Pile foundation punching device and method

A technology for pile foundations and holes to be opened, applied in drilling equipment and methods, earthwork drilling, construction, etc., can solve the problems of difficult to guarantee construction progress, limited opening depth, slow opening speed, etc., and achieve easy construction. and field operation, long service life and short forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

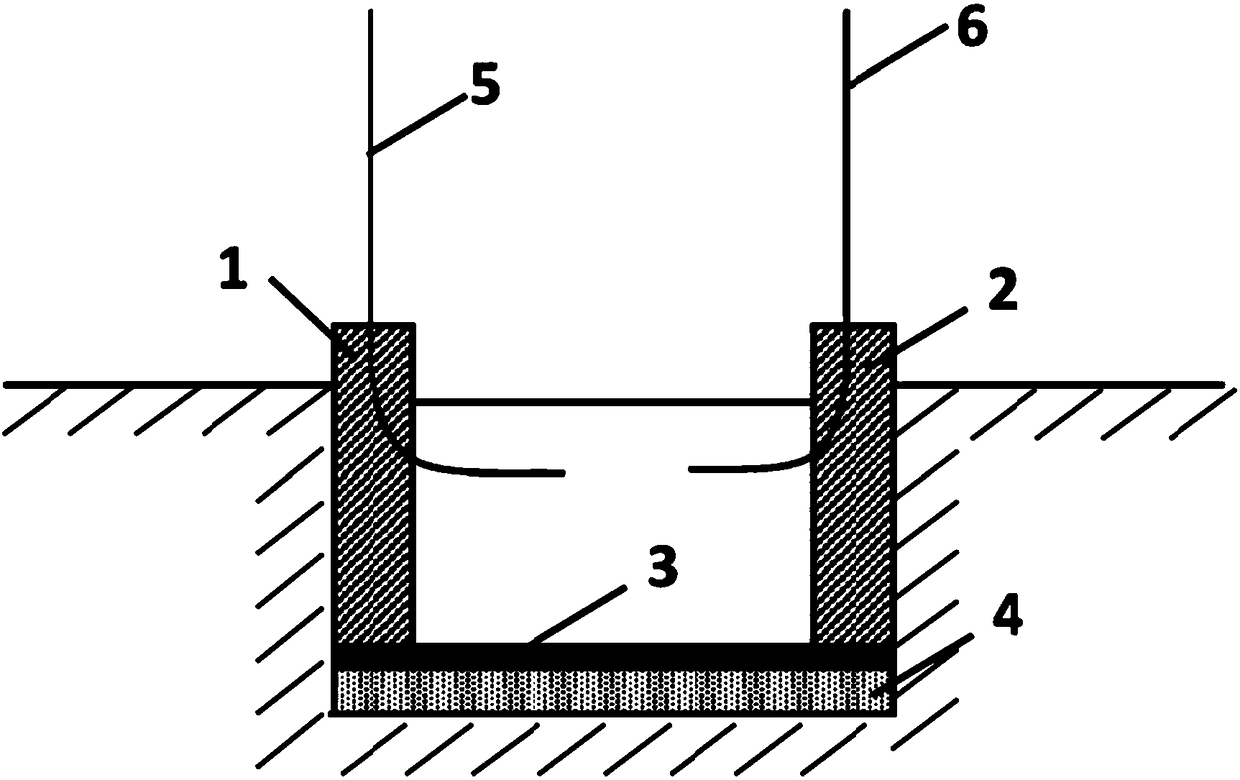

[0034] Such as figure 1 As shown, the overall structure of the cast-in-situ pile hole-forming device according to the embodiment of the present invention includes: a high-voltage electrode 1 , a ground electrode 2 , an aluminum wire 3 , a soil layer 4 , a water inlet pipe 5 , and a water outlet pipe 6 .

[0035] The aluminum wire 3 is arranged on the surface of the soil layer 4, and its two ends are respectively connected with the high voltage electrode 1 and the ground electrode 2. Water is filled between the high voltage electrode 1 and the ground electrode 2.

[0036] The hole forming method comprises the following steps:

[0037] (1) The aluminum wire 3 is placed close to the soil layer 4, arranged in parallel on the surface of the soil layer 4 along strips, and the two ends of the aluminum wire 3 are respectively connected to the high voltage electrode 1 and the ground electrode 3;

[0038] (2) Through the water inlet pipe 5, water is introduced between the high-voltage...

