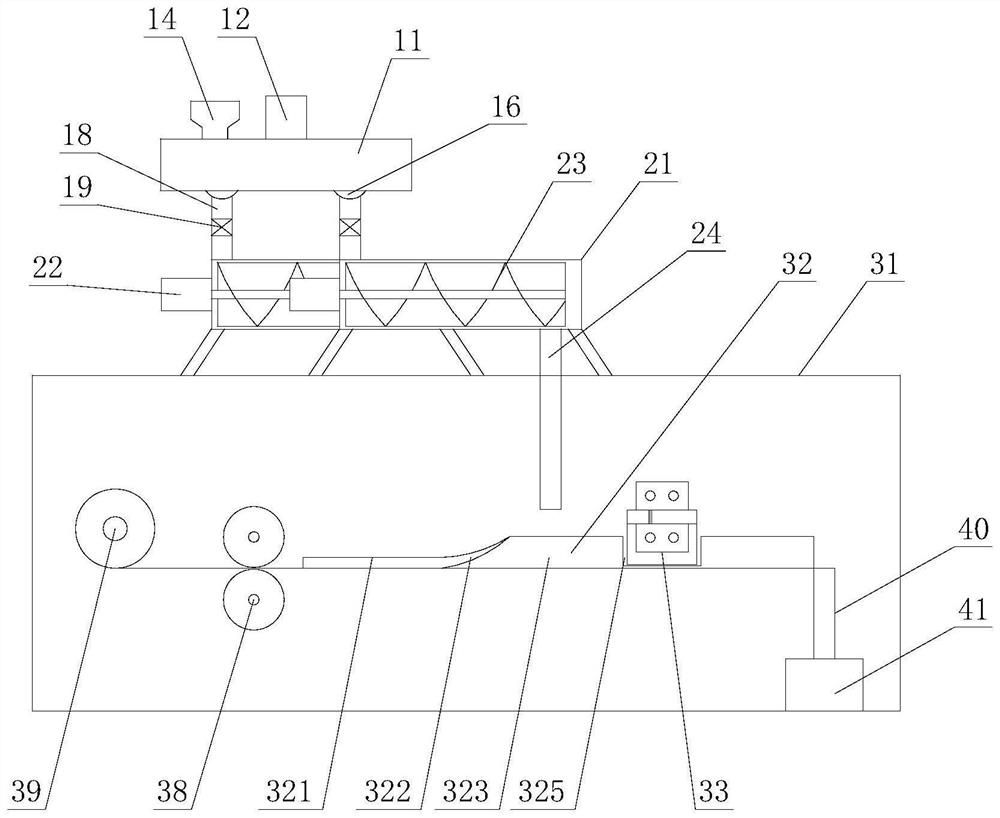

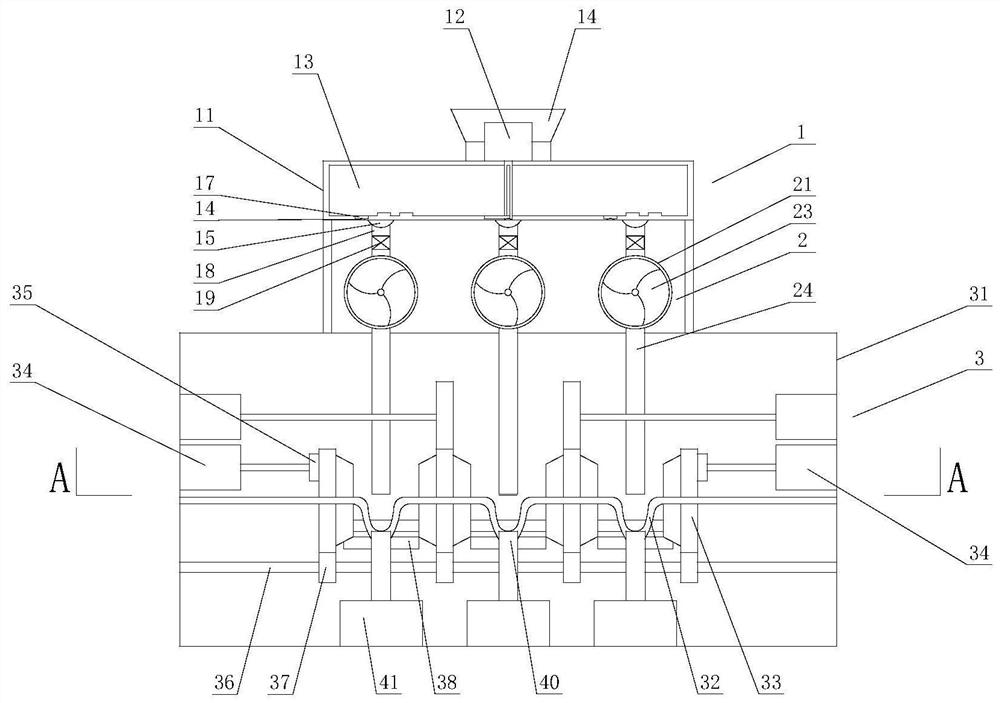

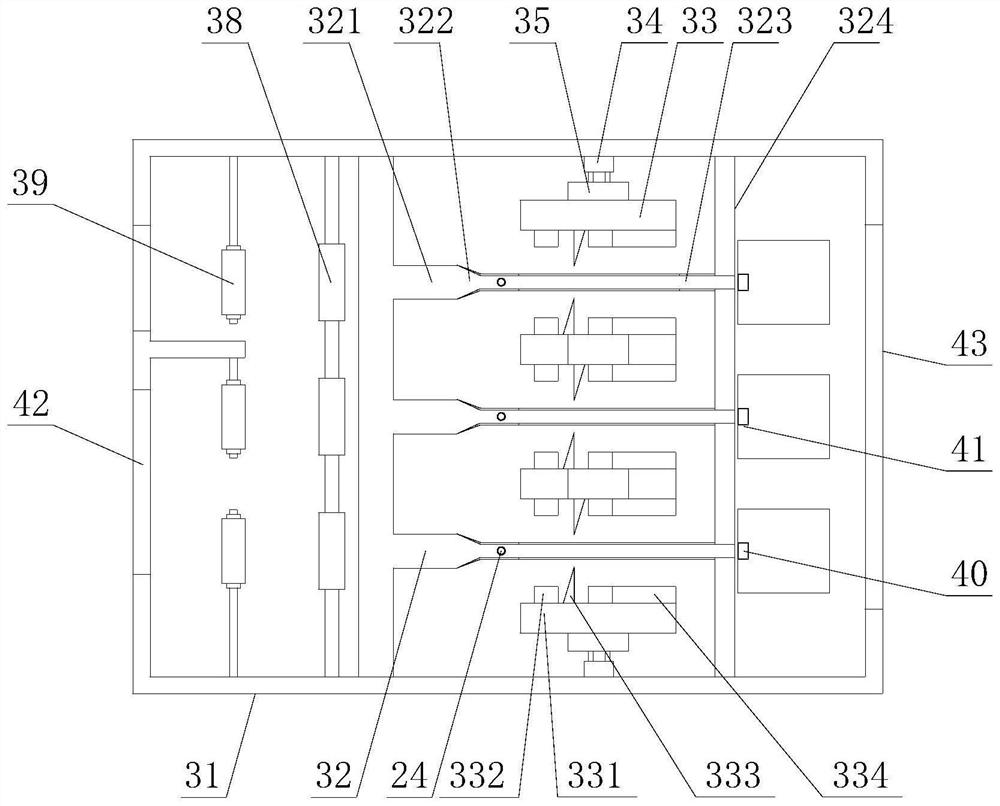

[0035] combined with Figure 1~3 As shown, a deoxidizer heat-sealing packaging machine related to the present invention includes a feeding device 1 , a feeding device 2 and a heat-sealing device 3 .

[0036] The feeding device 1 includes a feed box 11, the feed box 11 adopts a cylindrical structure, the top center of the feed box 11 is provided with a stirring motor 12 and a feed hopper 14, and the feed hopper 14 is used for deoxidizer particles added. The rotating shaft of the stirring motor 12 extends into the feeding box 11, and three evenly arranged stirring paddles 13 are arranged on the rotating shaft. The stirring paddles 13 adopt a mesh structure and are used to stir the deoxidizer par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com