Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve geological adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

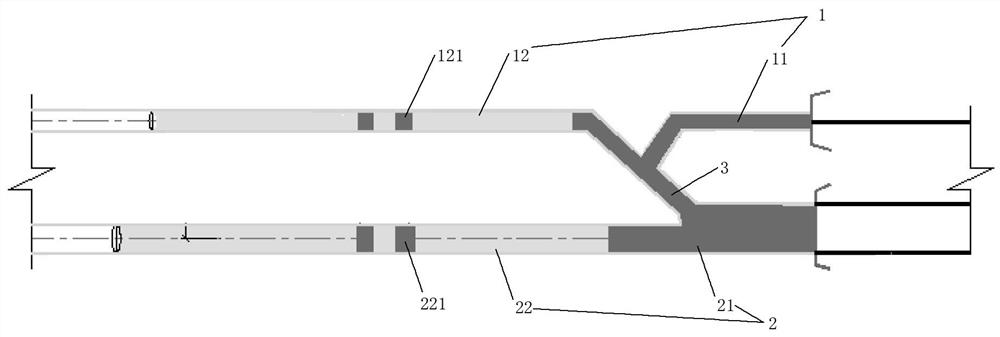

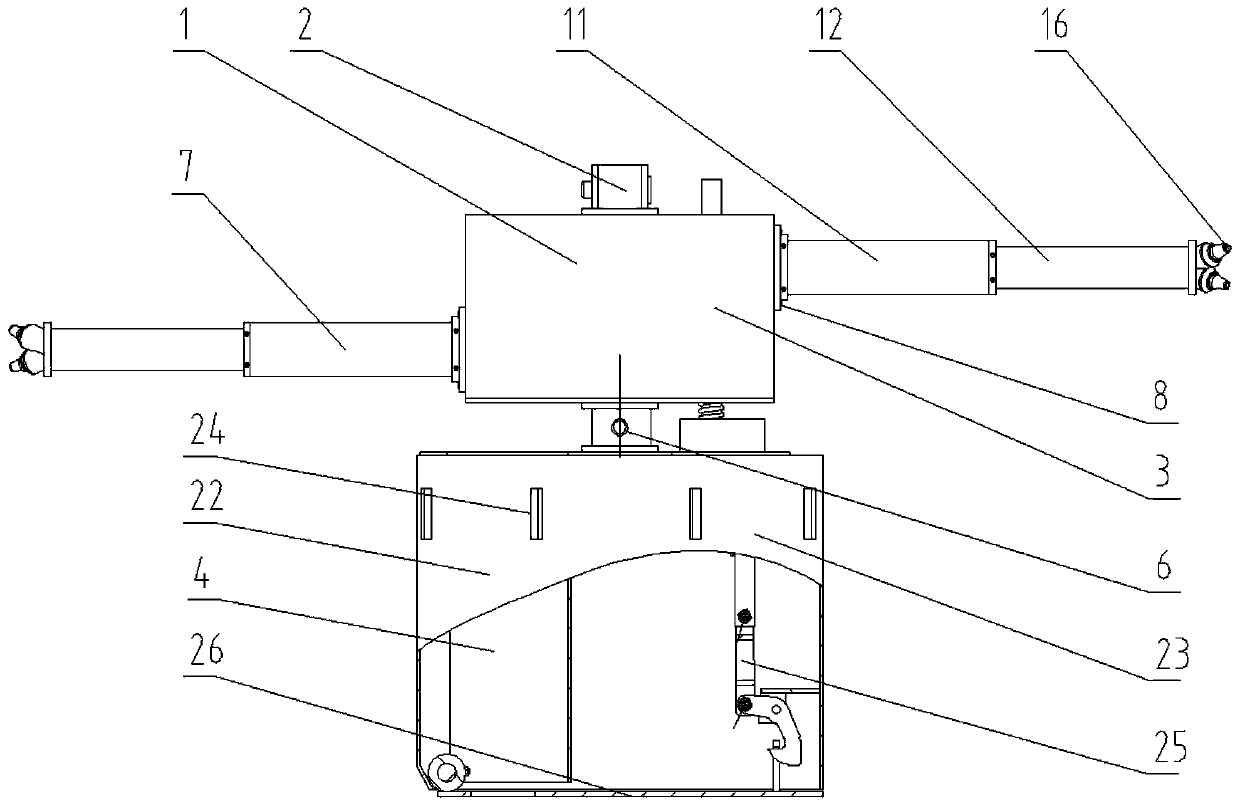

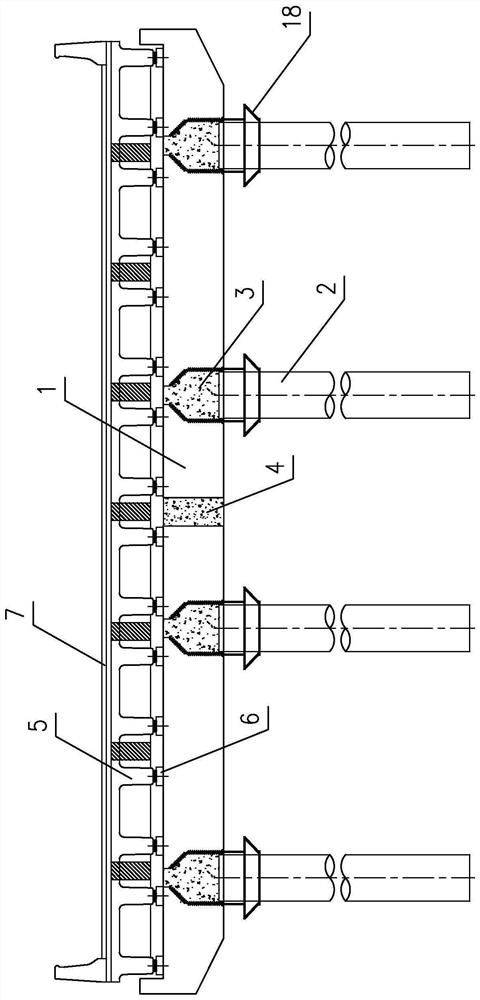

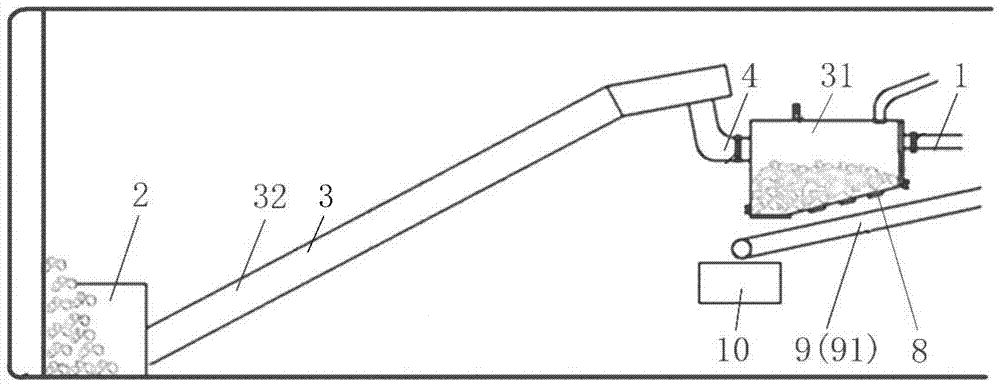

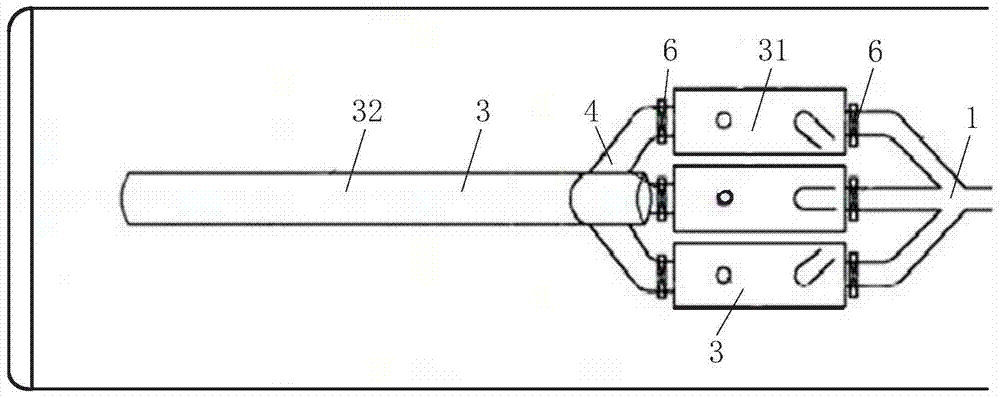

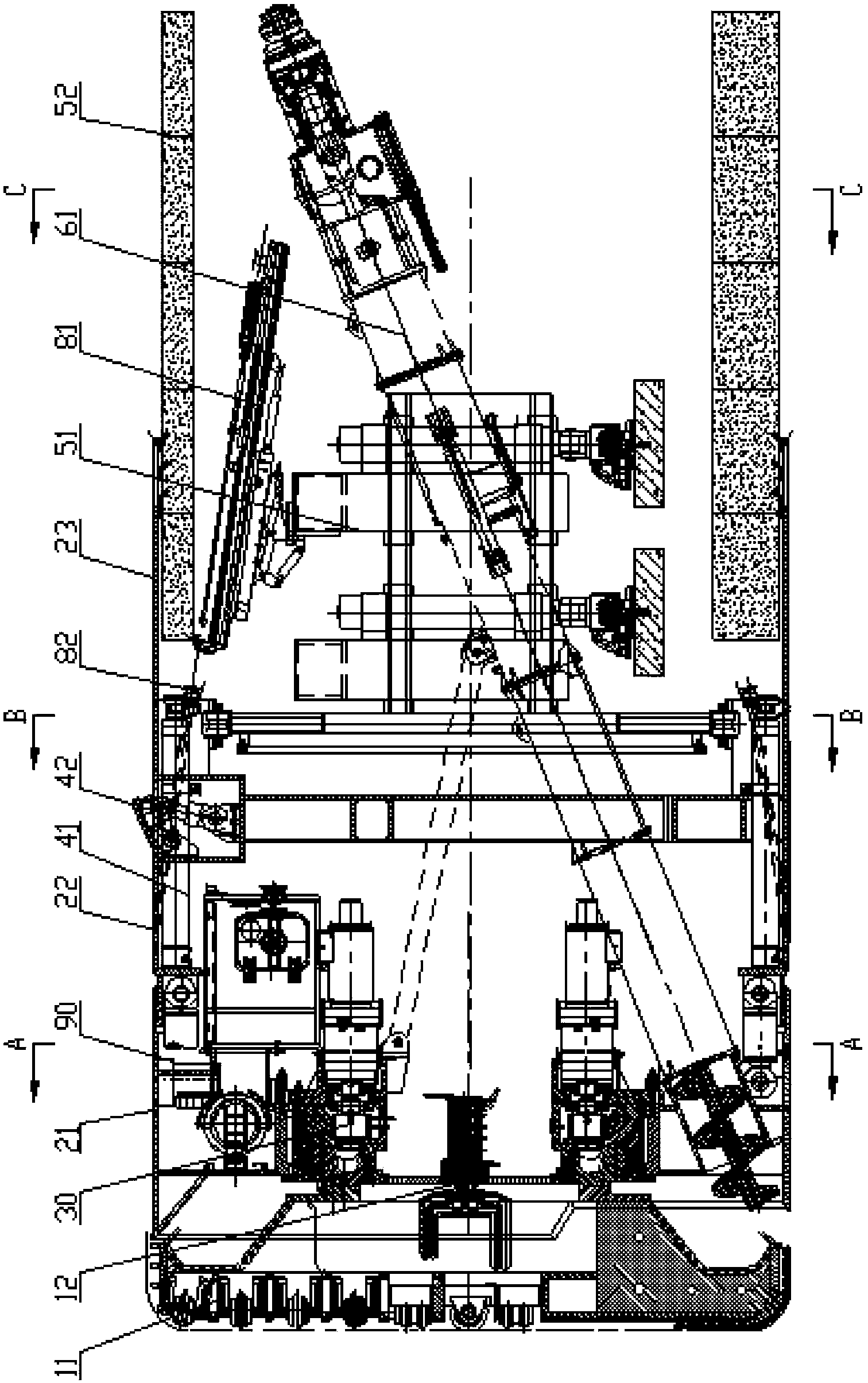

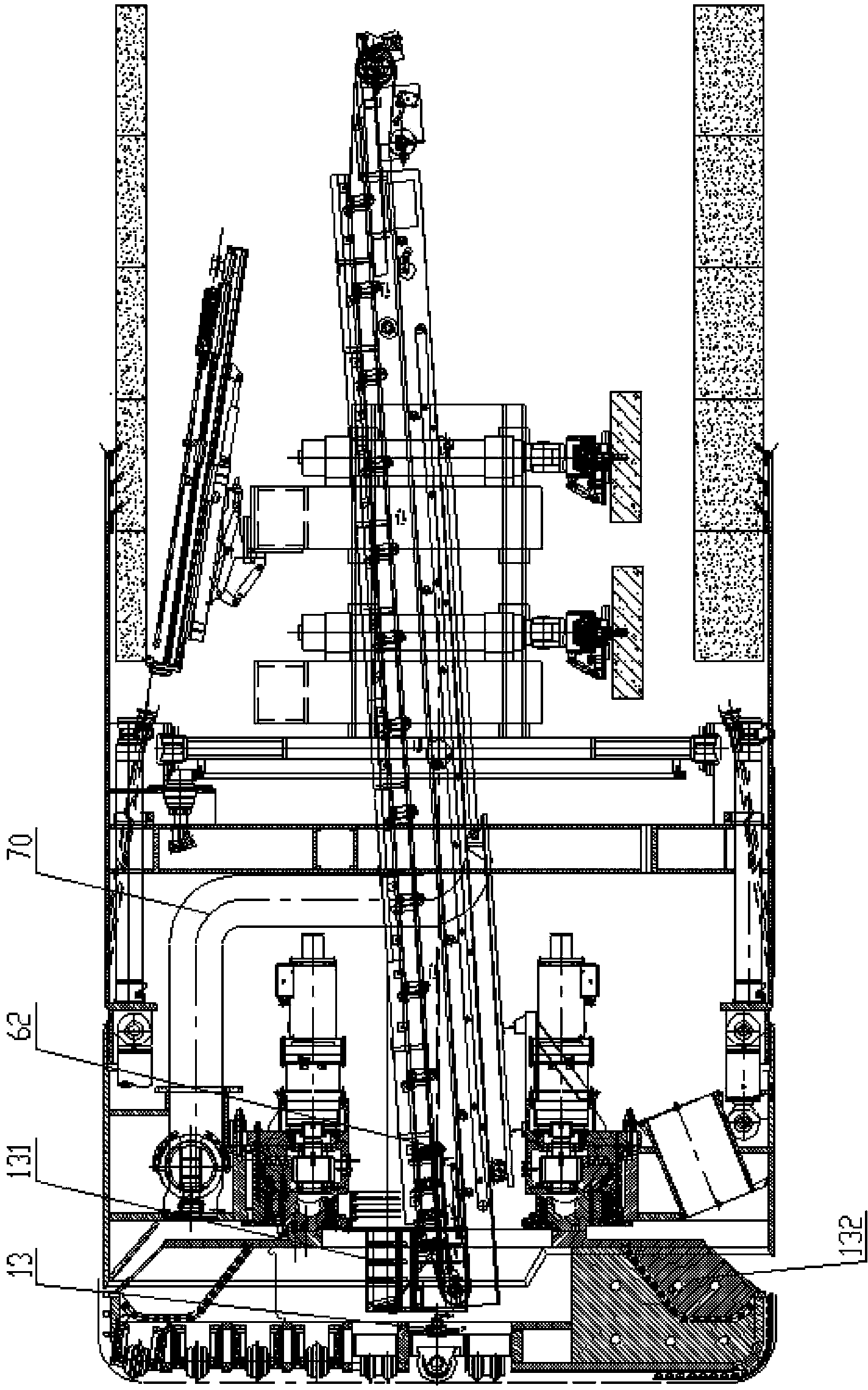

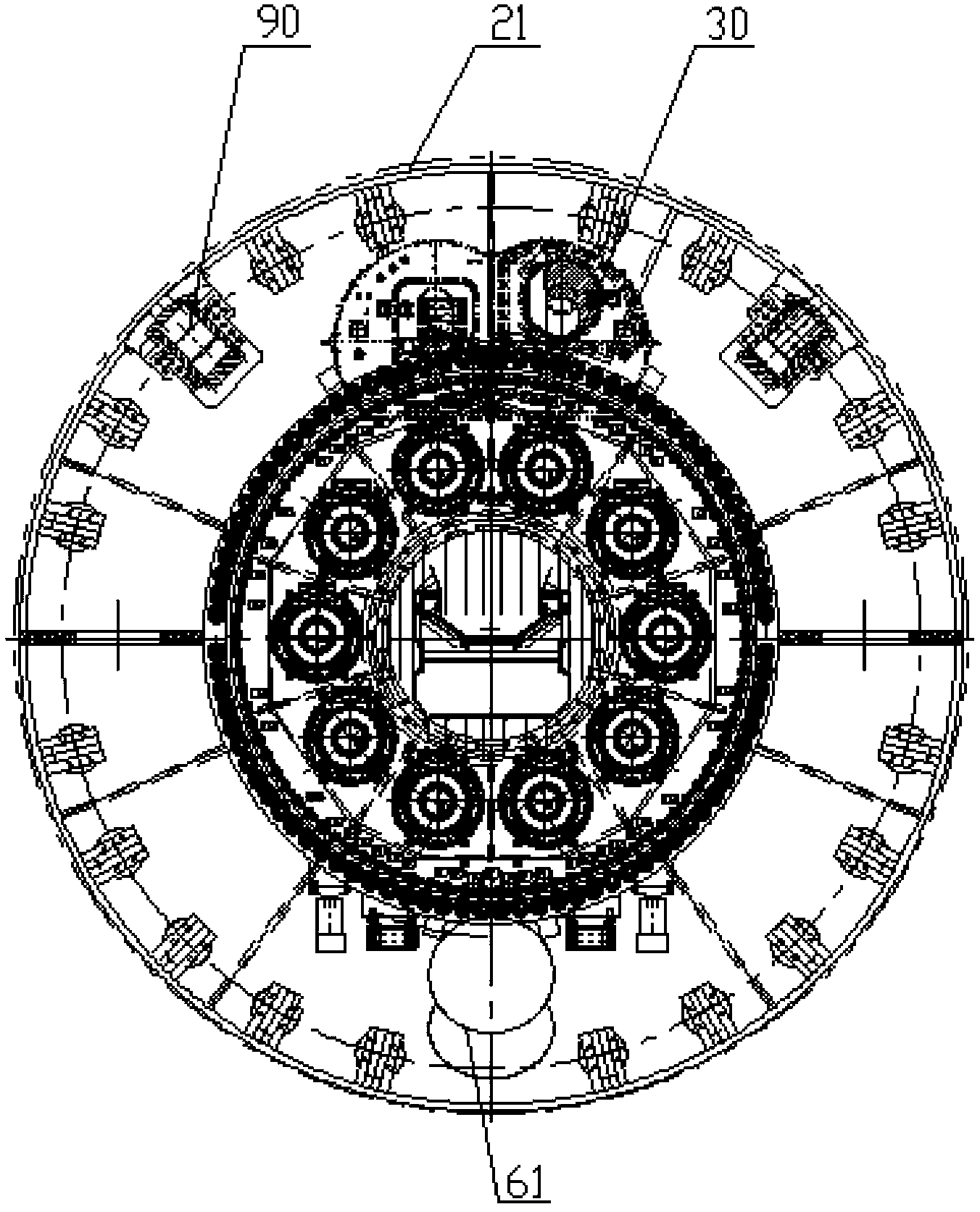

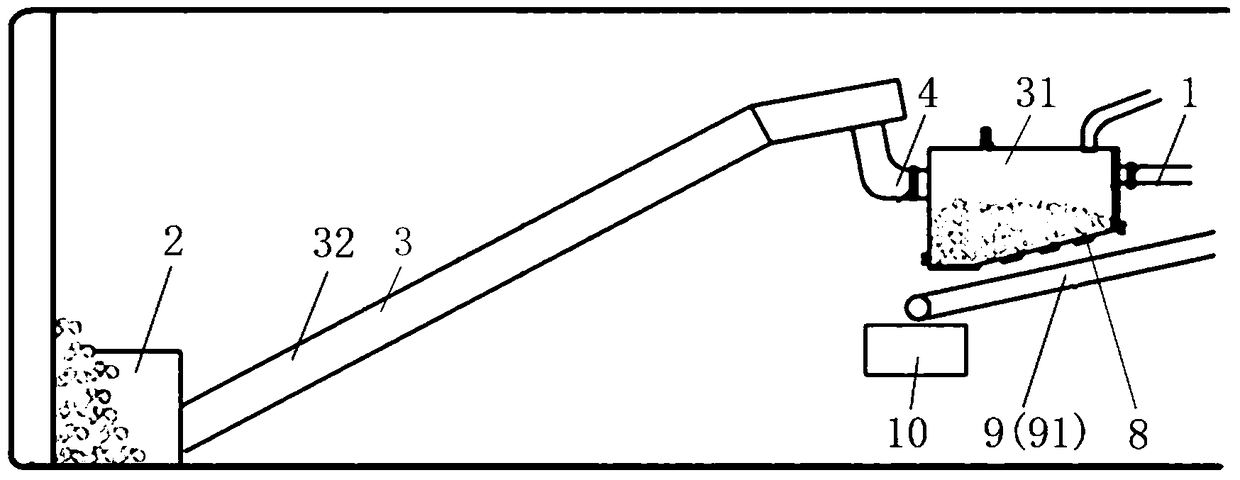

Slag discharging mechanism of shield tunneling machine and muddy water balance shield tunneling machine