Embodiment 2

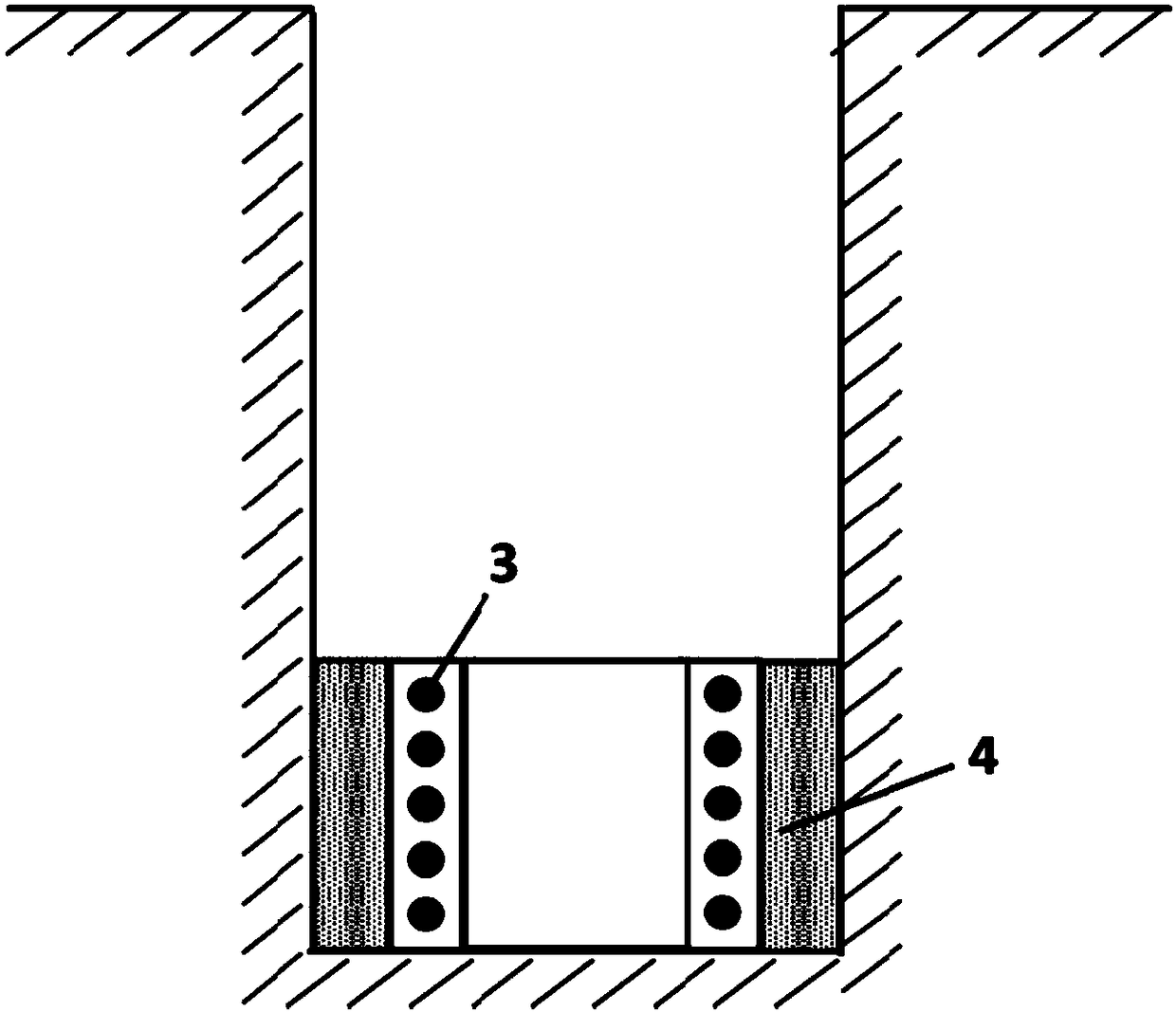

[0046] Such as figure 2 As shown, the overall structure of the reaming device according to the embodiment of the present invention includes: a coil 3 and a soil layer 4 .

[0047] The hole reaming method includes the following steps:

[0048](1) The coil 3 is placed in the water tank and placed close to the soil layer 4, and the water tank is filled with water;

[0049] (2) The coil 3 is energized. Since the coil 3 is made of aluminum material, the Joule heating effect is significant under high current, energy accumulates in the coil, the aluminum wire is gasified at high temperature, and an explosion occurs to generate a huge shock wave. At the same time, after the gasification of the aluminum , The contact surface with water is greatly increased, and the chemical reaction between aluminum and water produces hydrogen, which releases huge energy and further increases the impact force. The superposition of these two forces causes the extrusion and crushing of the soil layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com