Wiring auxiliary device for wire and cable

An auxiliary device, wire and cable technology, applied in the direction of connecting/terminating cables, etc., can solve the problems of inconvenient connector assembly and fixation, inconvenient rotation of cables, and inconvenient folding operations, etc., to save labor costs and improve Convenience and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 shown;

[0046] figure 1 It is a structural schematic diagram of the whole of the present invention;

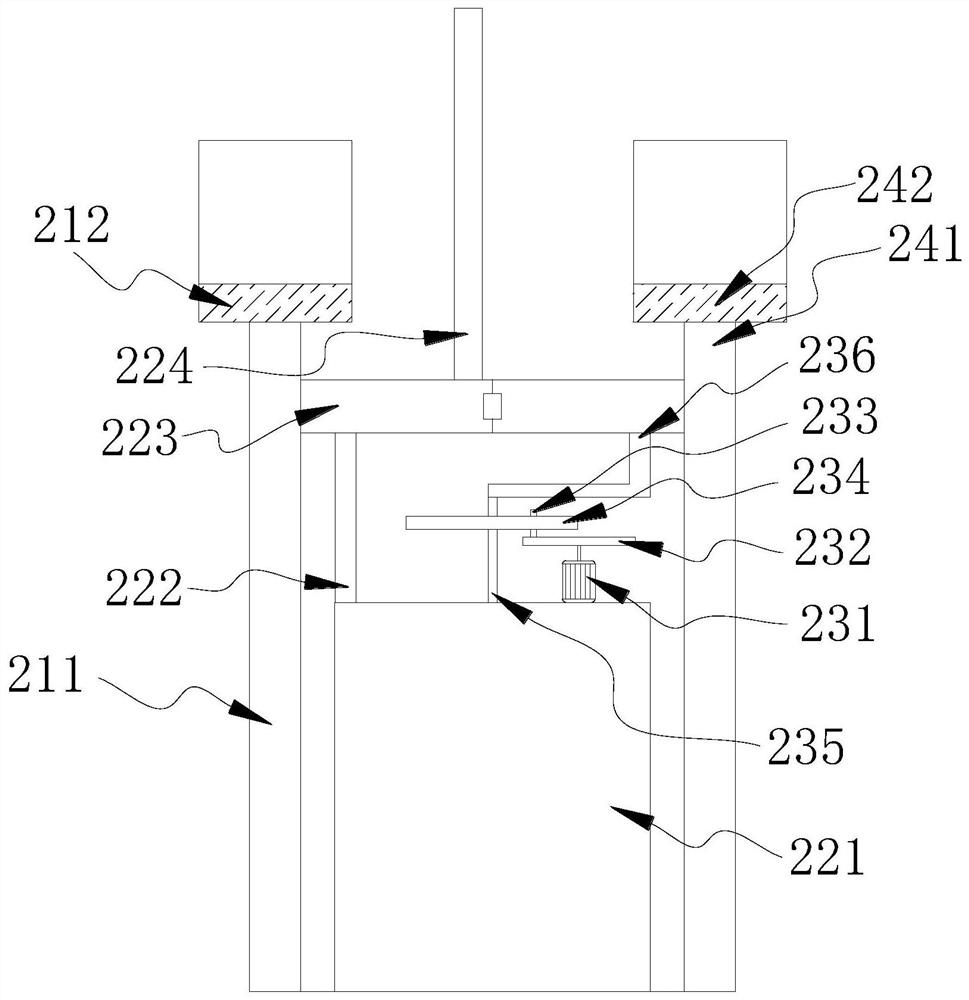

[0047] figure 2 It is an assembly drawing of the assembly mechanism in the present invention;

[0048] image 3 It is an assembly drawing of the rotating mechanism in the present invention;

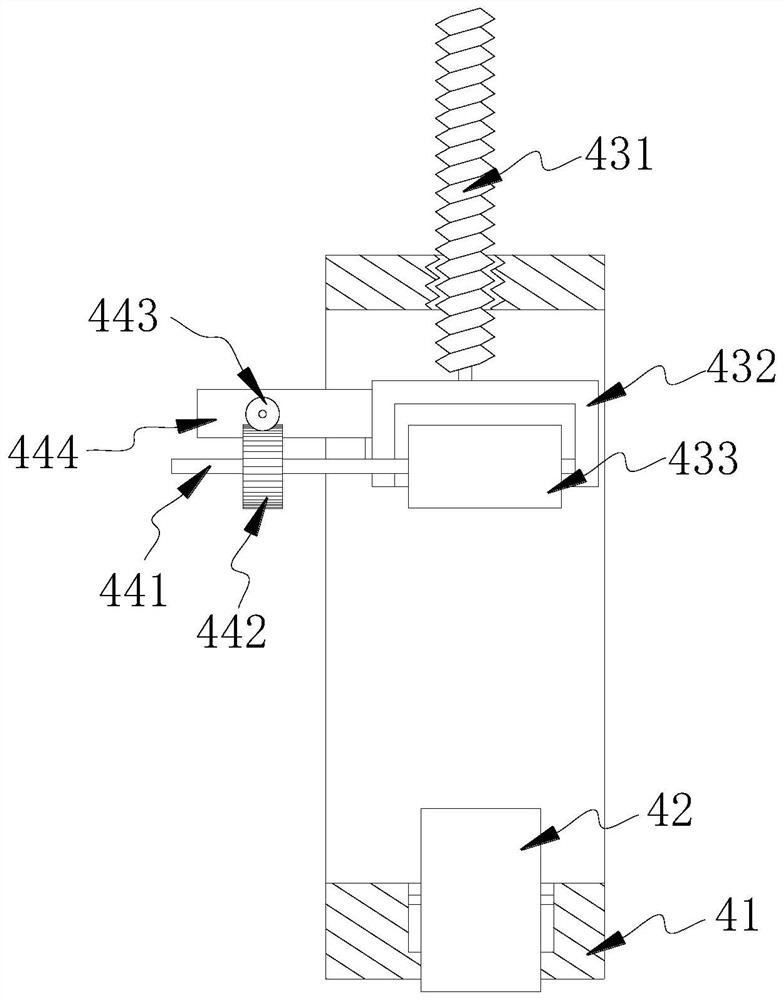

[0049] Figure 4 It is an assembly drawing of the heat-sealing mechanism in the present invention;

[0050] Figure 5 It is an assembly drawing of the heat-sealing mechanism in the present invention;

[0051] Figure 6 It is a schematic diagram of the installation structure of the sliding bar in the present invention;

[0052] Figure 7 It is a schematic diagram of the installation structure of the sheave in the present invention.

[0053] An auxiliary wiring device for wires and cables, comprising a bottom plate 1, an assembly mechanism 2 is fixedly connected to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com