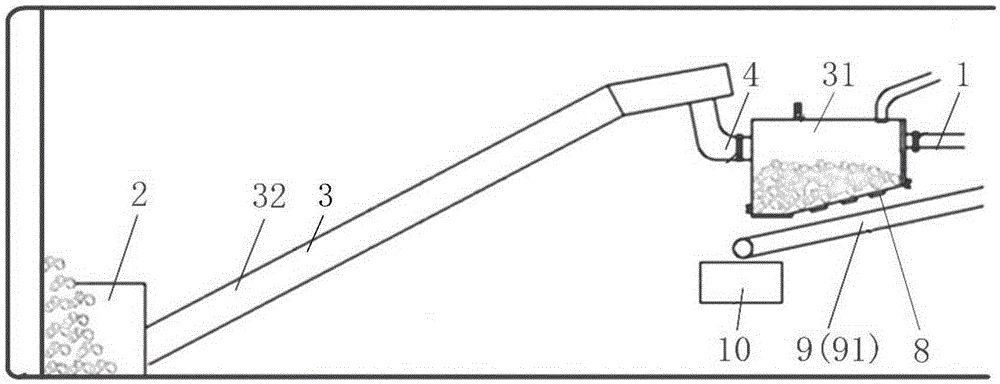

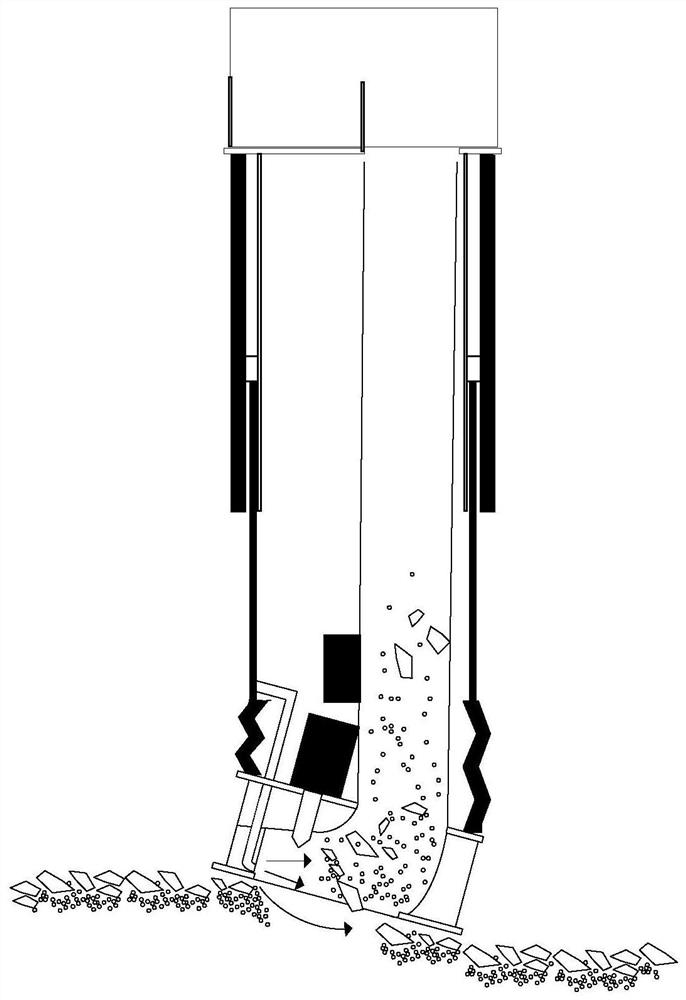

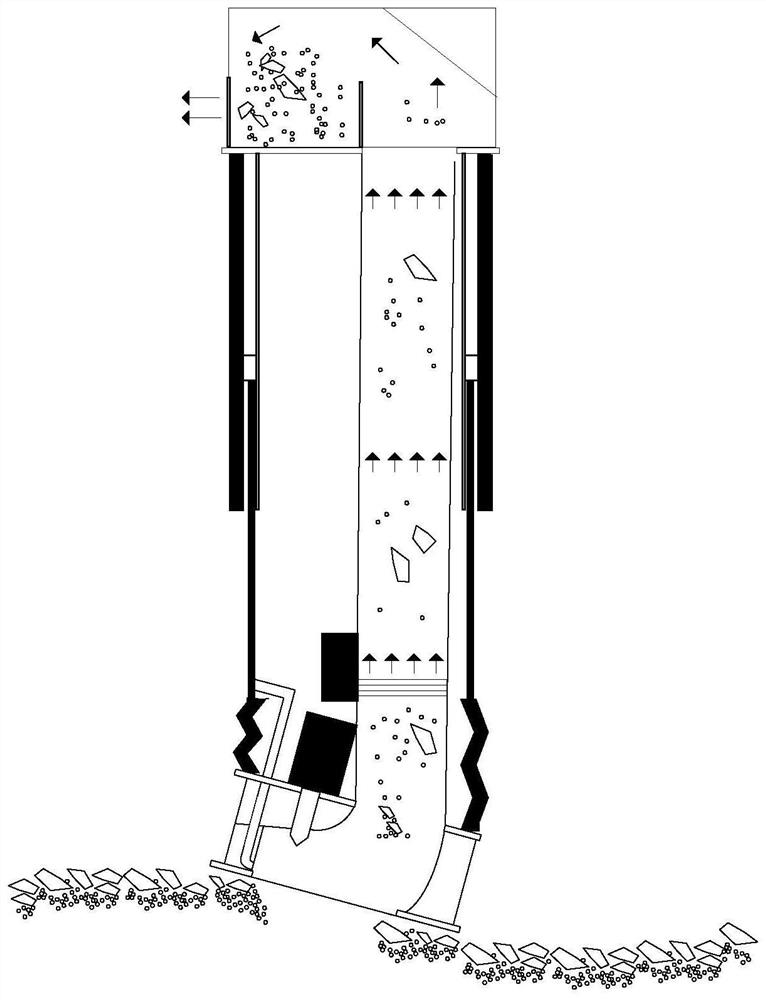

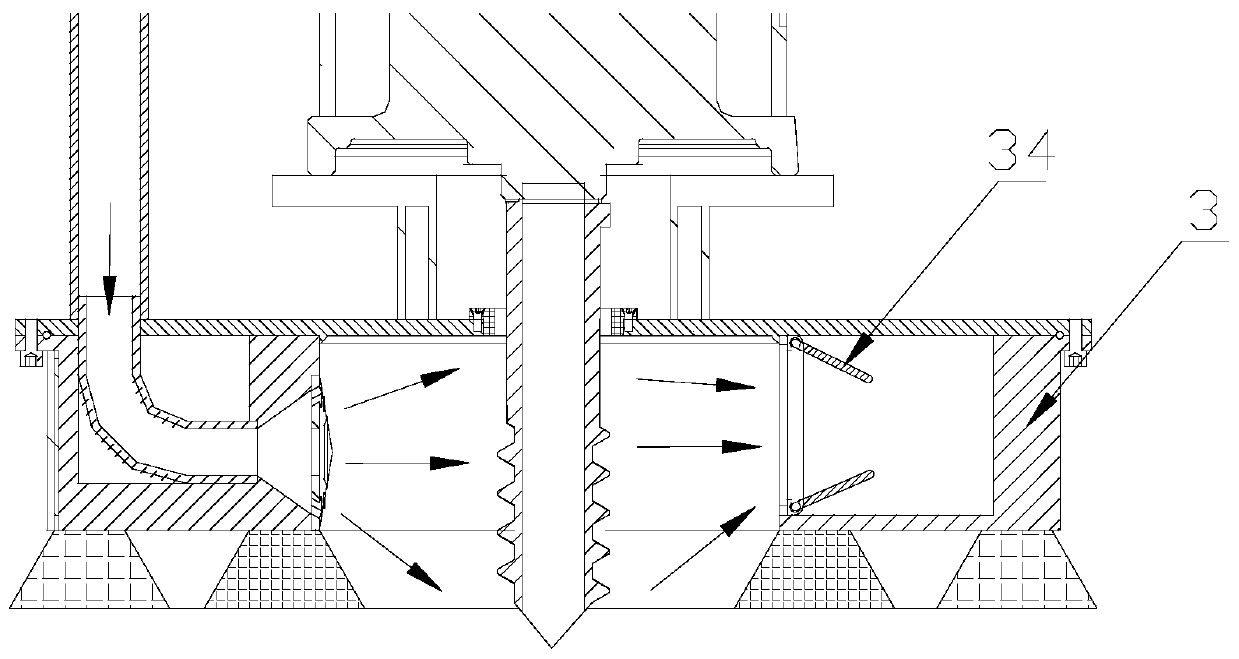

The invention discloses a muddy water balance shield tunneling machine and a slag discharging mechanism thereof. The slag discharging mechanism comprises a mud discharging pipeline and a soil bin for storing residue soil; a separating device for separating mud in the residue soil from gravels is arranged between the soil bin and the mud discharging pipeline; the soil bin communicates with a feeding end of the separating device; a mud discharging end of the separating device communicates with the mud discharging pipeline; and a gravel discharging end of the separating device is provided with a gravel discharging device. The muddy water balance shield tunneling machine comprises a shield and the slag discharging mechanism which is arranged in the shield. The slag discharging mechanism has the advantages that safety and stability of a slag outlet system of the muddy water balance shield tunneling machine are improved, and construction efficiency is also improved.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

