Finishing and packaging heat seal equipment

A technology of heat-sealing equipment and heat-sealing devices, which is applied in the directions of packaging, packaging sealing/fastening, transportation and packaging, etc., can solve the problems of being unsuitable for batch operations, high labor costs, and labor-intensive, etc., to expand the use range of the device, The effect of improving heat sealing quality and improving heat sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below through specific examples.

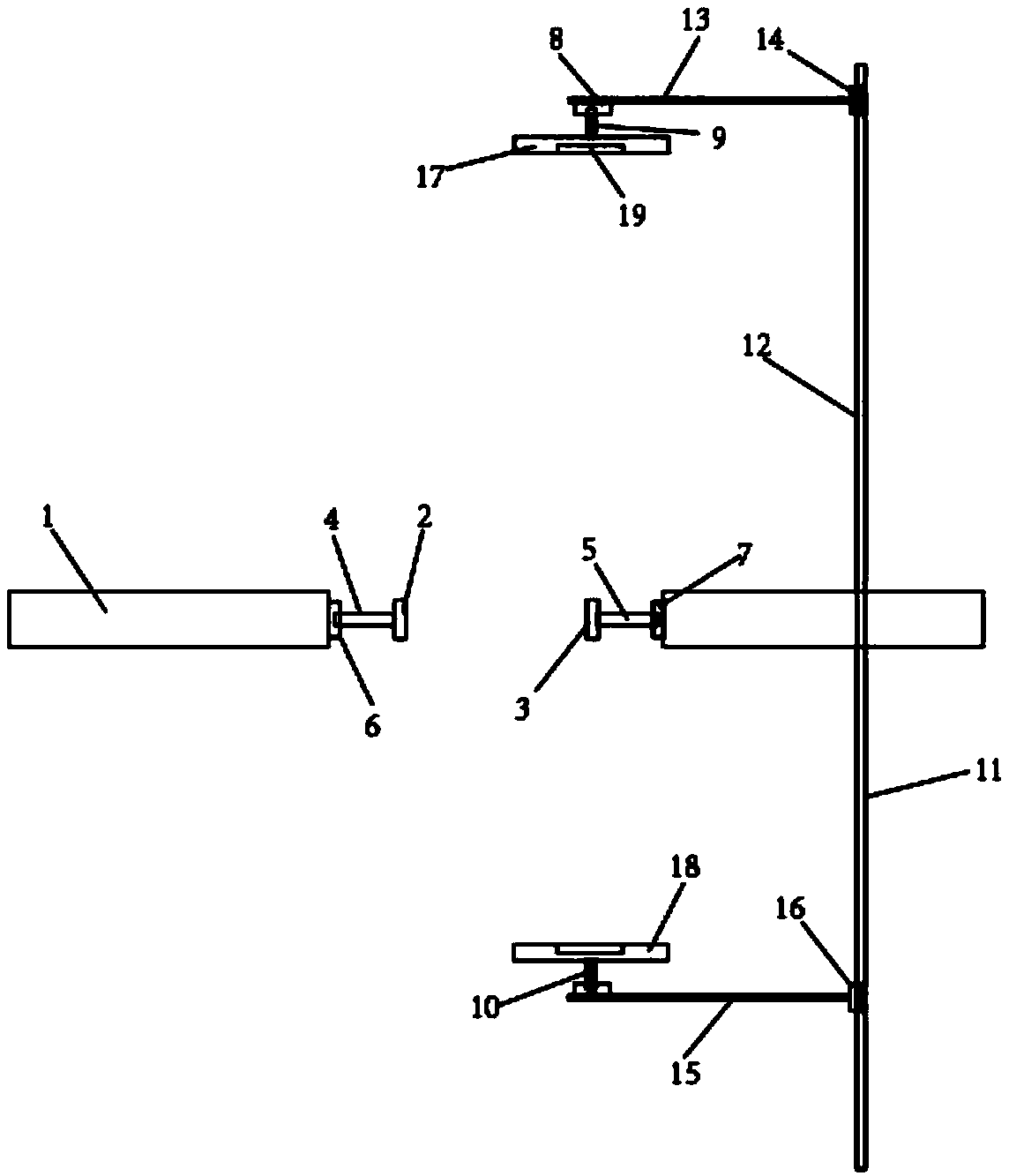

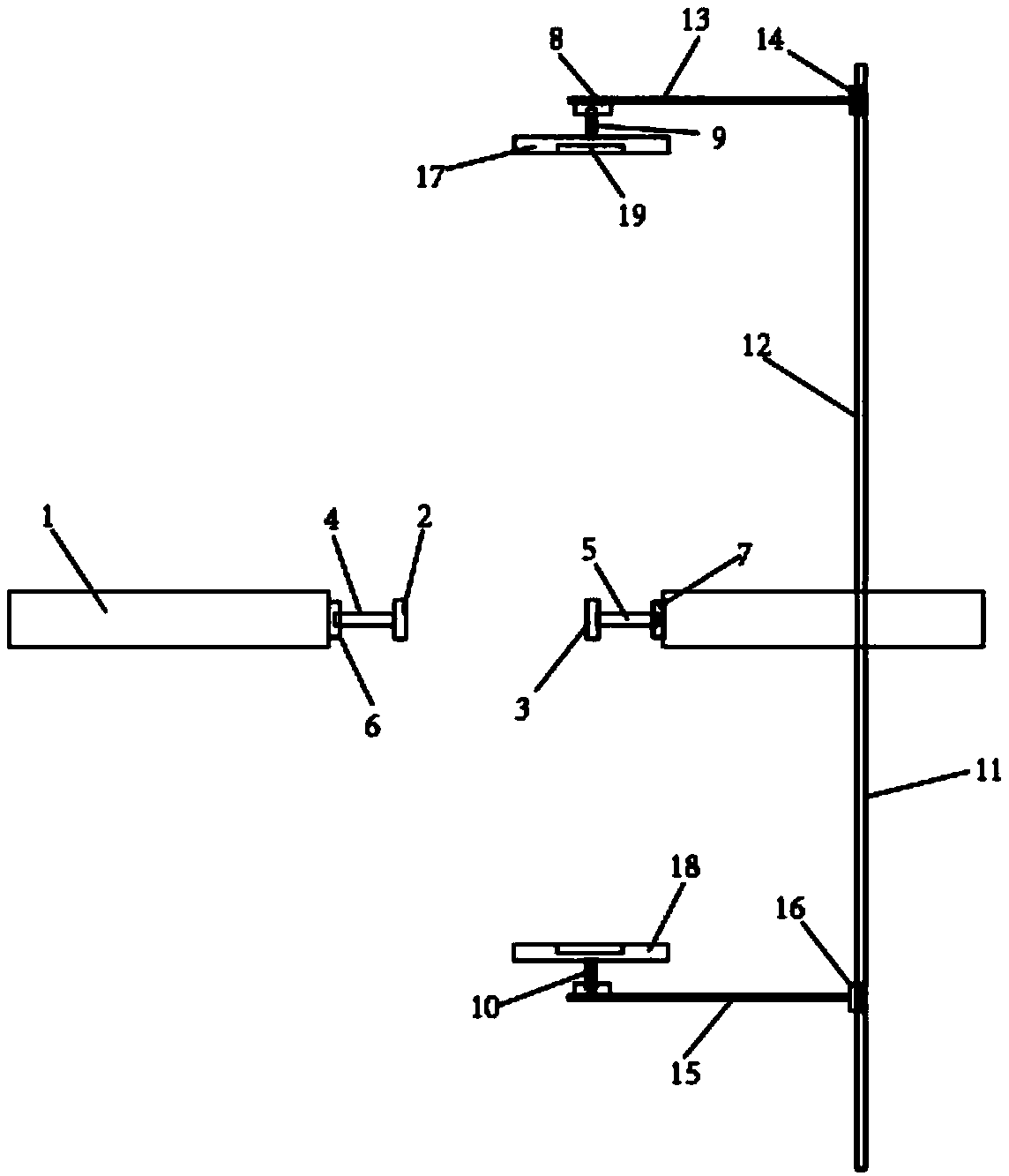

[0016] Such as figure 1 As shown, among them, 1 is the fixed plate, 2 is the left clamping part, 3 is the right clamping part, 4 is the left connecting rod, 5 is the right connecting rod, 6 is the left clamping cylinder, 7 is the right Clamping cylinder, 8 is the rotating motor, 9 is the rotating shaft, 10 is the speed regulator, 11 is the adjustment frame, 12 is the longitudinal adjustment rail, 13 is the top telescopic frame, 14 is the top telescopic motor, 15 is the bottom telescopic frame, 16 is a telescopic motor at the bottom, 17 is a heat-sealing device at the top, 18 is a heat-sealing device at the bottom, and 19 is a pressure sensor.

[0017] Finishing and packaging heat-sealing equipment, fixing device, heat-sealing device, rotating device and adjusting device, the adjusting device is arranged on the fixing device, and the heat-sealing device is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com