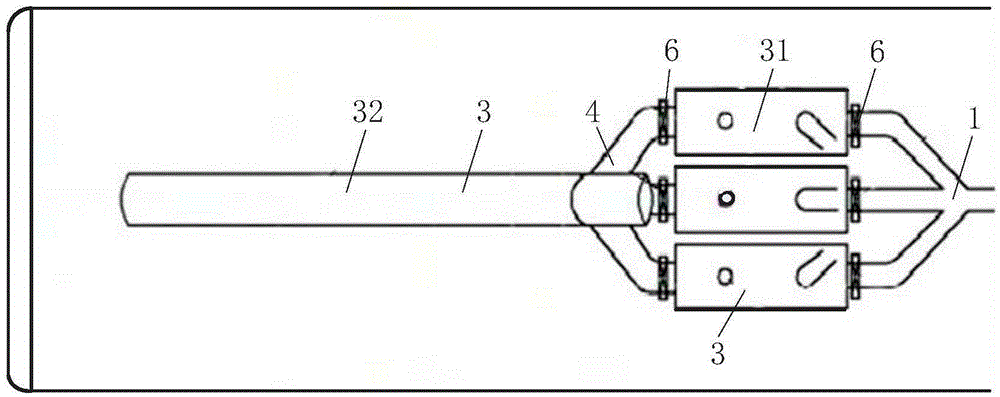

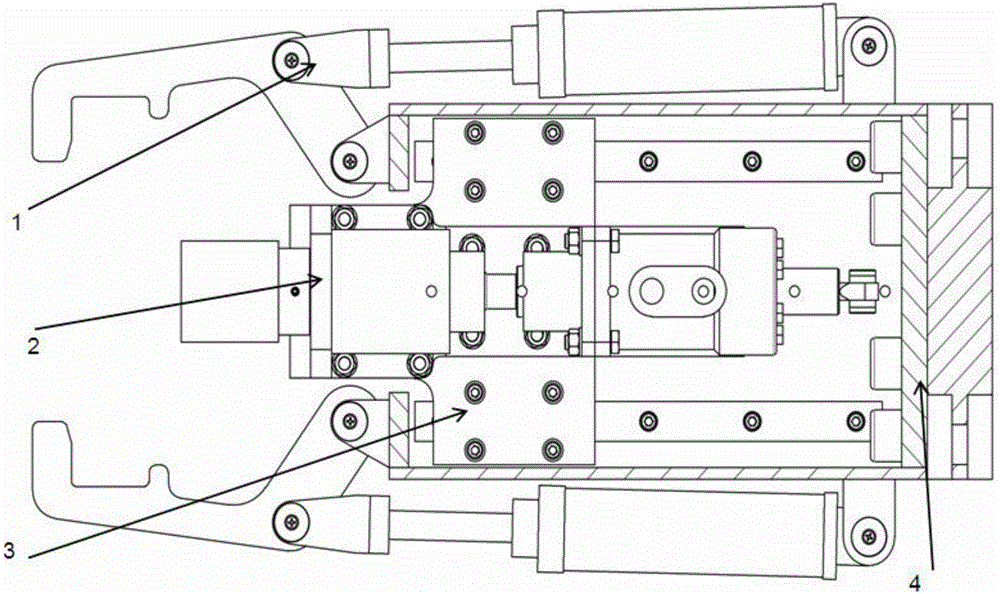

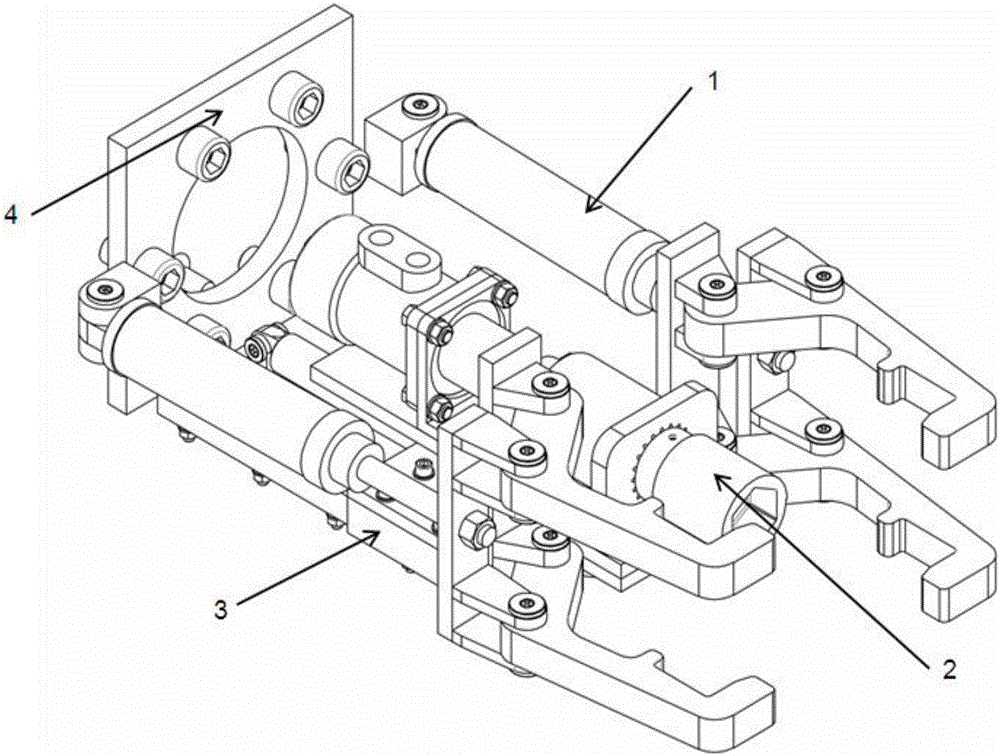

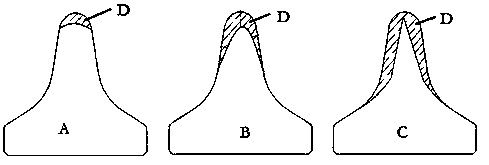

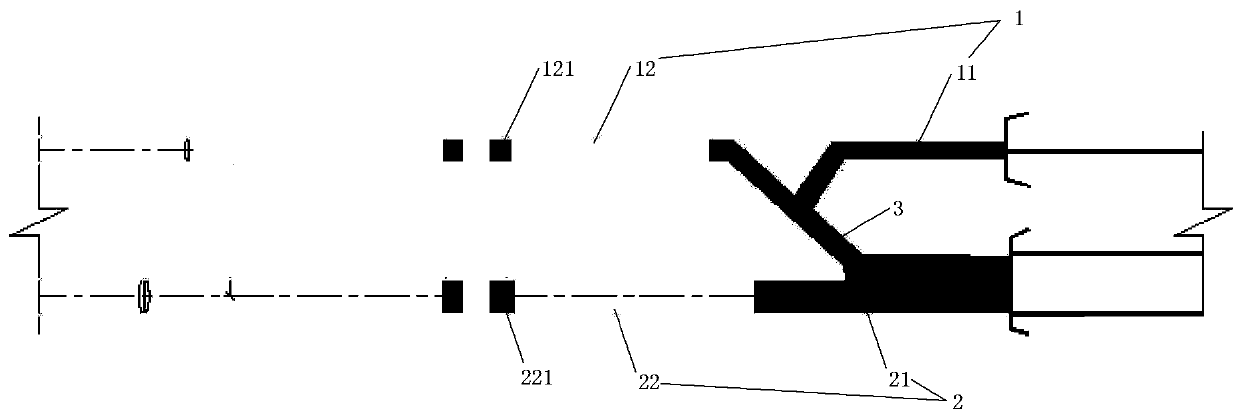

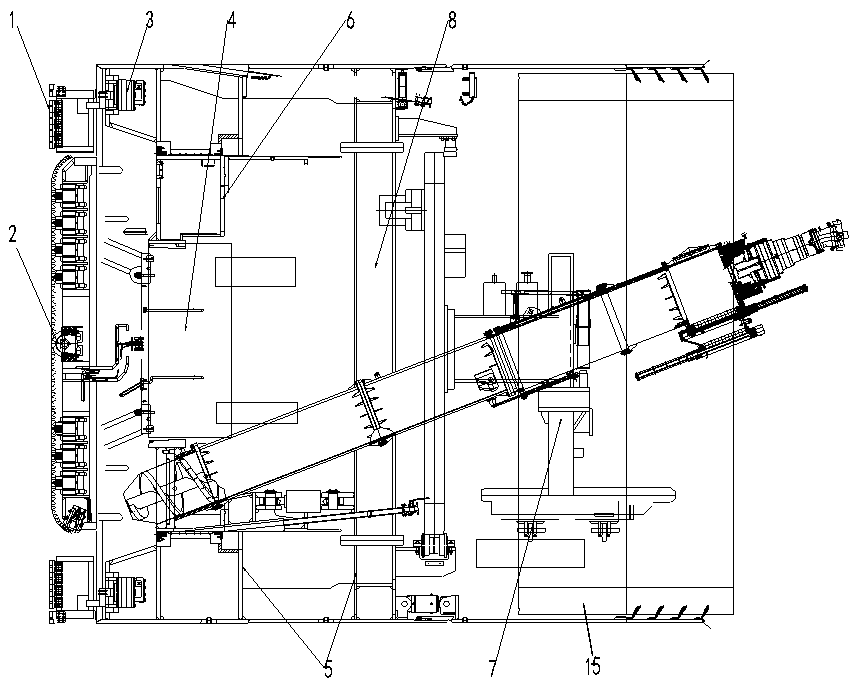

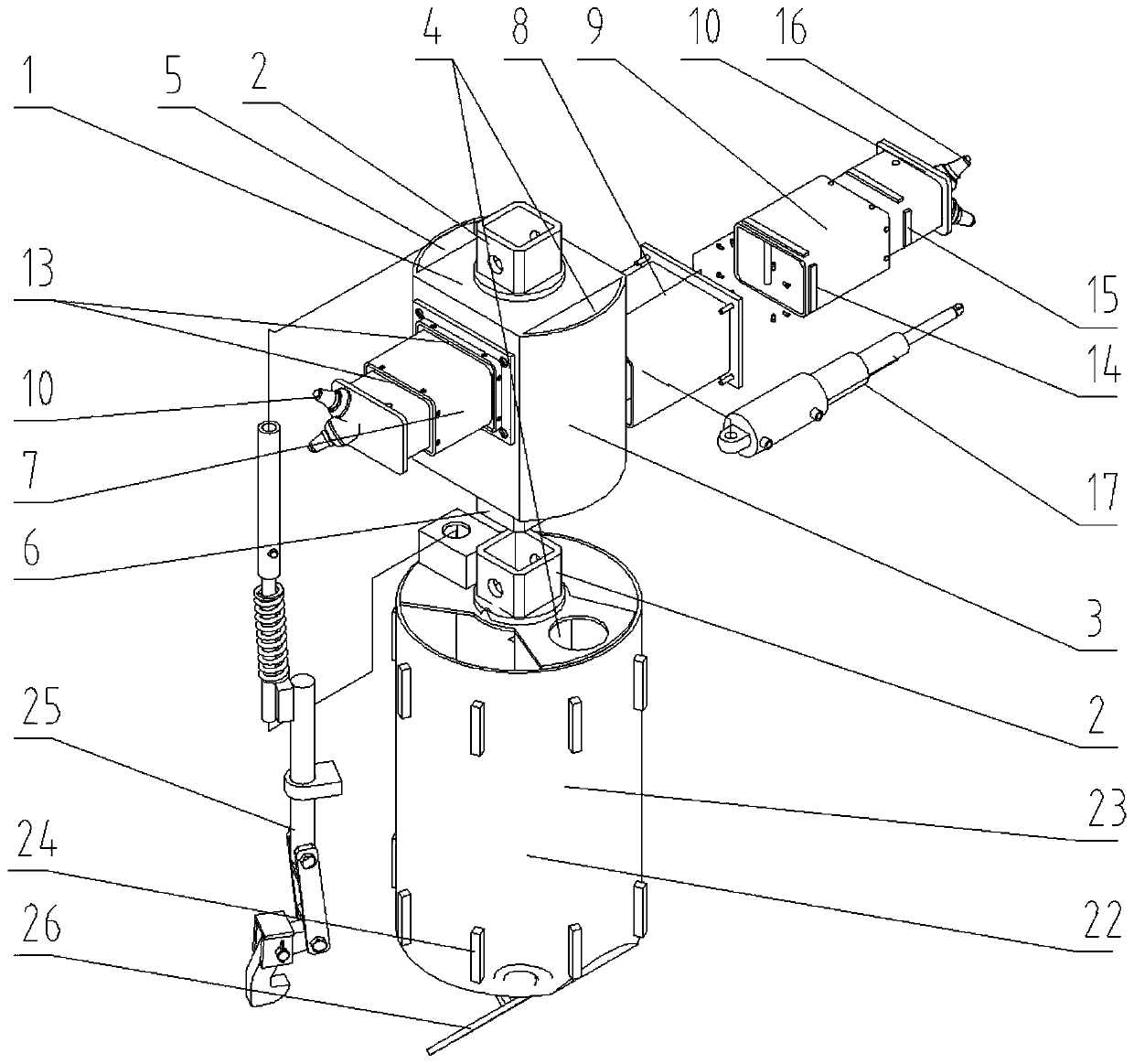

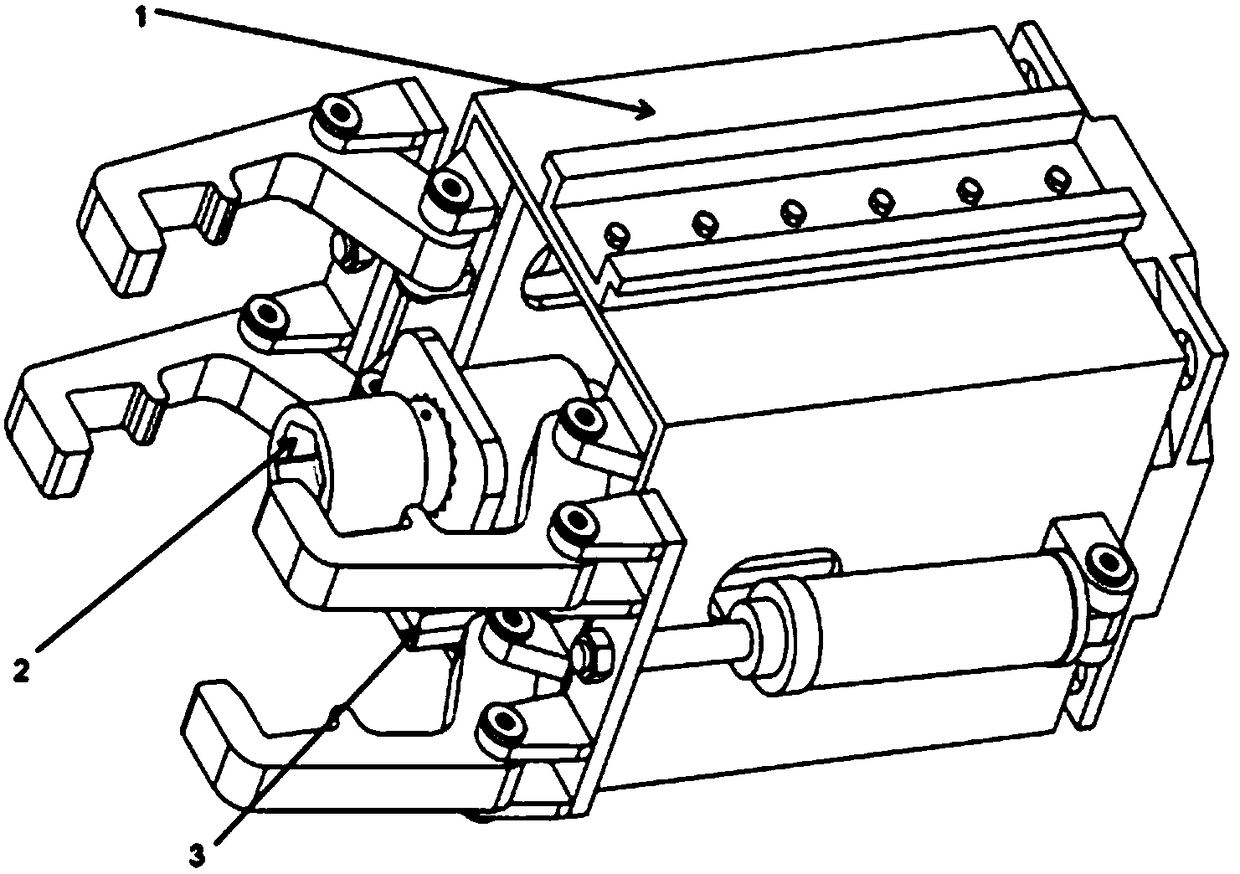

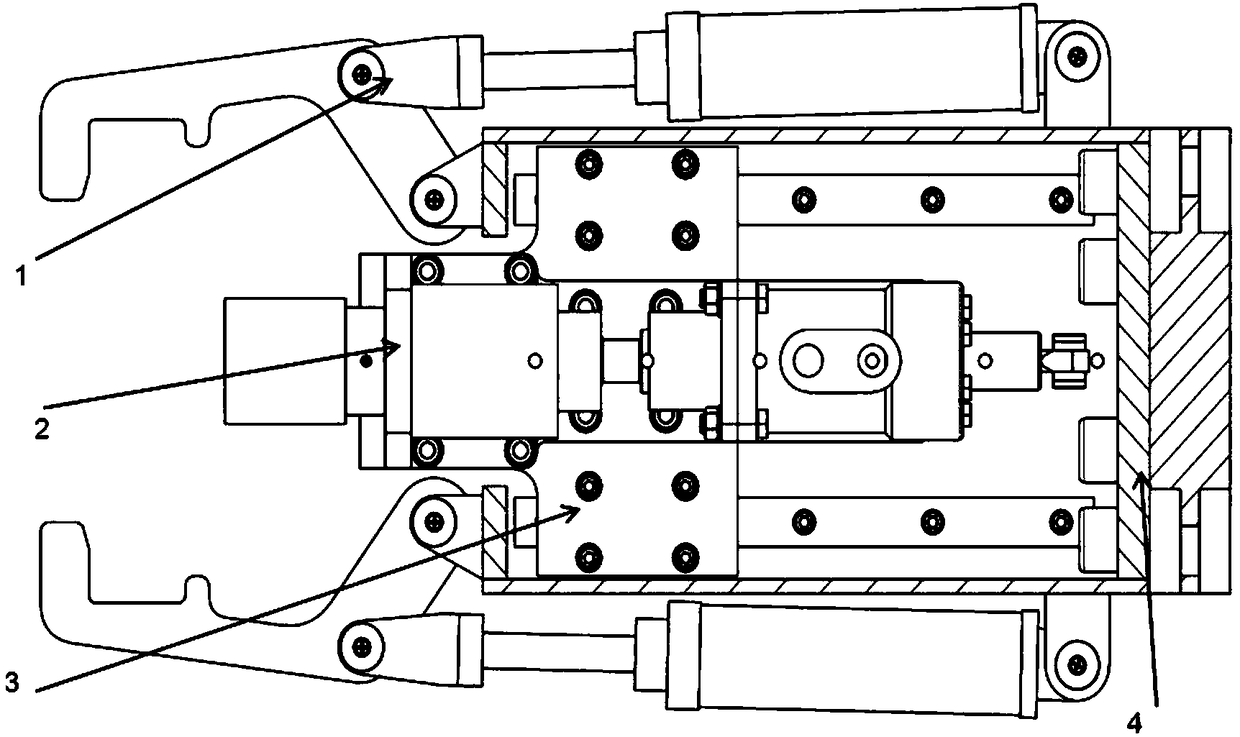

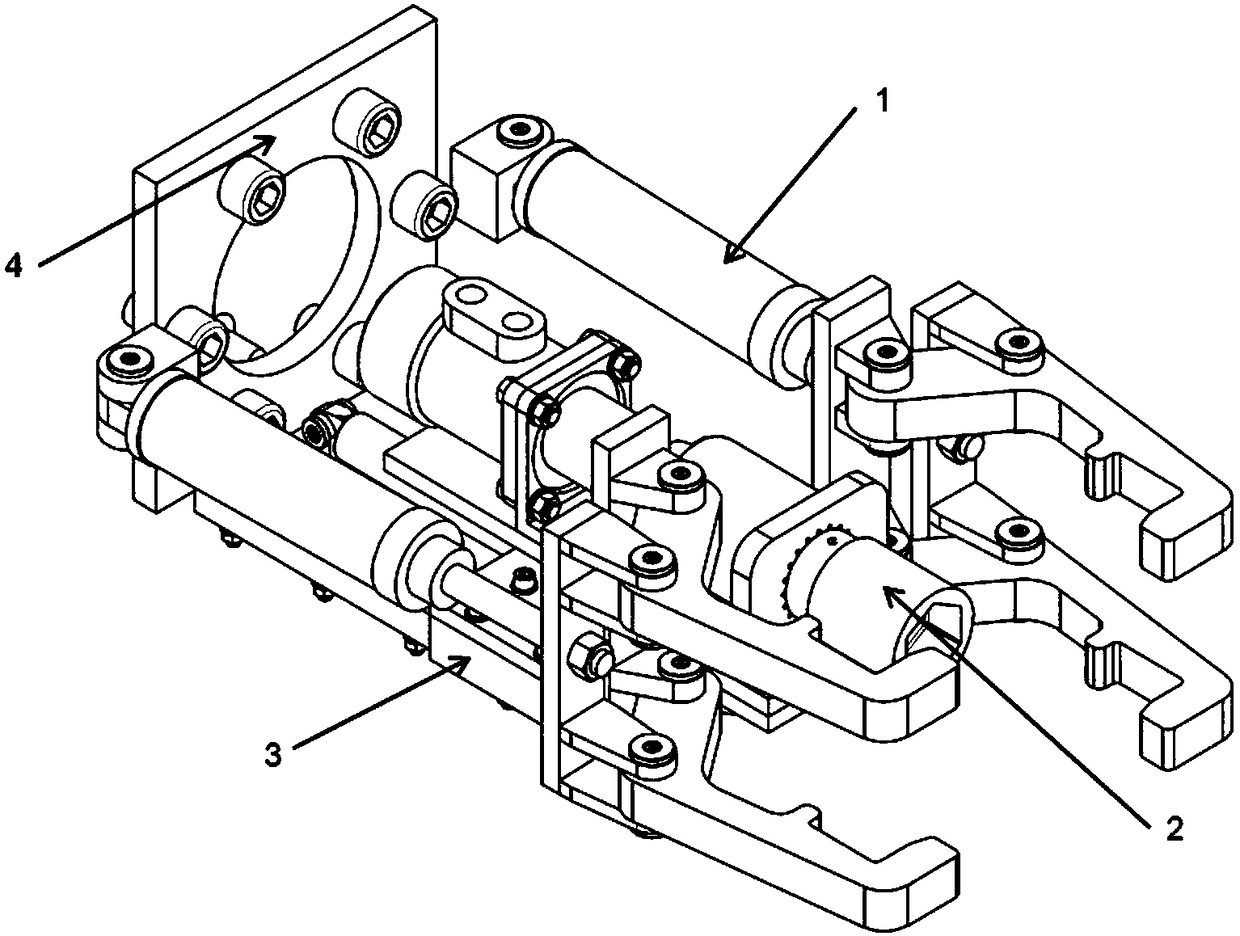

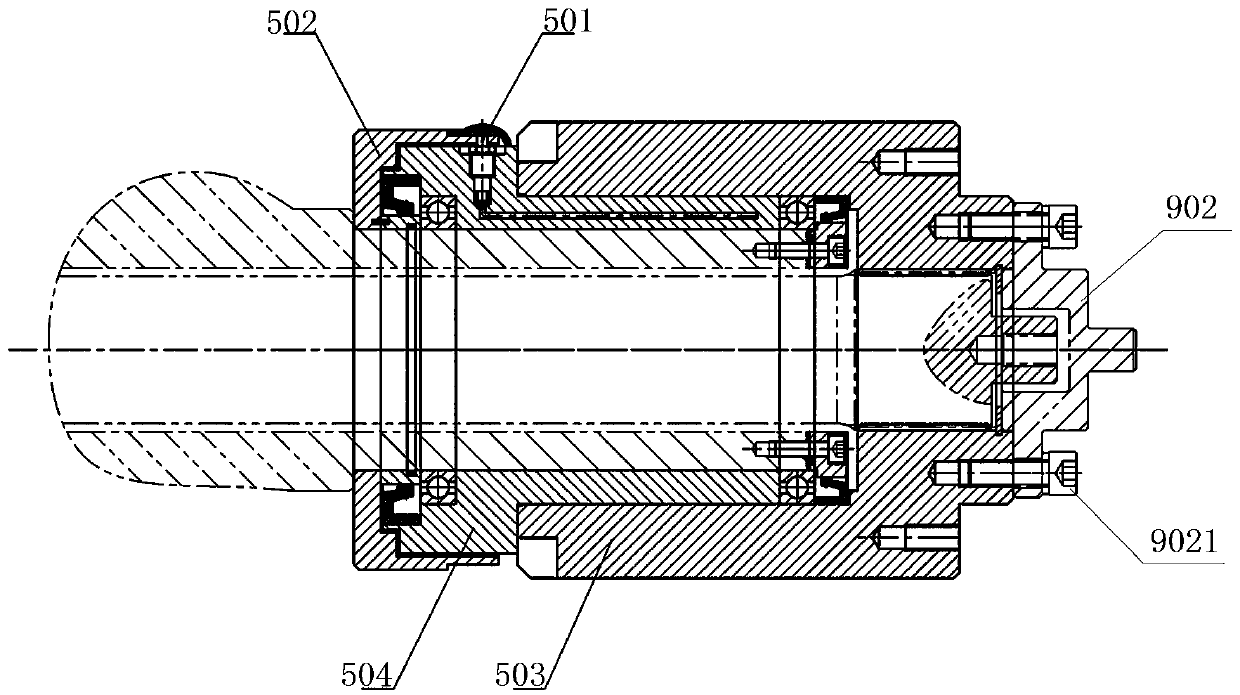

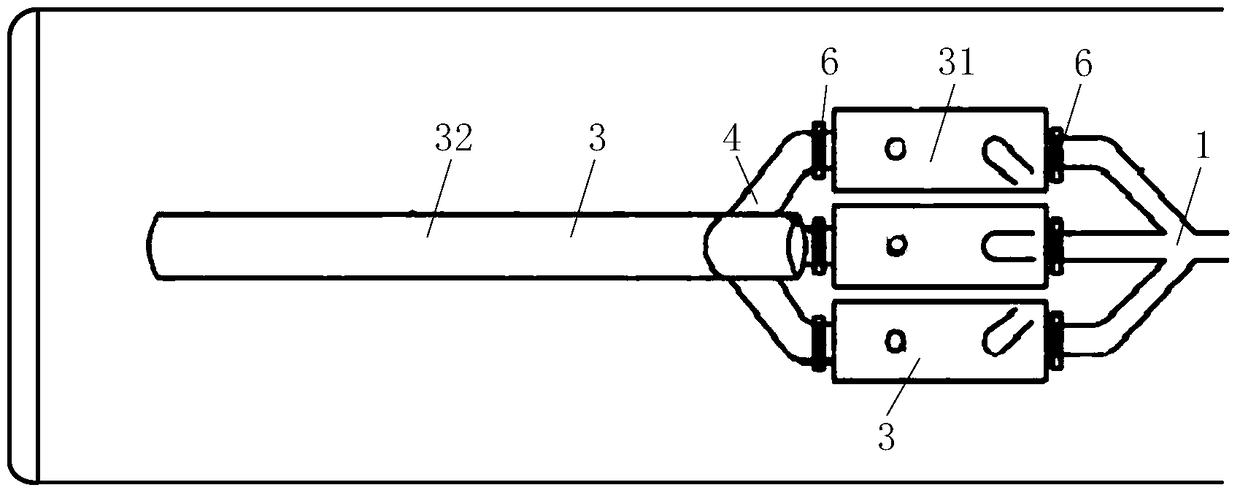

Shield tunneling machine disk type rolling knife knife changing mechanical arm end actuator

InactiveCN106761794AImprove securityImprove geological adaptabilityProgramme-controlled manipulatorGripping headsMotor speedHydraulic cylinder

The invention discloses a shield tunneling machine disk type rolling knife knife changing mechanical arm end actuator. The shield tunneling machine disk type rolling knife knife changing mechanical arm end actuator can be cooperatively used with a shield tunneling machine knife changing mechanical arm, an artificial knife changing technology is replaced, and a shield tunneling machine disk type rolling knife is automatically changed. The shield tunneling machine disk type rolling knife knife changing mechanical arm end actuator mainly comprises an end actuator body module, a bolt dismounting and fixing module and an axial movement module; the end actuator body module comprises two hydraulic cylinders which are used for driving four fingers to grab and fix a knife tool, each of the fingers has three contacting areas, when bolts at different positions are grabbed or dismounted, different contacting areas are in contact with the rolling knife; the bolt dismounting and fixing module adopts a cycloid motor as a power source, and the bolts are dismounted through bolt sleeves; the axial movement module brings convenience to dismounting of the bolts, the moving speed of the axial movement module is relevant to the rotating speed of a motor, and the axial movement module is fixed on the frame of the end actuator through a linear guide rail. According to the shield tunneling machine disk type rolling knife knife changing mechanical arm end actuator, the operation is convenient, the constructing efficiency can be sharply improved, the constructing risks are effectively reduced, and the improvement of people on an underground space utilization technology is quickened.

Owner:NORTHEASTERN UNIV

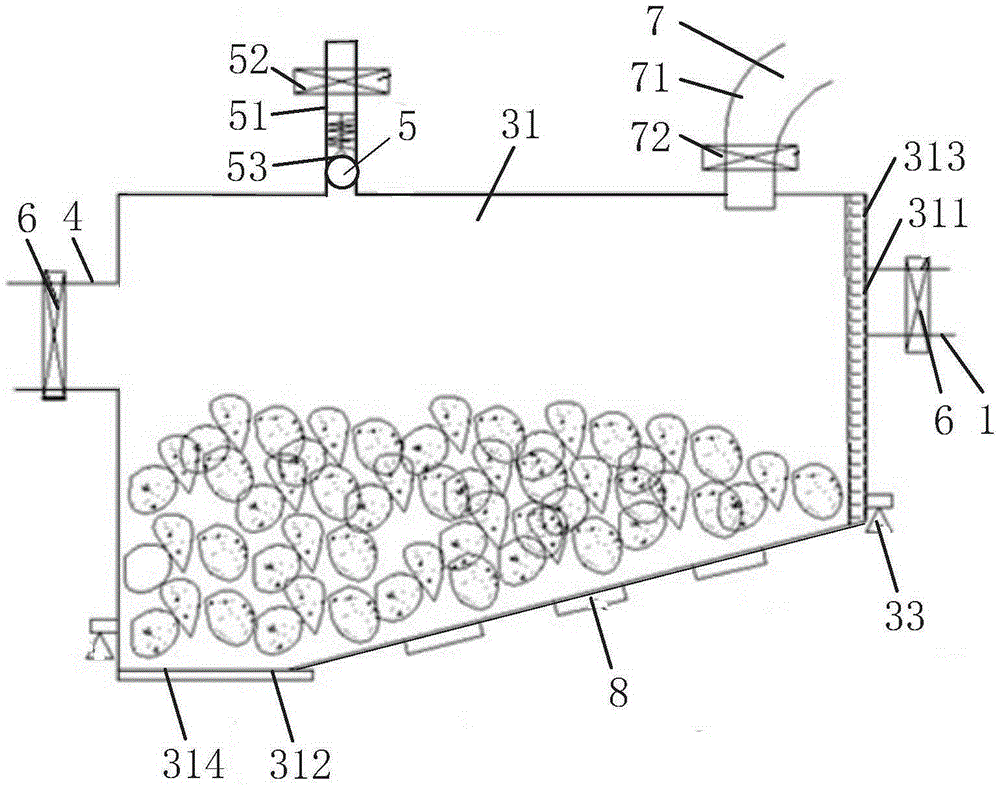

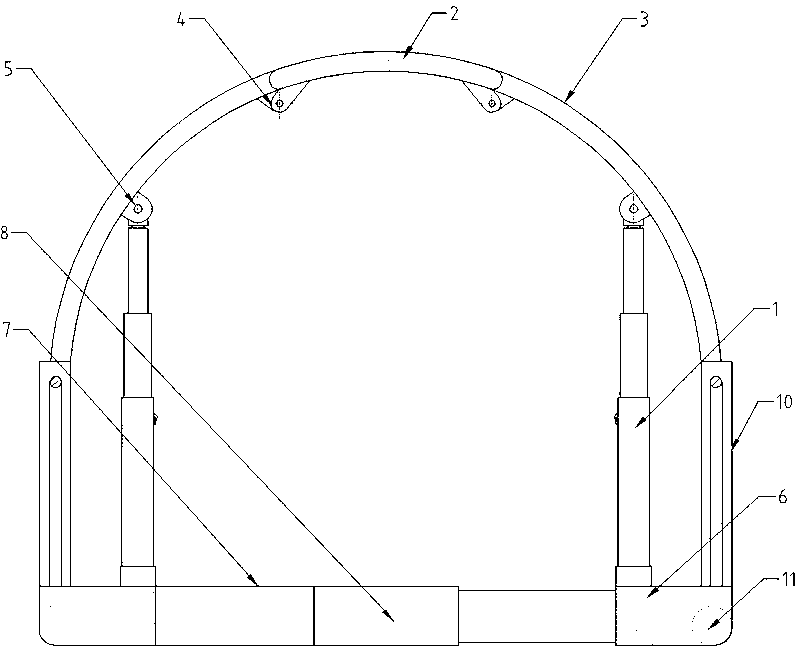

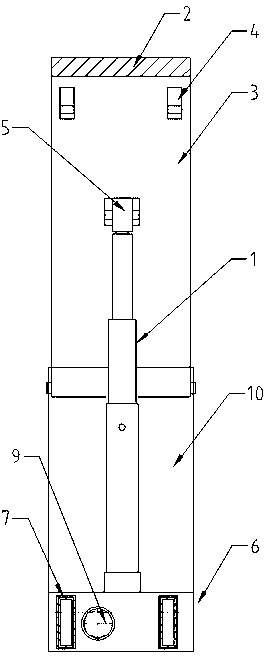

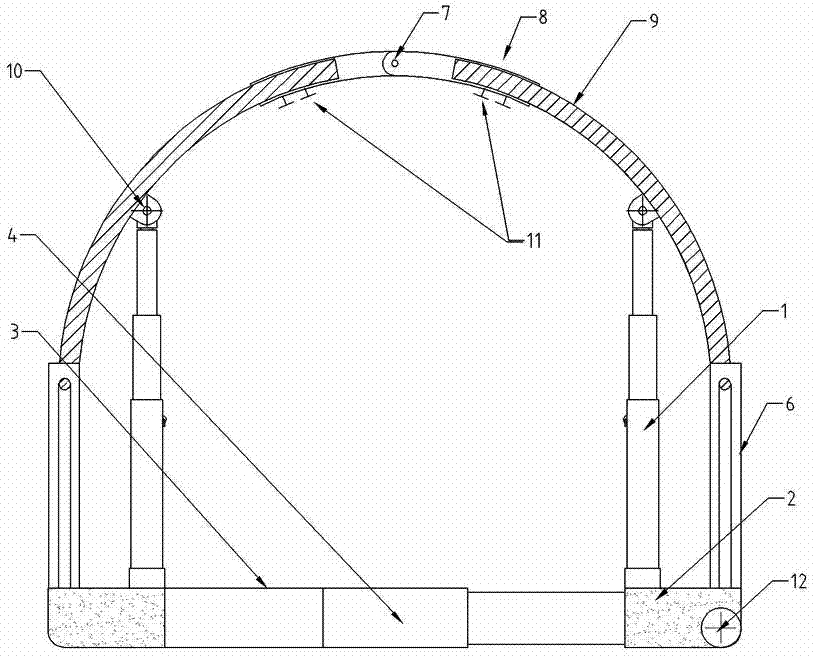

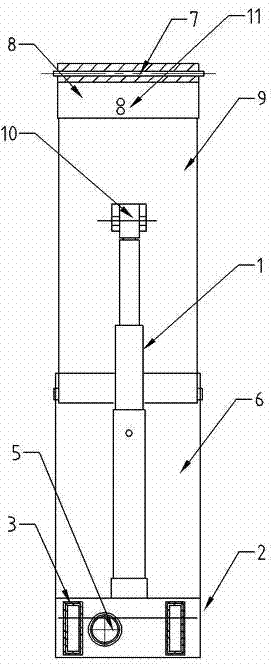

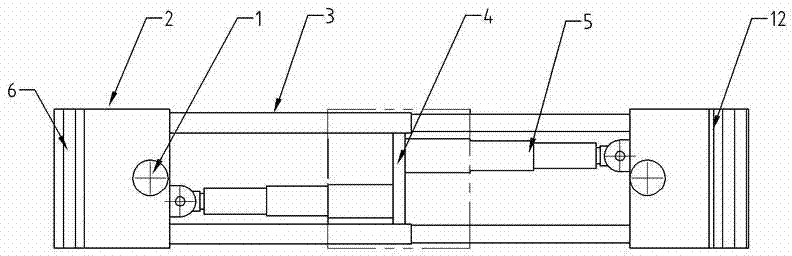

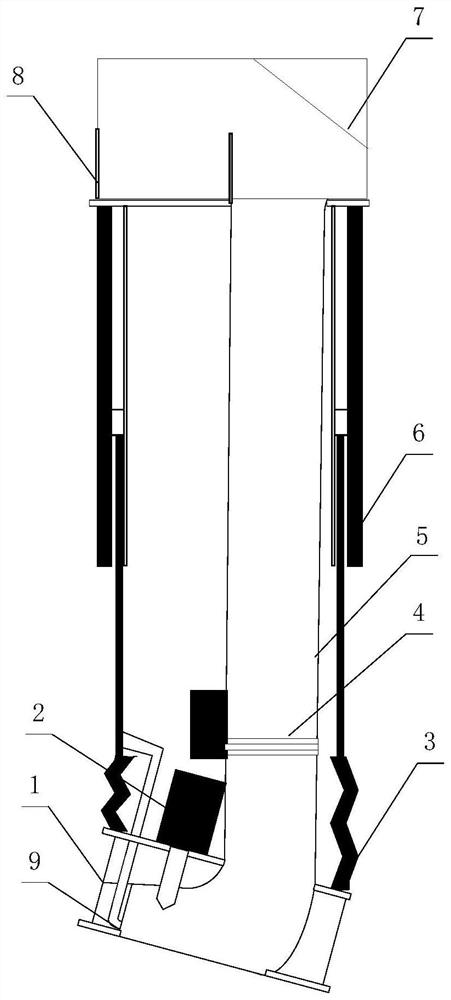

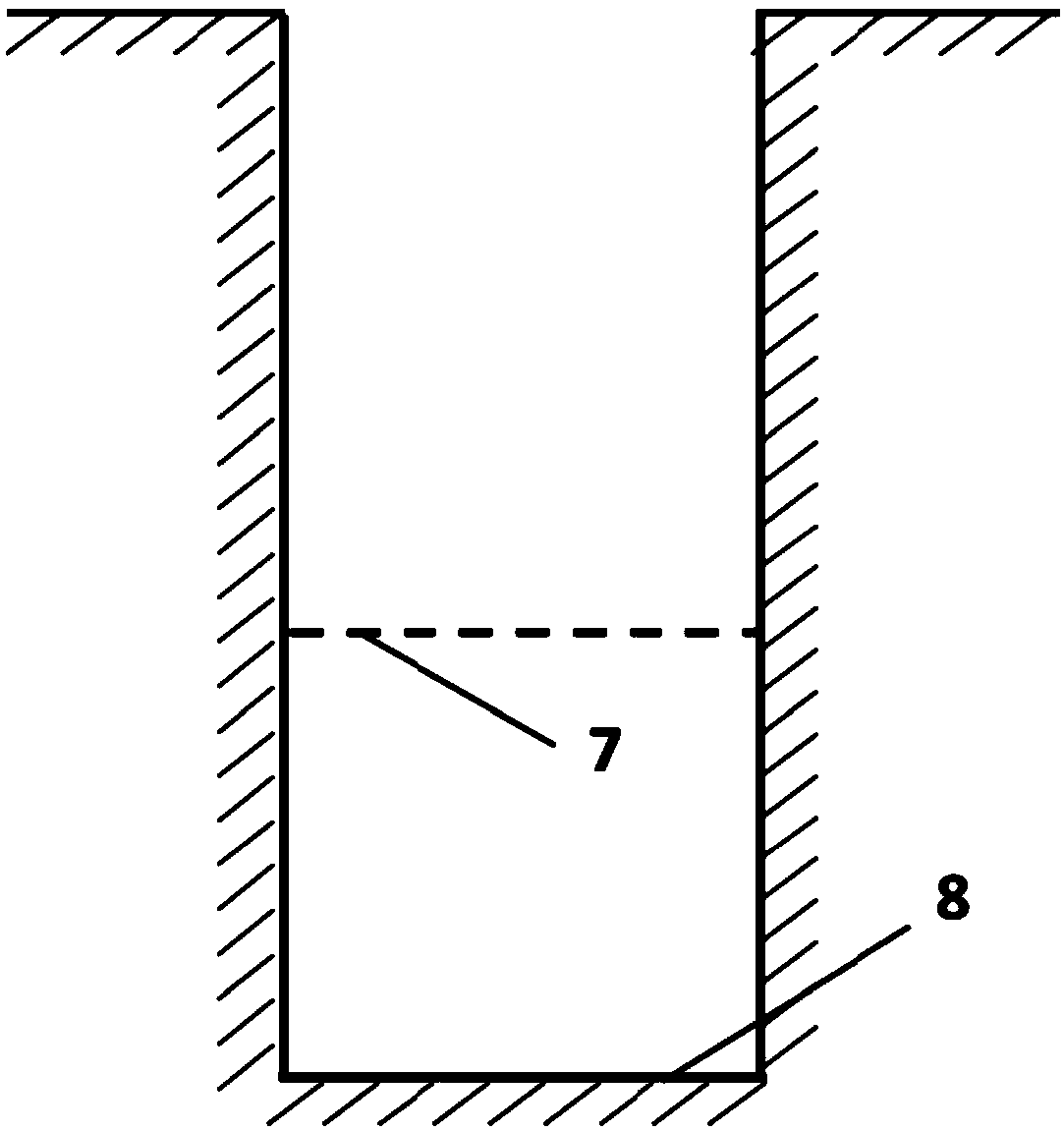

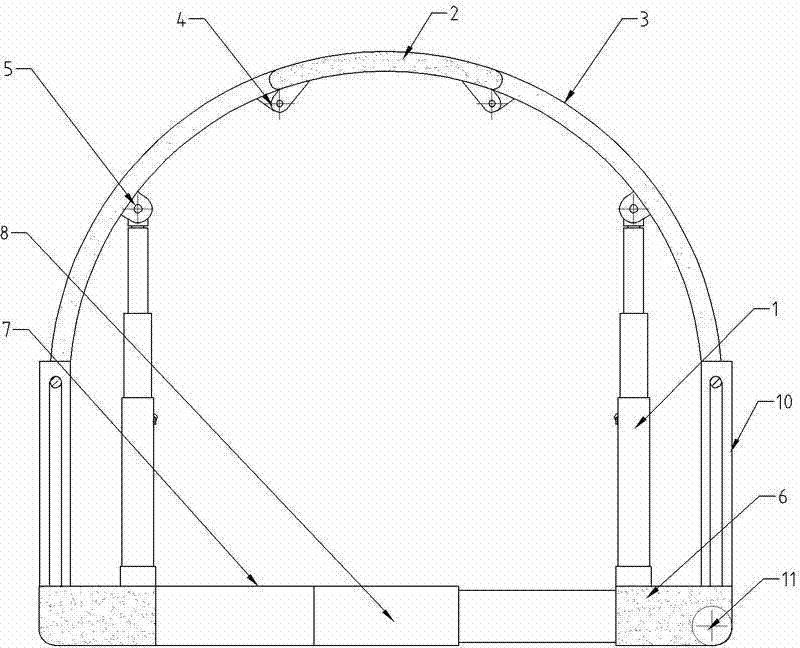

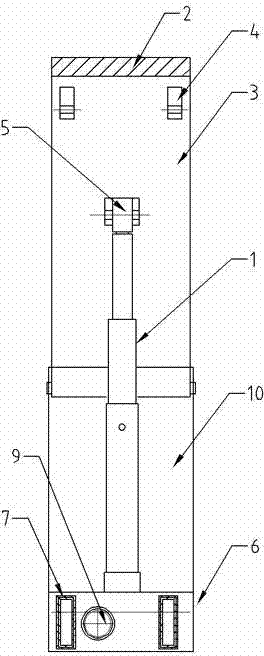

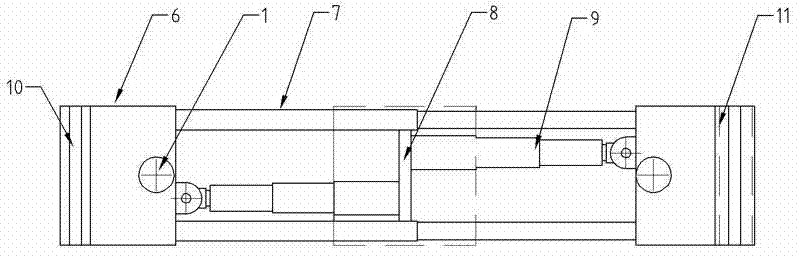

Soft rock roadway whole digging shield support

ActiveCN103104267AControl deformationLarge stretching roomProps/chocksEngineeringCompressive strength

The invention relates to a soft rock roadway whole digging shield support and belongs to the field of mining machinery manufacturing and application. The soft rock roadway whole digging shield support is composed of a semicircle protective arch, two hydraulic support pillars (1) which are arranged on the left side and the right side and a support seat. The upper ends of the two hydraulic support pillars (1) are connected with the semicircle protective arch respectively through a supporting lug (5) and a connecting pin. The lower ends of the two hydraulic support pillars (1) are respectively fixed on pillar fixing seats (6) of two sides of the support seat. Two groups of parallel telescopic guide rails (7) between the two pillar fixing seats(6) are connected to form the support seat. A pipe bending cylinder fixing seat (8) and two lateral pipe bending cylinder (9) are arranged in the middle of the middle portion of the two groups of parallel telescopic guide rails (7). The periphery of the soft rock roadway whole digging shield support can simultaneously bear pressure, compressive strength is high, bearing force is large, operation is convenient, and combination between components is tight. Through optimization design, from the aspects of convenient tunnel construction, the structure innovation and the like, Security, adaptation, technical advancement and economy of a soft rock supporting engineering are entirely improved.

Owner:范炳辉 +1

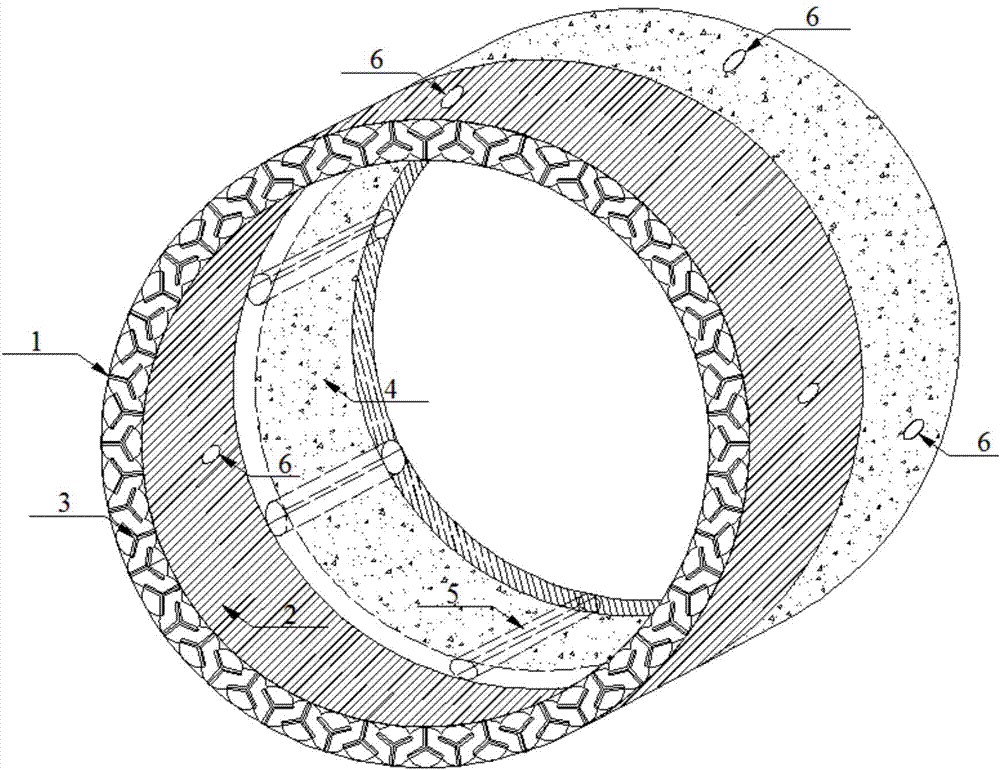

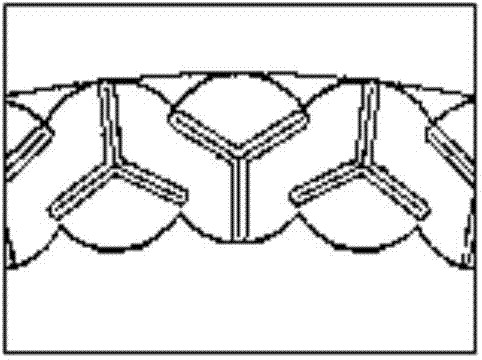

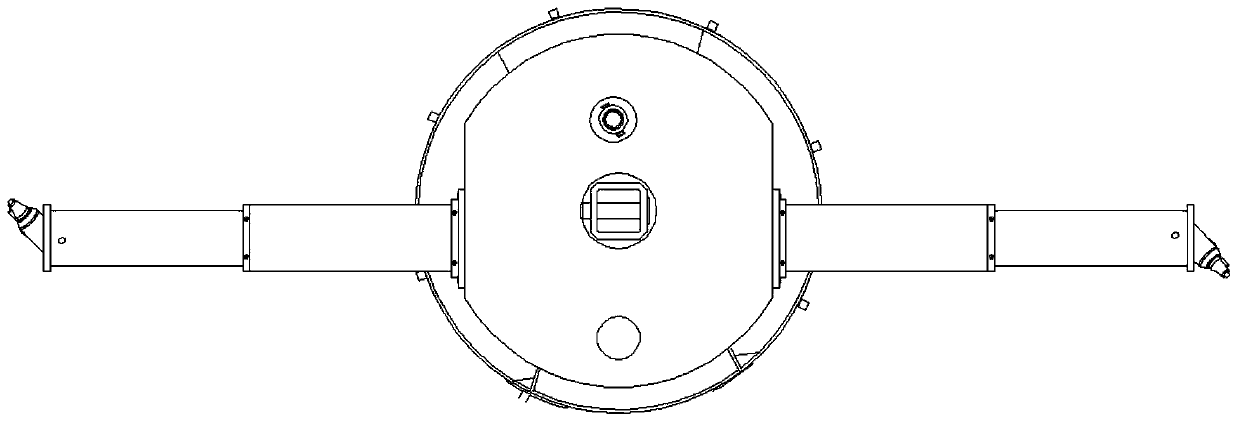

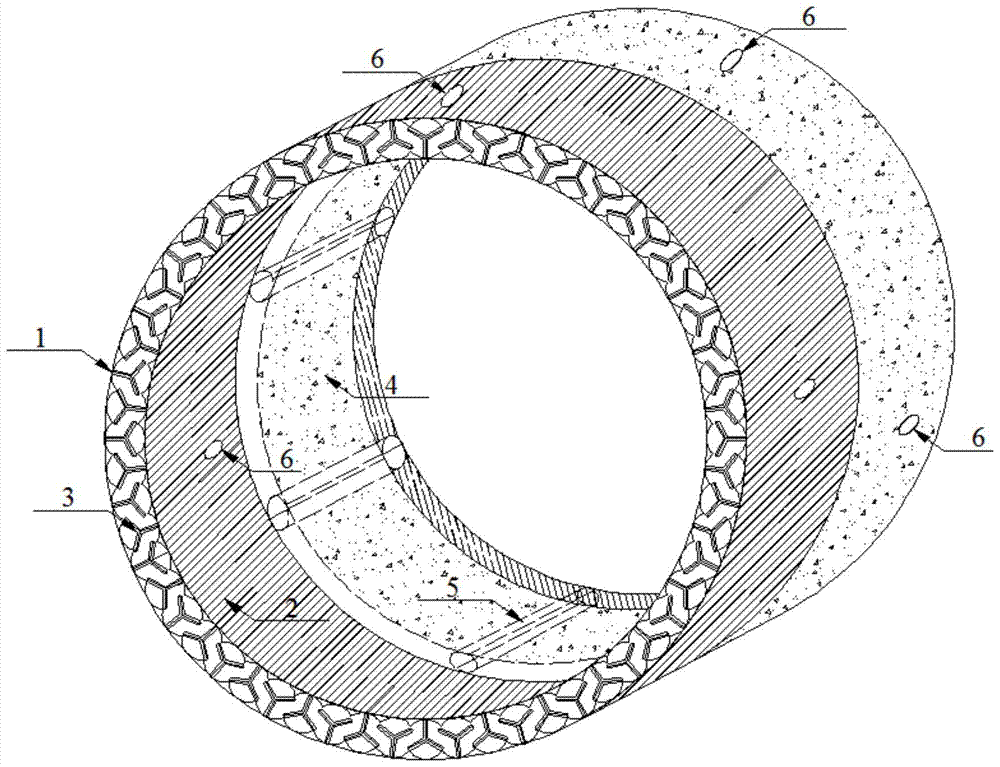

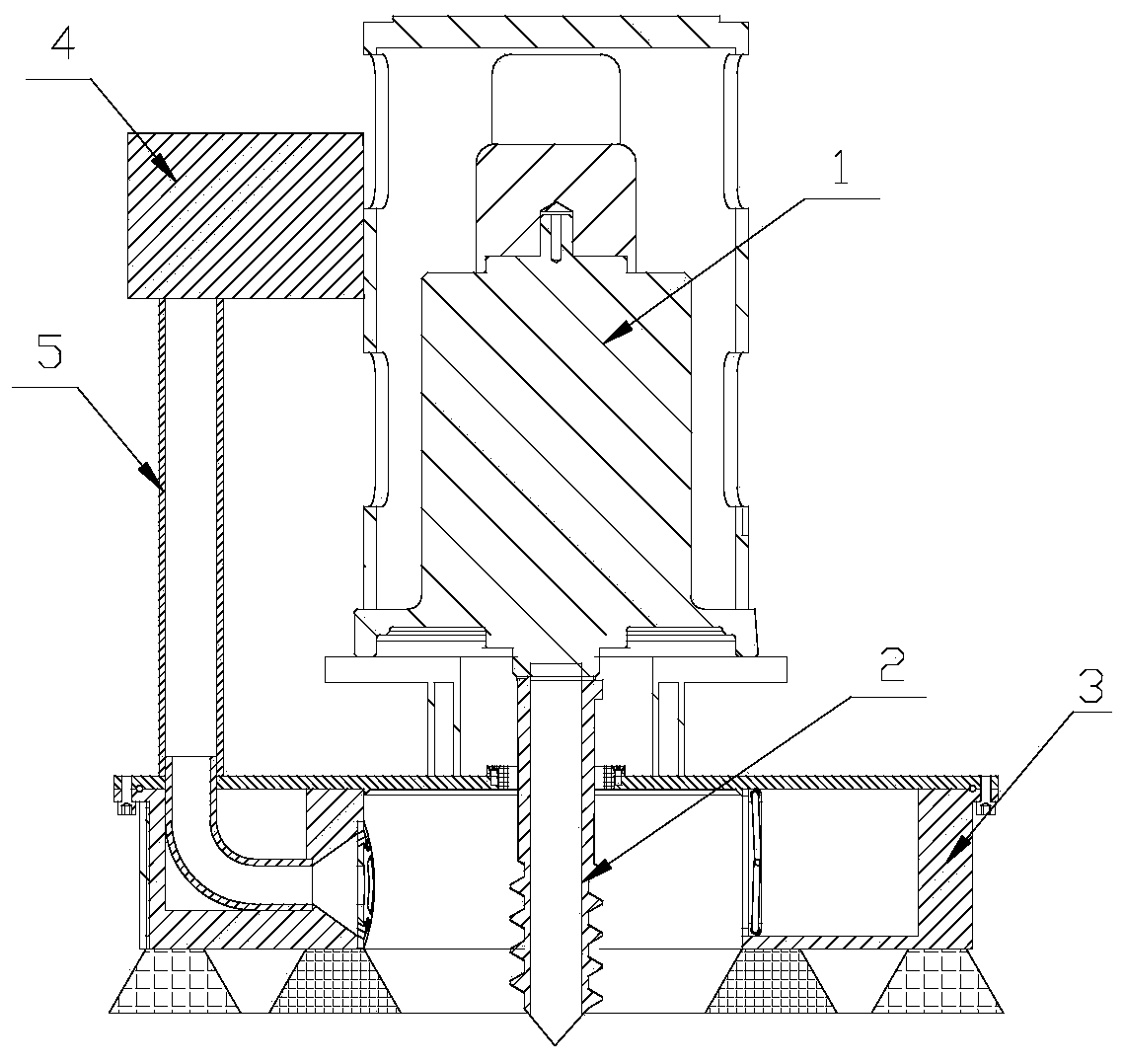

Annular pipe jacking machine

InactiveCN104712339ASolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

The invention relates to an annular pipe jacking machine which comprises an annular shell, a cutter head, a muddy water system, a synchronous grouting system, a jacking mechanism, a guide system and a control system. The annular shell comprises an outer-layer shell body and an inner-layer shell body, the cutter head is arranged in the annular shell, the muddy water system comprises a mud inlet and outlet pipeline and a mud and water separation treatment device, the mud and water separation treatment device is arranged on the ground, grouting pipes of the synchronous grouting system are arranged in the annular shell and sections of a jacking pipe respectively, thixotropic slurry is injected through a grouting hole, the jacking mechanism is arranged in a jacking pipe work well and used for jacking the sections of the jacking pipe, the guide system comprises a gyroscope, a tilt meter and a height gauge which are used for determining the posture of the annular pipe jacking machine and tunneling precision, and the control system is arranged on the ground and used for performing cooperative control on the cutter head, the muddy water system, the synchronous grouting system, the jacking mechanism and the guide system. Compared with the prior art, an excavated section is small, the shape of the section is flexible, and the annular pipe jacking machine is suitable for building tunnels with large sections and extra-large sections.

Owner:TONGJI UNIV

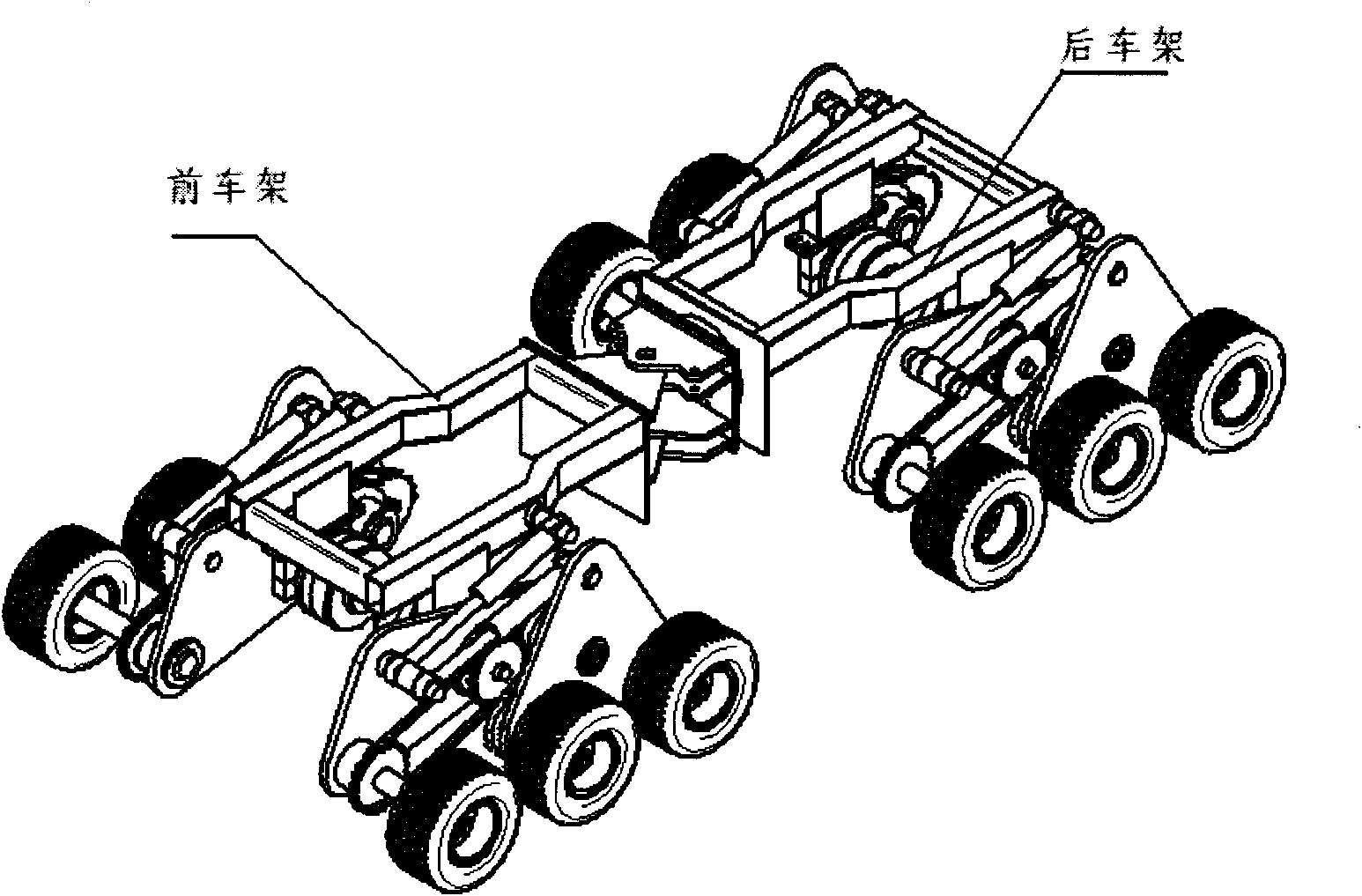

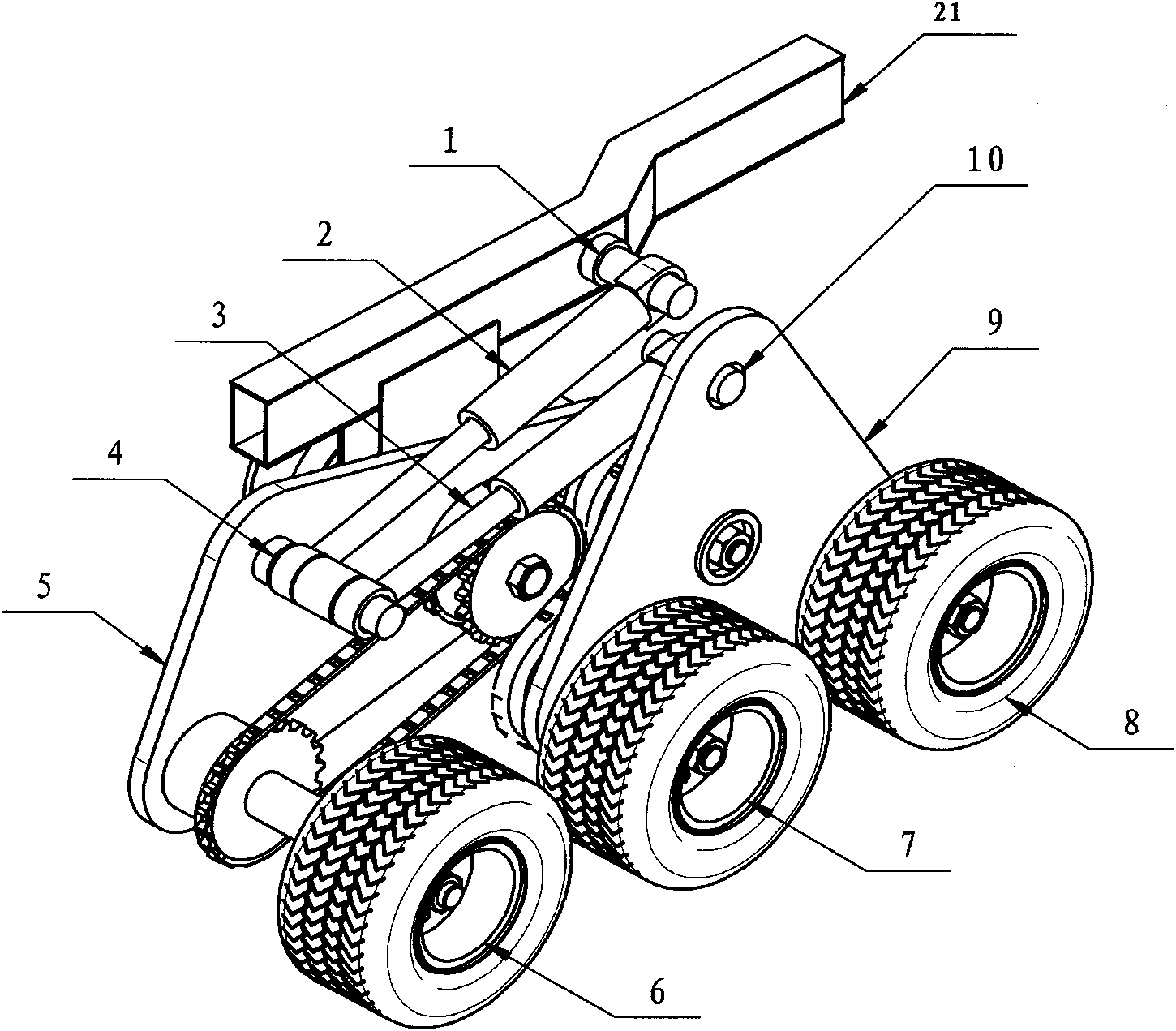

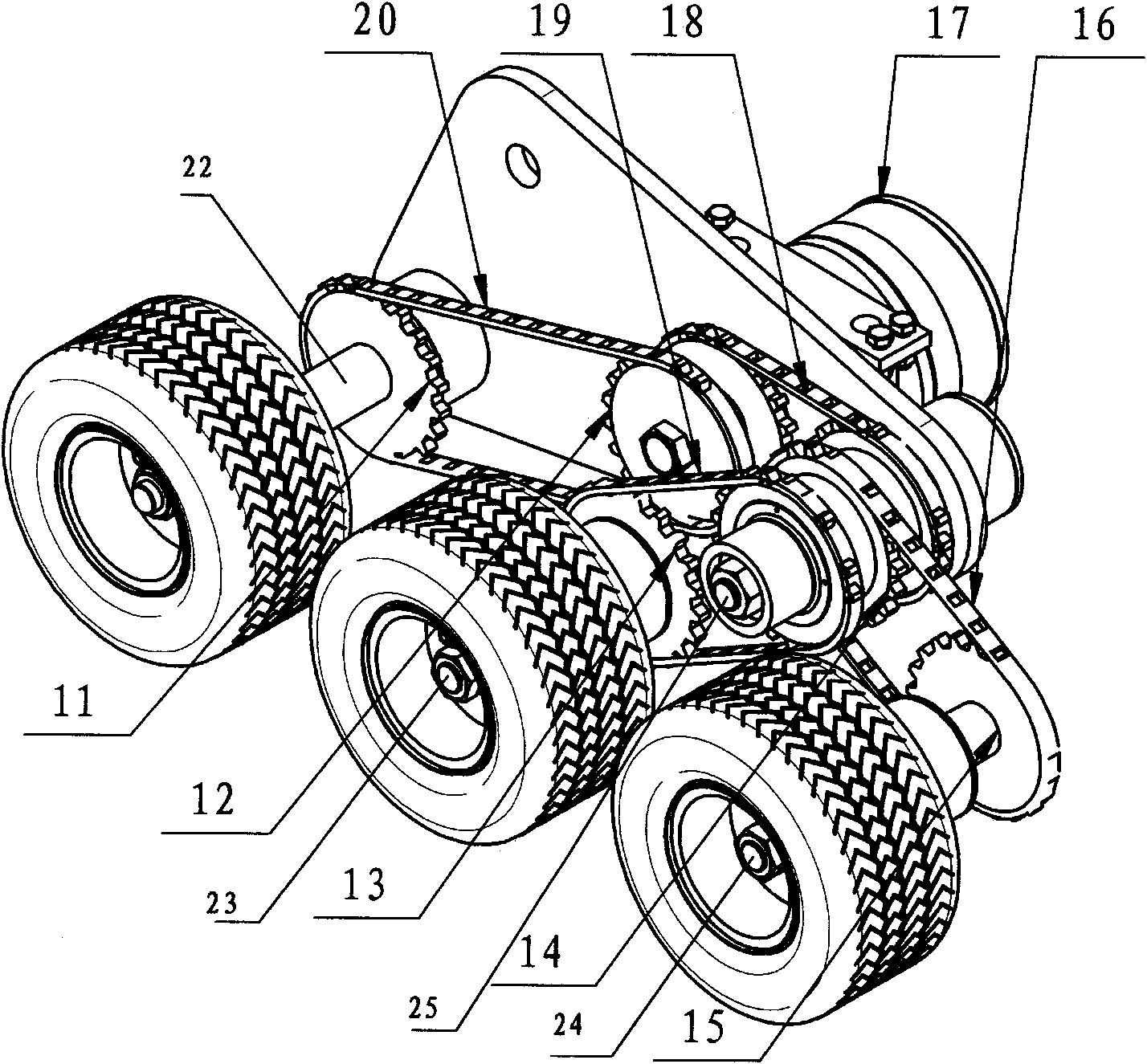

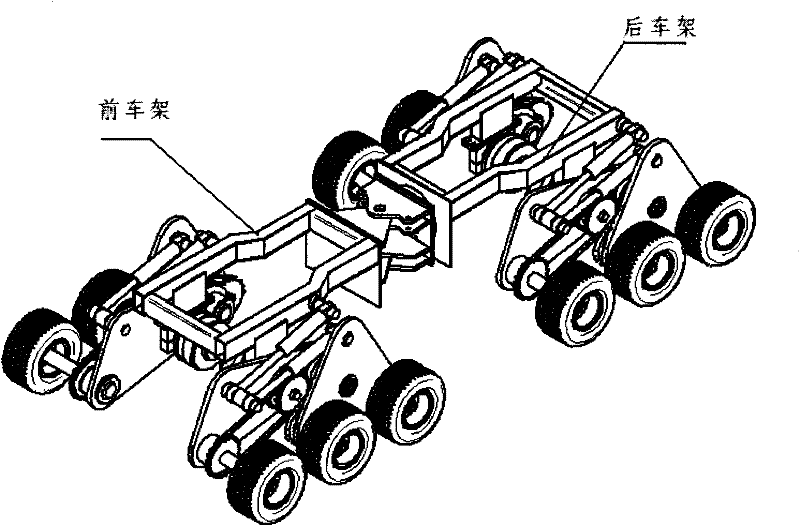

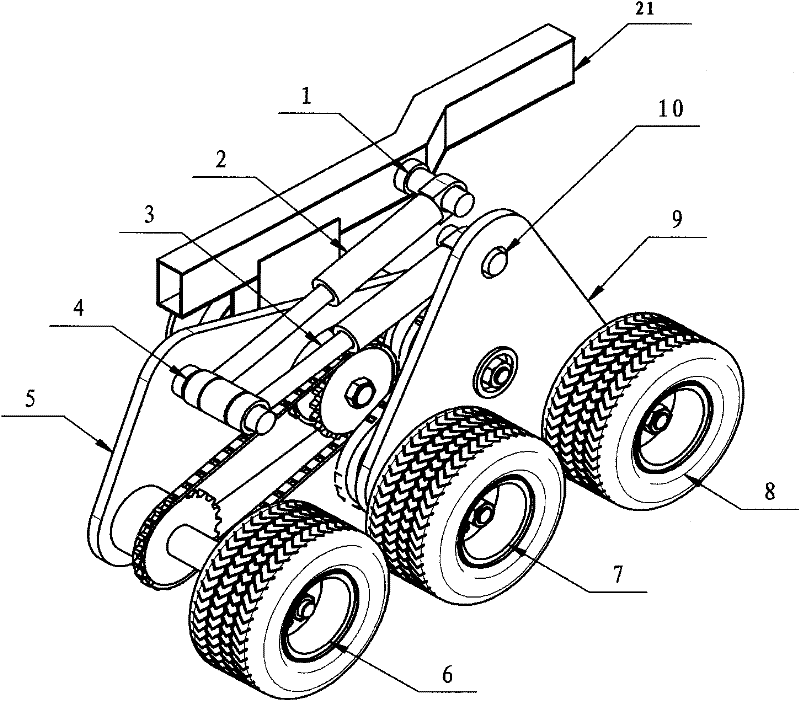

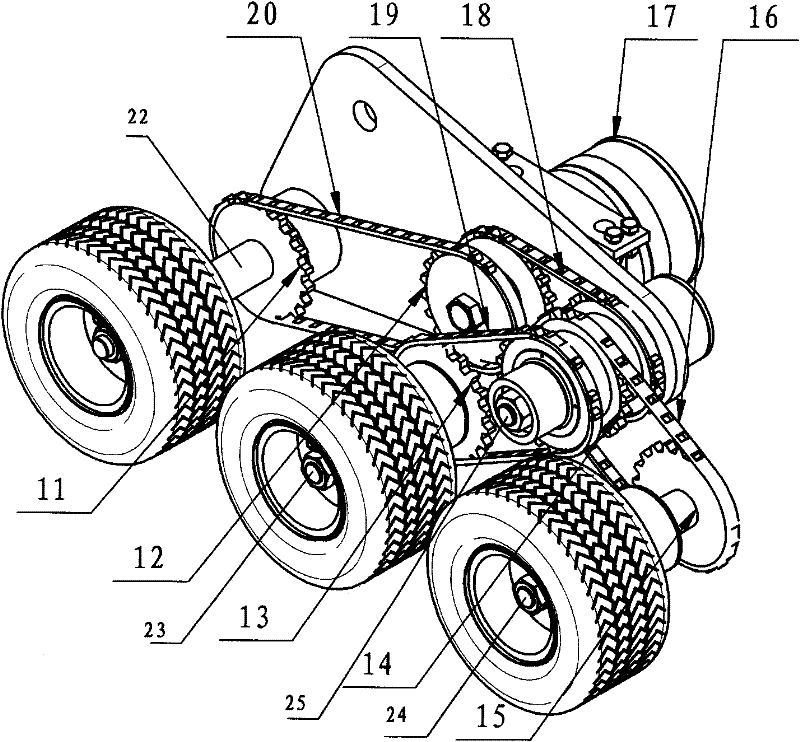

Self-adaptive sea bottom complex terrain compound wheel type traveling mechanism

InactiveCN101774409AEfficient and flexible movementImprove stabilityVehiclesControl devicesTerrainVehicle frame

The invention discloses a self-adaptive sea bottom complex terrain compound wheel type traveling mechanism which comprises an articulated frame and a compound gear train which is arranged at both sides of the frame and is provided with an independent driving system. The compound gear train comprises a front connecting plate, a back connecting plate and a front wheel, a middle wheel and a back wheel which are arranged on the front connecting plate and back connecting plate and are provided with the independent driving system; chain wheels exist among the front wheel, the middle wheel and the back wheel; the chain wheels transfer the power by chains; and the front connecting plate and the back connecting plate are articulated with a hydro-cylinder and the frame. The traveling mechanism adopts the active control mode for barrier crossing, can cross steps and bosses with the diameter larger than that of the tyre by two times, can stride a ditch less than the distance between the front wheel and the back wheel in the wheel train, can be adaptive to the high-low fluctuant road surface, causes the tyre and the road surface to be continuously contacted, furthest obtains the adhesive force of the road surface, effectively increases the dynamic performance and working efficiency in the sea bottom complex road condition. The traveling mechanism is simple and compact, has high efficient and flexible movement, low cost, wide adaptation range, good stability and high reliability.

Owner:UNIV OF SCI & TECH BEIJING

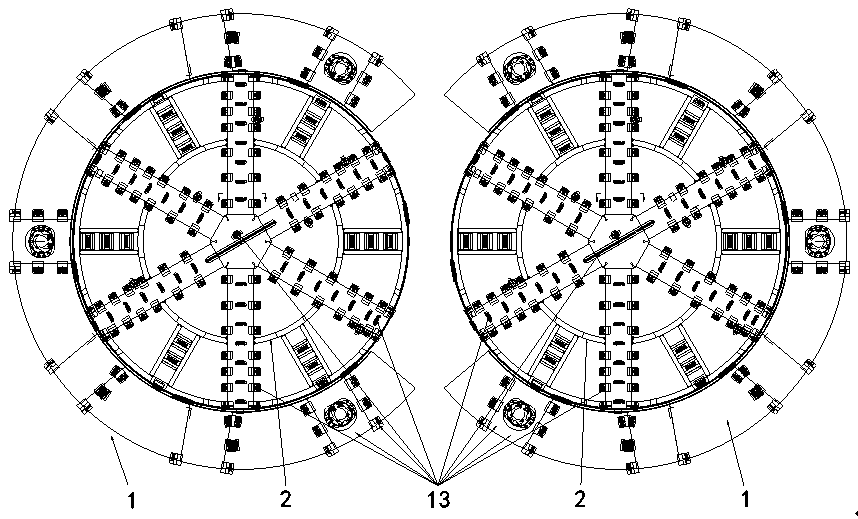

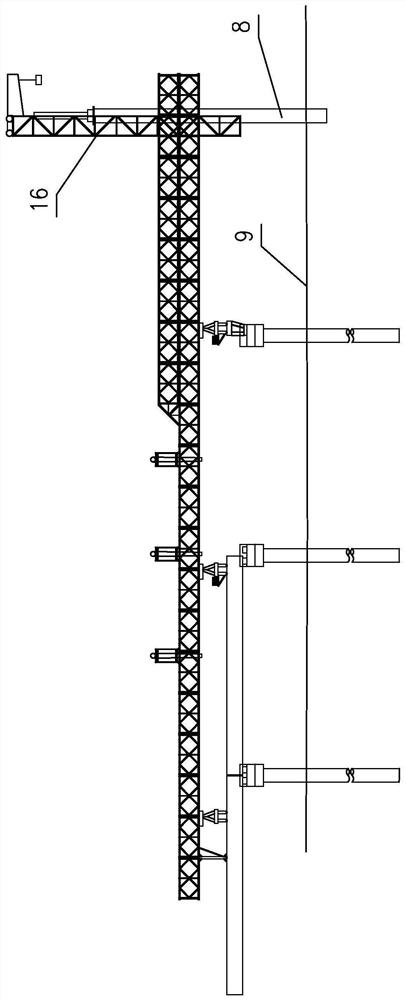

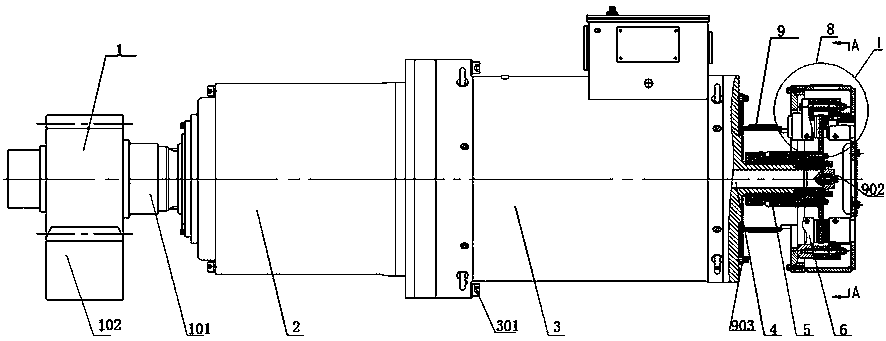

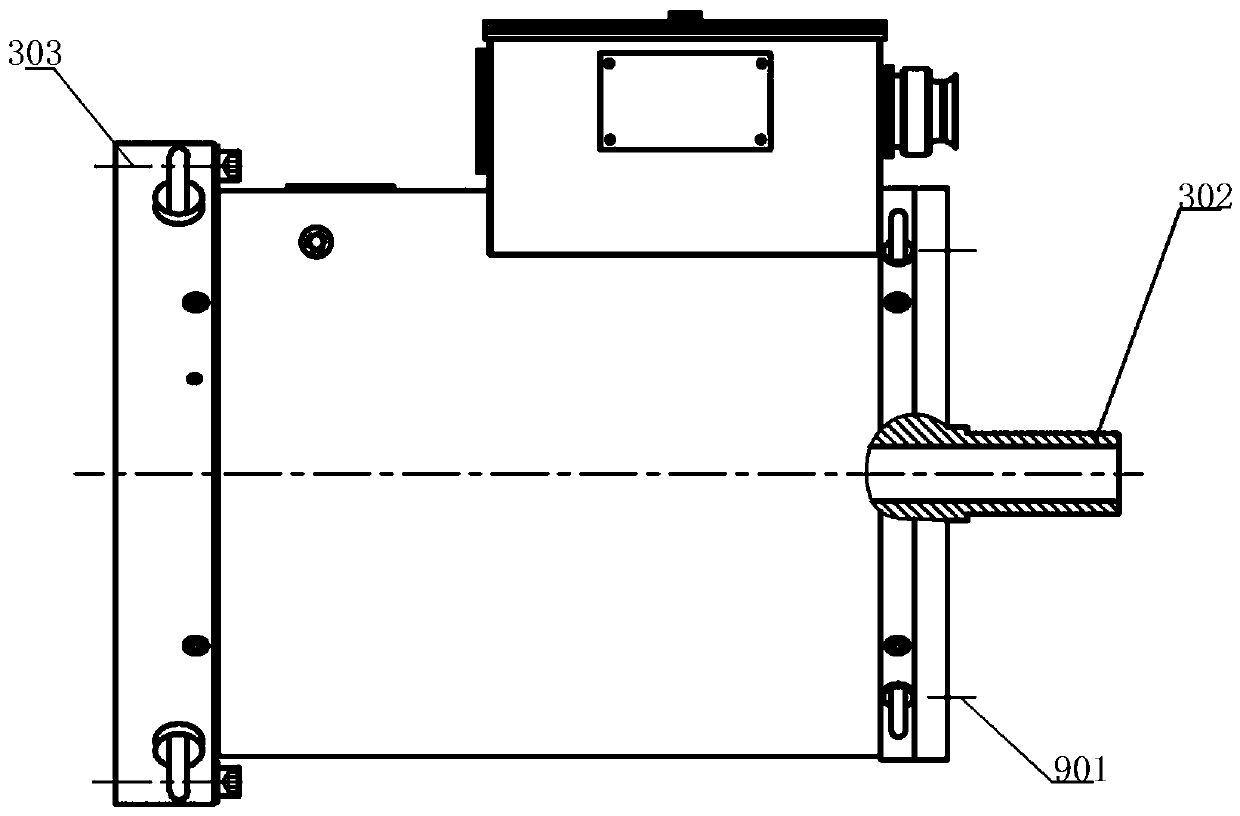

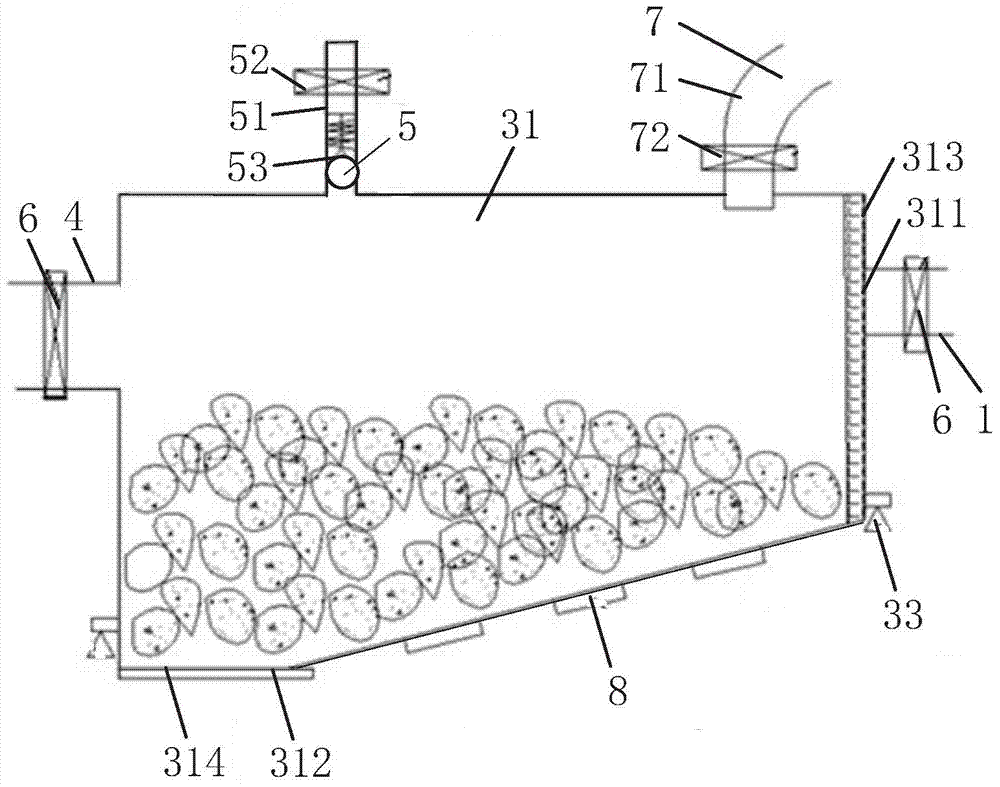

Compound driving device of TBM cutting disc motor hydraulic motor

The invention discloses a compound driving device of a hydraulic motor of a TBM (tunnel boring machine) cutting disc motor. The compound driving device comprises a big gear ring and a variable frequency motor driving mechanism, wherein the variable frequency motor driving mechanism comprises a first pinion, a first speed reducer and a variable frequency motor; the first pinion and the big gear ring are meshed; an output shaft of the first speed reducer and the first pinion are fixedly connected; an input shaft of the first speed reducer and an output shaft of the variable frequency motor are connected; in addition, the compound driving device also comprises a hydraulic motor driving mechanism, wherein the hydraulic motor driving mechanism comprises a second pinion, a second speed reducer, a viscosity clutch and a hydraulic motor; the second pinion and the big gear ring are meshed; an output shaft of the second speed reducer and the second pinion are fixedly connected; an input shaft of the second speed reducer and an output shaft of the viscosity clutch are connected; and an input shaft of the viscosity clutch and an output shaft of the hydraulic motor are connected. By utilizing the compound driving device, geological adaptability of a TBM cutting disc driving system and trouble-out ability of the TBM are obviously improved, so that driving characteristics of the cutting disc and geological characteristics of rock are matched, and the use ratio of the installed power is improved.

Owner:ZHEJIANG UNIV

Improved soft rock roadway integral tunneling protection support

InactiveCN103615269AControl the amount of roadway deformationLarge stretching roomProps/chocksHinge angleBuilding construction

The invention relates to an improved soft rock roadway integral tunneling protection support and belongs to the field of mining machinery manufacturing and application. The improved soft rock roadway integral tunneling protection support mainly consists of a semi-circular protective arch, left and right hydraulic supporting columns (1) and a support base. The semi-circular protective arch consists of two groups of arc-shaped supporting arch slabs which are symmetric, located on the left side and the right side and connected at the highest point of the arch through hinges (7), and each group of arc-shaped supporting arch slabs include an arc-shaped connecting arch slab (8) and an arc-shaped bearing plate (9). The upper ends of the left and right hydraulic supporting columns (1) are respectively connected with a supporting connection lug (10) on the corresponding-side arc-shaped bearing plate (9). The improved soft rock roadway integral tunneling protection support has the advantages of being capable of simultaneously bearing pressure through the periphery, high in compressive strength, large in bearing force, convenient to operate and tight in part combination. With respect to roadway construction convenience, structure innovation and the like, the safety, the adaptability, the technical advancement and the economical efficiency of the soft rock supporting projects are integrally improved through design optimization.

Owner:范炳辉

Touch sampler suitable for extraterrestrial celestial body

ActiveCN111947965ASampling implementationSampling multiple working conditionsWithdrawing sample devicesWater resource assessmentStar catalogueCelestial body

The invention relates to a touch sampler suitable for an extraterrestrial celestial body. The touch sampler comprises a sampling flow guide cover, a pneumatic impact rock breaking mechanism, a flexible spring and the like; wherein the sampling flow guide cover is located at the bottom end of the touch sampler, the gas excitation nozzle is located on the inner side of the sampling flow guide cover,the pneumatic impact rock breaking mechanism is installed on the inner side of the sampling flow guide cover, the flexible spring is installed at the upper end of the sampling flow guide cover, the pneumatic unfolding mechanism is installed at the upper end of the flexible spring; the sample channel is installed in the pneumatic unfolding mechanism, wherein one end is connected with a cavity in the sampling flow guide cover, and the other end is connected with the sample container; the sealing door is installed in the sample channel, and the sample container is fixed to the upper end of the pneumatic unfolding mechanism. According to the invention, the pneumatic impact rock breaking mechanism is used for breaking and stripping the surface of a star, meanwhile, a surface sample is blown into the sample container through gas excitation and transmission, recovery is completed, and the device has the advantages of being short in sampling time, high in star catalogue adaptability, capableof achieving repeated sampling and reliable in sampling.

Owner:BEIJING SATELLITE MFG FACTORY

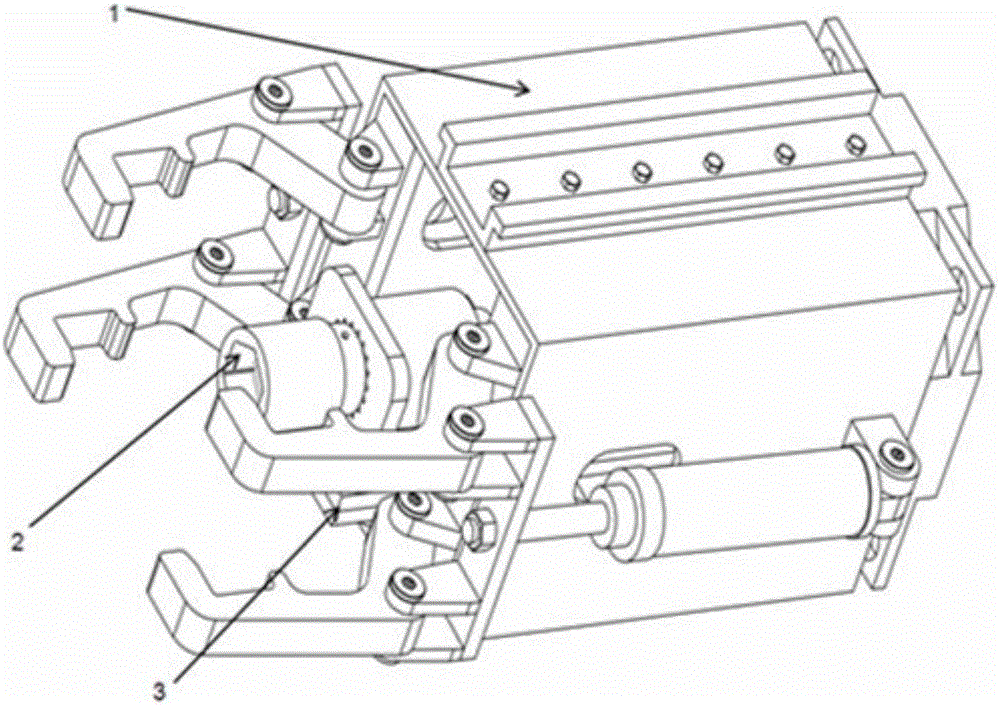

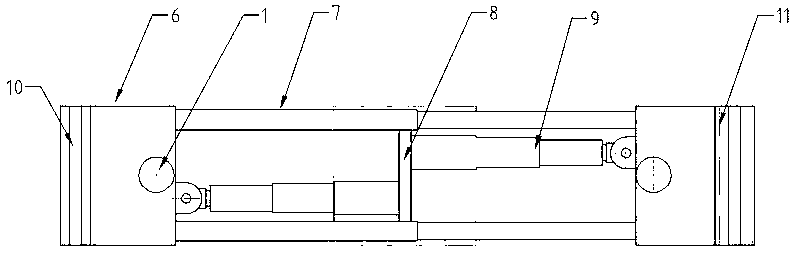

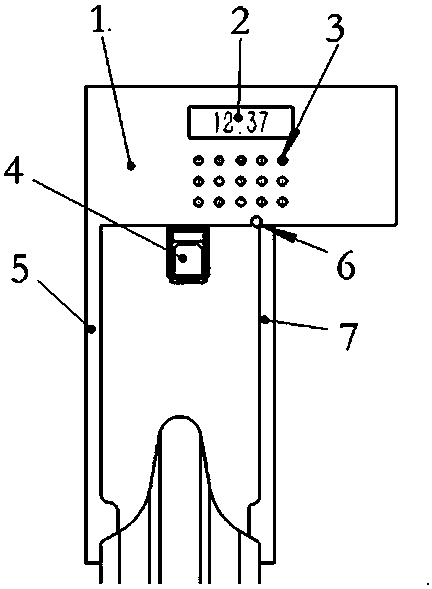

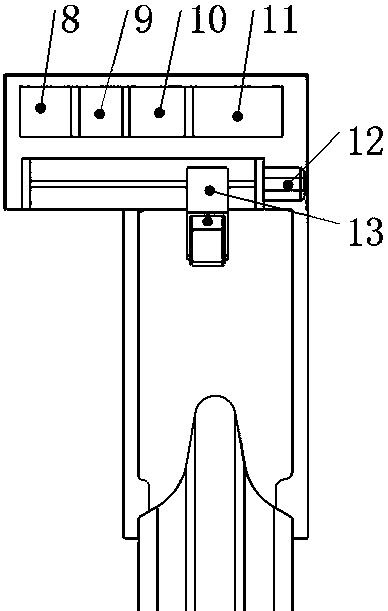

Portable intelligent detector for hobbing cutter and processing method for hobbing cutter wear data

The invention provides a portable intelligent detector for a hobbing cutter and a processing method for hobbing cutter wear data. The portable intelligent detector for the hobbing cutter comprises a casing, wherein a first sliding rail and an electric servo sliding rail are arranged in the casing; a first support leg and a second support leg which are used for clamping two ends of a hobbing cutterring are arranged on the first sliding rail; a laser measuring instrument is assembled on the electric servo sliding rail in a sliding manner; a storage battery, a memory, a processor and a wirelesscommunication module are also arranged in the casing; the power supply end of the processor is electrically connected with the storage battery; the data end of the processor is electrically connectedwith the memory and the wireless communication module; the communication end of the processor is electrically connected with the communication end of the laser measuring instrument; and the control end of the processor is electrically connected with a driving motor in the electric servo sliding rail. According to the portable intelligent detector and the processing method provided by the invention, the wear quantity of the hobbing cutter ring can be statically detected, and hobbing cutter wear quantity for cutter rings with different blade types and different sizes can be accurately and automatically measured; and in addition, a processing and analyzing method for the hobbing cutter wear data is improved so as to better provide shielding construction service at later stage.

Owner:中铁工程装备集团隧道设备制造有限公司

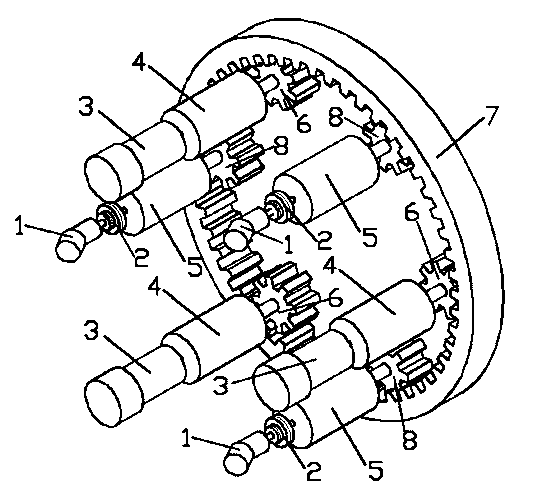

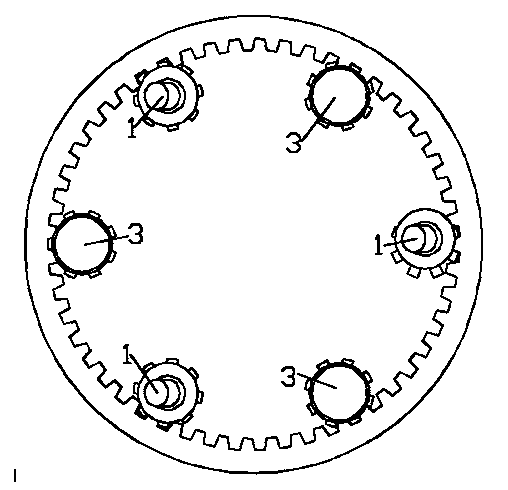

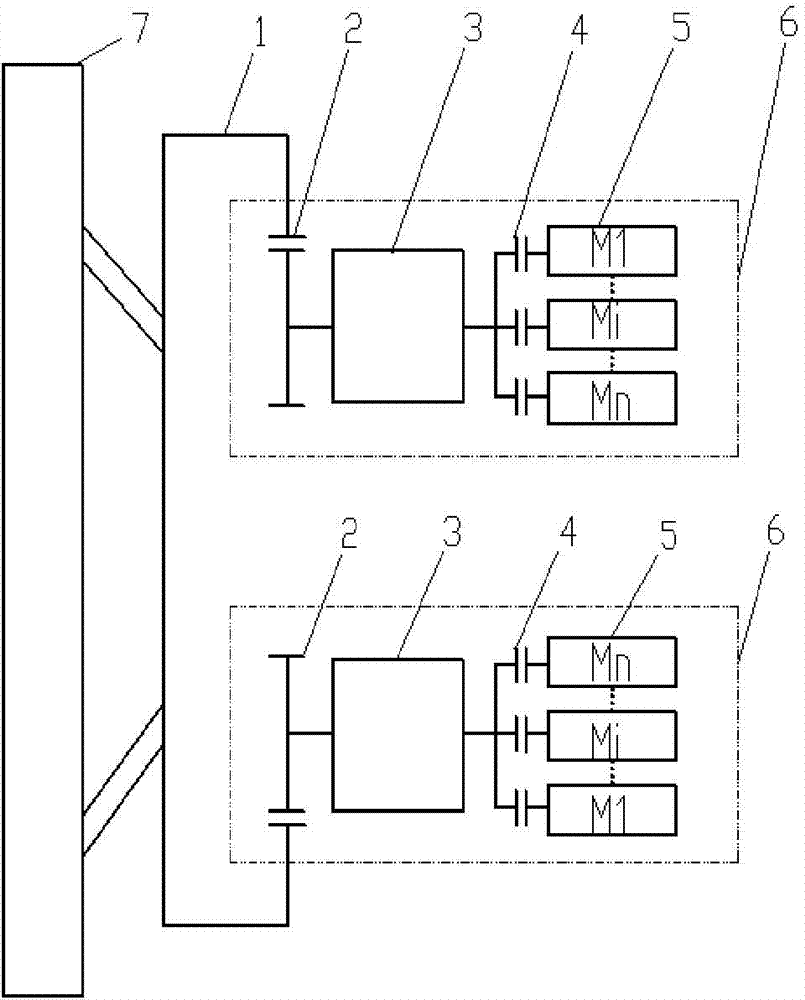

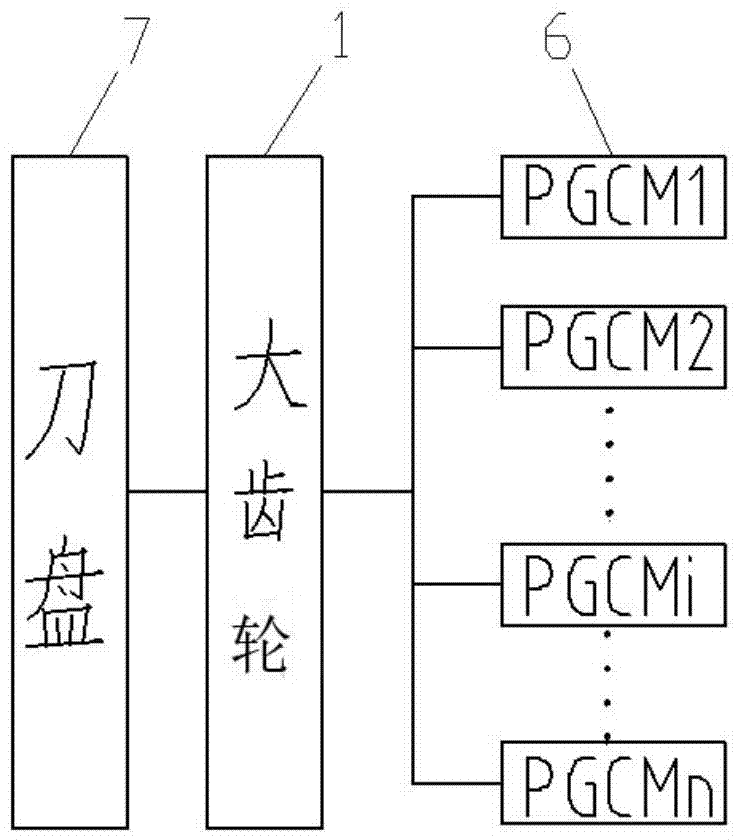

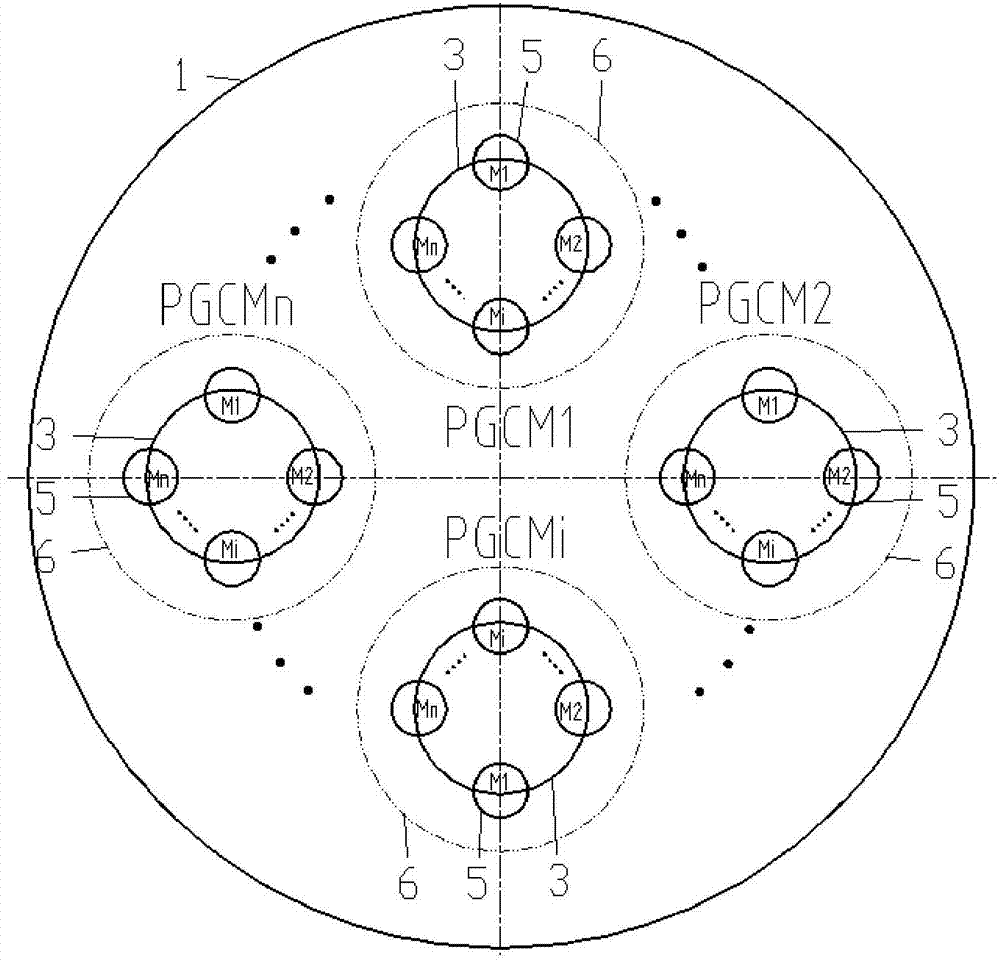

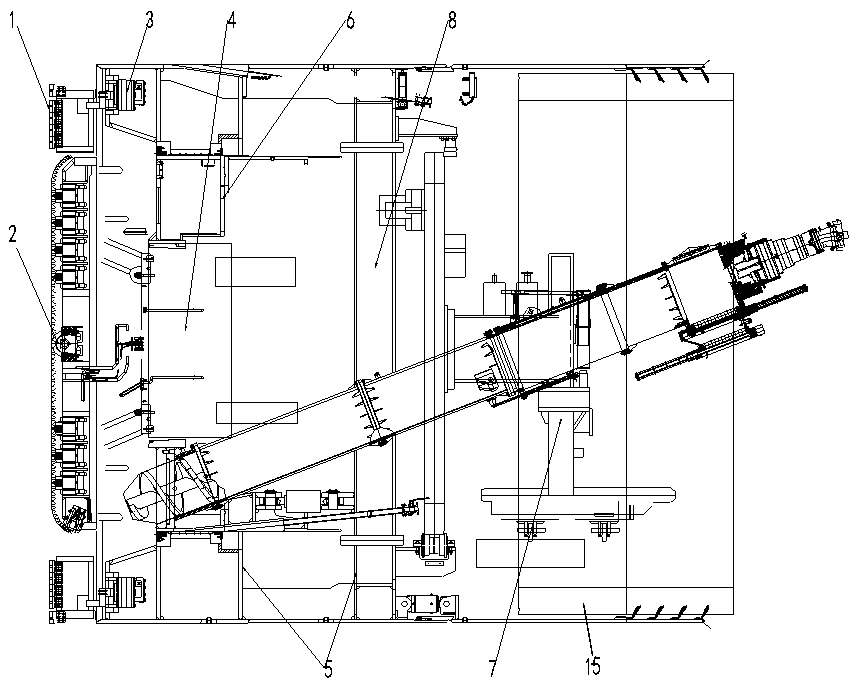

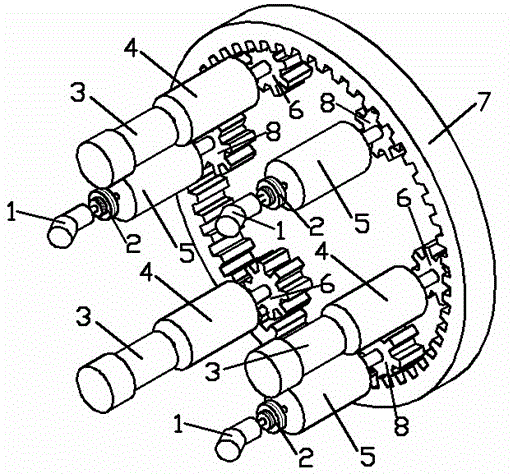

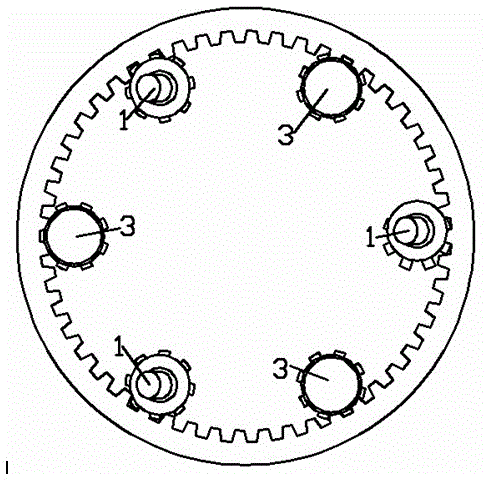

Driving system of shield tunneling machine and shield tunneling machine comprising driving system

InactiveCN104847368AImprove escape performanceImprove driving efficiencyTunnelsReduction driveReducer

The invention firstly aims to provide a driving system of a shield tunneling machine. The driving system comprises a big gear and a driving unit connected with the big gear or at least two driving units which are connected in parallel and arranged in an annular mode by taking the center of a cutter as a circle center, and the big gear and the driving units are arranged on the cutter. Each driving unit comprises a small gear, a sped reducer and a power driving component, wherein the small gear is meshed with the big gear, an output shaft of the speed reducer is connected with the small gear, and an output shaft of the power driving component is connected with an input shaft of the speed reducer through a clutch device. The driving system of the cutter of the shield tunneling machine has the characteristics of high geology adaptability, high installed power utilization ratio, large torque and convenient installation. A second purpose of the invention lies in providing a shield tunneling machine comprising the driving system, thereby enabling the shield tunneling machine to meet practical requirements and be high in practicability.

Owner:CHINA RAILWAY CONSTR HEAVY IND

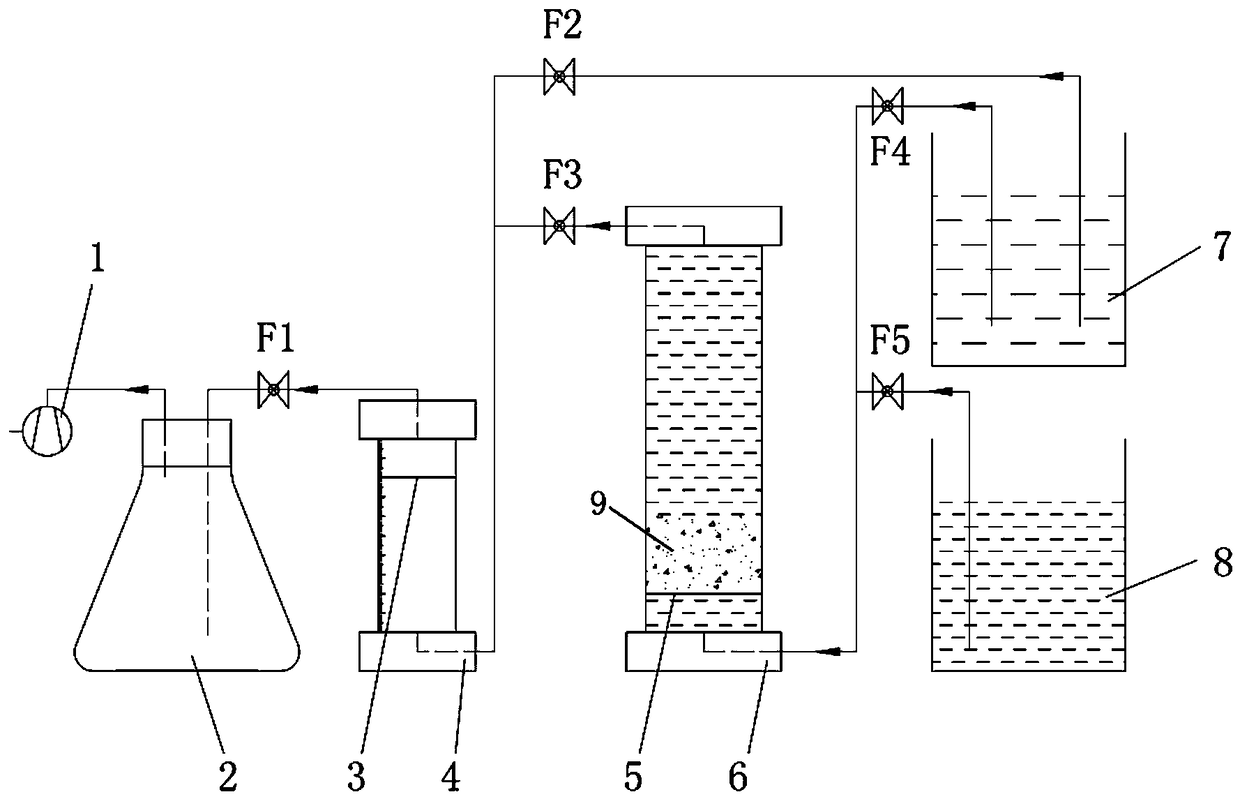

Measurement device and measurement method for residue carrying capability of mud

ActiveCN109061122ASimple structureEasy to operateMaterial testing goodsMaterial weighingMeasurement devicePerformance index

The invention discloses a measurement device and measurement method for residue carrying capability of mud. The device comprises a vacuum pump, a vacuum bottle, a measurement cylinder, a mixing cylinder and a mud tank, wherein the mud tank is connected to the bottom f the mixed cylinder by a pipe, the top of the mixed cylinder is connected to the bottom of the measurement cylinder by a pipeline, the top of the measurement cylinder is connected to the vacuum bottle by a pipeline, the vacuum pump is correspondingly connected with the vacuum bottle by an exhaust pipe, valves F5, F3 and F1 are respectively arranged between the mud tank and the mixed cylinder, between the mixed cylinder and the measurement cylinder and between the measurement cylinder and the vacuum bottle, filtering nets are respectively arranged at an upper part of the measurement cylinder and at a lower part of the mixed cylinder, and muck to be mixed is placed on the filtering net in the mixed cylinder. The device is simple in structure and is convenient to operate, a large amount of contrast experiments are appropriately developed under a laboratory condition, and the residue carrying capability of the mud and theinfluence of a main performance index of the mud on the residue carrying capability are determined.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

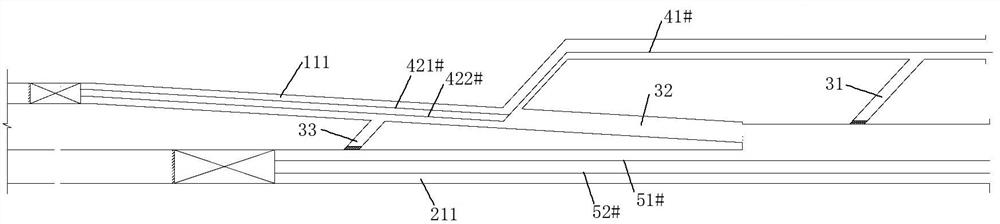

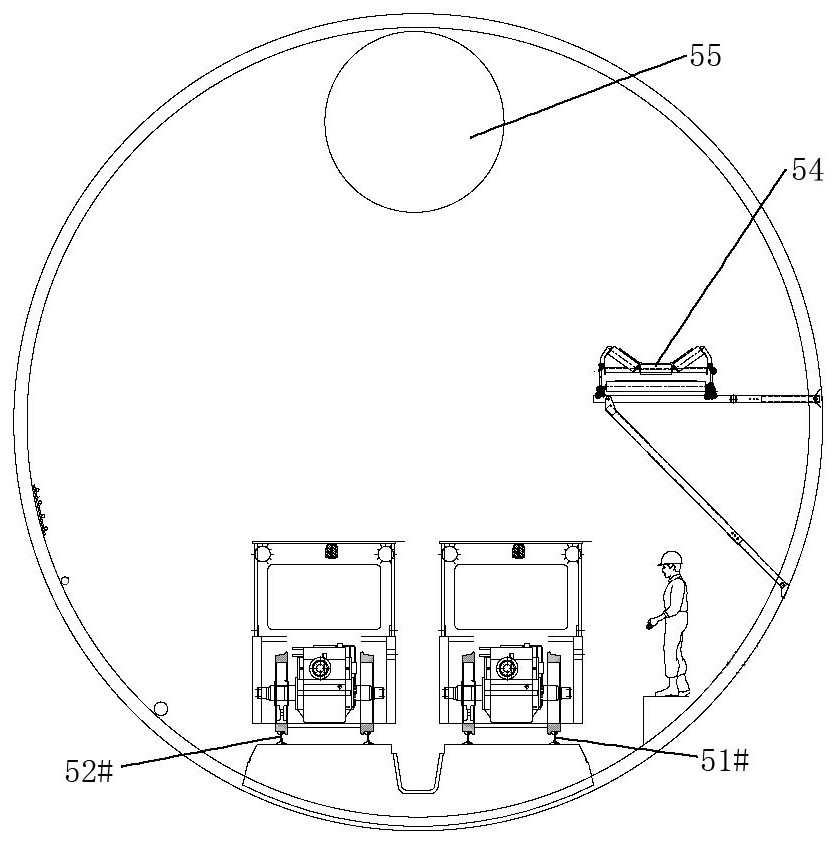

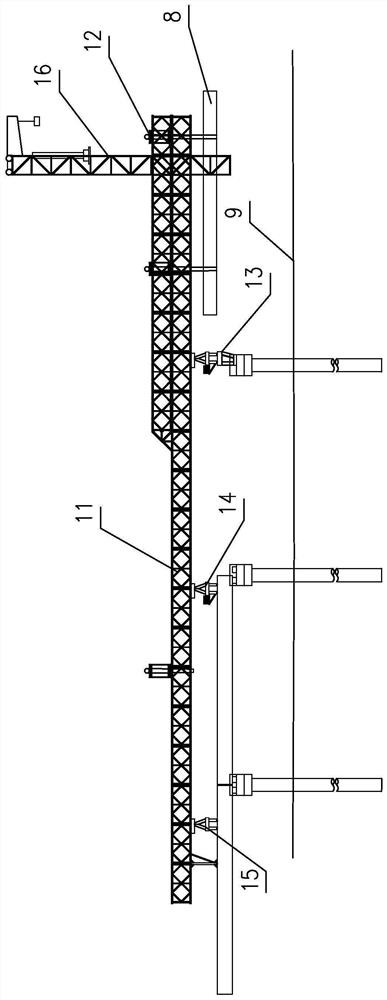

Material and muck transporting method for TBM tunnel construction

ActiveCN110410095AReduce weightExcavation progress is fastTunnelsMechanical conveyorsEngineeringMechanical engineering

The invention discloses a material and muck transporting method for TBM tunnel construction. A tunnel comprises a main tunnel, a parallel adit tunnel and an auxiliary channel used for communicating the main tunnel with the parallel adit tunnel. The parallel adit tunnel comprises a small TBM entrance segment and a small TBM tunneling segment. A temporary transporting line of dual rails is arrangedon the small TBM entrance segment. Three parallel adit transporting lines of four rails are arranged on the small TBM tunneling segment. A muck transporting belt and two main tunnel transporting linesof the four rails are arranged on the main tunnel. The tail of a large TBM crosses over the auxiliary channel, and after the parallel adit transporting lines are connected with the main tunnel transporting line through the auxiliary channel, a parallel adit transporting line extension line connected with the main tunnel transporting line is arranged in the auxiliary channel. During expanding excavation of the parallel adit tunnel, the parallel adit transporting lines are connected with the main tunnel transporting line through the auxiliary channel in front of the expanding excavation work face of the parallel adit tunnel, and then expanding excavation of the parallel adit tunnel is achieved through a borehole-blasting method. The method cooperates with the construction process, and material and muck transporting is matched with the excavation schedule.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

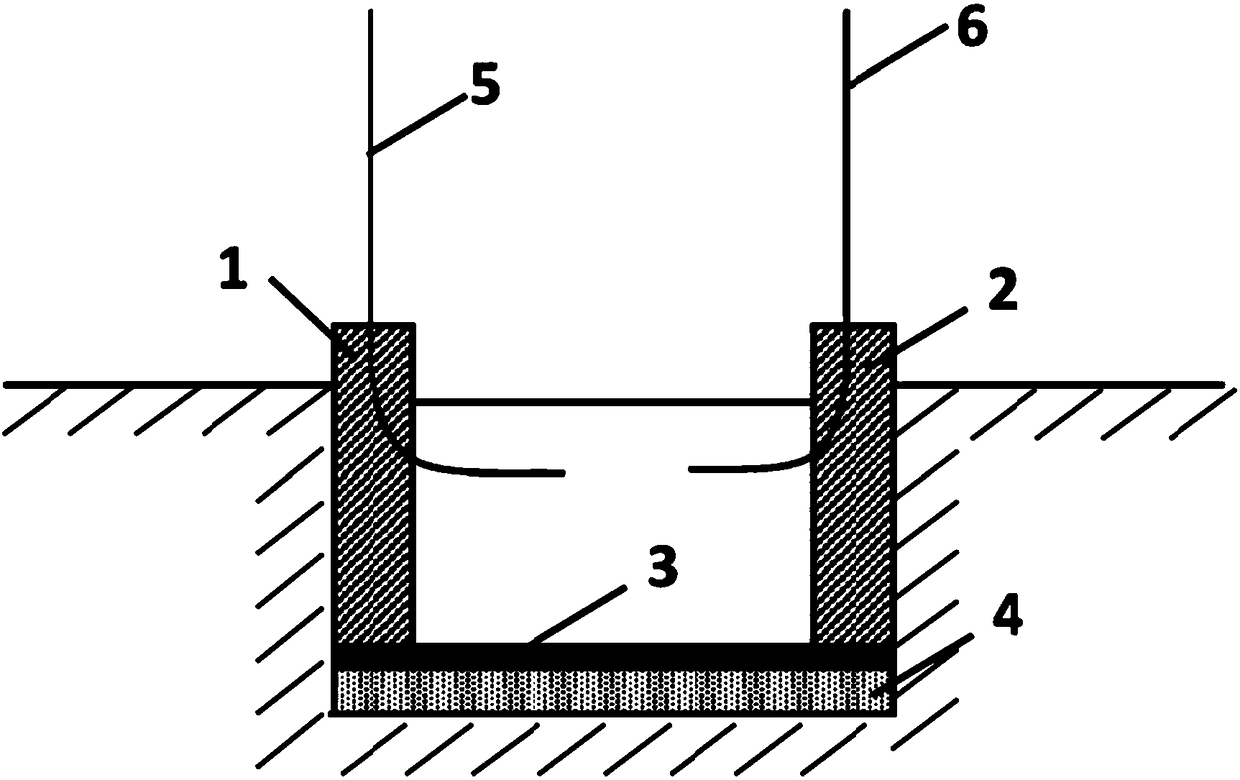

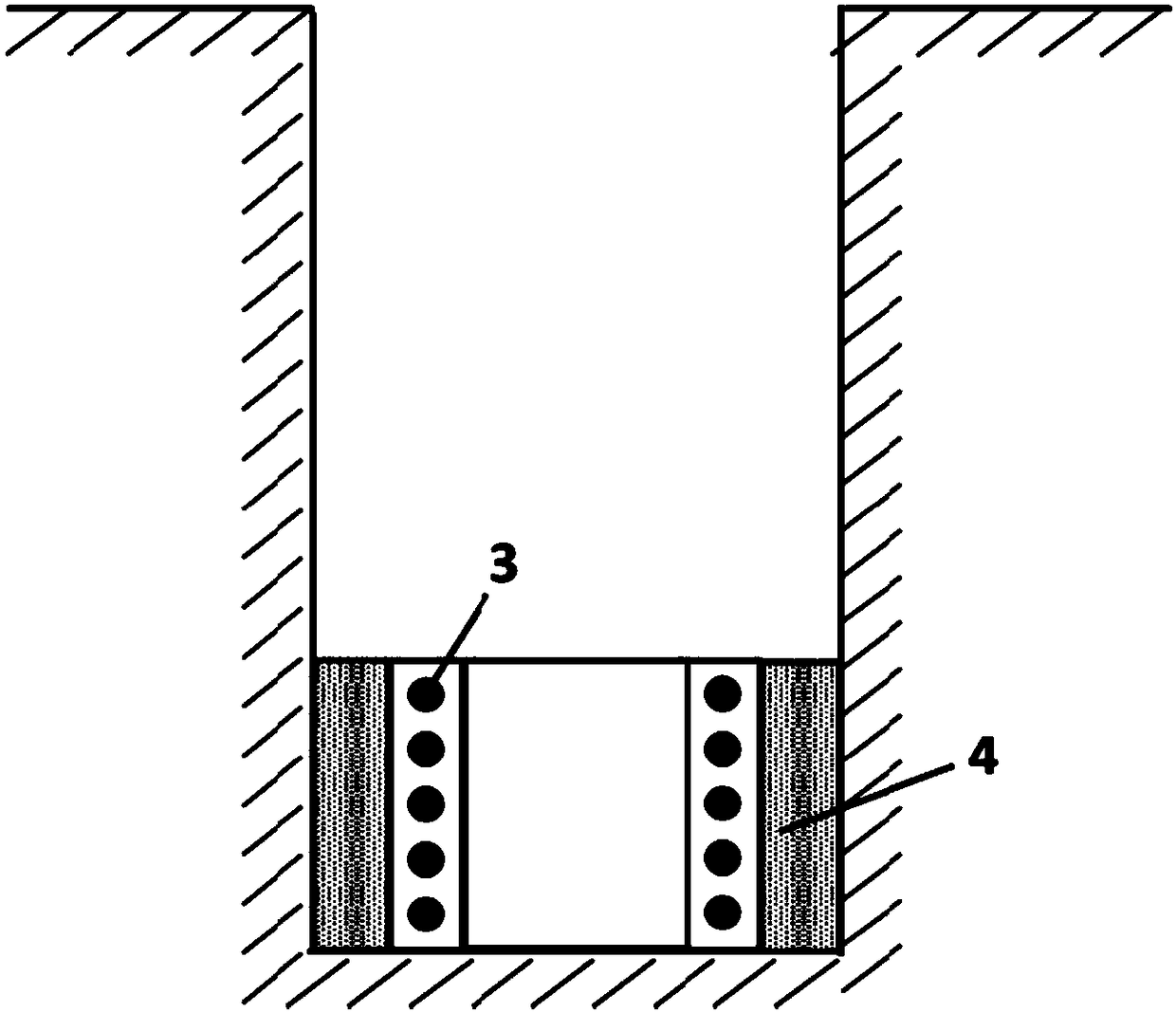

Pile foundation punching device and method

PendingCN108571286ASimple structureEasy to operateReciprocating drilling machinesConstructionsPunchingEngineering

The invention discloses a pile foundation punching device and method. The device comprises a punching force generating mechanism; the punching force generating mechanism comprises a metal channel and / or a liquid channel; the punching force generating mechanism is used to utilize a first impact force generated by a gasification explosion of an electrified mental in the metal channel, a second impact force generated by discharging on a liquid in the liquid channel by a power source, or a third impact force generated by the gasification explosion of the metal in the metal channel and a reaction between the mental and the liquid in the liquid channel as driving forces for punching; the driving forces cause the extrusion and crushing of a soil layer to be punched, so as to achieve a punching effect. The device can be used for forming holes and reaming holes of a pile foundation, can improve the working efficiency of pouring piles, and is simple in structure, convenient to operate, small inenergy consumption, safe, reliable and pollution-free; at the same time, the impact forces can be flexibly adjusted, and the device is suitable for different soils, especially suitable for forming holes and reaming holes in sand-gravel layers, hard soil layers, hard rock layers containing boulders and soil layers containing groundwater.

Owner:HUAZHONG UNIV OF SCI & TECH

Soft rock roadway whole digging shield support

The invention relates to a soft rock roadway whole digging shield support and belongs to the field of mining machinery manufacturing and application. The soft rock roadway whole digging shield support is composed of a semicircle protective arch, two hydraulic support pillars (1) which are arranged on the left side and the right side and a support seat. The upper ends of the two hydraulic support pillars (1) are connected with the semicircle protective arch respectively through a supporting lug (5) and a connecting pin. The lower ends of the two hydraulic support pillars (1) are respectively fixed on pillar fixing seats (6) of two sides of the support seat. Two groups of parallel telescopic guide rails (7) between the two pillar fixing seats(6) are connected to form the support seat. A pipe bending cylinder fixing seat (8) and two lateral pipe bending cylinder (9) are arranged in the middle of the middle portion of the two groups of parallel telescopic guide rails (7). The periphery of the soft rock roadway whole digging shield support can simultaneously bear pressure, compressive strength is high, bearing force is large, operation is convenient, and combination between components is tight. Through optimization design, from the aspects of convenient tunnel construction, the structure innovation and the like, Security, adaptation, technical advancement and economy of a soft rock supporting engineering are entirely improved.

Owner:范炳辉 +1

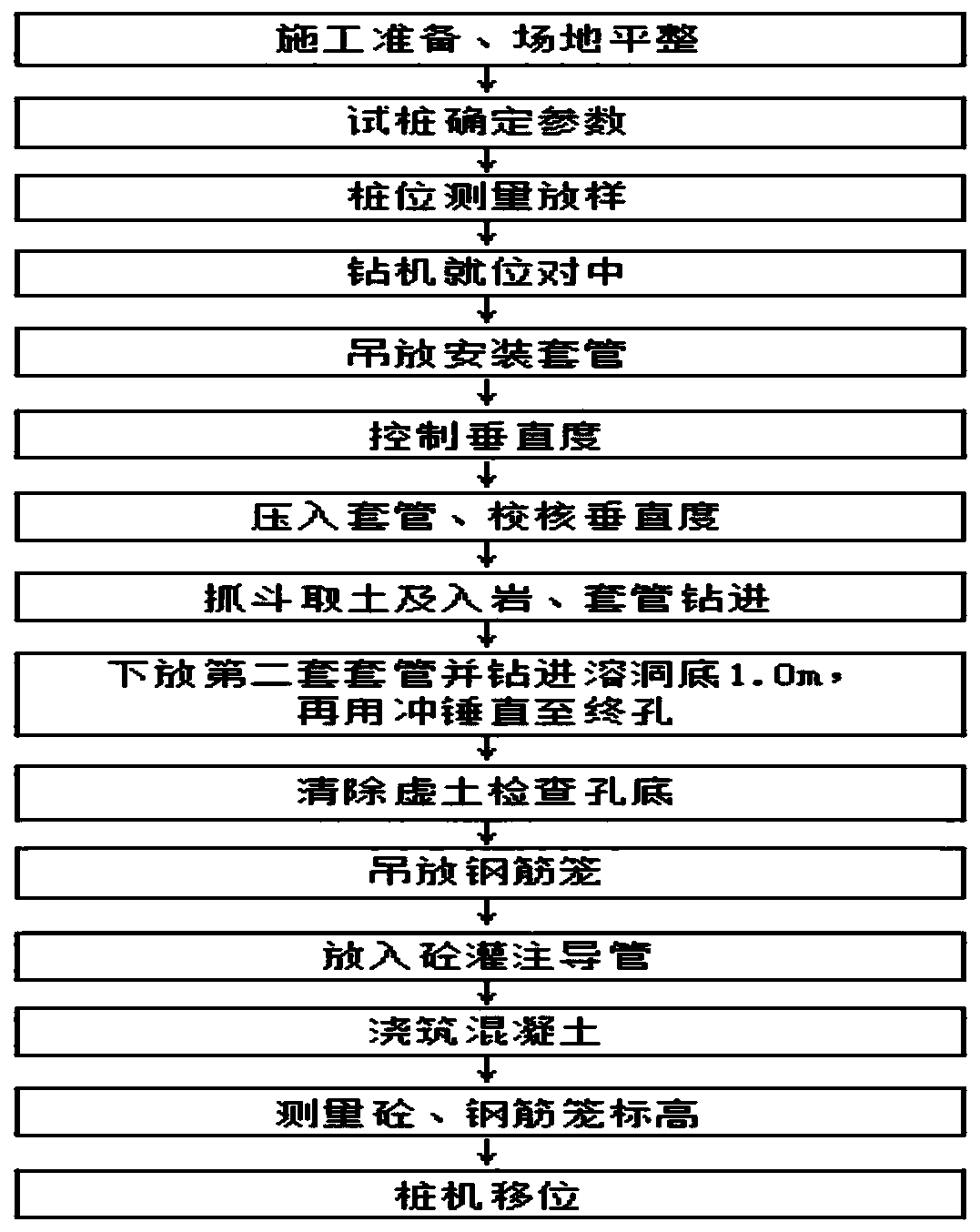

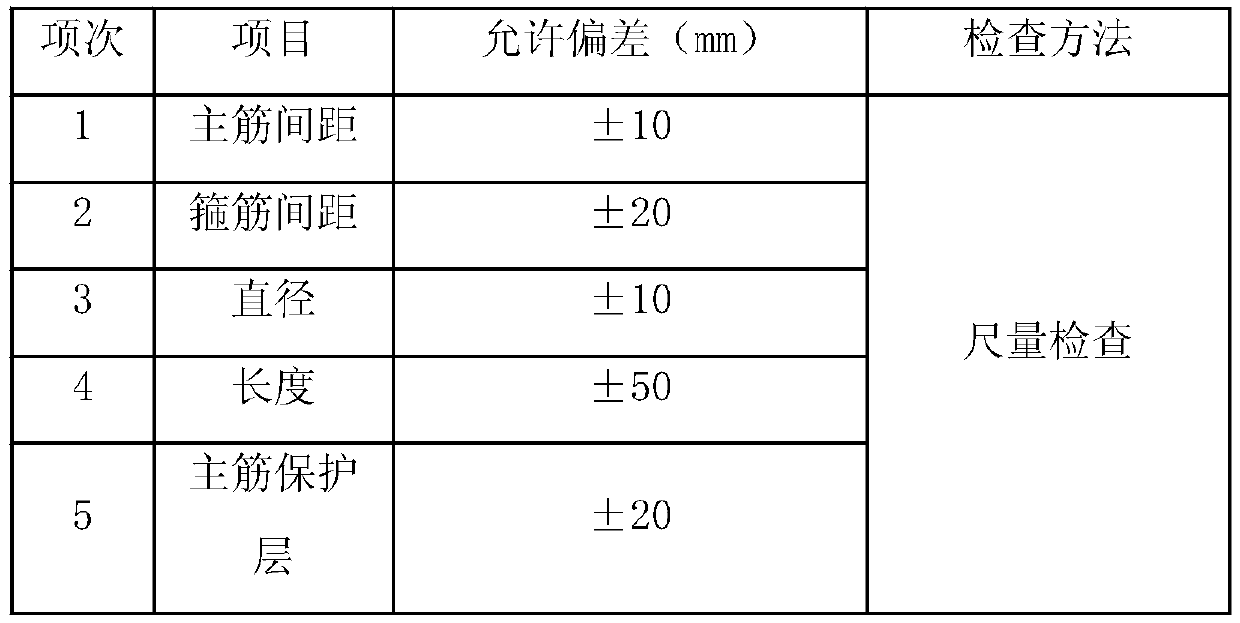

High-development karst area superfine hole pile construction method

InactiveCN110055957AImprove pile qualityUnaffected by geologyFoundation testingBulkheads/pilesPunchingProject success

The invention provides a high-development karst area superfine hole pile construction method, and belongs to the field of building engineering construction. By comprehensively considering the factorssuch as hydrogeological conditions, the construction period and existing machinery equipment, karst processing drilling cast-in-place piles are constructed by adopting a 360-degree rotation full sleeve, and a matched construction technology is formed. The high-development karst area superfine hole pile construction method is concluded and formed through successful application of the project to solve the problems that the engineering cost is greatly increased, the construction period is seriously delayed and even the construction is forced to be interrupted due to the engineering accident occurrence caused by hole collapse due to that fact that effective measures do not be adopted in the current drilling cast-in-place pile construction process. According to punching method construction adopted under the general conditions by the karst hydrogeological drilling cast-in-place piles, rubble and concrete backfilling and other measures are carried out in the punching process, the constructionprogress is slow, and as the number of backfill is uncontrollable, the construction period and the cost are uncontrollable.

Owner:CHINA RAILWAY ERJU 1ST ENG

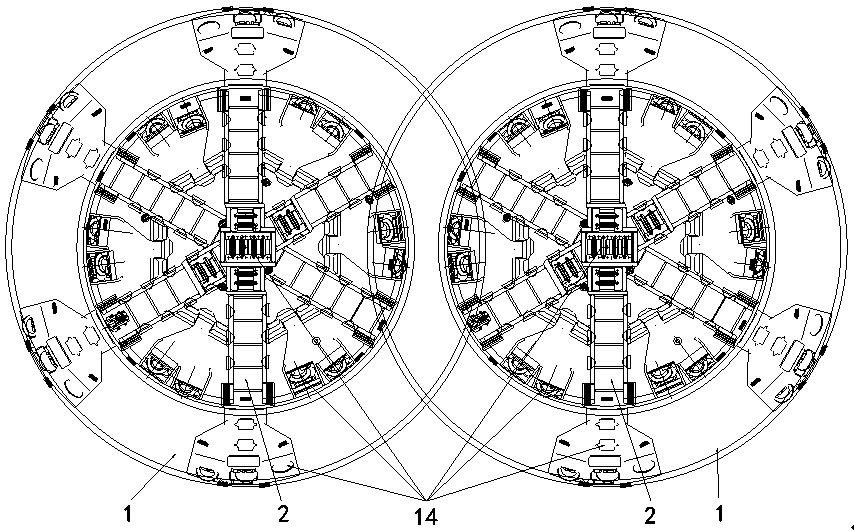

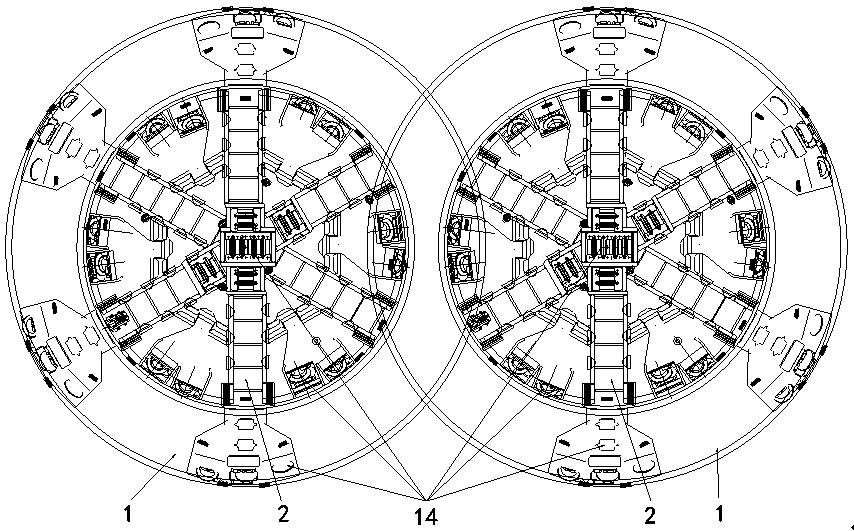

Child-mother shield tunneling machine construction method

The invention provides a child-mother shield tunneling machine construction method. When a mother shield tunneling machine and a child shield tunneling machine perform tunneling together, a mother machine shield body and a child machine shield body are connected together, a muck conveying system in the child machine shield body conveys the excavated muck to the rear part, and a mother machine propulsion system and a mother machine assembly machine complete the propulsion of shield and the assembly of segments; when the child shield tunneling machine is started, the mother machine shield body and the child machine shield body are disconnected and separated, and the child shield tunneling machine uses a counterforce frame in the mother machine shield body as the base for starting; and when the child shield tunneling machine performs tunneling, the muck conveying system in the child machine shield body conveys the excavated muck to the rear part, and the child machine propulsion system and a child machine assembly machine in the shield tunneling machine complete the propulsion of the shield and the assembly of segments. The child-mother shield tunneling machine construction method cansolve the one-excavation forming problem in the shield tunneling process of a non-circular-cross-section tunnel, saves the surface space, shortens the construction period, and improves the tunnelingefficiency and economy.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Self-adaptive sea bottom complex terrain compound wheel type traveling mechanism

InactiveCN101774409BEfficient and flexible movementImprove stabilityVehiclesControl devicesTerrainVehicle frame

The invention discloses a self-adaptive sea bottom complex terrain compound wheel type traveling mechanism which comprises an articulated frame and a compound gear train which is arranged at both sides of the frame and is provided with an independent driving system. The compound gear train comprises a front connecting plate, a back connecting plate and a front wheel, a middle wheel and a back wheel which are arranged on the front connecting plate and back connecting plate and are provided with the independent driving system; chain wheels exist among the front wheel, the middle wheel and the back wheel; the chain wheels transfer the power by chains; and the front connecting plate and the back connecting plate are articulated with a hydro-cylinder and the frame. The traveling mechanism adopts the active control mode for barrier crossing, can cross steps and bosses with the diameter larger than that of the tyre by two times, can stride a ditch less than the distance between the front wheel and the back wheel in the wheel train, can be adaptive to the high-low fluctuant road surface, causes the tyre and the road surface to be continuously contacted, furthest obtains the adhesive forceof the road surface, effectively increases the dynamic performance and working efficiency in the sea bottom complex road condition. The traveling mechanism is simple and compact, has high efficient and flexible movement, low cost, wide adaptation range, good stability and high reliability.

Owner:UNIV OF SCI & TECH BEIJING

Transportation method of materials and soil for tbm tunnel construction

ActiveCN110410095BBig excavation progressDigging progress is slowTunnelsMechanical conveyorsSlagArchitectural engineering

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Radial drive telescopic arm non-forming cutting digging drilling tool

PendingCN111236844AReasonable forceSave powerDrill bitsDrilling machines and methodsStructural engineeringDrilling machines

The invention discloses a radial drive telescopic arm non-forming cutting digging drilling tool. A box type telescopic arm cutting unit can be selectively installed in a radial hole formed in the outer side of a mounting base so as to adapt to the power and geological conditions of a drilling machine; the digging diameter expansion ratio can meet the requirement of three times of the diameter expansion ratio required by JGJ / T225-2010 Technical Regulations for Large Diameter Bottom Expanded Cast-in-place Piles and DL / T5219-2014 Technical Regulations for Foundation Design of Overhead Transmission Line, and a cutting tool and a driving oil cylinder are consistent in movement direction, the movement direction is perpendicular to the hole wall, the axial size is small, a non-forming cutting forming is adopted, the cutting resistance is small, the torsion resistance of the box-shaped arm in the stress direction is high, various hole types can be flexibly dug, the working effectiveness and reliability of the drilling machine and the drilling tool are improved, a displacement sensor is installed in the cutting unit, the reaming radial footage can be measured in real time, and the digging reaming quality is guaranteed.

Owner:闻志君

A ring pipe jacking machine

InactiveCN104712339BSolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

Owner:TONGJI UNIV

A construction method of mother-to-son shield machine

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

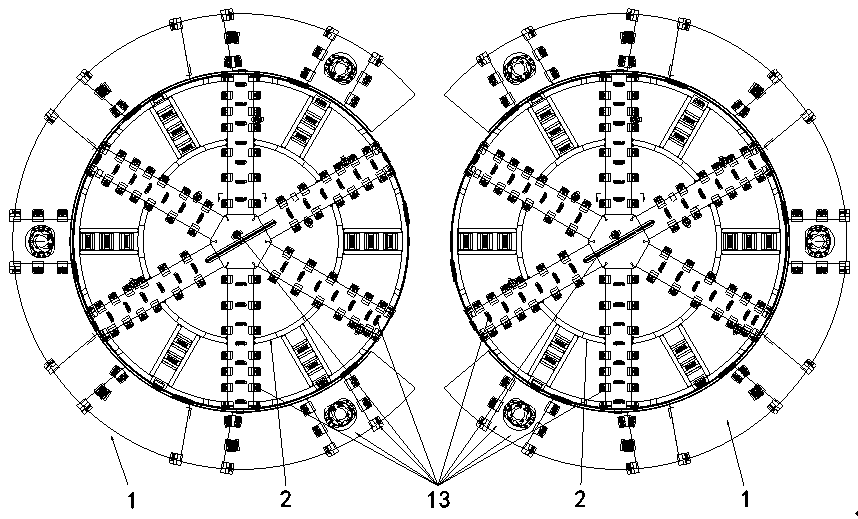

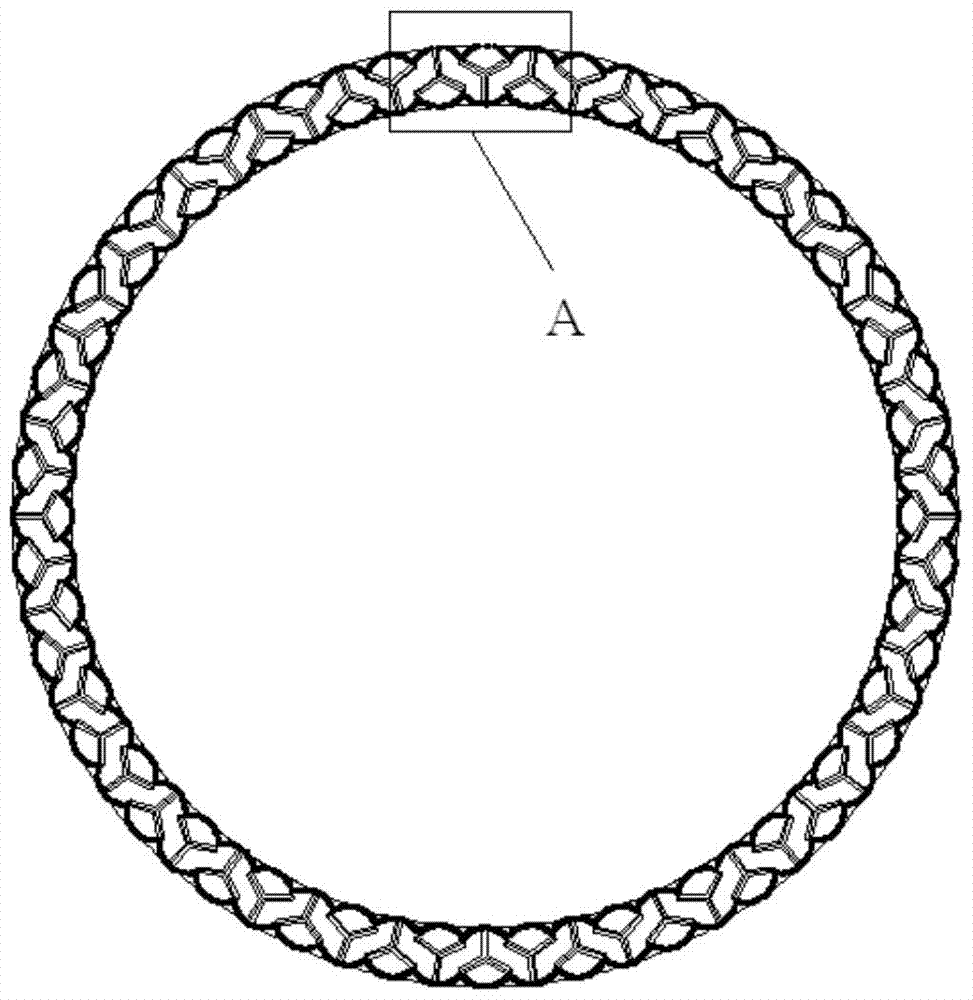

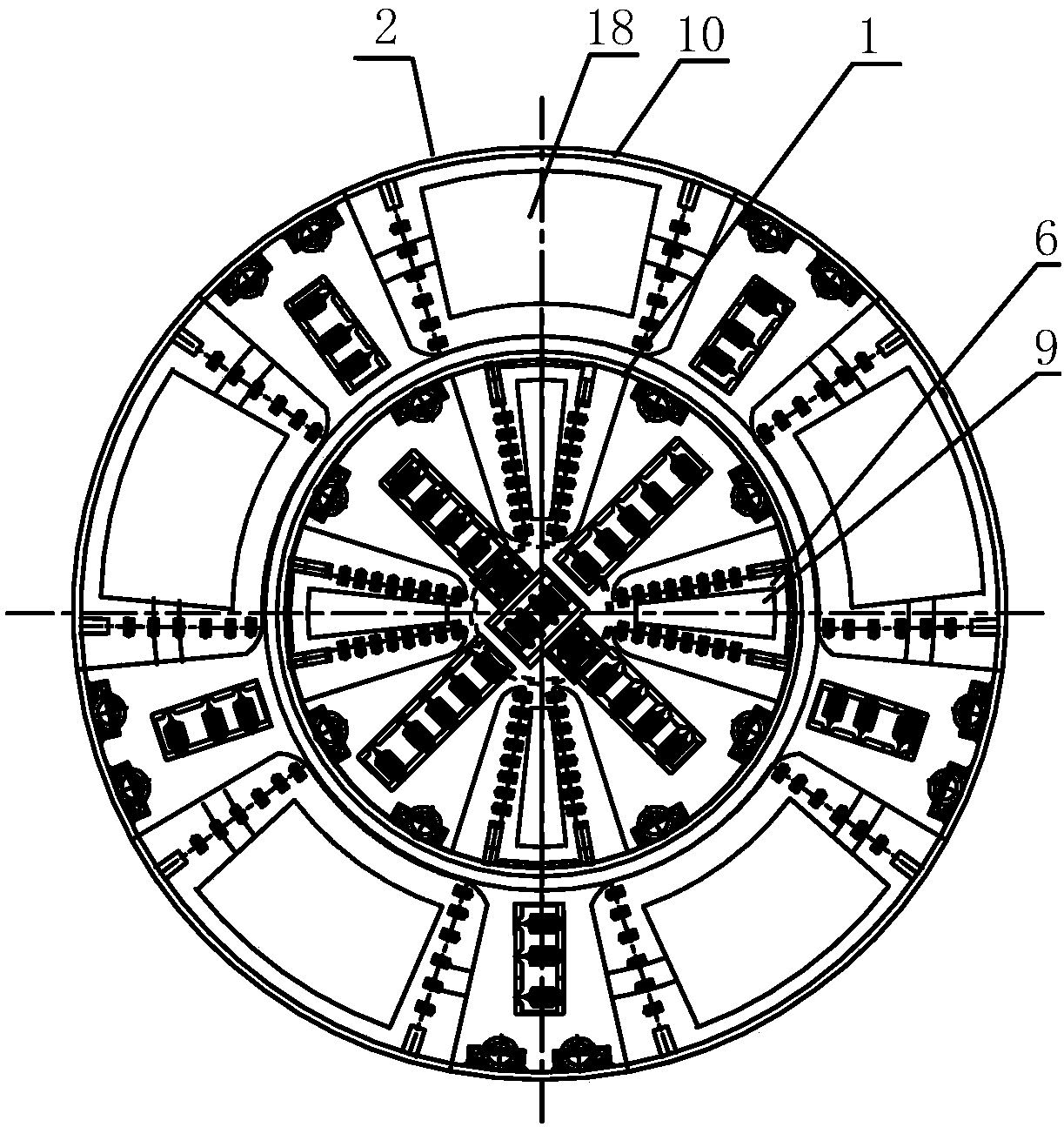

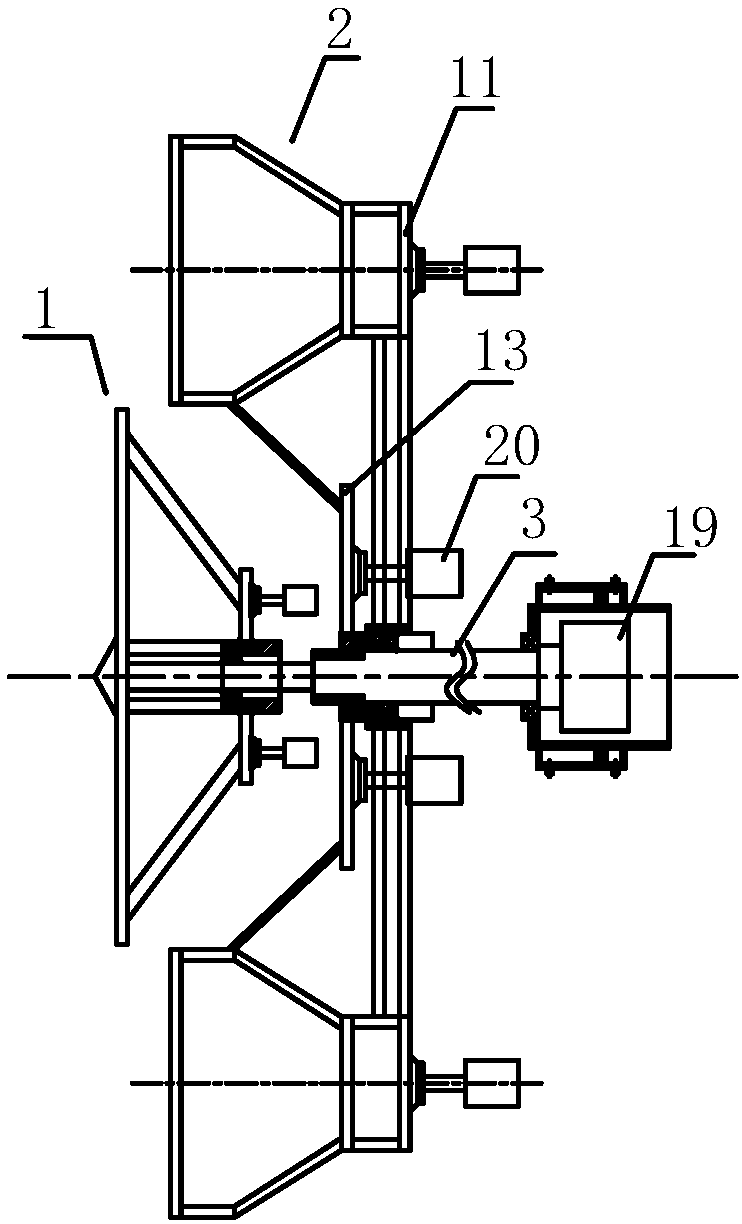

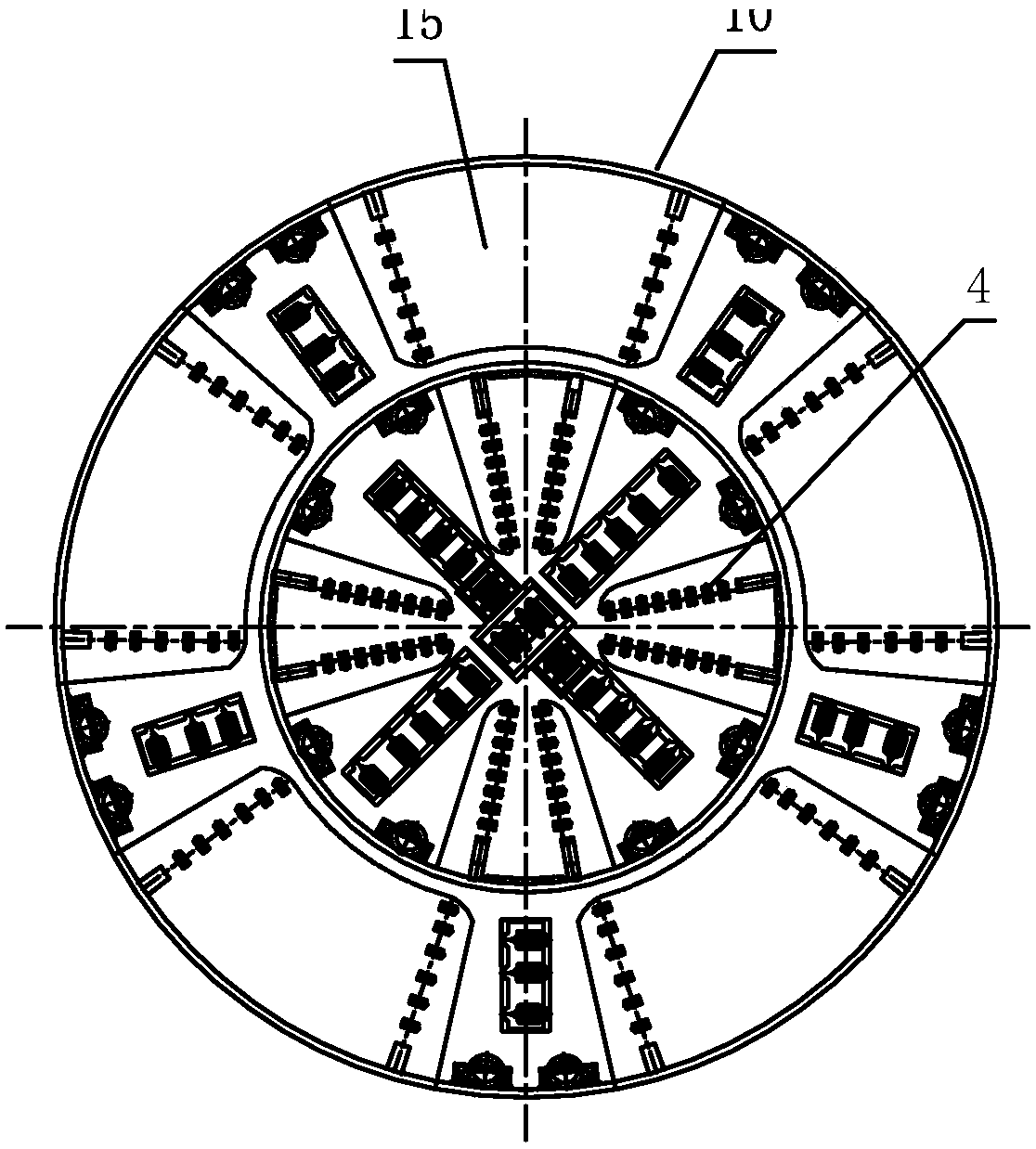

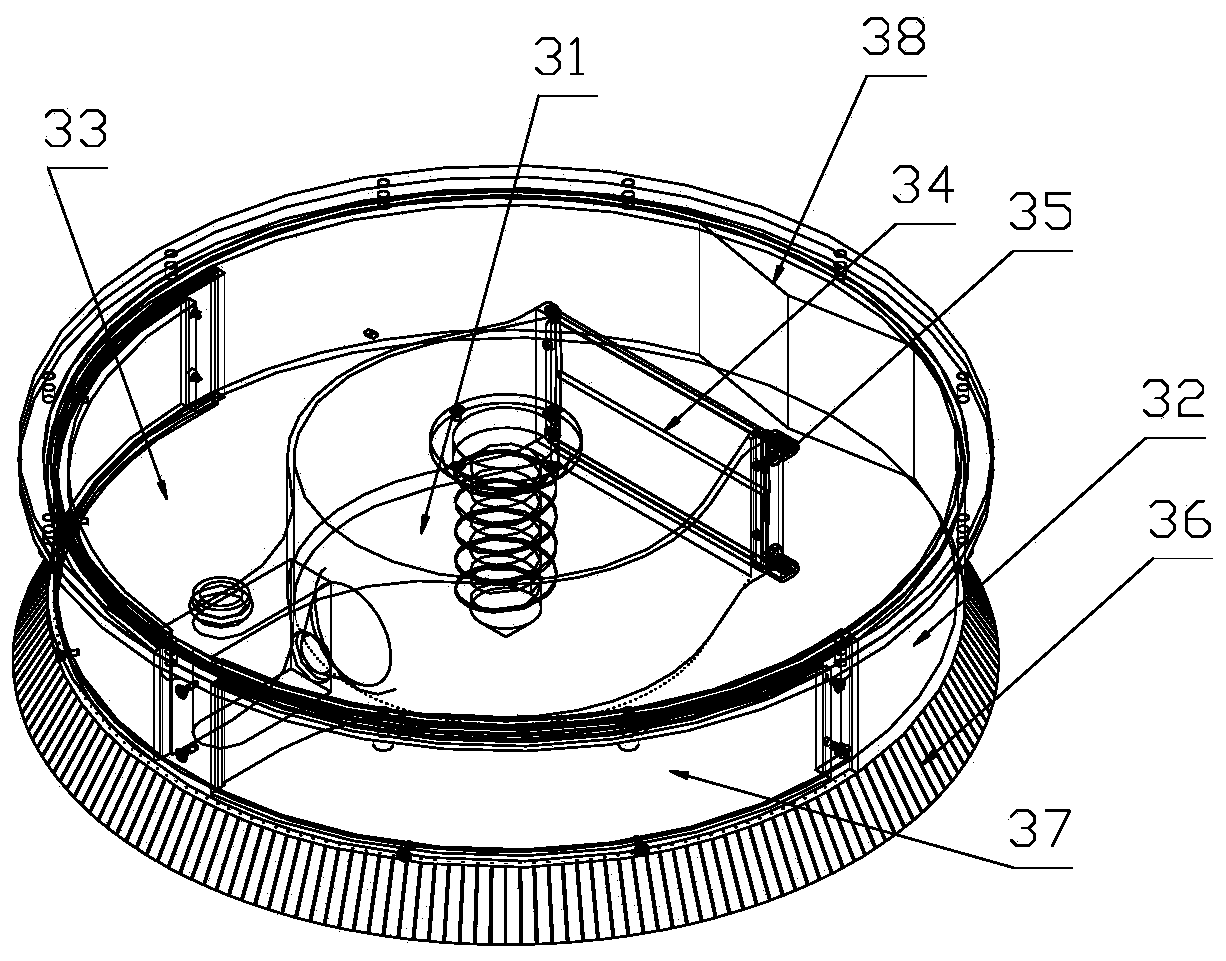

A two-stage telescopic roadheader combined cutter head with adjustable opening ratio

InactiveCN106050251BExtend effective lifeImprove geological adaptabilityTunnelsSlagUltimate tensile strength

The invention discloses a two-stage telescopic heading machine combined cutterhead with an adjustable open rate. The two-stage telescopic heading machine combined cutterhead comprises a first-stage cutterhead assembly, a second-stage cutterhead assembly and a driving device, wherein the first-stage cutterhead assembly and the second-stage cutterhead assembly are provided with axial propelling devices. Each stage of cutterhead assembly comprises a cutterhead body and a cutterhead center plate disc, a plurality of slag discharging holes are formed in each of the disc faces of the first-stage cutterhead body and the second-stage cutterhead body, the first-stage cutterhead center plate disc and the second-stage cutterhead center plate disc are provided with a plurality of center plates arranged in a radiation shape, and the number of the center plates and the number of the slag discharging holes are equal in each cutterhead assembly. Different heading modes of combined cutters and the open rate of each stage of cutterhead assembly can be controlled through the coordinative action of the corresponding axial propelling device and the driving device. When the combined cutterhead works, all the stages of cutterhead bodies bear small loads, the strength and rigidity of the structure and the distribution balance of loads are improved, and thus it is avoided that the cutterhead deforms due to excessive large stress and nonuniform stress. The adaptive heading capability of the cutterhead is improved, and the heading safety and heading efficiency are improved.

Owner:TIANJIN UNIV

Pile-beam integrated fully-prefabricated assembled bridge substructure, bridge and construction method thereof

PendingCN113073540AAll-in-one installationImprove geological adaptabilityBridge structural detailsBridge erection/assemblyIndustrial constructionUrban region

The invention discloses a pile-beam integrated fully-prefabricated assembled bridge substructure, a bridge and a construction method thereof.The pile-beam integrated fully-prefabricated assembled bridge substructure comprises a cover beam and a pier stud, the cover beam is arranged in the transverse bridge direction, and the pier stud is a prefabricated concrete pipe pile column formed by pouring concrete in a pile core of a prefabricated concrete pipe pile; the connecting joint of the upper end of the prefabricated concrete pipe pile column and the cover beam and the prefabricated concrete pipe pile column are formed by one-time concrete pouring. According to the invention, a full-prefabricated assembly concept is adopted, so that the integrated installation of the prefabricated concrete pipe pile column, the cover beam and the main beam can be realized. The construction method is easy to operate, convenient to construct, safe and reliable, the construction progress can be accelerated, the construction cost can be reduced, existing road transportation pipe piles can be utilized, construction shortcuts and construction temporary bridges do not need to be erected, occupied space is saved, good adaptability is achieved for regions with high construction environment requirements, and the construction method can be applied to the environment where the construction conditions are limited and shortcuts and temporary bridges cannot be erected. And full-prefabricated industrial construction and quick construction can be realized in urban regions with busy traffic.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Gas excitation sampler for celestial body

InactiveCN111044317AImprove geological adaptabilityImprove sampling efficiencyWithdrawing sample devicesCelestial bodyDeep space exploration

The invention, which belongs to the technical field of deep space exploration, provides a gas excitation sampler for celestial bodies. The sampler comprises a drilling machine, a rock breaking machinetool, a sample container, a gas source and a gas circuit. Wherein the sample container comprises an inner cavity, an outer cylinder and an upper cover; the two ends of the inner cavity are communicated, the inner cavity is sleeved with the outer cylinder, and the upper cover is installed on the outer cylinder. An annular cavity is formed between the inner cavity and the outer cylinder; the rock breaking machine tool penetrates through the upper cover, passes through the inner cavity and then is used for drilling to break rock; the drilling machine is used for driving the rock breaking machine; a packaging airtight door is arranged on the side wall of the inner cavity; gas of the gas source is blown into the inner cavity through the gas path and used for blowing a sample into the annular cavity through the packaging airtight door.

Owner:BEIJING SATELLITE MFG FACTORY

A shield machine disc-shaped hob tool changing mechanical arm end effector

InactiveCN106761794BImprove securityImprove geological adaptabilityProgramme-controlled manipulatorGripping headsMotor speedHydraulic cylinder

Owner:NORTHEASTERN UNIV LIAONING

Compound driving device of TBM cutting disc motor hydraulic motor

The invention discloses a compound driving device of a hydraulic motor of a TBM (tunnel boring machine) cutting disc motor. The compound driving device comprises a big gear ring and a variable frequency motor driving mechanism, wherein the variable frequency motor driving mechanism comprises a first pinion, a first speed reducer and a variable frequency motor; the first pinion and the big gear ring are meshed; an output shaft of the first speed reducer and the first pinion are fixedly connected; an input shaft of the first speed reducer and an output shaft of the variable frequency motor are connected; in addition, the compound driving device also comprises a hydraulic motor driving mechanism, wherein the hydraulic motor driving mechanism comprises a second pinion, a second speed reducer, a viscosity clutch and a hydraulic motor; the second pinion and the big gear ring are meshed; an output shaft of the second speed reducer and the second pinion are fixedly connected; an input shaft of the second speed reducer and an output shaft of the viscosity clutch are connected; and an input shaft of the viscosity clutch and an output shaft of the hydraulic motor are connected. By utilizing the compound driving device, geological adaptability of a TBM cutting disc driving system and trouble-out ability of the TBM are obviously improved, so that driving characteristics of the cutting disc and geological characteristics of rock are matched, and the use ratio of the installed power is improved.

Owner:ZHEJIANG UNIV

Hollow shaft motor reverse drive braking device for hard rock roadheader

ActiveCN105656242BCompact structureReduce weightAxially engaging brakesBrake actuating mechanismsTransmission brakeCoupling

The invention provides a hollow shaft motor reverse transmission braking device for a hard rock heading machine. The braking device comprises a transmission gear set, a planetary reducer, a hollow shaft motor, a concentric shaft, a hydraulic safety coupler and a braking mechanism. The braking mechanism is arranged on the hydraulic safety coupler. The hydraulic safety coupler is connected with the motor hollow shaft of the hollow shaft motor. The concentric shaft is arranged in the motor hollow shaft, one end of the concentric shaft is connected with the hydraulic safety coupler, and the other end of the concentric shaft penetrates through the motor hollow shaft and is connected with the input end of the planetary reducer. The output end of the planetary reducer is connected with the transmission gear set. Reverse transmission and reverse braking are achieved.

Owner:CITIC HEAVY INDUSTRIES CO LTD

A slag discharge mechanism of a shield machine and a mud-water balance shield machine

The invention discloses a muddy water balance shield tunneling machine and a slag discharging mechanism thereof. The slag discharging mechanism comprises a mud discharging pipeline and a soil bin for storing residue soil; a separating device for separating mud in the residue soil from gravels is arranged between the soil bin and the mud discharging pipeline; the soil bin communicates with a feeding end of the separating device; a mud discharging end of the separating device communicates with the mud discharging pipeline; and a gravel discharging end of the separating device is provided with a gravel discharging device. The muddy water balance shield tunneling machine comprises a shield and the slag discharging mechanism which is arranged in the shield. The slag discharging mechanism has the advantages that safety and stability of a slag outlet system of the muddy water balance shield tunneling machine are improved, and construction efficiency is also improved.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

Anti-explosion TBM (tunnel boring machine)

The invention discloses an anti-explosion TBM (tunnel boring machine), which includes a cutter head tunneling mechanism used for crushing coal rock, a driving device mounted at a front shield of a shielding device, connected with a cutter head of the cutter head tunneling mechanism and used for driving the cutter head to rotate, and a boosting oil cylinder mounted in a middle shield of the shielding device, wherein electric equipment of the driving device and hydraulic equipment of the boosting oil cylinder are anti-explosion equipment. As the electric equipment and the hydraulic equipment of the anti-explosion TBM are anti-explosion equipment, the anti-explosion TBM avoids the hidden danger of electric spark generation, and can be used in coal mine tunnels with coal dust and gas, and improves the operating safety.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

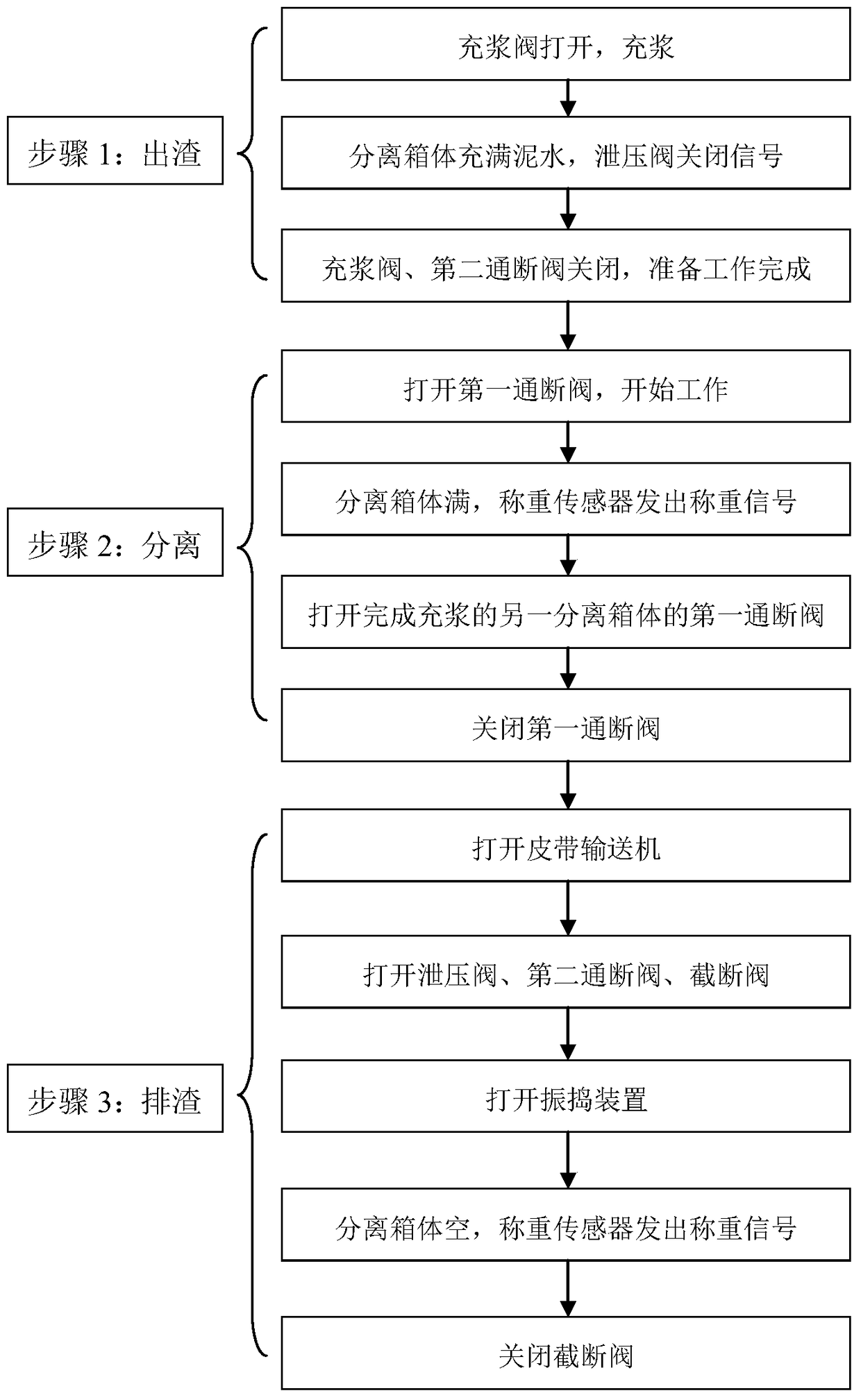

A kind of slag discharge method of shield machine

The invention discloses a shield machine slag discharging method. The method comprises a slagging step 1) in which slag cut by a cutter is conveyed to a soil storehouse of a shield machine; a separation step 2) in which gravel and slurry of the slag in the soil storehouse are separated; and a slag discharging step 3) in which the separated slurry is discharged through a slurry discharging pipe of the shield machine and the separated gravel is discharged through a gravel discharging device. By employing the method, the construction efficiency is improved, and the safety and stability of a slag discharging system are improved.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com